Page 1

V2.0

Page 2

Contents at a Glance

F9

Page

Introduction................................................................7

Section 1 ...............Getting Started

Chapter 1..................... Installation................................................15

Chapter 2..................... Getting Online.......................................... 26

Chapter 3..................... Engine Identification................................ 31

Chapter 4..................... Adjusting Haltech Maps ..........................34

Chapter 5..................... Starting the Engine................................... 44

Section 2 ...............Other Adjustable Features

Chapter 6..................... Throttle Effects........................................48

Chapter 7..................... Cold Starting and Running.......................51

Chapter 8..................... Correction Factors.................................... 53

Section 3 ...............Software Features

Chapter 9................... File Storage and Retrieval........................ 56

Chapter 10................... Printing Maps........................................... 59

Chapter 11................... Datalog.....................................................60

Chapter 12................... Customising the Software........................63

Section 4 ...............Appendices

Appendix A.................Troubleshooting....................................... 64

Appendix B................. Injector Impedance................................... 69

Appendix C................. Fuel Systems and Staging........................71

Appendix D.................Wiring Diagrams...................................... 76

F9A

Introduction.................................................................................... 79

Chapter 1..................... Wiring Notes............................................80

Chapter 2..................... Using the Software Features.................... 81

Chapter 3..................... Idle Speed Control...................................82

Chapter 4..................... Closed Loop Control................................ 84

Chapter 5..................... Auxiliary Outputs.....................................89

Appendix A.................Wiring Diagrams...................................... 99

1

Page 3

F9 Table of Contents

Introduction

Introduction............................................................................................... 7

Installation Overview....................................................................... 7

Before You Begin............................................................................ 8

Tool/Supply Requirements.............................................................. 9

How It Works................................................................................... 9

The Advanced Mode of the F9A ...................................................11

Haltech F9 Specifications ....................................................................... 12

Section One ..........Getting Started

Chapter 1 - Haltech F9 Installation......................................................... 15

1.1 Overview..............................................................................15

1.2 Installation Summary ........................................................... 16

1.3 Expanded Installation Guide................................................ 16

1.3.1 Manifold Absolute Pressure (MAP) Sensor............. 16

1.3.2 Coolant Temperature Sensor.................................... 17

1.3.3 Inlet Air Temperature Sensor................................... 19

1.3.4 Throttle Position Sensor...........................................20

1.3.5 Route Wiring Harness and Connect Sensors............20

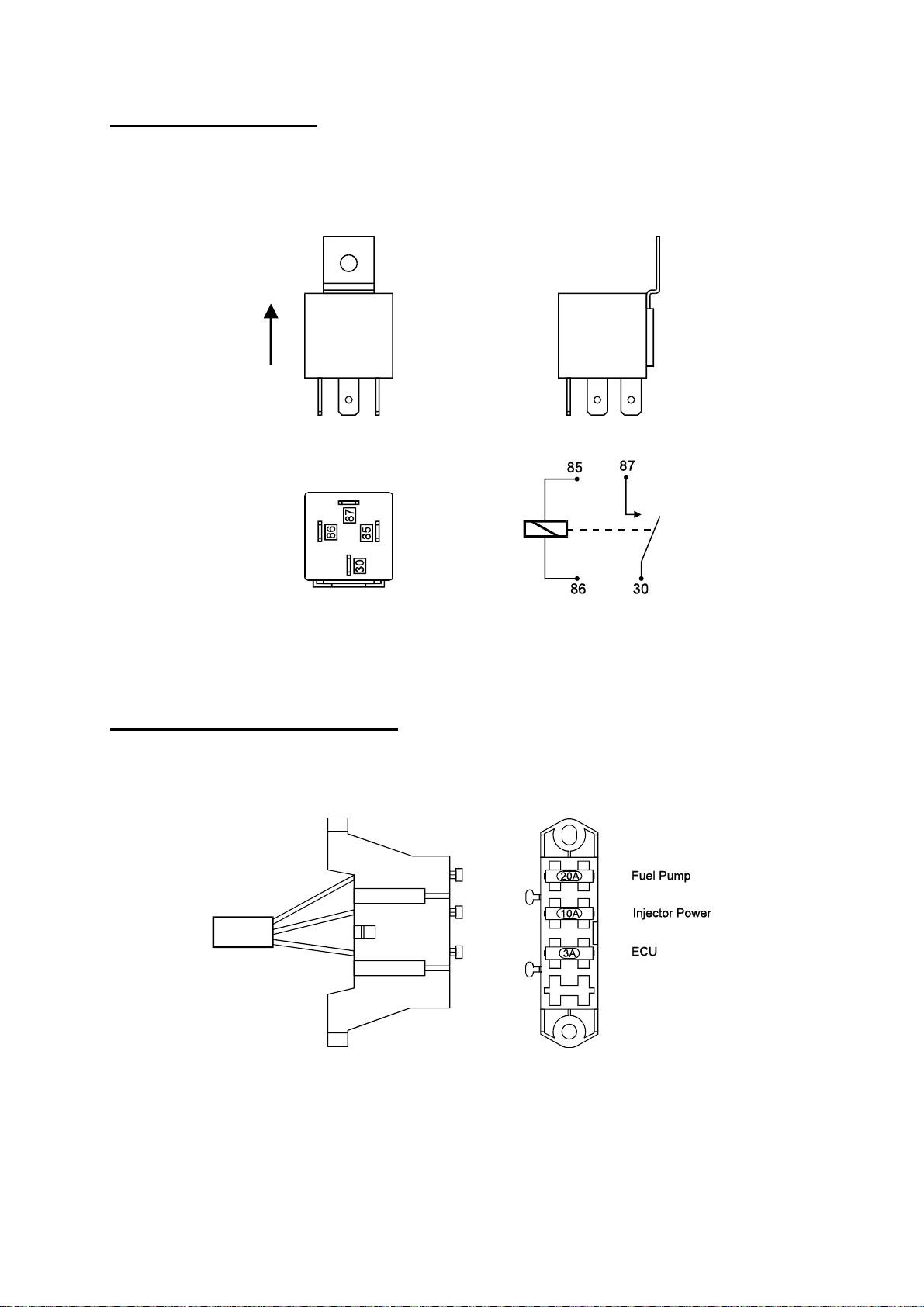

1.3.6 Power Relays............................................................ 21

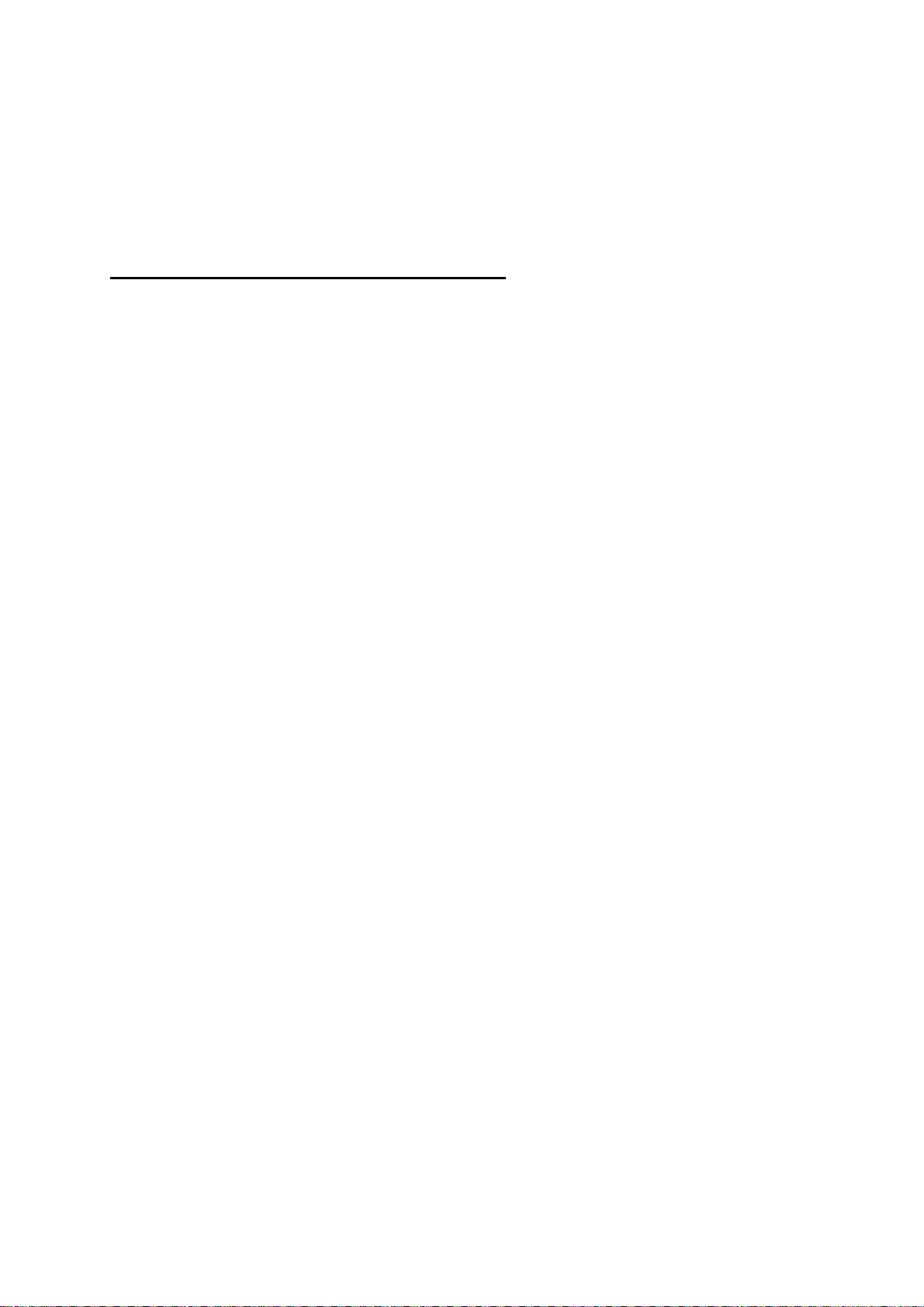

1.3.7 Fuse Block Assembly............................................... 21

1.3.8 Electronic Control Unit (ECU)................................ 22

1.3.9 Flying Leads............................................................. 23

1.3.10 Configure DIP switches............................................ 24

1.3.11 Route Optional Auxiliary Loom............................... 25

1.3.12 Connect the ECU......................................................25

Chapter 2 - Getting Online...................................................................... 26

2.1 Connecting the Haltech F9 to a Computer........................... 26

2.2 Operating the Software......................................................... 26

2.2.1 Computer Requirements........................................... 26

2.2.2 Installing the Software.............................................. 26

2.2.3 Running the Software from the Hard Disk...............28

2.2.4 Running the Software from the Floppy Disk ........... 28

2.2.5 Azerty Keyboards..................................................... 28

2.2.5 Acknowledging the Risks.........................................29

2.3 The Online and Offline Modes............................................. 29

2.4 Using the System Online......................................................29

2.5 The Main Menu.................................................................... 30

2.6 How to Quit.......................................................................... 30

2.7 Checking the Engine Data....................................................30

2

Page 4

Chapter 3 - Engine Identification............................................................ 31

3.1 Checking the Identification.................................................. 31

Chapter 4 - Adjusting Haltech Maps....................................................... 34

4.1 What are maps?....................................................................34

4.2 What is mapping the Engine?............................................... 34

4.3 Using the Software............................................................... 35

4.4 Accessing The Fuel Map......................................................35

4.4.1 Fuel Setup................................................................. 35

4.4.2 Adjusting Bar Height in the Map .............................37

4.5 How To Quit......................................................................... 38

4.6 Time Saving Functions......................................................... 38

4.6.1 Current Location....................................................... 38

4.6.2 All Ranges ................................................................38

4.6.3 Selecting Groups of Bars..........................................39

4.6.4 Percentage Changes..................................................39

4.6.5 Linearise...................................................................39

4.6.6 Numeric Mode..........................................................39

4.6.7 Bar Increments.......................................................... 40

4.6.8 Help Function........................................................... 40

4.7 Duty Cycles.......................................................................... 41

4.8 Command Summary for maps.............................................. 43

Chapter 5 - Starting the Engine............................................................... 44

5.1 Calibrating the Throttle Position Sensor.............................. 44

5.2 Checking the trigger............................................................. 44

5.3 Determining Engine Fuel Needs ..........................................44

5.3.1 Tuning for Idle.......................................................... 45

5.3.2 Tuning for No Load..................................................45

5.3.3 Loading the Engine................................................... 45

5.3.4 On the Dyno ............................................................. 46

5.3.5 On the Road.............................................................. 46

5.5.6 Fine Tuning the Engine............................................46

Section Two..........Other Adjustable Features

Chapter 6 - Throttle Effects..................................................................... 48

6.1 Throttle Response................................................................. 48

6.2 Zero Throttle Map................................................................ 49

6.3 Full Throttle Map .................................................................50

Chapter 7- Cold Starting and Running....................................................51

7.1 Cold Cranking ......................................................................51

7.2 Fuel Correction vs Coolant Temperature............................. 52

Chapter 8 - Correction Factors................................................................ 53

8.1 Fuel Versus Air Temp Map.................................................. 53

8.2 The Battery Voltage Map..................................................... 53

8.3 Barometric Correction..........................................................54

8.4 Post Start Enrichment...........................................................54

3

Page 5

Section Three .......Software Features

Chapter 9 - File Storage and Retrieval.................................................... 56

9.1 Saving Maps and Identification............................................ 56

9.1.1 The Save Command.................................................. 56

9.1.2 Giving Your Map A Filename.................................. 56

9.2 Loading Maps and Identification ......................................... 57

9.3 File Management..................................................................57

9.3.1 Erasing Unwanted Maps........................................... 57

9.3.2 Changing Directories................................................58

Chapter 10 - Printing Maps..................................................................... 59

10.1 The Print Function................................................................59

Chapter 11 - Datalog...............................................................................60

11.1 The Datalog Option.............................................................. 60

11.1.1 Setting Up the Datalog Page..................................... 60

11.1.2 Creating a Datalog....................................................60

11.1.3 Viewing the Datalog.................................................61

11.1.4 Datalog File Management ........................................61

11.1.5 Printing Datalogs...................................................... 62

Chapter 12 - Customising the Software ..................................................63

12.1 The Setup Page..................................................................... 63

12.1.1 The Display .............................................................. 63

12.1.3 Com Port................................................................... 63

Section Four.........Appendices

Appendix A - Troubleshooting ............................................................... 64

A.1 Overview..............................................................................64

A.2 Control Programme Problems.............................................. 65

A.3 Starting Problems................................................................. 66

A.4 Idling Problems ....................................................................67

A.5 Light Throttle and Cruising Problems..................................67

A.6 Full Power Problems ............................................................ 67

A.7 Throttle Response Problems.................................................67

A.8 Cold Running Problems ....................................................... 68

A.9 Fuel Consumption ................................................................68

Appendix B - Injector Impedance........................................................... 69

B.1 The F9 Injector Drivers........................................................ 69

Appendix C - Fuel Systems & Staging ...................................................71

C.1 Fuel Requirement ................................................................. 71

C.2 Injector Flow Capacity......................................................... 71

C.3 Injector Staging .................................................................... 72

4

Page 6

C.4 Fuel Pump Capacity.............................................................73

C.5 Fuel Rails and Pressure Regulators......................................74

Appendix D - Wiring Diagrams.............................................................. 75

5

Page 7

F9A Table of Contents

Introduction............................................................................................. 79

Chapter 1 - Wiring Notes........................................................................ 80

Chapter 2 - Using the Software Features ................................................ 81

2.1 Enabling Options..................................................................81

Chapter 3 - Idle Speed Control................................................................ 82

Chapter 4 - Closed Loop Control............................................................ 84

4.1 Using Different Oxygen Sensors.......................................... 86

Chapter 5 -Auxiliary Outputs..................................................................87

5.1 Turbo Waste Gate Control (TWG)....................................... 88

5.2 Dual intake Valve Control (DIV).........................................90

5.3 Torque Converter Lockup (TCC).........................................90

5.4 Electric Thermatic Fan Control (TF) ................................... 92

5.5 Electric Intercooler Fan Control (IF) ................................... 93

5.6 Shift Light Illumination (SL) ............................................... 94

5.7 Auxiliary Fuel Pump (AP) ................................................... 94

5.8 Anti-Stall Solenoid Control (AS)......................................... 96

5.9 Staging Signal Function (SS)............................................... 96

5.10 Turbo Timer (TT)................................................................. 97

Appendix A -F9A Secondary Harness Wiring Diagram......................... 98

Under copyright law, neither this manual nor its

accompanying software may be copied, translated or

reduced to electronic form, except as specified

herein, without prior written consent of Invent

Engineering Pty Ltd trading as Haltech.

© Copyright 1995 Invent Engineering

Pty Ltd

Unit 7 / 130-134 Taren

Point Rd

Taren Point, NSW 2229

Australia

MS_DOS is a registered trademark of Microsoft

Corporation. IBM is a registered trademark of

International Business Machines Corporation

Print Version : 1.5 ..................................................Date : 5 February 1998

6

Page 8

Introduction

Congratulations on your decision to install a Haltech Engine Management System to your

vehicle. Haltech EFI systems have been successfully installed on thousands of vehicles, from

power off-shore boats to twin-turbo Ferraris, from pylon racing aircraft to jet skis and

snowmobiles. Over the past several years, many motorsport enthusiasts have discovered that

the Haltech computer is easy to use and gets the job done correctly - that job being to reliably

make a lot of horsepower and torque in an engine by enabling users to precisely control

ignition timing and fuel-air mixture. Precise ignition and mixture control also leads to

excellent drivability and fuel economy - something that is often lacking in high-performance

carburetted engines.

Haltech users have discovered that the flexibility of the Haltech Electronic Control Unit

(ECU) and PC based programming software leads to the easiest possible installation on

everything from traditional pushrod V8s to high performance turbocharged racing

motorcycles. We are proud of the fact that some of the most respected professional racers and

supercar builders in the world use Haltech equipment for the same reasons that Haltech is

popular with motorsports enthusiasts: it is flexible and friendly; is installed easily; and you

can tune your Haltech simply without having to make the project a major research effort.

Installation Overview

The Haltech F9 system utilises a special-purpose programmable microcomputer designed for

engine management. The F9 system includes the ECU, engine sensors, and a special wiring

harness to connect them, plus programming software and cable for you to tune the system. In

the course of the installation, you will mount four electronic engine sensors, two for

temperature, one for throttle position, and one to sense vacuum/pressure. You will run the

wiring harness through the vehicle, connecting the 12V, ground and signal wires, and plug the

harness connectors into the engine sensors and fuel injectors. Finally, you will mount and

connect the ECU itself. Haltech systems provide electronic fuelling control. The engine must

already be configured with intake manifold and suitable injectors, a fuel rail with pressure

regulator, and a high-pressure pump. If you vehicle lacks one or more of these components,

your Haltech dealer can help you obtain them.

With the Haltech system installed, you tune it by connecting the ECU to an IBM compatible

PC via the supplied communications cable. The Haltech Programming software allows you to

configure and modify the ignition and fuelling data stored in the ECU: it's as simple as

adjusting the heights of the bar graphs displayed on your PC screen. Collectively, the bar

graphs form the "Maps" that instruct the ECU how to inject fuel under different conditions.

The programming software has been designed to be functional, "friendly" and intuitively easy

to use.

When the time comes to start your engine, the base fuel map already loaded in the system

could get you going immediately. If not, a little alteration with some assistance from this

manual should get your vehicle running. You then work on fine tuning your maps to suit your

engine exactly. An air:fuel ratio meter and a dyno make tuning easiest, but many people use

the traditional method of "seat of the pants" feel and tuning by ear, possibly checking spark

plug colour as an indication of fuel mixture. Whichever method you use, you will find that the

ability to instantly change mixtures by the stroke of a key, or the twist of a knob, will make

7

Page 9

tuning your Haltech system far easier than tuning a carburettor or mechanical injection

system, and with much better results.

Before You Begin...

1) IT IS BEST TO READ THIS ENTIRE MANUAL BEFORE STARTING.

At the very least, you should read Section One of the manual, and any of the Appendices that

are relevant to your installation. The greater your knowledge of the operation of the Haltech

system, the easier you will find it to understand what you are doing, and why.

2) Read any additional material accompanying this manual that updates the document since it

was written.

3) You may need special parts or additional tools or test equipment in order to complete

installation. Make sure you have these items on hand before you begin to avoid frustration.

Contact your Haltech dealer if you have difficulty.

4) Don't do the minimum work possible. Carelessness in the early stages of installation can

cause you major headaches later on, be it in a few days' or a few months' time. Carelessness

will cost you money and frustration in finding and fixing unnecessary problems. You have the

opportunity to make sure your Haltech system's operation is extremely dependable and easy

to use by doing it right the first time.

There is another reason to exercise care during this installation. You will be dealing with

explosive fuel under pressure, electricity and considerable heat. Inside the combustion

chamber, this is a happy combination. In the garage, they are not. The same kind of danger

exists when working underneath a jacked-up car. Please be careful.

Avoid open sparks, flames, or operation of electrical devices near flammable

substances.

Always disconnect the Battery cables when doing electrical work on your vehicle.

All fuel system components and wiring should be mounted away from heat

sources, shielded if necessary, and well vented.

Make sure there are no leaks in the fuel system and that all connections are

secure.

Disconnect the Haltech ECU from the electrical system whenever doing any arc

welding on the vehicle by unplugging the wiring harness connector from the

ECU.

5) Electromagnetic interference (EMI) from unsuppressed spark plugs and leads can cause

the ECU to fail. Please do not use them.

8

Page 10

6) In hot climates, or with turbocharged engines, you may need to employ heat shielding to

prevent heat soak and damage to electrical and fuel parts. Use the coolest surfaces of the

chassis as a heat sink for components and use thermally conductive brackets where

appropriate.

7) We recommend having your system tuned by professionals. An exhaust gas analyser and

fuel pressure meter make tuning vastly easier and help avoid potentially disastrous lean out

conditions that could destroy your engine. Should you wish to tune this unit yourself, make

sure you have some reliable means of determining if your engine is running lean.

Note: In this manual, reference will be made to MAP (Manifold Absolute Pressure - as in

MAP sensor) and the fuel maps stored in the ECU. Both are common industry terms, with

entirely different meanings.

Tool/Supply Requirements

Installation of this system can be easily carried out by professional mechanics and most

experienced home mechanics if the following tools and components are available:

Voltmeter or Test Light

A selection of screwdrivers and spanners

Soldering Iron and solder (we recommend soldering all connections)

Wire Cutters and Pliers

Crimping Tool and assorted terminals

Drill with assorted drill bits

3/8" NPT Tap

1/4" GAS Tap

Electrical Tape or Heat Shrink tubing

Teflon pipe sealing tape

Nylon cable ties

Jeweler’s file (may be needed for mounting Throttle Position Sensor)

Mounting hardware for ECU and relays (mounts/bolts/screws)

IBM-PC compatible computer (preferably laptop) with at least 640kb, one disk drive and

an RS232 serial port.

How It Works

While the technology involved with electronic fuel injection is complex, the underlying

principles of its operation are really quite straightforward. The object of any fuel delivery

system in a gasoline engine is to determine the amount of air being drawn by the engine, and

supply the appropriate quantity of fuel to "burn" all the oxygen in that mass of air.

A carburettor uses primarily only one parameter to determine fuel metering: air speed. Higher

air speeds through the carburettor result in larger pressure drops across the venturis, and thus

more fuel is sucked through the jets.

9

Page 11

Electronic fuel injection revolves around the use of solenoid actuated injectors. These devices

employ a coil attached to a valve. When the coil is energised, the valve opens and fuel is

allowed to flow. As long as the pressure between the fuel and the air in front of the injector

nozzle is held constant, the rate of fuel flow will remain the same. By accurately controlling

the length of time the injector remains open, precise quantities of fuel can be metered to the

engine.

Since we have no convenient means of directly measuring the amount of air entering the

engine to determine the amount of fuel to deliver, we use a number of engine parameters to

determine an injection opening time. We build a table that breaks the engine's operation into a

series of rpm ranges. At each range, we consider the load on the engine, using either the

position of the throttle or the manifold pressure as a reference to the load on the engine.

Collectively, the ranges in this table (also called a look-up table), form a map of the

volumetric efficiency for the engine. Our standing assumption, therefore, is that for any

combination of engine speed and load, we have a direct reference to the amount of air that is

being drawn into the engine by means of this map.

The Haltech F9 uses a digital microcomputer to measure engine speed and load, and uses

them to access the base fuel map. The base fuel map is a look-up table of injector opening

times stored in non-volatile memory i.e. when power is switched off, the contents of the

memory are retained. By using the programming software, the contents of this memory can be

changed so that you can match injector opening times to the injectors you are using, and to

suit the requirements of your engine.

Having determined the base injection time, the microcomputer then performs a number of

adjustments to this value. Corrections for air temperature and barometric pressure are applied,

since these variables affect the density of air. Extra injection time is also added, when

necessary, for transient throttle movement and the temperature of the engine. At the end of all

these calculations, the final injection time is determined: the time for which the injectors are

actually held open.

Injection pulses usually occur one or more times per engine cycle. The ECU uses a trigger

signal locked to engine speed in order to determine when to inject. When it receives an

appropriate trigger, the ECU applies a magnetising current to the injector coils for precisely

as long as the final computed injection time, providing an extremely accurate delivery of fuel

that will exactly suit the engine's needs.

The ignition timing is determined in a similar way to the fuel needs. The Haltech E6A ECU

has a look-up table configured in the same way as for the fuel, but instead of the fuel delivery

in the table the Ignition Map contains the Ignition Advance for that point. This means that the

ignition point can be controlled with much greater accuracy then ever possible with bobweights and vacuum advance in a distributor.

10

Page 12

The Advanced Mode Features of the F9A

This is an upgraded version of the F9 with expanded capabilities in controlling and using

various engine accessories. The F9A can perform such functions as Turbo Waste Gate

control, Closed Loop Lambda control, etc.

If you have purchased an F9A, these extra options would already be available. Refer to the

F9A Section of this manual for instructions in using the extra functions.

If you have an F9 system, and would like to make use of the F9A’s abilities, you can

upgrade at any time without having to strip your vehicles wiring or purchase a new ECU. A

supplementary loom is included with the upgrade that provides connection to all auxiliary

circuits. Contact your Haltech dealer for information on how to get your system upgraded.

11

Page 13

Haltech F9 Specifications

Engine Suitability

• up to 16,000 rpm

• 1, 2, 3, 4, 5, 6, 8, 10, 12 cylinders (1-2 rotors)*

• 2 or 4 stroke

• normally aspirated or supercharged up to 200 kPa (30 psi)

• load sensing by throttle position or manifold pressure

• multipoint, batch-fire, staged injection

Power Requirements

• Power Source

8.6 to 16 Volts DC

• Consumption

Haltech ECU: 270 mA at 12 Volts

Injector Load: Dependent on injector type

approx. proportional to injector duty cycle

(typically 0.6 Amps per injector)

Physical Specifications

• ECU Dimensions

Length: 168 mm (6 5/8")

Width: 145 mm (5 5/8")

Depth: 41 mm (1 5/8")

• Weight

ECU: 760g (1.68 lb)

Loom: 1.1kg (2.4 lb)

Sensors: 170g(1.1 lb)

Shipping Weight: 3kg (9.9 lb)

(Including manual/packaging)

Input Sensors

• Manifold Absolute Pressure (MAP) Sensor

1 Bar -100kPa to 0kPa (Naturally Aspirated)

2 Bar -100kPa to 100kPa (up to 1 Bar or 15 psi boost)

3 Bar -100kPa to 200kPa (up to 2 Bar or 30 psi boost)

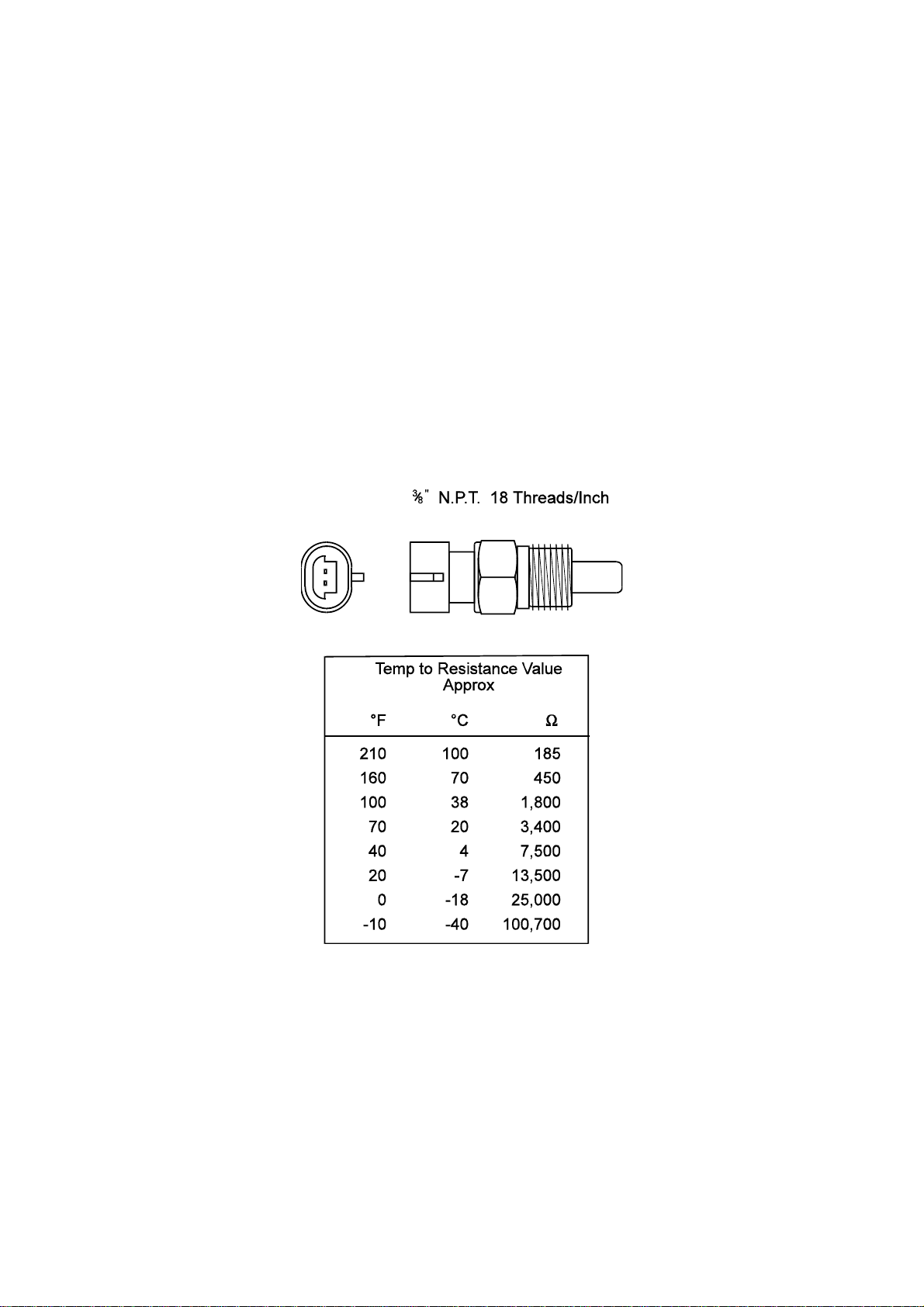

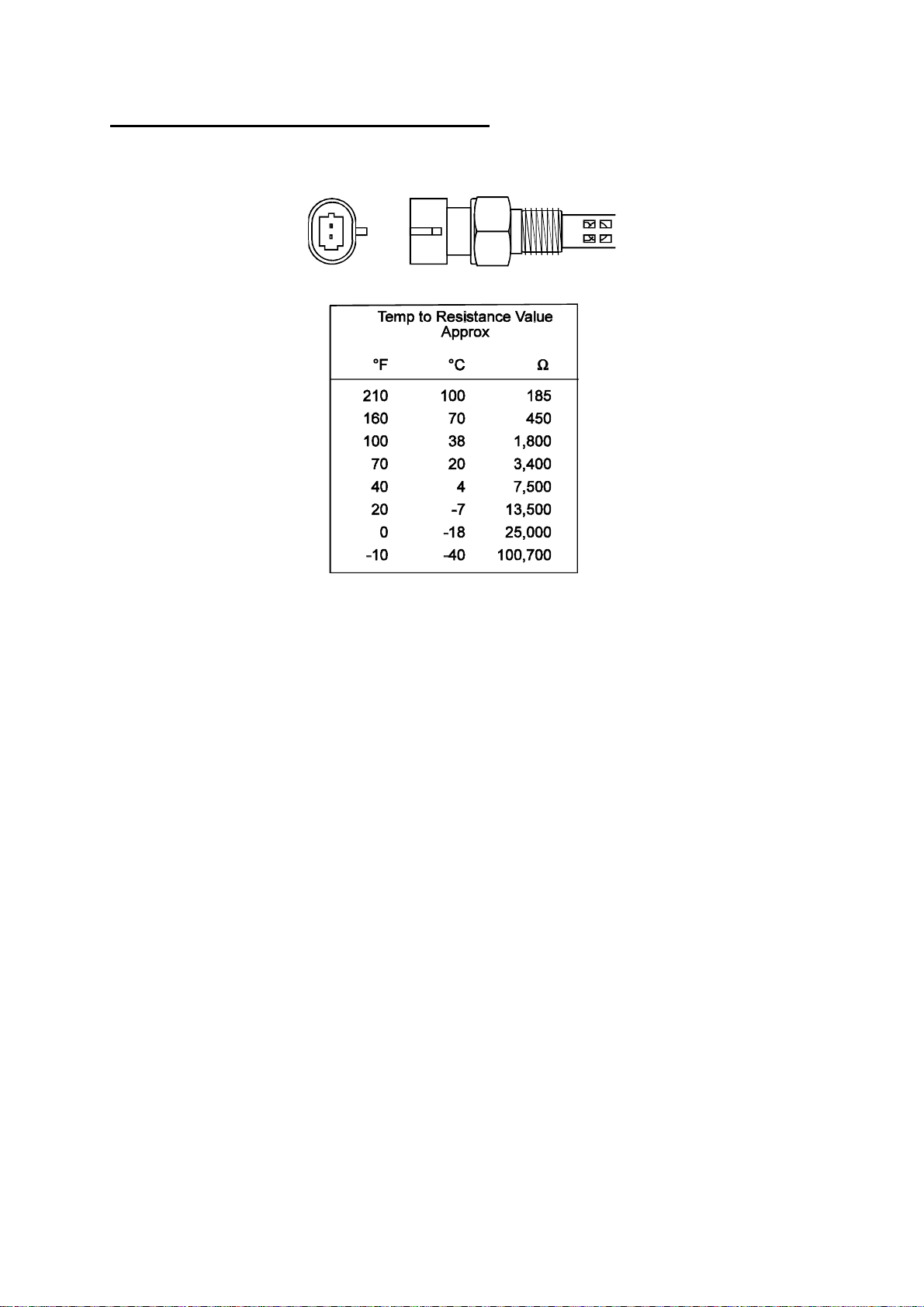

• Temperature Sensors (Air and Coolant)

NTC temperature dependent resistor type.

Operating Range

Continuous -40°C to 100°C (-40°F to 212°F)

Intermittent up to 125°C (257°F)

12

Page 14

• Throttle Position Sensor

10 kΩ rotary potentiometer driven from throttle shaft

• Engine Speed Pickup

Compatible with most trigger systems:

- 5 or 12 volt square wave;

- pull-to-ground (open collector)

Tach adaptor available for magnetic (or ‘reluctor’) triggers

ECU Outputs

• Injector Driver

4 x 4/1Amp peak-and-hold current limiting drivers:

- up to four low-impedance injectors*

- up to eight high-impedance injectors*

(Expandable using optional Driver Box. See Appendix C)

• Fuel Pump Control

20A fused relay, features automatic priming and switch-off.

* additional hardware may be required

System Programming Requirements

• Computer

IBM-PC or compatible, preferably laptop or notebooks

CGA, EGA or VGA, colour or monochrome display

640+ kb RAM

• Disk Drive

3.5" Floppy Disk Drive

(5.25" disk available on request)

• Serial Port

Standard RS232C port - 9 pin D connector

(25 pin cable available on request)

COM1 or COM2 (selectable)

Adjustable Features

• Base Fuel Map

22 Fuel ranges, every 500 RPM to 10,500, or

17 Fuel ranges, every 1000 rpm to 16,000

32 Load points per range, up to 16mS with 0.016mS resolution

• Correction Maps

• Fuel

Cold Start Prime - 32 points

13

Page 15

Coolant Temperature Enrichment - 32 points

Air Temperature Adjustment - 32 points

Battery Voltage Correction - 32 points

Closed Throttle (selectable) - 16 points

Full Throttle (selectable) - 32 points

• Programmable Rev-Limit

• Fuel Cut on Deceleration

• Accelerator Pump

Increase and sustain parameters

Coolant enrichment factor

Three speed ranges

• Idle Speed Control

Target Idle Speed

Cold Idle-up Rpm

Post-start Rpm setting

• Closed Loop Control

with both cruise and idle settings

• Programmable Output Options (Optional)

Miscellaneous

• Map Storage and Retrieval

Maps may be stored to disk and re-used

• Datalogging

Engine data information saved 5 times per second

Store to memory or disk

Limited only by available memory (approx. 11k/minute)

• US or Metric Units

• Real Time Programming

Instant, hesitation free adjustment while engine is running

• Optional Mixture Trim Module

Provides ±12½% or ±50% adjustment for fast tuning

• Rugged Aluminium Casing

Black anodised with integral cooling fins and mounting brackets.

14

Page 16

SECTION ONE

Getting Started

CHAPTER 1

Haltech F9 Installation

1.1 Overview

The Haltech F9 system comprises the following components

Haltech Electronic Control Unit (ECU)

Coolant Temperature Sensor

Inlet Air Temperature Sensor

Throttle Position Sensor (TPS)

Manifold Absolute Pressure (MAP) Sensor

(1,2 or 3 Bar Sensor - purchased separately to main kit)

Main Wiring Harness

Haltech F9 system Instruction Manual

Programming Cable

Programming Disk

Relays

Optional Items

Fuel Mixture Trim Control

F9A Upgrade Kit with Auxiliary Loom

Optional Items with F9A (Only)

Exhaust Gas Oxygen Sensor

Idle Speed Control Motor

Other components not supplied as part of the F9 system include:

Inlet Manifold

Throttle body

Throttle linkages

Velocity stacks

Injector Mounts

Fuel injectors

High pressure fuel pumps

Inlet Air Cleaners

Performance ignition systems

Trigger System

15

Page 17

1.2 Installation Summary

1. Mount Manifold Absolute Pressure Sensor.

2. Mount Coolant Temperature Sensor.

3. Mount Inlet Air Temperature Sensor.

4. Mount Throttle Position Sensor.

5. Route Main Wiring Harness and connect sensors.

6. Mount and connect Power Relays.

7. Mount Fuse Block.

8. Mount ECU inside passenger compartment.

9. Locate and connect flying wires: RED + 12 volts battery

GREY Ignition on 12 volts

BLACK Chassis ground

ORANGE (2 wires) Fuel Pump Circuit

BROWN Trigger Input

10. Configure Trigger dip-switches

11. Route Optional Auxiliary loom. (Optional)

12. Connect ECU and test.

1.3 Expanded Installation Guide

1.3.1. Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is used to convert the manifold pressure into an electrical signal for the F9

ECU to use. The sensor works in absolute pressures, thus its calibration is not affected by

changes in barometric pressure.

There are three types of MAP sensors that can be used with the F9 system. The sensor

required depends on the engine setup.

1 Bar Sensor (Part No. 039 4070)

( -100kPa to 0 kPa) Normally Aspirated Engines

16

Page 18

2 Bar Sensor (Part No. 886 3189)

(-100kPa to 100kPa) Turbo or Supercharged

Engines up to 100kPa boost

(15 psi, 1 atmosphere)

3 Bar Sensor (Part No. 749 3169)

(-100kPa to 200kPa) Turbo or Supercharged

Engines up to 200kPa boost

(30 Psi, 2 atmospheres)

Note: Make sure you have the correct MAP sensor for your engine. The first three digits

of the part number is stamped on the sensor housing.

Engines running in Throttle Position Mode must use a 1 Bar sensor, not connected to

the manifold, so as to measure the barometric pressure.

Installations using a Barometric Pressure sensor (F9A only) will have two MAP sensors

to connect. One sensor will be for the Manifold pressure, the other will be for

Barometric pressure. The Barometric sensor must be a 1 Bar sensor. It connects to the

Spare Input plug on the F9A loom. This sensor can be mounted with the ECU and must

be left open to the atmosphere.

Mounting

The MAP sensor is usually mounted high on the engine bay firewall or inner guard using two

screws and with the hose nipple facing outwards. Connect the sensor to the inlet manifold via

a short length of vacuum hose and fasten with either hose clamps or nylon cable ties. Connect

the sensor to the main wiring harness using the appropriate plug. (For 1 Bar sensors the plug

is green, for 2 and 3 Bar sensors the plug is orange). Avoid mounting the sensor below the

level of the fuel injectors, because fuel may collect in the vacuum hose and run down into the

sensor. The sensor assembly is weather-proof but it is good practice to mount the sensor in a

protected position away from moisture and heat.

Note: Throttle position mode installations.

If you are using the throttle position to determine engine load, a 1 Bar MAP sensor must be

used, disconnected from the manifold and open to the surrounding air. The F9 will use the

sensor signal to compensate for barometric pressure.

1.3.2. Coolant Temperature Sensor

The coolant temperature is used by the computer to determine warm up corrections and adjust

fuel mixtures.

The coolant temperature sensor has a solid brass temperature sensing tip. Refer to the diagram

for technical details of the sensor. The coolant sensor supplied is an industry standard

component and some engines may already have provision for this type of sensor.

17

Page 19

The coolant temperature sensor is designed to screw into a threaded hole and protrude into the

engine coolant stream. For air cooled engines, the sensor can be embedded directly into the

engine block or used to sense oil temperature.

Locate a suitable position on the engine which will allow the hole and thread to be machined,

and which gives access to the coolant stream. The sensor should be mounted after the engine

and before the thermostat in the coolant circuit. Since most engines have existing temperature

sensor holes, it is often possible to mount the Haltech sensor in one of these holes. A thread

adaptor is sometimes necessary. In some engines only one temperature sensor hole exists and

is used for the dashboard gauge sender. It is usually possible to install a tee-piece to allow

both the dashboard sender and the Haltech sender to share access to the same threaded hole.

If it is necessary to drain the coolant from the vehicle to fit the temperature sensor then the

factory manual for the engine should be consulted for the correct procedure to restore the

coolant and purge the cooling system of air.

18

Page 20

1.3.3. Inlet Air Temperature Sensor

14mm x 1.5

The air temperature sensor is used to compensate for changes in air density due to air

temperature. Cold air is denser than warm air and therefore requires a greater volume of fuel

to maintain the same air/fuel ratio. This effect is most noticeable in forced induction engines.

The Haltech F9 will automatically compensate using the signal received from the air

temperature sensor.

The sensor should be mounted to provide the best representation of the actual temperature of

the air entering the combustion chamber, i.e. after any turbo or supercharger, and intercooler,

and as close to the head as possible. The sensor needs to be in the moving air stream to give

fast response times and reduce heat-soak effects.

Note: The Haltech air temperature sensor will read temperatures up to 120° C and

temperatures above this will be interpreted as a fault condition. The air temperature

after some turbos and superchargers can exceed this. If this occurs with your engine you

should consider fitting an intercooler to reduce air temperature and increase charge

density. If this is not possible then the air temperature sensor should be placed upstream

of the turbo or supercharger to monitor ambient air temperature.

Once a suitable position has been located for the air temperature sensor a hole should be

drilled and tapped to accept the sensor. Remove the manifold or inlet tract from the engine

before machining the sensor mount. Do not allow any metal particles to enter the inlet

manifold of the engine as these will be drawn into the engine and damage it. Wash all

components before reassembly.

19

Page 21

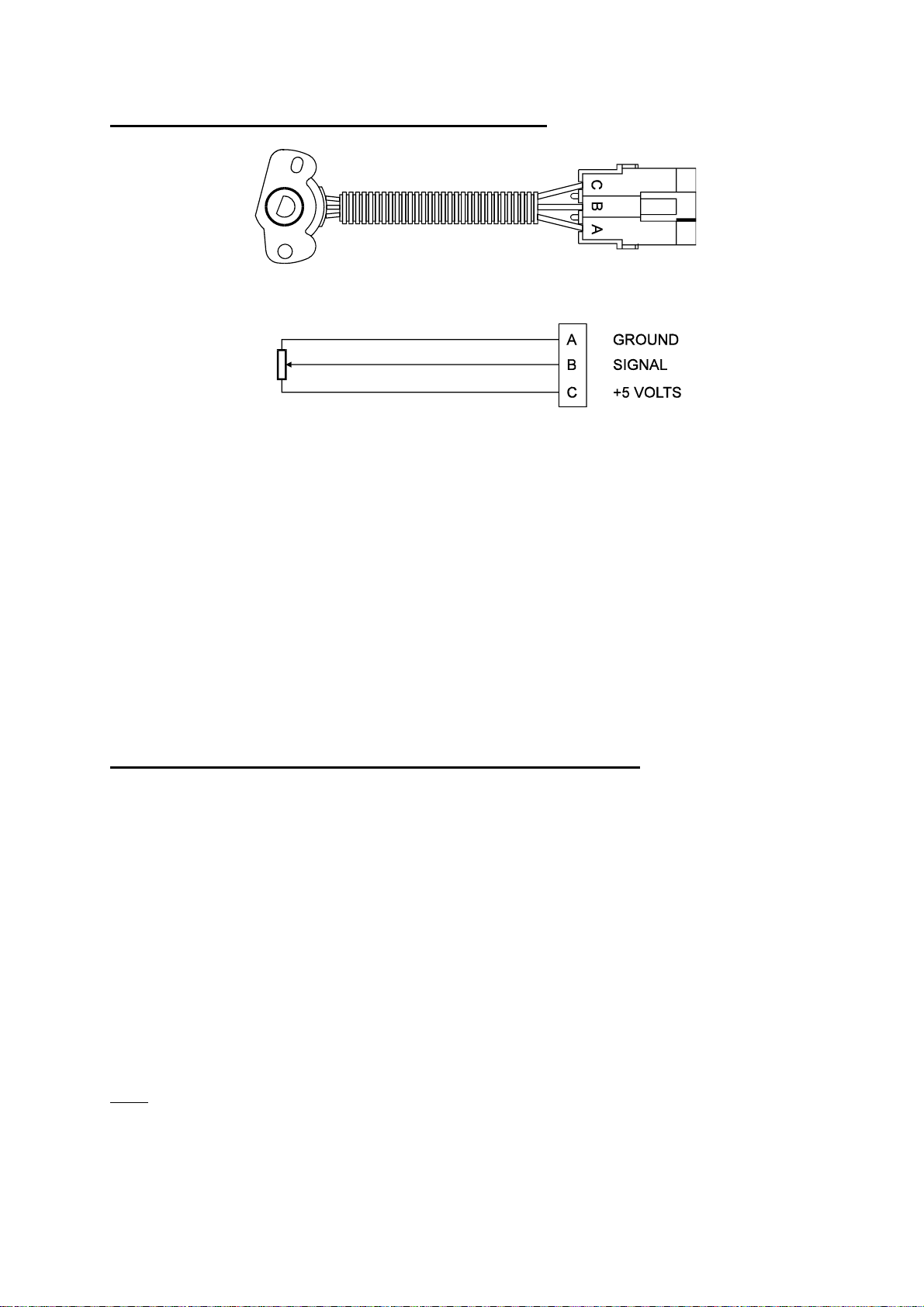

1.3.4. The Throttle Position Sensor (TPS)

The throttle position sensor is mounted to the throttle butterfly shaft to measure its rotation. A

TPS is common on many late model engines and the Haltech sensor should attach with little

or no modification. The throttle shaft must protrude from the side of the throttle body. This

may require the machining of the throttle body or the manufacture of a new throttle shaft. The

inner mechanism of the sensor rotates with the shaft. If the shaft is round then file a flat

surface on the shaft so that it will pass through the sensor assembly. The TPS should be

mounted against the side of the throttle body, using two screws, such that the throttle shaft

and the sensor mechanism can rotate freely. Make sure that the axis of rotation of the

shaft is exactly aligned with the axis of rotation of the sensor. Also, do not use the TPS as

a throttle stop. In either case, the TPS will be damaged. The absolute range of sensor

movement is not important as the sensor can be calibrated using the programming software.

Even if you are going to sense engine load via a MAP sensor, a TPS MUST BE

CONNECTED. The TPS allows the ECU to provide improved throttle response and

driveability.

1.3.5. Route Wiring Harness and Connect Sensors

Lay the main wiring harness out in the engine bay with the sensors mounted to ascertain the

best fit for the harness. Pass the wiring loom through a hole in the engine bay firewall and

into the passenger compartment where the ECU will be mounted. Either use an existing hole

or cut a new hole to suit. Use a rubber grommet or similar device to protect the harness from

being damaged by rubbing on the sharp edge of the hole.

IMPORTANT

• Do not allow the harness to touch hot exhaust parts including manifolds or

turbochargers.

• Try to route the main harness away from high voltage ignition leads. Under no

circumstances run any wiring parallel to, or in contact with the ignition leads.

Hint: Be neat. Run the harness in a tidy fashion. Try to run the harness along paths used by

original wiring. Use nylon cable ties to secure the harness in place, but do not stress the

wiring or connectors.

Once the harness is fitted, connect all the sensors to their appropriate plugs.

20

Page 22

1.3.6. Power Relays

There are two relays used with the Haltech F9, the Main Power Relay (with a grey wire) and

the Fuel Pump Relay (two orange wires). These relays are identical parts so it is not important

which relay goes in what connector.

These relays should be mounted on the firewall or an inner guard. Do not mount the relays

such that they could catch and collect splashed water. Residual water inside the relay housing

will cause them to fail. Mount them with the tab upwards as shown in the diagram.

1.3.7. Fuse Block Assembly

The fuse block assembly holds the fuses that protect the various components of the Haltech

F9 system.

The fuse block is supplied from the factory with fuses installed. The fuse ratings are shown in

the diagram and should not be changed as these have been selected for best protection.

Altering the fuse ratings could cause severe damage to the F9 system.

21

Page 23

The fuse block should be positioned so that it can be easily accessed in case of fuse failure.

Do not mount the fuse block where it could be exposed to water. Mount via the two screws

holes in the block. Ensure that vibration will not cause the screws to vibrate loose.

Connect the Fuse Block assembly to the Main Harness.

1.3.8. Electronic Control Unit (ECU)

The Haltech F9 is not designed to be waterproof. It is desirable that the ECU be given as

much protection from the environment as possible. It is recommended that the ECU be

mounted inside the passenger compartment, either on the firewall, under the dashboard or

under the passenger seat.

The ECU has four mounting holes that allow it to be mounted to most flat surfaces. In

extreme cases of vibration, the ECU should be mounted on rubber antivibration pads. When

mounting the ECU remember that the communications connector on the loom should remain

accessible for ease of programming.

22

Page 24

1.3.9. Flying Leads

Locate and connect the following flying leads.

Black - (Ground) Locate a good chassis ground point and connect the black wire. The best

spot is direct to the battery negative terminal.

Red - (Supply 12V) Locate a source of continuous 12 volts and connect the red wire.

Connecting direct to the positive battery terminal is suggested.

Grey - (Switched 12V) The grey wire is used to control the operation of the Haltech F9

power relay. It needs to be connected so that it sees 12V only when the ignition is on

and during cranking. This wire does not draw a large amount of current (< 0.5A). Do

not connect to the accessory outputs of the ignition switch.

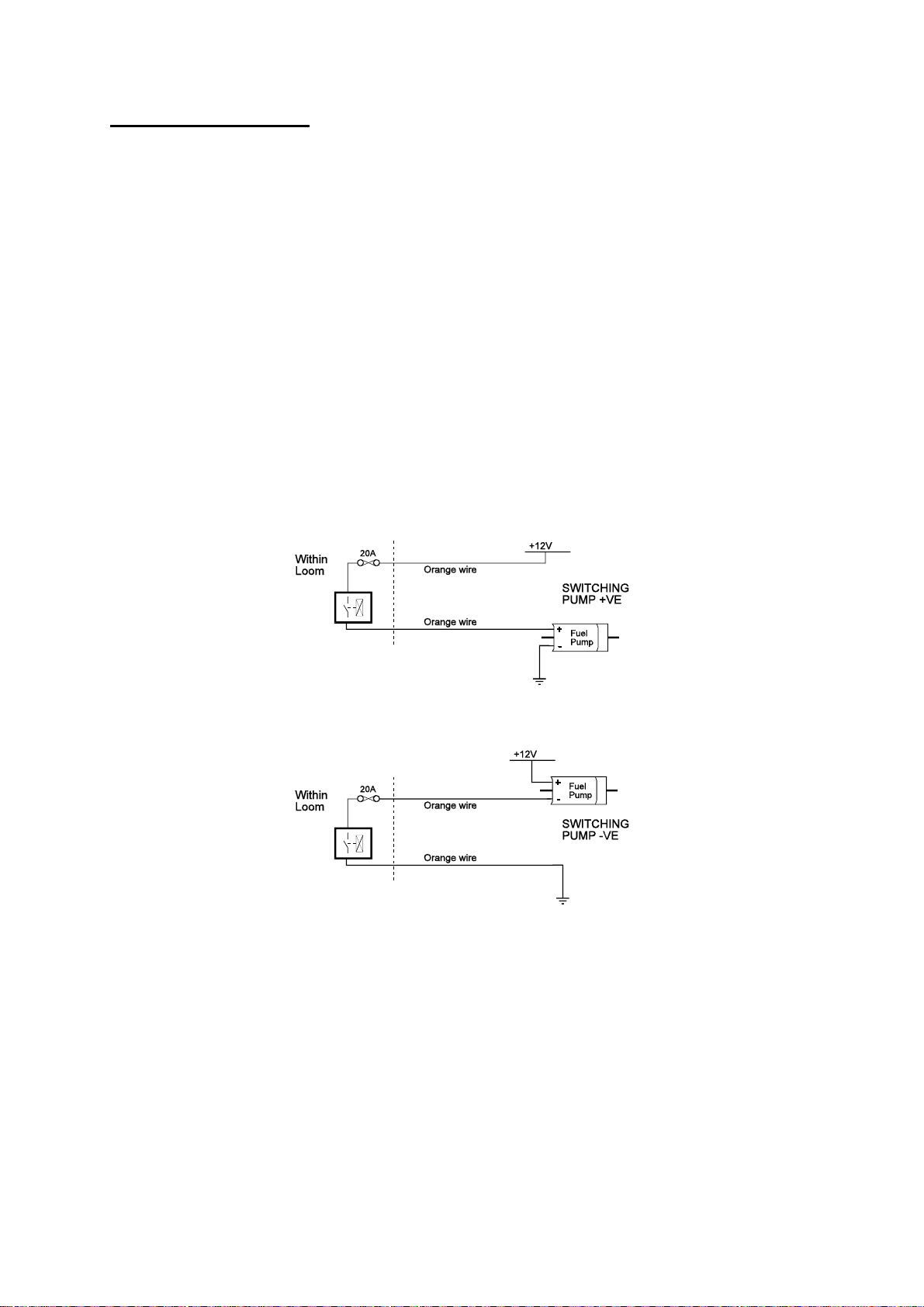

Orange - The two orange wires are used to operate the fuel pump. When the Haltech E6A

ECU wants to operate the fuel pump it will close the fuel pump relay connecting the

two orange wires together. The diagrams show two examples of wiring the fuel pump.

Do not add extra relays to the fuel pump circuit.

Brown - (Trigger) This is the wire used to sense how fast the engine is going. It should

connect directly to the negative terminal of the ignition coil. (On a rotary, the leading coil

negative is preferable). For engines with more than one coil, or for capacitive or multiplespark discharge systems, there is usually a tachometer output from the ignition system for the

dashboard tachometer to which the brown wire should be connected.

Blue - (Aux Input) This wire is used as an auxiliary input to the ECU, it is used by

applications such as the Staging Signal, Turbo Timer and Torque Converter Clutch.

23

Page 25

1.3.10. Configure Trigger DIP - Switches

The input trigger is used by the F9 to determine engine speed and when to fire the injectors.

The standard connection for this wire is to the negative terminal of the ignition coil. If the

engine does not use standard points or a electronic ignition system then it may be necessary to

reconfigure the input circuit. The trigger configuration DIP switches can be found by

removing the back cover from the F9 ECU. Refer to the following tables (see below) for DIP

switch functions and settings.

Switch 1 ON: Adds 1k pull-up resistor to battery.

Use an open collector (digital) outputs.

Switch 2 ON: Engage primary filter capacitor.

Switch 3 ON: Engage secondary filter capacitor.

Switch 4 & 5: Changes trigger threshold level (see below)

Trigger level Switch 4 Switch 5

+5.0 Volts OFF OFF

+3.4 Volts ON OFF

+2.5 Volts OFF ON

+2.0 Volts ON ON

Refer to the following tables for switch settings for common ignition systems. All ECU’s are

factory set for Category A ignition systems.

Category A Category B Category C Category D

Points style MSD 6A/6T Firepower ECI Porsche 911/930

Transistor MSD 7AL/7x Buick Indy

Assisted Direct Fire

Direct Fire MSD 8 GM MSD

GM HEI Electromotive

Jacobs

Stinger 1

Stinger

Thermo-Fire

(Most Others)

24

Page 26

Switch 1 2 3 4 5

Category A OFF ON ON ON OFF

Category B OFF OFF ON OFF ON

Category C OFF OFF OFF ON ON

Category D ON OFF OFF ON ON

1.3.11 Route Optional Auxiliary Loom

The auxiliary loom may be routed in a similar manner to that of the main loom. Refer to the

F9A Supplementary Manual for installation details.

1.3.12 Connect the ECU

The ECU can now be connected and tested. Be sure to engage the clip on the main connector.

This will make sure the main connector parts mate correctly and reduces the mechanical

strain on the connector bodies. The system can now be tested as described in the following

chapters.

25

Page 27

CHAPTER 2

Getting Online

Now that your Haltech F9 is installed with all the sensors in place the system can be

connected to the programming computer. This will allow the readings from all the sensors to

be displayed on the screen and checked for correct operation.

To connect the PC to the Haltech F9 ECU you will need the programming cable and

programming disk supplied.

2.1 Connecting the Haltech F9 to a Computer

The programming cable supplied with the Haltech F9 is a standard serial link extension cable.

One end of the cable will plug into the Main Harness PC Interface connector (near the main

connector). The other end should plug into the mating connector at the back of your

computer. The plug on the computer may be marked "Serial", "Mouse" or "COM". Almost all

laptops will have this plug. If there is no 9 pin plug which it will connect to, check to see if

there is a 25 pin D-type plug available (some desk top computers will have this). If this is the

case, an appropriate cable can be supplied on request. Alternatively, most electronic retailers

will have a 25-pin to 9-pin converter.

Any time you wish to communicate with the F9 ECU it needs to be supplied with power. This

usually involves just turning on the ignition switch. If at any stage power is not on, or the

programming cable is disconnected while attempting to communicate, the programming

software will display the message RECONNECT HALTECH. To rectify this, reconnect

power and/or the programming cable.

2.2 Operating the Software

2.2.1 Computer Requirements

The computer required to program the Haltech F9 can be any IBM-PC compatible personal

computer from the XT onwards (i.e. the AT, 386, 486 or Pentium computers). The

requirements are fairly modest. The computer must have at least 640K of RAM (with about

590kb free for executable programmes), one 3.5" disk drive and a CGA, EGA, or VGA

screen. (Virtually all reasonably modern laptops running MS-DOS (version 5.00 or higher)

will fit this description).

2.2.2 Installing the Software.

The Programming Disk supplied with the Haltech F9 has an installation programme that

allows you to install the software onto the PC’s Hard Disk. Most modern PCs have a hard

disk. If your PC does not have a hard disk, the F9 Programme can ran directly from the disk

26

Page 28

supplied. Installing the software on the Hard Disk will speed up the programme and avoid

having to fiddle around with floppy disks. The installation programme need only be run once.

If you do not have a Hard Disk, go to the section titled Running the Software from the

Floppy Drive.

To install the software follow these steps.

Boot up Computer

Turn your PCs power on and boot up MS-DOS as instructed by the computers Users Manual.

If a shell programme or menu utility runs automatically when you boot your computer, exit it

now. You should see something like this:

C:\>_

This is the ‘DOS Prompt’. It is DOS’ way of indicating that it is waiting for a command. The

C: indicates that the C drive is the drive currently selected. If you do not have a hard disk,

your prompt will probably look like this :

A:\>_

Select the Drive

To run the INSTALL programme, you must insert the supplied disk in the disk drive. If the

drive is the A drive, then it must be currently selected. To select the A drive (or B drive if it is

the required drive) type :

Dy or %y

The y key is the Enter Key. On some keyboards it may be called the Return key. You should

now see the prompt :

A:\>_ or B:\>_

Run the INSTALL Programme

To run the Install program type :

LQVWDOOy

The Install programme will now run. Follow the instructions given. The programme will

suggest that the software will be placed in the HALTECH directory. You can change the

destination directory, but it is not recommended that you do unless you understand how

directories work.

When it is finished, the installation programme will tell you if the installation is successful. If

it was not, consult the trouble shooting section of this manual.

27

Page 29

The F9 Programme is now ready to run.

2.2.3 Running the Software from the Hard Disk.

Boot your computer up as described earlier. If your computer is already on, make sure the C

drive is currently selected. To change to the HALTECH directory type :

F'?KDOWHFKy

or, if you used a different destination directory, type that path.

To start the programme type :

Iy

The F9 programme will now run. The next section is on running the software from a floppy

drive. You can skip this section and go straight to the section entitled Azerty Keyboards.

2.2.4 Running the Software from the Floppy Disk.

To run the software from a floppy drive, boot your computer up as described earlier. Insert

the Programming disk in the disk drive. If the drive is the A drive, then it must be currently

selected. To select the A drive (or B drive if it is the required drive) type :

Dy or %y

You should now see the prompt :

A:\>_ or B:\>_

To start the E6A program type :

The E6A program will now run.

HDy

2.2.5 Azerty Keyboards

Most countries use a keyboard where the first six letter keys across the top row are :

TZHUW\

This is called a Qwerty keyboard. Some countries use an alternative, which is called and

Azerty keyboard, where the Q and W keys are swapped with the A and Z keys respectively. If

you have an Azerty keyboard, you need to run the software slightly differently. When you

would normally type :

28

Page 30

HDy

to run the programming software (not the installation software), you need to instead type :

HDDy

The /A tells the programme you have an Azerty keyboard. The programme will adjust

accordingly.

2.2.6 Acknowledging the Risks

Once the program begins running a title page should appear briefly and then a warning screen

will be displayed. Read the warning and only proceed if you are prepared to accept the risks

involved in tuning your own engine. Faulty tuning can be dangerous and/or can damage your

engine.

2.3 The Online and Offline Modes

On the F9 system title page, the software asks whether to operate in ONLINE or OFFLINE

mode. The Offline mode is very useful to familiarise yourself with the Haltech software, but

should not be used to make lasting adjustments to the fuel maps unless there is a special

reason for doing so. If you wish to experiment and familiarise yourself with the software

press N for Offline mode, but if the ECU is installed and power is available then we suggest

the Online mode be selected. Press Y to select Online mode.

2.4 Using the System Online

In the Online mode there is a two-way flow of information between the ECU and the

programming computer. The communication cable must be installed and power must be

available to the ECU before the system can communicate. The Online mode will be used most

frequently. While using the system Online, you can view engine information directly and

make adjustments. Any changes or modifications made on the computer are instantaneous and

will be immediately recorded in the ECU. When the programming cable is removed and the

ignition switched off, the ECU will retain all of its memory. The maps do not need to be

saved, but keeping a copy on disk is always good practice and is recommended. (See 9.1)

29

Page 31

NOTE: If power is removed or the communication cable is disconnected or interfered with,

the following message will be displayed on the computer screen.

RECONNECT HALTECH

If this message appears check all connections and ensure that the communications cable is not

being interfered with. Also be sure that the Haltech F9 unit is receiving power. (i.e.. ignition

switch is turned "on".)

2.5 The Main Menu

When you select Online or Offline mode the Haltech MAIN MENU bar appears. This menu

bar allows access to submenus giving access to maps, file storage/retrieval, engine data and

options.

2.6 How to Quit

Throughout the program you can exit from any application by using the menu bars or hot

keys. Pressing tT in any page will prompt you to exit the program (i.e.. pressing T while

holding down the t key).If you wish to exit < press at the prompt.

2.7 Checking the Engine Data

The engine data option can only be used when the system is Online. This function allows all

of the engine data variables to be displayed on the screen

This is a very useful function for analysing the engine sensors. To bring up the engine data

press tH from any application. Otherwise it can be accessed through the menu bar by

pressing s2 and then ( for Engine Data.

Do not attempt start the engine if the Engine Identification has not been set up. Before

continuing check to see if all the sensors are operating correctly by viewing the engine data

page.

30

Page 32

CHAPTER 3

Engine Identification

3.1 Checking the Identification

The Identification page tells the F9 essential information about the engine characteristics.

Without this information being correct the engine cannot run properly. The Identification is

made up of several fields. Each field can have a number of settings, and you can change most

of the fields.

Use the Up and Down arrow keys (

Selection type, or Text type. The Selection type fields give you a number of valid entries for

that field. For example, the valid number of cylinders can be set to 1, 2, 3, 4, 5, 6, 8, 10 or 12.

The Tab and Enter keys (

of the Tab key will display the next selection. The Shift and Tab keys together will step

backwards through the selections. Once the desired selection is displayed, the Enter key is

pressed to programme that selection. Text Fields require you to enter either text or numbers.

Once the field is selected, the new text can be typed in, with the Enter key to finish. An

example is the Rev Limit. This field can be set between 2000 and 16000 rpm. If you want the

rev limit to occur at 7000rpm, then you would need to select this field using o or p and then

type y.

Here is a description of each of the Identification fields:

Cylinders: The number of engine cylinders needs to be entered here. This parameter is

used to determine the engine speed.

Load Sensing: The F9 can use either the manifold pressure or the throttle position as a means

of determining the engine load. Most engines operate using manifold pressure to sense

engine load. If your engine employs any form of supercharging, you must run in

manifold pressure mode. Only wild cams, motorbikes or heavily ported rotaries

require throttle mode - i.e.. engines whose vacuum signal is small, or fluctuates

greatly. If you are unsure what to use, contact your Haltech dealer.

v and y) keys are used to change this type of field. Each stroke

o and p) to move between fields. The fields are either

RPM Limit: The F9 can limit the maximum rpm to which the engine will operate to. Above

this level the F9 completely cuts fuel to the engine. When the engine speed drops

below the RPM Limit the F9 will resume normal fuel delivery. This is known as hard

limiting. If the RPM Limit is not needed then set this value above the highest

operating point of the engine.

Units: The Haltech F9 programming software can display parameters in either Metric or US

units.

31

Page 33

RPM Mode: The F9 fuel and ignition maps may be arranged either in 500 rpm increments to

10,500 rpm, or in 1000 rpm increments to 16,000 rpm. Select the high - or low - rpm

mode here. Changing settings alters the way the ECU reads the Maps, and will change

the tuning of the engine dramatically. Do not change this setting once tuned unless

necessary.

Road Speed Value: This value calibrates the Road Speed reading. Some applications in

Advanced Mode can not use the Road Speed input trigger, and this field will not be

displayed.

Trim Control: The optional Trim unit can be used to control one of several parameters. This

field selects the controlled parameter. If there is nothing connected to the trim plug,

the trim will have no effect (except with boost control). The available functions are :

Fuel (Fine) ±12.5% adjustment of fuel.

Fuel (Coarse) ±50% adjustment of fuel.

Boost Control (F9A) Boost trim for Wastegate control only.

Spare Input Function: The Spare input is an analogue input similar to the Trim Control

input that can be configured for one of several tasks. Its function is set by this field.

The available functions are :

General 0-5 volt input; no effect on ECU operation.

Fuel (Fine) ±12.5% adjustment of fuel.

Fuel (Coarse) ±50% adjustment of fuel.

Baro Sensor Barometric Pressure Sensor.

Exhaust MAP Sensor Exhaust Pressure.(does not affect on ECU operation)

Care must be taken when setting this field. The circuit is biased to 2.5 volts.

Therefore, if there is nothing connected to the plug, the input will read 2.5 volts. If one

of the trims is selected, there will be no effect. But if the Barometric Sensor is

selected, the reading will be incorrect, and will have a large effect on the operation of

the ECU.

2nd MAP Sensor: This field is only accessible when the Exhaust MAP Sensor is selected on

the Spare Input Function. It tells the software what sensor is being used (either 1 Bar,

2 Bar, or 3 Bar sensor) and how to calibrate the reading.

32

Page 34

Aux. In/Out Function: The Auxiliary Input/Output on the F9 can be configured for one of

several functions. Most of these functions relate to the configuration of the system.

The available functions are:

Disabled No effect on ECU operation.

Staging Signal Output - Logic output that indicates Staging

conditions. If Staging is selected, and the

Staged injector are firing, this signal will be

high (5 volts), otherwise it will be low (~ 0

volts).

TCC Input Input - This input is used in conjunction with the

TCC Optional Output. [16.4]

Turbo Timer Input - This input is used in conjunction with the

Turbo Timer Optional Output. [16.12]

Since the Auxiliary Input/Output line can only perform one duty, all of the above

functions are mutually exclusive. i.e. although two programmable outputs exist on the

F9, only one of the TCC and Turbo Timer functions may be chosen. Keep this

function in mind when deciding on the F9 configuration you wish to run.

33

Page 35

Chapter 4

Adjusting Haltech Maps

The tutorials presented in this chapter are examples of how you might use the available

functions to make typical modifications to the maps. These tutorials are aimed at explaining

both why and how some typical changes might be made. They assume that you have the

software running Online on your PC, with the ECU powered and connected via the supplied

programming cable.

4.1 What are maps?

The injection times needed by the engine at different conditions is stored by the F9 in a table

of numbers called a look-up table. The F9 determines the engine's load and speed, and uses

these two parameters as an index to the table. This table is called the Fuel Map. For

instance, at an engine speed of 4000 rpm and at -20kPa, the relevant number in the table

may be 4.35. If the engine approximates -20kPa at 4000 rpm, then the computer will extract

the value of 4.35ms from the table as the base injection time. This value is then adjusted to

compensate for numerous conditions, such as temperature or acceleration, and then the ECU

holds the injectors open for that time on the next injection.

It is possible to programme the F9 by directly changing the value of each number by

programming in the numerical mode, but this can be extremely difficult, so the Haltech

allows you to change the numbers by manipulating graphics in maps presented as bar

graphs. (This is much simpler and allows you to visualise the map)

Since it is difficult to interpret all the table's values at once, the programming software

divides the map by engine speed into a series of rpm ranges. Within the range, each load

point is represented by a vertical bar. Thus, when you view a range from the Fuel Map, you

see a bar chart of injection time versus load for all the load points in the table at that speed.

There are other tables in the F9, such as those used for temperature corrections. They are

indexed by only one parameter, and so are not divided into ranges. These tables are also

called maps.

4.2 What is mapping the Engine?

Mapping the engine is filling the look-up tables with the correct values for your engine. This

is done by adjusting the heights of the bars within the maps. Bars may be adjusted one at a

time, or in groups. The Haltech programming software has been designed to make engine

mapping as simple and intuitive as possible.

34

Page 36

4.3 Using the Software

In order to make the software easy to use, the programme presents you with a menus bar at

the top of the display. The menu bar is accessed through simple combinations of key

strokes. Once the appropriate menu has been accessed a sub-menu appears giving choices on

available page heading. To increase efficiency there is also a number of hot-keys that allow

you movement between pages without accessing the menu bar.

4.4 Accessing the fuel maps

Pressing sP will take you to the Maps Menu. From the Sub-menu choose the fuel maps

option. By using the cursor keys to move the highlight bar or pressing the underlined letter

of the option required in the case ). This will produce a further sub-menu that will allow

you to choose a range to be viewed.

4.4.1 Fuel Setup

The Fuel Setup works in an identical way to the Identification. It’s fields are different and

relate to the way the fuel is delivered to the engine. Enter the Fuel Setup by pressing

sVand then by pressing ) key. The fields in the Fuel Setup are:

Ign / By: Ignition Divide By is the number of ignition pulses that will be counted until the

next injection pulse. For almost all multipoint systems, injection should occur once

per revolution and so Ignition Divide By should be set to half the number of cylinders.

If the system is operating in Batch Fire or Sequential mode, or is a rotary, then a value

of 1 is suggested.

Decel Cut-Off: A common fuel saving feature in original equipment computers is a fuel cut-

off on deceleration. This will cut fuel delivery to the engine while coasting down hills

with closed throttle. This feature can be enabled or disabled on the F9. It is better,

when first tuning, to disable this function.

Injection Mode: The F9 splits its four injector driver outputs into two banks. INJ1 and INJ2

comprise the first bank. INJ3 and INJ4 form Bank 2 (refer to the wiring diagram at the

back of this manual.) In Basic Mode, Fuel can be injected in three different modes.

Multipoint injection fires all the injectors together. This is the most common setup

and will normally be used on engines with multipoint injection manifolds (one injector

per cylinder).

Batch-fire injection is usually used in throttle body or non-turbo rotary setups and

fires the two banks of injectors alternately. On eight and twelve injector fuel rails,

with high-flow injectors, this may also help reduce fuel pressure oscillations caused by

all injectors pulsing together.

Staged injection is usually used on high boost turbo engines. Injector Bank 1 fires all

the time, just as in a multipoint setup. Beyond a set boost pressure, the second bank of

injectors is enabled. These "staged" injectors are normally upstream of the primary

35

Page 37

injectors, adding to their fuel flow. The point at which the F9 switches in the

secondary injectors is set via the Staging Bar Number field. Staging permits high fuelflow capability, but maintains accuracy and controllability at light load and idle. See

Appendix D [D.3] for more details on staging.

Staging Bar Number: This field sets the point at which the staged injectors are enabled. See

Appendix D [D.3] for more details on staging. If the injection mode is not "Staged

Injection" then this field will not affect injection.

Zero Throttle Map: This feature allows the user to adjust a special fuel map that is used

only when the throttle is closed. This can allow a very quick and simple adjustment of

the idle fuel settings on engines with difficult idle characteristics. This option can be

disabled if not required.

Full Throttle Map: This feature allows the user to adjust a special fuel map that is used only

when the throttle is wide open on normally aspirated engines. With some manifold and

or throttle designs, pressures in the manifold can reach close to atmospheric pressure

before full throttle is applied. This effect can make tuning difficult around full throttle.

This map allows the full load settings to be easily set without interfering with lighter

load settings. The throttle position at which this Map is used is set by the Full Throttle

Threshold field.

Full Throttle Threshold: See the Full Throttle Map field above for information on this field.

This field can be set between 70 and 100.

Barometric Lock: If you wish to lock the barometric value that is stored by the ECU to a

set value and override the start-up barometric correction, enable this option.

Barometric Pressure Lock: Allows you to set the barometric value to which the ECU

corrections will be locked. Default is 1013mBars ( = 1 Atmosphere @ sea level)

See Chapter 3, Engine Identification for information on how to adjust these parameters.

Once you have set up the fuel delivery via the Fuel Setup, you can view the Fuel Maps.

Press sP then ) to view the Fuel Sub-Menu. Then chose the range you wish to view by

using the function keys. While in the Fuel map, each range can be accessed by pressing the

1,3and - keys to move to the next, previous range and jump to a particular range.

36

Page 38

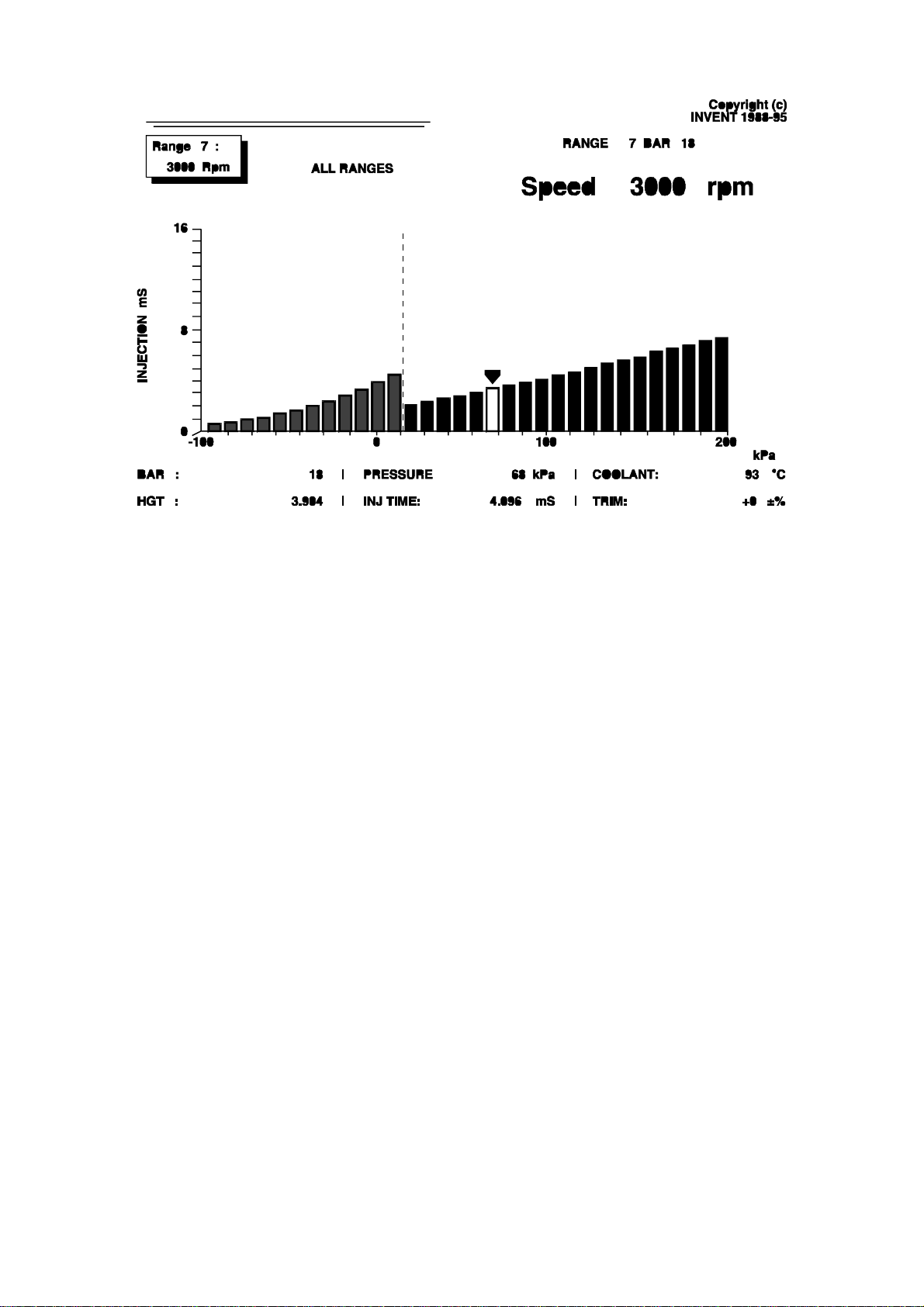

To view the map at the 3000 rpm range, press d. When in the Fuel Maps sub-menu your

display should look like this:

HALTECH F9 Fuel Map

Values from this bar chart would be used whenever the engine speed falls in the range

between 2750 and 3250 rpm (or, if in high-rpm mode, between 2500 and 3500 rpm).

In the top left is the range number and the speed range to which it corresponds. Opposite, in

large numerals, is the current engine rpm. The bar chart shows injection time, up to 16ms,

against the load parameter, either throttle position or manifold pressure. The axes are scaled

appropriately from the information in the Identification Page. Across the bottom of the

screen is written the number and height of the bar being adjusted, and other engine data.

Above the engine speed reading is the Range and Bar number that the ECU is currently

using to calculate injection time.

4.4.2 Adjusting Bar Height In The Map

The height of the Bars in the map can be readily adjusted by using the up and down arrows

keys, and the PgUp and PgDn keys (

section for a full list of key functions. The bar that is highlighted on the computer screen

indicates the bar that you are currently adjusting. To change the highlighted bar, use the left

and right arrow keys (r q).

). See the command summary at the end of this

Try pressing the Up arrow (p) once. Notice that the outlined bar gets taller. Now try

pressing the Down arrow (o) once. You are now changing the fuel delivery at 3000 rpm at

the load shown for the bar you have selected. Make sure you move the bar back to its

original height once you have tried adjusting it so as not to destroy the map you have

loaded.

37

Page 39

Now try using the key. The outlined bar should jump up 0.096 mS. As the bar gets taller,

the fuel delivery is increased and the engine is enriched at that speed and load. Now press

the key and the highlighted bar should move down 0.096 mS.

Note that the fuel delivery for the outlined bar is shown in the bottom corner of the display.

Note also that the injection time does not necessarily match the bar height as the injection

time is the actual injection time after various corrections have taken place. Also, the arrow

indicates the bar (i.e. number) currently being accessed by the engine. If the arrow was not

over the highlighted bar this would also cause the bar height and injection time to be

different as the bar height is the height of the bar being adjusted, not necessarily the value of

the bar currently being accessed by the engine. Try using the Control key and the Page Up

key together,

t,to move the bar up by 2mS. Move the Bar back down by using

t.

The changes you made took effect the instant you pressed the keys. You do not have to do

anything else to save these changes.

4.5 How To Quit

To return to the Fuel Map Menu from any of the map display pages press tI.Or through

the menus at the top of the display. Pressing tTkeys simultaneously at any page or

map will allow you to exit the Haltech program and will return you to MS-DOS. You should

always exit the program before switching off your computer.

4.6 Time Saving Functions

The following list of commands can be used whenever the graphs for most of the maps are

being displayed by the Haltech programming software.

Note: When two keys are displayed together, such as

must be pressed while the first key is held down. In this case, the

down while the

U key is pressed.

sU, this means that the second key

s key would be held

4.6.1 Current Location -

Pressing will take you to the range at which the engine is running, and highlight the bar

that is currently being used. This bar is easily identified by an arrow directly above it pointing

down. As the engine speed and load changes, the arrow moves with it. The Home key is

useful for finding the engine's operation point very quickly.

4.6.2 All Ranges - sU

Across the ranges, the curve of the fuel map does not change greatly. Usually the shape

remains much the same, and the height changes according to the volumetric efficiency of the

engine. In order for all the fuel ranges to initially be set up quickly, the Haltech F9 system

38

Page 40

allows you to programme all rpm ranges simultaneously with the same data. sU turns All

Ranges on, and the words All Ranges appears under the title.

When the All Ranges function is active, a bar adjusted on one graph is copied to the same bar

on all the ranges. If you use this option, you can set the shape of the map at any range, and all

other ranges will be identical at every bar you adjusted. This feature enables all graphs to be

given an initial shape that should run the engine, albeit rather roughly. Once you have used

the All Ranges option for a starting point, press sU once more to exit the All Ranges

option and tailor each map individually.

This option is only available on the Base Fuel and Ignition Maps.

4.6.3 Selecting Groups of Bars

Groups of adjacent bars may be highlighted and adjusted together.

Hold t while using the left or right arrow keys, r q, and you will highlight a group of

bars. This group will now act in unison when increasing or decreasing the height of the Bars.

To de-select the highlighted Bars use the s and arrow keys together.

4.6.4 Percentage Changes -sS

Using this function will prompt you to enter a percentage change to the selected bars. An

entry of "20" will increase each bar by 20%, while an entry of "-15" will decrease the bars by

15%. This change only affects the highlighted bar(s).

4.6.5 Linearise - sO

When a group of bars is selected (more than two), this function can be used to set the values

between the end points. Highlight the bars between two load points that are known to be

correct and press

between the two end points to form a straight line. This feature facilitates fast programming

and the smoothing of maps.

sO. The programming software will automatically adjust all the bars

4.6.6 Numeric Mode - sQ

This will take you into numerical mode, displaying the map as a spreadsheet. This mode is

available if wanted, but graphical mapping is recommended as it is much easier to use. To

exit from Numeric Mode and go back to using the maps press the } key.

39

Page 41

4.6.7 Bar Increments - sL

The Up and Down arrows,p o, normally change the bar height in the maps by a predetermined amount, usually the smallest possible increment. PgUp and PgDn change the bars

also by a pre-determined amount. These increments (the value of the keystroke) can be