Page 1

PLATINUM

SPORT 1000/2000

QUICK START GUIDE

Page 2

Lockin Pty Ltd trading as Haltech warrants the Haltech

Pin # Wire Colour Connection

Platinum Sport 1000

Platinum Sport 2000

1 Y <SHD> TRIGGER ( + )

Y Y

2 Y <SHD> HOME ( + )

Y Y

3 GY AIR TEMP

Y Y

4 V COOLA NT TEMP

Y Y

5 G <SHD> TRIGGER ( - )

Y Y

6 G <SHD> HOME ( - )

Y Y

7 GY/G DSI 1

Y Y

8 GY <SHD> DPI 1

Y Y

9 GY/B <SHD> DPI 2

Y Y

10 GY/BR <SHD> DPI 3

Y Y

11 R/W +13.8V ECU POWER

Y Y

12 GY/O <SHD> 02 INPUT

Y Y

13 GY/Y <SHD> AVI 1

Y Y

14 B/W BATTERY GROUND

Y Y

15 B/W SIGNAL GROUND

Y Y

16 B/W SIGNAL GROUND

Y Y

17

- -

- -

18

- -

- -

19 V/O DPO 4

Y Y

20 O/G AVI 5

N Y

21 O/L AVI 6

N Y

22 O/V AVI 7

N Y

23

-

CA N HIGH

Y Y

24

-

CA N LOW

Y Y

25

- -

- -

26

- -

- -

free from defects in material or workmanship for a period of 12 months from the date of purchase.

Proof of purchase, in the form of a bill of sale or receipted invoice, which indicates that the product is

within the warranty period, must be presented to obtain warranty service. Lockin Pty Ltd trading as

Haltech suggests that the purchaser retain the dealer’s dated bill of sale as evidence of the date of

retail purchase.

If the HaltechTM Programmable Fuel Injection System is found to be defective as mentioned above, it

will be replaced or repaired if returned prepaid along with proof of purchase. This shall constitute the

sole liability of Lockin Pty Ltd trading as Haltech.

To the extent permitted by law, the foregoing is exclusive and in lieu of all other warranties or

representations, either expressed or implied, including any implied warranty of merchantability or

fitness. In no event shall Lockin Pty Ltd trading as Haltech, be liable for special or consequential

damages.

IGNITION WIRING WARNING

This system is capable of controlling either Auto-Dwell (also known as intelligent or smart ignitors)

which have in-built dwell control or ECU Dwell ignitors (also known as dumb igniters or Constant

Charge Ignitors), which contain no such control. This allows standard ignitors to be used in many cases.

Auto-dwell ignitors are commonly found on early EFI engines with electronic ignition.

ECU-dwell ignitors are commonly found in modern ECU controlled ignition systems.

Most standard ignitors are ECU Dwell.

It is very important to set the system up to match the type of ignitor used!.

In the ignition set-up page the setting should be:

To control Auto-dwell ignitors set up as “Constant Duty”

To control ECU-dwell ignitors set up as “Constant Charge”

If the wrong setting is applied, damage to the ignition system may occur.

Burning out ignitors due to wrong set-up will not be regarded as Warranty!

Please ensure all power supplies are disconnected before commencing any wiring.

Failure to follow all the warnings and precautions in this manual can lead to damage to

engine components and may possibly void your warranty. Incorrect setup of the ECU can

also lead to damaged engine components.

Damaged components due to incorrect setup will not be regarded as warranty repairs.

GENERAL INSTALLATION WARNING

Avoid open sparks, flames or operation of electrical devices near flammable substances.

Always disconnect the battery cables when doing electrical work on your vehicle.

Do not charge the battery with a 24 Volt truck charger or reverse the polarity of the battery

or any charging unit. Do not charge the battery with the engine running as this could

expose the ECU to an unregulated power supply that could destroy the ECU and other

electrical equipment.

All fuel system components and wiring should be mounted away from heat sources,

shielded if necessary and well ventilated. Disconnect the Haltech ECU from the electrical

system whenever doing any arc welding on the vehicle by unplugging the wiring harness

connector from the ECU.

After completing the installation, make sure that there are no fuel leaks, and no wiring

left un-insulated in case a spark or short-circuit occurs and causes a fire. Also make sure

that you follow all proper workshop safety procedures. If you're working underneath

a jacked-up car, always use safety stands!

LIMITED WARRANTY

TM

Programmable Fuel Injection System to be

Y= Available N = Not Available

Page 3

PLATINUM Sport 1000/2000

Quick Startup Guide

Congratulations on purchasing a Haltech Engine Management System.

This fully programmable product opens the door to virtually limitless performance

modification and tuning of your vehicle. Programmable systems allow you to extract

all the performance from your engine by delivering precisely the required amount

of fuel and ignition timing that your engine requires for maximum output under all

operating conditions.

This quick startup guide will walk you through installation of a Haltech ECU into a

vehicle. This guide is accompanied by the full service manual located on the

software CD provided with the ECU that you or your tuner will need to refer to

before completing your installation and configuration. The Manual can also be

downloaded from the Haltech website www.haltech.com

Installation

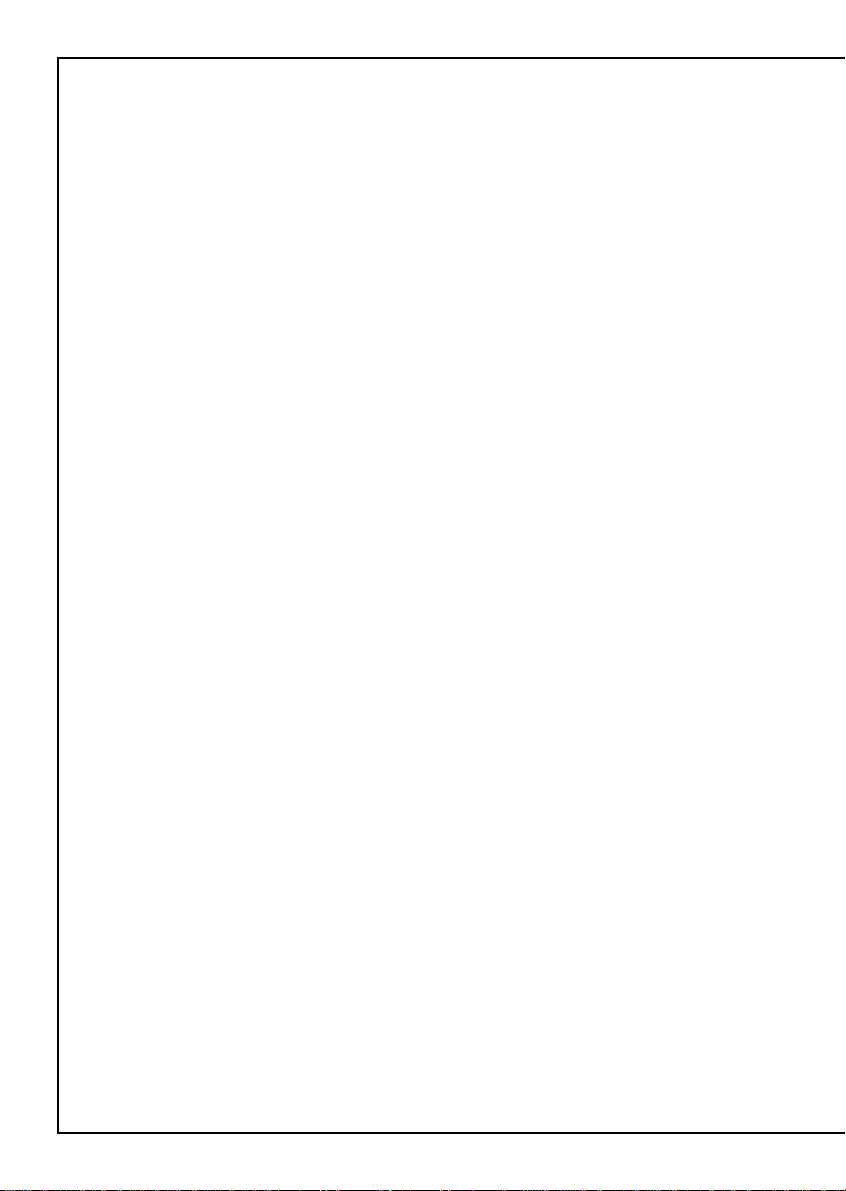

Air Temperature Sensor

The sensor should be mounted to provide the best representation of the actual

temperature of the air entering the combustion chamber, i.e. after any turbo or

supercharger, and intercooler, the optimum position being the intake pipe before the

throttle. The sensor needs to be in the moving air stream to give fast response times

and reduce heat soak effects.

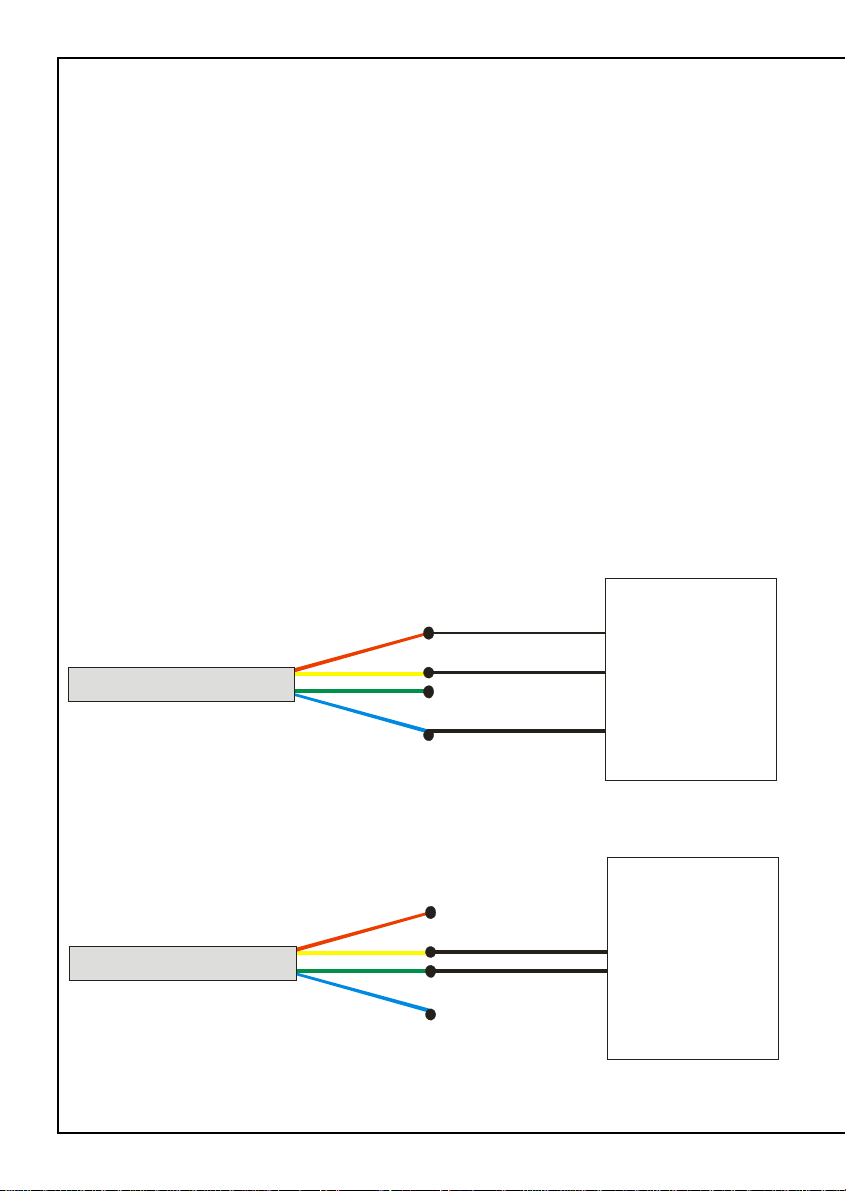

The air temp sensor plug is labeled with the letters A and B and should be wired with the

signal wire (Grey) to pin B and signal ground wire (Black/White) to pin A

Figure 1. Air Temperature Sensor and Terminations

Page 4

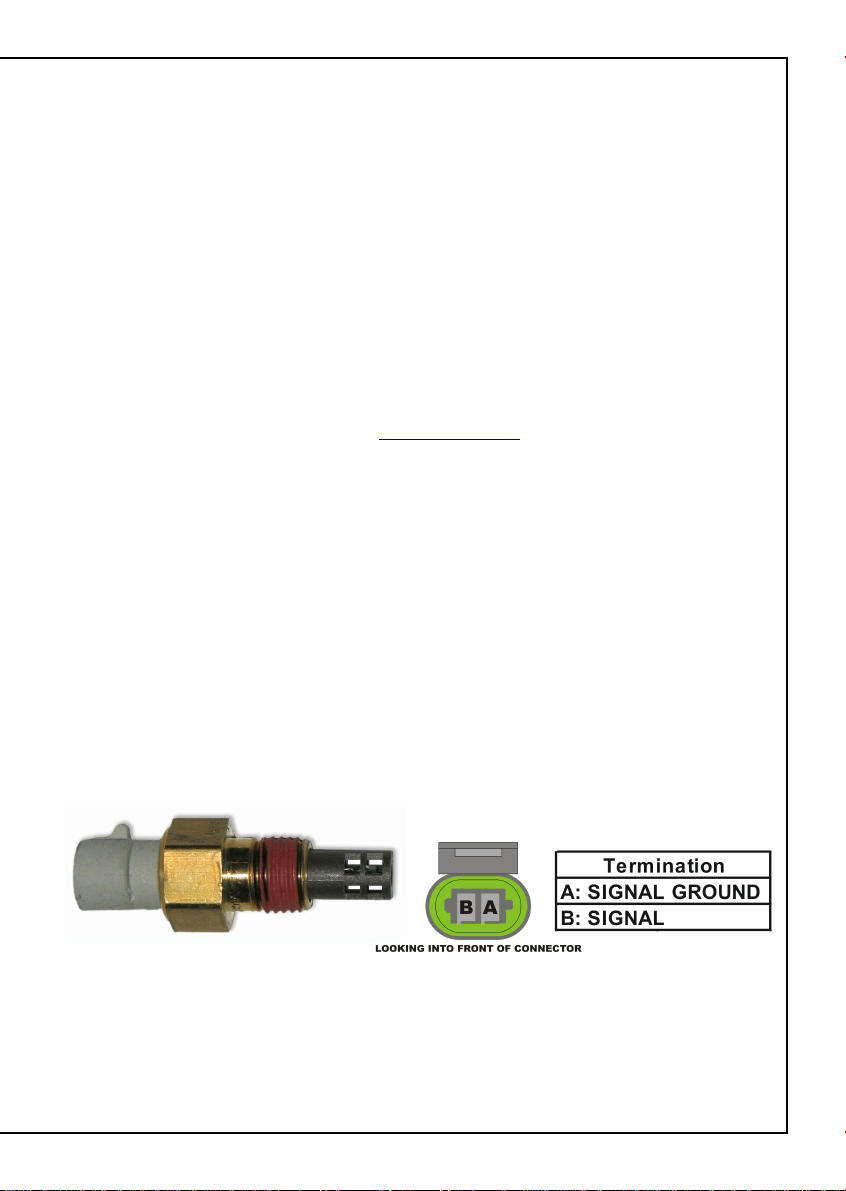

Coolant Temperature Sensor

The coolant temperature sensor is designed to screw into a threaded hole and

protrude into the engine coolant stream. For air-cooled engines, the sensor can be

embedded directly into the engine block or used to sense oil temperature.

Locate a suitable position on the engine which will allow the hole and thread to be

drilled and tapped, and which gives access to the coolant stream. The sensor

should be mounted before the thermostat in the coolant circuit. Since most engines

have existing temperature sensor holes, it is often possible to mount the Haltech

sensor in one of these holes.

The coolant temp sensor plug is labelled with the letters A and B and should be

wired with the signal wire (violet) to pin B and sensor ground wire (black/white) to pin A.

Figure 2 – Coolant Temperature Sensor and Terminations

Throttle Position Sensor (TPS)

Your engine may have a Throttle position sensor already fitted and it is often

possible to make use of this TPS. The Haltech supplied TPS has a resistance

value ranging from 0 to 10k ohms. The resistance value of the installed TPS does

not have to be the same, since the ECU uses a throttle calibration function to

determine the position of the throttle, based on the signal received from the TPS.

Be sure to wire the TPS so that the ECU sees a lower value when at zero throttle

than at full throttle.

Note: Make sure that the axis of rotation of the shaft is exactly aligned with the axis

of rotation of the sensor, otherwise some binding may occur. Also, do not use the

TPS as a throttle stop. In either case, the TPS will be damaged.

Figure 3 – Throttle Position Sensor

Page 5

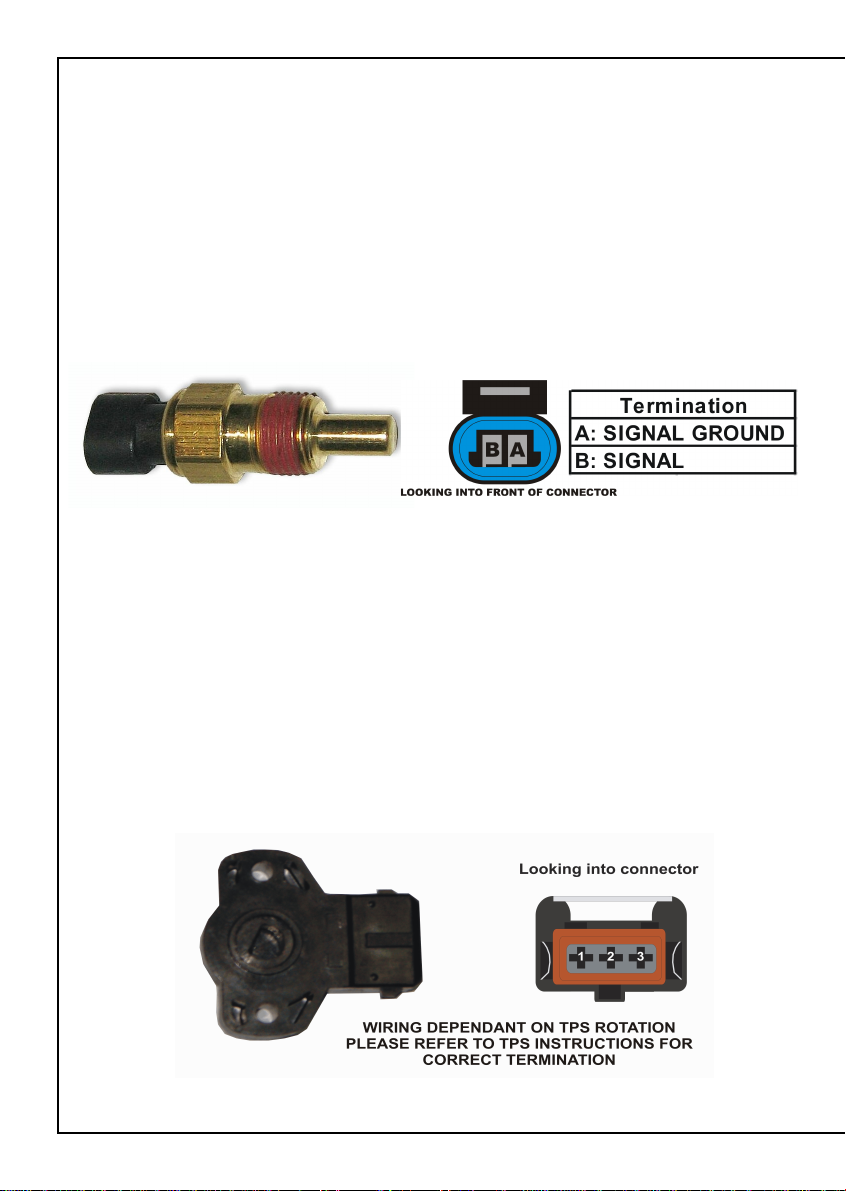

MAP Sensors

Inter nal M ap Sen sor

Vaccum Hos e Fittin g

CAN

Connec tor

USB

Connec tor

Blue Pow er

LED

Red Sta tus

LED

Serial Nu mber

Labe l

The Platinum Sport Series ECU's are fitted with an internal MAP sensor rated to

22PSI (150 kPa). Connect the internal sensor to the inlet manifold* via vacuum

hose to the external fitting on the ECU. * Tap into a high point on the inlet manifold

to avoid fuel entering the vacuum line, as damage to the sensor will occur.

Alternatively an external MAP sensor can be fitted via the harness allowing higher

manifold pressures.

The External MAP sensor when used are usually mounted high on the engine bay

firewall or inner guard using two screws and with the hose nipple facing outwards.

Connect the sensor to the inlet manifold via a short length of vacuum hose and fasten

with either hose clamps or nylon cable ties. Connect the sensor to the main wiring

harness using the appropriate plug and harness branch. Avoid mounting the sensor

below the level of the fuel injectors, because fuel may collect in the vacuum hose and

run down into the sensor. The sensor assembly is weatherproof but it is good practice to

mount the sensor in a protected position away from moisture and heat.

Haltech can supply 1 – 5 Bar Map sensors depending on your application , alternatively

OEM map sensors can be used as long as you have the calibration information to

calibrate the sensor in the ECU Manager Software.

Figure 4 – Internal Map Sensor Fitting

Figure 5 – Manifold Absolute Pressure Sensor and harness Termination

Page 6

Crank and Cam Position Sensors (Trigger and Home)

HALL EFF ECT SENSO R

+12 V

SIGNAL (+)

GRO UND

NO T CO N NECTE D

4 CO RE TR I GGER O R HO M E

CABLE FR O M ECU

REL UCT O R SE NSOR

SIGN AL (+)

NO T CO N NECTE D

4 CO RE TR I GGER O R HO M E

CABLE FR O M ECU

SIGN AL (-)

NO T CO N NECTE D

The Crank and Cam Position sensors are required so that the ECU has the necessary

information available to it to determine engine speed and position at any point in time.

Generally 2 sensors are required - a cam position and crank position.

However many cars will have just a cam position sensor that is capable of giving the ECU

enough information to run the engine correctly. Vehicles that have a crank position

sensor only are not capable of determining the difference between compression

stroke and exhaust stroke and therefore are not suitable for sequential fire

applications. In this case a cam position sensor may need to be added for the ECU

to determine if the engine is on compression or exhaust stroke.

There are generally 2 types of trigger signal:

● Hall effect signal (0-5v digital square wave signal)

Generally a hall effect sensor will require a power supply (could be 5V, 8V or

12V), a ground and have a signal wire. Most hall effect sensors have 3 wires.

● Reluctor signal (analogue style signal).

This type of Sensor will generally only have two wires, Signal Positive (+)

and Signal Negative ( - )

Figure 6 – Hall Effect Sensor Wiring

*

*Please Note: Red and Blue wires *

must be insulated to avoid shorting

Figure 7 – Reluctor Sensor Wiring

ECU Manager will upgrade earlier map versions when loading into ECU's with later

Page 7

Fuel Pumps

85 87 87

86 30

TO 12V IGNITION SUPPLY

TO - TRIGGER FROM ECU

TO FUEL PUMP + TERMINAL

TO 12V SUPPLY

FUEL PUMP

+

_

TO GROUND

VIA FUEL PUMP FUSE

FUSE

POSITIVE SWITCHED

FUEL PUMP CONTROL

12V FUEL PUMP RELAY

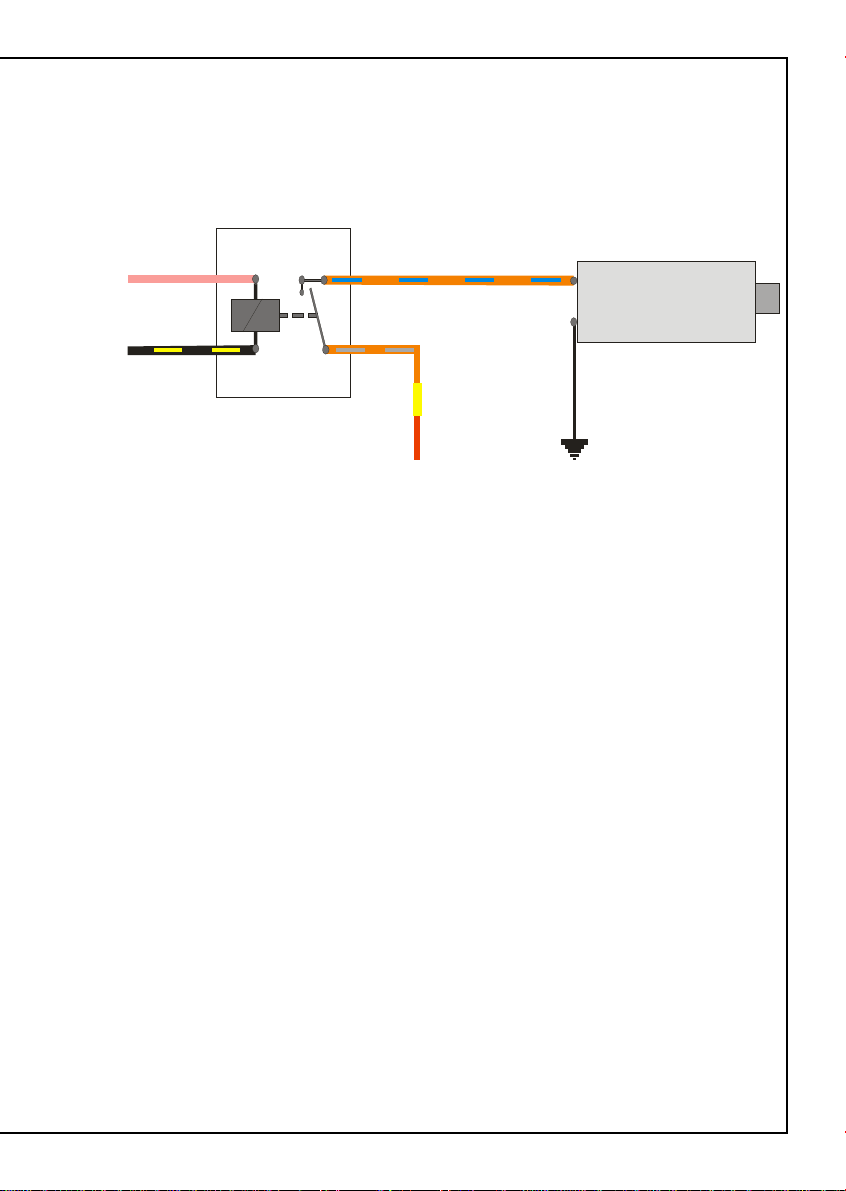

The Orange/Blue wire is used to operate the fuel pump. When the Haltech ECU

wants to operate the fuel pump it will close the fuel pump relay which will supply the

fuel pump with 12V From the Battery.

Figure 8 - Fuel Pump Wiring

Fuel Pumps continued

It is important that the fuel pump is capable of the correct fuel pressure at full

power, otherwise the engine could be damaged due to a lean fuel mixture. For

example, a 500hp engine requires approximately 210lb/hr for a petrol engine.

The fuel pump must always be mounted lower than the outlet of the fuel tank or

surge tank. Ensure that all care is taken to keep fuel cool. A change in fuel

temperature will change the air/fuel ratio because as fuel temperature increases its

density decreases.

Fuel Injectors

Fuel injectors are each wired with a 12V supply with the ground being supplied

through the ECU. The 12V power supply comes via the 20A fuel injector fuse in the

fuse block .

Within the Haltech wiring harness there is a dedicated 12V injector feed (Red / Blue)

wire this wire should be split and go to all injectors. The wires labeled as the injector

wires will provide the ground to each injector. These injector wires will need to be wired

to your injectors in cylinder number.

Always ensure fuel injector sizing is correct for your application and does not

exceed around 80% duty cycle for safe operation.

Page 8

Ignition Outputs

1. COIL NEGATIVE #1

2. CHASSIS GROUND

3. N/A

4. +12V IGNITION

5. ECU IGNITION OUTPUT #1

6. N/A

7. N/A

HALTECH

HECU1

7 6 5 4 3 2 1

+

-

+12 V SW ITC HED G ROUN D

Haltech HECU1 Pino ut

HALTECH 1 CHANN EL IGNIT ION MOD ULE

HALTECH

ECU

IGN 1

COIL # 1

+

-

+12 V SW ITC HE D

GRO UN D

HALTECH

ECU

IGN 1

COIL # 1

CDI UNIT

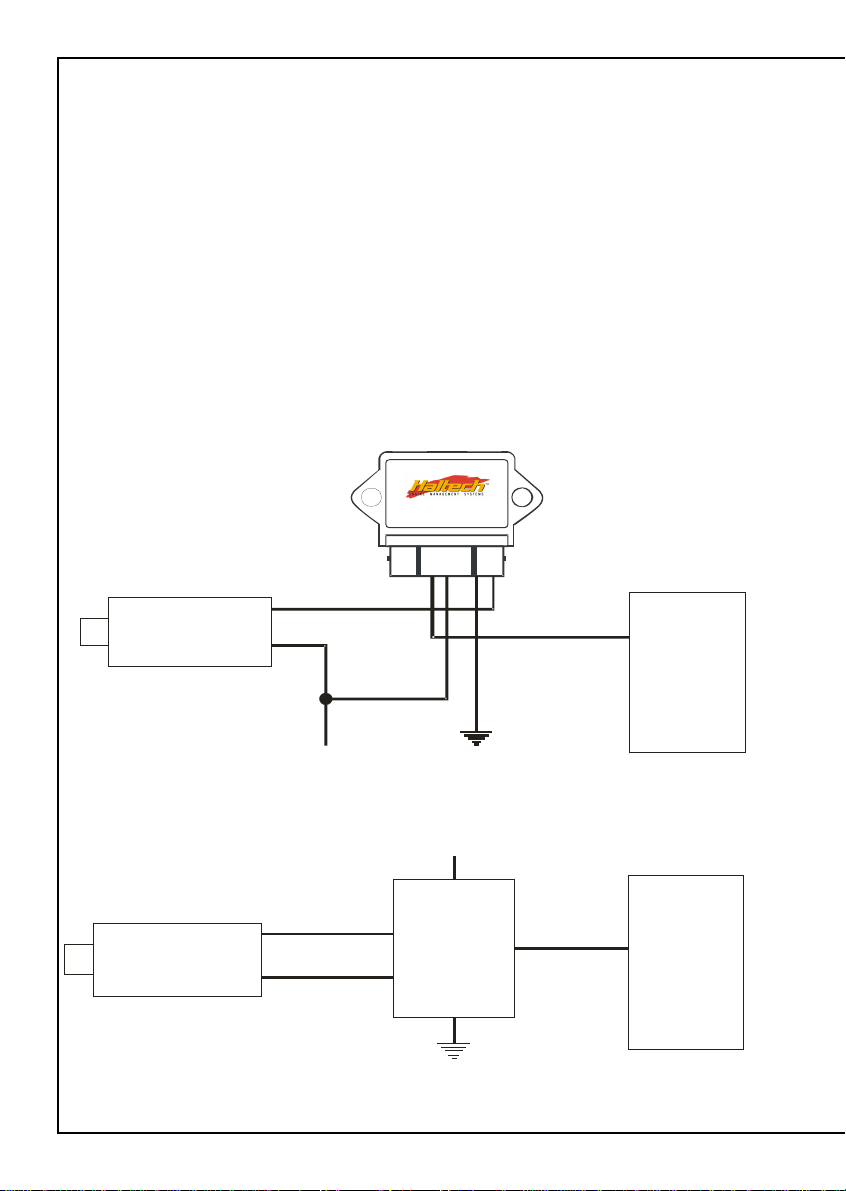

The Platinum Sport Series ECU's cannot control the ignition coils directly – rather some

sort of ignition amplifier such as a power transistor, Haltech ignition module or high

intensity spark unit (CDI unit eg MSD 6A, crane HI6, M&W pro12 etc) must be used

to interface the ECU with the coils. This ignition module supplies the ground to the

coil only when the ECU directs it to – each coil also requires a 12V source (with the

exception of CDI units where the 12V will often come from the CDI unit itself).

Many factory cars will have ignition modules external to the ECU also. These

factory modules can be used in conjunction with the Platinum Sport ECU's.

The ignition output wires from the Platinum Sport wire harness should be used to trigger

the ignition amplifier – when wiring the ignition amplifier ensure that the system is

wired in cylinder order for direct fire ignition setup or in order of the outputs for waste spark

setup. (ie Ign 1 will fire first, then Ign 2 will fire next etc until the last ignition channel is reached

regardless of engine firing order.)

First Error Code

Figure 10 – Ignition Wiring Using CDI Unit

Figure 9 – Ignition Wiring using Haltech Ignition Module

Next Error Code

Engine Cranking

Page 9

Digital Pulsed Outputs (DPO)

Digital Pulsed outputs are capable of outputting pulsed waveforms with varying duty

and frequency. DPO's can be used to control various devices such as thermo fans,

shift lights, bypass air control valves, boost control solenoids etc.

When a Digital Pulsed output is activated by the ECU the output will switch to ground.

Solenoid valves and shift lights etc can be run directly from the output, however

high current devices such as thermo fans and additional fuel pumps must be activated

through a relay. This way the DPO is only switching a relay and not a high current draw

device.

Digital Pulsed Outputs are limited to 800mA Max current draw.

Digital Pulsed Inputs (DPI)

Digital Pulsed Inputs are capable of accepting pulsed input information such as for a

road speed sensor. These inputs measure the time periods between the pulses and can

process this information to provide quantities such as road speed.

Digital Switched Inputs (DSI)

Digital Switched Inputs are capable of accepting on/off type of input information such as

from a switch. The active state of these inputs is when the input is connected to Ground.

The inactive state is when the input is not connected to Ground. The input active state

can be inverted by selecting an option in the Main Setup Page, so that connecting an

input to Ground results in an inactive state and disconnecting the input results in an

active state.

Analogue Voltage Inputs ( AVI )

Analogue Voltage Inputs accept variable voltage inputs from 0V to 5V. These inputs

can also accept switch inputs that change between two different voltage levels.

The On Voltage and Off Voltage define what the thresholds are between the On and Off

states. The Voltage can be viewed as a channel in the software to determine the

thresholds for a switched input.

High Tension Leads (spark plug leads) / Capacitive Discharge Ignition Units (CDI )

High tension leads and CDI units can cause significant noise or interference on the ECU

wiring.

Keep all ignition wires a minimum of 100mm from any other wires and ECU

components. If ignition wires must be crossed, ensure wires cross ignition leads at right

angles. Keep power and grounding points separate to those used for ECU.

Wire connections

When using crimp connectors ensure that the correct crimping tool is used

Solder all connections where possible.

Page 10

Powering up the ECU

BATTER Y GROUN D

CHASSIS GROUND

CH ASSIS

12V BATT TERY

+

IGNIT ION SWIT CH

+ 12V FR OM M AIN FUSE

SWI TCHED 12V IGNI TION (ECU )

ENGI NE CONTR OL RELAY

CHASSIS

The main power wire must be wired via the shortest route possible to the battery

positive terminal. The main power to the ECU must be connected to the battery and

NOT the ignition switch, the ignition switch will not be able to handle the current

required to operate the ECU (there is an additional pink wire within the Platinum Sport

loom that connects to the ignition switch to switch the ECU on).

Three Positive Cables need to be connected to the battery from the loom

( 1 x 2mm Red/Green , 1 x 2mm Red, 1 x 0.5mm Red/White )

To avoid damage to ignition components, never connect the ignition modules to the

ECU until the ECU is configured. The same applies to the fuel system, never connect

fuel injectors until the ECU is configured, otherwise the engine may flood with fuel.

Grounding

One of the most common wiring problems experienced is poor grounding. There

should be no paint, anodising or other surface layer protection between the ground

wire and engine block or chassis. Temporary wiring will almost certainly cause a

problem, use a proper ground eyelet terminal and do not use loctite or similar

locking agents as they may become insulators preventing good earth connection.

Chassis Ground (Black) should be connected to the chassis of the vehicle, and

Battery Ground (Black / White) should be connected directly to the Battery negative terminal.

Please make sure your Engine block has a ground strap to the chassis.

Figure 11 – Main Power Wiring

Page 11

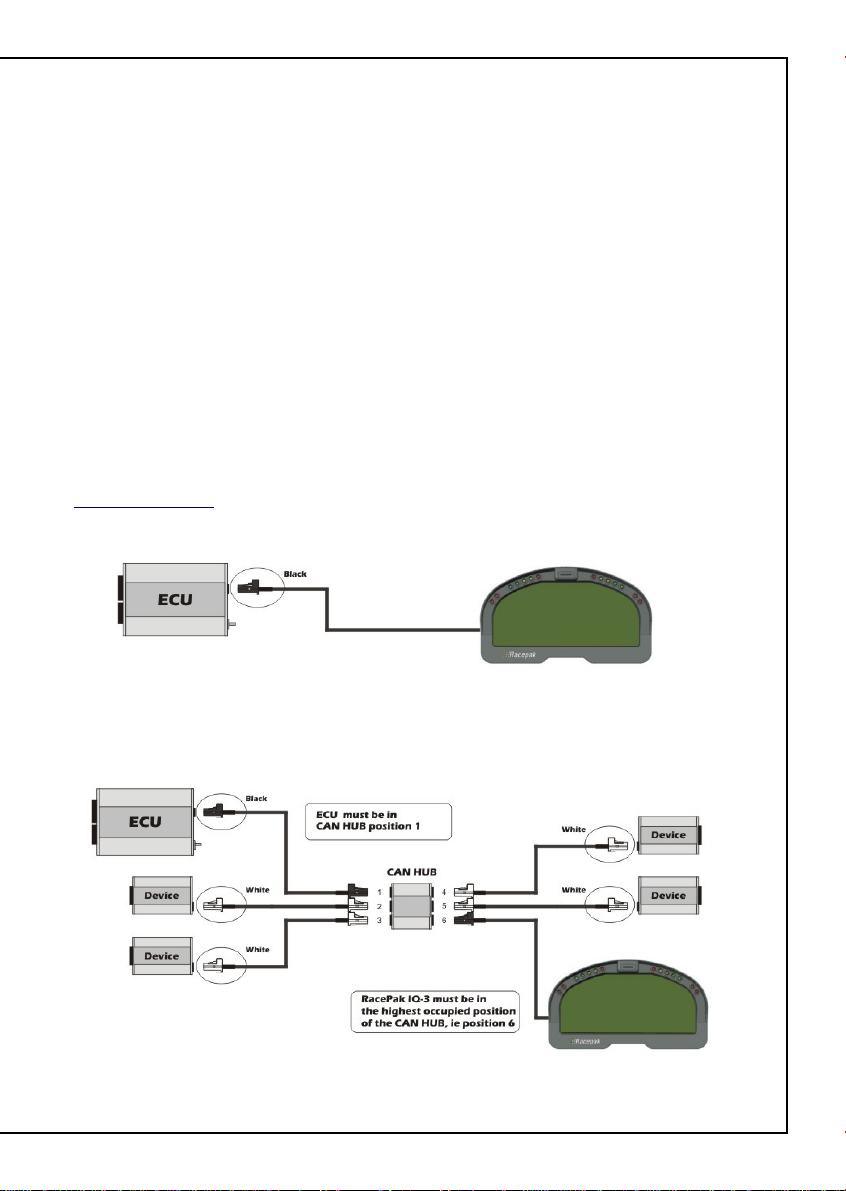

The Haltech CAN Network

The Haltech CAN network allows for simple and effective expansion in ECU capability

and functionality without having to go to the trouble of wiring in a whole new computer.

Expansion is made possible by the addition of multiple expansion devices that

communicate to the main ECU via a Control Area Network (CAN).

Installation time and costs are kept to a minimum as all expansion devices are

powered up from the main ECU via the pre-terminated connection cable that comes

with each expansion device.

Simply connect the device directly to the 8 pin CAN connector on the rear of the ECU

or connect using an optional Haltech CAN Hub (order as part # HT059991) if multiple

expansion devices are required).

Each expansion device is pre-programmed with a unique ID code which allows it to

be recognised on the network and work correctly first time every time.

For current available expansion devices please go to our website at

www.haltech.com

Figure 12 – Haltech ECU connected to a Racepak Dash

Figure 13– Haltech ECU connected to 5 Auxiliary CAN based devices

Page 12

Status LED Display

The Status Led can display the following information in 3 modes.

1. Start-up Check

2. Display Error Codes (if any)

3. Display Trigger / Home Status when engine is cranking.

Start up Check

To ensure that the Status LED is operating correctly, upon power up of the ECU,

the Status LED will light briefly for approximately 1.2 seconds.

Display Error Codes

Error codes are only displayed if the appropriate diagnostics features are enabled for

each sensor or condition.

• Each Code is two digits long

• Each digit is displayed as pulses for each digit, with 0.4 seconds between each pulse

• After the first digit is displayed / pulsed, there will be a 1.2 second delay to

separate the digits

• Consecutive codes are separated by 2 second delay

• End of code to start of code display again is separated by 4.5 seconds.

Error Codes

Code Description

11 Coolant temperature sensor fault

12 Air Temperature sensor fault

13 MAP sensor fault

14 Fuel Pressure sensor fault

15 Fuel Temperature sensor fault

16 Oil Pressure sensor fault

17 Oil Temperature sensor fault

18 Internal Baro sensor fault

19 EGT sensor fault

Display Trigger / Home Status

When the engine is cranking, the LED displays the Trigger / Home status.

The status is displayed as a single, double or triple flash.

Each flash is separated by 0.4 seconds, with a 1.2 second pause between

each status display.

• If only Trigger detected, single flash

• If only Home detected, double flash

• If Trigger and Home detected, then triple flash displayed

•

The Status light will be disabled when the engine RPM exceeds cranking RPM.

When using crimp connectors ensure that the correct crimping tool is used

Page 13

Status LED Display Sequence Example

Conditions: Ignition On

Engine Not Running

Power on

LED on for 1.2 Seconds

Pause 1 second

First Error Code

Next Error Code

Flash first digit of first code, 0.4 seconds

between flashes

Pause 1.2 seconds between digits

Flash second digit of first code, 0.4 seconds

between flashes

Pause 2 Seconds

Flash first digit of first code, 0.4 seconds

between flashes

Pause 1.2 seconds between digits

Flash second digit of first code, 0.4 seconds

between flashes

After last code, Pause 4.5 seconds

Engine Cranking

Conditions: Ignition On

• If only Trigger detected, single flash

• If only Home detected, double flash

• If Trigger and Home detected, then triple flash displayed

Trigger / Home Status is displayed

Page 14

ECU Manager Software

85 87 87

86 30

TO 12V IGNITION SUPPLY

TO - TRIGGER FROM ECU

TO FUEL PUMP + TERMINAL

TO 12V SUPPLY

FUEL PUMP

+

_

TO GROUND

VIA FUEL PUMP FUSE

FUSE

POSITIVE SWITCHED

FUEL PUMP CONTROL

12V FUEL PUMP RELAY

ECU Manager software is used for setup, calibration and diagnostics and can

be found on the CD supplied with this unit or downloaded from the Haltech website

www.haltech.com

Minimum System Requirements

Operating System: Windows 2000 SP4 / XP / Vista / Windows 7

Processor Speed: 1GHz

RAM: 256 Mb

Video Card: 128MB graphics card with 3D acceleration

USB: 1.1

Hard Drive Space: 250Mb

Minimum Screen Resolution: 1024 x 768 pixels

Installing ECU Manager

Installing ECU Manager onto your PC is performed similar to any other Windows

software package. Installation is outlined below to ensure correct installation:

1.Insert the CD-ROM into your PC’s CD-ROM drive. The CD should automatically

launch into the Haltech Browser. If the CD does not run automatically double

click on the “My Computer” icon on the desktop, double click on the Haltech icon

(CD- ROM drive) to start the browser software.

2.The Browser will display the disclaimer and you will need to agree to the

terms stated before allowing to progress. Read the Disclaimer and click on

AGREE if you agree.

3.Now you will be able to access all the information contained on the CD

4.To download the Platinum Software, click on the Platinum Series ECU Manager

Link. You will be prompted to install the software. Click “Install” to install

ECU Manager and the Data Log viewer.

5. Follow the software prompts and install the software.

With your programming cable (USB) attached to your ECU and the other end

connected to your laptop, power up the ECU by turning your key to IGN. Start the

programming software on your PC and go online with the ECU.

Page 15

ECU Manager / ECU Manuals

Detailed manuals can be found in the software by pressing your F1 key or by

selecting the Help tab located at the top left of the screen.

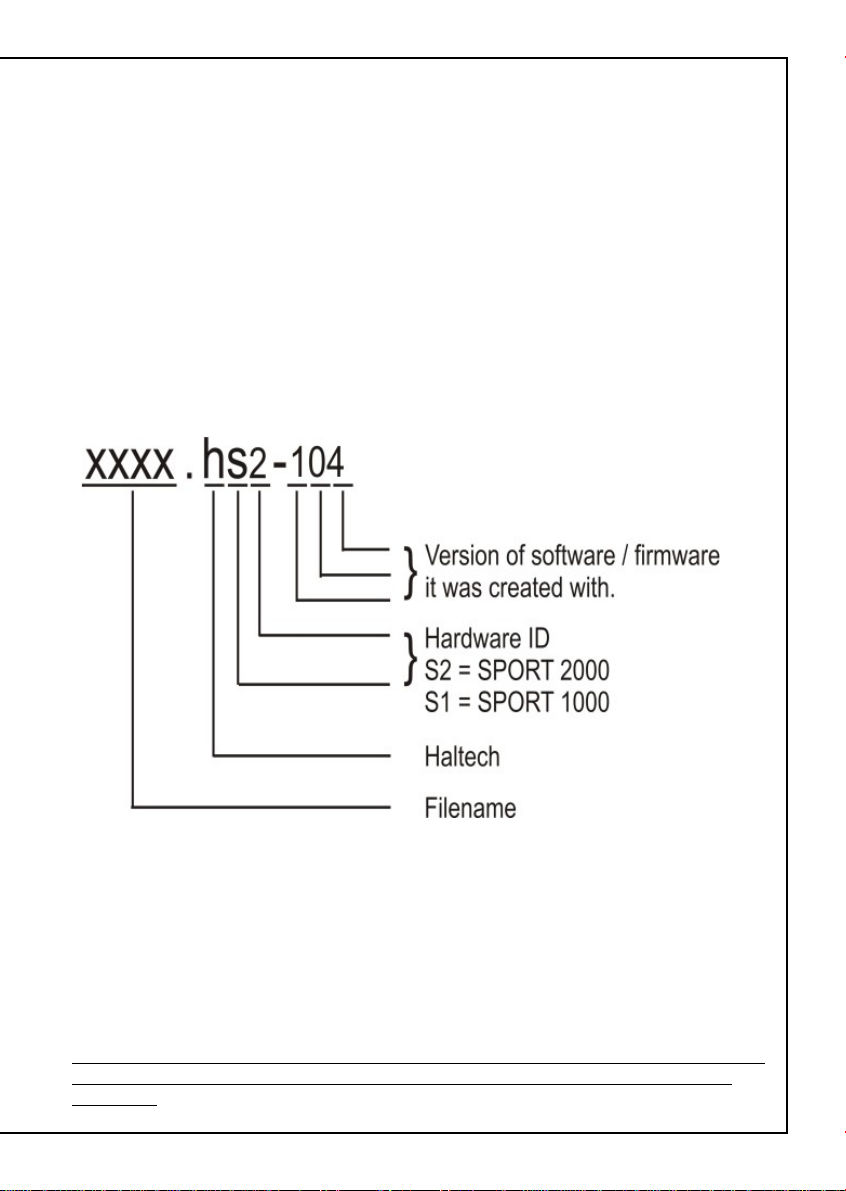

ECU Manager File Extensions

When ECU manager saves the map from the Haltech ECU, it saves the map with

a Haltech specific file extension.

The File extension can be broken down as follows:

Example File : xxxx.hs2-104

Later map versions cannot be loaded into ECU's with earlier firmware versions.

ECU Manager will upgrade earlier map versions when loading into ECU's with later

firmware versions.

ECU Manager upgrades maps between versions where equivalent settings are

available. However, new settings not in the original map, will be substituted with

values from the new version's default map.

Whenever ECU Manager converts your ECU map, you should always check your

map settings to ensure that all the appropriate settings have been converted

correctly.

Page 16

Initial Software Setup

Inter nal M ap Sen sor

Vaccum Hos e Fittin g

CAN

Connec tor

USB

Connec tor

Blue Pow er

LED

Red Sta tus

LED

Serial Nu mber

Labe l

Main Setup (Basic) Page

Set the basic engine parameters in the main setup page, number of cylinders ,

firing order, load source and map source (enable or disable the use of the internal map sensor)

Trigger Setup Page

Set the crank and cam (trigger and home) angle sensor type and description in the

Trigger setup page. If using a hall effect or optical style crank sensor then set trigger

type to hall effect.

In most stand alone applications the trigger pullup will need to be set to ON when

using a hall effect crank sensor. In a piggy back application the pullup will be set to

off. Trigger pullup will be set to off for all reluctor (sine wave) style trigger inputs.

Ignition Setup Page

Setting the base timing needs to be done with the ignition setup page open. Base

timing is the process of synchronising the ECU’s operations with the engines.

This needs to be done so that the ECU knows what the engine is doing at any point in

time. This is required for accurate fuel delivery and spark timing.

First, go to the fuel setup page and disable the fuel injectors (at this stage it is not

desired that the engine attempts to start). To reduce stress on started motor it is also

advisable to remove the spark plugs to help the engine crank more freely when

setting base timing.

Set lock timing to ON and lock timing angle to 10 degrees. Crank engine, using a

timing light connected to ignition lead for number 1 cylinder. Adjust the tooth offset

and trigger angle until timing reads 10 degrees as viewed with a timing light on

crank pulley. Tooth offset gives large changes to timing, trigger angle is used to fine

tune timing to exactly 10 degrees (any angle can be set as the lock timing angle; in

this example 10 degrees was used). It is however possible to set the lock timing to

zero degrees (or any other positive number) and adjust tooth offset and trigger

angle until the crank pulley shows this value when viewed with a timing light.

If there is no RPM being displayed in the software check for correct trigger setup, correct

sensor wiring, correct trigger type, pull ups enabled / disabled, trigger edge falling / rising.

Fuel Setup Page

Set the basic fuel parameters, injection mode, fuel pump prime time and injector resistance.

Injector resistance can be measured across the injector pins with a multimeter on the ohms

setting. Three settings are available in the software: 1-3 ohm , 3-8 ohm and high(above 8ohm).

After base timing has been set – (See ignition setup) ensure that the fuel injectors are

enabled in this setup page.

Page 17

Startup

With the software now calibrated with correct fuel setup, ignition setup and trigger

setup, go to the Main setup menu and calibrate the throttle

Check to ensure that the fuel and ignition maps all have sensible values in them.

Check that all sensors are reading correctly by going to the engine data page and

viewing their values. Ensure the throttle reads smoothly from 0-100% in its full

range of movement. The MAP sensor should read atmospheric pressure

when the engine is stopped.

Power up the fuel pumps and check entire fuel system for leaks before attempting

to start the engine.

Once verified that all sensors are correctly operating and fuel system is functional,

attempt to start the engine. If engine does not start check:

1. Ignition Timing

2. Correct Fuel Pressure

3. Spark Plugs are not fouled or wet

4. Engine Compression

5. Ignition is wired in correct firing order

6. Ignition is firing on intake stroke not exhaust stroke

Once engine is running, ensure fuel pressure remains correct under all conditions and

that battery is charging.

Page 18

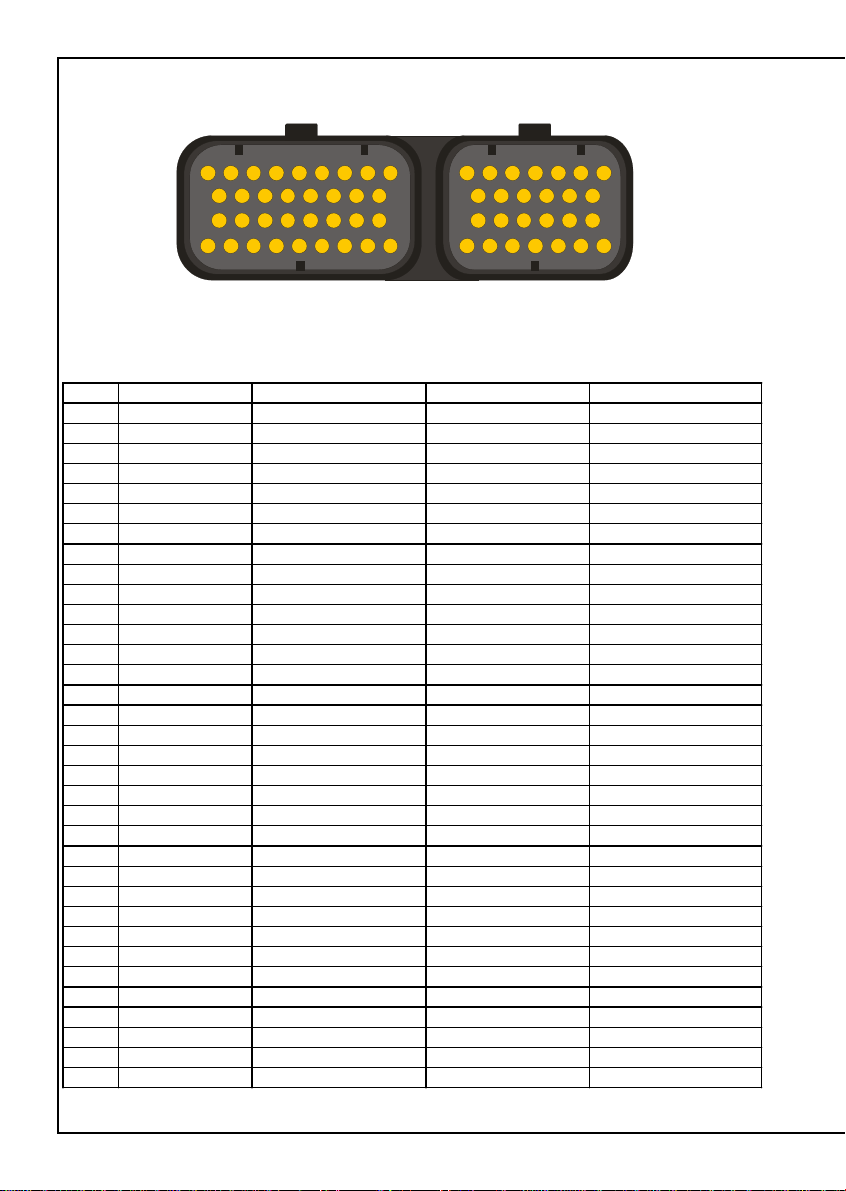

ECU Connection Table

Pin # Wire Colour Connection

Platinum Sport 1000

Platinum Sport 2000

1 V/BR DPO 2

Y Y

2 - -

- -

3 Y/B IGN 1 / DPO 5

Y Y

4 Y/R IGN 2 / DPO 6

Y Y

5 Y/O IGN 3 / INJ 10 / DPO 7

Y Y

6 Y/G IGN 4 / INJ 9 / DPO 8

Y Y

7 L/V IGN 5 / INJ 8 / DPO 9

N Y

8 L/G IGN 6 / INJ 7 / DPO 10

N Y

9 O +5V DC

Y Y

10 B CHASSIS GROUND

Y Y

11 B CHASSIS GROUND

Y Y

12 O/W +8V DC

Y Y

13 - -

- -

14 W TPS

Y Y

15 Y MA P

Y Y

16 O/B AV I 2

Y Y

17 O/R AVI 3

Y Y

18 V/B DPO 1

Y Y

19 L INJ 1 / DPO 16

Y Y

20 L/B INJ 2 / DPO 15

Y Y

21 L/BR INJ 3 / DPO 14

Y Y

22 L/R INJ 4 / DPO 13

Y Y

23 V/R DPO 3

Y Y

24 B/Y PUMP RELAY

Y Y

25 O/Y AV I 4

Y Y

26 R/L +13.8V INJECTOR PWR

Y Y

27 L/O INJ 5 / DPO 12

N Y

28 L/Y INJ 6 / DPO 11

N Y

29 L/W AUX 1 / INJ 12* / DPO 18

Y Y

30 L/GY AUX 2 / INJ 11* / DPO 17

Y Y

31 G IDL 1

Y Y

32 G/B IDL 2

Y Y

33 G/BR IDL 3

Y Y

34 G/R IDL 4

Y Y

1 2 3 4 5 6

10 11 12 13 14

182719 20 21 22

26 28 29 30 31

15 16 17

23 24 25

7 8

9

32 33 34

34 Pin

1 2 3 4 5 6

10 11 12 13

14 18819

20 21 22 26

16 17

24 25

15

23

7

9

Looking into the ECU

26 Pin

Figure 12- ECU Connector

34 Pin Connector

* INJ 11 and INJ 12 are only available to Platinum 2000

Page 19

26 Pin Connector

Pin # Wire Colour Connection

Platinum Sport 1000

Platinum Sport 2000

1 Y <SHD> TRIGGER ( + )

Y Y

2 Y <SHD> HOME ( + )

Y Y

3 GY AIR TEMP

Y Y

4 V COOLA NT TEMP

Y Y

5 G <SHD> TRIGGER ( - )

Y Y

6 G <SHD> HOME ( - )

Y Y

7 GY/G DSI 1

Y Y

8 GY <SHD> DPI 1

Y Y

9 GY/B <SHD> DPI 2

Y Y

10 GY/BR <SHD> DPI 3

Y Y

11 R/W +13.8V ECU POWER

Y Y

12 GY/O <SHD> 02 INPUT

Y Y

13 GY/Y <SHD> AVI 1

Y Y

14 B/W BATTERY GROUND

Y Y

15 B/W SIGNAL GROUND

Y Y

16 B/W SIGNAL GROUND

Y Y

17

- -

- -

18

- -

- -

19 V/O DPO 4

Y Y

20 O/G AVI 5

N Y

21 O/L AVI 6

N Y

22 O/V AVI 7

N Y

23

-

CA N HIGH

Y Y

24

-

CA N LOW

Y Y

25

- -

- -

26

- -

- -

Y= Available N = Not Available

Legend- Wire Colours

B=Black BR=Brown G=Green GY=Grey L=Blue

O=Orange P=Pink R=Red V=Violet Y=Yellow

W=White

<SHD> = Shielded Cable

When two Colours are used in a wire by the alphabetical code, the first letter

indicates the basic wire colour, the second colour indicates the colour of the

stripe.

Page 20

HALTECH HEAD OFFICE: PH: +612 9729 0999

FAX: +612 9729 0900

EMAIL: sales@haltech.com

HALTECH US OFFICE: EMAIL: usa@haltech.com

See the Haltech Website for your local authorized dealer.

www.haltech.com

Version 10

QUICK START GUIDE

Loading...

Loading...