Page 1

Document 7100.004364 10/2015

Instruction Manual

KAL 100/200 Calibration Device

with Rechargeable Battery

halstrup-walcher GmbH

Stegener Straße 10

D-79199 Kirchzarten, Germany

Tel.: +49 (0) 76 61/39 63–0

Fax: +49 (0) 76 61/39 63–99

E-mail: info@halstrup-walcher.com

Internet: www.halstrup-walcher.com

Page 2

Instruction Manual KAL 100/200

2

Table of Contents

1 Purpose of instruction manual 3

2 Conformity 3

3 Safety precautions 4

3.1 Appropriate use 4

3.2 Shipping, assembly, electrical connections and start-up 4

3.3 Troubleshooting, maintenance, repairs, disposal 4

3.4 Symbols 4

4 Instrument description 6

4.1 Functions 6

4.2 User interfaces 7

4.2.1 Power input, primary on/off switch, micro fuse 8

4.2.2 I/O switch 9

4.2.3 Menu key 9

4.2.4 Target value key 10

4.2.5 "Test" key 11

4.2.6 Pressure key 11

4.2.7 Pressure input port 12

4.2.8 Purge feature 12

4.3 Menu items 12

4.3.1 Incrementation 12

4.3.2 P-input 12

4.3.3 Units of pressure 13

4.3.4 Unit 2 (optional) 13

4.3.5 Zeroing 13

4.3.6 Language 13

4.3.7 Rechargeable battery 14

4.3.8 Default settings 14

5 Battery operation 15

5.1 Charging the rechargeable battery 15

5.2 What to do in the case of total discharge 16

6 Zeroing 17

6.1 Manual zeroing 17

7 Overpressure protection 17

8 USB port 18

8.1 Commands for the serial interface 19

8.1.1 Operating modes 19

8.1.2 Setting parameters 20

8.1.3 Miscellaneous 20

8.1.4 Query values 21

8.2 Interface configuration 23

9 PC software 24

9.1 Software downloads 24

10 Troubleshooting 25

11 Technical data 25

Page 3

Instruction Manual KAL 100/200

3

1 Purpose of instruction manual

Please read this instruction manual thoroughly before operating the instrument in order to avoid

injury or equipment damage caused by improper use of this instrument or failure to follow these

instructions.

This instruction manual describes the features of the KAL 200 calibration device and provides

guidelines for its use.

Any individual charged with handling this instrument must be trained in proper instrument

operation and informed of all potential hazards. The instruction manual, and in particular the

safety precautions contained therein, must be followed carefully. Please contact the

manufacturer immediately if you do not understand any part of this instruction manual or

if you require additional information.

Handle this manual with care and ensure that it

is readily available throughout the lifecycle of the instrument,

is provided to any individuals who assume responsibility for operating the instrument at a

later date, and

includes any supplementary materials provided by the manufacturer.

halstrup-walcher GmbH reserves the right to continue developing this instrument model without

documenting such development in each individual case. We will be happy to determine whether

this manual is up-to-date.

2 Conformity

This device is state of the art. It complies with the legal requirements of EC directives. This is

shown by the CE mark.

© 2010, 2014, 2015

The manufacturer owns the copyright to this instruction manual. It contains technical data,

instructions and drawings detailing the device’s features and how to use it. It must not be copied

either wholly or in part or made available to third parties.

Page 4

Instruction Manual KAL 100/200

4

3 Safety precautions

3.1 Appropriate use

The KAL 200 calibration device is used for testing and calibrating pressure sensors.

Always observe the operating requirements – particularly the permissible supply voltage –

indicated on the rating plate and in the “Technical data” section of this manual.

The instrument may only be handled as indicated in this manual. Modifications to the instrument

are prohibited. The manufacturer is not liable for damages caused by improper use or failure to

follow these instructions. Violations of this type render all warranty claims null and void.

3.2 Shipping, assembly, electrical connections and start-up

Please do not close the pressure inlets during shipping! Changes in barometric pressure may

damage devices with low measuring ranges.

Assembly and the electrical connections should only be handled by professionals. Only

technical personnel who are appropriately trained and authorized by the operator of the facility

may assemble the instrument and set up its electrical connections.

Pressurized air or breath is not to be used for performance tests, as this could damage

instruments with low measurement ranges.

Measurement errors may occur if the instrument is not kept protected from sunlight.

See the individual sections of this manual for specific safety precautions.

3.3 Troubleshooting, maintenance, repairs, disposal

The individual responsible for the electrical connections must be notified if the instrument is

damaged or if errors occur that cannot be corrected as indicated in Section 10.

This individual must take the instrument out of service until the error has been corrected and

ensure that it cannot be used unintentionally.

Always unplug the power cord before opening the instrument!

This instrument requires no maintenance.

Only the manufacturer may perform repairs that require the housing to be opened.

The electronic components of the instrument contain materials that can be reused. The

instrument must therefore be sent to a recycling plant when you no longer wish to use it. The

environment codes of your particular country must be complied with.

3.4 Symbols

The symbols shown here are used throughout the following text to highlight the hazards

associated with using the KAL 200 and to point out important information for operating the

instrument.

Page 5

Instruction Manual KAL 100/200

5

WARNING!

This warns you of a potential hazard that could lead to bodily injury up to and

including death if the corresponding instructions are not followed.

WARNING:

This warns you of a potential hazard that could lead to significant property

damage if corresponding instructions are not followed.

INFORMATION:

This indicates that the corresponding information is important for operating the

instrument properly.

Page 6

Instruction Manual KAL 100/200

6

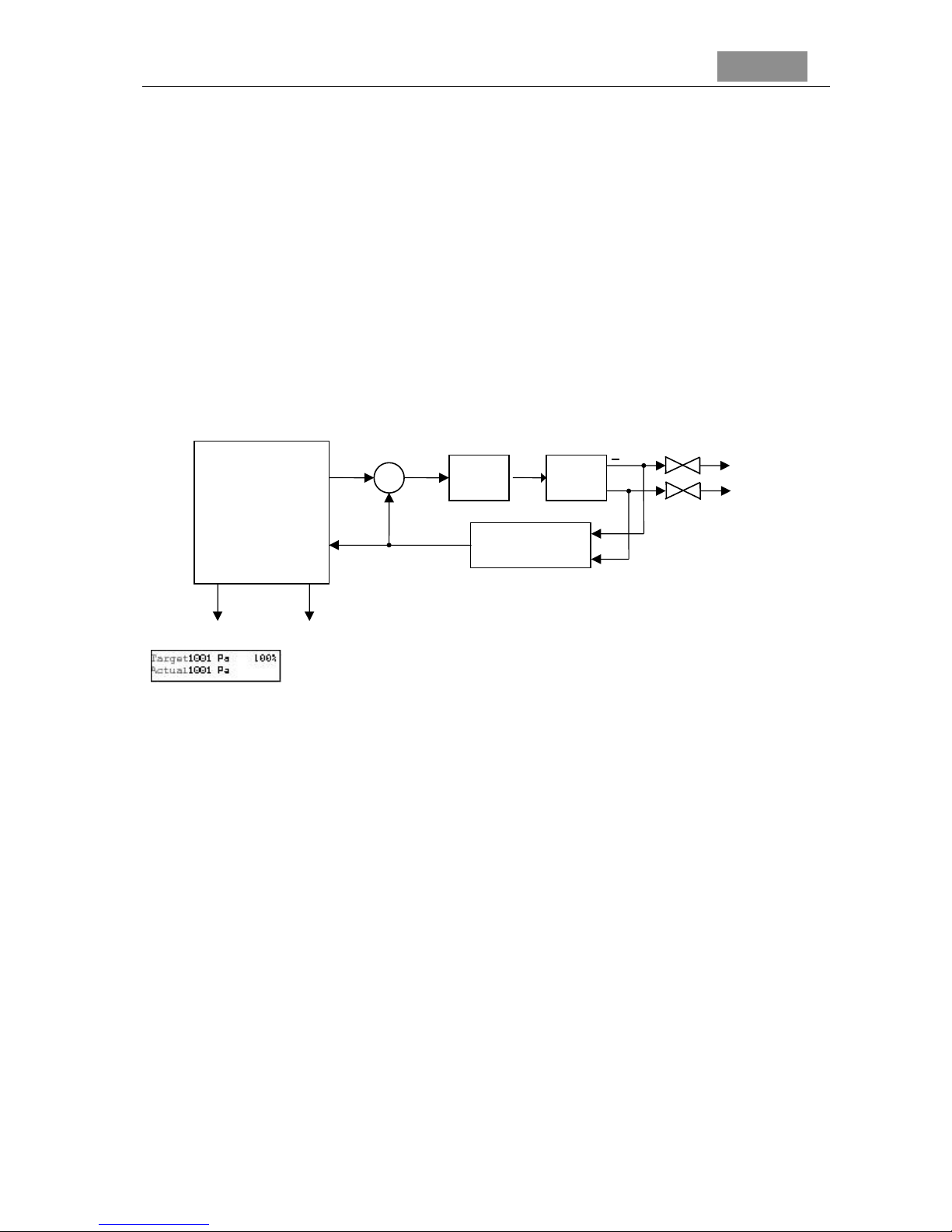

4 Instrument description

4.1 Functions

The KAL 200 microprocess-controlled pressure calibration device can be used for the following:

Simply generating positive and negative reference pressures

Measuring positive and negative pressures

Measuring differential pressure

Identifying leaks in a test object

Determining dynamic response behaviour of a test object

Fig. 1 Basic circuit diagram

Pressure

measurement

Controller

Pump

Pressure

actual value

Pressure

target value

actual and target values

USB

pos. pressure

Comparison of

neg. pressure

Microprocessor

PC interface

Display

+

Valves

Page 7

Instruction Manual KAL 100/200

7

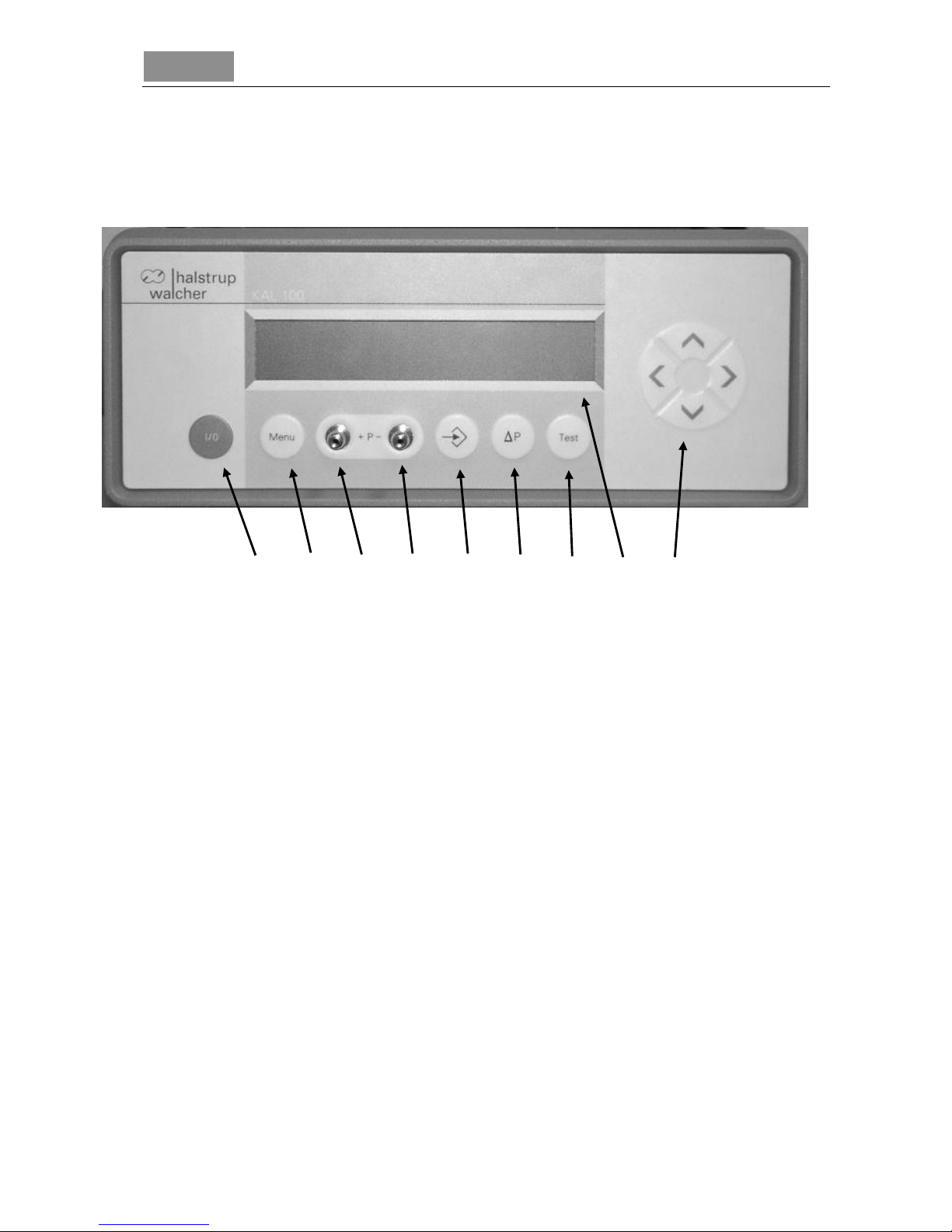

4.2 User interfaces

1 2 3 4 5 6 7 8 9

Fig. 2 Front

1

Secondary on/off switch

2

Menu

3

Positive pressure input/output

4

Negative pressure input/output

5

Target value

6

Pressure measurement

7

Test

8

Alphanumeric display

9

Navigation keys

Page 8

Instruction Manual KAL 100/200

8

11 12 13

Fig. 3 Rear

10

USB port

11

Inlet connector for non-heating apparatus

12

Micro fuse, 315 mAT, 5 x 20 mm

13

Primary on/off switch

14

Power supply +24V/125mA, galvanic separation

15

Ground for 24V/125mA

16

Input port for current measurement 0…20 mA,

input resistance 240 Ohm

17

Ground connector for voltage and current input

port

18

Voltage input 0…10V, Ri = approx. 40kOhm

4.2.1 Power input, primary on/off switch, micro fuse

The KAL 200 calibration device is designed at the factory to

accommodate a supply voltage of 230 VAC/50-60 Hz (115 VAC/50-60

Hz is optional). Voltage fluctuations of +6% to -15% are permissible.

The supply voltage connector (11) is located on the rear of the

instrument (inlet connector for non-heating apparatus + ground wire).

The instrument’s micro fuse (12) is located above this connector. Value:

315 mAT; dimensions: 5 x 20 mm. Located above the micro fuse is the

double-pole, primary on/off switch (13), which separates the KAL 200

from the supply voltage.

WARNING! Risk of Electrical shock! Failure to unplug the power supply cord

before replacing the fuse may result in fatal injuries!

10

14

15

16

17

18

11

13

12

Page 9

Instruction Manual KAL 100/200

9

4.2.2 I/O switch

Secondary on/off switch; in standby mode the power input is approx. 5 W.

Pressing the primary on/off switch, a double-pole switch located on the rear of the

instrument, separates the instrument from the power supply.

4.2.3 Menu key

Pressing the menu key allows the operator to adjust the following 8 settings:

Target value increments: 5, 10, 20, 25, 50, 100%

Pressure input: +P, -P, Diff (both)

Units of pressure: kPa, hPa, Pa, mbar, Torr, mmHg, mmH2O, inH2O

(Optional) Unit in the 2nd line (unit of pressure, V, mA)

Zeroing: on, off

Language: German, English, French, Italian, Spanish

Battery data: Voltage, present current, present current source, battery charge status

Default settings

Navigation keys

Item 1 is displayed when the menu function is first activated; users may select

other items by pressing the right/left navigation keys. The arrows on the

display indicate which navigation keys are active. Pressing any of the

operating mode keys (target value, pressure, test) exits the menu. Exiting the

menu saves user preferences, which will be automatically set the next time

the instrument is switched on.

I/O

Page 10

Instruction Manual KAL 100/200

10

4.2.4 Target value key

The target value function and integrated hose pump allow the user to enter a

predefined pressure. The target value is set using the navigation keys. The purge

valve is activated or deactivated by repeated pressing of the target value key.

Press the right/left navigation keys to position the blinking cursor over the digit to be changed.

Select the desired value by pressing the up/down keys. To change the sign of the target value,

position the cursor over the +/- sign and press the up/down keys to change. Move the cursor to

the right positions over the percentage symbol, to change the percentage by the increments

previously specified in the menu.

The target pressure to be set is the product of the target value and the percentage value.

Example: Increment set from the menu: 25 %; target value 1000 Pa

0 % => 0 Pa; 25 % => 250 Pa; 50 % => 500 Pa; 75 % => 750 Pa; 100 % => 1000 Pa

The actual pressure is shown in the lower portion of the display. It takes about 1s to adjust

settings when small volumes are connected. An additional pump is advisable if connecting

larger volumes, as it would otherwise take too long to adjust the settings. The maximum target

value may not exceed 120% of the measurement range.

If no tubing is connected to the pressure input valve and the target value has been set to 0 or

0%, the KAL 200 will constantly seek to correct for pressure differences (such as those caused

by temperature drift). To minimize this, the control unit (motor) shuts down after roughly 5 min.

The display reads "inactive".

Press any key (other than the I/0 switch) to return the instrument to the "active" state.

S +100.00 Pa 100 %

A + 99.98 Pa +OK

----standby---

I 0.61 Pa +P

Page 11

Instruction Manual KAL 100/200

11

4.2.5 "Test" key

The test feature blocks both pressure ports. This allows the operator to measure

a drop in pressure on the test object itself (leakage test).

Elapsed time and departure from the starting pressure (in %) are shown in the

top line of the display. Pressing the test key starts the measurement again. The

target value feature allows the user to restore the previous target pressure.

Only one pressure port may be connected if using the KAL 200 to generate

positive or negative overpressure. The hose pump draws in air through the

other pressure port.

4.2.6 Pressure key

This allows the user to measure both positive and negative pressures up to a

nominal pressure of +20%. In other words, a KAL 200 with a measurement range

of 1000 Pa can measure up to ±1200 Pa. The pressure measurement capsule is

protected if this value is exceeded. Differential pressures can be measured by

using both pressure ports. Navigation keys do not have any function in this case.

The purge valve is activated or deactivated by repeated pressing of the target

value key.

The P-input must be set properly in order to ensure that pressure measurements

are as accurate as possible. The KAL 200 should also be operated at room

temperature (22°C).

Test

Test 2s -0.02 %

A + 99.98 Pa +OK

Page 12

Instruction Manual KAL 100/200

12

4.2.7 Pressure input port

For technical reasons, the sensitivity of the pressure sensor

varies according to the pressure chamber used. Selecting the

pressure input allows the user to compensate for these

differences. The selected setting is displayed along with the

"+P", "-P" or "dP" symbols.

4.2.8 Purge feature

If the instrument is in target value or pressure mode, the purge feature can be activated or

deactivated by pressing the appropriate key again. This connects the two ports of the

instrument with each other internally in order to release any overpressure. This feature is also

useful if sensitive sensors are to be connected. The use of short lengths of tubing can result in

high pressures, which may damage or even destroy the sensor. No pressure can build if the

purge feature is activated as the air can escape through the free port. When the purge feature is

activated, the two pressure ports of the KAL200/100 are displayed in the lower line on the right.

4.3 Menu items

4.3.1 Incrementation

This feature allows the user to modify the percentage of the target value in the following

increments: 5 %, 10 %, 20 %, 25 %, 50 % and 100 %.

4.3.2 P-input

This allows the user to select the pressure input as: +P, -P or DIFF.

Page 13

Instruction Manual KAL 100/200

13

4.3.3 Units of pressure

This feature allows the operator to select the units used for displaying pressures. Certain

measurement ranges cannot be displayed meaningfully in some units, in which case the units in

question are not available. The following units may be selected:

hPa

mbar

Torr

mmHg

mmH2O

inH2O

kPa

Pa

4.3.4 Unit 2 (optional)

As an option, the KAL200 can now be fitted with an input port for voltage measurements and an

input port for current measurements. If this option is active, it can be used to display the

measurement, which is presented in the second line. For example, if the user selects V as the

unit, the voltage measured at the voltage input port will be displayed in the second line. This

also applies for the pressure and target value features. The KAL200 is therefore capable of

measuring the voltage and output current of a sensor. These values can also be readout using

the interface and, if necessary, processed directly in a form. The corresponding ports are

located on the rear of the instrument.

4.3.5 Zeroing

By default the instrument resets the zero point approximately 6 minutes after it is initially

switched on and then automatically every 30 minutes or after a major temperature change.

Zeroing always results in changes in volume and thus to pressure. This can disrupt certain

measurement sequences. Zeroing is automatically suppressed when the instrument is in test

mode. The instrument can also be zeroed by pressing and holding (approx. 0.5 s) any of the

operating mode keys (target value, pressure, test).

4.3.6 Language

This feature allows the operator to select the language used. The languages available are

German, English, French, Italian and Spanish.

Page 14

Instruction Manual KAL 100/200

14

4.3.7 Rechargeable battery

With this menu item, the user can display the voltage, present current, battery charge status and

present current source for the instrument. Use the UP and DOWN keys to select the parameters

to be displayed.

4.3.8 Default settings

Press the UP or DOWN navigation keys to restore the default settings. Default settings are as

follows:

Incrementation = 25%

P-input = +P

Units = hPa

Zeroing = ON

Page 15

Instruction Manual KAL 100/200

15

5 Battery operation

The device contains a rechargeable lithium ion battery, which allows the device to operate even

when not connected to a mains electricity supply. The operating time provided by the battery

depends on the mode of operation. When measuring pressure, a fully charged battery is

capable of powering the device for between 20 and 30 hours. The operating time is less in

target value mode as additional electricity is required to drive the device. However, even in this

mode, an operating time of 8…10 hours should pose no problem.

If you do not intend to use the device for a longer period of time, you should

fully charge the rechargeable battery beforehand in order to avoid total

discharge.

5.1 Charging the rechargeable battery

In order to maximise the operating life of the rechargeable battery, it is important to ensure that

it always has a sufficient residual charge. As the device continues to consume power when

switched off, albeit at a very low level, this is particularly important if it is to be left switched off

for a longer period of time. Consequently, there is a risk of the battery discharging completely

over an extended period.

While operating in normal mode, the battery is charged using a low current in order to prevent

additional heat being generated by the device itself. The charging time here is approx. 12 hours.

When the device is switched off (key on the front panel), it checks the status of the battery and

activates the charging mode if it is less than 80% charged. The display shows the following

message:

The device switches itself off when the battery is fully charged. If you wish to use the device

before charging has been completed, you can start the normal operating mode again at any

time by pressing the on/off switch on the front panel. Switching off the mains power supply

interrupts the charging process.

The charge level is displayed in 25%-steps. The 0% and the 25% Steps might be seen only

after a long period of not using the KAL. In the normal use the KAL would switch itself off at a

charge level of about 40%, which is aprox. at 13,5V. This early cutoff is done to avoid a deep

discharge during a longer period of storage.

Accu: Charging

Charging: xx.x%

Page 16

Instruction Manual KAL 100/200

16

After switching on the KAL, the charge level must be evaluated and sent to the Display unit.

Due to this the displayed charge level may be delayed or might show wrong values( 0.0%) for

some seconds.

The device cannot charge if it is not connected to the mains power supply or if the master switch

on the back of the device is not switched on. In this case, the following message will be

displayed for a few seconds as soon as the residual charge of the battery falls below 40%:

If the main power supply is not connected or switched off the device will switch off itself after a

few seconds. If this happens, the device should be connected to the mains power supply to

charge the rechargeable battery. This is particularly important if the device will not be used for a

longer period of time.

If, after switching on the power supply, the device reports with the normal operating mode

(display: KAL200 Rev. X.X), it can be put into the rapid charge mode described above by

pressing the on/off switch on the front panel.

Due to the 25% steps of the charge level, the level might show 100.0% for some time. At a real

charge level of aprox. 90% the display will switch the 90% Display, but the battery will continue

to charge. When the battery is fully charged (device has switched itself off), you can separate

the device from the mains power supply again. The charged battery has enough power to work

for 1 to 2 days with the KAL or some month of not using the KAL200.

5.2 What to do in the case of total discharge

The integrated rechargeable battery has its own protective switch. This completely switches off

the output voltage of the battery if it falls below a specified value. If this happens, the display of

the KAL200/100 may not show the battery symbol. Whenever it is switched on, the KAL100/200

will attempt to reactivate the rechargeable battery. It is therefore advisable in these

circumstances to switch the device on and off until the rechargeable battery symbol is visible

once again.

However, the most effective method is to avoid leaving the device with an empty battery

for an extended period and always to charge the battery before any longer periods during

which it will not be in use.

Charge < 40%

connect mains

Page 17

Instruction Manual KAL 100/200

17

Zeroadjust

6 Zeroing

External influences such as temperature, position or ambient pressure can shift the instrument’s

zero point, i.e. the value displayed when the pressure ports are open. Zeroing is the process by

which the instrument automatically registers this shift and figures it into the currently displayed

pressure value. The instrument always zeroes itself after it is switched on. If automatic zeroing

has been activated, it will zero itself again after 6 min. and then every 30 min.

Zeroing switches the internal valves, which necessarily involves a loss in pressure. If this

interferes with instrument operation, the automatic zeroing feature can be switched off.

Automatic zeroing is always suppressed when the instrument is in test mode.

Display when zeroing:

6.1 Manual zeroing

Pressing and holding the ‘pressure’, ‘target value’ or ‘test’ keys will cause the instrument to zero

itself regardless of the menu setting.

7 Overpressure protection

The KAL 200 has an internal overpressure safeguard that protects the precision pressure

measurement capsule from damage. Nevertheless, great caution should be taken when

connecting the instrument to an unknown pressure source.

Page 18

Instruction Manual KAL 100/200

18

8 USB port

The KAL 200 has a USB port, which is detected by a PC as a serial interface. This port allows

the instrument to exchange information and commands with a PC. This feature allows the

operator to save settings and to transfer results to a PC.

The interface (USB serial port (COMx)) has the following settings:

9600 baud

8 data bits

no parity

one stop bit

The following table provides an overview of commands and the corresponding data.

Page 19

Instruction Manual KAL 100/200

19

8.1 Commands for the serial interface

8.1.1 Operating modes

Command

Meaning

Echo

MT

Mode – test

MT

MZ

Mode – zeroing

MZ

MS

Mode – target value

MS

MP

Mode – pressure measurement

MP

MK1

Keyboard on

MK1

MK0

Keyboard off

MK0

MB

Block ports. Instrument is inactive.

Cancel using commands MS or MP

MB

ME

Cancel purge in pressure or target

value mode using MM

MM

Measure in pressure or target value

mode

MI0

Positive P-input

MI0

MI1

Negative P-input

MI1

MI2

Differential pressure measurement

MI2

Page 20

Instruction Manual KAL 100/200

20

8.1.2 Setting parameters

Command

Meaning

Format

Description

>PSxxx.xxxxx

Target value in

hPa

Floating

>PDx

Incrementation

1 digit, 8 bit 0..5

0: 5%

2: 20%

4: 50%

1: 10%

3: 25%

5: 100%

>PEx

Units

1 digit, 8 bit 0..9

0: kPa

2: hPa

4: psi

6: mmHg

8: inHg

1: Pa

3: mbar

5: Torr

7: mmH2O

9: inH2O

>PLx

Language

1 digit, 8 bit 0..4

0: German

2: French

4: Spanish

1:English

3: Italian

>PPxxx

Percentage value

1 digit, 8 bit 0 … 100

8.1.3 Miscellaneous

Command

Meaning

Echo

STOS

Save setting parameters

OK

RCLS

Load setting parameters

OK

RCLP

Load device parameters

OK

RV

Retrieve device revision

Kal200 Rev. X.X

Page 21

Instruction Manual KAL 100/200

21

8.1.4 Query values

Command

Meaning

Format

Output string

Range of values

?PS

Target value in hPa

Floating

PS vxxx.xxxxx

?PB

Measurement range in hPa

Floating

PB vxxx.xxxxx

?PD

Incrementation

1 digit

PD x

0..5 (see also 8.1.2)

?PE

Units

1 digit

PE x

0..9 (see also 8.1.2)

?PL

Language

1 digit

PL x

0..4 (see also 8.1.2)

?PP

Percentage value

3 digits

PP xxx

0..100

?MI

Input mode

1 digit

MI x

0..2 (see also 8.1)

?ST

Status

8 digits, binary

ST bbbbbbbb

bit 7 MSB, pressure

OK

bit 6, unused

bit 5, keys active

bit 4 pressure meas.

bit 3, test mode

bit 2, target value

mode

bit 1, zeroing active

bit 0, teach mode

?BR

Readout measurement

range

Floating, in hPa

BR vxxx.xxxxx

?AL

Battery charge status

Floating in %

AQ xxx.x

?AU

Battery voltage

Floating in %

AU xxx.x

?AI

Battery current

Floating in mA

AI xxx

?AQ

Active current source

String

"Mains" or

"Battery"

?IP

Readout actual pressure

Floating, in hPa

IP vxxx.xxxxx

?IV

Readout voltage

Floating in V

IV vxxx.xxxxx

?IA

Readout current

Floating in mA

IA vxxx.xxxxx

?ID

Readout pressure diff. (test)

Floating, in hPa

ID vxxx.xxxxx

?IZ

Readout duration (test)

5 places, in s

IZ xxxxx

v = prefix x = number, 0..9 b = binary digit; 0 or 1

Page 22

Instruction Manual KAL 100/200

22

8.1.4.1 Converting hPa/mbar to desired units

Multiplier

Units

100

Pa

0.0145038

psi

0.7500616827

Torr

0.7500616827

mmHg

10.1971623

mmH2O

0.0295299875

inHg

0.40146307597

InH2O

Page 23

Instruction Manual KAL 100/200

23

8.2 Interface configuration

Using Windows XP set up the following series interface configuration (COM port). The process

is similar for other Windows systems.

To find the interface configuration: go to Start/Settings/Control Panel: click on System and

select the Hardware tab. Click on Device Manager and select Ports. Double-click on the used

COM port and then select the Port Settings tab.

Fig. 4 Properties

Page 24

Instruction Manual KAL 100/200

24

9 PC software

9.1 Software downloads

You can download this PC software from the following link:

To find a short description go to the menu item “?” and select “help”.

Page 25

Instruction Manual KAL 100/200

25

10 Troubleshooting

Problem

Cause

Corrective Action

Instrument is not

functioning, display is

dark

No power

Check to see if the electrical cord is plugged in

properly at the inlet for non-heating apparatus

Switch on instrument at the primary switch (on

rear panel)

Check fuse; replace if necessary

Caution: Unplug power cord!

Instrument does not

reach set pressure;

pump runs

continuously

Leak in the system,

diameter of tubing too

large

Secure tubing properly; eliminate any leaks

Maximum tubing diameter 5 mm

11 Technical data

Measurement data

Measurement ranges

0-100 Pa, 0-1 kPa, 0-10 kPa, 0-100 kPa

Overpressure range

20 %

Overload capacity

600 kPa for 10 kPa and 100 kPa measurement ranges

200x for 100 Pa and 1 kPa measurement ranges

Linearity based on a

pressure/measurement range of 0...

100% at +17…+27°C

±0.1 % ±1 digit

±0.3 % (at 100 Pa)

±0.1 % (at 1…100 kPa)

Hysteresis

0.1 %

Resolution

0.01 % of the final value

Temperature-dependent drift in zero

point

none (cyclic zeroing)

Temperature-dependent drift in

measurement range

0.03 % / K

Voltage input

0..10V, Ri approx. 40 kOhm, accuracy: +/-0.2% of the final

value

Current input

0..20mA, output load 240 Ohm, accuracy: +/-0.2% of the

final value

Page 26

Instruction Manual KAL 100/200

26

Ambient conditions

Medium

Air, all non-aggressive gases

Operating temperature

+10°C to +40°C

Storage temperature

-10°C to +70°C

Relative humidity

0…80 %

EMC standards

EN 55011; EN 61000-4-3, EN 61000-4-6

Conformity

Declaration of conformity available upon request

Electrical data

Power consumption

16 VA

Supply voltage options

230 VAC/115 VAC +6 %/ -15 % (50-60 Hz)

Setting time

The setting time depends on the connected volume and

ranges from 10s – 30s

Digital output

USB port

Display

Alphanumeric LCD

Rechargeable battery

Operating endurance – pressure

> 20 h

Operating endurance – target value

> 8 h

Charging time – KAL200 in active

mode

approx. 12 h

Charging time – KAL200 switched off

approx. 6 h

Physical data

Pressure ports

Ø 6 mm for NW5 tubing (5mm internal diameter)

Dimensions (w x h x d)

288 x 102 x 247 mm

Weight

4.3 kg

Operating position

horizontal

Charging time – KAL200 in active

mode

approx. 12 h

Page 27

Instruction Manual KAL 100/200

27

Appendix A

Parts in contact with measurement medium

Beryllium bronze CuBe2

Araldite CY236 / HY988

Mu metal (nickel alloy)

Loctite 242e

Brass CuZn39Pb3

Carbonyl iron

Aluminium AlCuMgPb / AlMg3

KEL (FPM: (fluorinated rubber)

Silicon (tubing), optional: Viton

Vepuran Vu 4457/51

Crastin (PTBP)

UHU-Plus endfest 300 binder

Page 28

Instruction Manual KAL 100/200

28

Dimension drawing

7100.004364C_KAL200_Akku.doc 10/2015 Sie

Loading...

Loading...