Page 1

Table Of Contents

Introduction .........................................................................................1

Installation Overview ......................................................................................................... 1

Before You Begin............................................................................................................... 2

Tool/Supply Requirements................................................................................................. 3

How It Works..................................................................................................................... 4

The F10 and F10A.............................................................................................................. 5

Haltech F10 Specifications..................................................................................................... 6

SECTION 1 Getting Started ..........................................................10

CHAPTER 1 Haltech F10 Installation ........................................................................... 10

1.1 Overview .................................................................................................................... 10

1.2 Installation Summary ................................................................................................. 11

1.3 Expanded Installation Guide ...................................................................................... 11

1.3.1. Manifold Absolute Pressure (M AP) Sensor....................................................... 11

1.3.2. Coolant Temperature Sensor.............................................................................. 12

1.3.3. Inlet Air Temperature Sensor............................................................................. 14

1.3.4. The Throttle Position Sensor (TPS) ................................................................... 15

1.3.5. Mount Optional Exhaust Gas Oxygen Sensor.................................................... 15

1.3.6. Route Wiring Harness and Connect Sensors...................................................... 16

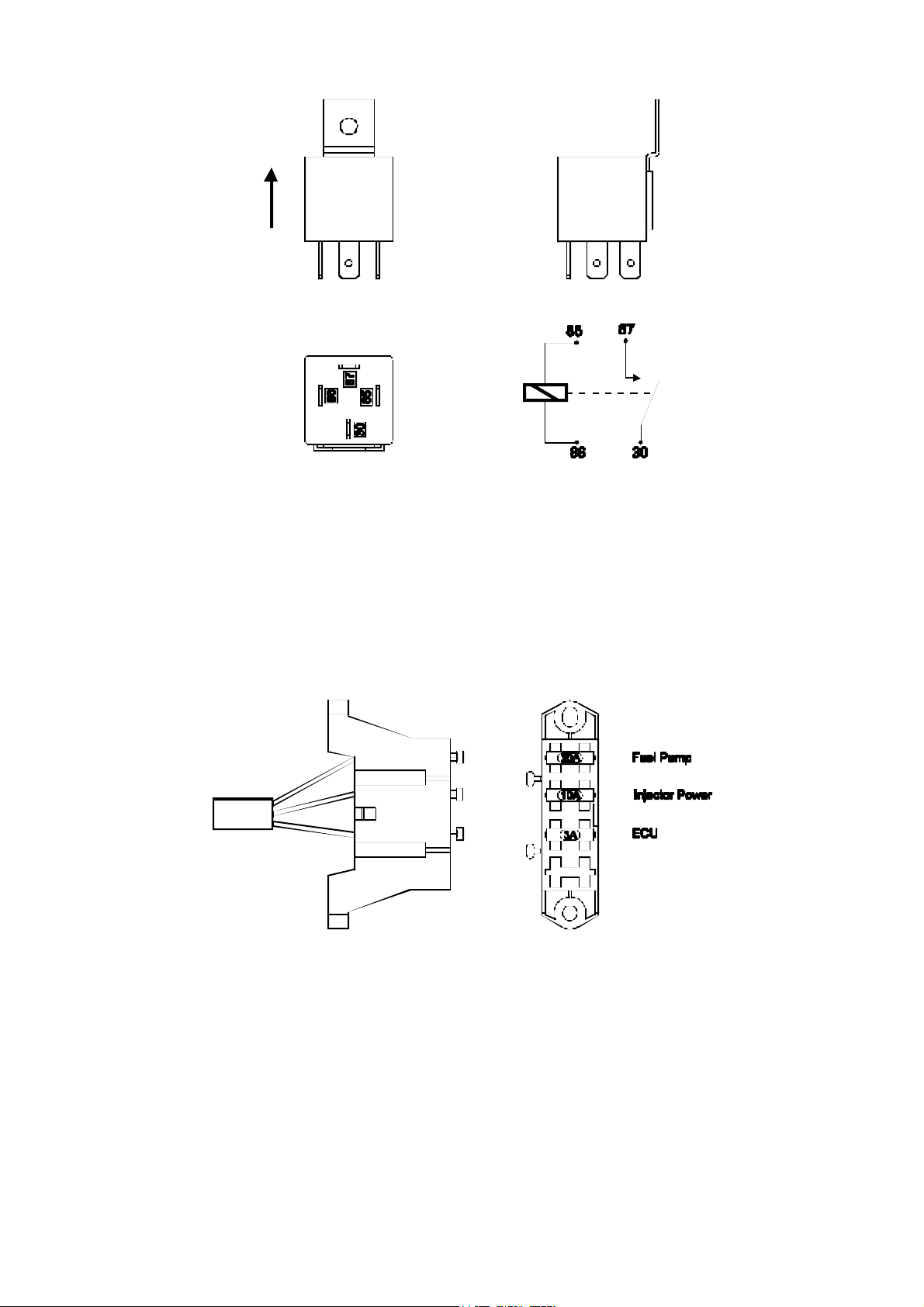

1.3.7. Power Relays...................................................................................................... 16

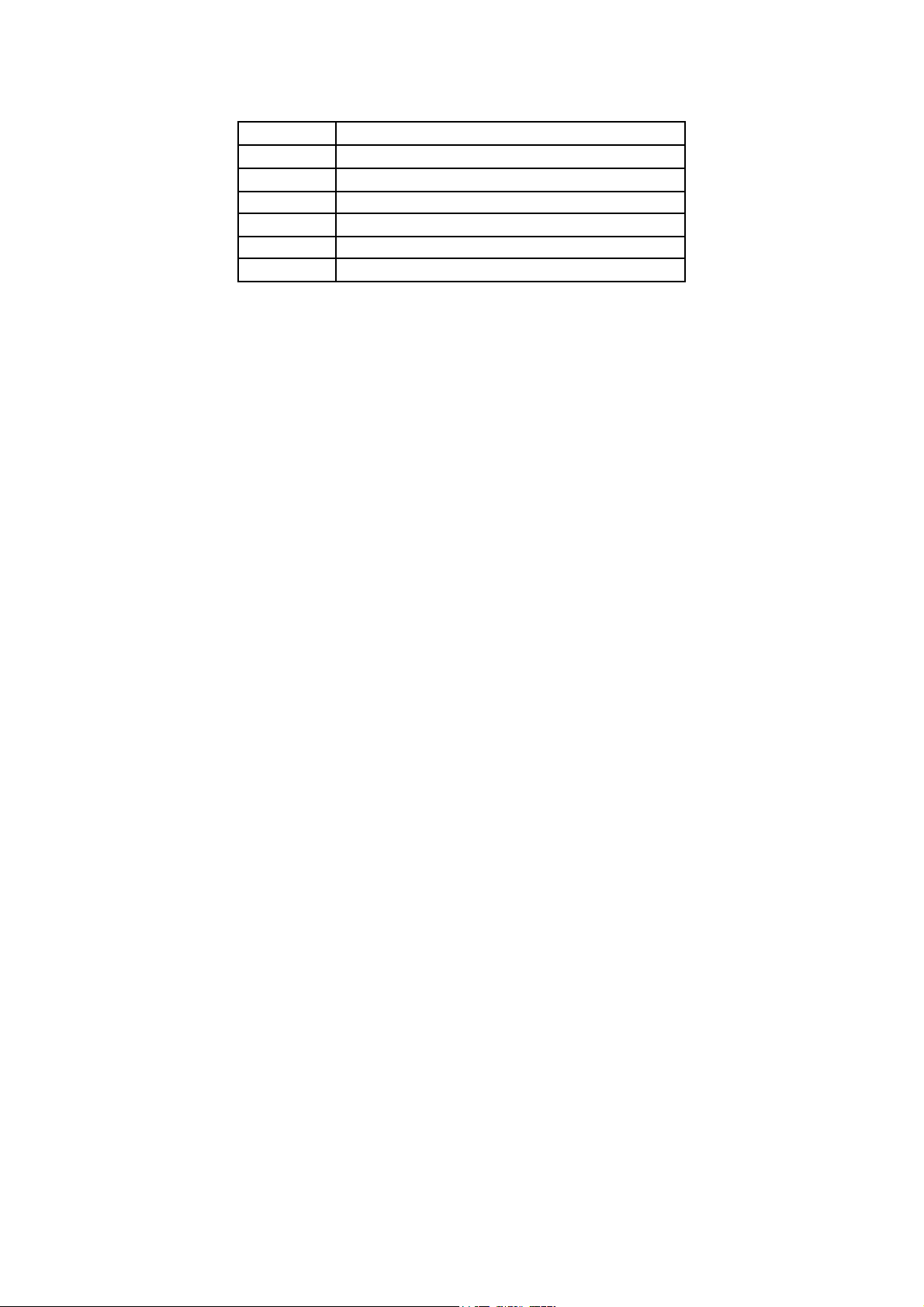

1.3.8. Fuse Block Assembly......................................................................................... 17

1.3.9. Electronic Control Unit (ECU).......................................................................... 18

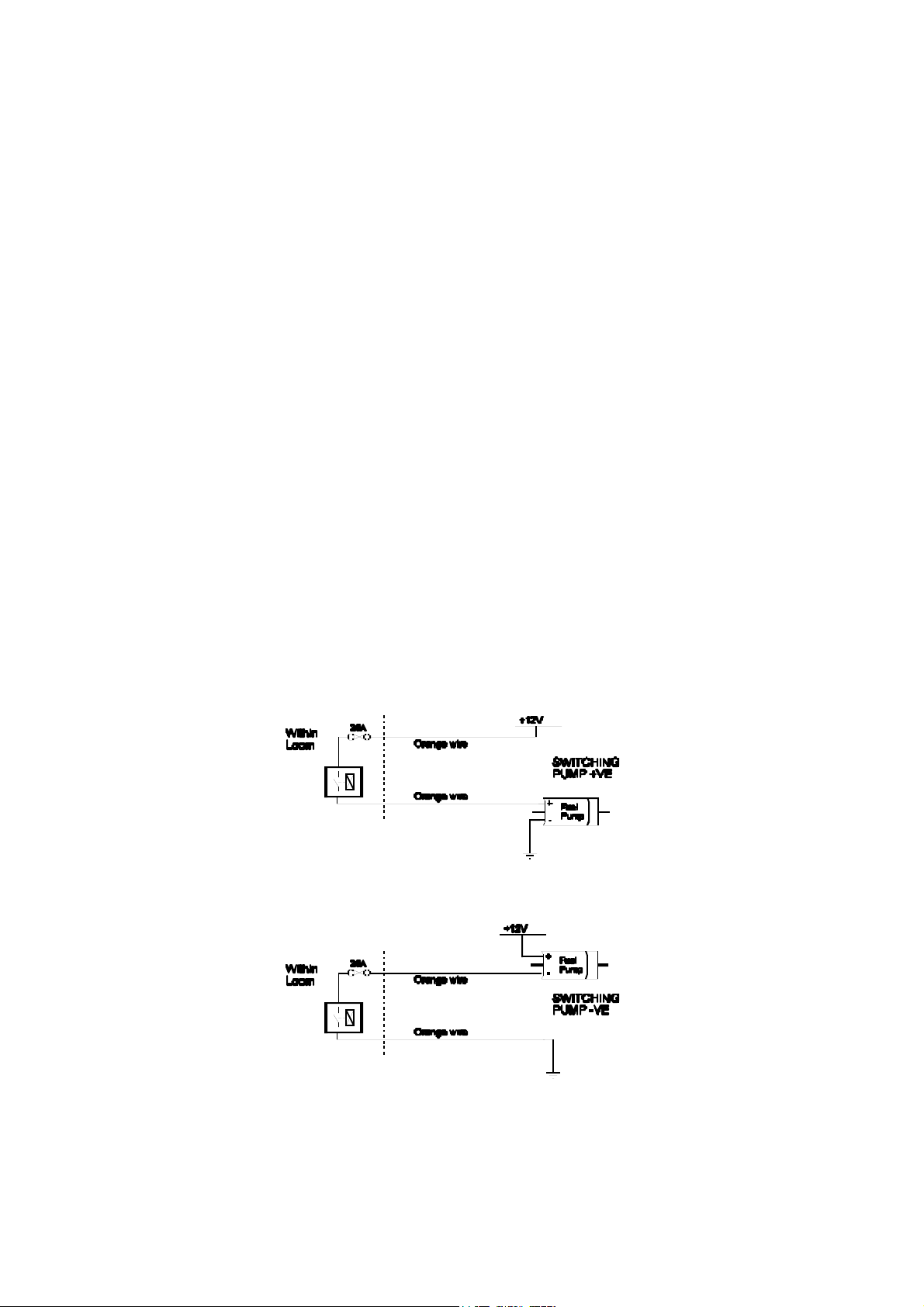

1.3.10. Flying Leads ..................................................................................................... 19

1.3.11. Install and connect Optional Idle Speed M otor................................................ 20

1.3.12. Install and connect any Optional Outputs ........................................................ 20

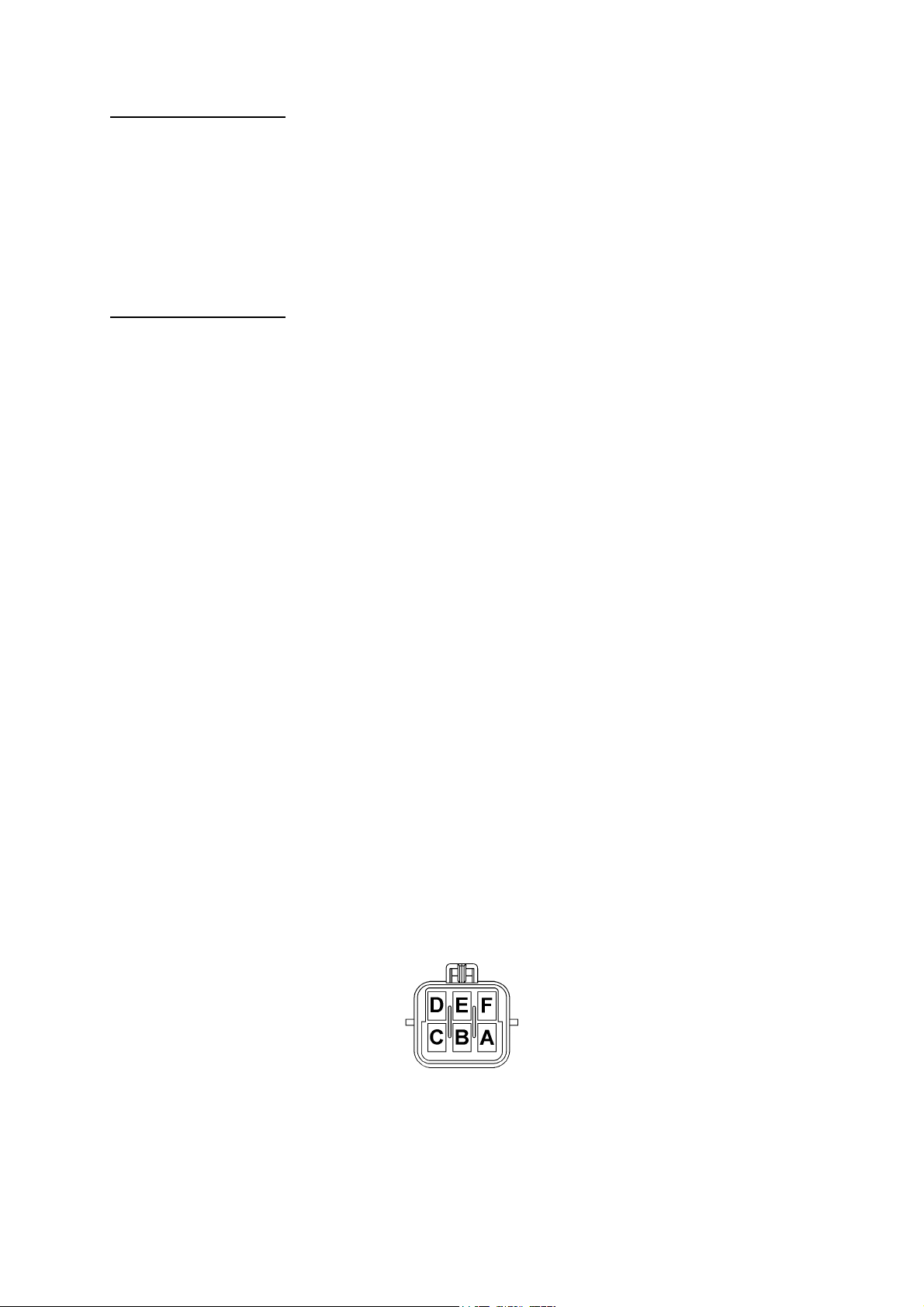

1.3.13 Connect the Trigger Sensor ............................................................................... 20

1.3.14 Connect the ECU............................................................................................... 21

CHAPTER 2 Getting ONLINE...................................................................................... 22

2.1 Connecting the Haltech F10 to a Computer............................................................... 22

2.2 Operating the Software............................................................................................... 22

2.2.1 Computer Requirements...................................................................................... 22

2.2.2 Installing the Software......................................................................................... 22

2.2.3 Running the Software from the Hard Disk.......................................................... 24

2.2.4 Running the Software from the Floppy Disk...................................................... 24

2.2.5 Azerty Keyboards................................................................................................ 24

2.3 The ONLINE and OFFLINE Modes.......................................................................... 25

2.4 Using the System ONLINE........................................................................................ 25

2.5 The M ain Menu.......................................................................................................... 25

2.6 How to Quit................................................................................................................ 26

2.7 Checking the Engine Data.......................................................................................... 26

CHAPTER 3 ECU Setup................................................................................................ 27

3.1 ECU Setup.................................................................................................................. 27

3.1.1 Navigating the Set-up pages................................................................................ 27

3.1.2 Main Set-up......................................................................................................... 27

3.1.2 Fuel Setup............................................................................................................ 28

3.1.3 Trigger Set-up...................................................................................................... 31

Chapter 4 Adjusting Haltech Maps................................................................................... 33

4.1 What are maps? .......................................................................................................... 33

i

Page 2

4.2 What is mapping the Engine?..................................................................................... 33

4.3 Using the Software..................................................................................................... 33

4.4 Accessing the fuel maps............................................................................................. 34

4.5 Navigating the M ap.................................................................................................... 35

4.5.1 Current Location.................................................................................................. 35

4.5.2 All Ranges ...........................................................................................................35

4.5.3 Selecting Group s of Bars..................................................................................... 35

4.5.4 Percentage Changes............................................................................................. 36

4.5.5 Linearise.............................................................................................................. 36

4.5.6 Numeric Mode..................................................................................................... 37

4.5.7 Bar Increments ....................................................................................................37

4.6 Duty Cycles................................................................................................................ 38

4.7 Command Summary for M aps ................................................................................... 40

Chapter 5 Starting the Engine ........................................................................................... 41

5.1 Calibrating the Throttle Position Sensor .................................................................... 41

5.2 Checking the trigger ................................................................................................... 41

5.3 Determining Engine Fuel Needs ................................................................................ 41

5.3.1 Tuning for Idle..................................................................................................... 42

5.3.2 Tuning with No Load .......................................................................................... 42

5.3.3 Loading the Engine ............................................................................................. 42

5.3.4 On the Dyno........................................................................................................ 43

5.3.5 On the Road......................................................................................................... 43

5.3.6 Fine Tuning the Engine ....................................................................................... 43

SECTION 2 Other Adjustable Features .......................................44

Chapter 6 Throttle Effects................................................................................................. 44

6.1 Throttle Response....................................................................................................... 44

6.1.1 Throttle-Pump software control .......................................................................... 44

6.2 Zero Throttle Map ...................................................................................................... 45

6.3 Full Throttle Map ....................................................................................................... 45

Chapter 7 Cold Starting and Running ............................................................................... 46

7.1 Cold Cranking ............................................................................................................ 46

7.2 Cold Engine Operation............................................................................................... 46

Chapter 8 Correction Factors ............................................................................................ 47

8.1 Air Temp Fuel Map.................................................................................................... 47

8.2 The Battery Voltage Map........................................................................................... 47

8.5 Barometric Correction................................................................................................ 48

8.6 Post Start Enrichment ................................................................................................. 52

SECTION 3 Software Features......................................................53

Chapter 9 File Storage and Retrieval ................................................................................ 53

9.1 Saving Maps and Set-up information......................................................................... 53

9.1.1 The Save Command ............................................................................................ 53

9.1.2 Giving Your Map a Filename.............................................................................. 53

9.2 Loading Maps and Set-up........................................................................................... 54

9.3 Upgrading from F9 ..................................................................................................... 54

9.4 File M anagement ........................................................................................................ 54

9.4.1 Erasing Unwanted Maps..................................................................................... 54

9.4.2 Changing Directories........................................................................................... 55

Chapter 10 Printing M aps ............................................................................................... 56

10.1 The Print Function.................................................................................................... 56

ii

Page 3

Chapter 11 Data-log........................................................................................................ 57

11.1 The Data-log Op tion................................................................................................. 57

11.1.1 Setting Up the Data-log Page............................................................................ 57

11.1.2 Creating a Data-log ........................................................................................... 57

11.1.3 Viewing the Data-log ........................................................................................ 58

11.1.4 Data-log File M anagement ................................................................................ 58

11.1.5 Printing Data-logs.............................................................................................. 59

Chapter 12 Software settings .......................................................................................... 60

12.1 The Program Set-up window.................................................................................... 60

12.1.1 The Display ....................................................................................................... 60

12.1.2 Com Port............................................................................................................ 60

12.2 Data Display Settings............................................................................................... 60

SECTION 4 F10 Inputs & Outputs ...............................................61

Chap ter 13 Software Access ........................................................................................... 61

13.1 The Input/Output Page ............................................................................................. 61

13.1.1 Trim Control and Spare A/D............................................................................. 61

13.1.2 Aux In and Aux Out .......................................................................................... 62

13.1.3 Extra Injector Driver Control ............................................................................ 62

13.2 The Output Options Page ......................................................................................... 64

13.3 The PWM Options Page........................................................................................... 64

13.4 Enabling Options...................................................................................................... 64

Chapter 14 Idle Speed Control........................................................................................ 65

14.1 Description............................................................................................................... 65

14.2 Using the Idle Speed Motor...................................................................................... 65

14.3 Adjusting the Idle Speed Control............................................................................. 66

Chapter 15 Closed Loop Control.................................................................................... 69

15.1 Description............................................................................................................... 69

15.2 Using Closed Loop Control...................................................................................... 69

15.3 Using Different Oxygen Sensors.............................................................................. 71

Chapter 16 PWM Outputs............................................................................................... 72

16.1 Description............................................................................................................... 72

16.2 Turbo Waste Gate Control (TWG)........................................................................... 72

16.2.1 Description........................................................................................................ 72

16.2.2 Using the Turbo Waste Gate Control................................................................ 73

16.2.3 Using the Boost Controller................................................................................ 74

16.3 Bypass Air Control (BAC) Valve ............................................................................ 74

16.3.1 Description........................................................................................................ 74

16.3.2 Using BAC Valves/Solenoids ........................................................................... 75

16.4 Dual Intake Valve Control (DIV)............................................................................. 75

16.5 Torque Converter Clutch Lockup (TCC)................................................................ 76

16.6 Electric Thermatic Fan Control (TF)....................................................................... 77

16.7 Electric Intercooler Fan Control (IF)....................................................................... 78

16.8 Shift Light Illumination (SL) .................................................................................. 79

16.9 Auxiliary Fuel Pump (AP)...................................................................................... 79

16.10 Anti-Stall Solenoid Control (AS) .......................................................................... 80

16.11 Staging Signal Function (SS) ................................................................................ 81

16.12 Turbo Timer (TT)................................................................................................... 81

SECTION 5 Appendices .................................................................82

Appendix A Troubleshooting............................................................................................ 82

iii

Page 4

A.1 Overview ................................................................................................................... 82

A.2 Control Program Problems ........................................................................................ 83

A.3 Starting problems....................................................................................................... 84

A.4 Idling Problems ......................................................................................................... 85

A.5 Light throttle and Cruising Problems ........................................................................ 85

A.6 Full Power Problems ................................................................................................. 85

A.7 Throttle Response Problems...................................................................................... 85

A.8 Cold Running Problems ............................................................................................ 86

A.9 Fuel Consumption ..................................................................................................... 86

Appendix B Fuel Injectors ................................................................................................ 87

B.1 Injector Impedance .................................................................................................... 87

B.2 The F10 Injector Drivers ...........................................................................................87

B.3 Injector Driver Box.................................................................................................... 88

Appendix C Fuel Systems & Staging ............................................................................... 89

C.1 Fuel Requirement....................................................................................................... 89

C.2 Injector Flow Capacity .............................................................................................. 89

C.3 Injector Staging.......................................................................................................... 90

C.4 Fuel Pump Capacity................................................................................................... 90

C.5 Fuel Rails and Pressure Regulators ........................................................................... 91

Appendix D Trigger Interface........................................................................................... 92

D.1 Hall Effect and Optical Trigger Pick-ups.............................................................. 92

Typical set-ups - S3.......................................................................................................... 94

Index..................................................................................................................................... 98

Appendix E Wiring Diagrams .......................................................................................... 99

iv

Page 5

Under copyright law, neither this manual nor its

accompa nying so ftware may be cop ied, translated or

reduced to electronic form, except as specified

herein, without prior written consent of Invent

Engineering Pty Ltd trading as Haltech.

Copyright 1999 Invent Engineering Pty Ltd

A.C.N. 000 613 832

Also trading as HALTECH

10 Bay Road

Taren Point, NSW 2229

Australia

Ph: (+61) (02) 9525 2400

Fax: (+61) (02) 9525 2991

Sales-au@haltech.com

Haltech USA

Suite 309, 2156W

Northwest Highway

Dallas Texas

USA

Ph: (+1) (972) 831 9800

Fax: (+1) (972) 831 9802

Sales-us@haltech.com

www.haltech.com

MS_DOS is a registered trademark of Microsoft

Corporation. IBM is a registered trademark of

International Business Machines Corporation

Print Version: 3.0

Date: 22 September 2003

This manual should accompany:

IBM compatible PC software v7.08

Firmware Series 10

Firmware Version 8

v

Page 6

Introduction

Congratulations on your decision to install a Haltech Engine Management System on your

vehicle. Haltech EFI systems have been successfully installed on thousands of vehicles such

as power offshore boats, twin-turbo Ferraris, py lon racing aircraft, jet skis and snowmobiles.

Many motor sport enthusiasts have discovered that the Haltech computer is easy to use and

gets the job done correctly. The Haltech ECU enables y ou to precisely control fuel-air

mixtures that lead to consistent horsepower and torque from an engine. Precise mixture

cont rol also leads to excellent drivability and fuel e conomy, something that is often lacking in

high-performance carburettor engines.

Haltech users have discovered that the flexibility of the Haltech Electronic Control Unit

(ECU) and PC based programming software leads to easy installation on everything from

traditional pushrod V8s to high performance turbocharged racing motorcycles. We are proud

of t he fact that some of the most resp ect ed professional racers and sup er-car builders in the

world use Haltech equip ment for t he same reasons that Halt ech is pop ular wit h performance

enthusiasts: it is flexible and friendly ; is installed e asily; and you can tune your Halt ech

simply, without having to make the project a major research effort.

Installation Overview

The Haltech F10 sy stem uses a sp ecial-purp ose p rogrammable microcomput er desi gned for

engine management. The F10 system includes the ECU, engine sensors, a special wiring

harness to connect t hem, programmin g software and cable for y ou to tune the syst em. In the

course of the installation, you will mount four electronic engine sensors, two for temperature,

one for throttle position, and one to sense vacuum/pressure. You will run t he wiring harness

through the vehicle, connecting the 12V, ground and signal wires, and plug the harness

connectors into the engine sensors and fuel injectors. An ignition outp ut module will b e

mounted in the engine bay and connected to the harness. Finally, y ou will mount and connect

the ECU itself. The engine must already be configured with intake manifold and suitable

injectors, a fuel rail with pressure regulator, and a high-pressure pump. If your vehicle lacks

one or more of these components, your Haltech dealer can help you obtain them.

With the Haltech system installed, y ou tune it by connecting the ECU to an IBM compatible

PC via the supplied communications cable. The Haltech Pro grammin g software allows y ou to

configure and modify the fuelling data stored in t he ECU: it's as simple as adjusting the

heights of the bar graphs displayed on your PC screen. Collectively, the bar graphs form the

"M aps" that instruct the ECU how to inject fuel under different conditions. The programming

software has been designed to be functional, "friendly" and intuitively easy to use.

When t he time comes to st art your engine, the base fuel map already lo aded in the sy stem

could get you going immediately, if not, a little alteration with some assistance from this

manual should get your vehicle running. Once the engine is running it is time to work on

fine-tuning your maps to suit your engine exactly, an air-fuel ratio meter and a dyno make

tuning easiest, but many people use the traditional method of "seat of the pants" feel and

tuning by ear, possibly checking sp ark plug colour as an indication of fuel mixture.

Whichever method you use, you will find t hat the abilit y to instant ly change mixtures by the

stroke of a key, or the twist of a knob, will make tuning your Halt ech system far easier than

tuning a carburettor or mechanical injection system, and with much better results.

1

Page 7

Before You Begin...

WARN IN G:

AVOID O P EN S PARKS , FLAMES , OR OPERATION O F

ELECTRICAL DEVICES NEAR FLAMMABLE SUBSTANCES.

ALWAYS DISCONNECT THE BATTERY CABLES WHEN DOING

ELECTRICAL WORK ON YOUR VEHICLE.

DO NOT CHARGE THE BATTERY WITH A 24VOLT TRUCK

CHARGER OR REVERSE THE POLARITY OF THE BATTERY OR

ANY CHARGIN G UNIT

DO NOT CHANGE THE BATTERY WITH THE ENGINE RUNNING

AS THIS CO ULD EXPO S E THE ECU TO AN UN REGULAT ED

PO WER S UPP LY TH AT CO ULD DES TRO Y THE ECU AN D O THER

ELECTRICAL EQUIPMENT.

ALL FUEL SYSTEM COMPONENTS AND WIRING SHOULD BE

MO UN TED AWA Y F ROM H EAT S OURCES , S HIELDED IF

NECES S ARY, AND WELL VENT ED.

MAKE SURE THERE ARE NO LEAKS IN THE FUEL SYSTEM AND

THAT ALL CONNECTIONS ARE S ECURE.

DISCONNECT THE HALTECH ECU FROM THE ELECTRICAL

S YS TEM WH EN EVER D O ING AN Y ARC W E LD IN G O N THE

VEHICLE BY UNPLUGGING THE WIRING HARNESS CONNECTOR

FRO M TH E ECU.

1) IT IS BEST TO READ THIS ENTIRE MANUAL BEFORE S TARTING.

At the very least, you should read Section One of the manual, and any of the Appendices that

are relevant to your installation. The greater your knowledge of the op eration of the Haltech

syst em, the easier y ou will find it t o understand what you are doing, and why. Throughout the

manual are Warnin gs and Not es that will help y our installation run smoothly and indic at e t he

dangers that can exist for you the installer and the Haltech ECU.

2) Read any additional material accompanying this manual that updates the document since it

was written.

3) You may need special parts or additional tools or test equipment in order to complete

installation. Make sure you have these items on hand before you begin to avoid frustration.

Contact y our Haltech dealer if you have difficulty.

4) Don't do the minimum work p ossible. Carelessness in t he early stages of installation can

cause you major headaches later on, be it in a few days' or a few months' time. Carelessness

will cost y ou money and frustration in finding and fi xing unnecessary problems. You have the

opportunity to make sure your Haltech system's operation is extremely dependable and easy

to use by doing it right the first time.

There is another reason to exercise care during this installation. You will be dealin g with

2

Page 8

exp losive fuel under pressure, electricity and considerable heat. Inside the combustion

chamber, this is a happy combination. In the garage, they are not. The same kind of danger

exists when working underneath a jacked-up car. Please be careful.

5) Electromagn etic interference (EMI) from unsuppressed spark plugs and leads can cause the

ECU to fail. Please do not use them.

6) In hot climates, or with turbocharged engines, you may need to employ heat shielding to

prevent heat soak and damage to electrica l and fuel parts. Use t he coolest surfaces of the

chassis as a heat sink for components and use thermally conductive brackets where

app rop riate.

7) We recommend having your system tuned by professionals. An exhaust gas analyser and

fuel pressure meter make tuning easier and help avoid potentially disastrous lean conditions

that could destroy your engine. Should you wish to tune this unit yourself, make sure you

have some reliable means of determining whether your engine is running lean, Haltech offer

the Haltuner for this purpose. The Haltuner is an inexpensive air-fuel ratio indicator that

gives a full-scale deflection from rich to lean over a disp lay of 30 bar segments. It is

compatible with all O xygen Sensors that output a 0-1V and can be configured upon request

for other sensor ranges. If used in conjunction with a Haltech O xygen Sensor, the Haltuner

will p rovide air-fuel indication for a range of 11.5:1 to 17:1.

Note: In this manual, reference will be made to M AP

Pressure - as in MAP sensor) and the fuel maps stored in the ECU. Both are

common industry terms, with entirely different meanings.

(Manifold Absolute

Tool/Supply Requirements

Installation of this system can be easily carried out by p rofessional mechanics and most

exp erienced home mechanics if t he followin g tools and comp onents are availabl e:

Voltmeter or Test Light

A selection of screwdrivers and spanners

Soldering Iron and solder (we recommend soldering all connections)

Wire Cutters and Pliers

Crimping Tool and assorted terminals

Drill wit h assorted drill bits

3/8" NPT Tap

14mm x 1.5 Tap

Electrical Tape or Heat Shrink tubing

Teflon pipe sealing tape

Ny lon cable ties

Jeweller’s file (may be needed for mounting Throttle Position Sensor)

Mounting hardware for ECU and relays (mounts/bolts/screws)

IBM-PC compatible computer (preferably laptop) with at least 640kb, one disk drive and

an RS232 serial port.

3

Page 9

How It Works

While the technology involved with electronic fuel injection is complex, the underlying

principles of its operation are really quite straightforward. The object of any fuel delivery

system in a gasoline engine is to determine the amount of air being drawn by the engine, and

supply the appropriate quantity of fuel to "burn" all the oxy gen in that mass of air.

A carburettor uses primarily only one parameter to determine fuel metering: air speed. High er

air speeds through the carburettor result in larger pressure drop s across the venturis, and thus

more fuel is sucked through the jets.

Electronic fuel injection revolves around the use of solenoid-actuated injectors. These devices

employ a coil att ached to a valve. When the coil is energised, the valve op ens and fuel is

allowed to flow. As long as the p ressure between the fuel and t he air in front of the injector

noz z le is held constant, the rate of fuel flow will remain the same. By accurately cont rollin g

the length of time the injector remains op en, precise quantities of fuel can be metered to the

engine.

Since we have no convenient means of directly measuring the amount of air entering the

engine to determine the amount of fuel to deliver, we use a number of engine parameters to

determine an injection opening time. We build a table that breaks the engine's operation into a

series of rp m ranges. At each ran ge, we consider t he load on the en gin e, using either the

position of the throttle or the manifold pressure as a reference to the load on the engine.

Collectively, the ranges in this table (also called a look-up table), form a map of the

volumetric efficiency for the engine. Our standing assumption, therefore, is that for any

combination of engine sp eed and load, we have a direct reference to the amount of air that is

being drawn into the engine by means of this map.

The Haltech F10 uses a digital microcomputer to measure engine speed and load, and uses

them to access the base fu el map. The base fuel map is a look-up table of injector opening

times stored in non-volatile memory i.e. when power is switched off, the contents of the

memory are retained. By using the programming software, the contents of this memory can be

chan ged so that y ou can match inje ct or op ening times to t he injectors y ou are using, and to

suit the requirements of your engine.

Having determined the base injection time, the microcomputer then performs a number of

adjustments to this value. Corrections for air temperature and barometric pressure are app lied,

since these variab les affect the density of air. Extra injection time is also add ed, when

necessary, for transient throttle movement and the temperature of the engine. At the end of all

these calculations, the final injection t ime is det ermined: the t ime for which the injectors are

actually held open.

Inject ion p ulses usually occur one or more t imes per en gine cy cle. T he ECU uses a trigger

signal lo cked to en gine sp eed in order to determin e when to inject. When it receives an

app rop riate trigger, t he ECU ap p lies a magnet isin g current to the injector coils for p recisely as

long as the final computed injection time, providing an extremely accur at e delivery of fuel

that will exactly suit the engine's ne eds.

4

Page 10

The F10 and F10A

The F10 offers a basic fuel injection sy st em with limit ed functionality for simp le applications,

the F10A offers optional outputs such as: Idle Speed Control and O2 Closed Loop fuel control

which are dedicated outputs and four programmable outputs. The optional outputs available

wit h the F10A allow the feat ures availab le on mod ern cars such as idle control and t hermofans be run by the F10A ECU. The F10 has no optional outputs.

(Refer Chapter 16 PWM Outputs, 72).

5

Page 11

HALTECH F10 SPECIFICATIONS

Engine Suitability

• Up to 16,000 rpm

• 1, 2, 3, 4, 5, 6, 8, 1 0, 12 cy l i nder s (1-2 rot o rs)

• 2 or 4 stroke

• Normally aspirated or supercharged up to 200 kPa (30psi) - Higher boost pressure MAP sensors

available by s peci al arrangem ent

• Load sensing by throttle position or manifold pressure

• Multipoint, batch-fire or staged

Power Re qui reme nts

•••• Power S ou rce

8.6 to 16 Volts DC

•••• Consumption

Haltech ECU: 270 mA at 12 Volts

Injector Load:Dependent on injector type

approx. proportional to injector duty cycle

(typically 0.6 Amps per injector)

Physical Specifications

• ECU Dimensions

Length: 140 mm (5 17/32")

Width: 145 mm (5 5/8")

Depth: 41 mm (1 5/8")

• Weight

ECU: 615g (1.35 lb)

Loom: 1.92kg (4.2 lb)

Sensors: 500g(1.1 lb)

Shipping Weight: 4.5kg (9.9 lb)

(Including manual/packaging)

Input S ensors

• Man ifold Absolute Pressure (MAP) Sen sor (supplied at ex tra cost)

1 Bar -100kPa to 0kPa (Naturally Aspirated)

2 Bar -100kPa to 100kPa (up to 1 Bar or 15 psi boost)

3 Bar -100kPa to 200kPa (up to 2 Bar or 30 psi boost)

Higher boost pressure MAP sensors available by special arrangement

• Temperature Sensors (Air and Coolant)

NTC temperature dependent resistor type.

O perati ng Range

Continuous -40°C to 100°C (-40°F to 212°F)

Intermittent up to 125°C (257°F)

6

Page 12

• Throttle Position S ensor

10 kΩ rotary potentiometer driven from throttle shaft

• Engine Speed Pickup

Compatible with most “ standard trigger” systems:

- 5 or 12 volt square wave;

- Pull-to-ground (open collector)

- Coil Negative triggering

ECU O u tpu t s

• Injector Dri ver

F10 and F10A Only

8 x 4/1Amp peak-and-hold current limiting drivers:

- Up to 4 low-impedance injectors*

- Up t o 8 high-impedance injectors*

F10-8 and F10A-8 Only

8 x 4/1Amp peak-and-hold current limiting drivers:

- Up to 8 low-impedance injectors*

- Up t o 16 high-i mpedance injectors*

(Expandable using optional Driver Box; Refer B. 3 Injector Driver Box, 88)

F10A and F10A-8 Only

• Pulse Width Modulated (PWM) Output

4 x Dedicated PWM outputs

- Suitable for controlling turbo wastegate, solenoids, valves, shift lights, etc.

• Fuel Pump Control

20A fused relay, features automatic priming and switch-off.

F10A and F10A-8 Only

• S tep per Motor driver for idle control

Capable of driving bipolar stepper motors used for idle control.

* Additional hardware may be required

System Programming Requirements

• Computer

IBM-PC or compatible, preferably laptop or notebooks

CGA, EGA or VGA, colour or monochrome display

640+ kb RAM

• Disk Drive

3.5" Floppy Disk Drive

(5.25" disk available on request)

• S erial Port

Standard RS232C port - 9 pin D connector

(25 pin cable available on request)

COM1 or COM2 (selectable)

7

Page 13

Adjustable Features

• B ase Fuel Map

22 Fuel ranges, every 500 RPM to 10,500, or

17 Fuel ranges, every 1000 rpm to 16,000

32 Load points per range, up to 16ms with 0.016ms resolution

• Correction Map s

Cold Start Prime - 32 points

Coolant T emperature Enrichment - 32 points

Air Temperature Adjustment - 32 points

Battery Voltage Correction - 32 points

Closed Throttle (selectable) - 16 points

Full Throttle (selectable) - 32 points

• Programmable Rev-Limit – fu el cut

•••• Fuel Cu t on Decelera tion

• Accel era tor Pu mp

Increase and sustain paramet ers

Coolant enrichment factor

T hree speed ranges

F10A and F10A-8 Only

• Idle Sp eed Con trol

T arget Idle Speed

Cold Idle-up Rpm

Post-start Rpm setting

F10A and F10A-8 Only

• Closed Loop Control

With both cruise and idle settings

F10A and F10A-8 Only

• Programmable Output Options

Miscel l ane ous

• Data logging

Engine data information logged at a nominal rate of 10 times per second Stored to memory or disk

Limited only by available memory (approx. 11k/minute).

• Map Storage and Retrieval

Maps may be stored to disk and re-used.

• Real Time Programming

Instant, hesitation free adjustment while engine is running.

8

Page 14

• Rugged Aluminium Casing

Black anodised with integral cooling fins and mounting brackets.

• US or Metric Units.

•••• Optional Boost Control Solenoid.

•••• Optional Dual Hall Effect Sensor Kit.

•••• Optional Extra Injector Driver Kit.

•••• Optional Four Wire Heated Oxygen Sensor.

•••• Optional Fully Terminated and Sheathed Wiring Harness

In Lieu of Flying Wire Lead Harn ess.

• Optional Haltuner

Inexpensive dash mounted Air-Fuel Ratio Meter.

F10A and F10A-8 Only

• Optional Idle Air Control Motor Housing.

F10A and F10A-8 Only

•••• Optional Id le Air Control Motor.

•••• Optional Mix tu re / Boost Trim Modul e

Provides ±12½% or ±50% adjustment for fast tuning

Provides ±100% adjustment.

9

Page 15

SECTION 1 Getting Started

CHAPTER 1 HALTECH F10 INSTALLATION

1.1 Overvie w

The Haltech F10 sy stem comp rises the following components

Haltech Electronic Control Unit (ECU)

Coolant Temperature Sensor

Inlet Air Temperature Sensor

Throttle Position Sensor (TPS)

Manifold Absolute Pressure (M AP) Sensor

(1,2 or 3 Bar Sensor - purchased separately to main kit at extra cost)

Main Wiring Harness

Haltech F10 system Instruction M anual

Programming Cab le

Programming Disk

Relays

Optional Items

Fuel Mixture / Boost Trim Control

Driver Box

F10A and F10A-8 Only

Exh aust Gas Oxygen Sensor

Idle Sp eed Control M otor

Other components not supplied as p art of the F10 system include:

Inlet M anifold

Throttle body

Throttle linkages

Velocity stacks

Injector M ounts

Fuel injectors

High-pressure fuel pumps

Inlet Air Cleaners

Performance ignit ion sy stems

Trigger System

Haltuner Air/Fuel Ratio M eter

10

Page 16

1.2 Installation Summary

- M ount M anifold Absolute Pressure Sensors

- M ount Coolant Temperature Sensors

- M ount Inlet Air Temperature Sensors

- M ount Throttle Position Sensors

- M ount optional Exhaust Gas Oxygen Sensor (if used)

- Route M ain Wiring Harness and connect sensors

- M ount and connect Power Relays

- M ount Fuse Block

- M ount ECU inside passenger co mp art ment

- Locate and connect flying wires:

RED + 12 volts battery

GREY Ignition on 12 volts

BLACK Chassis ground

ORANGE (2 wires) Fuel Pump Circuit

- Connect Trigger signal

- Connect ECU and test.

F10A and F10A-8 Only

- Install and connect the optional Idle Speed Motor

- Install and connect any Optional Outputs

1.3 Expanded Installation Guide

1.3.1. Manifold Absolute Pressure (MAP) Sensor

The MAP sensor is used to convert the manifold pressure into an electrical signal for the F10

ECU to use. The sensor works in absolute p ressures, thus its calibration is not affected by

changes in barometric pressure. The vacuum and, in the case of forced air induction engines,

the pressure under boost, is proportional to the load under which the engine is op erating and

the ECU uses the electrical signa l as a lo ad refer ence.

There are three types of M AP sensors that can be used with F10 sy stem. Which sensor is

required depends on the engine set-up.

1 Bar Sensor (Part No. 039 4070)

(-100kPa to 0 kPa) Normally Aspirated Engines

11

Page 17

2 Bar Sensor (Part No. 886 3189)

(-100kPa to 100kPa) Turbo or Supercharged

Engines up to 100kPa boost

(15 p si , 1 atmosphere)

3 Bar Sensor (Part No. 749 3169)

(-100kPa to 200kPa) Turbo or Supercharged

Engines up to 200kPa boost

(30 Psi, 2 atmospheres)

Note: M ake sure you have the correct M AP sensor for your engine. The first

three digits of the p art number are stamped on the sensor housing.

If the engine is running in Throttle Position mode, a 1 Bar M AP sensor (left

open to atmosphere) is used to measure the barometric pressure.

If the engine is running in Manifold Pressure M ode, at least one M AP sensor

must be used. The first MAP sensor must be connected to the M AP Input p lug

on the wiring loom and provides an indication of the engine load.

The second MAP sensor (1 Bar MAP sensor left open to atmosphere) is used

to measure barometric pressure can be fitted. It connects to the Spare Input

plug near the M ain Connector.

Mounting

The MAP sensor is usually mounted high on the engine bay firewall or inner guard using two

screws and with the hose nipp le facing outwards. Connect the sensor to the inlet manifold via

a short length of vacuum hose and fasten with either hose clamps or nylon cable ties. Connect

the sensor to the main wiring harness using the appropriate plug. (For 1 Bar sensors the plug

is green, for 2 and 3 Bar sensors the plug is orange). Avoid mounting the sensor below the

level of the fuel injectors, because fuel may collect in the vacuum hose and run down into the

sensor. The sensor assembly is weatherproof but it is good practice to mount the sensor in a

protected p osit ion away from moisture and heat .

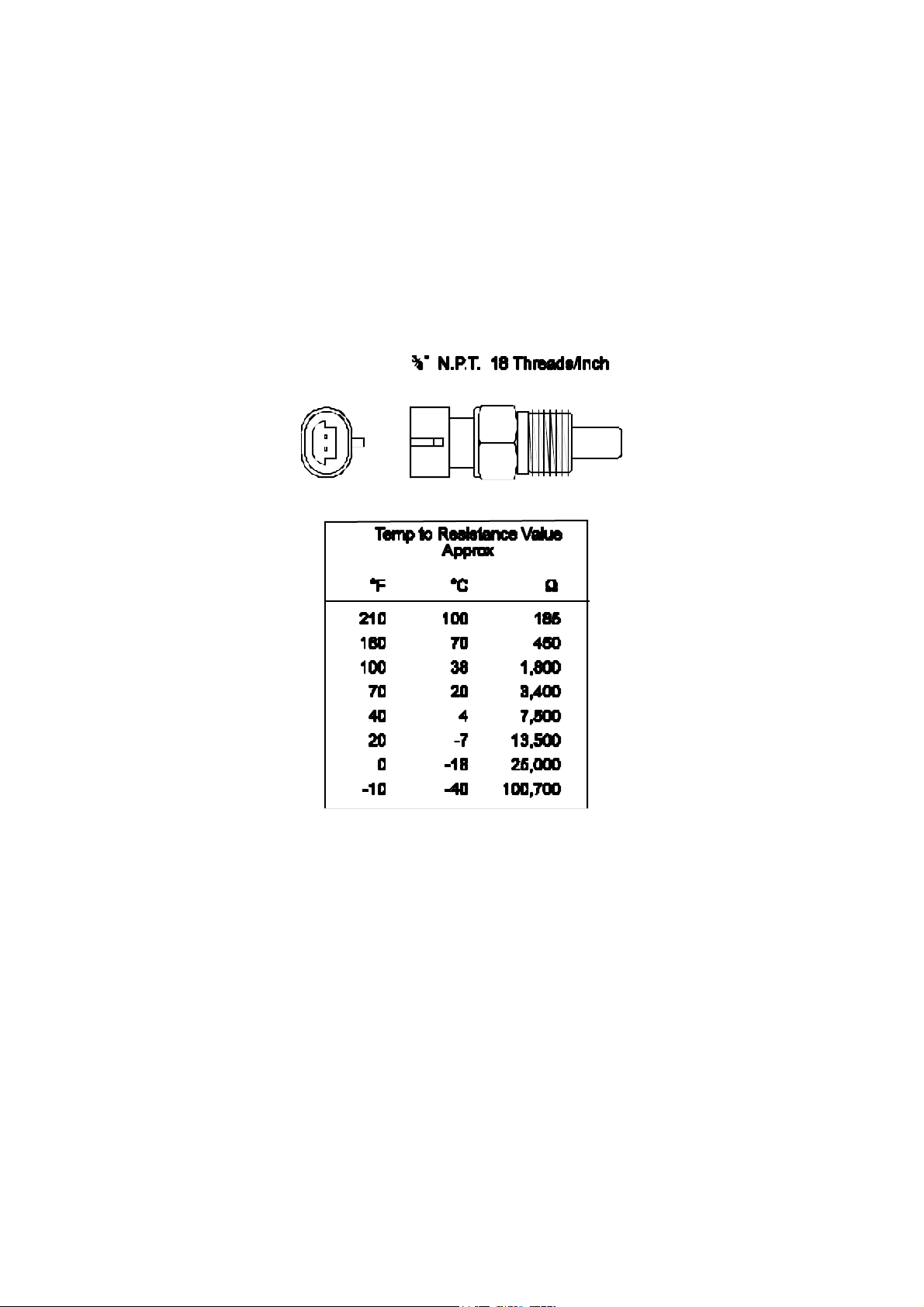

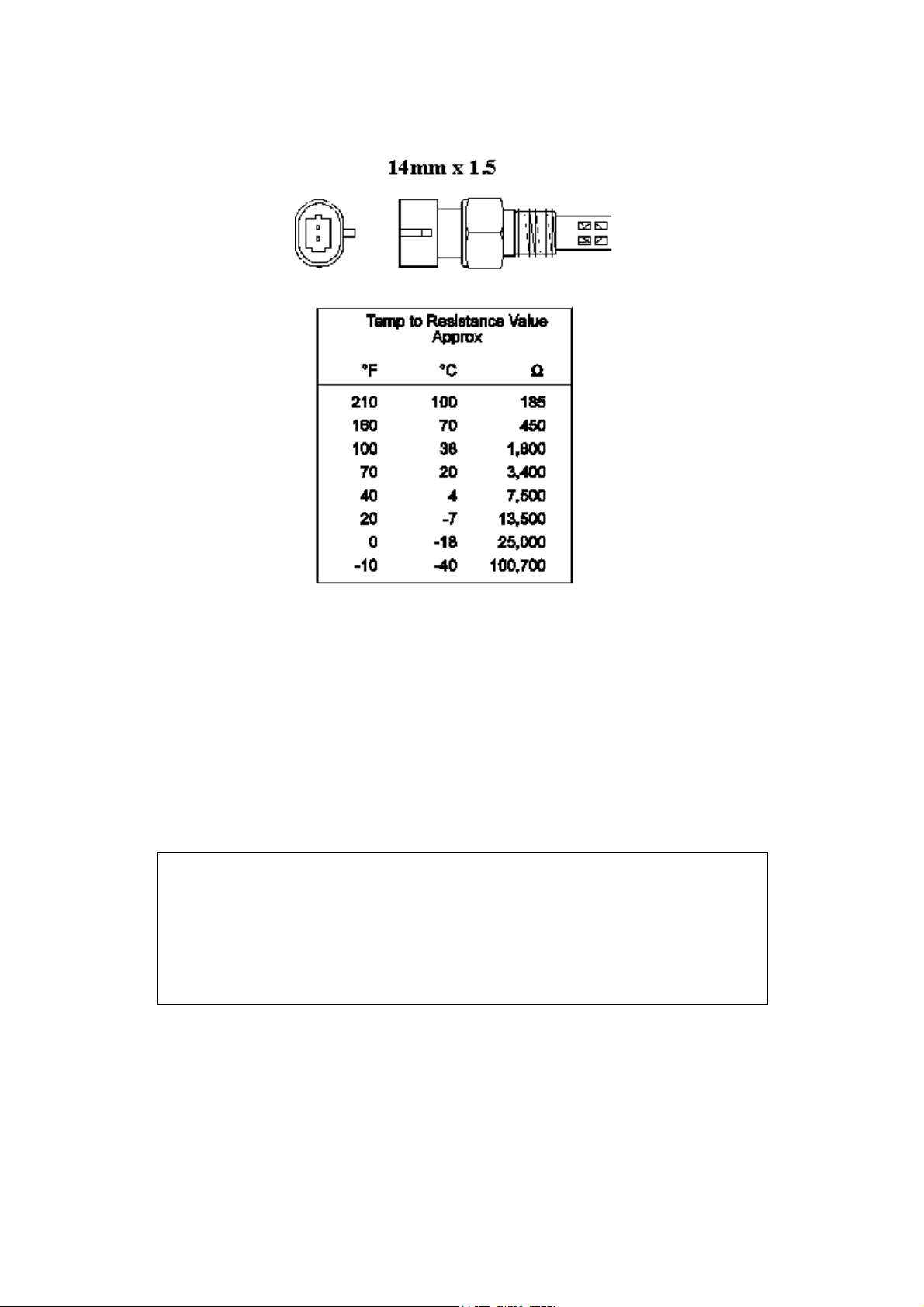

1.3.2. Coolant Temperature Sensor

The coolant temp erature is used to determine t he fuel mixture corrections requir ed when not

at op erating temp erature.

The coolant temp erature sensor has a solid brass t emp erat ure sensing tip . Refer to the diagram

below for technical details of the sensor. The coolant sensor supplied is an industry standard

component and some engines may already have provision for this type of sensor.

The coolant temperature sensor is designed to screw into a threaded hole and protrude into the

engine coolant stream. For air-cooled engines, the sensor can be embedded directly into the

engine block or used to sense oil temperature.

Locate a suitable p osition on the en gine which will allow the hole and t hread t o be machined,

12

Page 18

and which gives access to the coolant stream. The sensor should be mounted after the engine

and before the thermostat in the coolant circuit. Since most engines have existing temperature

sensor holes, it is often p ossible to mount the Haltech sensor in one of these holes. A thread

adapter is sometimes necessary. In some engines only one temperature sensor hole exists and

is used for the dashboard gauge sender. It is usually possible to install a tee-piece to allow

both the dashboard sender and the Haltech sender to share access to t he same t hreaded hole.

If it is necessary t o drain t he coolant from the vehic le t o fit the t emp erature sensor t hen the

factory manual for the engine should be consulted for the correct p rocedure to restore the

coolant and purge the cooling sy stem of air.

13

Page 19

1.3.3. Inlet Air Temperature Sensor

The air t emp erat ure sensor is used to compensate for changes in air density due to air

temperat ure. Cold air is denser than warm air and t herefore requires a great er volume of fuel

to maint ain the same air/fuel ratio. This effect is most not iceable in forced induction engines.

The Haltech F10 will automat ical ly comp ensat e using the signal received from the a ir

temperature sensor.

The sensor should be mounted to provide the best representation of the actual temperature of

the air enterin g the combust ion cha mber, i.e. aft er any turbo or supercharger, and intercooler,

and as close to the head as p ossible. T he sensor needs to be in the moving air stream to give

fast response times and reduce heat-soak effects.

Note: The Haltech air t emp erature sensor will read temperat ures up to 120° C

and temperatures above this will be int erpret ed as a fault condition. The air

temperat ure aft er some turbos and sup erchargers can exceed t his. If this occurs

with your engine you should consider fitting an intercooler to reduce air

temperat ure and increase char ge density . If t his is not possible then the air

temperature sensor should be p laced upstream of t he turbo or supercharger t o

monit or ambient air temp erature.

Once a suitable position has been located for the air temperature sensor a hole should be

drilled and tapped t o accept the sensor. Remove the manifold or inlet tract from the en gine

before machining the sensor mount. Do not allow any metal particles to enter the inlet

manifold of the engine as these will be drawn int o the engine and damage it. Wash all

components before reassembly.

14

Page 20

1.3.4. The Throttle Position Sensor (TPS)

The throttle position sensor is mounted to the throttle butterfly shaft to measure its rotation. A

TPS is common on many late model engines and the Haltech sensor should attach with little

or no modification. The throttle shaft must protrude from the side of the throttle body. This

may require the machining of the throttle body or the manufacture of a new throttle shaft. The

inner mechanism of the sensor rotates with the shaft. If the shaft is round then file a flat

surface on the shaft so that it will p ass through the sensor assembly . The TPS should be

mounted against the side of the throttle body, using two screws, such that the throttle shaft

and t he sensor mechanism can rotate freely. The absolute range of sensor movement is not

important as the sensor can be calibr at ed using the programmin g software.

Your engine may have a Throttle position sensor already fitted and it is often possible to make

use of this TPS. The Haltech supplied TPS has a resistance value ranging from 0 to 10kΩ.

The resistance value of t he installed TPS does not have to be the same since the ECU uses a

throttle calibration function to determine the position of the throttle based on the signal

receiv ed from the TPS. Be sure to wire t he TPS so that the ECU sees a closed valu e when the

throttle is closed, the Engine data page field “throttle position” should read “closed” or “0%”

when the t hrott le is closed.

Note: M ake sure that the axis of rotation of the shaft is exactly aligned with the

axis of rotation of the sensor. Also, do not use the TPS as a throttle stop. In

either case, t he TPS will be damaged.

F10A and F10A-8 Only

1.3.5. Mount Optional Exhaust Gas Oxygen Sensor

The optional exhaust gas oxygen sensor must be mounted in the exhaust pipe near the exh aust

header or e xtractors, usually aft er the collector. The sensor uses the exhaust gas to detect if

the engine is lean or rich. M any late model engines already have provision for an exhaust gas

oxygen sensor and the sensor provided should fit any standard exhaust mount. Some exh aust

systems have the sensor mount up to around half a meter (2 feet) down stream from the

exh aust headers.

If the exhaust system does not have an existing sensor mount then a new mount will have to

15

Page 21

be welded to the exh aust system.

When rout ing the elect rical conn ect ions to the exhaust gas oxygen sensor do not allow the

harness to t ouch the exhaust p ip e as t he heat will damage them.

See Chapter 15 [15.3] for more information on exhaust gas oxygen sensors.

1.3.6. Route Wiring Harness and Connect Sensors

Lay the main wiring harness out in the engine bay with the sensors mounted to ascertain the

best fit for the harness. Pass the wiring loom through a hole in the engine bay firewall and

into t he passenger compartment where the ECU will be mounted. Either use an existing hole

or cut a new hole to suit. Use a rubber grommet or similar device to p rotect the harness from

being damaged by rubbing on the sharp edge of the hole.

WARN IN G:

DO NO T ALLOW TH E HARN ESS TO TOUCH HO T EXHAUS T

PARTS INCLUDIN G MAN IFOLDS OR TURBO C HARGERS .

TRY TO RO UT E TH E M AIN H A RN ES S AWAY FRO M HIGH

VOLT AG E IGNIT IO N LEADS . UNDER NO CIRCUMS TANCES RUN

ANY WIRING PARALLEL TO, OR IN CONTACT WITH THE

IGNITION LEADS .

Note: Be neat. Run the harness in a tidy fashion. Try to run the harness along

paths used by original wiring. Use nylon cable ties to secure the harness in

place, but do not stress the wiring or connectors.

Once the harness is fit ted, connect all the sensors to their app ropriat e p lugs.

1.3.7. Power Relays

There are two relays used with the Haltech F10, the Main Power Relay (with a grey wire) and

the Fuel Pump Relay (two orange wires). These relays are identical parts so it is not important

which relay go es in what connector.

16

Page 22

These relays should be mounted on the firewall or an inner guard. Do not mount the relays

such that they could catch and collect splashed water. Residual water inside the relay housing

will cause t hem to fai l. Mount them with the tab upwards as shown in the diagram.

1.3.8. Fuse Block Assembly

The fuse block assembly holds the fuses that protect the various components of the Haltech

F10 system.

The fuse block is supplied from the factory with fuses installed. The fuse ratings are shown in

the diagram and should not be changed as these have been selected for best protection.

Altering the fuse ratings could cause severe damage to the F10 system.

The fuse block should be positioned so that it can be easily accessed in case of fuse f ailure.

Do not mount the fuse block where it could be exposed to water. M ount via the two screws

holes in t he block. Ensure that vibration will not cause t he screws to vibrate loose.

Connect the Fuse Block assembly to the M ain Harness.

17

Page 23

1.3.9. Electronic Control Unit (ECU)

The Haltech F10 is not designed to be waterproof. It is desirable that the ECU be given as

much protection from the environment as possible. It is recommended that the ECU be

mounted inside the passenger compartment, either on the firewall, under the dashboard or

under the passenger seat.

The ECU has four mounting holes that allow it to be mounted to most flat surfaces. In

extreme cases of vibration, the ECU should be mounted on rubber anti-vibration pads. When

mounting the ECU remember that the communications connector on the loom should remain

accessibl e for ease of programmin g.

18

Page 24

1.3.10. Flying Leads

Locate and conn ect the following flying leads.

Black (Ground)

Locate a good chassis ground point and connect the black wire.

Re d

(Battery Supply +12V) Locate a source of continuous +12 volts and connect the red

wire. Connecting direct to the positive battery terminal is suggested.

Grey

(Ignition Switched +12V) The grey wire is used to control the operation of the Haltech

F10 power relay. It needs to be connected so that it sees 12V only when the ignition

switch is on and during cranking. This wire does not draw a large amount of current (<

0.5A). Do not connect to the accessory outputs of the ignit ion swit ch.

Green

(Aux In) The green wire is used as the Aux In channel. This is used if you wish to use

the Aux Inp ut for Torque Converter control, a turbo timer, etc (Refer Chapter 16

PWM Outputs, 72).

Orange

The two orange wires are used to op erate the fuel p ump. When t he Halt ech F10 ECU

wants t o op erate the fuel p ump it will close t he fuel p ump relay connecting the two

orange wires together. The diagrams show two examples of wiring the fuel p ump. Do

not add extra relays to the fuel pump circuit.

Ex ampl e 1: Connecting to the p ositive si de of the fuel pump.

Ex ampl e 2: Connecting to the n egative side of the fuel pu mp.

Regardless of which e xample is used bot h will operate correctly . Note t hat the orange wires

are connected internally within the loom when the relay is closed. As a result it does not

matter which orange wire is used to connect to the fuel pump.

19

Page 25

F10A and F10A-8 Only

1.3.11. Install and connect Optional Idle Speed Motor

If y ou are not using the Idle Speed Cont rol, tie the loom connector back neatly in t he engine

bay . If t he engine has a suitable Id le Sp eed Motor then you may connect it to the wiring loo m,

otherwise y ou can inst all a Haltech supp lied idle air cont rol mot or. For details on how t o

install and plumb the Idle Sp eed Motor, see Chapter 14.

F10A and F10A-8 Only

1.3.12. Install and connect any Optional Outputs

If you are planning to use any of the Programmable Op tional Outputs, install and connect

them now. Dep ending on what opt ions y ou are using, the wirin g will b e different .

(Refer SECTION 4 F10 Inputs & Outputs, 61)

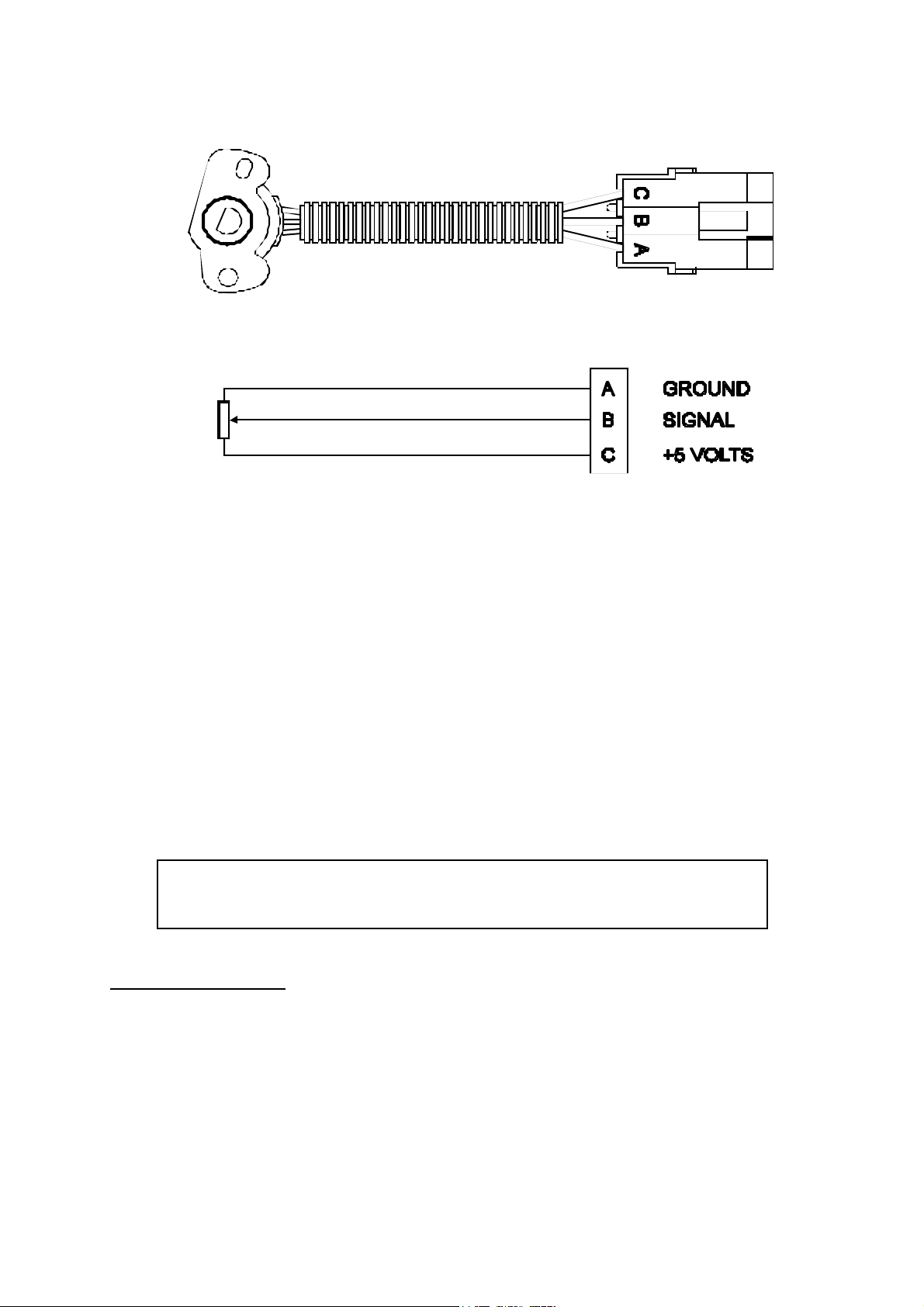

1.3.13 Connect the Trigger Sensor

The F10 requires a trigger signal on each spark event in the engine rotation ie. A 4-stroke V8

will have 4 sp ark events per engine rot at ion (or 8 sp ark events p er cam rot ation). The trigger

signal can be one of the following:

Coil Negative:

The F10 can use the switching voltage at the negative terminal of the ignition coil as a

trigger signal in what is called a “coil negative” trigger set-up. To wire the F10 for

this trigger set-up; connect the trigger wire in the Haltech loom to the negative

terminal of the ignition coil.

Tacho Output:

Some popular ignition systems have a tacho output signal which can be used to trigger

the F10. It is necessary to use this output if the ignition system used is a Capacitive

Discharge Ignition system with a multiple spark function.

Hall Effect and Optical Triggers:

The F10 can also accept a signal from Hall Effect and Op tical triggers sy stems. T hese

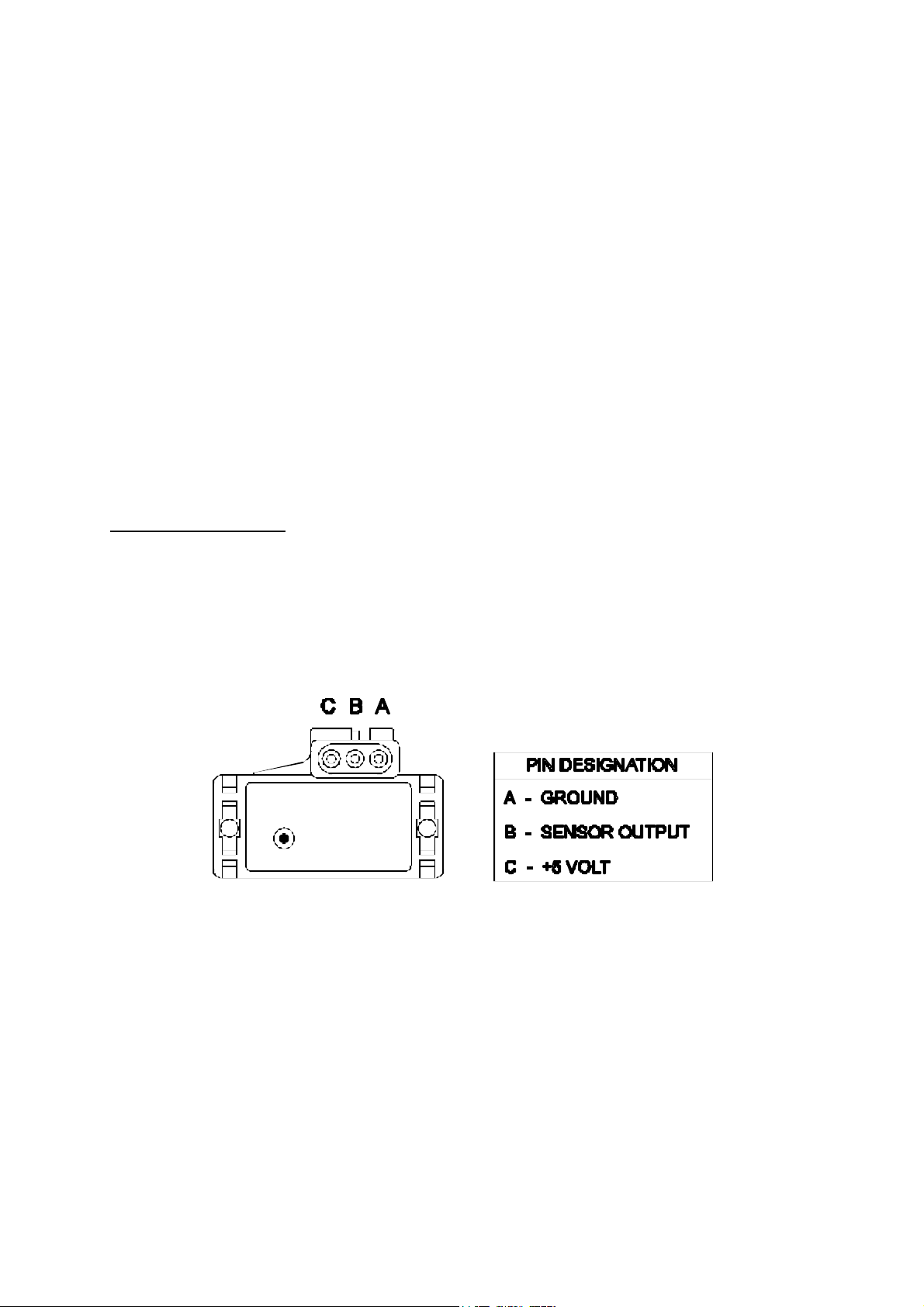

trigger dev ices genera lly 3 have connections each - ground, p ower and the signal. The

trigger connector on the Main Harness has six pins. These pins and their connections

are shown in the diagram below.

20

Page 26

PIN FUNCTION

A GROUND

B MAIN TRIGGER

C N/A

D N/A

E N/A

F 13.8 V DC

For more information on the F10 trigger system; (Refer Appendix D Trigger Interface,

92).

1.3.14 Connect the ECU

The ECU can now be connected and tested. Be sure to engage the clip on the main connector,

this will mak e sure the main connector p art s mate correctly and redu ces the m echanical strain

on the connector bodies. The system can now be tested as described in the following chapters.

21

Page 27

CHAPTER 2 GETTING ONLINE

Now that your Haltech F10 is installed with all the sensors in place the system can be

connected to t he programm in g comp uter. T his will allow the readings from all the sensors to

be displayed on the screen and checked for correct operation.

To connect the PC to t he Halt ech F10 ECU you will need the p rogrammin g cable and

programmin g disk supplied.

2.1 Connecting the Haltech F10 to a Computer

The p rogramming cable supplied with t he Halt ech F10 is a standard seria l link extension

cable. One end of the cable will plug into t he Main Harness PC Interface connector (near the

main connector). The other end should plug into the mating connector at the back of y our

computer. The plug on the computer may be marked "Serial", "Mouse" or "COM". Almost all

laptops will have this plug. If t here is no 9 pin plug which it will connect to, check to see if

there is a 25 p in D-type p lug av ail able (some desk top computers will have this). If this is t he

case, an ap p ropriate cable can be supp lied on request . Alt ernatively , most electronic retailers

will have a 25-p in to 9-pin converter.

Any time you wish to communicate with the F10 ECU it needs to be supplied with power.

This usually involves just turning on the ignition switch. If at any stage power is not on, or the

programmin g cab le is disconnected while attempting to communicate, the programming

software will display t he message RECONNECT HALTECH. To rectify this, reconnect

power and/or the p rogramming cable.

2.2 Ope rating the Software

2.2.1 Computer Requirements

The comp uter required to program the Haltech F10 can be any IBM-PC compatible p ersonal

computer from the XT onwards (i.e. the AT, 386, 486 or Pentium computers). The

requirements are fairly modest. The computer must have at least 640K of RAM (with about

590kb free for executable programs), one 3.5" disk drive and a CGA, EGA, or VGA screen.

(Virtually all reasonably modern laptops running MS-DOS (version 5.00 or higher) will fit

this description).

2.2.2 Installing the Software

The Programming Disk supplied with the Haltech F10 has an installation program that allows

you to install the software onto the PC’s Hard Disk. M ost modern PCs have a hard disk. If

your PC does not have a hard disk, the F10 Program can run directly from the disk supplied.

Installing the soft ware on the Hard Disk will sp eed up t he program and avoid hav in g to fiddl e

around with floppy disks. The installation program need only be run once.

22

Page 28

If you do not have a Hard Disk, go to the section titled Running the Software from the

Fl oppy Dri ve .

To install the software follow these steps.

Boot up Computer

Turn your PCs power on and boot up M S-DOS as instructed by the computers Users Manual.

If a shell program or menu utility runs automatically when you boot y our computer, exit it

now. You should see something like this:

C:\>_

This is the ‘DOS Prompt’. It is DOS’ way of indicating that it is waiting for a command. The

C: indicates that the C drive is the drive currently selected. If you do not have a hard disk,

your p romp t will p robably look like this :

A:\>_

Select the Drive

To run the INSTALL program, you must insert the supplied disk in the disk drive. If the drive

is t he A drive, then it must be currently selected. T o select the A drive (or B drive if it is the

required drive) type :

The yyyy key is the Enter Key. On some keyboards it may be called the Return key. You should

now see the prompt :

A:\>_ or B:\>_

Run the INSTALL Program

To run the Install program type :

The Install program will now run. Follow the instructions given. The program will suggest

that the software will be placed in t he HALTECH direct ory . You can change t he dest ination

directory, but it is not recommended that you do unless you understand how directories work.

When it is finished, t he installation p rogram will t ell y ou if the installation is successful. If it

was not, consult the trouble shooting section of this manual.

The F10 Program is now ready to run.

Dy or %y

LQVWDOOy

23

Page 29

2.2.3 Running the Software from the Hard Disk

Boot your computer up as described earlier. If your computer is already on, make sure the C

drive is currently selected. To change to the HALTECH directory type :

or, if you used a different destination directory, type that path.

To start the program type :

)y

The F10 p rogram will now run. The next section is on running the software from a floppy

drive. You can skip this section and go straight to the section entitled Azerty Keyboards.

F'?KDOWHFKy

2.2.4 Running the Software from the Floppy Disk

To run the software from a floppy drive, boot your computer up as described earlier. Insert the

Programming disk in the disk drive. If t he driv e is t he A drive, then it must be currently

selected. To select the A drive (or B drive if it is the required drive) type :

You should now see the prompt :

A:\>_ or B:\>_

To start the F10 program typ e :

Dy or %y

The F10 program will now run.

)y

2.2.5 Azerty Keyboards

M ost countries use a keyboard where t he first six letter key s across the top row are :

This is called a Qwerty keyboard. Some countries use an alternative, which is called an

Azerty keyboard, where the Q and W keys are swapped with the A and Z keys respectively. If

you have an Azerty keyboard, y ou need to run the software slightly differently. When you

would normally type:

TZHUW\

)y

24

Page 30

to run the programmin g software (not the installation software), you need to instead type :

The /A tells t he program y ou have an Azerty key board. The program will adjust accordin gly.

)Dy

2.3 The ONLINE and OFFLIN E Modes

On the F10 system title page, the software asks whether t o op erate in ONLINE or OFFLINE

mode. The OFFLINE mode is very useful to familiarise yourself with the Haltech software,

but cannot be used to make lasting adjustments to the fuel maps except by modifying maps

then saving those maps and re-loading them to the ECU in the on-line mode. Also lasting

changes to the main, fuel and M ain Set-up p ages cannot be made in the OFFLINE mode. Do

not att empt to make lasting changes to the ECU unless there is a special reason for doing so.

If you wish to exp eriment and familiarise yourself with the software press N for OFFLINE

mode, but if the ECU is installed and power is available then we suggest the ONLINE mode

be selected. Press Y to select ONLINE mode.

2.4 Using the System ONLINE

In the ONLINE mode there is a two-way flow of information between the ECU and the

programmin g computer. The communication cable must be installed and power must be

available t o the ECU before the sy stem can communicate. T he ONLINE mode will be used

most frequently. While using the system ONLINE, you can view engine information directly

and make adjustments. Any changes or modifications made on the computer are instantaneous

and will be imm ediately recorded in the ECU. When the p rogrammin g cable is remov ed and

the ignition switched off, the ECU will retain all of its memory. The maps do not need to be

saved, but keeping a copy on disk is always good practice and is recommended. (See 9.1)

Note: If p ower is removed or the communication cable is disconnected or

interfered with, the following message will be displayed on the computer

screen.

RECONNECT HALTECH

If this message app ears check all connections and ensure that the communications cable is not

being interfered with. Also be sure that the Haltech F10 unit is receiving power. (i.e.. ignition

switch is turned "on".)

2.5 The Main Menu

When y ou select ONLINE or OFFLINE mode the Halt ech M AIN M ENU bar app ears. T his

menu bar allows access to submenus giving access to maps, file storage/retrieval, engine data

and options.

25

Page 31

2.6 How to Quit

Throughout the p rogram you can exit from any application by using the menu bars or hot

tT

keys. Pressing

while holding down the

tT

tTtT

in any page will p rompt you to exit the p rogram (i.e.. p ressing

key). If you wish to exit, p ress

tttt

at the p rompt.

<<<<

TTTT

2.7 Checking the Engine Data

The engine data option can only be used when the system is ONLINE. This function allows

all of the engine data variables to be displayed on the screen

This is a very useful function for analysing the engine sensors. To bring up the engine data

tH

press

pressing

Do not attempt to start the engine if the Engine Main Set-up page has not been completed.

Before continuin g check to see if all the sensors are operat in g corr ectly by viewing the engine

data page.

tH

tHtH

from any application. Otherwise it can be accessed throu gh the menu bar by

s2

s2

s2s2

and then

for Engine Data.

((((

26

Page 32

CHAPTER 3 ECU SETUP

3.1 ECU Setup

The F10 ECU can be used to control fuel delivery to many different types of engines and

requires specific information about the engine that it is to control. The F10 software has a

series of set-up pages that allow t he user to p rogram the F10 with these settings, these are:

Main-Setup

Fuel Setup

3.1.1 Navigating the Set-up pages

The F10 Set-up p ages are made up of a series of f ields t hat define the charact erist ics of the

engine that the F10 is to control. These fields can be navigated as follows:

and

Use the Up and Down arrow keys (

Selection typ e, or Text type. The Selection typ e fields give you a number of valid entries for

that field. For example, the valid number of cylinders can be set to 1, 2, 3, 4, 5, 6, 8, 10 or 12.

oooo

) to move between fields. The fields are either

pppp

The Tab and Enter keys (

of t he Tab key will disp lay t he next selection. The Shift and Tab keys together will step

backwards through the selections. Once the desired selection is displayed, the Enter key is

pressed to program that selection. Text Fields require you to enter either text or numbers.

Once the field is selected, the new text can be typed in, with the Enter key to finish. An

example is the Rev Limit. This field can be set between 2000 and 16000 rpm. If you want the

rev limit to occur at 7000rpm, then you would need to select this field using

typ e y

y

yy

.

vvvv

and

) keys are used to change this type of field. Each st roke

yyyy

or

oooo

and then

pppp

3.1.2 Main Set-up

To access t he M ain Setup page press Alt – S to open the Set-up menu then scroll t o the M ain

Set-up menu item and press enter.

Cylinders

The number of engine cylinders needs to be entered here. This parameter is used to

determine the en gine speed.

The valid values for this parameter are: 1,2,3,4,5,6,8,10,12 and 16

Load S ensing

The F10 can use either the manifold pressure or the throttle p osit ion as a means of

determining the engine load. M ost engines op erate using man ifold p ressure to sense

engine load. If your engine employs any form of supercharging, y ou must run in

manifold p ressure mode. Only wild cams, motorbikes or heavily port ed rotaries

require throttle mode - i.e. engines whose vacuum signal is small, or fluctuates greatly.

If you are unsure what to use, contact your Haltech dealer.

The valid values for this parameter are: Throttle and M anifold

27

Page 33

MAP Sensor

The F10 needs to know the type of Manifold Absolute Pressure (M AP) sensor being

used. Enter the correct description here to match. If using throttle p osition mode, set

this parameter to a 1 Bar sensor.

The valid values for this parameter are: 1 BAR, 2 BAR and 3 BAR

RPM Limit

The F10 can limit the maximum rpm at which t he engine will operate. Above this

level the F10 comp let ely cuts fuel or ignition (see be low) to the engine. When the

engine speed drops below the RPM Limit the F10 will resume normal fuel or ignition

delivery. This is known as hard limiting. If the RPM Limit is not needed then set t his

value abov e t he highest operating point of the engin e.

The valid values for this parameter are: 2,000rpm – 16,000rpm

Units

The Haltech F10 programming software can display parameters in either Metric or US

units.

The valid valu es for this paramet er are: M etric, US

RPM Mode

The F10 fuel and ignition maps may be arranged either in 500 rpm increments to

10,500 rpm, or in 1000 rpm increments to 16,000 rpm. Changing settings alters the

way the ECU reads t he M aps, and will chan ge the t uning of the en gine dram atically .

Do not change this setting once tuned unless necessary.

The valid values for this parameter are: 10,500rpm – 16,000rpm

Road S peed Value

This paramet er is a multip lier t hat allows the user to calibrat e t he road-speed input by

comp aring the road-speed value on t he Engine Dat a Page with that of the vehicles

sp eedometer. To calibrate the road-sp eed inp ut, modify this value until the road-sp eed

value on the engine data page matched that on the vehicle speedometer.

The valid values for this parameter are: 100 – 60,000

F10 Type

This field is only accessible by Haltech but serves as an indication of which of the 4

F10 variants is connected.

The valid values for this parameter are: F10, F10A, F10-8, and F10A-8

3.1.2 Fuel Setup

To access t he Fuel Setup page press Alt – S to open the Set-up menu then scroll t o the Fuel

Set-up menu item and press enter.

Ign / By

Ignition Divide By is the number of ignition p ulses t hat will be counted until the next

injection pulse (remember the trigger wire for the F10 should ideally have one trigger

event for each sp ark event). For almost all mult ip oint sy stems, injection should occur

once per revolution and so Ignition Divide By should be set to half the number of

cylinders. If the sy stem is operating in Batch Fire mode, or is a rotary, then a value of

1 is suggested.

28

Page 34

The valid values for this parameter are: 1, 2, 3, 4, 5 and 6

Decel Cut-Off

A common fuel saving feature in original equipment computers is a fuel cut-off on

decelerat ion. This will cut fuel delivery to the engine while coasting down hills with a

closed throttle. This feature can be enabled or disabled on the F10. It is better, when

first tuning, to disable this function.

The valid valu es for this paramet er are: Enab le and Disable

Inje ction Mode

Depending on the ECU settings the F10 splits its four (F10 and F10A) or eight (F10-8

and F10A-8) injector driver outp uts into two banks (see chapter 13, 13.1). INJ1 and

INJ2 comprise the first bank. INJ3 and INJ4 form Bank 2. The fuel can be injected in

three different modes.

Multipoint injection f ires all the inj ectors t ogether. This is t he most common set-up

and will normally be used on engines with mult ip oint injection manifo lds (one in ject or

per cylinder).

Batch-fire injection is usually used in throttle body or non-turbo rotary set-ups and

fires the two banks of injectors alternately. On eight and twelve injector fuel rails, with

high-f low injectors, t his may also help reduce fuel pressure oscillations caused by all

injectors p ulsing together.

Staged injection is usually used on high boost turbo engines. Injector Bank 1 fires all

the time, just as in a multip oint set-up. Beyond a set boost pressure, the second bank

of injectors is enabled. These "staged" inje ctors are normally upstream of the primary

injectors, addin g to t heir fuel flow. The p oint at which the F10 switches in the

secondary injectors is set via the Staging Bar Number field. Staging permits high fuelflow cap ability, but maintains accuracy and cont rollability at light load and idl e.

(Refer C.3 Injector Staging, 90).

WHEN FINISHED SETTING THE INJECTION MODE, SEE

(INPUT/OUTPUT PAGE) TO S ET THE INJ 1 - 4 DRIVERS TO THE

THIS IS IMPORTANT AS THE ECU WILL NOT OPERATE

CORRECTLY IF THE INJ 1-4 DRIVERS HAVE NOT BEEN

CONFIGURED P ROP ERLY. AT WORS T, SO ME INJ ECTORS MAY

NOT FIRE OR THE INJECTOR DRIVERS MAY DESTRUCT AFTER

THE F10 AND F10A ARE NOT CAPABLE OF DRIVING 8 LOW

IMPEDANCE INJECTORS. THES E ECU DO NOT HAVE THE

WARN IN G:

CHAPTER 13.1

CORRECT STATE: ENABLED OR DISABLED:

A PERIOD O F TIM E.

F10 AND F10A ONLY

EXTRA INJECTOR DRIVERS MENTIONED ABOVE.

29

Page 35

Post Start Temp Limit

This field sets the temp erature at which the post start correction map is either enabled

or disabled. The following field “Above/Below” allows the user to enable the Post

map above or below the temperature set in Post Start Temp limit (this is p art icularly

useful for engine, which when hot require extra fuel due to vapour lock. From when

the mot or is st arted to when t he engine temperature reaches the Post Start Temp limit,

the Post Start correction map will app ly correction to the injection times.

The valid values for this parameter are: 0°C – 127°C (Above and Below)

Post Start Time Limit

This field sets the time for which the post start correction map adds corrections to the

fuel from t he post start map. Post Start is the p eriod of time from when the motor is

st arted to t he Post Start Time limit.

The valid values for this parameter are: 1s – 120s

Staging Bar Number

This field sets t he point at which the staged injectors are en abled (Ref er C.3 Injector

Staging, 90). If t he injection mode is not "Staged Injection" then t his field will not

affect injection.

The valid values for this parameter are: 1-16

Ze ro Throttl e Map

This feature allows t he user to enable or disable a sp ecia l fuel map t hat is used only

when the throttle is closed. This feature should be used for engines that produce

constant vacuum while cruising but irregular vacuum when idling. Typ ical engine

configurations that fall into this category are multiple throttle body set-ups and wild

cams. The zero throttle M ap can allow a very quick and simp le adjustment of the idle

fuel settings. This option can be disabled if not required.

The valid valu es for this paramet er are: Enab le and Disable

Throttle Pump Deadband

This field defines the p ercentage change in throt t le p osition t hat must occur before the

throttle pump is act ivated. This fe at ure allows for “ jit t er” in the throttle that would

otherwise over-fuel the engine.

The valid values for this parameter are: 1% - 20%

Ful l Throttle Map

This feature allows t he user to enable or disable a sp ecia l fuel map t hat is used only