Page 1

Instruction Manual

PSx3xxDN

halstrup-walcher GmbH

Stegener Straße 10

D-79199 Kirchzarten, Germany

Phone: +49 (0) 76 61/39 63-0

Fax: +49 (0) 76 61/39 63-99

E-mail: info@halstrup-walcher.com

Internet: www.halstrup-walcher.com

Document 7100.004144 03/2017

Page 2

PSx3xxDN Instruction Manual

2

Table of Contents

1 Safety precautions ............................................................................................................ 4

1.1 Appropriate use .............................................................................................................. 4

1.2 Shipping, assembly, electrical connections and start-up................................................. 4

1.3 Troubleshooting, maintenance, repairs, disposal............................................................ 4

1.4 Symbols ................................................................................................ ......................... 5

2 Device description ......................................................................................................... 5

2.1 Features ..................................................................................................................... 5

2.2 Installation .................................................................................................................. 5

2.3 Pin assignment........................................................................................................... 6

2.4 Setting the device address and baud rate .................................................................. 7

2.5 Start-up ...................................................................................................................... 9

2.6 CAN Bus .................................................................................................................... 9

3 Sequence of positioning steps ........................................................................................ 26

4 Special features .............................................................................................................. 27

5 Technical data ................................................................................................................. 33

Page 3

PSx3xxDN Instruction Manual

3

Purpose of instruction manual

This instruction manual describes the features of PSx3xxDN positioning systems and

provides guidelines for their use.

Improper use of these devices or failure to follow these instructions may cause injury

or equipment damage. All individuals responsible for operating these devices must

therefore be properly trained and aware of the hazards. The instruction manual, and

in particular the safety precautions contained therein, must be followed carefully.

Contact the manufacturer if you do not understand any part of this instruction

manual.

Handle this manual with care:

It must be readily available throughout the lifecycle of the devices.

It must be provided to any individuals who assume responsibility for operating the

device at a later date.

It must include any supplementary materials provided by the manufacturer.

The manufacturer reserves the right to continue developing this device model without

documenting such development in each individual case. The manufacturer will be

happy to determine whether this manual is up-to-date.

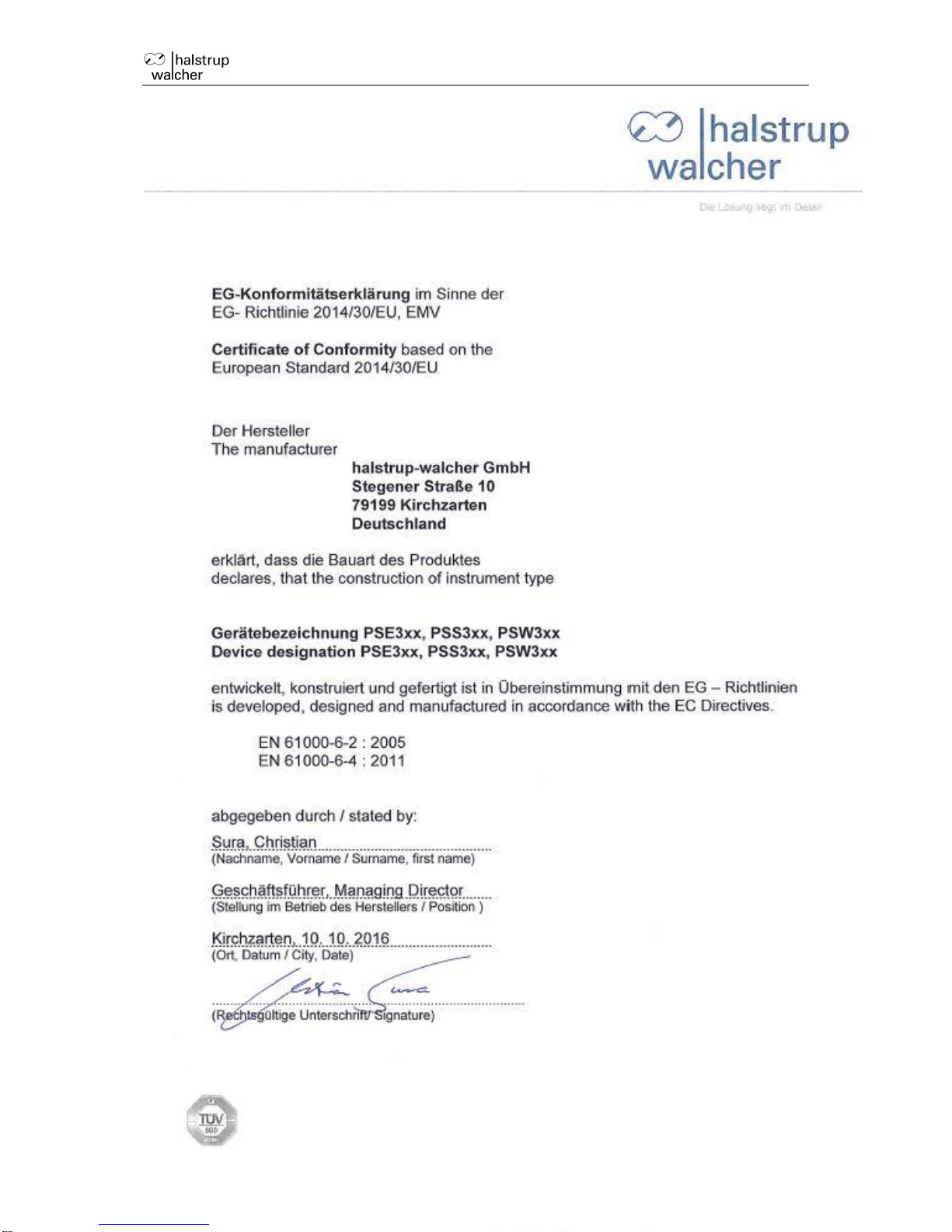

Conformity

This device corresponds to the state of the art and meets all legal requirements set

forth in EC directives as evidenced by the CE label.

© 2010, 2015, 2016, 2017

The manufacturer owns the copyright to this instruction manual. This manual contains

data, instructions and drawings pertaining to the features and usage of these devices;

copying this manual in part or in full or distributing it to third parties is prohibited.

Page 4

PSx3xxDN Instruction Manual

4

1 Safety precautions

1.1 Appropriate use

Positioning systems are especially suitable for automatically setting tools, stops or

spindles for wood-processing equipment, packing lines, printing equipment, filling

units and other types of special machines.

PSx3xxDN positioning systems are not stand-alone devices and may only be

used if coupled to another machine.

Always observe the operating requirements—particularly the permissible supply

voltage—indicated on the rating plate and in the “Technical data” section of this

manual.

The device may only be handled as indicated in this manual. Modifications to the

device are prohibited. The manufacturer is not liable for damages caused by improper

use or failure to follow these instructions. Violations of this type render all warranty

claims null and void.

1.2 Shipping, assembly, electrical connections and start-up

Only technical personnel who are appropriately trained and authorized by the

operator of the facility may assemble the device and set up its electrical connections.

The device may only be operated by appropriately trained individuals who have been

authorized by the operator of the facility.

Specific safety precautions are given in individual sections of this manual.

1.3 Troubleshooting, maintenance, repairs, disposal

The individual responsible for the electrical connections must be notified immediately

if the device is damaged or if errors occur.

This individual must take the device out of service until the error has been corrected

and ensure that it cannot be used unintentionally.

This device requires no maintenance.

Only the manufacturer may perform repairs that require the housing to be opened.

The electronic components of the device contain environmentally hazardous

materials and materials that can be reused. For this reason the device must be

recycled in accordance with the environmental guidelines of the jurisdiction in

question once it has been taken permanently out of service.

Page 5

PSx3xxDN Instruction Manual

5

1.4 Symbols

The symbols given below are used throughout this manual to indicate instances when

improper operation could result in the following hazards:

WARNING! This warns you of a potential hazard that could lead to bodily injury up

to and including death if the corresponding instructions are not followed.

WARNING: This warns you of a potential hazard that could lead to significant

property damage if corresponding instructions are not followed.

INFORMATION: This indicates that the corresponding information is important

for operating the device properly

2 Device description

2.1 Features

The PSx3xxDN positioning system, an intelligent, compact, complete solution for

positioning auxiliary and positioning axes, consists of an EC motor, gear power

amplifier, control electronics, absolute measuring system and DeviceNet interface.

The integrated absolute measuring system eliminates the need for a time-consuming

reference run. Connecting to a bus system simplifies the wiring. A hollow shaft with

adjustable collar makes assembly quite simple. The positioning system is especially

suitable for automatically setting tools, stops or spindles for wood-processing

equipment, packing lines, printing equipment, filling units and other types of special

machines.

PSx3xxDN positioning systems convert a digital positioning signal into an angle of

rotation.

2.2 Installation

Hollow shaft:

The PSx3xxDN is mounted onto the machine by sliding the hollow shaft of the

positioning gear onto the axis to be driven and then securing it with an adjustable

collar (recommended diameter of the axis is either 8h9 or 14h9; wrench torque for

screw: 1.5Nm). The adjustable collar should be tightened only just to the point where

it can no longer rotate freely.

Securing the pin under the hollow shaft into an appropriate bore will prevent further

rotation.\line (see drawing)

Page 6

PSx3xxDN Instruction Manual

6

Solid shaft:

The PSx3xxDN is mounted on the machine by fixing the solid shaft with coupling and

intermediate flange to the axis of the machine.

Never apply force to the housing cover, e.g., for supporting weight.

Driving the PSx3xxDN rearward is prohibited (e.g. it’s not allowed to turn

the output shaft by an external force).

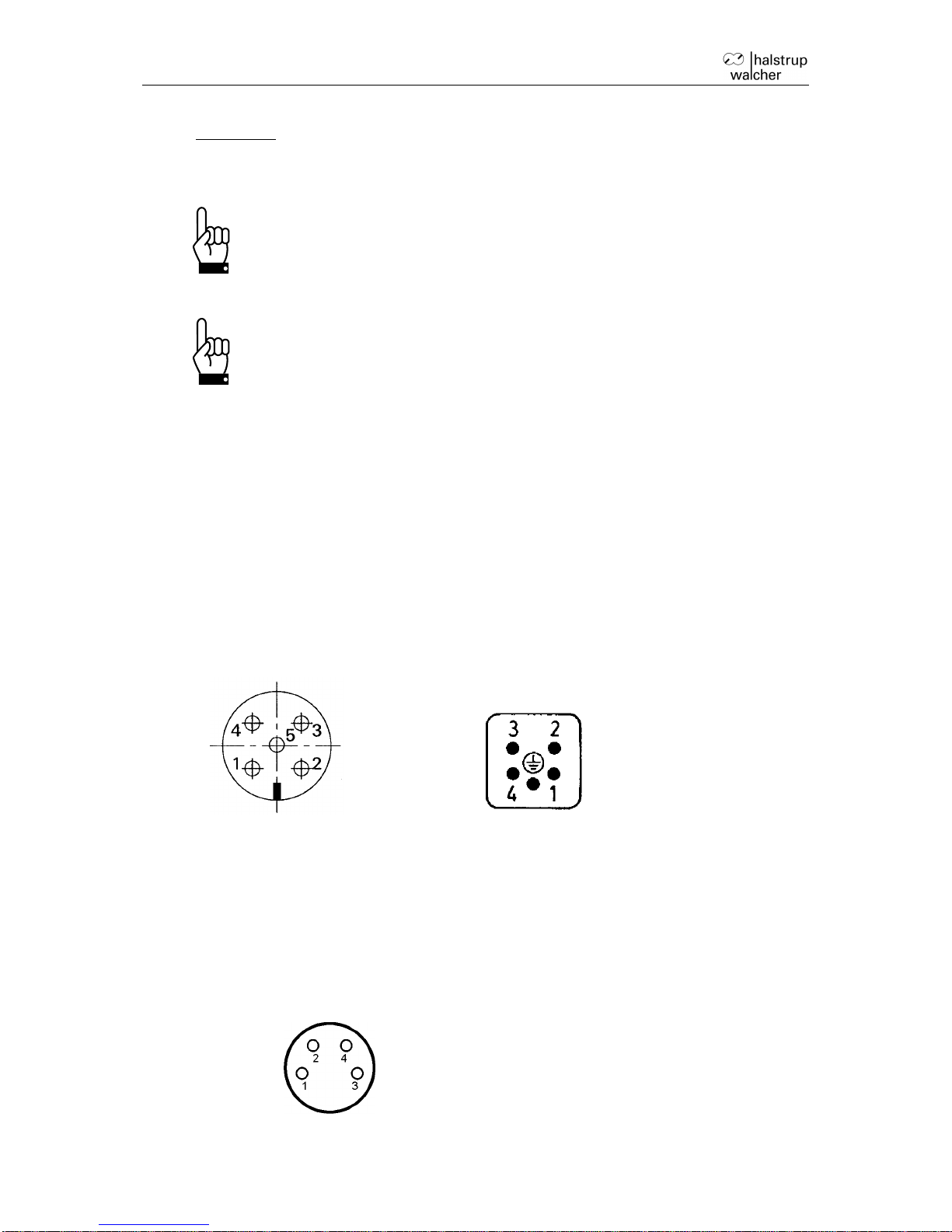

2.3 Pin assignment

For the supply voltage either a Binder series 715 (B-coded) round, 5-pin plug for PSE

and PSS devices or a 5-pin Harting plug with protective sleeve (HAN4A) for the

PSE34xx devices is located in the housing cover of the PSx3xxDN.

A series 713 (A coded) 5-pin round socket and 5-pin plug are provided for connecting

the CAN bus.

A Binder series 718 4-pin plug is used to connect the jog keys (optional).

Connector for supply to motor:

Round plug Harting plug

(external top view)

1 +24V motor

2 GND motor

3 not assigned

4 not assigned

5 housing/air drill

Connector for jog keys:

(external top view)

1 +24V (output)

2 forward key

3 reverse key

4 ground

Page 7

PSx3xxDN Instruction Manual

7

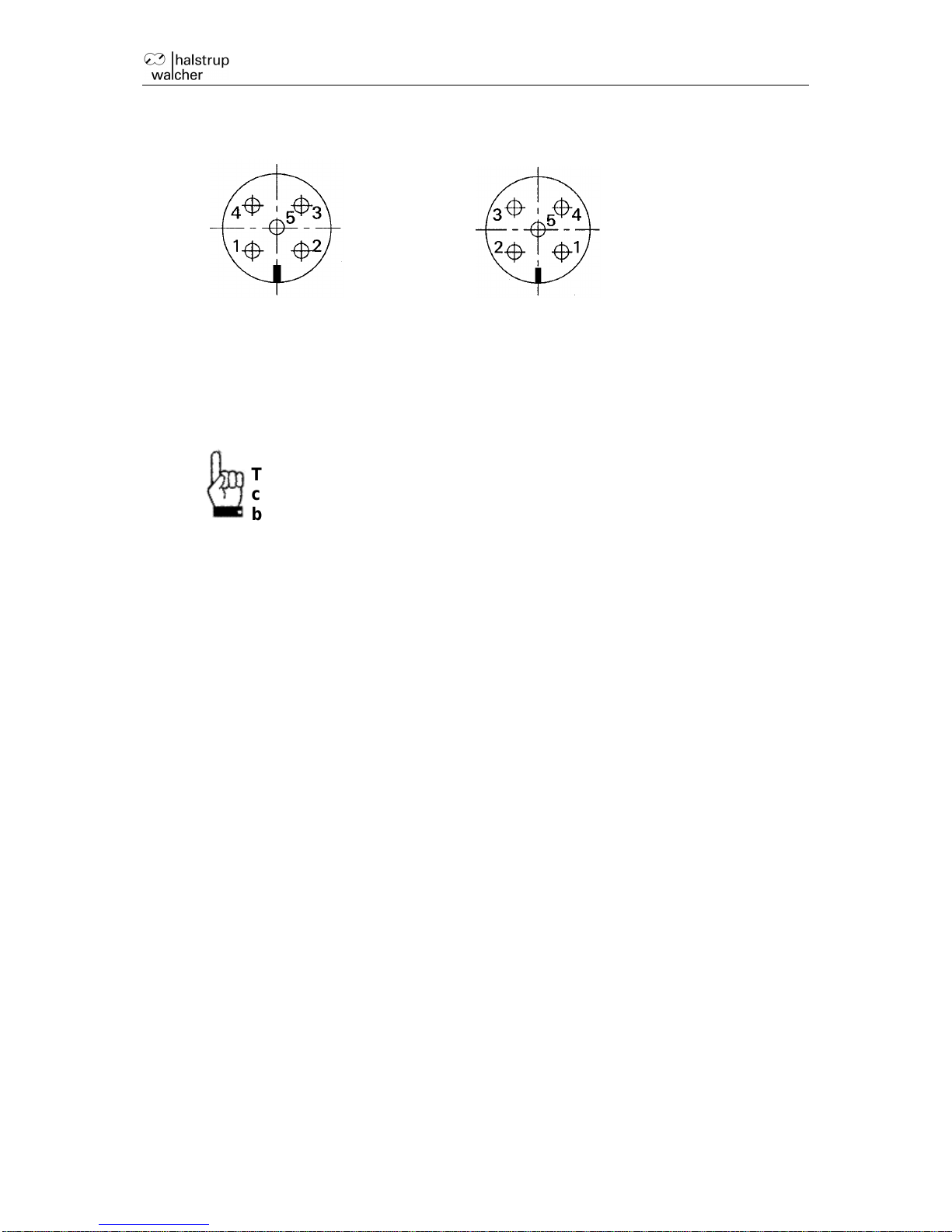

Round plug for CAN bus: Round socket for CAN bus:

(external top view) (external top view)

1 shield

2 +24V control module

3 GND

4 CAN_H

5 CAN_L

To prevent the ingression of fluids into the PSW-housing during

cooldown, use a special cable with an airtube for pressure

balancing of your PSW.

Electrical grounding

Next to the connecting plugs there is a M4 stud bolt. It is recommended to connect

the positioning system with a cable as short as possible to the machine base. The

minimum wire cross section therefor is 1.5mm².

2.4 Setting the device address and baud rate

Removing the protective cap provides access to two rotary switches for setting the

device address at the bus and a 2-pin sliding switch for setting the baud rate.

The rotary switches indicate the tens and ones places of the address selected. If the

switches are resting in positions between 64 and 99, the address is set using

DeviceNet (PSE object; class 100, instance 1, attribute 38; starting from software

version 147).

The delivery setting is 99, the PSx3xxDN reports to the bus with the address 63.

If the switches have been used to set the address (i.e. the switch setting is < 64), this

value cannot be changed via DeviceNet.

The yellow LED represents the state of the motor supply voltage, the red and green

LEDs represent the DeviceNet state.

Page 8

PSx3xxDN Instruction Manual

8

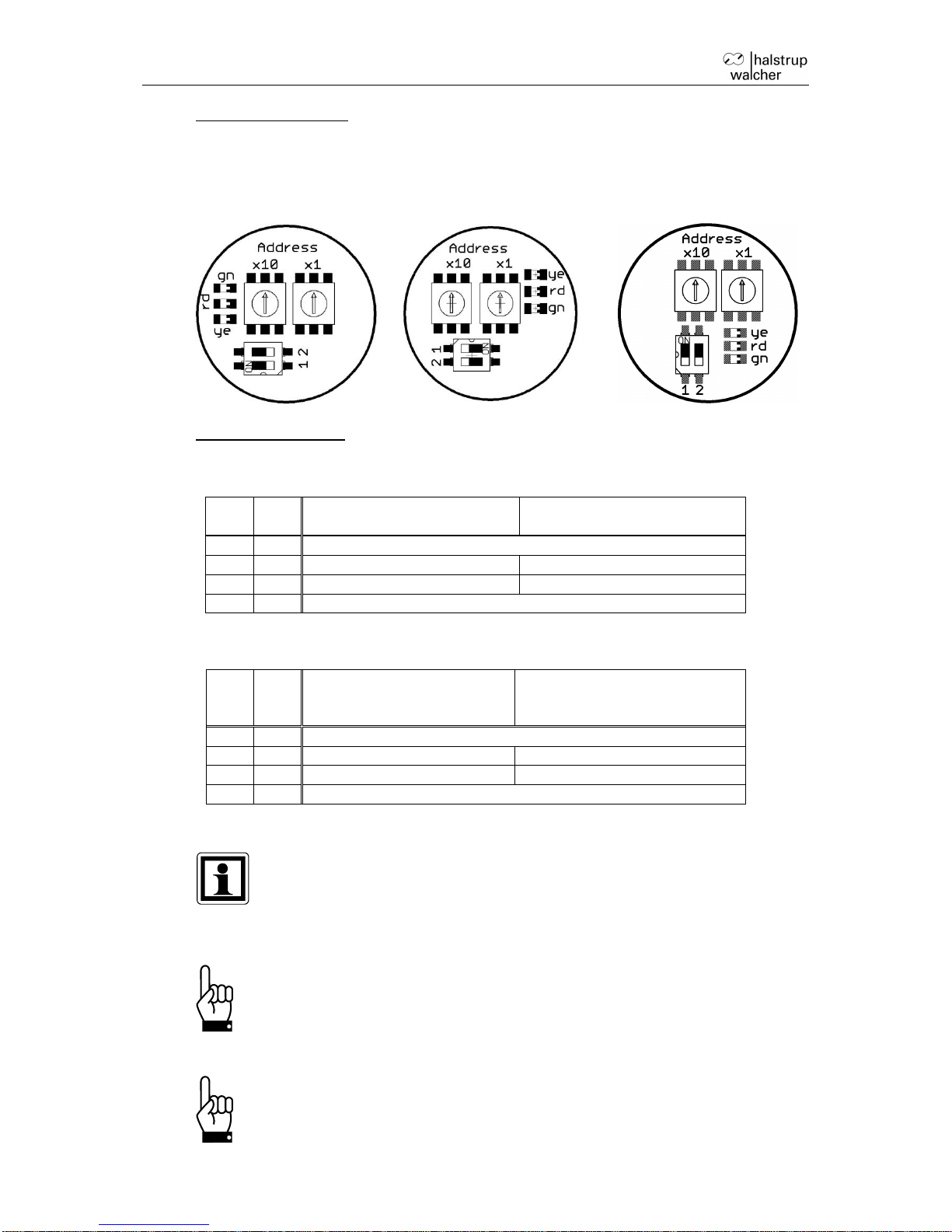

Switch configurations:

PSx30xDN, PSx31xDN-8,

PSx32xDN, PSE31xxDN

PSx31xDN-14, PSx33xDN

PSE 34xxDN

Setting the baud rate:

Up to firmware version 210:

1

2

PSx30xDN, PSx31xDN-8,

PSx32xDN, PSx31xxDN,

PSx31xDN-14, PSx33xDN,

PSx34xxDN,

OFF

OFF

125 kBaud

OFF

ON

500 kBaud

250 kBaud

ON

OFF

250 kBaud

500 kBaud

ON

ON

baud rate is set via bus (default = 125 kBaud)

For firmware version 211 and higher

1

2

PSx30xDN, PSx31xDN,

PSx31xxDN, PSx32xDN,

PSx33xDN

PSx34xxDN,

OFF

OFF

125 kBaud

OFF

ON

500 kBaud

250 kBaud

ON

OFF

250 kBaud

500 kBaud

ON

ON

baud rate is set via bus (default = 125 kBaud)

If the device names are given without the diameter of the output shaft (-8, -

14), the relevant information is valid for all offered output shafts (applies

throughout the document).

‘x’ in the device name stands for a number in the range 0..9. ‘xx’ in the

device name stands for a number in the range 10..999.

Important: Always replace the protective cap after setting the address.

This will prevent dust and contaminants from entering the device.

In some stainless steel variants the protective cap is not present. In this

case, device address and baud rate can only be set via bus.

Page 9

PSx3xxDN Instruction Manual

9

2.5 Start-up

Positioning sequence (with reference loop)

The PSx3xxDN distinguishes between the following steps of a positioning sequence

(Presumption: the target position is always approached through forward motion):

1. New position value is larger than the current value: position approached directly.

2. New position value is smaller than the current value: the device reverses an

additional 5/8 of one rotation and approaches the exact position after resuming

forward motion.

3. New position value after reverse run without loop: the device always approaches

the position by moving in forward direction; if necessary, it will first reverse by 5/8

of a rotation.

Once the target position has been reached, the device compares it to the internal

absolute encoder status. If a discrepancy is detected, the device then sets the “error”

bit (bit 9 in the status word).

Positioning sequence (without loop)

The “positioning without loop” mode is used primarily for moving the small distances

involved in fine adjustments. In this case, each position is approached directly. This

does NOT eliminate any play present in the spindle in question. The PSx3xxDN

internal gear backlash does not play a role in this case, as position data are acquired

directly at the output shaft.

Runs which involve specifically a block run (e.g. reference runs on block),

may only be started with reduced torque (max. torque max. 10% of the

nominal torque).

2.6 CAN Bus

A DeviceNet protocol corresponding to ODVA CIP Networks Library Volume One

Edition 3.1 and Volume Three Edition 1.3 is the protocol used for the CAN bus

interface:

A group 2 server with UCMM support

2 explicit connections to the master

4 fixed mapping assemblies

I/O messages via poll, bit strobe and change-of-state/cyclic

Multicast poll is not supported

Heartbeat, default = inactive

DeviceNet LED that displays status as follows:

off:

either the device is switched off or no CAN bus is connected

green, steady:

CAN communication OK, device operational

green, flashing:

either no UCMM connection to the master or no learning run has been

performed

Page 10

PSx3xxDN Instruction Manual

10

red, flashing:

relatively minor error, at least one I/O connection has timed out

red, steady:

major error, e.g., bus conflict with another station

red-green, flashing:

communication error

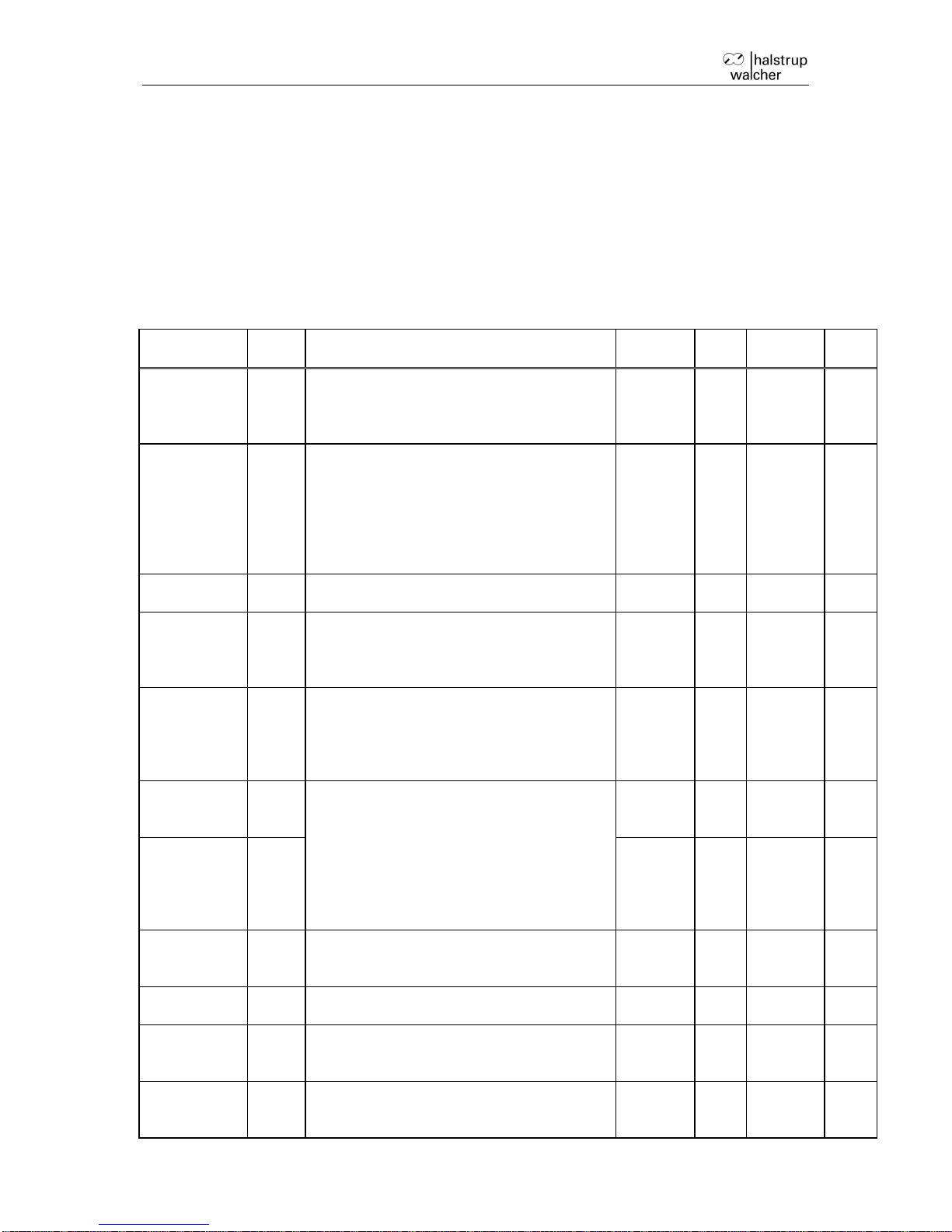

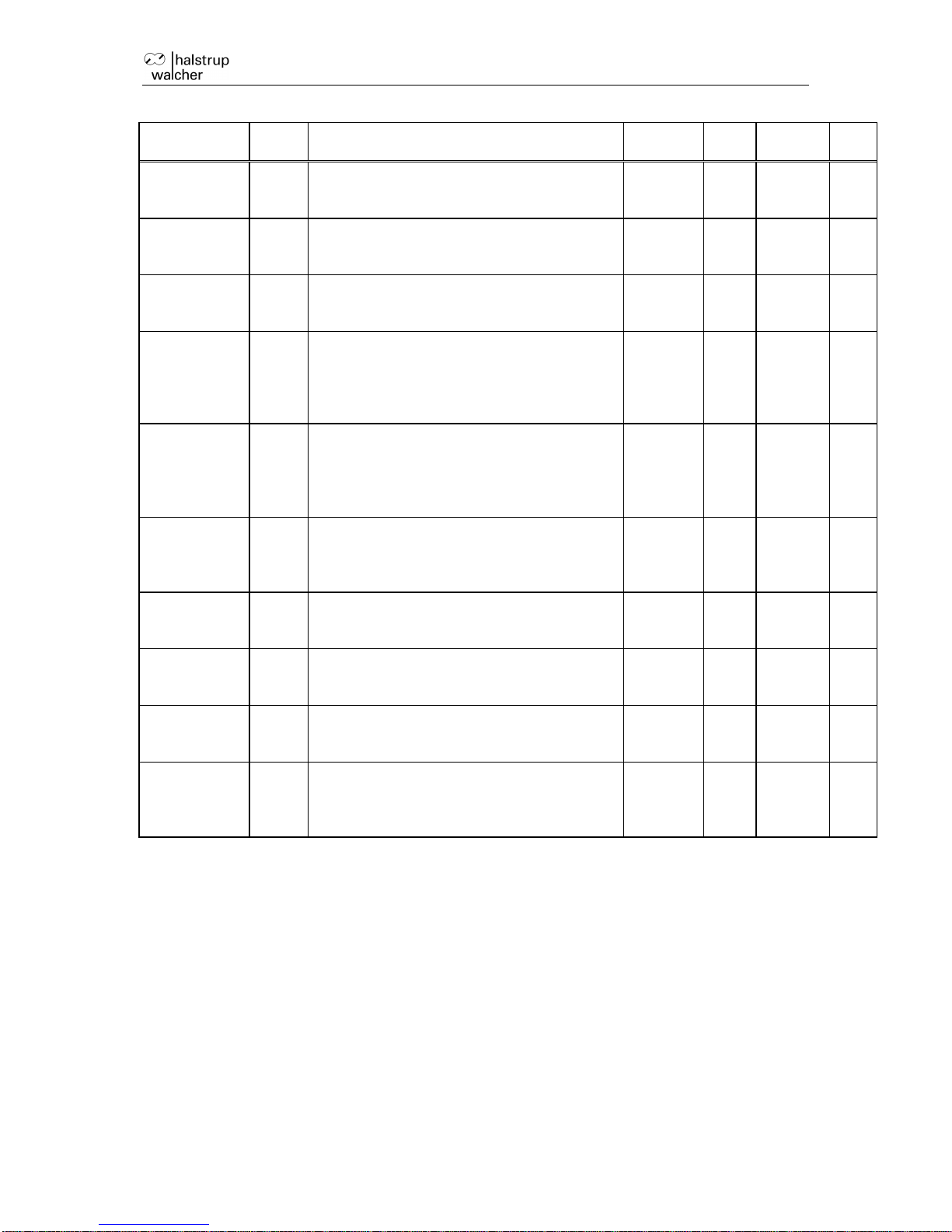

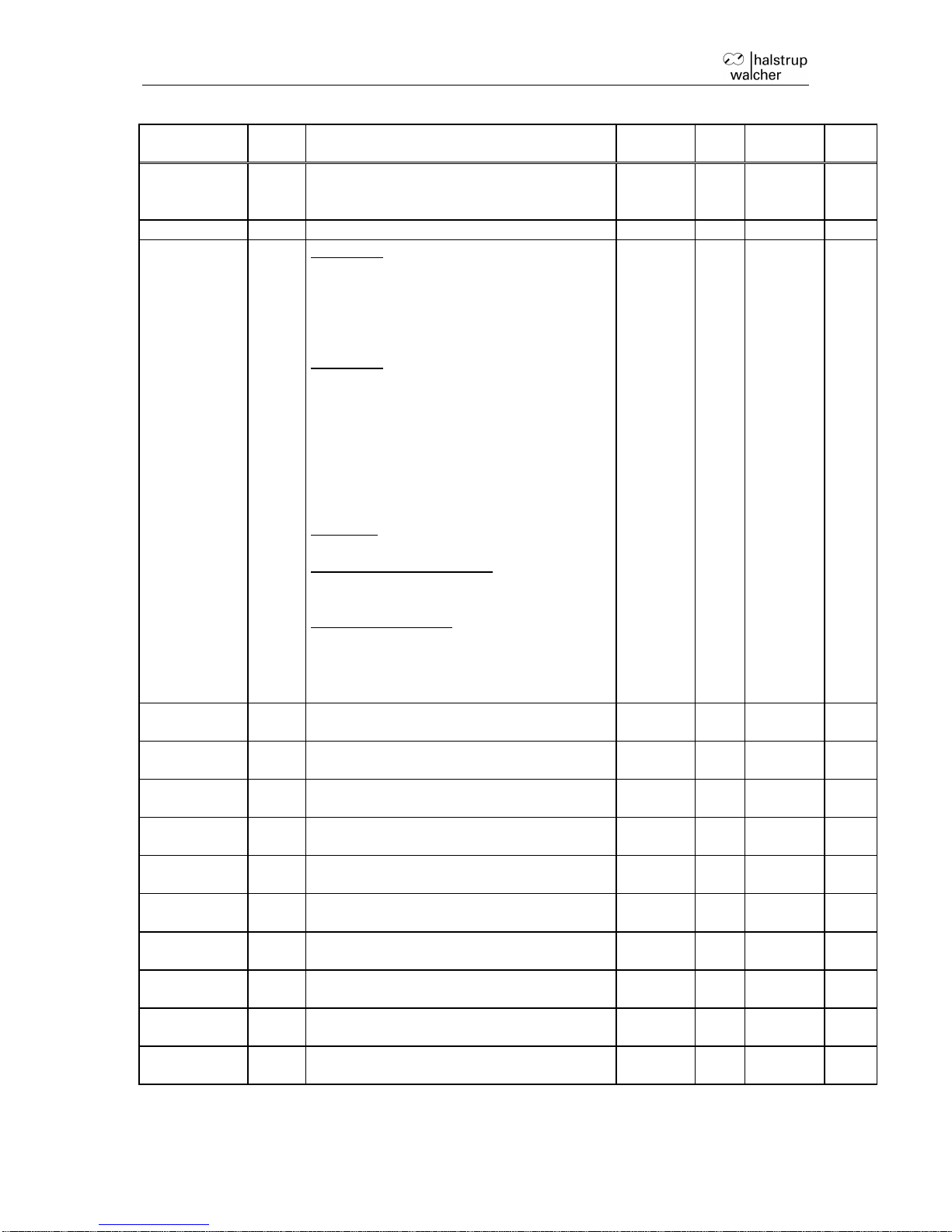

a) Table of implemented attribute entries

The following attributes are part of the PSE object (class ID 100), 1st instance:

Description

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

target value

1

target position to be achieved

value in 1/100 mm (for default settings of

numerator, Attr. 16 and denominator, Attr.

17)

31 bit

no 0 R/W

actual value

3

current actual position

value in 1/100 mm (for default settings of

numerator, Attr. 16 and denominator, Attr.

17)

Writing onto this index number causes the

current position to be "referenced" onto

the transferred value

31 bit

no R/W

reference

value

4

correction factor for the target, actual and

limit switch values

31 bit

yes 0 R/W

drag error

5

maximum drag error before the “drag

error" bit is set.

Value given in increments (at a resolution

of 0.5 mm)

20...1000

16 bit

yes

40

R/W

positioning

window

6

permissible difference between target and

actual values for “position reached” bit

The maximum value that can be set

changes according to the same factor as

the resolution

1...100

16 bit

yes 2 R/W

actual value

assessment,

numerator

16

These values can be used to set a

desired user resolution to the drive.

For a numerator factor of 400, the

denominator factor holds the spindle pitch

per resolution

e.g.: spindle pitch 1.5 mm with resolution

1/100 mm:

numerator = 400, denominator = 150

1...10000

16 bit

yes

400

R/W

actual value

assessment,

denominator

17

1...10000

16 bit

yes

400

R/W

target rpm

posi

18

value in rpm

maximum rpm to be used for positioning

runs

see table

16 bit

yes

see table

R/W

target rpm

hand

19

value in rpm

maximum rpm to be used for manual runs

see table

16 bit

yes

see table

R/W

maximum

torque

20

Applies after completion of start phase

(during start phase the value of Attr. 24

applies); value in cNm

see table

16 bit

yes

see table

R/W

upper limit

22

maximum permitted target position

permissible values: (-252...+509)*spindle

pitch + reference value

31 bit

yes

101200

R/W

Page 11

PSx3xxDN Instruction Manual

11

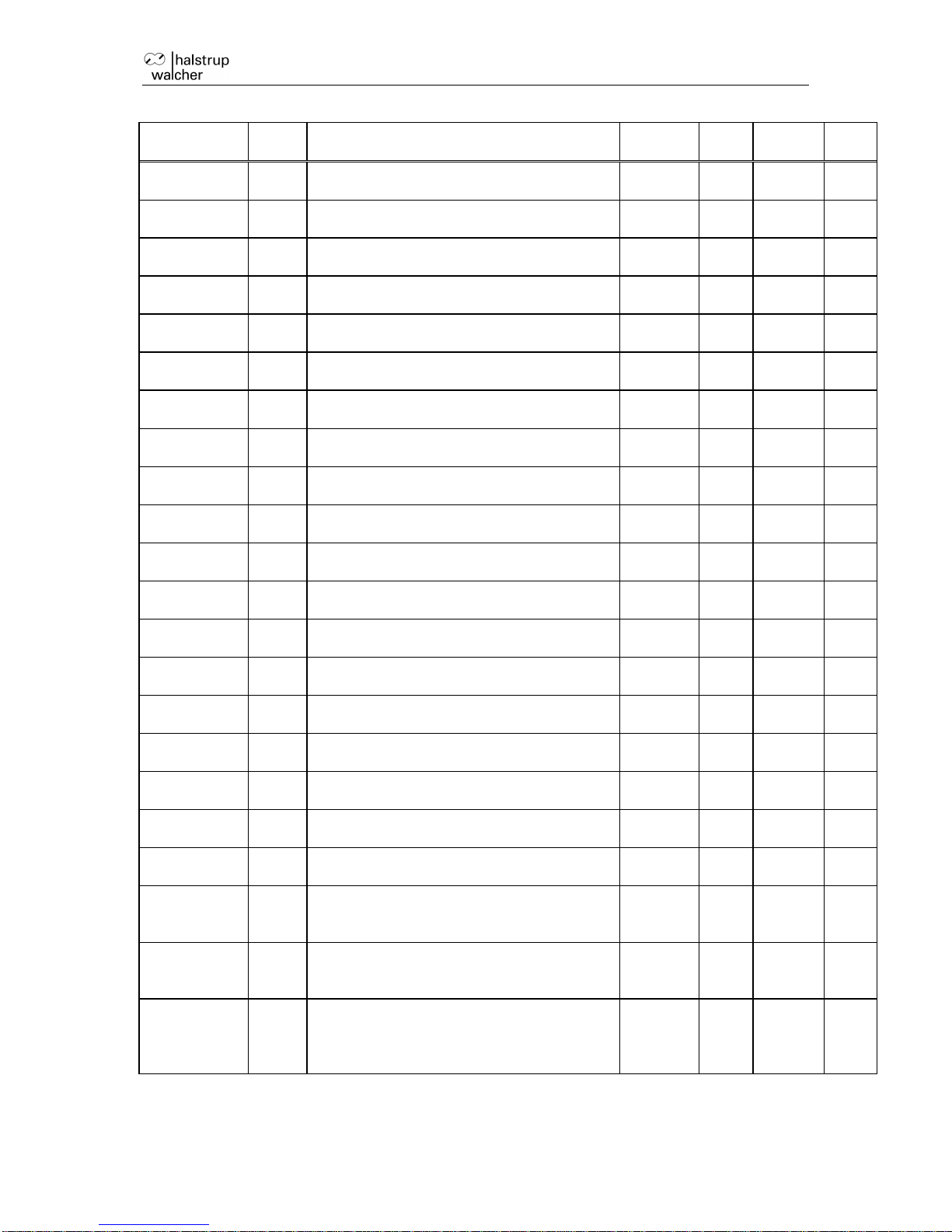

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

lower limit

23

minimum permissible target position

permissible values: upper limit -

0...250*spindle pitch + reference value

31 bit

yes

1200

R/W

maximum

start-up

torque

24

value in cNm

see table

16 bit

yes

see

table

R/W

time period

for start-up

torque

25

value in msec

10...1000

16 bit

yes

200

R/W

rpm limit for

aborting run

26

value in % of the target rpm

30...90

16 bit

yes

60

(PSx3110

and

PSx3125)

30

(all others)

R/W

time elapsed

until speed

falls below

rpm limit for

aborting run

27

value in msec

50...500

16 bit

yes

200

R/W

length of loop

31

minimum number of increments which the

drive moves in a pre-defined direction

when approaching a target position

value in increments (value = 0 no loop)

0.025…1

rotations

or 0

32 bit

yes

250

R/W

maximum

rpm, counterclockwise

32

value in rpm

see table

16 bit

yes

see

table

R/W

maximum

rpm,

clockwise

33

value in rpm

see table

16 bit

yes

see

table

R/W

size of

individual

increment

34

number of increments when external keys

pressed (or when activating a jog run bit)

for a short-time

1...100

16 bit

yes 1 R/W

idle period for

manual run

35

Span of time a manual run key must be

pressed (or a jog run bit must be

activated) in order to begin a manual run

value in steps of 5 msec

20...2000

16 bit

yes

200

R/W

Page 12

PSx3xxDN Instruction Manual

12

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

control word

36

Bit 0: manual run to larger values

Bit 1: manual run to smaller values

Bit 2: transfer target value (when

transferring a target value with the help of

the poll I/O connection, a positioning run is

only started if this bit is set)

Bit 3: release for manual run in jog key

mode: if this bit is not set, only single steps

are possible in jog key mode

Bit 4: release: the axle will only run if this

bit is set (exception is the jog key mode

with the external keys or with bits 8/9)

Bit 5: release for jog key mode with the

external keys: If the CAN bus is

connected, the external keys are only

active if this bit is set

Bit 6: run without loop

Bit 7: start initial reference loop

Bit 8: jog run to larger values

Bit 9: jog run to smaller values

Bit 10: release readjustment

Bit 11: execute braking-free-run

Bit 12: run with drag error correction

All other bits must be set to 0!

16 bit

no 0 R/W

status word

37

Bit 0: target position reached

Bit 1: drag error

Bit 2: reverse jog key active

Bit 3: forward jog key active

Bit 4: motor power present

Bit 5: positioning run aborted

Bit 6: drive is running

Bit 7: temperature exceeded

Bit 8: movement opposite loop direction

Bit 9: error

Bit 10: positioning error (block)

Bit 11: manual displacement

Bit 12: incorrect target value

Bit 13: motor power was missing

Bit 14: positive range limit

Bit 15: negative range limit

0...FFFF

h

16 bit

no R

CAN address

38

address of drive (if set by CAN bus)

This value cannot be changed if the

address switches are used (i.e. the switch

setting is < 64).

This attribute exists for software versions

starting from version 147.

0...63

8 bit

yes

63

R/W

Page 13

PSx3xxDN Instruction Manual

13

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

baud rate

39

0: 125 kBaud 1: 250 kBaud

2: 500 kBaud

This value cannot be changed if the baud

rate switch is used (i.e. the switch setting

is not ON-ON).

This attribute exists for software versions

starting from version 147.

0...2

8 bit

yes 0 R/W

upper

mapping end

40

definition of the positioning range relative

to the absolute measuring system

permissible values:

(1 + ref.value) … (204800 *

denominator / numerator - 1 + ref.value)

31 bit

yes

102400

R/W

holding

torque

43

maximum holding torque at standstill in

cNm

see table

16 bit

yes

see table

R/W

direction of

rotation

44

0: clockwise (as seen at the output shaft)

1: counter clockwise

0 or 1

16 bit

yes 0 R/W

running

direction for

approaching

target

positions

45

0:with 5/8 forward rotation

1:with 5/8 reverse rotation

(5/8 rotation is the default value, see attr.

31)

0 or 1

16 bit

yes 0 R/W

idle period

46

idle period in msec when reversing the

direction of rotation

10...10000

16 bit

yes

10

R/W

actual rpm

48

value in rpm

16 bit

no R

maximum

torque

49

maximum torque occurring during the

most recent run (start phase, during

which the maximum start-up torque

applies, see attr. 24/25, and the phase

when the drive is braking down, are not

considered)

value in cNm

16 bit

no R

actual torque

51

value in cNm

16 bit

no R

U control

58

current supply voltage for control unit

given in increments of 0.1 V

16 bit

no R

U motor

59

current supply voltage for motor given in

increments of 0.1 V

16 bit

no R

Umot limit

60

voltage limit for bit ‘motor power present’

given in increments of 0.1 V

180...240

16 bit

yes

185

R/W

Umot filter

61

average time for measuring current

power to motor; given in 5 msec

increments

100...100

16 bit

yes

100

R

temperature

limit

62

upper temperature limit in °C

10...70

16 bit

yes

70

R

device

temperature

63

internal device temperature in °C

16 bit

no R

production

date

64

year and week of manufacturing

(given as an integer)

YYWW

16 bit

yes R

serial

number

65

serial device number

0...65535

16 bit

yes R

Page 14

PSx3xxDN Instruction Manual

14

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

waiting time

for brake

(end of run)

69

time period after the end of run, in which

the brake stays released (value in msec)

0...3000

16 bit

yes

1000

R/W

version

78

software version number

16 bit

yes R

delivery state

79

writing ‘-1’:

generates the delivery state without

modifying the CAN address and the baud

rate (starts initial reference loop, then

positioning to the middle of the

measurement range)

writing ‘-2’:

generates the delivery state (sets CAN

address attr. 38 to 63, baud rate attr. 39

to 125 kBaud, starts initial reference loop,

then positioning to the middle of the

measurement range)

A different CAN address or baud rate is

only active after reset or reset

communication!

writing ‘1’:

saves all parameters in the EEPROM

reading directly after boot:

0 content of memory correct

≠ 0 content of memory incorrect

reading after saving:

0 saving finished successfully

≠ 0 saving is still in progress or is

finished incorrectly (the time for saving is

up to 100 msec)

-1, -2 or

1

16 bit

no R/W

control word,

bit 0

80

manual run to larger values

0,1

8 bit

no R/W

control word,

bit 1

81

manual run to smaller values

0,1

8 bit

no R/W

control word,

bit 2

82

transfer target value

0,1

8 bit

no R/W

control word,

bit 3

83

release for manual run in jog key mode

0,1

8 bit

no R/W

control word,

bit 4

84

release

0,1

8 bit

no R/W

control word,

bit 5

85

release for jog key mode with the external

keys

0,1

8 bit

no R/W

control word,

bit 6

86

run without loop

0,1

8 bit

no R/W

control word,

bit 7

87

start initial reference loop

0,1

8 bit

no R/W

control word,

bit 8

88

jog run to larger values

0,1

8 bit

no R/W

control word,

bit 9

89

jog run to smaller values

0,1

8 bit

no R/W

Page 15

PSx3xxDN Instruction Manual

15

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

control word,

bit 10

90

release readjustment

0,1

8 bit

no R/W

control word,

bit 11

91

execute braking-free-run

0,1

8 bit

no R/W

control word,

bit 12

92

run with drag error correction

0,1

8 bit

no R/W

status word,

bit 0

96

target position reached

0,1

8 bit

no R

status word,

bit 1

97

drag error

0,1

8 bit

no R

status word,

bit 2

98

reverse jog key active

0,1

8 bit

no R

status word,

bit 3

99

forward jog key active

0,1

8 bit

no R

status word,

bit 4

100

motor power present

0,1

8 bit

no R

status word,

bit 5

101

positioning run aborted

0,1

8 bit

no R

status word,

bit 6

102

drive is running

0,1

8 bit

no R

status word,

bit 7

103

temperature exceeded

0,1

8 bit

no R

status word,

bit 8

104

movement opposite loop direction

0,1

8 bit

no R

status word,

bit 9

105

error

0,1

8 bit

no R

status word,

bit 10

106

positioning error (block)

0,1

8 bit

no R

status word,

bit 11

107

manual displacement

0,1

8 bit

no R

status word,

bit 12

108

incorrect target value

0,1

8 bit

no R

status word,

bit 13

109

motor power was missing

0,1

8 bit

no R

status word,

bit 14

110

positive range limit

0,1

8 bit

no R

status word,

bit 15

111

negative range limit

0,1

8 bit

no R

waiting time

for brake

(begin of run)

146

time period before the begin of run, in

which the brake can be released without

the motor is moving (value in msec)

0...2000

16 bit

yes

150

R/W

number of

braking-free

steps

147

number of steps for the braking-free-run

1...50

16 bit

yes

see

table

R/W

maximum

holding

torque at end

of run

153

value in cNm

see table

16 bit

yes

see

table

R/W

Page 16

PSx3xxDN Instruction Manual

16

Name

Attr.

No.

Function

Range of

value

Back

up

Delivery

State

R/W

duration of

maximum

holding

torque at end

of run

154

time period at end of run, in which the

‘maximum holding torque at end of run’

applies (value in msec)

0...1000

16 bit

yes

200

R/W

acceleration

155

value in rpm per sec.

see table

16 bit

yes

see

table

R/W

deceleration

156

value in rpm per sec.

see table

16 bit

yes

see

table

R/W

10 general

purpose

registers

157…

166

to archive any kind of data (e.g. the

function of a drive within an installation

16 bit

yes 0 R/W

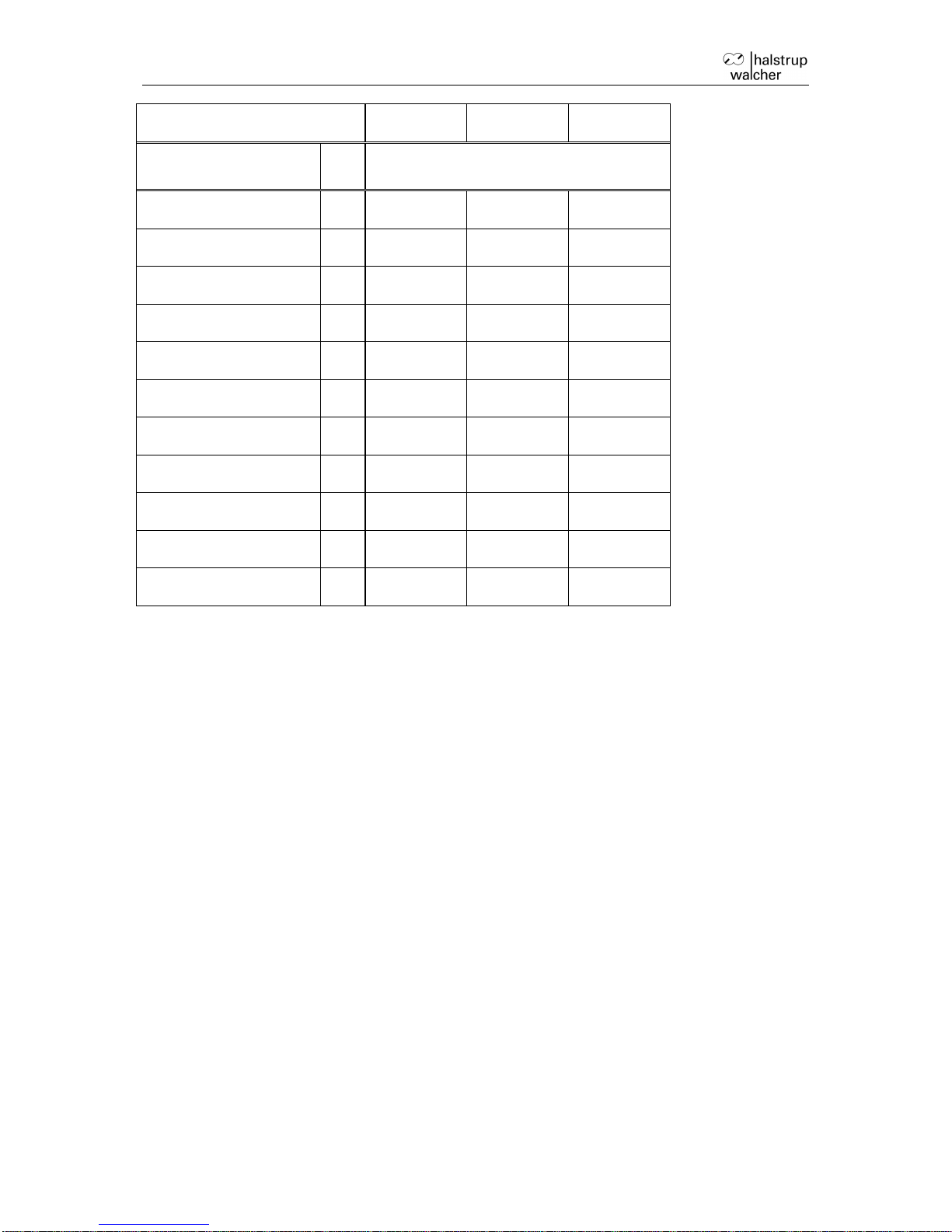

Table of rated speed and torque values for the various device models

Device model

PSE and PSS

301-x

311-x

302-x

312-x

305-x

315-8

322-14

332-14

325-14

335-14

328-14

Name

Attribute

No.

Range of value

Delivery State

target rpm

posi

18

15...230

230

10...150

150

3...70

70

20...200

170

10...100

85

5...45

45

target rpm

hand

19

15...230

80

10...150

50

3...70

20

20...200

80

10...100

40

5...45

22

max. rpm,

counter

clockwise

32

15...230

230

10...150

150

3...70

70

20...200

170

10...100

85

5...45

45

max. rpm,

clockwise

33

15...230

230

10...150

150

3...70

70

20...200

170

10...100

85

5...45

45

acceleration

155

97...600

600

50...400

400

23...130

130

97...525

525

50...260

260

22...100

100

deceleration

156

97...600

600

50...400

400

23...130

130

97...525

525

50...260

260

22...100

100

maximum torque

20

2...100

100

10...200

200

50...500

500

10...200

200

20...400

400

80...800

800

maximum startup torque

24

2...125

125

10...250

250

50...600

600

10...250

250

20...500

500

80...960

960

max. holding

torque

43

0...90

30

0...150

50

0...300

100

0...100

35

0...200

70

0...450

150

max. holding

torque at end of

run

153

0...180

60

0...300

100

0...600

200

0...200

70

0...400

140

0...900

300

number of

braking-free

steps

147

1...50

4

1...50

4

1...50

3

1...50

4

1...50

4

1...50

3

Page 17

PSx3xxDN Instruction Manual

17

Device model

PSW

301-x

311-x

302-x

312-x

305-x

315-8

322-14

332-14

325-14

335-14

328-14

Name

Attri

bute

No.

Range of value

Delivery State

target rpm

posi

18

15...180

180

10...125

125

3...60

60

20...150

125

10...80

60

5...35

35

target rpm

hand

19

15...180

80

10...125

50

3...60

20

20...150

80

10...80

40

5...35

22

max. rpm, counter

clockwise

32

15...180

180

10...125

125

3...60

60

20...150

125

10...80

60

5...35

35

max. rpm, clockwise

33

15...180

180

10...125

125

3...60

60

20...150

125

10...80

60

5...35

35

acceleration

155 97...600

600

50...400

400

23...130

130

97...525

525

50...260

260

22...100

100

deceleration

156 97...600

600

50...400

400

23...130

130

97...525

525

50...260

260

22...100

100

maximum torque

20

2...100

100

10...200

200

50...500

500

10...200

200

20...400

400

80...800

800

maximum start-up

torque

24

2...125

125

10...250

250

50...600

600

10...250

250

20...500

500

80...960

960

max. holding torque

43

0...90

30

0...150

50

0...300

100

0...100

35

0...200

70

0...450

150

max. holding torque

at end of run

153 0...180

60

0...300

100

0...600

200

0...200

70

0...400

140

0...900

300

number of brakingfree steps

147 1...50

4

1...50

4

1...50

3

1...50

4

1...50

4

1...50

3

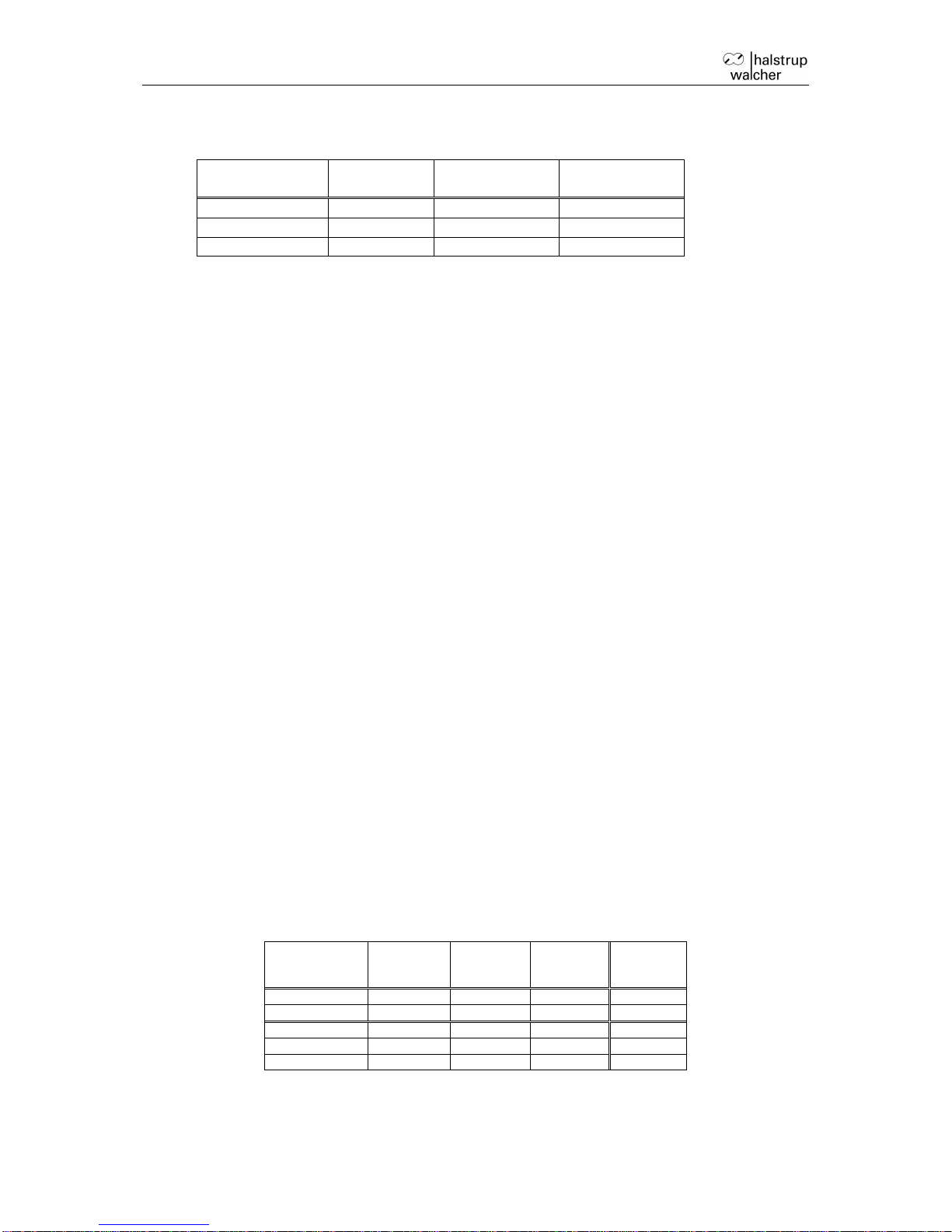

Device model

PSE

3110-14

3125-14

3410-14

Name

Attri

bute

No.

target rpm

posi

18

1…30

30

1…12

12

10...100

100

target rpm

hand

19

1…30

12

1…12

5

10...100

40

max. rpm, counter

clockwise

32

1…30

30

1…12

12

10...100

100

max. rpm, clockwise

33

1…30

30

1…12

12

10...100

100

acceleration

155

9…50

50

4…20

20

20...350

350

deceleration

156

9…50

50

4…20

20

20...350

350

maximum torque

20

100...1000

1000

250...2500

2500

100...1000

1000

maximum start-up

torque

24

100...1200

1200

250...3000

3000

100...1200

1200

max. holding torque

43

0...600

200

0...1250

450

0...300

200

max. holding torque at

end of run

153

0...1200

400

0...2500

900

0...600

400

number of braking-free

steps

147

1...50

3

1...50

3

1...50

4

Page 18

PSx3xxDN Instruction Manual

18

Device model

PSE

3210-14

3310-14

3218-14

3325-14

Name

Attri

bute

No.

Range of value

Delivery State

target rpm

posi

18

5…40

40

3…22

22

2…12

12

target rpm

hand

19

5…40

20

3…22

10

2…12

6

max. rpm, counter

clockwise

32

5…40

40

3…22

22

2…12

12

max. rpm, clockwise

33

5…40

40

3…22

22

2…12

12

acceleration

155

25…130

130

15…70

70

10...50

50

deceleration

156

25…130

130

15…70

70

10...50

50

maximum torque

20

100...1000

1000

200...1800

1800

300...2500

2500

maximum start-up

torque

24

100...1200

1200

200...2000

2000

300...3000

2800

max. holding torque

43

0...500

200

0...900

300

0...1200

400

max. holding torque at

end of run

153

0...1000

300

0...1800

600

0...2500

800

number of braking-free

steps

147

1...50

4

1...50

4

1...50

4

b) UCMM connection

Because the PSxxxDN is UCMM capable, the only way to communicate with the

device is through a UCMM-compliant connection.

The PSxxxDN only supports the 8/8 body format, which means that the UCMM

request parameters are fixed as follows:

Source MAC ID = address of the master

Service code = 0x4B

Requested message body format = 0

Group select = 3

Source message ID = 0

The PSxxxDN will then confirm the connection request, whereby the connection

instance ID is 5 (provided this is the first time the device is establishing a UCMM

connection).

A (random) message must now be sent to the device on a cyclical basis (the standard

expected packet rate is 10 sec.) in order to keep the connection active. Otherwise,

this value must be changed (a value of 0 deactivates the monitoring function).

Explicit messages may be sent to the device from now on, whereby the

corresponding ID can be determined from the following parameters:

Message ID = 0

Source MAC ID = address of the master

Message group = 3

Page 19

PSx3xxDN Instruction Manual

19

Deactivating timeout monitoring for the UCMM connection, for instance, requires the

following explicit message:

Message ID = 0

Destination MAC ID = slave address

Service code = 0x10

Class ID = 5

Instance ID = 5

Attribute ID = 9 (expected packet rate)

Value = 0x0000 (16 bit)

c) Explicit connection

Explicit messages can be used to read and write the attributes from a).

Identifier:

Message ID = 0

Source MAC ID = address of the master

Message group = 3

Content:

Destination MAC ID = slave address

Service code = 0x10 (write); 0x0E (read)

Class ID = 100

Instance ID = 1

Attribute ID according to list a)

Value (if written)

d) I/O connections

The PSx3xxDN supports the following types of I/O messages:

Poll (class ID 5, instance 2)

Bit strobe (class ID 5, instance 3)

Change-of-state/cyclic (class ID 5, instance 4), with or without master

acknowledge

Setting up an I/O connection first requires the use of an explicit connection to allocate

the desired I/O connection; the corresponding identifiers are then reserved and the

connection is set to "configuring" status. The next step is to set the expected packet

rate, after which point the I/O connection will be in place.

The expected packet rate is always attribute 9 (for a given instance in class 5).

WARNING: Activating the change-of-state/cyclic connection may cause the CAN bus

to be flooded with messages as soon as the EPR has been set; to prevent this from

occurring, the inhibit time (class ID 5, instance 4, attribute 17), which indicates the

minimum amount of time that must elapse before a change-of-state event actually

triggers an I/O message, should be set prior to establishing this type of connection.

Only then should the EPR be set.

e) Mapping I/O assemblies

The following 4 assemblies are permanently stored in the PSx3xxDN:

Assembly object (class ID 4), instance 100, attribute 3:

Page 20

PSx3xxDN Instruction Manual

20

Bit

Byte

Meaning

Source

0-31

0-3

actual value

PSE object (class ID 100), instance 1, attr. 3

32-47

4-5

status word

PSE object (class ID 100), instance 1, attr. 37

48-63

6-7

actual rpm

PSE object (class ID 100), instance 1, attr. 48

Assembly object (class ID 4), instance 101, attribute 3:

Bit

Byte

Meaning

Source

0-16

0-1

status word

PSE object (class ID 100), instance 1, attr. 37

Assembly object (class ID 4), instance 103, attribute 3:

Bit

Byte

Meaning

Source

0-31

0-3

target value

PSE object (class ID 100), instance 1, attr. 1

32-47

4-5

control word

PSE object (class ID 100), instance 1, attr. 36

Assembly object (class ID 4), instance 104, attribute 3:

Bit

Byte

Meaning

Source

0-7 0 control word,

bit 4 (release)

PSE object (class ID 100), instance 1, attr. 36

These assemblies cannot be changed and no additional assemblies may be added.

f) Assigning mapping I/O assemblies to available I/O connections

The PSx3xxDN allows the user to change how mapping I/O assemblies are assigned

to available I/O connections. The current settings for each type of I/O connection are

recorded in the connection object (class ID 5), instance 0, attr. 100-104. The following

provides possible settings and default values:

Name

Attr.

No.

Function

Range of

values

Back

up?

Delivery

state

R/W

select

input_poll

100

assembly instance that the device uses

when establishing a poll connection for

sending messages to the master (i.e., for

a poll response message)

100, 101

8 bit

no

100

R/W

select

output_poll

101

assembly instance that the device uses

when establishing a poll connection for

receiving messages from the master (i.e.,

for a poll command message)

103

8 bit

no

103

R/W

select

input_bit

strobe

102

assembly instance that the device uses

when establishing a bit-strobe connection

for sending messages to the master (i.e.,

for a bit-strobe response message)

101

8 bit

no

101

R/W

select

output_bit

strobe

103

assembly instance that the device uses

when establishing a bit-strobe connection

for receiving messages from the master

(i.e., for a bit-strobe command message)

104

8 bit

no

104

R/W

select

input_COS

104

assembly instance that the device uses

when establishing a change-ofstate/cyclic connection for sending

messages to the master

100, 101

8 bit

no

100

R/W

Page 21

PSx3xxDN Instruction Manual

21

g) Identifiers used for available I/O connections

The identifiers used for available I/O connections can be determined from the

predefined master/slave connection set:

Bits for identifier

Meaning

10 9 8 7 6 5 4 3 2 1 0

1 0 slave MAC ID

1 0 1

poll command message (master)

0 1 1 1 1

slave MAC ID

poll response message (slave)

1 0 master MAC ID

0 0 0

bit-strobe command message (master)

0 1 1 1 0

slave MAC ID

bit-strobe response message (slave)

0 1 1 0 1

slave MAC ID

change-of-state/cyclic message (slave)

1 0 slave MAC ID

0 1 0

change-of-state/cyclic acknowledge message

(master)

h) Detailed description of status bits

Bit 0: target position reached

This bit is set:

- when a transferred target position has been reached successfully

- after running an initial reference loop, when the actual value corresponds to

the previously transferred target value

This bit is reset:

- after transferring a target position if the difference from the actual value is

larger than the positioning window (PSE object; class 100, instance 1,

attribute 6)

- by a manual run

- if an invalid target value has been transferred

- if rotated manually when on standstill

Bit 1: drag error

This bit is set:

- if, after the acceleration phase, the maximum speed setting has not been

achieved

This bit is reset:

- with each new run command

Bit 2: reverse jog key active

This bit is set:

- if Pin 3 on the key connector is connected with Pin 1 (+24V)

This bit is reset:

- if Pin 3 on the key connector is deconnected from Pin 1 (+24V)

Bit 3: forward jog key active

This bit is set:

- if Pin 2 on the key connector is connected with Pin 1 (+24V)

This bit is reset:

- if Pin 2 on the key connector is deconnected from Pin 1 (+24V)

Bit 4: motor power present

This bit is set:

- if the supply voltage to the motor is above the Umot limit (PSE object; class

100, instance 1, attribute 60) and below 30V

This bit is reset:

- if the supply voltage to the motor is below the Umot limit or above 30V

Page 22

PSx3xxDN Instruction Manual

22

Bit 5: positioning run aborted

This bit is set:

- if a positioning run is aborted because release in the control word has been

withdrawn

This bit is reset:

- when a new run command is transmitted

Bit 6: drive is running

This bit is set:

- when the drive is rotating

This bit is reset:

- when the drive is on standstill

Bit 7: temperature exceeded

This bit is set:

- if the internal device temperature device exceeds the limit value (PSE object;

class 100, instance 1, attribute 62)

This bit is reset:

- if the internal device temperature falls below the limit value by 5°C

Bit 8: movement opposite loop direction

This bit is set:

- during a manual run in the direction opposite that of the loop direction (a

subsequent manual run in the loop direction will not reset this bit)

- during a positioning sequence in the direction opposite that of the loop

direction

This bit is reset:

- when a transferred target position has been reached successfully (in the loop

direction)

- after the initial reference loop

Bit 9: error

This bit is set:

- if an internal problem is detected when calculating a position

No run commands (except the initial reference loop) can be executed when

the error bit is set!

This bit is reset:

- when an initial reference loop is completed correctly

Bit 10: positioning error (block)

This bit is set:

- if a positioning run is aborted because the device is overloaded (block,

extreme difficulty while running)

This bit is reset:

- by transmitting a new positioning command

- after an initial reference loop has been executed correctly

Bit 11: manual displacement

This bit is set:

- if, while on standstill, the drive is turned externally by more than the value in

the positioning window

This bit is reset:

- by transmitting a new positioning command

- after an initial reference loop has been executed correctly

Page 23

PSx3xxDN Instruction Manual

23

Bit 12: incorrect target value

This bit is set:

- when a transferred target value lies outside of the limit switches; also

caused, for instance, because of the actual value of the reference value (attr.

4)

- when a transferred target value lies inside of the limit switches; but because

of a necessary loop run the specified interval would be left

This bit is reset:

- by transmitting a valid target value

Bit 13: motor power was missing

This bit is set:

- if the power to the motor lies below the Umot limit (PSE object; class 100,

instance 1, attribute 60) or above 30V when initiating a positioning run or an

initial reference loop

- if during the run the voltage leaves the given corridor

This bit is reset:

- if the power to the motor is above the Umot limit and below 30V when

initiating a positioning run or an initial reference loop

Bit 14 / 15: positive / negative range limit

This bit is set:

- if the limit value is reached during a manual run (but not if reached during a

positioning run)

- if a limit value is modified such that the current position lies beyond the limit

- if, while on standstill, by means of an external force the drive is moved to a

position which is outside the area which is defined by the range limits

This bit is reset:

- by initiating a positioning run, an initial reference loop or a manual run

i) Detailed description of control bits

Bit 0: manual run to larger values

Bit 1: manual run to smaller values

Bit 2: transfer target value: When transferring a target value with the help of an I/O

connection, positioning will only take place if this bit is set.

Bit 3: Release for manual run in jog key mode: This bit must be set in order to

switch from jog key mode (run activated via the keys, if bit 5 is set; or via

command if bit 8 or 9 is set in the control word, if bits 4 and 5 are not set) to

manual run mode by holding down a key (or activating a jog run bit for a

longer time). Single increments are the only option in jog key mode if this bit is

reset.

Bit 4: Release: Run commands will only be executed if this bit is set (exception is

the jog key mode with the external keys or with bits 8/9 of the control word).

This bit must be set for positioning runs, manual runs and must not be set for

jog runs.

If this bit is cleared during a run, the run will be aborted and status bit 5 will be

set (‘positioning run aborted’).

Page 24

PSx3xxDN Instruction Manual

24

Bit 5: Release for jog key mode with the external keys: If the CAN bus is active, jog

key mode via the external keys is only possible if this bit is set and bit 4 is

reset. For jog key mode via CAN (bits 8 or 9 in the control word), this bit must

not be set.

Bit 6: Run without loop: If this bit is set during positioning runs, all target positions

will be approached directly (without loop).

Bit 7: Start initial reference loop: the device performs 5/8 of one rotation opposite to

the loop direction; it will then perform 5/8 of a rotation in loop direction at

manual run speed.

In earlier versions, this command had to be executed after switching on the

device; that is no longer the case.

Bit 8: Jog run to larger values: Comes up to a keystroke of forward key (bit 3 in the

status word). Bits 4 and 5 must not be set in this mode!

Bit 9: Jog run to smaller values: Comes up to a keystroke of reverse key (bit 2 in the

status word). Bits 4 and 5 must not be set in this mode!

Bit 10: Release readjustment: Only if this bit is set the drive readjusts when it is

displaced out of its position in the direction opposite to that of the loop

direction at the end of a run. If bit 6 („run without loop“) is being set, the drive

readjusts the position in both directions.

Bit 11: Execute braking-free-run: At the beginning of a positioning at first the brake is

released and the “waiting time for brake” is being awaited (attribute 146).

Within this time the brake should move towards its working position (in this

position of the brake the motor can move freely). After this waiting time the

motor moves a certain distance in both directions, in order to release a brake

which is eventually stucked. This distance (“number of braking-free steps”) is

being set in attribute 147. For the execution of this command, bit 4 has to be

set simultaniously.

Bit 12: Run with drag error correction: If the bit is set, the drive trys (under

consideration of the configured maximum torque) to compensate a drag error

which has been developped. By controling the rpm on a value which is slightly

above or below the configured ‘target rpm posi’ (attr. 18), the drag error

decreases. The drag error correction operates only in positioning runs, i.e. not

in manual runs or in jog key mode. Furthermore it operates only while

accelerating and cruising with constant rpm, not while decelerating. The timedependent setting value for the rpm while accelerating arises out of the rpm at

beginning of the positioning as well as the acceleration setting (attr. 155).

Bit 13: reserved, must be programmed to 0

Bit 14: reserved, must be programmed to 0

Bit 15: reserved, must be programmed to 0

Page 25

PSx3xxDN Instruction Manual

25

j) Quick test for checking the drive and the DeviceNet interface

Switch device off.

Set device address to 63.

Set baud-rate selector switch to 125 kBaud.

Connect both plugs for the motor supply voltage and the CAN plug.

Set the CAN receiver to 125 kBaud and activate.

Switch the device on.

The device will send 2 messages at an interval of precisely 1 sec. along with

the duplicate MAC ID check message (ID 0x5FF). The message contains the

serial number and production date.

Establish the UCMM connection:

781 3F 4B 00 30

Set the expected packet rate to 0 within 10 sec.:

601 3F 10 05 05 09 00 00

Set the target value to 5000, fragment 1:

601 BF 00 10 64 01 01 88 13

Set the target value to 5000, fragment 2:

601 BF 81 00 00

Set the control word to 0x14:

601 3F 10 64 01 24 14 00

The drive will move to position 5000.

Set the target value to 50000, fragment 1:

601 BF 00 10 64 01 01 50 C3

Set the target value to 50000, fragment 2:

601 BF 81 00 00

The drive will move to position 50000.

Page 26

PSx3xxDN Instruction Manual

26

3 Sequence of positioning steps

a) Positioning run

- In order to control the drive using I/O connections, you must first establish an explicit

connection using the UCMM; this connection is then used to allocate and configure

the desired I/O connection.

- Transfer target value:

- Poll I/O message with control word 14h and target value

OR

- If release has not been set in the control word: set target value explicitly (using the

PSE object; class 100, instance 1, attribute 1); bit-strobe message, bit is set.

OR

- If release has been set in the control word: set explicit target value (using the PSE

object; class 100, instance 1, attribute 1).

Drive begins run.

- Aborting a run by withdrawing release:

- Poll I/O with control word 0

OR

- Bit strobe; bit is reset

OR

- Control word set explicitly to 0

- If a new target value is transferred during a positioning run, the device will

immediately proceed to the new target. This will occur with no interruption provided

the direction of rotation does not need to be altered.

- If a manual run is transmitted during a positioning run, the positioning run will be

aborted (speed will be reduced to that of a slow run) and the operator may proceed

with the manual run.

The following sequence of steps is also possible:

Starting condition:

- release has not been set

- Target value has already been transferred (in case of poll I/O transfer the release in

the control word was not set already)

Set release: drive begins run

b) Positioning run without a reference loop

The sequence corresponds to that of a positioning run with a loop; in addition to setting

the release, however, bit 6 in the control word also has to be set to execute the run

without loop.

c) Manual run

- Transfer manual run:

- Poll I/O with control word 11h or 12h

OR

- Set control word explicitly to 11h or 12h (using the PSE object; class 100, instance

1, attribute 36)

Drive begins run.

- End manual run by withdrawing manual run:

- Poll I/O with control word 10h

Page 27

PSx3xxDN Instruction Manual

27

OR

- Set control word explicitly to 10h (using the PSE object; class 100, instance 1,

attribute 36)

- End manual run by withdrawing release:

- Poll I/O with control word 0h

OR

- Bit strobe with bit 0

OR

- Set control word explicitly to 0h (using the PSE object; class 100, instance 1,

attribute 36)

- Transferring a target value during a manual run will end the run and the device will

immediately move on to the transmitted position.

4 Special features

a) Speed, acceleration and deceleration

The initial reference loop and the manual run are performed at the maximum speed

specified in the PSE object; class 100, instance 1, attribute 19; positioning runs are

performed at the maximum speed specified in attr. 18. When the run is

counterclockwise, additionally the maximum speed in attr. 32 applies, when the run is

clockwise, the one in attr. 33 applies. For all runs the maximum acceleration of attr.

155 and the maximum deceleration of attr. 156 apply. At the end of each run the

maximum deceleration decreases during the approach to the destination successively

in order to realize a harmonic transient behaviour.

b) Response of drive in case of block or manual displacement

If during a run the achievable rate of speed falls below the threshold parameter (30%

of the selected maximum speed; attr. 26) for longer than 200 ms (attr. 27), the device

detects blocking, aborts the run and sets the "positioning error" bit (here the default

values are given).

New run commands can then be transmitted with no further steps to take. An

exception is, if the run should go to the same target than before. In this case,

deassert the release (bit 4 of the control word) and assert it again, then transfer the

target position one more time (either by Poll I/O or explicit).

If the PSx3xxDN is displaced by external force during standstill opposite to the loop

direction and the release bit (bit 4) as well as the release readjustment bit (bit 10) in

the control word are being set, the device will attempt to reach the previously

transmitted target value once again (readjustment). The device does not attempt to

readjust if rotated in the loop direction; it merely sets the ‘manual rotation’ bit. If bit 6

(„run without loop“) is being set, the drive readjusts the position in both directions.

Deasserting the release and/or the release readjustment bit can completely stop the

readjustment process.

c) Calculating the absolute physical position

The PSx3xxDN actuator includes an absolute measuring system with measurement

range of 250 rotations. This allows the user to determine the direction of rotation for

any desired portion of these 250 rotations.

Page 28

PSx3xxDN Instruction Manual

28

The mapping of the desired positioning range to the physical positioning range is

done with the help of the parameter ‘upper mapping end’ (attr. 40).

In the delivery state, the drive is at position 51200, the upper limit switch is set to

101200 and the lower limit switch is set to 1200, yielding a positioning range of ±125

rotations (±50000 increments). So if the desired positioning range doesn’t exceed

±125 rotations, in delivery state none of the following actions to adjust the positioning

range have to be taken.

For the realization of any desired positioning range independent of the possible

positioning range which is defined by the mounting situation (physical positioning

range) there are the following two possibilities:

1) Move the axle (for example a spindle) to the desired position, then move the drive

(with opened collar) to the position value which belongs to the physical position of

the axle, only then close the collar.

Examples:

a) Move the axle in middle position, then move the drive at no-load (with opened

collar) also to middle position (position 51200), then close the collar. The drive

is now capable of moving 125 rotations (±50000 increments by default) in each

direction.

b) Move the axle completely to the left (resp. bottom), then move the drive at no-

load (with opened collar) without loop to the lowest position (position 1200),

then close the collar. The drive is now capable of moving 250 rotations

(±100000 increments by default) to the right (resp. top).

c) Move the axle completely to the right (resp. top), then move the drive at no-load

(with opened collar) to the highest position (position 101200), then close the

collar. The drive is now capable of moving 250 rotations (±100000 increments

by default) to the left (resp. bottom).

2) Mount the drive in any position on the axle, close the collar, then adjust the

positioning range with the help of attr. 40. Attr. 40 defines the upper end of the

positioning range. By default, the upper end is at +256 rotations (position 102400).

If the positioning range doesn’t suit to the actual displayed position after mounting

the drive, the upper end of the positioning range can be adjusted between -256

rotations and +512 rotations.

Examples:

a) After mounting the drive, the displayed position is 51200 (which corresponds

the delivery state). But the positioning range shall solely spread to the right

(resp. top) Set attr. 40 to 152400.

b) After mounting the drive, the displayed position is 100000. But the positioning

range shall solely spread to the right (resp. top) Set attr. 40 to 201200.

c) After mounting the drive, the displayed position is 2000. But the positioning

range shall solely spread to the left (resp. bottom) Set attr. 40 to 3200.

Remarks:

1) When calculating the upper mapping end (attr. 40), a security reserve of 3

rotations has to be kept in mind (1200 increments by default, see the examples

above), because the highest possible position value is 3 rotations below the upper

mapping end. The lowest possible position value is 253 rotations below the upper

mapping end.

2) The above given increment and position values relate to the following settings,

which correspond to the delivery state:

a) referencing value (attr. 4) = 0

b) actual value assessment, numerator (attr. 16) = 400

c) actual value assessment, denominator (attr. 17) = 400

These 3 attributes have an influence on the above given increment and position

values: With the help of the referencing value a shift can be reached, with the help

Page 29

PSx3xxDN Instruction Manual

29

of the actual value assessment numerator and denominator a stretching or

distension can be reached (see below).

3) When changing the direction of rotation (attr. 44), the referencing value (attr. 4),

the upper mapping end (attr. 40) and the upper and lower limit (attr. 22 and 23) are

set to delivery state.

4) When changing the upper mapping end (attr. 40), the upper and lower limit (attr.

22 and 23) are set to delivery state.

5) When changing the actual value assessment numerator or denominator (attr. 16 or

17), the target value, the actual value, the referencing value, the upper mapping

end, the upper and lower limit, the positioning window and the length of loop are

re-calculated.

6) When changing the referencing value (attr. 4), the target value, the actual value,

the upper mapping end and the upper and lower limit are re-calculated.

7) If the user wants to go over any automatic re-calculation of values when setting up

the device, the optimum order of transfering the parameter is the following:

a) direction of rotation (attr. 44),

actual value assessment, numerator (attr. 16),

actual value assessment, denominator (attr. 17)

b) referencing value (attr. 4)

c) upper mapping end (attr. 40)

d) upper limit (attr. 22),

lower limit (attr. 23),

positioning window (attr. 6),

length of loop (attr. 31)

8) In order to save the settings permanently in the EEPROM, write 1 to attr. 79. As

soon as reading of attr. 79 shows 0, the saving is finished.

Referencing value (attr. 4):

The referencing process affects all transferred values, i.e., the target value, actual

value, upper mapping end and upper and lower limit.

There are two ways of setting the referencing value:

1) Directly, by writing the referencing value to attr. 4.

2) Indirectly, by writing an actual value to attr. 3. This makes it possible to assign any

“true” actual value to the current, physical actual value. The resulting difference is

then the referencing value. This value will immediately be included in calculations

for each transferred value and can also be read via attr. 4.

When changing the referencing value, automatically the target value, the actual value,

the upper mapping end and the upper and lower limit are re-calculated.

The removal of the motor power supply has no affect on the internal

measuring system.

d) Using actual value assessment factors to set the spindle pitch

The PSE object; class 100, instance 1, attribute 16 (numerator factor) and attribute 17

(denominator factor) can be used to represent any desired spindle pitch.

Both factors are set to a value of 400 by default, resulting in a resolution of 0.01 mm

at a spindle pitch of 4 mm.

The denominator factor serves as a simple means of setting the spindle pitch and

resolution.

The numerator factor is primarily used for setting "unlevel" resolutions.

Page 30

PSx3xxDN Instruction Manual

30

Examples:

Spindle pitch

Resolution

Numerator

factor

Denominator

factor

4 mm

1/100 mm

400

400

1 mm

1/100 mm

400

100

2 mm

1/10 mm

400

20

Numerator and denominator factors may take on values between 1 and 10,000.

e) Drag error

During a positioning run, the device compares the computed target position with the

current actual value. If the difference is larger than the “drag error” value (PSE object;

class 100, instance 1, attribute 5), the device sets the corresponding bit in the status

word. This applies in particular if the target speed cannot be achieved due to external

influences (required torque, motor voltage too low).

f) Aborted run when the master fails

If the connection to the master is interrupted during a positioning run, the master

cannot abort a run that is already underway. Automatically aborting a run in this case

requires an I/O connection with an expected packet rate greater than 0; this

connection must be set up in advance and used for initiating the positioning run. Poll

I/O and bit-strobe I/O may be considered for this connection. Another option would be

to set up a change-of-state/cyclic connection with master acknowledge and an

expected packet rate greater than 0. In this case, the run could be aborted regardless

of how the positioning run had been initiated (i.e., even when using an explicit

connection).

g) Optional: Manual run using external keys (jog key mode)

A manual run can be performed using external keys under the following conditions:

1) when the CAN bus is not connected and the address 99 is set with the help of the

address switches

2) when the CAN bus is connected and in the control word bit 5 is active (‘release for

jog key mode’) and bit 4 is inactive (‘release for positioning by bus’)

Altogether there’s the following assignment:

CAN bus

connected

address

control

word

bit 4

control

word

bit 5

external

keys

no

0..98 X X

inactive

no

99 X X

active

yes X X

0

inactive

yes X 1 X inactive

yes X 0 1 active

Bit 5 (‘release for jog key mode with the external keys’) and bit 4 (‘release for

positioning by bus’) cannot be set simultaneously. Changing the release while running

Page 31

PSx3xxDN Instruction Manual

31

(for example from jog key mode to positioning by bus) aborts a run in the other

operation mode.

The operator can adjust the number of increments for a single step via attr. 34. The

single step is being executed if one of the external keys is being pressed. If the

external key has been released before the end of the single step, it will be completed

nevertheless. If the external key stays pressed further on, after a short waiting time a

continuous manual run might join the single step under some circumstances. This

continuous manual run will run as long as the external key stays pressed. The

continuation of a single step with a manual run is always enabled if the CAN bus is

not active. If the CAN bus is active, additionnally to bit 5 of the control word also bit 3

(‘release for manual run in jog key mode’) has to be activated. If bit 3 is not set, each

pressing of the external key results in a single step, even if the key is pressed longer

than the duration of the single step.

The idle period before the drive switches into manual run is specified with attr. 35. In

manual run the drive runs maximum to the specified limit switch position (attr. 22

resp. 23).

If during an jog run both external keys are pressed, the run is aborted immediately. A

new jog run is only possible if both keys are released.

To prepare the function of the external keys, the corresponding key contact (pin 2 or 3

of the 4-pin plug) must be connected with +24V (pin 1). If the key signal is generated

by a voltage source which is galvanically separated from the internal voltage source

of the drive, GND (pin 4) must be connected.

Jog runs without external keys:

Jog runs are also possible without external keys. For this purpose bit 8 (‘jog run to

larger values’) and bit 9 (‘jog run to smaller values’) are provided, these bits simulate

the pressing of the corresponding external keys.

Requirement: Bits 4 and 5 of the control word have to be reset.

h) Devices with optional holding brake

The device models PSx30xDN-14, PSx31xDN-14, PSx32xDN and PSx33xDN can be

supplied with an optional holding brake. This brake prevents the output shaft from

turning when the power supply to the motor is removed, or, if the motor holding torque

is too low, to a maximum of the level of the nominal torque. A small degree of rotation

always occurs at the output, i.e. the brake cannot be used to hold the drive at a

defined position (for this purpose where appropriate the holding torque might be

increased with the help of attr. 43 and attr. 153).

To release the brake when a run command is transmitted, these devices first wait for

a short time (by default 0.15 sec before beginning the run, attr. 146) and then run a

few increments against the actual direction of movement (number of increments: attr.

147). The brake is closing at the end of every run (by default 1 sec after the end of

the run, attr. 69). The advantage of this feature is, that in case of many subsequent

runs the brake has not to be released anew each time.

To adjust the position of the drive manually, it is first necessary to remove the rubberplug in the top cover (see drawings at the end of these instructions). Then release the

brake by pressing down and simultaneously turning using a hex wrench NW3

(PSx31xDN and PSx33xDN) or NW4 (PSx30xDN and PSx32xDN).

Page 32

PSx3xxDN Instruction Manual

32

i) Devices with optional friction brake

The device model PSE34xxDN can be supplied with an optional friction brake. This

brake prevents the output shaft from turning when the power supply to the motor is

removed, or, if the motor holding torque is too low.

A run command is not approached immediately but only after a short idle period to

tighten the brake.

The brake releases at the end of every run.

To adjust the drive manually, it is first necessary to remove the corresponding rubberplug in the top cover (see drawings at the end of these instructions). The drive can

then be rotated using a hex wrench NW4. This is quite difficult as the operator has to

overcome both any torque present at the output and the force of the friction brake.

j) Reference runs

The PSx3xxDN positioning system is equipped with an absolute measuring system,

therefore there’s no need for a reference run when powering on the drive. However, if

in certain cases a reference run onto a hard block should be desired (e.g. uniquely

when installing the drive at a machine), the course of action should be the following:

1) Before commanding the reference run the following settings have to be carried

out:

- set the maximum torque (attr. 20) and the maximum start-up torque (attr. 24)

to max. 10% of the nominal torque

- set the maximum holding torque (attr. 43) and the maximum holding torque at

end of run (attr. 153) to 0

- set the rpm limit for aborting run (attr. 26) to 60

- set the time elapsed until speed falls below rpm limit for aborting run (attr. 27)

to 100

(The span of time in which the drive trys to get over the block, decreases:

With the reduced values the positioning will be aborted if the speed stays

below 60% of the target speed for longer than 100ms. By default, these

values are 30% and 200ms.)

- set the corresponding upper and lower limit (attr. 22 or 23) in a way that the

block location lays considerable within the area between the upper and lower

limit

(Otherwise there’s the danger that the block is located within the positioning

window and consequently won’t be recognized.)

- Where appropriate, reduce the target speed for manual run (attr. 19).

2) Now start the reference run as manual run (set bit 0 or 1 in the control word).

3) Wait for the drive moving (bit 6 in the status word is set).

4) Wait for the drive has stopped and a positioning error has appeared (bit 6 in the

status word is cleared, bit 10 is set).

5) Start a manual run in the opposite direction with the same settings (move a

certain distance away from the hard stop in order the drive can move freely).

6) Only now adjust the desired settings of the adove mentioned attributes for normal

operation.

Page 33

PSx3xxDN Instruction Manual

33

5 Technical data

Ambient conditions

ambient temperature

0 °C to +45 °C