Best 30 G. C. No. 41 333 50 EC 0087/AT/5342

Best 40 G. C. No. 41 333 51

Best 50 G. C. No. 41 333 52

Best 60 G. C. No. 41 333 53

Best 80 G. C. No. 41 333 56

SUPPLY PRESSURE 20 mbar

0086

TO BE LEFT WITH THE USER

FOR USE WITH NATURAL GAS ONLY (G20)

CAST IRON

WALL MOUNTED

FAN ASSISTED BOILER

BRITISH MADE BOILERS

USER

INSTRUCTIONS

FOR THE

HALSTEAD

30/40/50/60/80

30/40/50/60/80

HALSTEAD

Best db

Best db

GAS SAFETY (INSTALLATION AND USE) REGULATIONS 1996

(AS AMENDED).

It is the law that all gas appliances are installed by a registered person, in

accordance with the above regulations. Failure to install appliances correctly

could lead to prosecution. It is in your own interest, and that of safety, to ensure

that the law is complied with.

WARNING: It is essential that the appliance is correctly earthed. An

electricity supply of 230V 50Hz is required, fused at 3 Amp.

Should a fault on the appliance be known or suspected, the appliance

should not be used until it has been corrected by a competent person.

Read these instructions carefully before attempting to operate the appliance.

Comply with all applicable warnings. Do not interfere with any sealed

components, and use the appliance only in accordance with these instructions.

20/22 First Avenue, Bluebridge Industrial Estate,

Halstead, Essex C09 2EX

Tel: (01787) 272800 Fax: (01787) 474588

SERVICE HOTLINE 024 7635 1424

British Made Boilers

©

HALSTEAD BOILERS LTD. 1998 HB 09-99-750740

The Halstead Best db 30,40,50,60 and 80 are wall mounted, fan assisted

balanced flue, natural gas boilers incorporating a cast iron heat exchanger. The

appliance has the benefit of automatic direct burner ignition and electronic

temperature control. It features an attractive white enamelled case with a

removeable front panel, which when removed enables the appliance to be fitted

within a standard kitchen wall unit. (Refer to Installation Instructions).

2

LIGHTING THE BOILER

Ensure that all secondary controls (timer, room thermostat and cylinder

thermostat where fitted) are turned to maximum. Turn on the electrical supply

and check the pump is working and is circulating water through the system.

If fitted, remove the front boiler panel by lifting it approximately 10mm then

moving it away from the boiler.

Turn the boiler thermostat fully clockwise to its maximum setting. After a few

seconds the boiler will light. The burner flame can be viewed through the viewing

glass in the front of the sealed inner case.

Turn the boiler thermostat and all the external controls to their required setting.

If the boiler fails to light, and the ignition reset neon illuminates, wait 15 seconds

and reset the ignition by depressing the reset button once. Ensure all secondary

controls are turned to maximum before attempting to reset ignition.

Refit the front panel.

3

TO TURN OFF THE BOILER

If you wish to switch off for short periods, turn the boiler thermostat knob fully

anti-clockwise to the position marked 'O'. To restart, turn the knob clockwise to

the required setting. If you wish to switch off for longer periods, turn the boiler

thermostat knob fully anti-clockwise to the position marked 'O' and isolate the

boiler and system from the electrical supply. Refer to section 5 for frost

protection.

4

ELECTRICAL FAILURE

In the event of electrical failure the boiler will go out.

Normal operation of the boiler should continue when the supply is restored.

However, should the boiler fail to re-light, check the warning neons on the boiler

control panel.

If the ignition neon is illuminated allow 15 seconds then press the reset button to

restart the boiler.

If the ignition and over-heat neons are illuminated allow the boiler to cool, switch

the electrical supply off then on again, the over-heat neon will now be out, the

ignition reset button can now be pressed to restart the boiler.

Should the boiler fail to light and the over-heat neon become illuminated again

the boiler has not been allowed to cool sufficiently.

5

FROST PROTECTION

If the boiler is turned off during severe conditions, it is recommended that the

whole heating system be drained. If in doubt ask your Service Engineer.

If a frost thermostat is fitted, leave the boiler with the boiler thermostat turned to

position 1, and turn off the time control switch only.

1

INTRODUCTION

Please ensure that you have a Log Book supplied with your appliance. This Log

Book should be completed by your installer(s) to verify that the correct installation

and commissioning procedure was followed.

Failure to complete the logbook may result in difficulties should a problem arise

with your appliance during the guarantee period.

This logbook forms part of the industry’s Benchmark code of practice for the

installation, commissioning and servicing of central heating systems.

All CORGI Registered Installers carry a CORGI ID card and have a registration

number. Both should be recorded in your log book. You can check your installer is

CORGI registered by calling CORGI on 01256 372300.

LOGBOOK

6

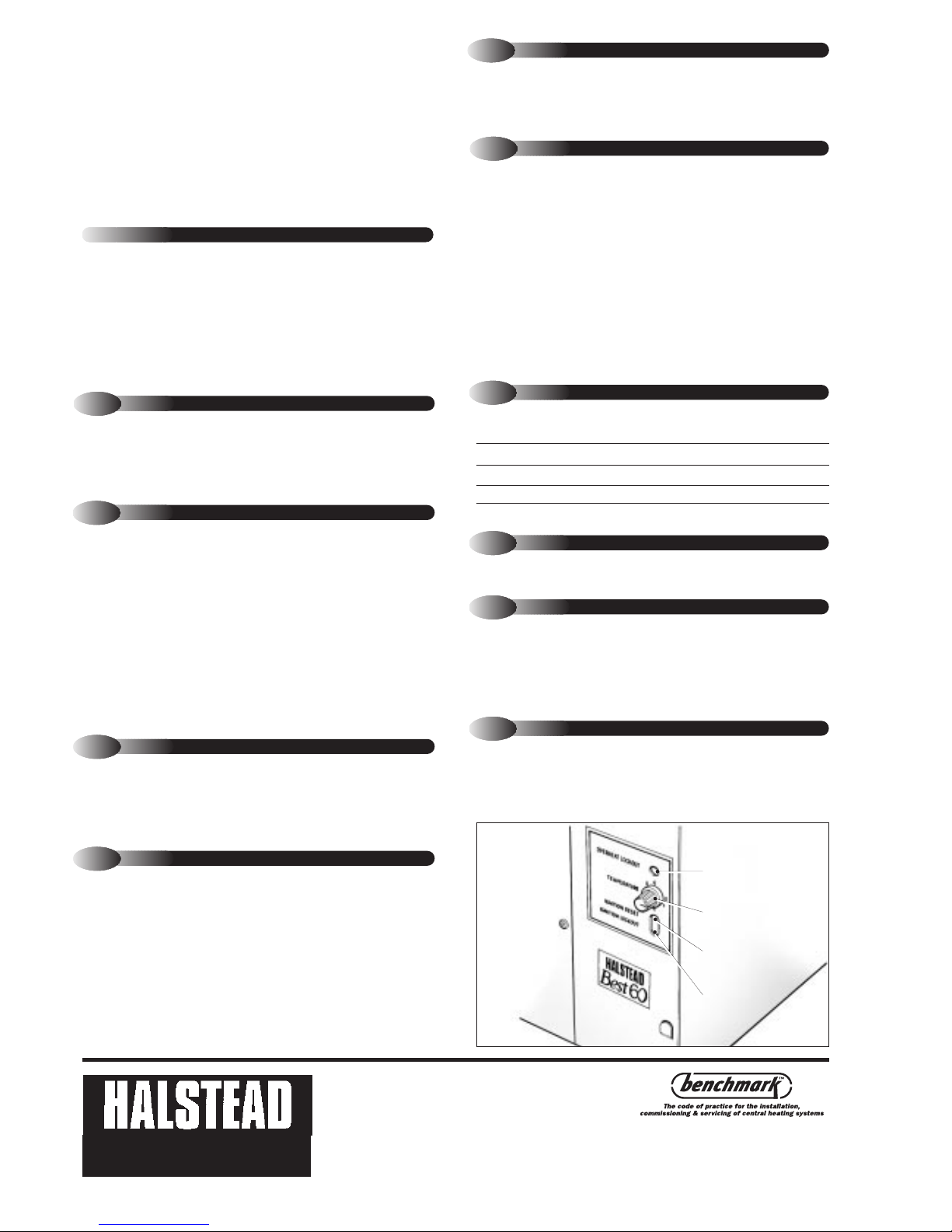

OVER-HEAT NEON ILLUMINATION

When the over-heat neon is illuminated it shows that an over-heat situation has

occurred.

The boiler may be restarted, provided it has been allowed to cool, by pressing

the ignition reset.

The boiler may continue to run without further problems, although the over-heat

neon will still be illuminated. Ensure all secondary controls are turned to

maximum before attempting to reset the boiler.

A Service Engineer should be called to check the BOILER AND SYSTEM for any

possible faults.

The over-heat neon will stay illuminated providing the permanent electrical

supply to the boiler is maintained. It may be turned off by switching off the

electrical supply to the boiler. When the electrical supply is switched on again the

over-heat neon will be off.

7

MINIMUM CLEARANCES

The following MINIMUM CLEARANCES must be available for servicing the boiler:

Above the boiler case 200mm 8 in

At the right hand side 6mm

1

/4in

At the left hand side 6mm

1

/4in

Below the case 100mm 4 in

In front of the case 300mm 12 in

8

GENERAL CARE

The front panel, being an enameled white finish should be cleaned with a damp

cloth and mild detergent. Do not use abrasive cleaners.

9

ROUTINE SERVICING

To ensure continued efficient operation of the appliance, it is recommended that

it is checked and serviced as necessary at regular intervals. The frequency of

servicing will depend upon the particular installation conditions and usage but in

general once a year should be adequate. It is the law that any service work must

be carried out by a competent person such as British Gas or other CORGI

registered personnel.

10

WARNING

If a gas leak is suspected or exists, turn the gas OFF at the incoming

mains (adjacent to the meter). Do not operate any electrical switches.

Do not operate any electrical appliances. Open all windows and

doors. Do not smoke. Extinguish all naked lights. Contact the Gas

Supplier Immediately.

OVER-HEAT

INDICATOR NEON

ON/OFF

TEMPERATURE

CONTROL

IGNITION RE-SET

BUTTON

IGNITON

LOCKOUT

INDICTOR

NEON

Halstead Boilers are continuously improving their products and therefore reserve the right to change

specifications without prior notice and accept no liability for any error or omission in the information

contained in this document.

Loading...

Loading...