Halsey Taylor RWM13A-2 Installation Manual

Halsey Taylor Owners Manual

Glass Filler Plumbing Kit

Part No. 73-26857-51-550

For Use On Halsey Taylor RWM Cooler Models

With Copper Water Lines.

Section A: RWM8A-2 (8 Gal.)

Section B: RWM13A-2 (13 Gal.)

WARRANTY IS VOID IF:

*This plumbing kit is not specified for use by Halsey Taylor for your particular model

water cooler.

*Installation is not made in accordance with instructions enclosed.

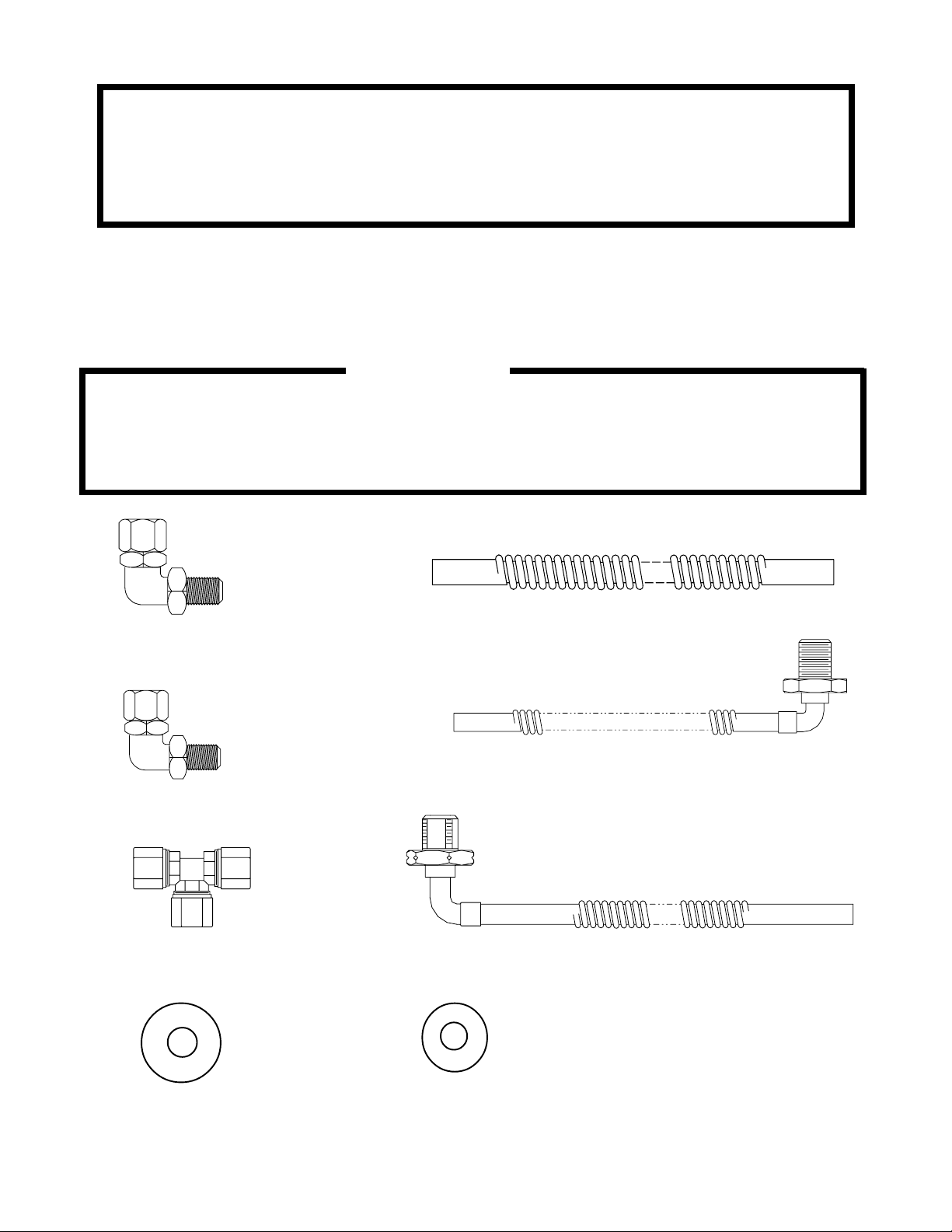

PARTS LIST

WARNING!

Elbow 3/8 OD X 3/8 NPT

(1) 70572C

Elbow-5/16OD X3/8NPT

(1) 70568C

Glass Filler Service Line

(1) 16-15657-16-550

Flex Tube Assembly

(1) 60-26858-51-550

Compression Tee

(1) 70632C

Gasket

(1) 10-08540-40-740

Proj Serv Line

(1) 60-26649-51-550

Gasket-Black

(4) 10-03227-40-560

96693C

Section A: Installation Instructions

For 8 Gal. Model

NOTE: All service to be performed by an authorized service

person.

1. Remove wrap around panel by removing two bolts, one

on each side, from the bottom of the unit and carefully

pulling the panel off.

2. Disconnect power cord from the wall box.

3. Shut off water inlet supply. Depress push button to

relieve

any residual water pressure.

4. Remove the strainer plate, drain plug, and bubbler.

5. Remove the nuts holding the receptor on, 2 each side,

and remove the receptor from the unit.

6. Remove tank drain plug and drain water out of tank. Then

replace drain plug using teflon thread tape.

7. Disconnect the water inlet from the regulator/valve

assembly (item 1, figure 1).

8. Disconnect the line from the regulator/valve outlet to the

chiller inlet and discard (item 2, figure 1).

9. Turn elbow (item 1, figure 2) on chiller inlet so it is facing

down. Connect water inlet line disconnected in step 6 to the

elbow (item 2, figure 2).

NOTE: Item 2 - Figure 2 may need to be cut back shorter to

fit new inlet. Use new elbow if required.

10. Cut chiller outlet line approx. 1" before the braze joint,

(see figure 3). There must be enough straight tube on the

chiller outlet to attach a tee (approx 3/4").

NOTE: Use IMP or equivalent tube cutter. DO NOT use

hacksaw!

11. Install tee (item 1, figure 4, P/N 70632C) to chiller outlet

line with side connection facing the back, left corner of the

cooler.

NOTE: The tubing supplied is a copper flex tubing and is

made for easy bending. However, bending the tube too

tightly can kink it and excessive bending could make it

brittle. Try and make the routing complete with as few

bends as possible.

12. Connect the glass filler service line to the side connection of the tee (item 2, figure 4, P/N 60-26858-51-550).

13. Connect the flex tube assembly to the remaining

connection of the tee. (item 3, figure 4)

14. Bend the flex tube assembly to connect to the regulator/

valve inlet (item 3, figure 4). Care should be taken not to

kink the tubing. Bend should be approx as shown (item 4,

figure 2). Make sure the tubing does not interfere with the

operation of the regulator/valve lever and is away from the

tank drain.

15. Connect the bubbler service line to the regulator/valve

outlet (item 5, figures 2 & 4). Use new line if required.

16. Install gaskets provided with kit to glass filler nipple, (1

gasket P/N 10-08540-40-740) and bubbler nipple (2 black

gaskets P/N 10-03227-40-560) item 6, figure 4.

17. Find the plug bufton located at back of receptor and

remove it.

18. Install the receptor, aligning glass filler and projector

nipples with the holes in receptor. If additional bending is

required, care should be taken not to kink the tubing.

19. Install the bubbler. Install glass filler using gasket

.provided. Install the drain plug and strainer plate.

CAUTION: DO NOT reuse old gaskets! Use only those

provided with this or other Halsey Taylor kits.

20. Verify that all connections and water flow routes are as

96693C

shown in figures 2 and 4.

21. Turn on water and check all connections for leaks.

Repair leaks if necessary.

22. Re-connect power cord.

23. Install wrap around panel

Section B: Installation Instructions

For 13 Gallon Model.

NOTE: All service to be performed by an authorized service

person.

1. Remove wrap around panel by removing two bolts, one

on each side, from the bottom of the unit and carefully

pulling the panel off.

2. Disconnect power cord from the wall box.

3. Shut off water inlet supply. Depress push button to

relieve any residual water pressure.

4. Remove the strainer plate, drain plug, and bubbler.

5. Remove the nuts holding the receptor on, 2 each side,

and remove the receptor from the unit.

6. Remove tank drain plug and drain water out of tank

then replace drain plug using Teflon thread tape.

7. Disconnect precooler from regulator/valve inlet (item 1,

figure 5).

8. Remove 1/4 x 5/16 elbow from regulator/valve inlet and

replace it with the 1/4 x 3/8 elbow (item 2, figure 5).

NOTE: Elbow should be at a slight angle or pointed

straight down (item 1, figure 6).

9. Disconnect the line from the regulator/valve outlet to the

chiller inlet and discard (item 2, figure 1).

10. Remove the elbow from the chiller inlet and replace it

with the 3/8 x 5/16 elbow (item 2, figure 6). Elbow should

be facing the back of the unit and slightly down.

11. Carefully bend the precooler outlet line to connect with

the elbow in the chiller inlet. Care sold be taken not to

kink the tubing, or put excess stress on the plastic

elbow

NOTE: It may be necessary to cut back precooler outlet

line to avoid kink and give better fit (item 1, figure 5).

12.Cut chiller outlet line approx. 1" from braze joint (see

figure 3). There must be enough straight tubing on the

chiller outlet to aftach a tee fitting(approx 3/4").

NOTE: Use IMP or equivalent tube cutter.

hacksaw!

13. Install tee (item 1, figure 4, P/N 70632C) to chiller

outlet line with side connection facing the back, left corner

of the cooler.

NOTE: The tubing supplied is a copper flex tubing and is

made for easy bending. However, bending the tube too

tightly can kink it and excessive bending could make it

brittle. Try and make the routing complete with as few

bends as possible.

14.Connect the glass filler service line to the side

connection of the tee (item 2, figure 4, P/N 60-26858-51-

550).

15.Connect the flex tube assembly to the remaining

connection of the tee (item 3, figure 4).

16.Bend the flex tube assembly to connect to the

regulator/valve (item 3, figure 4). Care should be taken not

to kink the tubing. Bend should be approx as shown (item

4, figure 2). Make sure the tubing does not interfere with

the operation of the regulator/ valve lever and is away from

the tank drain.

PAGE 2

DO NOT use

Loading...

Loading...