Page 1

Instruction Manual

PSx3xxSE

halstrup-walcher GmbH

Stegener Straße 10

D-79199 Kirchzarten

Phone: +49 (0) 76 61/39 63–0

Fax: +49 (0) 76 61/39 63–99

E-Mail: info@halstrup-walcher.com

Internet: www.halstrup-walcher.com

Document 7100.005054 03/2017

Page 2

Instruction Manual PSx3xxSE

2

Table of Contents

1 Safety precautions ........................................................................................... 4

1.1 Appropriate use ........................................................................................... 4

1.2 Shipping, assembly, electrical connections and start-up .............................. 4

1.3 Troubleshooting, maintenance, repairs, disposal......................................... 4

1.4 Symbols ...................................................................................................... 5

2 Instrument description ..................................................................................... 5

2.1 Functions .................................................................................................... 5

2.2 Assembly Hollow shaft: .............................................................................. 5

2.3 Pin assignment ........................................................................................... 6

2.3.1 Supply voltage connector ............................................................................ 6

2.3.2 Sockets for the bus ..................................................................................... 6

2.3.3 Electrical grounding ..................................................................................... 6

2.4 Setting the device address .......................................................................... 6

2.5 LEDs and address switches ........................................................................ 7

2.6 sercosIII cycle data ..................................................................................... 7

2.6.1 Master to PSx3xxSE (MDT) ........................................................................ 7

2.6.2 PSx3xxSE to Master (AT) ........................................................................... 8

2.7 Parameters ................................................................................................. 9

2.7.1 Read only parameters ................................................................................. 9

2.7.2 Writable parameters .................................................................................. 10

2.7.3 Table of type-dependent values ................................................................ 13

2.7.4 Commands ................................................................................................ 14

2.8 Error messages ......................................................................................... 14

2.8.1 Error (C1D) ............................................................................................... 14

2.8.2 Warnings (C2D) ........................................................................................ 15

3 Special features............................................................................................. 15

3.1 Positioning ................................................................................................ 15

3.1.1 Positioning sequence with loop ................................................................. 16

3.1.2 Positioning sequence without loop ............................................................ 16

3.2 Speed, acceleration and delay .................................................................. 16

3.3 Response if the drive encounters an obstacle or is turned manually ......... 16

3.4 Drag error.................................................................................................. 17

3.4.1 Monitoring ................................................................................................. 17

3.4.2 Correction ................................................................................................. 17

3.5 Readjustment ............................................................................................ 17

3.6 Absolute measuring system ...................................................................... 17

3.6.1 Positioning range (S-0-0278)..................................................................... 17

3.6.2 Scale for the positional data (S-0-0079 and P-0-0079) .............................. 18

3.6.3 Direction of rotation (S-0-0055) ................................................................. 19

3.6.4 Referencing (S-0-0175) and/or (S-0-0052) ................................................ 19

3.6.5 Setting parameters without automatic adjustment ..................................... 19

4 Technical data ............................................................................................... 20

4.1 Ambient conditions .................................................................................... 20

4.2 Electrical data ........................................................................................... 20

4.3 Physical data ............................................................................................. 21

Page 3

Instruction Manual PSx3xxSE

3

Purpose of instruction manual

This instruction manual describes the features of the

PSx3xxSE positioning system and provides guidelines for its use.

Improper use of these instruments or failure to follow these instructions may cause injury or

equipment damage. All individuals responsible for operating these instruments must therefore

be properly trained and aware of the hazards. The instruction manual, and in particular the

safety precautions contained therein, must be followed carefully. Contact the manufacturer if

you do not understand any part of this instruction manual.

Handle this manual with care:

It must be readily available throughout the lifecycle of the instruments.

It must be provided to any individuals who assume responsibility for operating the instrument

at a later date.

It must include any supplementary materials provided by the manufacturer.

The manufacturer reserves the right to continue developing this instrument model without

documenting such development in each individual case. The manufacturer will be happy to

determine whether this manual is up-to-date.

Conformity

This device is state of the art. It complies with the legal requirements of EC

directives. This is shown by the CE mark.

© 2011, 2015, 2016, 2017

The manufacturer owns the copyright to this instruction manual. It contains technical data,

instructions and drawings detailing the devices’ features and how to use them. It must not be

copied either wholly or in part or made available to third parties.

Page 4

Instruction Manual PSx3xxSE

4

1 Safety precautions

1.1 Appropriate use

Positioning systems are especially suitable for automatically setting tools, stops or spindles for

wood-processing equipment, packing lines, printing equipment, filling units and other types of

special machines.

PSx3xxSE positioning systems are not stand-alone instruments and may only be used if

coupled to another machine.

Always observe the operating requirements—particularly the permissible supply voltage—

indicated on the rating plate and in the “Technical data” section of this manual.

The instrument may only be handled as indicated in this manual. Modifications to the

instrument are prohibited. The manufacturer is not liable for damages caused by improper use

or failure to follow these instructions. Violations of this type render all warranty claims null and

void.

1.2 Shipping, assembly, electrical connections and start-up

Assembly and the electrical connections should only be handled by professionals. They should

be given proper training and be authorised by the operator of the facility.

The instrument may only be operated by appropriately trained individuals who have been

authorized by the operator of the facility.

Specific safety precautions are given in individual sections of this manual.

1.3 Troubleshooting, maintenance, repairs, disposal

The individual responsible for the electrical connections must be notified immediately if the

instrument is damaged or if errors occur.

This individual must take the instrument out of service until the error has been corrected and

ensure that it cannot be used unintentionally.

This instrument requires no maintenance.

Only the manufacturer may perform repairs that require the housing to be opened.

The electronic components of the instrument contain environmentally hazardous materials and

materials that can be reused. The instrument must therefore be sent to a recycling plant when

you no longer wish to use it. The environment codes of your particular country must be

complied with.

Page 5

Instruction Manual PSx3xxSE

5

1.4 Symbols

The symbols given below are used throughout this manual to indicate instances when

improper operation could result in the following hazards:

WARNING!

This warns you of a potential hazard that could lead to bodily injury up to

and including death if the corresponding instructions are not followed.

CAUTION!

This warns you of a potential hazard that could lead to significant property

damage if corresponding instructions are not followed.

INFORMATION!

This indicates that the corresponding information is important for operating

the instrument properly.

2 Instrument description

2.1 Functions

The PSx3xxSE positioning system, an intelligent, compact, complete solution for positioning

auxiliary and positioning axes, consists of an EC motor, gear power amplifier, control

electronics, absolute measuring system and sercos 3 interface. The integrated absolute

measuring system eliminates the need for a time-consuming reference run. Connecting to a

bus system simplifies the wiring. A hollow shaft with adjustable collar makes assembly quite

simple. The positioning system is especially suitable for automatically setting tools, stops or

spindles for wood-processing equipment, packing lines, printing equipment, filling units and

other types of special machines.

PSx3xxSE positioning systems convert a digital positioning signal into an angle of rotation.

2.2 Assembly

Hollow shaft:

The PSx3xxSE is mounted onto the machine by sliding the hollow shaft of the positioning gear

onto the axis to be driven and then securing it with the adjustable collar (recommended

diameter of the axis is either 8h9 or 14h9; wrench torque for screw: 1.5Nm). The adjustable

collar should be tightened only just to the point where it can no longer rotate freely.

Securing the pin under the hollow shaft into an appropriate bore will prevent further rotation.

Solid shaft:

The PSx3xxSE is mounted on the machine by fixing the solid shaft with coupling and

intermediate flange to the axis of the machine.

Never apply force to the housing cover, e.g., for supporting weight.

Page 6

Instruction Manual PSx3xxSE

6

Never run the PSx3xxSE in reverse (i.e. do not apply external force to the

output shaft in order to turn it).

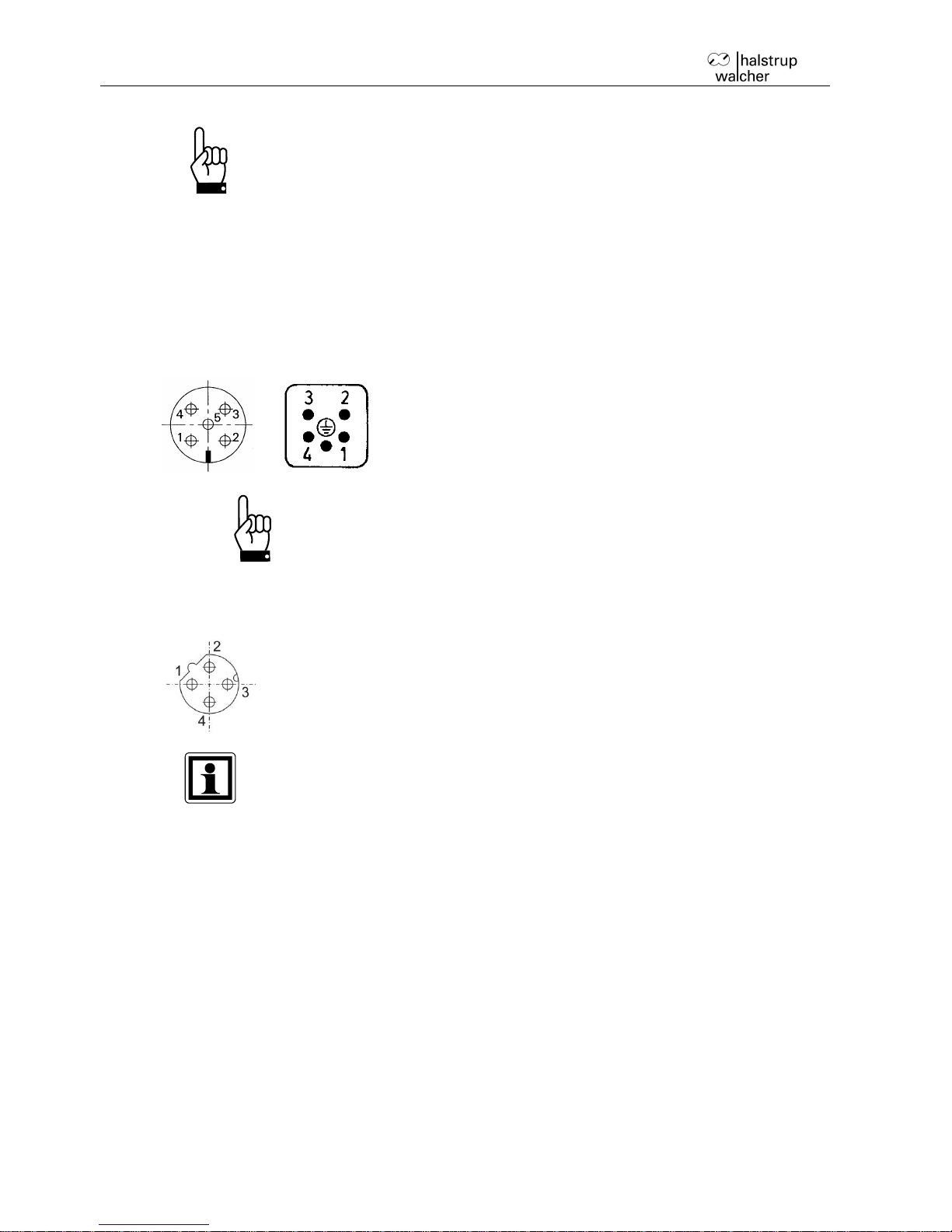

2.3 Pin assignment

For the supply voltage either a Binder series 713/763 (A-coded) round, 5-pin plug for PSE and

PSS devices or a 5-pin Harting plug with protective sleeve (HAN4A) for the PSE34xx devices

is located in the housing cover of the PSx3xxSE.

Two round 4-pin sockets, Binder series 825 (D-coded) are provided for connection to the bus.

2.3.1 Supply voltage connector

1. +24V motor

2. ground (motor)

3. +24V control unit

4. ground (control unit)

5. housing/pressure balance

To prevent the ingression of fluids into the PSW-housing during

cooldown, use a special cable with an airtube for pressure

balancing of your PSW.

2.3.2 Sockets for the bus

1. TD+ (WH/GN, white/green)

2. RD+ (WH/OG, white/orange)

3. TD- (GN, green)

4. RD- (OG, orange)

Due to the use of 4-pin sockets, only four-wire cables should be used.

2.3.3 Electrical grounding

Next to the connecting plugs there is a M4 stud bolt. It is recommended to connect the

positioning system with a cable as short as possible to the machine base. The minimum wire

cross section therefor is 1.5mm².

2.4 Setting the device address

In its delivery state, the PSx3xxSE has the address 1. A different address can be assigned

using the parameter S-0-1040 or via the optional address switches. If the switches are resting

in the position 00 or not available, the address is set using S-0-1040. The change in address is

saved automatically and therefore continues to be available after the device is restarted.

If you set the address using the switches (i.e. switches set to > 00) you cannot change this

value using the bus.

Page 7

Instruction Manual PSx3xxSE

7

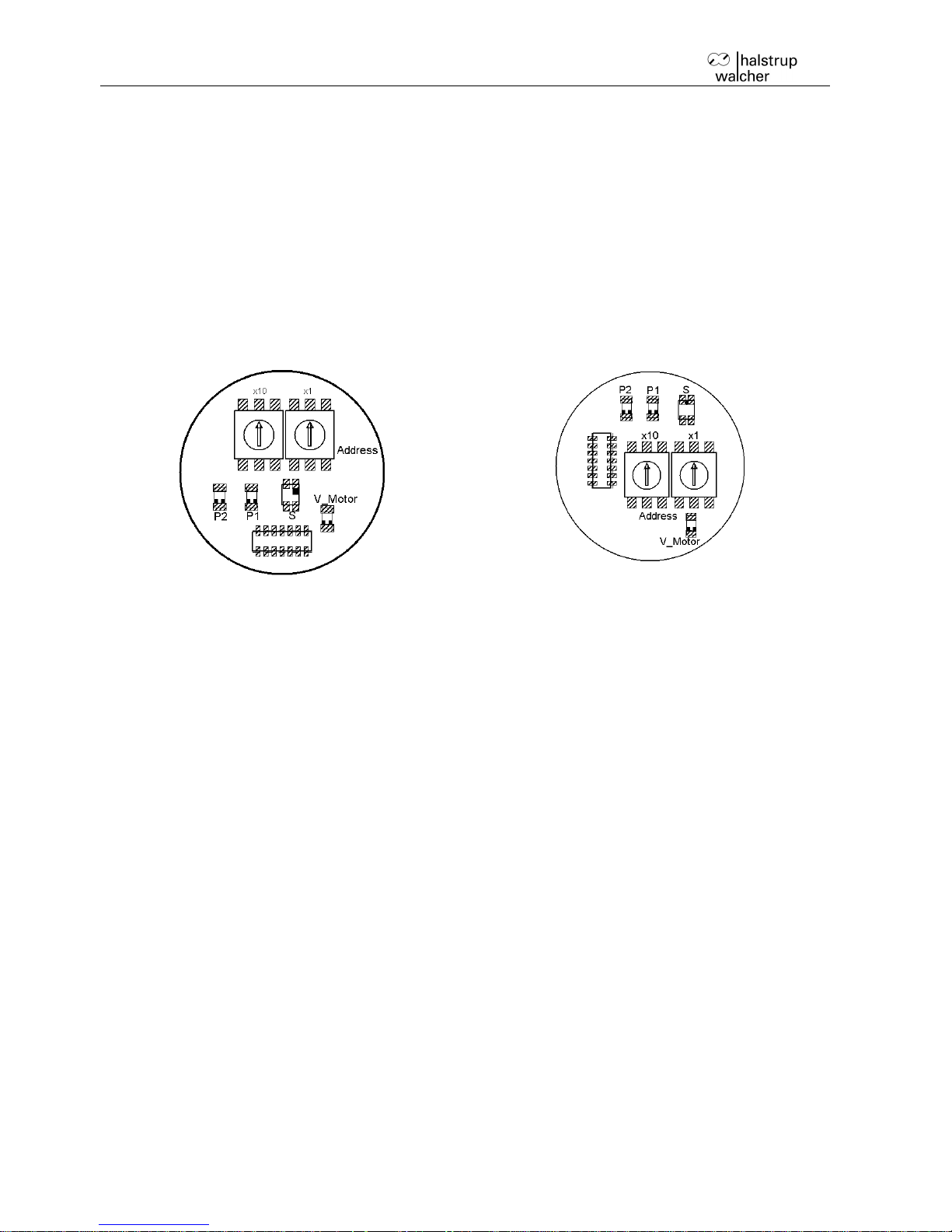

2.5 LEDs and address switches

The following LEDs are located under the transparent sealing plug:

P1/P2: Green link LEDs for ports 1 and 2

S: sercos LED (see sercosIII specifications)

V-Motor: The LED is illuminated yellow when power is available to the motor.

OFF Motor power supply is too high or low

ON Motor power supply ok

flashing Motor power supply ok, PSx in delivery state

Address switch:

The rotary switches indicate the tens and ones places of the address selected. If the switches

are resting in the position 00 or are not available, the address is set using S-0-1040.

The delivery setting is 00, the PSE reports to the bus with the address 1.

If you set the address using the switches (i.e. switches set to > 00) you cannot change this

value using the bus.

2.6 sercosIII cycle data

The IO-profile is used with a fixed configuration (SCP_FixCFG). When configuring the

connections, you must be aware of the following:

S-0-1050.0.x are the settings for the AT (producer)

S-0-1050.1.x are the settings for the MDT (consumer)

The command and/or status bytes 'Connection Control', 'Positioning Control' and 'Producer

RTB word container' are initialised with 0 during the change from CP3 to CP4.

2.6.1 Master to PSx3xxSE (MDT)

Bit

Byte

Meaning

Corresponding IDN

0-15

0-1

Connection control

S-0-1050.1.08

16-31

2-3

I/O Control

S-0-1500.00.01

32-47

4-5

Positioning control

S-0-0346

48-79

6-9

Positioning command value

S-0-0282

Page 8

Instruction Manual PSx3xxSE

8

Connection Control

Bit 15-12: Counter

Bit 1: New Data

Bit 0: Producer ready

A run command will only accepted if this bit is set.

I/O Control

Bit15: Output operation state

A run command will only accepted if this bit is set.

Positioning control (control word)

Bit 2-1: Positioning modes

00: Positioning Drive moves to the transferred target value

01: Jogging + Drive moves to the upper limit switch

10: Jogging - Drive moves to the lower limit switch

11: Positioning Halt Drive brakes with the specified deceleration ramp

(can also be used in jogging mode)

Bit 0: Toggle

Must be toggled if a run command is to be accepted.

2.6.2 PSx3xxSE to Master (AT)

Bit

Byte

Meaning

Corresponding IDN

0-15

0-1

Connection control

S-0-1050.0.08

16-31

2-3

I/O status

S-0-1500.00.02

32-47

4-5

Producer RTB word container

S-0-0144

48-63

6-7

Torque feedback value

S-0-0084

64-95

8-11

Velocity feedback value 1

S-0-0040

96-127

12-15

Position feedback value 1

S-0-0051

Connection Control

Bit 15-12: Counter

Bit 1: New data

Bit 0: Producer ready

I/O status

Bit 15: Outputs ready to operate

is set as soon as bit 15 is set in the I/O control

Bit 14: Inputs valid

always 1

Bit 13: Error of resource I/O (C1D)

Error code is in S-0-0390 and diagnosis text in S-0-0095

Bit 12: Warning of resource I/O (C2D)

Error code is in S-0-0390 and diagnosis text in S-0-0095

Producer RTB word container (status word)

Bit 3: Positioning halt

Drive was stopped (by 'positioning halt' command in the control word)

Bit 2: In position (S-0-0336, bit 0)

Drive is within the positioning window

Bit 1: Status command value processing (S-0-0135, bit 3)

Drive is running

Bit 0: Takeover positioning command value (S-0-0419, bit 0)

Accept target value (is toggled)

Page 9

Instruction Manual PSx3xxSE

9

2.7 Parameters

2.7.1 Read only parameters

Name,

designation

IDN

Function

Unit

Byte count/ data

type

Actual rpm

S-0-0040

Current rpm

rpm

4 /

signed decimal

Actual position

S-0-0051

Current position

*

4 /

signed decimal

Actual torque

S-0-0084

Current torque value

cNm

2 /

signed decimal

In position

S-0-0336

Drive is in the positioning

window

-

2 /

binary

Motor supply

voltage

S-0-0380

Current supply voltage for

the motor

V

2 /

unsigned decimal

Temperature

S-0-383

Internal temperature of the

device

°C

2 /

unsigned decimal

Error text

S-0-0095

Error in text form

-

Full text

Diagnosis code

S-0-0390

Code for errors and/or

warnings (see Section 0)

-

4 /

hexadecimal

Vendor code

S-0-1300.0.3

sercosIII Vendor code (10)

-

2 /

unsigned decimal

Device type

S-0-1300.0.5

PSE3xx-xx bzw.

PSE3xxVG-xx

-

Full text

Software version

S-0-1300.0.9

x.xx

-

Full text

Serial number

S-0-1300.0.12

Device serial number

-

Full text

Production date

S-0-1300.0.13

YYYY-MM-DDTHH:MM:SSZ

-

Full text

Maximum torque

P-0-0084

Maximum torque value

during the last run, not valid

in the acceleration and

deceleration phase

cNm

2 /

signed decimal

Control unit

voltage

P-0-0380

Current supply voltage for

control unit

V

2 /

unsigned decimal

* The units are dependent on the scale (S-0-0079 and P-0-0079).

Page 10

Instruction Manual PSx3xxSE

10

2.7.2 Writable parameters

Name,

designation

IDN

Function

Byte

/

Type

Upper limit

S-0-0049

Maximum permitted target position

Unit: *

Min.: lower limit

Max.: positioning range – 3 rotations

Default setting: 101200

Changes only possible when at a standstill

4 /

sd

Lower limit

S-0-0050

Minimum permissible target position

Unit: *

Min.: positioning range – 253 rotations

Max.: upper limit

Default setting: 1200

Changes only possible when at a standstill

4 /

sd

Referencing of

the position

S-0-0052

Writing causes the current position to be "referenced" onto

the transferred value The limit switch and the positioning

range are also shifted. The difference is found in S-0-0175.

Unit: *

Min./Max.: Any desired value

Default setting: 0

Changes only possible when at a standstill

4 /

sd

Direction of

rotation

S-0-0055

When looking at the output shaft:

16: clockwise

23: counter clockwise

Default setting: 16

Changes only possible when at a standstill

2 /

bin

Positioning

window

S-0-0057

Permissible difference between target and actual values for

the "in position" bit (S-0-0336)

Unit: *

Min.: 1*

Max.: 100*

Default setting: 2

Changes only possible when at a standstill

4 /

ud

Loop length

S-0-0058

Number of increments, which the drive runs to a target in a

specified direction.

Run without loop with value 0

Unit: *

Min.: -400*

Max.: 400*

Default setting: -250

Changes only possible when at a standstill

4 /

sd

Scale for

positional data

S-0-0079

Increments per revolution, e.g. spindle pitch 1.5 mm with

resolution 1/100 mm 150

Min.: 1

Max.: 10000

Default setting: 400

Changes only possible when at a standstill

4 /

ud

Maximum

torque

S-0-0092

Max. permissible torque during the run

Unit: cNm

Default setting: **

2 /

ud

Page 11

Instruction Manual PSx3xxSE

11

Name,

designation

IDN

Function

Byte

/

Type

Drag error

S-0-0159

Max. drag error before a C2D warning is generated

Monitoring deactivated with 0.

Unit: *

Min.: 0

Max.: 1000*

Default setting: 0

4 /

ud

Reference

value

S-0-0175

Correction factor for the target, actual and limit switch

values

Unit: *

Min./Max.: Any desired value

Default setting: 0

Changes only possible when at a standstill

4 /

sd

Target rpm

S-0-0259

Rpm to be used for positioning runs

Unit: rpm

Min./Max.: **

Default setting: **

4 /

sd

Acceleration

S-0-0260

Acceleration ramp

Unit: rotations/(min * sec)

Min./Max.: **

Default setting: **

4 /

sd

Positioning

range

S-0-0278

Definition of the positioning range relative to the absolute

value encoder

Unit: *

Min.: actual position + 3 rotations

Max.: actual position + 253 rotations

Default setting: 102400

Changes only possible when at a standstill

4 /

sd

Target value

S-0-0282

Specified target position (can be written using SVC in CP24 ), stop by writing the same target value once again

Unit: *

4 /

sd

Deceleration

S-0-0359

Deceleration ramp

Unit: rotations/(min * sec)

Min./Max.: **

Default setting: **

4 /

sd

Holding torque

S-0-0533

Holding torque at standstill

Unit: cNm

Min.: 0

Max.: **

Default setting: **

4 /

sd

Maximum startup torque

S-0-0822

Max. permissible torque in the start-up phase

Unit: cNm

Min./Max.: **

Default setting: **

2 /

ud

Time for startup torque

S-0-0823

Time in which the start-up torque applies

Unit: msec

Min.: 10

Max.: 1000

Default setting: 200

2 /

ud

Page 12

Instruction Manual PSx3xxSE

12

Name,

designation

IDN

Function

Byte

/

Type

Address

S-0-1040

sercosIII address

Min.: 1

Max.: 511

Default setting: 1

2 /

ud

Extended scale

for positional

data

P-0-0079

Used in combination with S-0-0079 to set "unlevel"

resolutions

Min.: 1

Max.: 10000

Default setting: 400

Changes only possible when at a standstill

4 /

ud

Drag error

correction factor

P-0-0159

Drag error correction is deactivated with the value 0.

Min.: 0

Max.: 10

Default setting: 0

Changes only possible when at a standstill

2 /

ud

Holding torque

at completion of

run

P-0-0822

Holding torque at completion of run

Unit: cNm

Min.: 0

Max.: **

Default setting: **

2 /

ud

Time for holding

torque at

completion of

run

P-0-0823

Time for holding torque at completion of run

Unit: cNm

Min.: 0

Max.: **

Default setting: **

2 /

ud

Adjustment

release

P-0-0900

Adjustment with value = 1 (only for PSE without brake)

Min.: 0

Max.: 1

Default setting: 0

2 /

ud

* * The units and/or values are dependent on the scale (S-0-0079 and P-0-0079).

** The value depends on the type of device (see following table).

Page 13

Instruction Manual PSx3xxSE

13

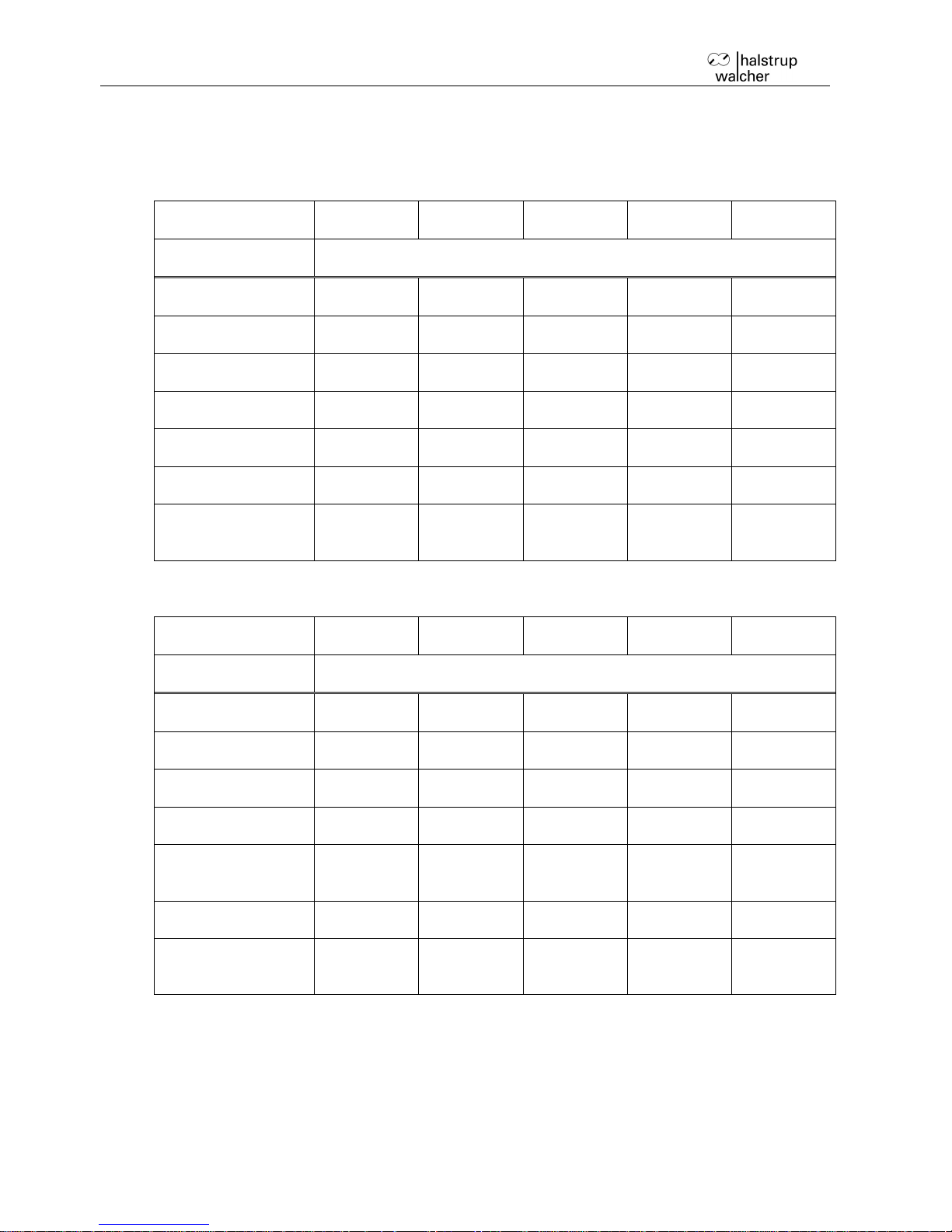

2.7.3 Table of type-dependent values

Device type

PSE and PSS

301-x

311-x

302-x

312-x

305-x

315-8

322-14

332-14

325-14

335-14

Name, designation

IDN

Range of values

Delivery state

Max. torque

S-0-0092

2..125

100

10..250

200

50..600

500

10..250

200

20..500

400

Target rpm

S-0-0259

15..230

230

10..150

150

3..70

70

20..200

170

10..100

85

Acceleration

S-0-0260

97..600

600

50..400

400

23..130

130

97..525

525

50..260

260

Delay

S-0-0359

97..600

600

50..400

400

23..130

130

97..525

525

50..260

260

Holding torque

S-0-0533

0..90

30

0..150

50

0..300

100

0..100

35

0..200

70

Start-up torque

S-0-0822

2..125

125

10..250

250

50..600

600

10..250

250

20..500

500

Holding torque at

completion of run

P-0-0822

0..180

60

0..300

100

0..600

200

0..200

70

0..400

140

Device type PSW

301-x

311-x

302-x

312-x

305-x

315-8

322-14

332-14

325-14

335-14

Name, designation

IDN

Range of values

Delivery state

Max. torque

S-0-0092

2..125

100

10..250

200

50..600

500

10..250

200

20..500

400

Target rpm

S-0-0259

15..180

180

10..125

125

3..60

60

20..150

125

10..80

60

Acceleration

S-0-0260

97..600

600

50..400

400

23..130

130

97..525

525

50..260

260

Delay

S-0-0359

97..600

600

50..400

400

23..130

130

97..525

525

50..260

260

Holding torque

S-0-0533

0..90

30

0..150

50

0...300

100

0..100

35

0..200

70

Start-up torque

S-0-0822

2..125

125

10..250

250

50..600

600

10..250

250

20..500

500

Holding torque at

completion of run

P-0-0822

0..180

60

0..300

100

0..600

200

0..200

70

0..400

140

Page 14

Instruction Manual PSx3xxSE

14

Device type PSE

3110-14

3125-14

3410-14

3418-14

Name, designation

IDN

Range of values

Delivery state

Max. torque

S-0-0092

100..1200

1000

250..3000

2500

200..1200

1000

500..2000

1800

Target rpm

S-0-0259

1..30

30

1..12

12

10..100

100

10..90

90

Acceleration

S-0-0260

9..50

50

4..20

20

20..350

350

10..315

315

Delay

S-0-0359

9..50

50

4..20

20

20..350

350

10..315

315

Holding torque

S-0-0533

0..600

200

0..1250

450

0..300

200

0..450

300

Start-up torque

S-0-0822

100..1200

1200

250..3000

3000

200..1200

1200

500..2000

2000

Holding torque at

completion of run

P-0-0822

0..1200

400

0..2500

900

0..600

400

0..900

600

2.7.4 Commands

Name, designation

IDN

Function

Delete error

S-0-0099

Deletes the C1D error

Load default settings

S-0-0262

The default settings are loaded. In order to save these

permanently, you must subsequently execute S-00264

Save settings

S-0-0264

Saves the parameter in EEPROM

2.8 Error messages

Errors (C1D) and warnings (C2D) are reported using bits 13 and 12 in the I/O status. The

diagnosis code is stored in S-0-0390 and the diagnosis text in S-0-0095.

2.8.1 Error (C1D)

The sercos LED is illuminated red when an error occurs.

When an error occurs during the run, the run is aborted. No further run commands will be

accepted until the error is deleted. Errors are deleted using IDN S-0-0099. If the error

continues, the error message will be displayed again.

The type of error can be found in the diagnosis code (S-0-0390).

0xC00F2019: Internal device temperature exceeds specified limit.

0xC00F2026: Motor voltage too low (voltage < 17.5V).

0xC00F2055: Obstruction (extreme difficulty running, insufficient torque).

0xC00F8022: Error in calculating/determining the absolute position.

This error cannot be deleted. If necessary, restart drive.

0xC00F8025: Motor voltage too high (voltage > 30V).

0xC00F8028: Motor current too high.

0xC10F6320: Incorrect parameters (error in loading or saving).

This error cannot be deleted. Restart the drive and, if the error continues, load the default

settings with S-0-0262.

Page 15

Instruction Manual PSx3xxSE

15

2.8.2 Warnings (C2D)

A warning does not result in a run being aborted. Run commands continue to be accepted

when warnings are active. The drive issues the following warnings (S-0-0390):

0xC00E2028: Drag error (see Section 3.4)

A new run command deletes this warning.

0xC00E2053: Invalid target value, target value lies outside the permissible positioning range.

A new run command deletes this warning.

0xC00E6043: Upper limit exceeded.

Warning is deleted as soon as the drive is within the permissible positioning range.

0xC00E6044: Lower limit exceeded.

Warning is deleted as soon as the drive is within the permissible positioning range.

3 Special features

3.1 Positioning

To perform a positioning run, the control word (positioning control) must be written as follows

in the MDT: bit 2-1 = 00 and bit 0 must be toggled. When the run command has been

successfully accepted, the bit 0 in the status word (Producer RTB word container) is toggled in

the AT.

Here are the responses in various situations:

New target value during a run

The new target position is accepted immediately. If a change of direction is required, the drive

brakes using the set deceleration ramp and then approaches the new target value.

Stop command

To perform a stop command, the control word (positioning control) is written as follows in the

MDT: bit 2-1 = 11 and bit 0 must be toggled.

Stop command during a run:

The drive brakes using the maximum possible deceleration ramp.

There will be no readjustment of the position (see also readjustment P-0-0900).

Bit 3 (positioning halt) in the status word (Producer RTB word container) will be set.

Stop command during standstill:

Bit 2 (in position) in the status word (Producer RTB word container) will be set to 0.

There will be no readjustment of the position (see also readjustment P-0-0900).

Toggling bit 0 of the control word (positioning control) in the MDT leads to

the generation of a run command in the drive even if the drive is already at

the target value because the internal resolution is higher. Constant toggling

of bit 0 must therefore be avoided.

Runs, which involve a run to an obstruction (e.g. reference runs to a block),

may only be started with reduced torque (max. run torque < 10% of

nominal torque).

Underwater usage of the PSW is not allowed.

Page 16

Instruction Manual PSx3xxSE

16

3.1.1 Positioning sequence with loop

The loop length (S-0-0058) has the effect of ensuring that a target value is always approached

from the same direction. This allows you, for example, to eliminate the lash in a driven spindle.

The diagram below illustrates the function of the loop length:

If the target value is above the current position (actual value 1) and the loop length is > 0, the

drive runs past the target value by the specified loop length (run 1a) and then runs to the

target value (run 1b).

If the target value is below the current position and the actual value (actual value 2) is outside

the loop length, the drive approaches the target value directly (run 2).

If you wish to approach the position from the left, the loop length must be < 0.

It is not possible to perform a positioning run to the upper limit (S-0-0049)

with a loop length > 0 because the drive would have to run past the upper

limit in order to do so. The same applies to the lower limit (S-0-0050) with a

loop length < 0.

3.1.2 Positioning sequence without loop

Positioning runs from both directions are possible without a loop if the loop length (S-0-0058)

is set to 0. This does NOT eliminate any lash present in the spindle. The PSx3xxSE internal

gear backlash does not play a role in this case, as position data are acquired directly at the

output shaft.

3.2 Speed, acceleration and delay

The target speed from S-0-0259, acceleration from S-0-0260 and delay from S-0-0359 apply

for all runs. As the drive approaches the target at the end of the run, the delay is successively

reduced in order to ensure a harmonious transient response.

If a stop command is executed, the drive brakes with the maximum possible deceleration

ramp.

3.3 Response if the drive encounters an obstacle or is turned manually

If during a run the achievable rate of speed falls below the threshold parameter (30% of the

target speed) for longer than 200 ms, the instrument registers an obstacle, aborts the run and

a C1D error message is generated (diagnosis code: 0xC00F2055). The drive then stands still

with the set holding torque (S-0-0533). A new run command will only be accepted when the

error has been deleted (see Section 0).

If, when the drive is at a standstill, it is pushed out of the positioning window, the bit 'In

Position' (see Section 2.6.2) will be deleted. If readjustment is active (S-0-0900), the drive will

return to the target value.

Page 17

Instruction Manual PSx3xxSE

17

3.4 Drag error

3.4.1 Monitoring

During a positioning run, the instrument compares the computed target position with the

current actual value. If the difference is greater than the value "drag error" (S-0-0159), a

warning (C2D) is generated (diagnosis code: 0xC00E2028). This applies in particular if the

target speed cannot be achieved due to external influences (required torque, motor voltage too

low). Monitoring of the drag error can be deactivated by setting S-0-0159 to 0.

3.4.2 Correction

The drag error correction can be activated with P-0-0159. The target rpm is increased or

reduced by the specified factor proportionally to the drag error. It is recommended that you set

the parameter to 4.

3.5 Readjustment

When P-0-0900 is set to the value 1, the drive performs a readjustment if it is pushed out of

the positioning window after a run has been completed. If the loop length (S-0-0058) is not

equal to 0, the drive will only readjust if it is pushed out of position in the direction of the loop. If

the loop length = 0, the drive will readjust in both directions.

If a stop command is sent, the drive will only readjust when a new run command is sent.

This function is only available for drives without brake.

3.6 Absolute measuring system

The PSx3xxSE actuator includes an absolute measuring system capable of covering a range

of 256 rotations. In order to prevent an overrun if the drive is rotated by an external force when

it is switched off, the drive can be positioned in a range of 250 rotations. The three lower and

upper rotations of the measurement range are therefore blocked.

Removal of the supply voltage to the motor has no effect on the internal

measurement system.

3.6.1 Positioning range (S-0-0278)

S-0-0278 is used to map the desired positioning range onto the physical range of the machine.

In the delivery state, the drive is at position 51200, the upper limit switch is set to 101200 and

the lower limit switch is set to 1200, yielding a positioning range of ±125 rotations (±50000

increments). If the desired positioning range does not exceed ±125 rotations, none of the

steps described below are required to set the range.

The following two options are available to allow you to realise any desired positioning run

distances independently of the run distance set by the mounting orientation of the

measurement system (physical positioning range):

1. Bring the axle to be moved (e.g. a spindle) into the desired position, run the drive to the

appropriate position with the adjustable collar open and then close the adjustable collar.

Examples:

Bring the axle to be positioned into the mid-position, run the drive to the mid-position (position

51200) with the adjustable collar open, then close the adjustable collar. The drive can now run

125 rotations in both directions (default ±50000 increments).

Page 18

Instruction Manual PSx3xxSE

18

Bring the axle to be positioned all the way to the left (or bottom), run the drive without a loop to

the smallest position (position 1200) and with the adjustable collar open, and then close the

adjustable collar. The drive can now run 250 rotations to the right (or top) (default ±100000

increments).

Bring the axle to be positioned all the way to the right (or top), run the drive to the largest

position (position 101200) with the adjustable collar open, then close the adjustable collar. The

drive can now run 250 rotations to the left (or bottom) (default ±100000 increments).

2. Mount the drive in the required position on the axle, close the adjustable collar, then

adjust the positioning range using S-0-0278. The parameter sets the upper end of the

positioning range. Default setting: upper end at +256 rotations (position 102400). If, after

mounting the drive, the positioning range does not match the currently displayed position, you

can select the positioning range between +3 …+253 rotations from the current position as

required.

Examples:

After mounting the drive, the position 51200 is displayed (this corresponds to the delivery

state). The positioning range should point exclusively to the right (or top) +253 rotations:

Positioning range = actual position + scale * number of rotations

S-0-0278 = S-0-0051 + (400 * S-0-0079 / P-0-0079) * number of rotations

152400 = 51200 + (400 * 400 / 400 ) * 253

After mounting the drive, position 100000 is displayed. However, the positioning range should

point exclusively to the right (or top) +253 rotations:

Positioning range = actual position + scale * number of rotations

S-0-0278 = S-0-0051 + (400 * S-0-0079 / P-0-0079) * number of rotations

201200 = 100000 + (400 * 400 / 400 ) * 253

After mounting the drive, position 2000 is displayed. However, the positioning range should

point exclusively to the left (or bottom) +3 rotations:

Positioning range = actual position + scale * number of rotations

S-0-0278 = S-0-0051 + (400 * S-0-0079 / P-0-0079) * number of rotations

3200 = 2000 + (400 * 400 / 400 ) * 3

The numbers of increments or position values indicated relate to the following settings, which

correspond to the delivery state:

Referencing value (S-0-0175) = 0

Scale for the positional data (S-0-0079 and P-0-0079) = 400

When the positioning range (S-0-0278) is changed, the upper limit is set to the value

(positioning range – 3 rotations * scale) and the lower limit to the value (positioning range –

253 rotations * scale). This gives a total positioning range of 250 rotations.

3.6.2 Scale for the positional data (S-0-0079 and P-0-0079)

These parameters influence the number of increments generated per rotation.

The scale can be calculated using the following formula:

00790

00790*400

P

S

rotation

increments

The most advisable approach is to leave P-0-0079 at 400 and then set the increments/rotation

using S-0-0079.

Examples:

Page 19

Instruction Manual PSx3xxSE

19

The positional data should be scaled in degrees relating to the output shaft:

1 rotation = 360° S-0-0079 = 360; P-0-0079 = 400

The drive is to be operated on a 4mm spindle with a resolution of 1/100 mm:

1 rotation = 4 mm= 400 increments S-0-0079 = 400; P-0-0079 = 400

The drive is to be operated on a 4mm spindle with a resolution of 1/10 mm:

1 rotation = 4 mm= 40 increments S-0-0079 = 400; P-0-0079 = 40

The drive is to be operated on a 2mm spindle with a resolution of 1/100 mm:

1 rotation = 2 mm= 200 increments S-0-0079 = 200; P-0-0079 = 200

The drive is to count 138.23 increments per rotation:

1 rotation = 138.23 increments S-0-0079 = 320; P-0-0079 = 926

When you change the scale for the positional data, the actual value, the referencing value, the

positioning range, the upper and lower limits, the positioning window and the loop length are

recalculated.

3.6.3 Direction of rotation (S-0-0055)

The direction of rotation allows you to specify in which direction the drive should rotate during

runs to larger target values.

When looking at the output shaft, the following values are possible:

16: clockwise

23: counter clockwise

When you change the direction of rotation (S-0-0055), the referencing value (S-0-0175), the

positioning range (S-0-0278) and the upper and lower limits (S-0-0049 and S-0-0050) are set

to the delivery state.

3.6.4 Referencing (S-0-0175) and/or (S-0-0052)

Using the referencing value (S-0-0175) you can shift the whole range of values. There are two

ways of setting the referencing value:

Directly – by writing the referencing value in S-0-0175.

Indirectly – by writing a position value in S-0-0052. This allows any actual value to be assigned

to the current actual value. The resulting difference is then the referencing value (in S-0-0175).

A change to the referencing value automatically shifts the actual value, positioning range and

the upper and lower limits by the same value.

3.6.5 Setting parameters without automatic adjustment

If the user wants to avoid any automatic adjustment of values when setting the parameters for

the drive, the optimum order for sending the parameters is as follows:

Direction of rotation (S-0-0055)

Scale for the positional data (S-0-0079)

Extended scale for the positional data (P-0-0079)

Referencing value (S-0-0175) and/or referencing of the position (S-0-0052)

Positioning range (S-0-0278)

Upper limit (S-0-0049)

Lower limit (S-0-0050)

Positioning window (S-0-0057)

Loop length (S-0-0058)

In order to save the settings permanently in the EEPROM, you must then use S-0-0264 (see

Section 2.7.4).

Page 20

Instruction Manual PSx3xxSE

20

4 Technical data

4.1 Ambient conditions

ambient temperature

0 °C to +45 °C

storage temperature

-10 °C to +70 °C

shock resistance according to

DIN IEC 68-2-27

50 g 11 msec

resistance to vibration

according to DIN IEC 68-2-6

10 Hz to 55 Hz 1.5 mm

55 Hz to 1000 Hz 10 g

10 Hz to 2000 Hz 5 g

EMC standards

CE

conformity

CE declaration of conformity available upon request

protection class

PSE

IP 54

PSS

IP 65

PSW

IP 66 (in operation)

IP 68 (at standstill)

duty cycle

Device model

Duty cycle in

%

Base time in sec.

PSE34xx

PSE30xx to 33xx

PSS

PSW

20

30

20

20

300

300

600

600

4.2 Electrical data

Nominal power output

PSx30xSE, PSx31xSE,

PSE31xxSE

25 W with 30 % OT

PSx32xSE, PSx33xSE

35 W with 30 % OT

PSE34xxSE

100 W with 20 % OT

Supply voltage

24 VDC ±10 % (supply voltages for motor and control

unit are galvanically separated)

Recommendation: Use a regulated power adapter

Nominal current, control unit

0.15 A

Nominal current, motor

PSx30xSE, PSx31xSE,

PSE31xxSE

2.2 A

PSx32xSE, PSx33xSE

3.0 A

PSE34xxSE

7.8 A

Positioning resolution

0,9°

Positioning accuracy

0.9°

Absolute value acquisition

Optical - magnetic

Page 21

Instruction Manual PSx3xxSE

21

4.3 Physical data

Positioning range

250 usable rotations, no mechanical limits

measuring system has a span of 256 turns, minus 3

turns security stock at upper and lower range limit

torsional rigidity

(angle of rotation when

switching from operation

without backlash to maximum

torque)

max. 0.2°

gear backlash

(without spindle

compensation run)

max. 0.5°

Spindle lash compensation

Automatic reference loop after every positioning run

(may be activated or deactivated)

Output shaft

PSE30xSE-8,

PSE31xSE-8

8H9 hollow shaft with

adjustable collar

PSE30xSE-14,

PSE31xSE-14,

PSE32xSE, PSE33xSE

14H7 hollow shaft with

adjustable collar

PSE31xxSE,

PSE34xxSE

14H7 hollow shaft with

clamp and feather key

PSS3xxSE-8

PSW3xxSE-8

8H9 hollow shaft with

adj. collar or

8h8 solid shaft

PSS3xxSE-14

PSW3xxSE-14

14H7 hollow shaft with

adj. collar or

14h8 solid shaft

recommended diameter of

the spindle head

according to the hollow shaft diameter with an

interference fit of h9

Maximum radial force

40 N

Maximum axial force

20 N

Dimensions (l x w x h)

see catalog data on our website

Weight (approx.)

PSx30xSE-8

650 g

PSx30xSE-14, PSx32xSE

1200 g

PSx31xSE-8

700 g

PSx31xSE-14, PSx33xSE

700 g

PSE31xxSE

1200 g

PSE34xxSE

1900 g

For additional specifications and dimension drawings, please visit our website at

http://www.halstrup-walcher.de/en/produkte/positioniertechnik/positioniersysteme/index.php

7100.005054G_PSx3xxSE.doc 03/2017Ed

Page 22

Instruction Manual PSx3xxSE

22

Loading...

Loading...