Page 1

Introduction.........................................................................................1

Installation Overview ........................................................................................................1

Before You Begin..............................................................................................................2

Tool/Supply Requirements................................................................................................3

How It Works ....................................................................................................................4

The Features of the IG5.....................................................................................................4

Haltech IG5 Specifications....................................................................................................5

SECTION 1 Getting Started............................................................8

CHAPTER 1 Haltech IG5 Installation ............................................................................8

1.1 Overview .....................................................................................................................8

1.2 Installation Summary...................................................................................................8

1.3 Expanded Installation Guide ......................................................................................9

1.3.1. Manifold Absolute Pressure (MAP) Sensor.......................................................9

1.3.2. Coolant Temperature Sensor............................................................................10

1.3.3. Inlet Air Temperature Sensor ...........................................................................10

1.3.4. The Throttle Position Sensor (TPS) .................................................................12

1.3.5. Mounting the Igniter.........................................................................................12

1.3.6. Route Wiring Harness and Connect Sensors....................................................14

1.3.7. Power Relays....................................................................................................14

1.3.8. Electronic Control Unit (ECU) .......................................................................15

1.3.9. Flying Leads .....................................................................................................15

1.3.10. Install and connect any Optional Outputs ......................................................15

1.3.11 Connect the Trigger Sensor..............................................................................15

1.3.12 Connect the ECU..............................................................................................16

CHAPTER 2 Getting Online .........................................................................................17

2.1 Connecting the Haltech IG5 to a Computer ..............................................................17

2.2 Operating the Software.............................................................................................17

2.2.1 Computer Requirements.....................................................................................17

2.2.2 Installing the Software........................................................................................18

2.2.4 Running the Software from the Floppy Disk. ....................................................19

2.2.5 Azerty Keyboards...............................................................................................20

2.3 The Online and Offline Modes..................................................................................20

2.4 Using the System Online...........................................................................................20

2.5 The Main Menu.........................................................................................................21

2.6 How to Quit...............................................................................................................21

2.7 Checking the Engine Data.........................................................................................21

CHAPTER 3 Engine Identification ...............................................................................22

3.1 Setting Engine Identification.....................................................................................22

3.2 Ignition Set-up...........................................................................................................23

Chapter 4 Using Haltech Software...................................................................................26

4.1 Using the Software ....................................................................................................26

4.2 What is mapping the Engine?....................................................................................26

4.3 What are maps? .........................................................................................................26

4.4 Accessing the Ignition Maps .....................................................................................27

4.5 The Ignition Maps .....................................................................................................27

4.6 Altering a Map...........................................................................................................28

4.7 How To Quit..............................................................................................................29

4.8 Time Saving Functions..............................................................................................29

ii

Page 2

4.8.1 Current Location.................................................................................................29

4.8.2 All Ranges ..........................................................................................................29

4.8.3 Selecting Groups of Bars....................................................................................30

4.8.4 Percentage Changes............................................................................................30

4.8.5 Linearise .............................................................................................................30

4.8.6 Numeric Mode....................................................................................................30

4.8.7 Bar Increments....................................................................................................30

4.8.8 Online Help ........................................................................................................31

4.9 Command Summary for Maps .................................................................................32

Chapter 5 Starting the Engine ..........................................................................................33

5.1 Calibrate the Throttle Position Sensor .....................................................................33

5.2 Check the trigger signal............................................................................................33

5.3 Check the Base Timing ............................................................................................33

5.4 Loading an Ignition Library Map .............................................................................34

5.4.1 On the Dyno .......................................................................................................35

5.4.2 On the Road........................................................................................................36

SECTION 2 Other Adjustable Features......................................37

Chapter 6 Cold Starting and Running..............................................................................37

6.1 Cold Cranking ..........................................................................................................37

Chapter 7 Correction Factors ...........................................................................................38

7.1 The Ignition Coolant Map .........................................................................................38

7.2 The Ignition Inlet Air Temperature Map..................................................................38

SECTION 3 Software Features.....................................................39

Chapter 8 File Storage and Retrieval ...............................................................................39

8.1 Saving Maps and Identification................................................................................39

8.1.1 The Save Command ...........................................................................................39

8.1.2 Giving Your Map A Filename............................................................................39

8.2 Loading Maps and Identification..............................................................................40

8.3 File Management......................................................................................................40

8.3.1 Erasing Unwanted Maps ....................................................................................40

8.3.2 Changing Directories..........................................................................................41

Chapter 9 Printing Maps ..................................................................................................42

9.1 The Print Function....................................................................................................42

Chapter 10 DataLog.......................................................................................................43

10.1 The Data-log Option...............................................................................................43

10.1.1 Setting Up the Data-log Page ...........................................................................43

10.1.2 Creating a Data-log ..........................................................................................43

10.1.3 Viewing the Datalog.........................................................................................44

10.1.4 Data-Log File Management..............................................................................44

10.1.5 Printing Datalogs..............................................................................................45

Chapter 11 Customising the Software ...........................................................................46

11.1 The Set-up Page......................................................................................................46

11.1.1 The Display ......................................................................................................46

11.1.2 Com Port ..........................................................................................................46

SECTION 4 IG5 Optional Outputs..............................................47

Chapter 12 Software Access ..........................................................................................47

iii

Page 3

12.1 The Output Options Page .......................................................................................47

12.2 Enabling Options....................................................................................................47

Chapter 13 Auxiliary Outputs........................................................................................48

13.1 Description ..............................................................................................................48

13.2 Turbo Waste Gate Control (TWG).........................................................................48

13.2.1 Description .......................................................................................................48

13.2.2 Using the Turbo Waste Gate Control...............................................................49

13.2.3 Using the Boost Controller...............................................................................50

13.3 Dual Intake Valve Control (DIV)...........................................................................51

13.4 Torque Converter Lockup (TCC)..........................................................................52

13.5 Electric Thermatic Fan Control (TF)......................................................................53

13.6 Electric Intercooler Fan Control (IF).....................................................................54

13.7 Shift Light Illumination (SL)..................................................................................54

13.8 Anti-Stall Solenoid Control (AS)...........................................................................55

13.9 Turbo Timer (TT)....................................................................................................55

13.10 NOS Switch...........................................................................................................56

SECTION 5 Appendices ................................................................58

Appendix A Troubleshooting ..........................................................................................58

A.1 Overview .................................................................................................................58

A.2 Control Program Problems......................................................................................59

A.3 Starting problems .....................................................................................................60

A.4 Idling Problems ........................................................................................................60

Appendix B ..................................................................................................................61

B.1 The IG5 Outputs ......................................................................................................61

B.2 Direct Fire Ignition ..................................................................................................62

B.2.1 Ignition Outputs.................................................................................................62

B.2.2 Coil Setup ..........................................................................................................62

B.2.3 Converting Individual Coils to Waste Spark.....................................................63

B.3 Rotary Engines..........................................................................................................63

B.4 Igniters ......................................................................................................................64

B 4.1 Constant Charge or “Dumb Igniters”.................................................................65

B.5 Alternative Ignition Systems ....................................................................................66

B.6 Pull-up Resistor Dip Switch Settings .......................................................................68

Appendix C Trigger Inputs ..............................................................................................69

C.1 The Input Trigger.....................................................................................................69

C.2 Trigger Devices ........................................................................................................70

C.2.1 Hall Effect Sensors ............................................................................................70

C.2.2 Optical Sensors ................................................................................................76

C.2.3 Magnetic Reluctor Sensors................................................................................76

C.3 Home Signal (synchronising) ..................................................................................78

C.3.1 Multitooth Triggers............................................................................................79

C.3.2 Motronic Triggers..............................................................................................79

C.3.3 Twin Triggers and Twin Distributors................................................................80

Appendix D Rotor Phasing ..............................................................................................81

iv

Page 4

Under copyright law, neither this manual nor its

accompanying software may be copied, translated or

reduced to electronic form, except as specified

herein, without prior written consent of Invent

Engineering Pty Ltd trading as Haltech.

Copyright 1999 Invent Engineering Pty Ltd

A.C.N. 000 613 832

Also trading as HALTECH

10 Bay Road

Taren Point, NSW 2229

Australia

Ph: (+61) (02) 9525 2400

Fax: (+61) (02) 9525 2991

Sales-au@haltech.com

Haltech USA

Suite 309, 2156W

Northwest Highway

Dallas Texas

USA

Ph: (+1) (972) 831 9800

Fax: (+1) (972) 831 9802

Sales-us@haltech.com

www.haltech.com

MS_DOS is a registered trademark of Microsoft

Corporation. IBM is a registered trademark of

International Business Machines Corporation

Print Version: 3.0 ...................................................................................... Date: 3 August 2000

This manual should accompany:

IBM compatible PC software .....................................................................................v1.4

Firmware Series ...............................................................................................................4

Firmware..................................................................................................................... v1.4

v

Page 5

Introduction

Congratulations on your decision to install a Haltech Ignition System to your vehicle. Haltech

systems have been successfully installed on thousands of vehicles, from power off-shore boats

to twin-turbo Ferraris, from pylon racing aircraft to jet skis and snowmobiles. Over the past

several years, many motor sport enthusiasts have discovered that the Haltech computer is easy

to use and gets the job done correctly - that job being to reliably make a lot of horsepower and

torque in an engine by enabling users to precisely control ignition timing. Precise ignition

control also leads to excellent drivability and fuel economy - something that is often lacking

in high-performance engines.

Haltech users have discovered that the flexibility of the Haltech Electronic Control Unit

(ECU) and PC based programming software leads to the easiest possible installation on

everything from traditional pushrod V8s to high performance turbocharged racing

motorcycles. We are proud of the fact that some of the most respected professional racers and

supercar builders in the world use Haltech equipment for the same reasons that Haltech is

popular with motor sports enthusiasts: it is flexible and friendly, is installed easily and you can

tune your Haltech simply, without having to make the project a major research effort.

Installation Overview

The Haltech IG5 system utilises a special-purpose programmable microcomputer designed for

engine management. The IG5 system includes the ECU, engine sensors, and a special wiring

harness to connect them, plus programming software and cable for tuning the system.

Installation requires the mounting of four electronic engine sensors; two for temperature, one

for throttle position and one to sense intake manifold pressure. A harness is supplied for

connecting the 12V, ground and signal wires, and plugs to the engine sensors. An igniter will

be mounted in the engine bay and connected to the harness or the original igniter may be used.

Finally the ECU is mounted. The ECU requires a trigger with a fixed timing relationship to

the engine crankshaft from a distributor, crank angle sensor, or cam angle sensor. If you

vehicle lacks one or more of these components, your Haltech dealer can help you obtain them.

When component installation is completed an IBM compatible PC is connected to the ECU

via the supplied communications cable. The Haltech Programming software then allows you

to configure the IG5 to your engine requirements. The programming software has been

designed to be functional, "friendly" and intuitively easy to use.

For initial engine start up the ECU has a quick map feature This feature which is discussed in

more detail later in the manual offers you a simple and effective way of forming an ignition

curve as a starting point. Once the motor is running, fine-tuning to develop maximum

performance can be easily accomplished through the Haltech software.

1

Page 6

Before You Begin...

1) IT IS BEST TO READ THIS ENTIRE MANUAL BEFORE STARTING.

At the very least you should read Section One of the manual and the Appendices relevant to

your installation. The greater your knowledge of the operation of the Haltech system, the

easier you will find it to understand what you are doing, and why. Throughout the manual are

Warnings and Notes that will help your installation run smoothly and indicate the dangers that

can exist for you the installer and the Haltech ECU.

2) Read any additional material accompanying this manual that updates the document since it

was written.

3) You may need special parts or additional tools or test equipment in order to complete

installation. Make sure you have these items on hand before you begin to avoid frustration.

Contact your Haltech dealer if you have difficulty.

4) Don't do the minimum work possible. Carelessness in the early stages of installation can

cause you major headaches later on, be it in a few days or a few months time. Carelessness

will cost you money and frustration in finding and fixing unnecessary problems. You have

the opportunity to make sure your Haltech system's operation is extremely dependable and

easy to use by doing it right the first time.

WARNING:

AVOID OPEN SPARKS, FLAMES, OR OPERATION OF

ELECTRICAL DEVICES NEAR FLAMMABLE SUBSTANCES.

ALWAYS DISCONNECT THE BATTERY CABLES WHEN DOING

ELECTRICAL WORK ON YOUR VEHICLE.

DO NOT CHARGE THE BATTERY WITH A 24VOLT TRUCK

CHARGER OR REVERSE THE POLARITY OF THE BATTERY OR

ANY CHARGING UNIT

DO NOT CHANGE THE BATTERY WITH THE ENGINE RUNNING

AS THIS COULD EXPOSE THE ECU TO AN UNREGULATED

POWER SUPPLY THAT COULD DESTROY THE ECU AND OTHER

ELECTRICAL EQUIPMENT.

ALL FUEL SYSTEM COMPONENTS AND WIRING SHOULD BE

MOUNTED AWAY FROM HEAT SOURCES, SHIELDED IF

NECESSARY, AND WELL VENTED.

MAKE SURE THERE ARE NO LEAKS IN THE FUEL SYSTEM AND

THAT ALL CONNECTIONS ARE SECURE.

2

Page 7

DISCONNECT THE HALTECH ECU FROM THE ELECTRICAL

SYSTEM WHENEVER DOING ANY ARC WELDING ON THE

VEHICLE BY UNPLUGGING THE WIRING HARNESS CONNECTOR

FROM THE ECU.

5) Electromagnetic interference (EMI) from unsuppressed spark plugs and leads can cause the

ECU to fail. Please do not use them.

6) In hot climates, or with turbocharged engines, you may need to employ heat shielding to

prevent heat soak and damage to electrical and fuel parts. Use the coolest surfaces of the

chassis as a heat sink for components and use thermally conductive brackets where

appropriate.

7) IGNITION MODULES It is essential that the user fully understands what type of ignition

module (igniter) is to be used with the Haltech ECU. Constant charge and constant duty igniters

are available and the ignition set-up page must be set accordingly before power is applied and the

ignition modules are connected to the main loom. Failure to do so may damage the igniters and

coils.

Constant Duty is used with “Intelligent” igniters such as the Haltech supplied EB023. Constant

Charge is used with “Dumb” igniters that can also be obtained from Haltech as single, double or

triple igniters.

Most standard OEM supplied igniters are of the “dumb” type but if in any doubt it is necessary to

check or purchase suitable igniters through your Haltech supplier.

WARNING:

HALTECH WILL NOT REPLACE ANY IGNITION COMPONENTS

DAMAGED BY FAILURE TO COMPLY WITH THE ABOVE

PROCEDURES.

Previously Haltech ECU’s were only compatible with constant duty type igniters; therefore

numerous references are made to the EB023 BOSCH module which is supplied by Haltech.

Haltech can supply both constant duty and constant charge modules to suit the IG5. Many of the

modules have a similar external appearance and it is essential that the installer be able to identify

the unit as constant charge or constant duty.

Note: In this manual, reference will be made to a MAP sensor (Manifold

Absolute Pressure sensor) and the ignition maps that are tables stored in the

ECU. Both are common industry terms but with entirely different meanings.

Tool/Supply Requirements

Installation of this system can be easily carried out by professional mechanics and most

experienced home mechanics if the following tools and components are available:

Voltmeter or Test Light

A selection of screwdrivers and spanners

Soldering Iron and solder (we recommend soldering all connections)

3

Page 8

Wire Cutters and Pliers

Crimping Tool and assorted terminals

Drill with assorted drill bits

3/8" NPT Tap

1/4" GAS Tap

Electrical Tape or Heat Shrink tubing

Teflon pipe sealing tape

Nylon cable ties

Jeweler’s file (may be needed for mounting Throttle Position Sensor)

Mounting hardware for ECU and relays (mounts/bolts/screws)

IBM-PC compatible computer (preferably laptop) with at least 640kb, one disk drive and an

RS232 serial port.

A good quality Timing Light

How It Works

The Haltech IG5 uses a digital microcomputer to measure engine speed and load and uses these

values to access a look-up table of ignition advance (°BTDC). This look-up table is called a base

ignition map and is stored in non-volatile memory (i.e. memory which is retained when power is

switched off). Programming software allows the contents of this memory to be changed to match

the requirements of the engine.

The Features of the IG5

The IG5 is designed to be easily programmed and is capable of being used on a wide variety of

applications. A typical IG5 installation could be 4, 6 or 8 cylinders, turbo/supercharged or

normally aspirated, distributed ignition (only one ignition output) or Direct Fire ignition (multiple

ignition coils). It will also provide the ability to control some other features, such as Turbo

Wastegate Control, Thermofans, Torque Converter Clutch Lockup, etc.

Note: You should read Appendix B & C before you install the system to be

fully aware of your hardware and installation requirements.

The following variants are catered for by the Haltech IG5 system

Direct Fire Ignition

Rotary Engines

Twin Triggers

Twin Distributors

Multitooth Trigger Systems

The above will be determined by your engine configuration. If your engine has no distributor, for

example, you will need to use Direct Fire. All the features will be determined by your engine setup.

4

Page 9

HALTECH IG5 SPECIFICATIONS

Engine Suitability

• Up to 16,000 rpm

• 1, 2, 3, 4, 5, 6, 8, 10, 12 or 16 cylinders (1-2 rotors)*

• 2 or 4 stroke

• Normally aspirated or supercharged up to 200 kPa (30 psi) – Higher boost pressure MAP sensors

available by special arrangement

• Load sensing by throttle position or manifold pressure

• Distributed ignition systems, or direct fire systems with 1 to 4 coils

Power Requirements

•••• Power Source

8.6 to 16 Volts DC

•••• Consumption

Haltech ECU: 270 mA at 12 Volts

Physical Specifications

• ECU Dimensions

Length: 153 mm (6 1/16")

Width: 105 mm (4 1/8")

Depth: 32 mm (1 1/4")

• Weight

ECU: 760g (1.68 lb)

Loom: 1.92kg (4.2 lb)

Sensors: 500g(1.1 lb)

Shipping Weight: 4.5kg (9.9 lb)

(Including manual/packaging)

Input Sensors

• Manifold Absolute Pressure (MAP) Sensor, (optional at extra cost)

1 Bar -100kPa to 0kPa (Naturally Aspirated)

2 Bar -100kPa to 100kPa (up to 1 Bar or 15 psi boost)

3 Bar -100kPa to 200kPa (up to 2 Bar or 30 psi boost)

Higher boost pressure MAP sensors available by special arrangement

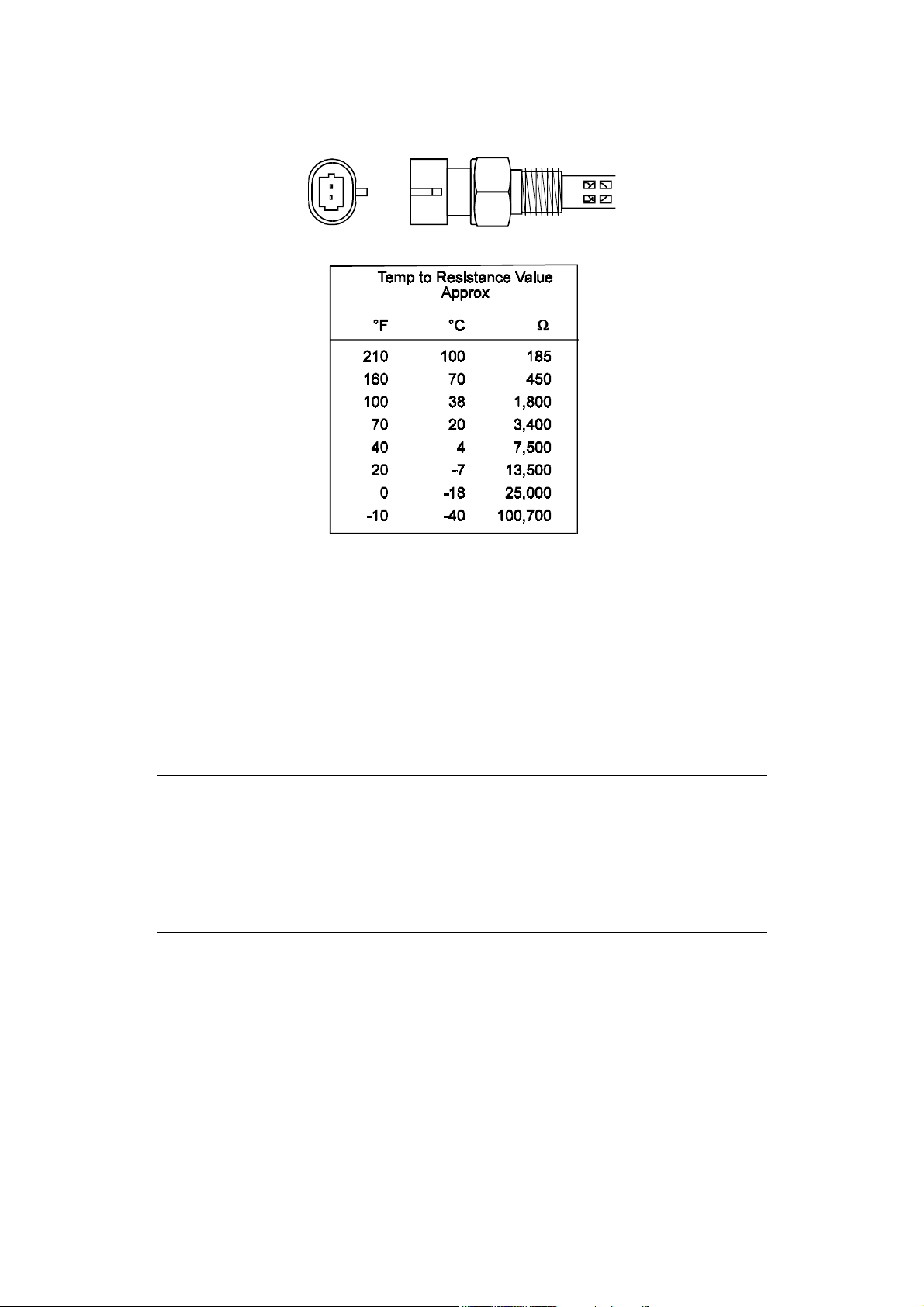

• Temperature Sensors (Air and Coolant), (optional at extra cost)

NTC temperature dependent resistor type.

Operating Range

Continuous -40°C to 100°C (-40°F to 212°F)

Intermittent up to 125°C (257°F)

• Throttle Position Sensor, (optional at extra cost)

10 kΩ rotary potentiometer driven from throttle shaft

5

Page 10

• Engine Speed Pickup

Compatible with most trigger systems:

- 5 or 12-volt square wave;

- Pull-to-ground (open collector)

A Reluctor adaptor is available for magnetic (or ‘reluctor’) triggers supporting most standard tooth

patterns. Applications requiring a motronic trigger input need to be specified at the time of order.

Only a 60-tooth wheel with 2 teeth missing is supported.

ECU Outputs

• Ignition Output

(May also be compatible with other igniters. Ask your Haltech dealer.)

Optional ECU triggered Haltech Ignition Module for firing the coil.

System Programming Requirements

• Computer

IBM-PC or compatible, preferably laptop or notebooks

CGA, EGA or VGA, colour or monochrome display

640+ kb RAM

• Disk Drive

3.5" Floppy Disk Drive

(5.25" disk available on request)

• Serial Port

Standard RS232C port - 9 pin D connector

(25 pin cable available on request)

COM1 or COM2 (selectable)

Adjustable Features

• Ignition Map

22 Ignition ranges, every 500 RPM to 10,500, or

17 Ignition ranges, every 1000 rpm to 16,000

32 Load points per range, up to 50° advance, with 1° resolution

6

Page 11

• Correction Maps

• Ignition

Crank Advance - 32 points

Coolant Temperature Advance/Retard - 32 points

Air Temperature Advance/Retard - 32 points

• Programmable Rev-Limit

• Programmable Output Options

• Turbo Wastegate Control

• Dual Intake Valve Control

• Torque Converter Lock-Up

• Electric Thermatic Fan Control

• Intercooler Fan Control

• Shift Light

• Anti-Stall Solenoid Control

• Turbo Timer

• NOS Switch

Miscellaneous

• Map Storage and Retrieval

Maps may be stored to disk and re-used

• Datalogging

Engine data information saved at a nominal rate of 10 samples per second.

Data storage to memory or disk.

Limited only by available memory (approx. 11k/minute).

• US or Metric Units

• Real Time Programming

Instant, hesitation free adjustment while engine is running

•••• Optional Ignition Trim Module

Provides -8° to +7° adjustment for fast tuning

• Rugged Aluminium Casing

Black anodised with integral cooling fins and mounting brackets.

– cuts ignition preventing over revving of the engine

7

Page 12

SECTION 1 Getting Started

CHAPTER 1 HALTECH IG5 INSTALLATION

1.1 Overview

The Haltech IG5 system comprises the following components

Haltech Electronic Control Unit (ECU)

Main Wiring Harness

Haltech IG5 system Instruction Manual

Programming Cable

Programming Disk

Relay

Optional Items (at extra cost)

Coolant Temperature Sensor

Inlet Air Temperature Sensor

Throttle Position Sensor (TPS)

Manifold Absolute Pressure (MAP) Sensor, (1,2 or 3 Bar)

Ignition Module

Ignition Timing Trim Control

Reluctor Adaptor - for magnetic triggers

Ignition Coils

Haltech Dual Hall-Effect sensor

1.2 Installation Summary

1. Mount Manifold Absolute Pressure Sensor. (If applicable)

2. Mount Coolant Temperature Sensor. (If applicable)

3. Mount Inlet Air Temperature Sensor. (If applicable)

4. Mount Throttle Position Sensor. (If applicable)

5. Mount Ignition Module

7. Route Main Wiring Harness and connect sensors and ignition module.

8. Mount and connect Power Relay.

9. Mount ECU inside passenger compartment.

10. Locate and connect flying wires:-

RED + 12 volts battery

GREY Ignition on 12 volts

BLACK Chassis ground

11. Install and connect any Optional Outputs

12. Connect Trigger signal

13. Connect ECU and test.

8

Page 13

1.3 Expanded Installation Guide

1.3.1. Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is used to convert the manifold pressure into an electrical signal for the IG5

ECU to use. The sensor works in absolute pressures, thus its calibration is not affected by

changes in barometric pressure.

There are three types of MAP sensors that can be used with the IG5 system. The sensor

required depends on the specific engine configuration.

1 Bar Sensor (Part No. 039 4070)

( -100kPa to 0 kPa) Normally Aspirated Engines

2 Bar Sensor (Part No. 886 3189)

(-100kPa to 100kPa) Turbo or Supercharged

Engines up to 100kPa boost

(15 psi , 1 atmosphere)

3 Bar Sensor (Part No. 749 3169)

(-100kPa to 200kPa) Turbo or Supercharged

Engines up to 200kPa boost

(30 Psi, 2 atmospheres)

Note: Make sure you have the correct MAP sensor for your engine. The first

three digits of the part number is stamped on the sensor housing.

Mounting

The MAP sensor is usually mounted high on the engine bay firewall or inner guard using two

screws with the hose nipple facing outwards. Connect the sensor to the inlet manifold via a

short length of vacuum hose and fasten with either hose clamps or nylon cable ties. Connect

the sensor to the main wiring harness using the appropriate plug. (For 1 Bar sensors the plug

is green, for 2 and 3 Bar sensors the plug is orange). Avoid mounting the sensor below the

level of the fuel system, because fuel may collect in the vacuum hose and run down into the

sensor. The sensor assembly is weather-proof but it is good practice to mount the sensor in a

protected position away from moisture and heat.

9

Page 14

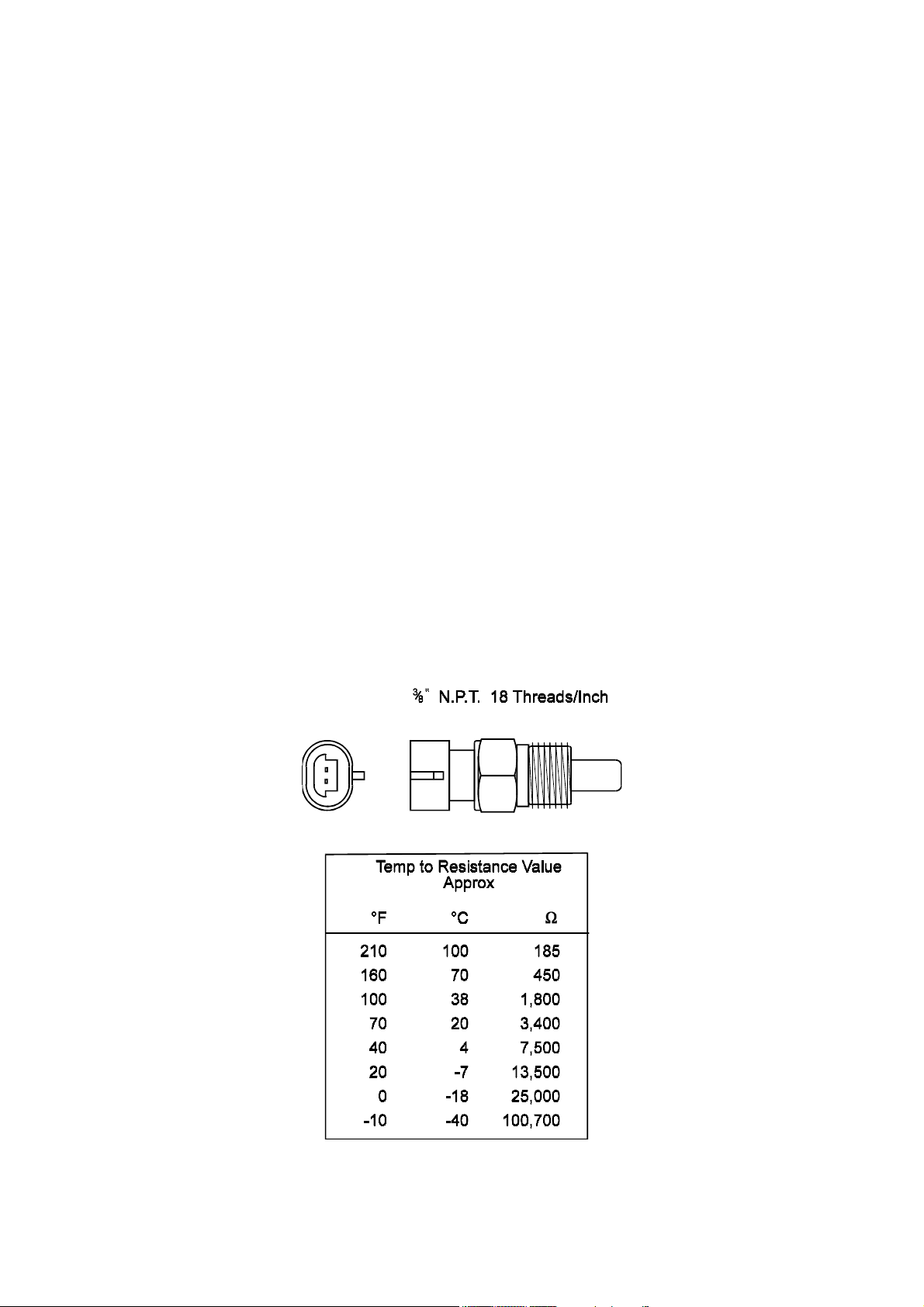

1.3.2. Coolant Temperature Sensor

The coolant temperature is used by the computer to determine the required corrections to

ignition timing.

The coolant temperature sensor has a solid brass temperature sensing tip. Refer to the

diagram for technical details of the sensor. The coolant sensor supplied is an industry

standard component and some engines may already have provision for this type of sensor.

The coolant temperature sensor is designed to screw into a threaded hole and protrude into the

engine coolant stream. For air-cooled engines, the sensor can be embedded directly into the

engine block or used to sense oil temperature.

Locate a suitable position on the engine which will allow the hole and thread to be machined,

and which gives access to the coolant stream. The sensor should be mounted before the

thermostat in the coolant circuit. Since most engines have existing temperature sensor holes,

it is often possible to mount the Haltech sensor in one of these holes. A thread adaptor is

sometimes necessary. In some engines only one temperature sensor hole exists and is used for

the dashboard gauge sender.

If it is necessary to drain the coolant from the vehicle to fit the temperature sensor then the

factory manual for the engine should be consulted for the correct procedure to restore the

coolant and purge the cooling system of air.

1.3.3. Inlet Air Temperature Sensor

10

Page 15

14mm x 1.5

The air temperature sensor is used to compensate for changes in air density due to air

temperature. This effect is most noticeable in forced induction engines. The Haltech IG5 will

allow compensation for ignition timing using the signal received from the air temperature

sensor.

The sensor should be mounted to provide the best representation of the actual temperature of

the air entering the combustion chamber, ie. after any turbo or supercharger, and intercooler,

and as close to the head as possible. The sensor needs to be in the moving air stream to give

fast response times and reduce heat-soak effects.

Note: The Haltech air temperature sensor will read temperatures up to 120° C

and temperatures above this will be interpreted as a fault condition. The air

temperature after some turbocharger's and superchargers can exceed this. If

this occurs with your engine you should consider fitting an intercooler to

reduce air temperature and increase charge density. If this is not possible then

the air temperature sensor should be placed upstream of the turbo or

supercharger to monitor ambient air temperature.

Once a suitable position has been located for the air temperature sensor a hole should be

drilled and tapped to accept the sensor. Remove the manifold or inlet tract from the engine

before machining the sensor mount. Do not allow any metal particles to enter the inlet

manifold of the engine as these will be drawn into the engine and damage it. Wash all

components thoroughly before reassembly.

11

Page 16

1.3.4. The Throttle Position Sensor (TPS)

The throttle position sensor is mounted to the throttle butterfly shaft to sense its rotation. A TPS is

common on many late model engines and the Haltech sensor should attach with little or no

modification. The throttle shaft must protrude from the side of the throttle body. This may require

the machining of the throttle body or the manufacture of a new throttle shaft. The inner mechanism of

the sensor rotates with the shaft. If the shaft is round then file a flat surface on the shaft so that it will

pass through the sensor assembly. The TPS should be mounted against the side of the throttle body,

using two screws, such that the throttle shaft and the sensor mechanism can rotate freely. Make sure

that the axis of rotation of the shaft is exactly aligned with the axis of rotation of the sensor.

Also, do not use the TPS as a throttle stop. In either case, the TPS will be damaged. The

absolute range of sensor movement is not important as the sensor can be calibrated using the

programming software.

Note: If a Throttle Position Sensor is already fitted this sensor can often be

used instead of a Haltech supplied TPS. The rotary potentiometer in the

Haltech TPS has 10k Ω resistance value but the alternate TPS can have a

different value as the software allows calibration of the throttle input.

1.3.5. Mounting the Igniter

The igniter must be mounted on a flat surface (eg. the firewall) to ensure proper heat dissipation and

to avoid stress on the wiring connections. It is important to protect the module from overheating by

mounting it away from hot components such as exhaust manifolds and turbocharger's.

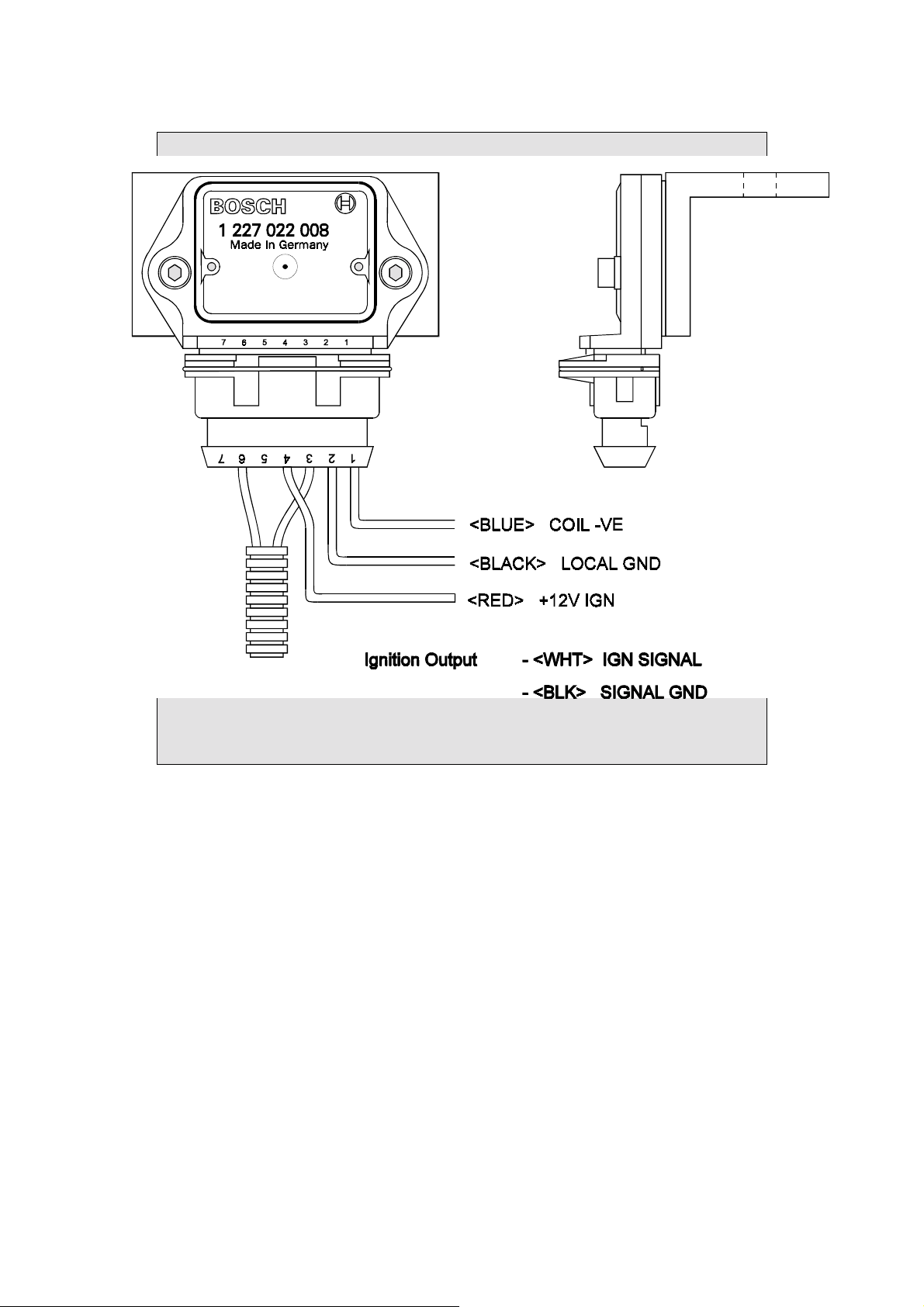

Included with the Bosch Ignition Module (the EB023 supplied by Haltech) is the ignition subloom. This connects the Ignition module to the Main Harness. Locate this loom and connect

it to the ignition module but do not connect the ignition sub-loom to the main loom until

the ignition settings in the ECU are verified by connecting the ECU to a computer.

Connect the 3 flying leads of the ignition sub-loom. The black wire with the eye terminal is a ground

connection. This should NOT be grounded to the same point as the ECU to prevent ignition noise

getting into the power supply circuit of the ECU. The blue wire goes to the negative side of the coil.

The red wire should be supplied with 12 volts when the ignition is on. This can often be obtained

from the positive side of the coil.

12

Page 17

WARNING:

NOTE: IF USING THE BOSCH IGNITION MODULE (THE EB023

SUPPLIED BY HALTECH ON AN ANGLE BRACKET) CONSTANT

DUTY SHOULD BE SELECTED IN THE IGNITION SETUP PAGE.

Bosch Ignition Module. The module must be mounted on the bracket, and the bracket must be

mounted to a suitable surface.

13

Page 18

1.3.6. Route Wiring Harness and Connect Sensors

Lay the main wiring harness out in the engine bay with the sensors mounted to ascertain the

best fit for the harness. Pass the wiring loom through a hole in the engine bay firewall and

into the passenger compartment where the ECU will be mounted. Either use an existing hole

or cut a new hole to suit. Use a rubber grommet or similar device to protect the harness from

being damaged by rubbing on the sharp edge of the hole.

WARNING:

DO NOT ALLOW THE HARNESS TO TOUCH HOT EXHAUST

PARTS INCLUDING MANIFOLDS OR TURBOCHARGER'S.

TRY TO ROUTE THE MAIN HARNESS AWAY FROM HIGH

VOLTAGE IGNITION LEADS. UNDER NO CIRCUMSTANCES RUN

ANY WIRING PARALLEL TO OR IN CONTACT WITH THE

IGNITION LEADS.

Note: Be neat. Run the harness in a tidy fashion. Try to run the harness along

paths used by original wiring. Use nylon cable ties to secure the harness in

place, but do not stress the wiring or connectors.

Once the harness is fitted, connect all the sensors to their appropriate plugs.

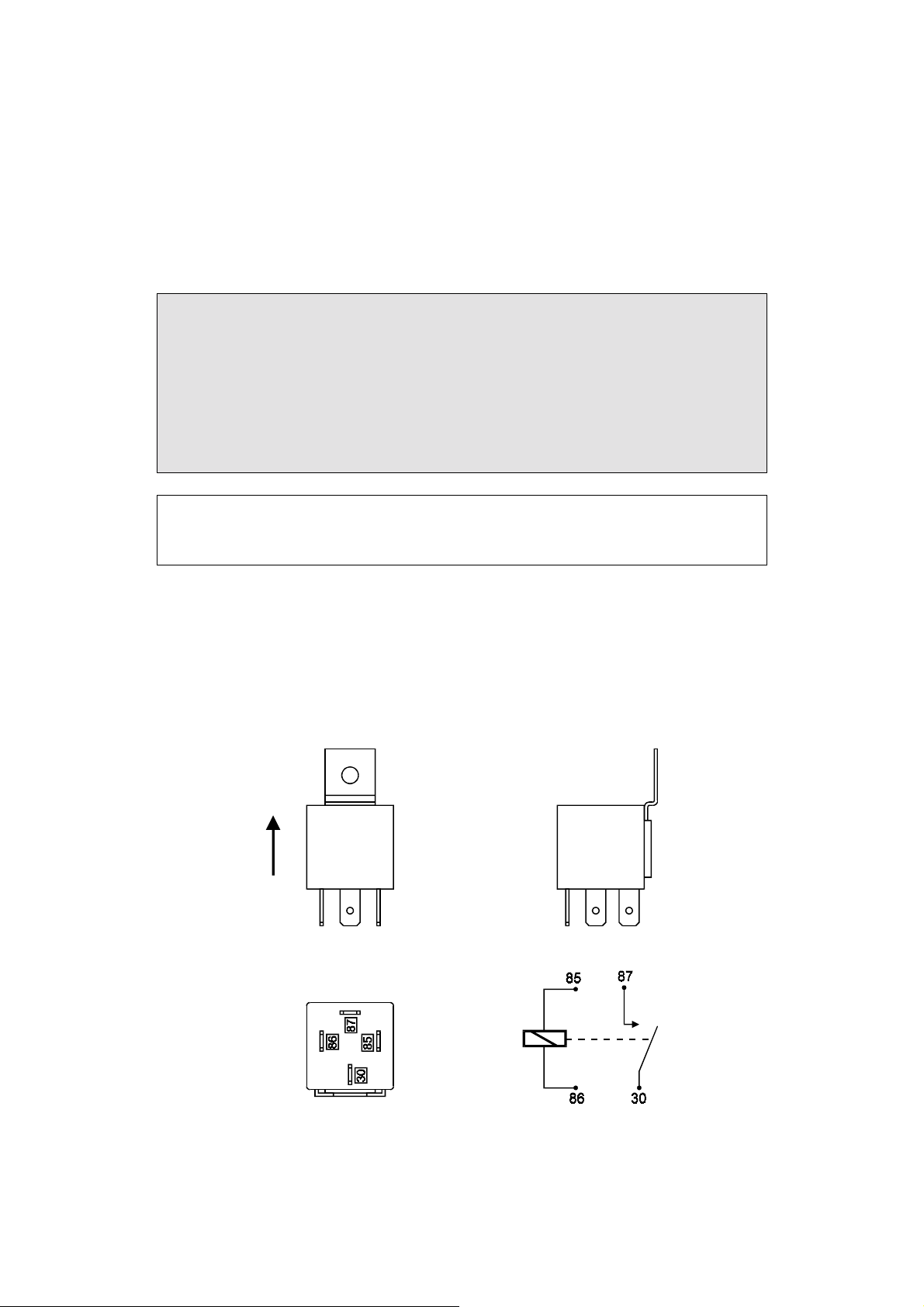

1.3.7. Power Relays

There is one relay used with the Haltech IG5, (the Main Power Relay)

It should be mounted on the firewall or an inner guard with the connector terminals to the

bottom as shown in the diagram.

14

Page 19

1.3.8. Electronic Control Unit (ECU)

The Haltech IG5 is not designed to be waterproof. It is desirable that the ECU be given as

much protection from the environment as possible. It is recommended that the ECU be

mounted inside the passenger compartment, either on the firewall, under the dashboard or

under the passenger seat.

The ECU has four mounting holes that allow it to be mounted to most flat surfaces. In

extreme cases of vibration, the ECU should be mounted on rubber anti-vibration pads. When

mounting the ECU remember that the communications connector on the loom should remain

accessible for ease of programming.

1.3.9. Flying Leads

Locate and connect the following flying leads.

Black - (Ground) Locate a good chassis ground point and connect the black wire. The best

spot is direct to the battery negative terminal.

Red - (Supply 12V) Locate a source of continuous 12 volts and connect the red wire.

Connecting direct to the positive battery terminal is suggested.

Grey - (Switched 12V) The grey wire is used to control the operation of the Haltech IG5

power relay. It needs to be connected so that it sees 12V only when the ignition is on

and during cranking. This wire does not draw a large amount of current (< 0.5A). Do

not connect to the accessory outputs of the ignition switch.

1.3.10. Install and connect any Optional Outputs

If you are planning to use any of the Programmable Optional Outputs, install and connect

them now. Depending on what options you are using, the wiring will be different. For details

on wiring your particular options, refer to Chapter 13, Auxiliary Outputs.

1.3.11 Connect the Trigger Sensor

Refer to Appendix C Trigger Inputs for detailed information on trigger connections. If the

engine has a magnetic reluctor type signal which requires a Reluctor Adaptor you should

install the Reluctor Adaptor now. For details on how to connect the Reluctor Adaptor to the

main loom and to the trigger refer to Appendix E Wiring Diagrams.

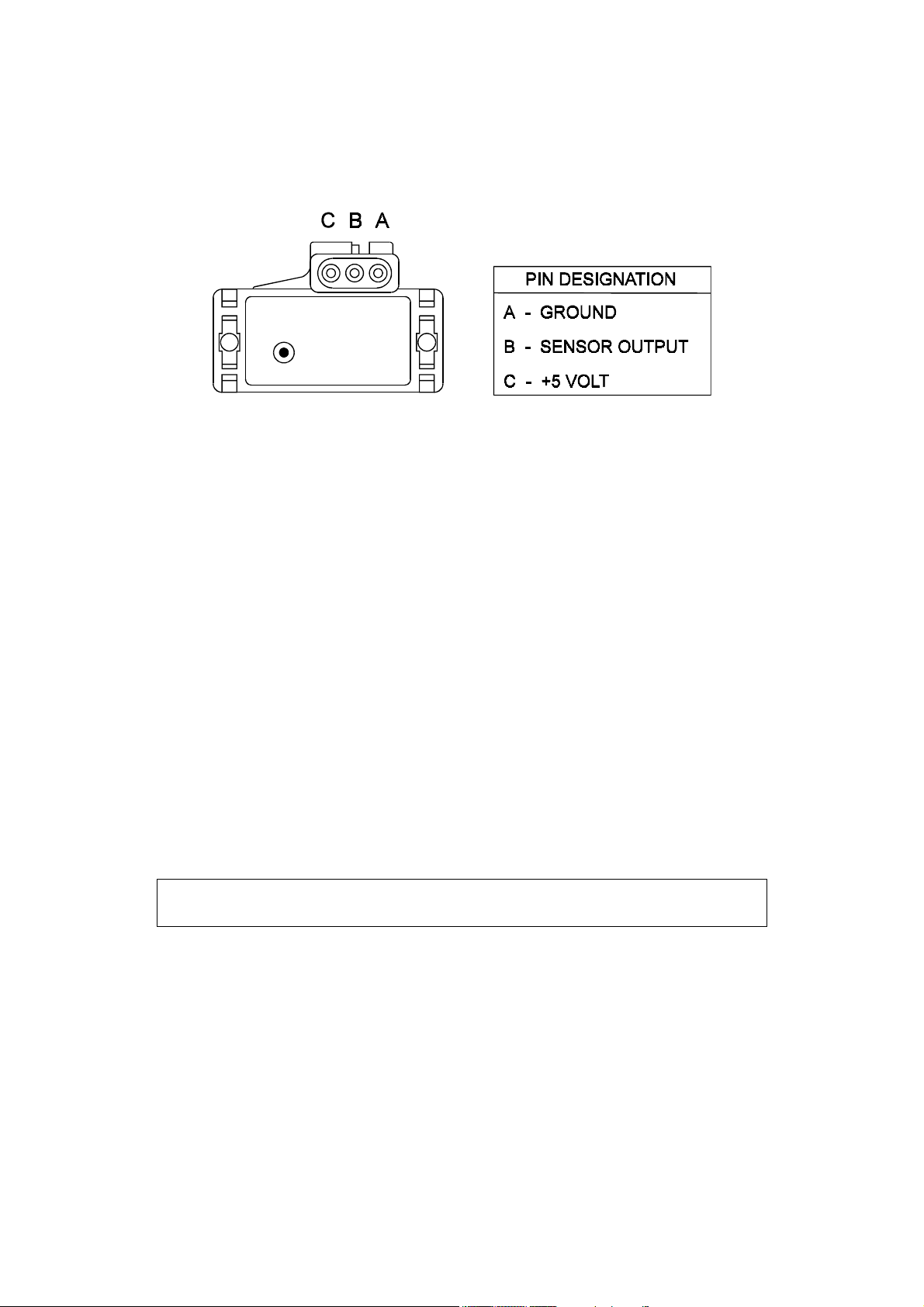

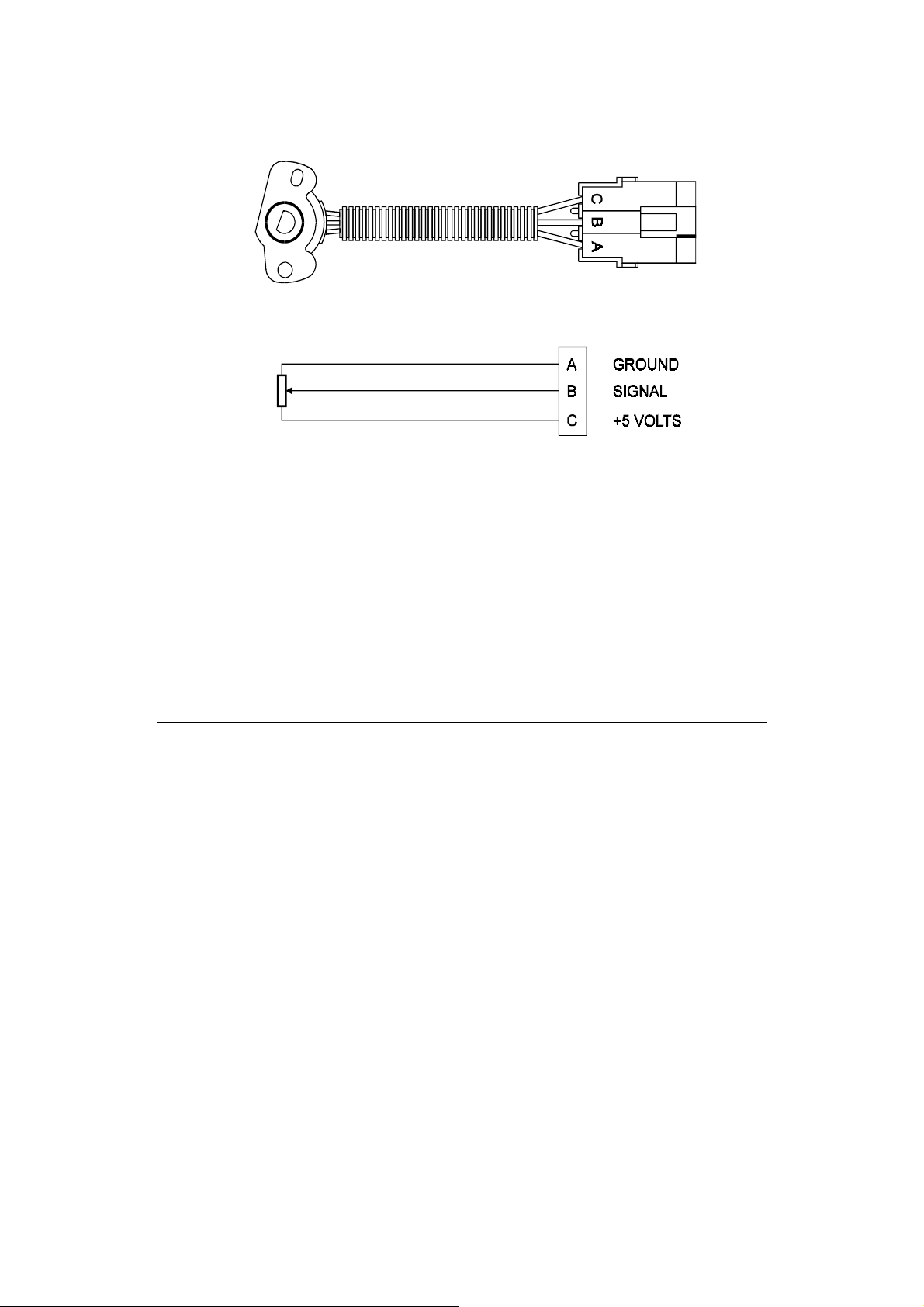

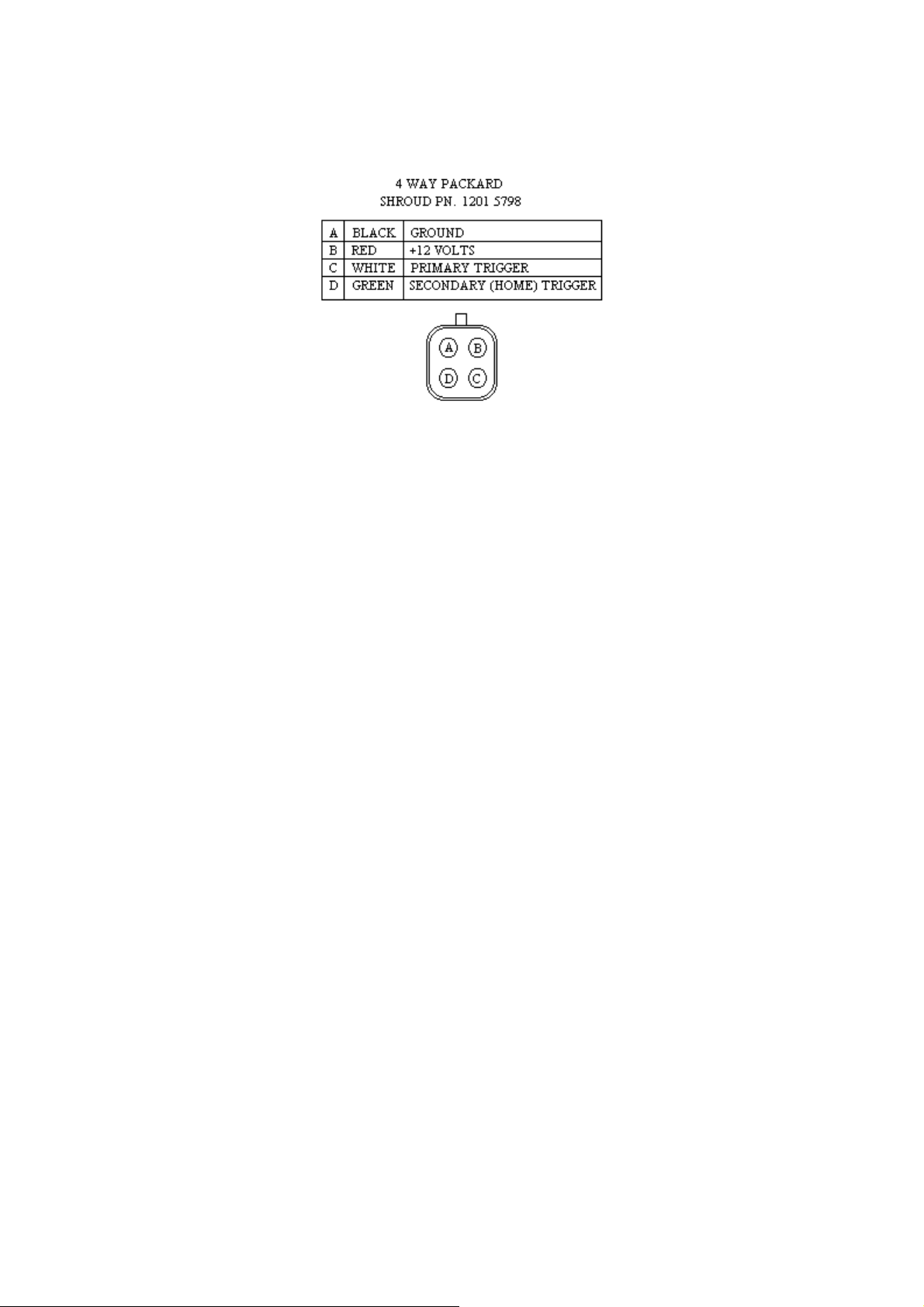

Hall Effect and Optical triggers have three connections - ground, power and signal. The

trigger connector on the Main Harness has four pins shown in the diagram below. The

Secondary (Home) Trigger is used for Direct Fire Applications. (See Appendix C.3).

15

Page 20

The secondary input can also be used as the Road Speed input if it is not being used as a home

trigger.

You will need to know what wiring your trigger requires. Some triggers need a series resistor

on the power line in order to limit current. Check your trigger system thoroughly. An

incorrectly wired trigger can cause damage, usually to the trigger.

The IG5 requires one trigger input signal per ignition event. For example, a V8 engine will

require 4 triggers per engine revolution. It is recommended that you read Appendix C,

Trigger Inputs for more detailed information on the trigger requirements of the IG5.

1.3.12 Connect the ECU

The ECU can now be connected. The system can now be tested as described in the following

chapters.

16

Page 21

CHAPTER 2 GETTING ONLINE

Now that your Haltech IG5 is installed with all the sensors in place the system can be

connected to the programming computer. This will allow the readings from all the sensors to

be displayed on the screen and checked for correct operation.

To connect the PC to the Haltech IG5 ECU you will need the programming cable and

programming disk supplied.

2.1 Connecting the Haltech IG5 to a Computer

The programming cable supplied with the Haltech IG5 is a standard serial link extension

cable. One end of the cable will plug into the Main Harness PC Interface connector (near the

main connector). The other end should plug into the mating connector at the back of your

computer. The plug on the computer may be marked "Serial", "Mouse" or "COM". Almost

all laptops will have this plug. If there is no 9 pin plug which it will connect to, check to see

if there is a 25 pin D-type plug available (some desk top computers will have this). If this is

the case, an appropriate cable can be supplied on request. Alternatively, most electronic

retailers will have a 25-pin to 9-pin converter.

Any time you wish to communicate with the IG5 ECU it needs to be supplied with power.

This usually involves just turning on the ignition switch. If at any stage power is not on, or

the programming cable is disconnected while attempting to communicate, the programming

software will display the message RECONNECT HALTECH. To rectify this, reconnect

power and/or the programming cable.

2.2 Operating the Software

2.2.1 Computer Requirements

The computer required to program the Haltech IG5 can be any IBM compatible personal

computer from the XT onwards (ie. the AT, 386, 486 or Pentium computers). The

requirements are fairly modest. The computer must have at least 640K of RAM (with about

615kb free for executable programs), one 3.5" disk drive and a CGA, EGA, or VGA screen.

(Virtually all reasonably modern laptops running MS-DOS (version 5.00 or higher) will fit

this description).

17

Page 22

2.2.2 Installing the Software

The Programming Disk supplied with the Haltech IG5 has an installation program that allows

you to install the software onto the PC’s Hard Disk. Most modern PCs have a hard disk. If

your PC does not have a hard disk, the IG5 Program can run directly from the disk supplied.

Installing the software on the Hard Disk will speed up program execution and avoid having to

fiddle around with floppy disks. The installation program needs only to be run once.

If you do not have a Hard Disk, go to the section titled Running the Software from the

Floppy Drive.

To install the software follow these steps.

Boot up Computer

Turn your PCs power on and boot up MS-DOS as instructed by the computers Users Manual.

If a shell program or menu utility runs automatically when you boot your computer, exit it

now. You should see a prompt similar to this:

C:\>_

This is the ‘DOS Prompt’. It is DOS’ way of indicating that it is waiting for a command. The

C: indicates that the C drive is the drive currently selected. If you do not have a hard disk,

your prompt will look similar to this:

A:\>_

Select the Drive

To run the INSTALL program, you must insert the supplied disk in the disk drive. To select

the appropriate disk drive (this will most probably be A: or B:) type:

The ←←←← key is the Enter Key. On some keyboards it may be called the Return key. You

should now see the prompt:

A:\>_ or B:\>_

Run the INSTALL Program

To run the Install program type:

α:←

or

ινσταλλ←

Β:←

18

Page 23

The Install program will now run. Follow the instructions given. The program will suggest

that the software will be placed in the HALTECH directory. You can change the destination

directory, but this is not recommended unless you understand how directories work.

When it is finished, the installation program will tell you if the installation is successful. If it

was not, consult the trouble shooting section of this manual.

The IG5 Program is now ready to run.

2.2.3 Running the Software from the Hard Disk

Boot up your computer as described earlier. If your computer is already on, make sure the C

drive is currently selected. To change to the HALTECH directory type:

or, if you used a different destination directory, type that path.

To start the program type:

The IG5 program will now run. The next section is on running the software from a floppy

drive. If you intend to run the program from the hard drive you can skip this section and go

straight to the section entitled Azerty Keyboards.

χ∆ ∴ηαλτεχη←

ιγ5←

2.2.4 Running the Software from the Floppy Disk.

To run the software from a floppy drive, boot up your computer as described earlier. Insert

the Programming disk in the disk drive. To select the appropriate disk drive (this will most

probably be A: or B:) type:

You should now see the prompt :

A:\>_ or B:\>_

To start the IG5 program type :

The IG5 program will now run.

α:←

or

ΙΓ5←

Β:←

19

Page 24

2.2.5 Azerty Keyboards

Most countries use a keyboard where the first six letter keys across the top row are :

This is called a Qwerty keyboard. Some countries use an alternative, which is called an

Azerty keyboard, where the Q and W keys are swapped with the A and Z keys respectively. If

you have an Azerty keyboard, you need to run the software slightly differently. When you

would normally type :

to run the programming software (not the installation software), you need to type:

The /A tells the program you have an Azerty keyboard. The program will adjust accordingly.

θωερτψ

ΙΓ5←

ΙΓ5/α←

2.3 The Online and Offline Modes

On the IG5 system title page, the software asks whether to operate in ONLINE or OFFLINE

mode. The Offline mode is very useful to familiarise yourself with the Haltech software, but

should not be used to make lasting adjustments to the ignition maps unless there is a special

reason for doing so. If you wish to experiment and familiarise yourself with the software

press N for Offline mode, but if the ECU is installed and power is available then we suggest

the Online mode be selected. Press Y to select online mode.

2.4 Using the System Online

In the Online mode there is a two-way flow of information between the ECU and the

programming computer. The communication cable must be installed and power must be

available to the ECU before the system can communicate. The Online mode will be used

most frequently. While using the system Online, you can view engine information directly

and make adjustments. Any changes or modifications made on the computer are

instantaneous and will be immediately recorded in the ECU. When the programming cable is

removed and the ignition switched off, the ECU will retain all of its memory. The maps do

not need to be saved, but keeping a copy on disk is always good practice and is recommended.

Note: If power is removed or the communication cable is disconnected or

interfered with, the following message will be displayed on the computer

screen.

RECONNECT HALTECH

20

Page 25

If this message appears check all connections and ensure that the communications cable is not

being interfered with. Also be sure that the Haltech IG5 unit is receiving power. (i.e. ignition

switch is turned "on".)

2.5 The Main Menu

When you select Online or Offline mode the Haltech MAIN MENU bar appears. This menu

bar allows access to sub-menus giving access to maps, file storage/retrieval, engine data and

options.

2.6 How to Quit

Throughout the program you can exit from any application by using the menu bars or hot

♣θ

keys. Pressing

♣θ

in any page will prompt you to exit the program (i.e. pressing

♣θ♣θ

θθθθ

while

holding down the

♣♣♣♣

key). If you wish to exit press

ΨΨΨΨ

when prompted.

2.7 Checking the Engine Data

The engine data option can only be used when the system is Online. This function allows all

of the engine data variables to be displayed on the screen

This is a very useful function for analysing the engine sensors. To display the engine data

♣ε

♣ε

press

pressing

Do not attempt start the engine if the Engine Identification has not been set up. View the

engine data page to ensure all the sensors are operating properly.

from any application. Alternatively it can be accessed through the menu bar by

♣ε♣ε

ƒΟ

ƒΟ

and then

ƒΟƒΟ

ΕΕΕΕ

for Engine Data.

21

Page 26

CHAPTER 3 ENGINE IDENTIFICATION

3.1 Setting Engine Identification

The Identification page tells the IG5 information about the engine characteristics. Without

this information being correct the engine cannot run properly. The Identification is made up

of several fields. Each field can have a number of settings, and you can change most of the

fields.

′′′′

Use the Up and Down arrow keys (

Selection type, or Text type. The Selection type fields give you a number of valid entries for

that field. For example, the valid number of cylinders can be set to 1, 2, 3, 4, 5, 6, 8, 10 or 12.

and

≤≤≤≤

) to move between fields. The fields are either

The Tab and Enter keys (

the Tab key will display the next selection. The Shift and Tab keys together will step

backwards through the selections. Once the desired selection is displayed, the Enter key is

pressed to program that selection. Text Fields require you to enter either text or numbers.

Once the field is selected, the new text can be typed in, with the Enter key to finish. An

example is the Rev Limit. This field can be set between 2000 and 16000 rpm. If you want the

rev limit to occur at 7000rpm, then you would need to select this field using

7000←

7000←

type

7000←7000←

Here is a description of each of the Identification fields:

Cylinders

Load Sensing

MAP Sensor

RPM Limit

.

The number of engine cylinders needs to be entered here. This parameter is used to

determine the engine speed.

The IG5 can use either the manifold pressure or the throttle position as a means of

determining the engine load. Most engines operate using manifold pressure to sense

engine load. If your engine employs any form of supercharging, you must run in

manifold pressure mode. Only wild cams, motorbikes or heavily ported rotaries

require throttle mode – i.e. engines whose vacuum signal is small, or fluctuates

greatly. If you are unsure what to use, contact your Haltech dealer.

The IG5 needs to know the pressure range of Manifold Absolute Pressure (MAP)

sensor being used. Refer to Chapter 1 [1.3.1]. The selected value can be 1, 2 or 3bars.

The IG5 can limit the maximum rpm at which the engine will operate. Above this

level the IG5 completely cuts ignition to the engine. When the engine speed drops

below the RPM Limit the IG5 will resume normal ignition delivery. This is known as

hard limiting. If the RPM Limit is not wanted then set this value above the highest

operating point of the engine.

♥♥♥♥

and

←←←←

) keys are used to change this type of field. Each stroke of

′′′′

≤≤≤≤

or

and then

22

Page 27

Units

The Haltech IG5 programming software can display parameters in either Metric or US

units.

RPM Mode

The IG5 ignition maps may be arranged either in 500 rpm increments to 10,500 rpm,

or in 1000 rpm increments to 16,000 rpm. Select the high - or low - rpm mode here.

Changing settings alters the way the ECU reads the Maps, and will change the tuning

of the engine dramatically. Do not change this setting once tuned.

Road Speed Value

This value calibrates the Road Speed reading. Some configurations cannot use the

Road Speed input trigger in which case this field will not be displayed.

Trim Control

The optional Trim unit can be used to control one of several parameters. This field

selects the controlled parameter. If there is nothing connected to the trim plug, the

trim will have no effect (except with boost control). The available functions are :

Ignition +7 to -8 degrees adjustment of ignition advance.

Ign Trailing +7 to -8° adjustment for Rotaries only

Boost Control Boost trim for Wastegate control only.

Aux. In Function

The Auxiliary Input on the IG5 can be configured for one of a number of functions.

Most of these functions relate to the configuration of the system. The available

functions are:

Disabled No effect on ECU operation.

Nos Input Input - This input is used in conjunction with the

Nos Optional Output. [13.10]

TCC Input Input - This input is used in conjunction with the

TCC Optional Output. [13.4]

Turbo Timer Input - This input is used in conjunction with the

Turbo Timer Optional Output. [13.9]

Since the Auxiliary Input line can only perform one duty, all of the above functions are

mutually exclusive, i.e. although four programmable outputs exist on the IG5, only one of the

NOS, TCC and Turbo Timer may be chosen. Keep this function in mind when deciding on

the IG5 configuration you wish to run.

3.2 Ignition Set-up

The Ignition Set-up works in an similar way to Engine Identification. Its fields relate to the

way the ignition advance is determined for the engine. Enter the Ignition Set-up by pressing

ƒσ

ƒσ

ƒσƒσ

then

ΙΙΙΙ

. The fields in the Ignition Set-up are:

23

Page 28

Trigger Degrees

This field tells the ECU where to expect the Main Trigger to occur. This field is very

important for the correct operation of the ignition. If it is incorrect, the spark advance

will also be incorrect, which could lead to engine damage. The ECU needs to receive

an input trigger at a fixed engine angle Before Top Dead Center (BTDC) for each

spark. This trigger may be set between 60° and 100° BTDC. See Chapter 5 for

details.

Lock Timing at 10 Degrees

This field is used for testing the trigger input. It allows the timing to be locked at ten

degrees regardless of the engine speed and ignores the ignition map settings. This

feature is further discussed in Appendix C

Trigger Edge

This field determines whether the IG5 is to trigger on a rising or a falling edge. Refer

to Appendix C - Trigger Interface for details on how to determine this setting. If a

Reluctor Adaptor is being used, this field should be set to Falling.

Output Type

This field is used to determine how the ignition output signal is to be defined.

Constant Duty should only be used with the Bosch type Haltech Ignition Module or

other “intelligent” igniters and special after market systems that perform dwell control.

Constant Charge may be selected if the igniter operates simply as a switch (ie a

“dumb” igniter) and requires a dwell signal.

INCORRECTLY SETTING THIS FIELD WILL CAUSE FAULTY

OPERATION AND MAY BURN OUT THE IGNITER(S). DAMAGE

CAUSED BY INCORRECT SETTING WILL NOT BE REGARDED AS

Coil Charge Time

Only required if Constant Charge selected as Output Type. This is the time require to

charge the coil fully, or until the igniter’s current limit is reached, typically 4-5 ms.

Refer to Appendix B for additional information.

Output Edge

The Output Edge should be falling with a 30% switch when using a Bosch igniter (the

EB023 supplied by Haltech). This is the default setting. If you are using any other

igniter, refer to Appendix B for details on how to set this field for the igniter used.

Trigger Type

This field defines the trigger pattern the ECU will see coming from the crank or cam

angle sensors. The IG5 currently supports the following trigger types:

Standard This trigger pattern sends one trigger for each spark event. For example a

V8 has 4 firing strokes for each crank revolution, for this engine the ECU would

expect to see 4 trigger events for each crank revolution or 8 events for each cam

revolution.

WARNING:

WARRANTY.

24

Page 29

Multi-tooth This trigger pattern is the same as that for the Standard Trigger except that

there are multiple trigger events for each spark event. The number of teeth for a

multitooth trigger must be a multiple of the spark events. This trigger requires a home

signal for synchronisation of the trigger and engine position.

Motronic This trigger is a variation of the multitooth trigger pattern. This setting is

compatible with the BOSCH Motronic controlled engines. The Motronic wheel has

multiple teeth with a set number of teeth missing for synchronization removing the

need for a separate home signal. The BOSCH Motronic wheel usually has 60 teeth

positions with 58 teeth and 2 missing teeth.

Twin Trigger This trigger is used in conjunction with twin distributor ignition

systems. Since it is a distributed system there is no requirement for a home signal so

this channel is used to carry the second trigger.

Number of Teeth

This field is only applicable if the trigger type is Multitooth or Motronic. The Number

of teeth:

Multitooth The number of teeth on the multitooth wheel

Motronic The number of teeth on the motronic wheel including the missing teeth

Tooth Offset

This field is only applicable if the trigger type is Multitooth or Motronic. The offset is

the number of teeth the synchronisation event occurs prior to the trigger

Home Edge

This field is similar to Trigger Edge it defines the active edge for the Home channel.

If a reluctor adaptor is being used this field should be set to falling.

Spark Mode

This field defines the ignition delivery used, the options are: Distributor, Direct Fire or

Twin Distributor.

Coils on 4-cylinder motor

This field is only applicable if the spark mode is Direct Fire and the number of

cylinders in the main set-up is “4”. The options for this field are: “2” or “4”. If “2”

is selected waste spark is used. If “4” is selected there is one coil for each cylinder.

Engine Type

This field defines the engine type: Piston or Rotary.

25

Page 30

CHAPTER 4 USING HALTECH SOFTWARE

The tutorials presented in this chapter are examples of how to use the Haltech software.

They assume that you have the software running online on your PC, with the ECU powered

and connected via the supplied programming cable.

4.1 Using the Software

In order to make the software easy to use, the program presents you with a menus bar at the

top of the display. The menu bar is accessed through simple combinations of key strokes.

Once the appropriate menu has been accessed a sub-menu appears with the headings of the

available pages.

4.2 What is mapping the Engine?

Mapping the engine is filling in the look-up tables with the correct values for your engine.

This is done by adjusting the heights of bars in bar maps. Bars may be adjusted one at a

time, or in groups. The Haltech programming software has been designed to make engine

mapping as simple and intuitive as possible.

4.3 What are maps?

Ignition Maps

The ignition advance needed by the engine under different speed and load conditions are

stored in the IG5 in a look-up table called the Ignition Map. The IG5 uses the engine's load

and speed as an index to the table. For instance, at an engine speed of 4000 rpm and a

manifold pressure of -20kPa the relevant number in the table may be 35. When the engine is

running at 4000 rpm and -20kPa manifold pressure the computer will extract the value of 35

from the table and fire the ignition at 35 degrees. This value may be modified slightly by

other correctional maps also under user control which are described later. The programming

software divides the table into rpm range maps. Within each rpm range map there are 32

load points along the horizontal axis, each represented by a vertical bar. The greater the

vertical height of the bar, the greater the ignition advance. The load points usually represent

incremental changes in intake-manifold pressure but may, for certain engine types, be set up

by the user to represent changing throttle positions. When you view a Map (see section

4.3.1) you see a bar chart of ignition time versus load for all the load points in that particular

speed range.

Other maps

There are other tables in the IG5 which are also called maps. They are indexed by only one

parameter and so are not divided into ranges and are described later..

26

Page 31

4.4 Accessing the Ignition Maps

ĵ

Pressing

Ignition maps. Or you can access the ignition maps directly through

application.

ĵ

from any page will take you to the Maps Menu. From here you choose

ĵĵ

4.5 The Ignition Maps

ΙΙΙΙ

for the

♣Ι

♣Ι

from any other

♣Ι♣Ι

The ignition map shown above is explained in detail here.

The Menu Bar

This has the names of four major software menus embedded in it. Any of these may

be accessed by holding down the Alt key of the PC keyboard and pressing the initial

of the required group

Range 1

This range information (in a box - top left) refers to the bar graph map currently

displayed . The rpm beneath it will depend on the rpm mode previously selected on

the Engine Identification page. The displayed map range is selected by either the F

keys along the top of the keyboard or from the Ignition Map.

Engine Data

This is displayed across the bottom of the page is the live data of the running engine

when the system is in the “on-line” mode

27

Page 32

Range 3 Bar 13

This information refers to the instantaneous engine speed and load and will follow any

changes in these values.

°Advance

This is the vertical axis of the ignition maps and indicates the advance selected for the

relevant engine speed and load.

-100 to 100 kPa

This is the horizontal axis of the ignition maps and indicates load range at the current

engine speed (defined by Range X). This particular map is used in conjunction with a

turbo-charged engine operating up to 1 bar of boost.

Highlighted bar

In the example above this is the bar above 0 kPa. It is the bar that will be altered in

height if the up or down arrows are pressed (see next section).

Arrow above bar

If the displayed map is in the same speed range as that at which the engine is actually

running, an inverted triangle will display above the vertical bar corresponding to the

actual load point of the engine. This is very useful when running an engine on a dyno

and you want to see what effect a change in ignition advance will have. The current

map can be accessed through the Ignition Map selection display by pressing the Home

key.

4.6 Altering a Map

ƒξ

Note: When two keys are displayed together, such as

second key must be pressed while the first key is held down. In this case, the

key would be held down while the

The height of the Bars in the map can be adjusted by using the up and down arrow keys for

small changes of the PgUp and PgDn keys (

summary at the end of this section for a full list of key functions. The bar that is highlighted

on the computer screen indicates the bar that you are adjusting. To select a different bar, use

the left and right arrow keys (

bottom of the display.

The ignition advance displayed does not necessarily match the bar height shown on the on

the map rather it is the final ignition advance after the various corrections have been made.

The ignition advance displayed in the engine data is indicated by the arrow above the

applicable bar, this is not necessarily the highlighted bar.

Changes made take effect the instant the keys are pressed. You do not have to do anything

else to save these changes.

∞∞∞∞ ⁄⁄⁄⁄

). The ignition advance for the outlined bar is shown at the

≥≥≥≥ ××××

) for larger increments. See the command

ƒξ

, this means that the

ƒξƒξ

ξξξξ

key is pressed.

ƒƒƒƒ

28

Page 33

It is possible to program the IG5 numerically. To enter the numeric mode press

spreadsheet of ignition advance data versus engine load and speed will appear. Use the

arrow keys to navigate the spreadsheet by moving the highlighted cursor to the required

field. Changes can be made by typing the ignition advance as a decimal number

representing degrees of advance (°BTDC). The whole spreadsheet is too large to display all

at once and the remainder can be accessed by using the arrow keys to shift the spreadsheet to

the left or right.

To return to the standard bar graph mode by hitting the ESC key. This method of mapping

can be extremely time consuming so the Haltech allows you to change the numbers by

manipulating maps presented as bar graphs which is much simpler and allows you to

visualize the result.

ƒƒƒƒνννν

. A

4.7 How To Quit

♣θ

Pressing

you to MS-DOS. You should always exit the program before switching off your computer.

The best way to initialize the Ignition Map is to use the Library Maps, and then return to the

Ignition Map later if the ignition curve needs modification. Ignition Library Maps are

explained in Chapter 5 [5.4], Starting the Engine.

♣θ

at any page or map will allow you to exit the Haltech program and will return

♣θ♣θ

4.8 Time Saving Functions

The following is a list of commands that can be used when the ignition maps are displayed.

These commands provide easy access to specific areas of the maps during tuning.

4.8.1 Current Location

Pressing

is currently being used. This bar is easily identified by the arrow above it pointing down. As

the engine speed and load changes, the arrow moves with it. The Home key can be used to

find the engine's operating point quickly.

″″″″

will take you to the range at which the engine is running, and highlight the bar that

4.8.2 All Ranges

ƒρ

The All Ranges function allows the user to initialize all RPM ranges with the same data.

enables the All Ranges function and “All Ranges” will appear under the title.

When the All Ranges function is active, a bar adjusted on one graph is copied to the same bar

on all the ranges. If you use this option, you can set the shape of the map at any range, and all

other ranges will be identical at every bar you adjusted. This feature enables all graphs to be

given an initial shape that should run the engine, albeit rather roughly. Once you have used

ƒρ

ƒρƒρ

29

Page 34

ƒρ

the All Ranges option for a starting point, press

and tailor each map individually.

This option is only available on the Base Ignition Maps.

ƒρ

once more to exit the All Ranges option

ƒρƒρ

4.8.3 Selecting Groups of Bars

Groups of adjacent bars may be highlighted and adjusted together.

♣♣♣♣

Hold

This group will now act in unison when increasing or decreasing the height of the Bars. To

deselect the highlighted Bars use the

while using the left or right arrow keys,

ƒƒƒƒ

and arrow keys together.

∞∞∞∞ ⁄⁄⁄⁄

, and you will highlight a group of bars.

4.8.4 Percentage Changes

Using this function will prompt you to enter a percentage change to the selected bars. An

entry of "20" will increase each bar by 20%, while an entry of "-15" will decrease the bars by

15%. This change only affects the highlighted bar(s).

4.8.5 Linearise

When a group of bars is selected (more than two), this function can be used to set the values

between the end points. Highlight the bars between two load points that are known to be

ƒλ

correct and press

between the two end points to form a straight line. This feature facilitates fast programming

and the smoothing of maps.

ƒλ

. The programming software will automatically adjust all the bars

ƒλƒλ

4.8.6 Numeric Mode

This will take you into numerical mode, displaying the map as a spreadsheet. This mode is

available if wanted, but graphical mapping is recommended as it is much easier to use. To

exit from Numeric Mode and go back to using the maps press the

°°°°

key.

4.8.7 Bar Increments

The Up and Down arrows,

determined amount, usually the smallest possible increment. PgUp and PgDn also change the

bars by a pre-determined amount. These increments (the value of the keystroke) can be

ƒι

changed by the user.

particular keys can be changed.

ƒι

ƒιƒι

≤≤≤≤ ′′′′

, normally change the bar height in the maps by a pre-

will bring you to a screen where the increments associated with

30

Page 35

Normally, the bars are altered by adding or subtracting a fixed amount. The adjustment keys

ƒπ

may instead apply a percentage change on each keystroke.

♣φ

will switch to percentage increments,

ƒλ

ƒλ

will space out increments evenly between the Up/Down Arrows field and the Ctrl

ƒλƒλ

PgUp/PgDn field.

♣φ

will return you to fixed increments.

♣φ♣φ

ƒπ

on the Bar Increment Screen

ƒπƒπ

4.8.8 Online Help

♣Η

The current version of software offers the “help shortcut key”:

is not available. Please refer to your manual for help with aspects of installation and

operation of your Haltech system.

♣Η

unfortunately this feature

♣Η♣Η

31

Page 36

4.9 Command Summary for Maps

,

- move left/right highlighted bar(s)

∞∞∞∞

⁄⁄⁄⁄

,

- increase/decrease highlighted bar(s)

≤≤≤≤

′′′′

,

≥≥≥≥

♦≥

♦≥

♦≥♦≥

♦×

♦×

♦×♦×

♣≥

♣≥

♣≥♣≥

- increase/decrease highlighted bar(s)

××××

,

- increase/decrease highlighted bar(s)

,

♣×

♣×

♣×♣×

♣⁄

♣⁄

♣⁄♣⁄

♣∞

♣∞

♣∞♣∞

ƒ⁄

ƒ⁄

ƒ⁄ƒ⁄

İ

İ

İİ

ƒΠ

ƒΠ

ƒΠƒΠ

ƒΛ

ƒΛ

ƒΛƒΛ

ƒΙ

ƒΙ

ƒΙƒΙ

ƒΝ

ƒΝ

ƒΝƒΝ

ƒΡ

ƒΡ

ƒΡƒΡ

ΝΝΝΝ

- increase/decrease highlighted bar(s)

,

- select (highlight) next bar

,

- deselect end bar

- enter Percentage change to highlighted bars

- Linearise between end points of highlighted bars

- set Increments

- enter Numeric mode

- toggle All Ranges mode

- move to Next range

- move to Previous range

ΠΠΠΠ

ϑϑϑϑ

- jump to range of value entered

- go to current engine range/bar

″″″″

- switches option in setup pages

♥♥♥♥

32

Page 37

CHAPTER 5 STARTING THE ENGINE

There are a few things that need to be done before starting the engine. Make sure that the