Page 1

Assembly instructions

halstrup-walcher GmbH

Stegener Straße 10

79199 Kirchzarten, GERMANY

Tel. +49 (7661) 39 63-0

info@halstrup-walcher.de

www.halstrup-walcher.de

© 18.03.2019, Kö

7100.006194 PS17 Assembly instructions

1 2 3

4

5

6a

6b

PS17 Differential pressure transmitter

PS 17 Differential pressure transmitter

The PS17 is a stationary differential pressure transmitter used

for recording positive and negative differential pressures and

converting them into electrical signals.

The device is designed for use in cleanrooms, machines, filter

technology and heating, ventilation and air-conditioning systems

(HVAC). It is used to measure the differential pressure of nonaggressive and non-combustible gases up to 10 kPa.

The device may only be used in the allowed measuring range

(see type label).

Symmetrical and asymmetrical measurement ranges can be

measured with the piezoresistive pressure transmitter.

Models

The device is available in different models:

- With one fixed measurement range or

toggling between 4 different measurement ranges

- 3 supply connection options:

a. 24 VAC / DC (with reverse polarity protection)

b. 15.. 32 VDC (2-wire)

c. 24 VDC (with galvanic separation)

- 3 electrical connection options:

a. 2 cable glands M16

b. 1 cable gland M20 (not for version with relay)

c. 1 connector M12 (not for version with relay)

- Optional with 3 ½-digit display

- Optional with contact point/relay (not for 2-wire, cable gland

M20 or connector M12)

The time constant and output signal are default settings (see

type label). However, these settings can be configured.

Configure settings

The device has numerous possible settings:

- Adjustment of time constant

- Zero-point calibration of measured values

- Fine adjustment of final value

- Restore factory settings

- Configure output signal

- Adjust measuring range (optional)

- Set relay/switching threshold (optional)

To adjust these functions, please use the detailed operating

instructions at:

www.halstrup-walcher.de/technischedoku.

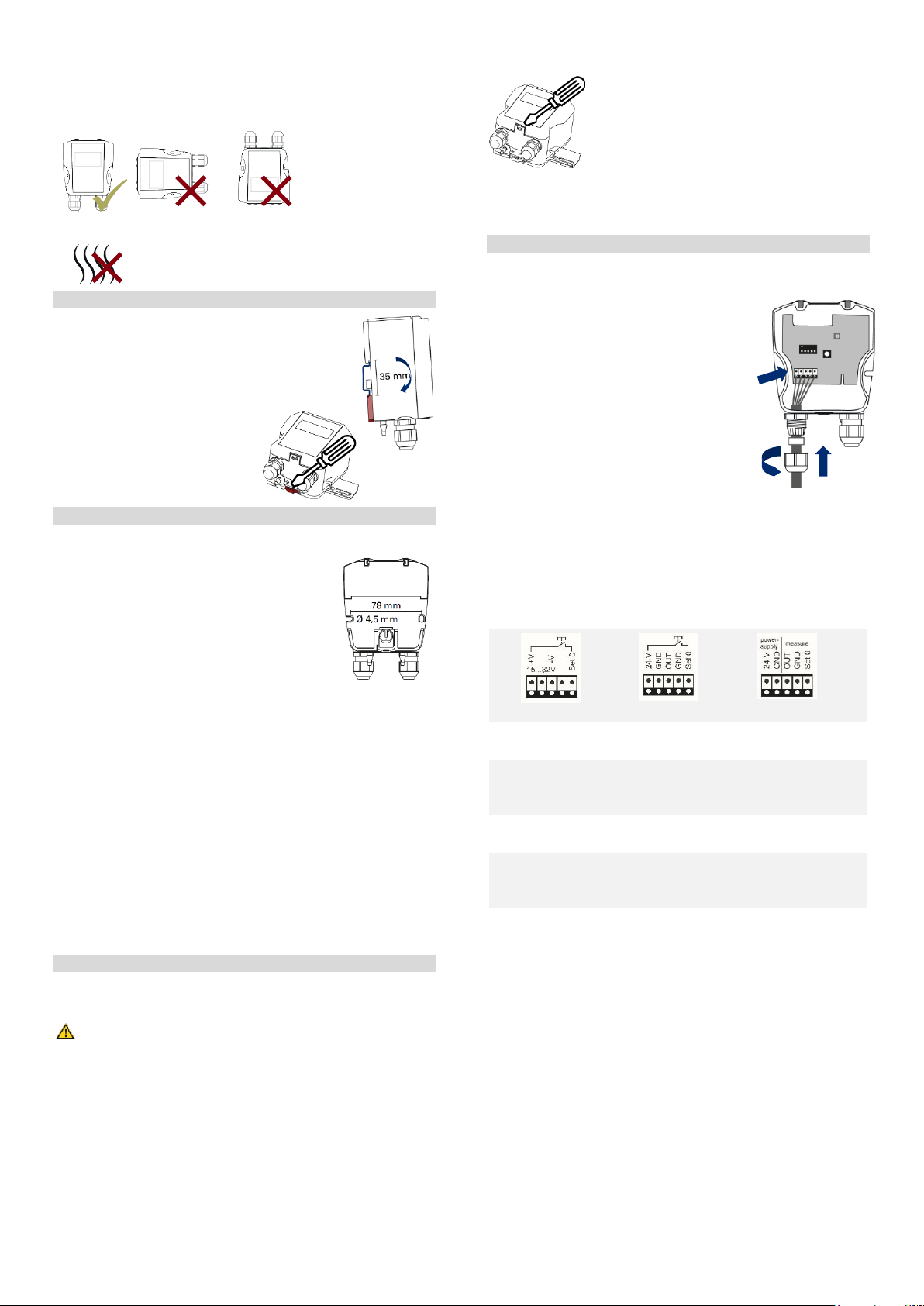

Control units and dimensions of the device

1. Display (optional)

2. Mounting option

- Wall mounting with 2 screws

- Top-hat rail mounting

3. Electrical connection option

- 2 cable glands M16

- 1 cable gland M20

- 1 connector M12

4. Hose connections 4 or 6 mm

5. Flap for opening the housing

6. Type label

a. Version without display

b. Version with display

Safety precautions

These assembly instructions are part of the product. Please read

the instructions carefully, follow our handling instructions and

pay particular attention to the safety precautions. The

instructions should be on hand at all times. Please contact the

manufacturer if you do not understand any parts of these

instructions.

The device has been designed and tested to ensure its safety.

However, it may still be dangerous if used inappropriately.

Always observe the operating requirements indicated on the

type label and in the data sheet – particularly the permissible

supply voltage.

Installation may only be carried out by qualified personnel. The

device requires no maintenance. The device may only be

cleaned from the outside with a damp cloth. The individual

responsible for the electrical connections must be notified

immediately if the device is damaged. In the event of

malfunctions, please consult the detailed operating instructions

at:

www.halstrup-walcher.de/technicaldocu.

Repairs should only be carried out by the manufacturer.

WARNING

Inside the device there may be electrical conductors with a

voltage of 230 V (relay option).

The device must be disconnected from the power supply

and secured before opening!

The device may only be opened and connected to an

electrical power source by qualified personnel.

Page 2

Assembly instructions for differential pressure transmitter PS17

ZWL

2-wire

15 .. 32 VDC

AC/DC

3-/4-wire

24 VAC/DC

VDC

4-wire with

galv. separation

24 VDC

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1

+ connection

Inlet for

supply voltage

Inlet for

supply voltage

2

not assigned

Ground for

supply voltage or

output signal

Ground for

supply voltage

3

- connection

Output signal

(voltage/current)

Output signal

(voltage/current)

4

not assigned

Ground for

supply voltage or

output signal

Ground for

output signal

5

Zero-point

calibration input

+24V = active

Zero-point

calibration input

+24V = active

Zero-point

calibration input

+24V based on

ground for output

signal = active

Installing the device

You can mount the device on a top-hat rail or screw it to a wall.

Please observe the recommended mounting position.

Do not place the device too close to heat and

radiation sources.

1. Mounting on a top-hat rail/dismantling

The housing is prepared for mounting on a tophat rail.

1. Place the housing in the desired position with

the upper gap on the top-hat rail.

2. Lock the device in place by pushing it down.

The device is now mounted.

Note: To dismount the device,

use a screwdriver to pull the red

lug down.

2. Wall mounting

The device can be wall-mounted using 2 screws.

1. Prepare the drill holes.

2. Place the device on the wall.

3. Screw the right-hand screw into the wall

first, but don't make it too tight yet.

4. Screw in the left-hand screw.

5. Use the slots for alignment/adjustment.

6. Then tighten all the screws.

The device is now installed on a wall.

1. Loosen the flap with a screwdriver.

2. Fold the cover upwards until it locks in

place and remains open by itself.

The device is now open.

Note: To close the device, carefully push the cover towards the

closing flap of the housing until it locks in place. Make sure that

the device is properly closed to provide IP protection.

2. Connect supply voltage and output signal

You can connect the supply voltage, output signal and zero-point

calibration input. For devices with cable glands, the cables are

guided through the housing to the terminals.

1. Open the cable glands and thread the

cable in.

2. Guide the cable ends into the housing.

3. The terminals are located at the bottom

left of the circuit board.

4. Connect the cable ends according to

your version (see also connection

diagram in housing cover).

5. Ask your planner whether the digital

zero-point calibration input (Set 0) is

used.

6. Check the connection and close the

cable gland.

Connection diagram of supply options:

Connecting the hoses

You can connect hoses with a 4 or 6 mm inner diameter. Your

planner will instruct you about where to connect what hose.

Connecting to an electrical power

source

To connect the device to an electrical power source, you must

determine which connection version you have. In versions with

cable glands, you must open the housing to connect the device

to the electrical power.

Special versions with M12 supply plugs can be connected with

the prepared mating plugs on site. In this case, your planner will

provide the details.

1. Opening/closing the device

Carefully open the cover of the device to connect it to an

electrical power source.

WARNING

Inside the device there may be electrical conductors with a

voltage of 230 V (relay option).

The device must be disconnected from the power supply

and secured before opening!

The device may only be opened and connected to an

electrical power source by qualified personnel.

© 18.03.2019, Kö - 2 - 7100.006194 PS17 Assembly instructions

The device is now connected.

Outlook: After switching on, the device requires a warm-up

time of approx. 15 minutes until the temperatures of the

electronics and sensor have levelled off. The output signal may

behave unstable during this time.

Page 3

Assembly instructions for differential pressure transmitter PS17

3. Connect relay (optional)

You can connect the optional relay.

WARNING

Inside the device there may be electrical conductors with a

voltage of 230 V (relay option).

The device must be disconnected from the power supply

and secured before opening!

The device may only be opened and connected to an

electrical power source by qualified personnel.

1. The device must be switched off (free

of voltage) and opened

(see 1. Opening/closing the device).

2. Carefully slide the protective cover for

the relay contact to the left. To do this,

use the surface marked with an arrow

(above the pointer).

3. Now you have access

to the relay terminal.

4. Connect the relay’s supply voltage in

accordance with the connection diagram also

located on the circuit board above the

terminal:

5. Use the same procedure as in 2. Connect supply voltage.

6. Carefully slide the cover to the right again until it locks in

place. In doing so, please ensure that all relay connection

cables are under the cover.

The relay is now connected.

Close the device again.

© 18.03.2019, Kö - 3 - 7100.006194 PS17 Assembly instructions

Loading...

Loading...