Page 1

Instruction Manual

REG 21 Pressure

Regulator

Document 7100.003674 Version 2.1 05/2009

halstrup-walcher GmbH

Stegener Straße 10

D-79199 Kirchzarten

Germany

Phone: +49 (0) 76 61/39 63–0

Fax: +49 (0) 76 61/39 63–99

E-Mail: info@halstrup-walcher.com

Internet: www.halstrup-walcher.com

Page 2

Instruction Manual REG 21

Table of Contents

1 Safety precautions ................................................................................................................ 5

1.1 Appropriate use.................................................................................................................. 5

1.2 Shipping, assembly, electrical connections and start-up.................................................... 5

1.3 Troubleshooting, maintenance, repairs, disposal............................................................... 5

1.4 Symbols ............................................................................................................................. 6

2 Instrument description........................................................................................................... 7

3 Start-up ................................................................................................................................. 7

3.1 Features ............................................................................................................................. 7

3.1.1 Inputs and outputs .......................................................................................................... 7

3.1.2 Display elements............................................................................................................. 8

3.1.3 Keypad............................................................................................................................ 8

3.2 User functions .................................................................................................................... 9

3.3 Device parameters...........................................................................................................10

3.4 Switching behaviour.........................................................................................................11

3.5 Zero-point calibration ....................................................................................................... 12

3.5.1 Sequence of zero-point calibration steps...................................................................... 12

3.6 Overload protection.......................................................................................................... 12

4 Identification ........................................................................................................................ 13

4.1 Included in shipment ........................................................................................................13

4.2 Product labelling .............................................................................................................. 13

4.3 Models ............................................................................................................................. 13

5 Electrical connections and installation................................................................................. 14

5.1 Installation........................................................................................................................ 14

5.2 Instrument connections.................................................................................................... 14

5.2.1 Pressure ports............................................................................................................... 14

5.2.2 Electrical connections ................................................................................................... 15

5.2.3 Option light emitting diodes (LED) ................................................................................ 15

6 Start-up ............................................................................................................................... 16

6.1 Setting parameters........................................................................................................... 17

6.1.1 Overview of parameter setting functions and parameters............................................. 17

6.1.2 Launching a parameter setting function........................................................................ 18

6.2 Setting parameters........................................................................................................... 18

6.2.1 Notes on setting switching value parameters................................................................ 20

7 Troubleshooting .................................................................................................................. 21

8 Technical data..................................................................................................................... 22

2

Page 3

Instruction Manual REG 21

9 Dimension drawings...........................................................................................................24

3

Page 4

Instruction Manual REG 21

Purpose of instruction manual

This instruction manual describes the features of the REG 21 pressure regulator and

provides guidelines for its use.

Improper use of this instrument or failure to follow these instructions may cause injury

or equipment damage. All individuals responsible for operating this instrument must

therefore be properly trained and aware of the hazards, and must carefully follow

these operating instructions and the safety precautions detailed within. Contact the

manufacturer if you do not understand any part of this instruction manual.

Handle this manual with care:

It must be readily available throughout the lifecycle of the instrument.

It must be provided to any individuals who assume responsibility for operating the

instrument at a later date.

It must include any supplementary materials provided by the manufacturer.

The manufacturer reserves the right to continue developing this instrument model

without documenting such development in each individual case. The manufacturer

will be happy to determine whether this manual is up-to-date.

Conformity

This instrument corresponds to the state of the art and meets all legal requirements

set forth in EC directives as evidenced by the CE label.

© 2002

The manufacturer owns the copyright to this instruction manual. This manual contains

data, instructions and drawings pertaining to the features and usage of this

instrument; copying this manual in part or in full or distributing it to third parties is

prohibited.

4

Page 5

Instruction Manual REG 21

1 Safety precautions

1.1 Appropriate use

The REG 21 pressure regulator is designed for measuring, displaying, monitoring and

regulating positive and negative overpressures and differential pressures of nonaggressive, gaseous media.

Always observe the operating requirements—particularly the permissible supply

voltage—indicated on the rating plate and in the “Technical data” section of this

manual.

The instrument may only be handled as indicated in this manual. Modifications to the

instrument are prohibited. The manufacturer is not liable for damages caused by

improper use or failure to follow these instructions. Violations of this type render all

warranty claims null and void.

1.2 Shipping, assembly, electrical connections and start-up

Do not close the pressure input ports when shipping, as changes in barometric

pressure could damage instruments with low measuring ranges.

Only technical personnel who are appropriately trained and authorized by the

operator of the facility may assemble the instrument and set up its electrical

connections.

The instrument may only be operated by appropriately trained individuals who have

been authorized by the operator of the facility.

Pressurized air or breath is not to be used for performance tests, as this could

damage instruments with low measurement ranges.

Measurement errors may occur if the instrument is not kept protected from sunlight.

Specific safety precautions are given in individual sections of this manual.

1.3 Troubleshooting, maintenance, repairs, disposal

The individual responsible for the electrical connections must be notified immediately

if the instrument is damaged or if errors occur.

This individual must take the instrument out of service until the error has been

corrected and ensure that it cannot be used unintentionally.

Always unplug the power cord before opening the instrument!

This instrument requires no maintenance.

Only the manufacturer may perform repairs that require the housing to be opened.

5

Page 6

Instruction Manual REG 21

The electronic components of the instrument contain environmentally hazardous

materials and materials that can be reused. For this reason the instrument must be

recycled in accordance with the environmental guidelines of the jurisdiction in

question once it has been taken permanently out of service.

1.4 Symbols

The symbols given below are used throughout this manual to indicate instances when

improper operation could result in the following hazards:

WARNING! This warns you of a potential hazard that could lead to bodily injury up

to and including death if the corresponding instructions are not followed.

WARNING: This warns you of a potential hazard that could lead to significant

property damage if corresponding instructions are not followed.

INFORMATION: This indicates that the corresponding information is important

for operating the instrument properly.

6

Page 7

Instruction Manual REG 21

2 Instrument description

The REG 21 pressure regulator measures differential pressures between its two

pressure ports, which lead to two chambers of a pressure measurement capsule.

Pressure is measured via a beryllium bronze membrane spring, which is displaced by

the pressure difference between the two chambers. Inductive displacement

transducers measure membrane deflection without contacting the membrane. The

instrument has no frictional parts or parts subject to mechanical wear, and performs

the following tasks:

Displays the measured value

Provides the voltage (current is also an option) proportional to the measured value.

Its two switching outputs make it suitable for use as either a two-point or a three-point

controller

The following are some additional features worth highlighting:

Overload protection

Adjustable switching hysteresis

High level of sensitivity

High level of accuracy and long-term stability

Automatic zero-point correction

Low temperature dependence

3 Start-up

3.1 Features

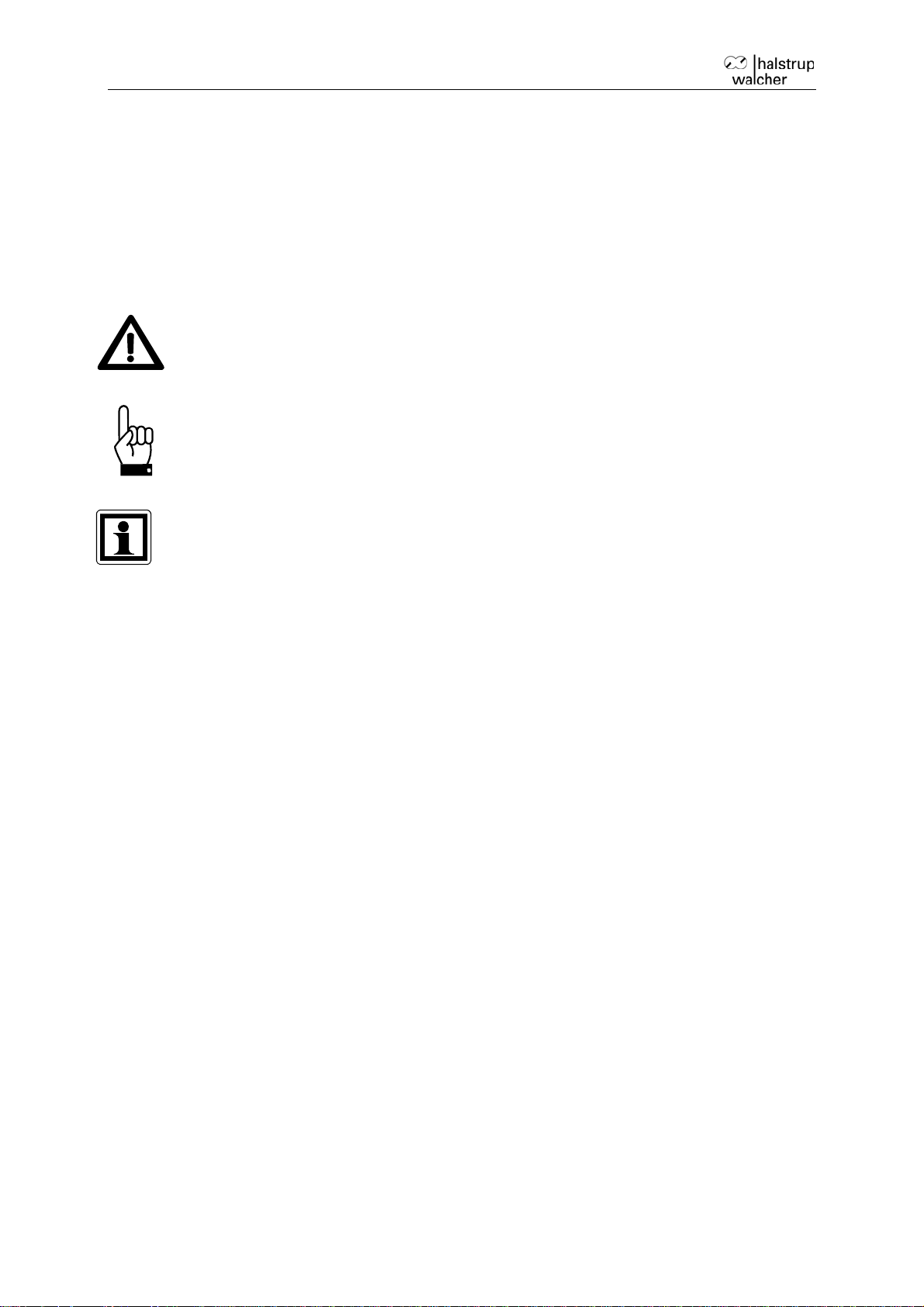

3.1.1 Inputs and outputs

power supply

pressure

ports

Fig. 1: basic circuit diagram

Power supply: Depending on the model, the power is supplied as either 230 V-AC,

155 V-AC, 24 V-AC or 24 V-DC. The details of the supply voltage are given on the

rating plate.

Pressure ports: (-) port: reference pressure; (+) port: pressure to be measured.

The measurement range is given on the rating plate.

Analogue output: The instrument produces a voltage output proportional to the

measured pressure. Output is in the range of 0...10 V (ranges of -5…+5 V, 4...20

mA or 0...20 mA are optional). The spread of the analogue output values is

proportional to the measurement range. The type of analogue output is indicated on

the rating plate.

analog output

switching output 1

switching output 2

7

Page 8

Instruction Manual REG 21

Switching outputs 1 and 2: The instrument comes equipped with 2 relay outputs (2

transistor outputs are also an option). The type of switching output is indicated on

the rating plate. Switching outputs are triggered when values exceed and/or fall

below switch-on and switch-off values. See section 3.4 for a more detailed

description of switching behaviour. The instrument utilizes changeover relays and

bipolar NPN transistors, making it possible to create either open-collector or openemitter circuits.

digital

input

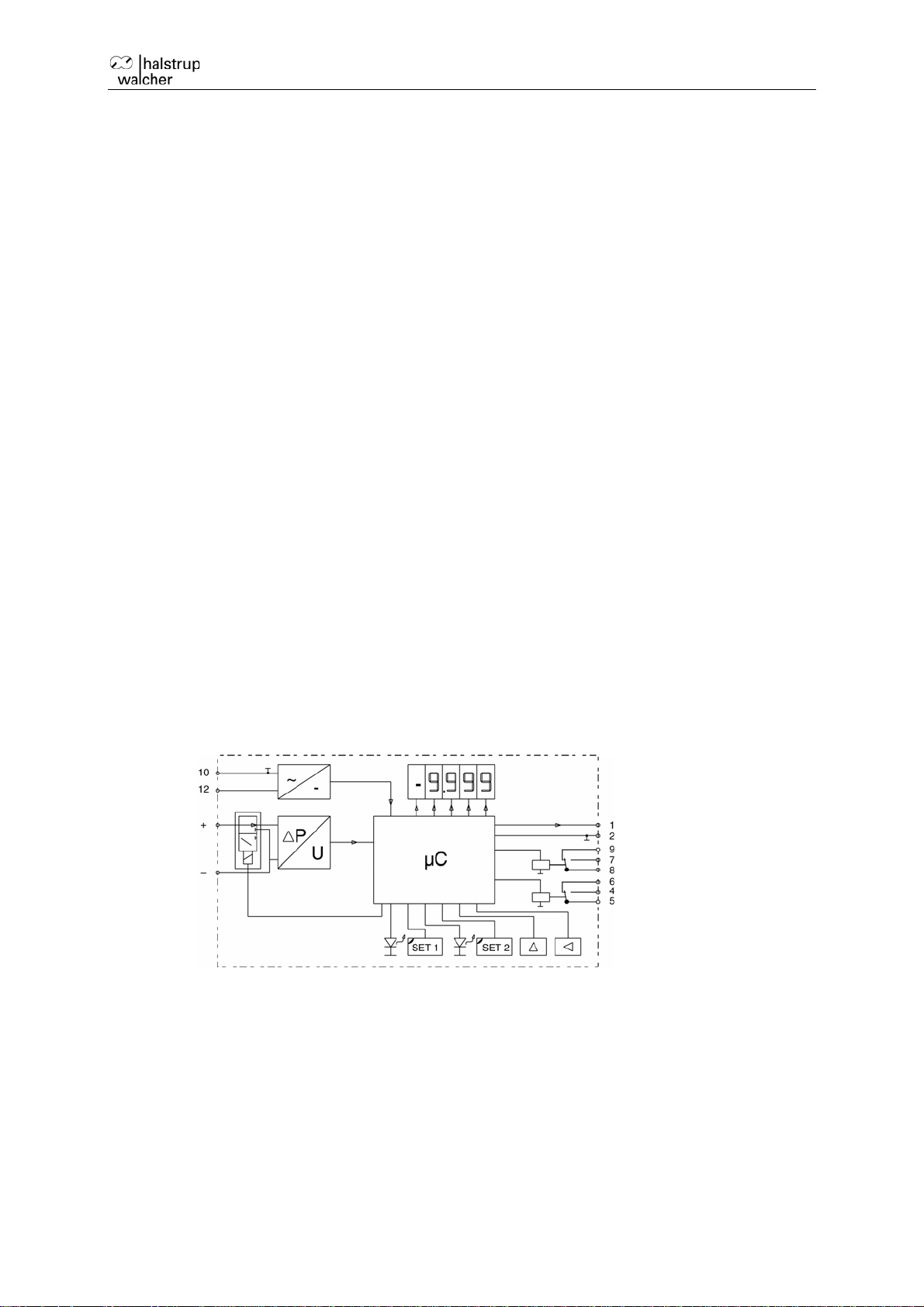

Fig. 2 Transistor output (optional) a) open-collector circuit b) open-emitter circuit

3.1.2 Display elements

LED 1

LED 2

Fig. 3 Front view of the instrument

Display: The display shows the measured differential pressure or overpressure in

the units indicated on the housing next to the display. Positive values are displayed

as is; negative values are indicated by a preceding minus sign.

LED 1: LED 1 shows the status of switching output 1 and is illuminated whenever

the switch-on value exceeds or falls below that set for switching output 1 (see fig. 5).

LED 2: LED 2 shows the status of switching output 2 in a way analogous to that of

output 1.

digital

input

,

Table 1

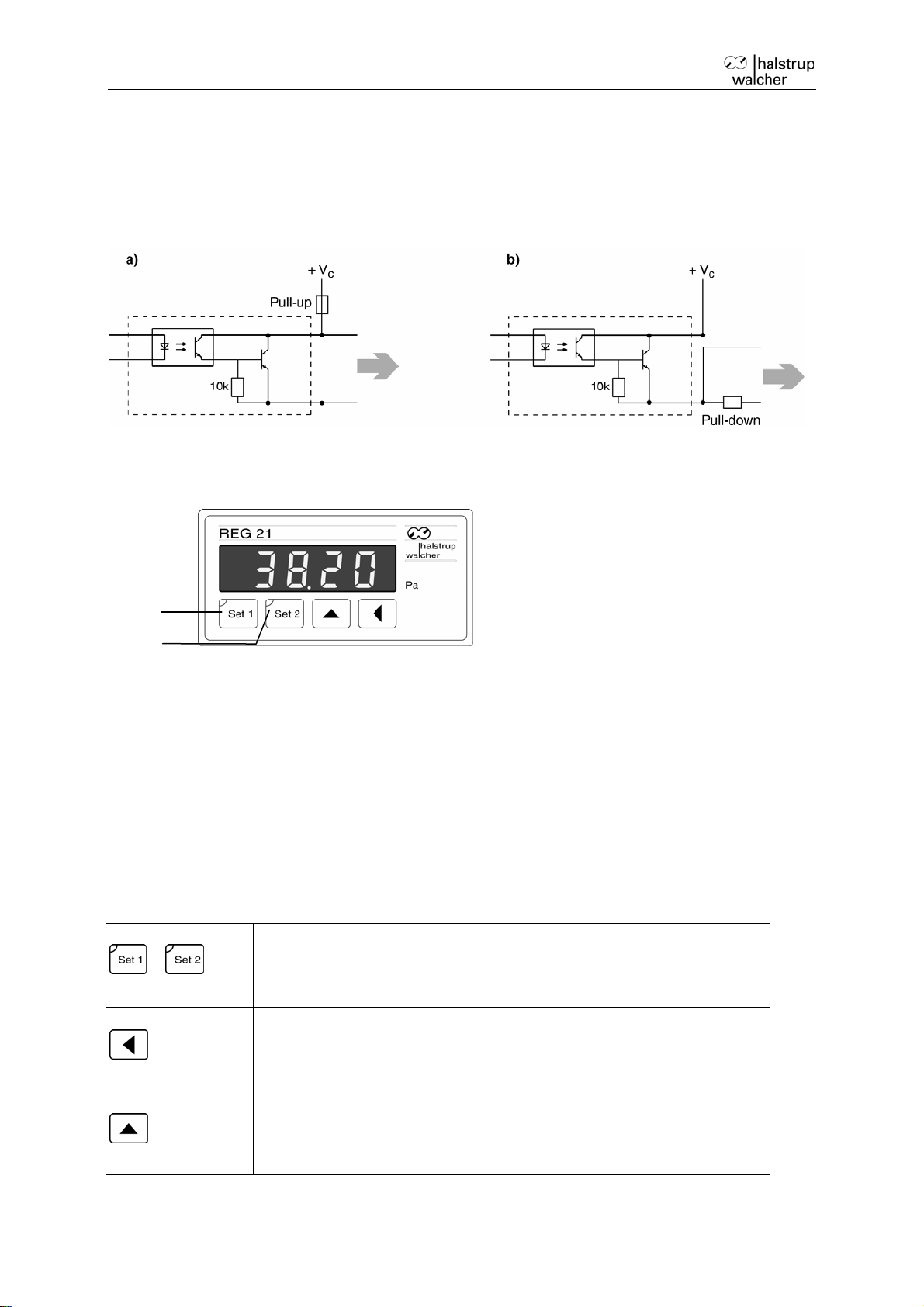

3.1.3 Keypad

The instrument is set by means of 4 keys, whose functions are described in the

following:

Set key:

Call up and exit parameter setting and display functions

Save parameters

Enter key:

Begin and end settings

Select decimal places and +/- sign

Select key:

Select values or parameters

Set numerical values

8

Page 9

Instruction Manual REG 21

3.2 User functions

User functions include setting device parameters, displaying switching output

parameters and manually performing a zero-point calibration.

Users call up these functions by pressing the set keys; the specific function called up

depends on whether the keys are pressed individually or in combination, and for how

long they are pressed. Moving decimal points indicate that the instrument is no longer

displaying measured values (see fig. 7).

Function

Key sequence Process flow

parameter setting

basic settings

see section 6.1

press both and

hold for <2 s*

setting parameters for

switching output 1

setting parameters for

switching output 2

hold for >2 s**

hold for >2 s**

see section 6.1

see section 6.1

display functions

displaying parameters

for switching output 1

hold for <2 s*

Values for switching on and off as well

as the switching direction (see section

3.4) are displayed one after the other.

The display then returns to the

measured value.

displaying parameters

for switching output 2

hold for <2 s*

Values for switching on and off as well

as the switching direction (see section

3.4) are displayed one after the other.

The display then returns to the

measured value.

Other functions

Start manual zero-point

calibration

depress

The zero-point calibration is performed

automatically. The display then returns

to the measured value.

simultaneously and

hold for >2 s**

* hold for <2 s: depress the key(s) until the decimal points on the measured value

display begin to move (see fig. 7 (2))

** hold for > 2 s: depress the key(s) until the “PPP” release code appears (see fig. 7

(3)).

Table 2 User functions for the REG 21 pressure regulator

9

Page 10

Instruction Manual REG 21

3.3 Device parameters

Several parameters are available for adapting instrument operation to a number of

different applications. Section 6.1 describes how to set parameters; table 3 provides

an overview of available parameters.

Parameter

Description

basic settings

time constant the amount of time required for the display, analogue output and (if

the corresponding parameters are set) switching outputs to

respond to changes in pressure

brightness display brightness

zero-point

automatic or manual zero-point calibration options

calibration

relay output 1

switch-on value pressure threshold value that activates the switching output, see

section 3.4

switch-off value pressure threshold value that disables the switching output, see

section 3.4

switch direction parameter for selecting one of the two possible directions between

the two relay/transistor output states, see section 3.4

switching output 2 (analogous to switching output 1)

switch-on value see above

switch-off value see above

switch direction see above

Table 3 parameters for the REG 21 pressure regulator

10

Page 11

Relay 1

LED 1 “on”

LED 1 “off”

Instruction Manual REG 21

3.4 Switching behaviour

The behaviour of the switching outputs is determined by the settings for the switchon, switch-off and switch direction parameters.

Both switching outputs can each be used individually as two-point controllers or in

combination as three-point controllers. The following diagrams illustrate this feature

and define the behaviour of the switching outputs.

Relay1

hysteresis

Relay 1

LED 1 “on”

LED 1 / 2 “off”

LED 2 “on”

Relay 2

p: pressure

p1: switch-on value,

relay 1

p2: switch-off value,

relay 1

p3: switch-on value,

relay 2

p4: switch-off value,

relay 2

The numbers indicate the terminal assignment (see fig. 6)

Fig. 4 Behaviour of switching outputs; switch direction = “0” a), b) relay 1 as a twopoint controller c), d) relay 1 and 2 in combination as a three-point controller

The following are the equivalents for transistor outputs:

If the “switch direction” parameter is set to “1,” the switching output behaviour will be

reversed. The following are transposed in fig. 4:

Relay1

Relay2

output states

relay 1

“blocking transistor”

“conducting transistor”

“blocking transistor” “conducting transistor”

output states

relay 2

11

Page 12

Instruction Manual REG 21

3.5 Zero-point calibration

The instrument’s zero point can be calibrated either automatically or manually; the

type of calibration is determined by the “zero-point calibration” parameter setting (see

section 6.1)

If this parameter is set to “automatic zero-point calibration,” the zero point will be

calibrated automatically as soon as the instrument is switched on and then again

15 minutes later. A calibration will then be performed every 60 min.

If this parameter is set to “manual zero-point calibration,” the automatic zero-point

calibration feature is suppressed.

The zero point will be calibrated any time the manual zero-point calibration feature is

triggered (see table 2)—even if the zero-point calibration parameter is set to

automatic.

The zero point can only be calibrated manually on instrument models with no

bypass valve (see section 4.3).

3.5.1 Sequence of zero-point calibration steps

When calibrating the zero point, a valve briefly closes both pressure ports for six

seconds (∆p = 0).

The instrument then checks for 3 seconds to determine whether the deviation from

zero is within the permissible range. If not, e.g., if the pressure measurement

capsule has been overloaded and damaged, the instrument returns error message

E004.

If the deviation is within the permissible range, the zero point will be measured for

an additional 3 seconds in order to obtain a mean value.

After opening the bypass valve, the instrument returns to measurement mode. Each

measured value is then corrected by the stored zero-point deviation value (offset

value).

Pressure cannot be monitored during zero-point calibration; instead, the most

recently measured value prior to calibration is read out and displayed.

3.6 Overload protection

Only available for instrument models with a bypass valve (see section 4.3)

This valve, which is bypassed during the zero-point calibration process, performs an

additional function: it briefly closes the pressure input ports as soon as the pressure

(measured differential pressure value) is 50% higher than the nominal pressure (final

value of the measurement range).

12

Page 13

Instruction Manual REG 21

4 Identification

4.1 Included in shipment

The instrument model ordered

This instruction manual

4.2 Product labelling

The rating plate provides the following information:

measurement range

type of analogue output

precision class

supply voltage

number and type of switching outputs

product number

the CE emblem

The second label indicates the pin assignment.

4.3 Models

The following instrument models are available:

measurement ranges:

analog outputs: 0 ... 10 V -5 ... 5 V 0 ... 20 mA 4 ... 20 mA

power supply: 230 V-AC 115 V-AC 24 V-AC 24 V-DC

switching outputs:

0 ... 50 Pa to 0 ... 100 kPa

2 relays 2 transistors

zero-point calibration

and overload protection

Table 4

bypass valve

(automatic zero-point

calibration and overload

protection available)

13

no bypass valve

(automatic zero-point

calibration and overload

protection not available)

Page 14

Instruction Manual REG 21

5 Electrical connections and installation

5.1 Installation

The instrument should be installed in a control panel with a rectangular

recess (92 + 0.8 mm x 45 + 0.6 mm) using the installation parts included

in the shipment.

5.2 Instrument connections

5.2.1 Pressure ports

Connect tubing ( 6,5 mm) for reference pressure at the (-) port.

Connect tubing ( 6,5 mm) for measured pressure at the (+) port.

pressure ports

terminal strip

Fig. 5 rear view of the REG 21 pressure regulator

14

Page 15

Instruction Manual REG 21

5.2.2 Electrical connections

WARNING! The instrument is available in a number of different models. The

model is identifiable by the features described in section 4.2 and indicated on

the rating plate and on the second housing label. The model must be

identified before making any electrical connections.

WARNING! RISK OF ELECTRICAL SHOCK! Do not attempt to make any

electrical connections unless the cables attached to both switching outputs

are at zero potential and the power supply has been switched off.

The instrument is operates with a floating ground

Set up the electrical connections as indicated on the housing label or in fig. 6.

Relay 1 Relay 2

analog

output

a.

switching

output 2

switching

output 1

power

supply

230 V-AC

50...60 Hz

(standard)

b.

Fig. 6 Pin assignment for terminal strip (from fig. 5):

a. standard unit with 24 V / 115 V-AC options;

b. 24 V-DC option;

c. with optically coupled transistor output (output 1)

5.2.3 Option light emitting diodes (LED)

Pin assignment for terminal for LED

1 – Cathode(-) LED A

2 – Cathode(-) LED B

3 – Cathode(-) LED C

4 – not connected

4 3

5

2 1

5 – common anode(+)

transistor output 2 is

similarly run through

terminals 4 and 5.

c.

15

Page 16

Instruction Manual REG 21

6 Start-up

Switch on unit by connecting the power supply.

The instrument will automatically execute the following sequence of steps:

The unit will run a check, causing all display segments to light up for 2 seconds.

Both outputs are switched off and the corresponding LED goes dark.

Basic settings are automatically checked for plausibility. If they fail, the

instrument generates an error message (see section 7).

The zero point is then calibrated if this function is part of the instrument’s

program. If zero point lies outside of the permissible range, the instrument

generates an error message (see section 7).

Transition to monitoring and display mode:

Displays current pressure

Reads out an analogue value proportional to the pressure

Controls switching outputs in keeping with set parameters

Displays output states with LED

Setting instrument parameters as detailed in section 6.1.

After its parameters have been set, the instrument is in monitoring and display mode, in

which it can perform its measurement, control and monitoring functions.

16

Page 17

Instruction Manual REG 21

6.1 Setting parameters

If parameter mode is not released within 5 s of calling up a parameter

setting function, the instrument returns to monitoring and display mode.

Press either of the set keys ( or ) to exit parameter mode while

setting parameters (prior to concluding the session by depressing the enter

key

).

The instrument will return to monitoring and display mode if no parameters

are entered within 30 s of entering parameter mode.

The original parameters will not be affected in either of these cases.

While in parameter mode, the instrument will continue to monitor pressure and

control the switching outputs and analogue outputs.

WARNING! Hysteresis is critical for all switching values (see fig. 5) in order to

prevent the relay from “fluttering” or the transistors from periodically switching

on/off.

6.1.1 Overview of parameter setting functions and parameters

Parameter Parameter ID Options Default

values

basic settings:

depress both keys;

function

hold for <2 s*

time constant

parameter

n 1, n 2, n 5, n 10

F 1, F 2, F 5, F 10

F 1

1, 2, 5, 10: time constants in s

n: time constants apply to display,

analogue output and switching

outputs

F: time constants apply to display

and analogue output; switching

outputs will be triggered 20 ms

later

brightness

unitless value of 1…15

5

zero-point

calibration

switching output 1

switch-on

value

AU: automatic zero-point

calibration

nor

nor: manual zero-point calibration

hold for >2 s**

entire measurement range

35 %

17

Page 18

Instruction Manual REG 21

switch-off

value

switch direction

switching output 2:

switch-on

entire measurement range

0, 1 0

hold for >2 s**

entire measurement range

value

switch-off

value

switch direction

entire measurement range

0, 1 0

* hold for <2 s: depress the key(s) until the decimal points on the

measured value display begin to move (see fig. 7 (2))

** hold for > 2 s: depress the key(s) until the “PPP” release code appears

(see fig. 7 (3)).

Table 5

6.1.2 Launching a parameter setting function

(see fig. 7)

Call up the desired parameter function as indicated in table 5 (1).

25 %

50 %

10 %

Enter parameter mode by pressing the following keys in sequence:

“Function and parameter ID” will appear (5).

Example: Calling up the “basic settings” parameter function

measured

value display

(1)

press both and

hold for <2 s

moving decimal

points

display

automatically

request for confirmation

(flashing)

(4)

press one after the

other in sequence

Fig. 7

6.2 Setting parameters

Use the following procedure (starting from “function and parameter ID”) to set

parameters (see fig. 8).

Press

to select the parameter to be changed (0).

parameter

(0...2)

“function and

parameter ID”

, , (4).

function

(0...2)

Press the enter key

to open the parameter settings dialog (1).

18

Page 19

Instruction Manual REG 21

(0)

The display shows the value currently set for the parameter (2).

parameter

time constant

brightness

type of zero-

point calibration

display

Press

Press the enter key

(multiple times) to select the desired value (3).

to confirm the selected value (4).

Press one of the set keys ( or ) to save the value (5).

The instrument will display the function and parameter ID for the next parameter (6).

Set the remaining parameters in the same way (7).

Example: Setting the “basic settings” parameters

(1)

(2)

(0)

(6)

(3) (4)

multiple times

desired time

constant value

flashing

display

(5)

(6)

save

(7)

(7)

Fig. 8

19

Page 20

Instruction Manual REG 21

(6)

6.2.1 Notes on setting switching value parameters.

Switching values can be entered as decimal figures; each place must be set

individually, proceeding as follows and beginning with the “function and parameter

code” (see fig. 9):

Press the enter key

to open the parameter settings dialog (1).

The current value is displayed; the numbers of the final decimal place will be

flashing (2).

Continue as follows until you have reached and set the +/- place:

Press

to set the flashing digit (or +/- sign) (3).

Press the enter key

to return to the decimal places (4).

Press the enter key

to complete the setting process (5).

Press one of the set keys (

or ) to save the values (6).

The instrument will display the function and parameter ID for the next parameter (7).

Example: Setting the switch-on value for switching output 1

(1)

(2)

(4)

flashing

(3)

multiple times

(3)

flashing

(4)

(5)

flashing flashing

(3)

multiple times

(7)

flashing

Fig. 9

flashing

flashing

display

save

20

Page 21

Instruction Manual REG 21

7 Troubleshooting

The instrument recognizes the following problems and responds by returning an error

message:

Error

message

Problem Cause Corrective Action

E003 overloaded

pressure

measurement

capsule

E004 pressure

measurement

capsule is

pressurized during

zero-point

calibration

Table 6

pressure too high send the instrument to the

manufacturer for repair

pressure has not been

disconnected

defective pressure

measurement capsule

reduce pressure

send the instrument to the

manufacturer for repair

21

Page 22

8 Technical data

Measurement data

Instruction Manual REG 21

measurement ranges

measurement principle inductive

change in volume 0.1…0.3 mL

overload capacity 200x (for measurement ranges < 2.5 kPa)

600 kPa (for measurement ranges > 2.5 kPa)

linearity ± 1%

± 0.5 % (optional for measurement ranges > 250 Pa)

temperature-dependent drift in

measured values

temperature-dependent drift in the

zero point

zero-point drift over time 0.5 %/year

Ambient conditions

medium air, all non-aggressive gases

operating temperature +10° to +50°C

storage temperature -10° to +70°C

relative humidity 0 ... 80 %

0 ... 50 Pa to 0 ... 100 kPa;

see rating plate

0.04% / K (+10° to +50°C)

0.04% / K (+10° to +50°C)

EMC standards EN 55011; EN 61000-4-3, EN 61000-4-6

conformity

Electrical data

power consumption 3 VA

supply voltage options

standard 230 V-AC, +6 % / -15 % (50...60 Hz)

(optional) 24 V-AC, 115 V-AC, +6 % / -15 % (50…60 Hz)

(optional) 24 V-DC, +20 % / -15 %

analogue output

standard

(optional) -5 ... 5 V; 0 ... 20 mA; 4 ... 20mA

time constant 1 sec. (standard), 2.5 and 10 s may be set by user

switching outputs

standard 2 floating changeover relays; up to 230 V-Ac (50/60

(optional) 2 bipolar NPN transistors; UCE < 50 V; IC < 200 mA,

declaration of conformity available upon

request

0..10 V (RL ≥2 kΩ)

Hz), 6 A w/ ohmic load

floating

time constant 20 ms (standard), 1,2,5 and 10 s may be set by user

electrical connections 12-pin terminal strip

connected cross-sections 0.5 ... 2 mm2

22

Page 23

Instruction Manual REG 21

Physical data

pressure port 2 pressure ports, Ø = 6.5 mm

housing material glass reinforced Noryl

mounting orientation horizontal

Table 7

23

Page 24

9 Dimension drawings

switch panel housing

Fig. 10 housing dimensions

Instruction Manual REG 21

24

Loading...

Loading...