Halsey Taylor RC12AQ-A Installation Manual

RC8AQ*A RC12AQ*A

Halsey Taylor Owners Manual

Fully-Recessed Barrier-Free Water Cooler

RC RC W/CUP DISPENSER

INSTALLER

To assure you install these models easily and correctly,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE

INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH PLUMBING, ELECTRICAL, AND OTHER APPLICABLE CODES. After

installation, leave these instructions with the Water Cooler for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO WA TER

LINES IS A COMMON PROCEDURE. THIS GROUNDING MA Y BE IN THE BUILDING OR MA Y OCCUR A WA Y

FROM THE BUILDING . THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK INTO A FOUNT AIN, CREA TING

AN ELECTROL YSIS WHICH CAUSES A MET ALLIC TASTE OR AN INCREASE IN THE MET AL CONTENT OF THE

WA TER. THIS CONDITION IS AVOIDABLE BY USING THE PROPER MA TERIALS AS INDICA TED. ANY DRAIN

FITTINGS PROVIDED BY THE INST ALLER SHOULD BE MADE OF PLASTIC T O ELECTRICALL Y ISOLA TE THE

FOUNT AIN FROM THE BUILDING PLUMBING SYSTEM.

3/8" O.D. UNPLATED COPPER TUBE CONNECT COLD WATER SUPPLY

1/4" O.D. TUBE WATER INLET TO COOLER

NOTE: WATER FLOW DIRECTION

FIG. 1 FIG. 2

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

97884C (Rev. B - 3/08)PAGE 1

RC8AQ*A RC12AQ*A

WALL FRAME INSTALLATION INSTRUCTIONS

FOR THE

RC MODELS DRINKING FOUNTAIN

(with and without cup dispenser)

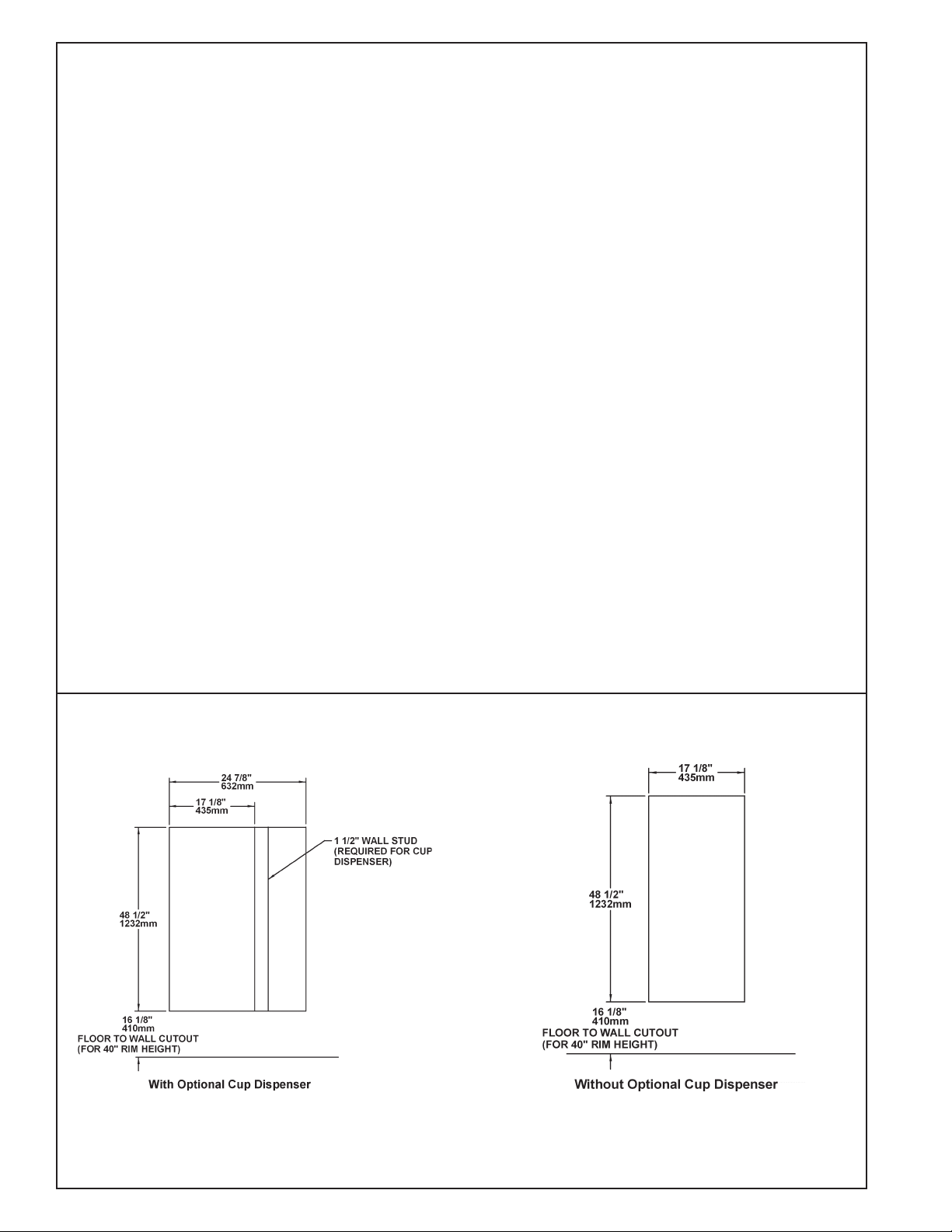

1. Cut a wall opening 24 7/8 W x 48 1/2 H (with cup dispenser), 17 1/8 W x 48 1/2 H (without cup dispenser). The bottom

edge of the opening should be approx. 16 1/8” above the floor (See Fig. 3 with cup dispenser). See Fig. 4 without cup

dispenser. Check local codes for height requirement.

2. After opening is completed, reinforce opening on all sides so that it may adequately support water cooler which

weighs up to 150 lbs. and also provides a means of securing Wall Frame in place. (Install a wall stud indicated on

Fig. 3 (with cup dispenser). NOTE: Building construction must allow for adequate airflow on both sides and top of

chiller unit. 4” minimum required.

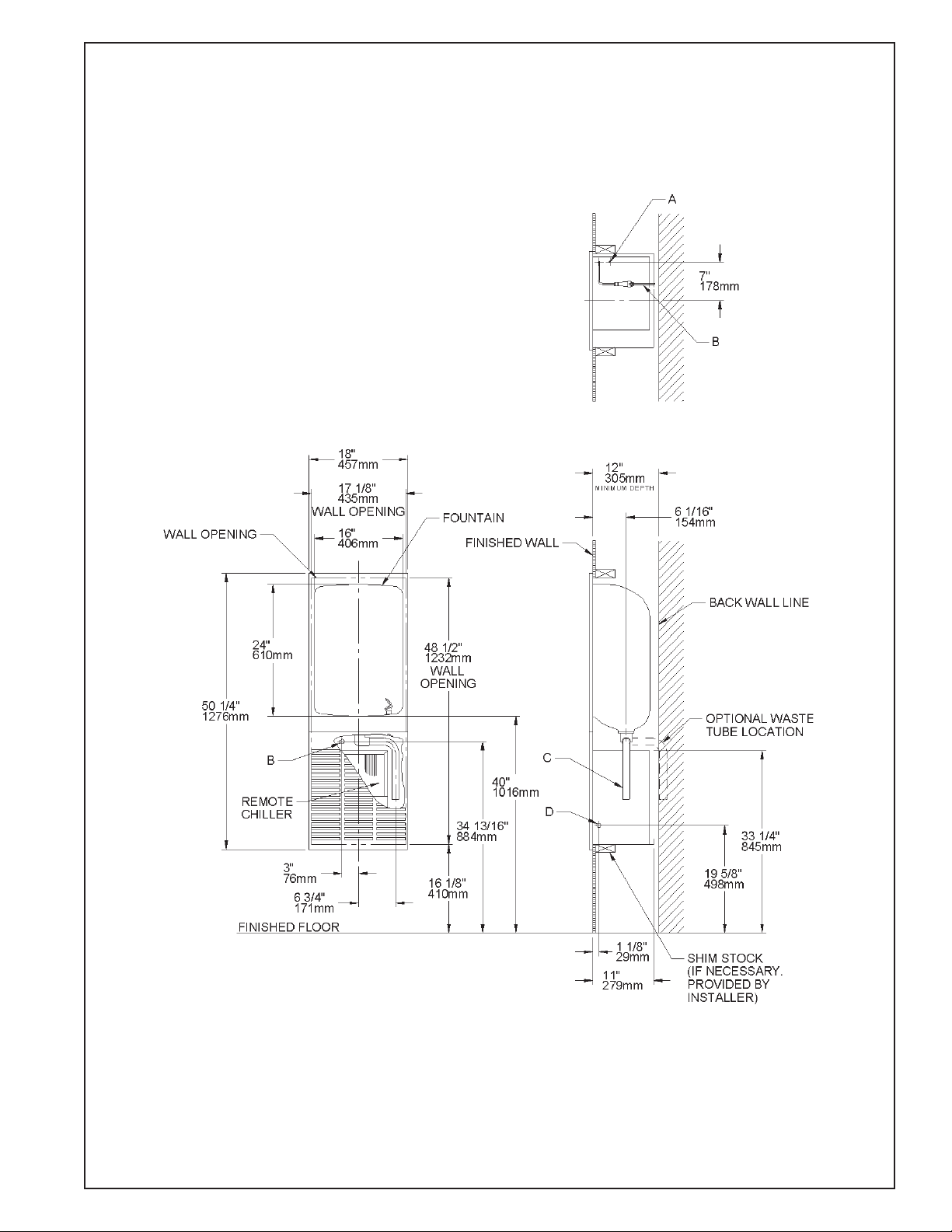

3. Install rough plumbing to fountain. See Fig. 5 for location of supply water inlet to chiller and location of waste water

outlet.

*For cup dispenser model without glass filler plumbing, continue with step no. 5.

4. (Cup dispenser Models) Install rough plumbing to cup dispenser. See Fig. 15 for location of waste water outlet.

5. Cut plastic ties holding chiller shelf support rods to framework.

6. Install wall frame assembly in wall opening with front edge of frame flush with finished wall face. Secure frame

through holes in top and sides to wall support members with 5/16” diameter fasteners (bolts or lag screws) as

required by wall constructions. (14) bolts/screws required. CAUTION: DO NOT USE LESS THAN REQUIRED

QUANTITY AND SIZE (DIAMETER) OF F ASTENERS.

7. Install chiller shelf. Place shelf on lower frame member and attach support rods. Secure front edge of the frame and

wall construction using two 5/16” diameter lag screws or bolts. Tighten securely.

8. Install electrical conduit. Fig. 5 shows electrical conduit connection location.

9. Now you are ready to install fountains.

97884C (Rev. B - 3/08)

FIG. 3 FIG. 4

PAGE 2

RC8AQ*A RC12AQ*A

PLUMBING ROUGH-IN

* NOTE: If wall opening height has been adjusted

to meet local codes (see Step No. 1 of installation

instructions), height dimensions must be adjusted

accordingly.

FIG. 5

LEGEND

A = 1/4” O.D. TUBE CONNECT (CHILLER WATER OUTLET)

B = 3/8” O.D. TUBE CONNECT (CHILLER WATER INLET) SHUT OFF VALVE BY OTHERS

C = 1-1/4” O.D. WASTE WATER OUTLET TUBE (TRAP NOT FURNISHED)

D = ELECTRICAL INLET

97884C (Rev. B - 3/08)PAGE 3

RC8AQ*A RC12AQ*A

INSTALLATION INSTRUCTIONS

RC MODELS DRINKING FOUNTAIN

(refrigerated and non-refrigerated)

1. Familiarize yourself with the RC Wallframe which should already be in place in the wall. If not, refer to the

“RC Wallframe” Installation Instructions before proceeding.

2. Determine location of rough plumbing. At this point, you should decide which style trap you plan to use. For

easier installation, we recommend the use of a swivel trap.

3. Install the basin (See Fig. 7). Hold the basin flush against the wall, positioning the top edge just above the upper

edge of the wallframe. Then slide the basin down slowly until it engages the hanger bracket. Be sure the basin is

firmly engaged before releasing it.

4. Finish securing basin in place. Align the brackets at the bottom of the basin with the bracket on the frame. Fasten

the brackets together using screws and speednuts (provided with fountain).

5. Install tailpiece assembly. Slide the slip nut and gasket from the trap onto the tailpiece. Insert the tailpiece

assembly into the trap and align its other end with the drain hole in the basin. Place rubber gasket between the

tailpiece assembly and the basin, then screw in the drain plug from above. Tighten the drain plug. Tighten slip

nut and swivel joint. Snap the strainer plate into the drain plug.

6. Install a service stop (not provided) on the supply water inlet line. Turn on supply water and flush thoroughly.

7. Install refrigeration unit. Slide refrigeration unit into the wallframe and position tight against left side and flush

with the front edge of wallframe. WARNING: Adequate space must be maintained behind the refrigeration unit for

air circulation.

8. Water supply connections (See Figs. 8, 9, & 10)

RC8A Models – Make connections between remote chiller and building supply line. Inlet port is marked on the

chiller (1/4” O.D. copper tube). Bend the copper tube (provided) at an appropriate length from chiller to opening in

frame. Install the in-line strainer (provided with chiller) by pushing it in until it reaches a positive stop, approximately 3/4” (19mm) on the marked chiller inlet port. Connect building supply line to strainer. DO NOT SOLDER

TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-RINGS MA Y RESULT. (See Fig. 8)

Make connections between remote chiller outlet tube and fountain. Outlet port is marked on the chiller (1/4”O.D.

copper tube). Install a 1/4” x 1/4” union (provided) on the marked chiller outlet port. Insert the 1/4” poly tubing

coming from the fountain into the union. Turn on the water supply and check for leaks. DO NOT SOLDER

TUBES INSERTED INTO THE UNION AS DAMAGE T O THE O-RINGS MA Y RESUL T . (See Fig. 8)

9. RC8A Model Filter units. Mount filter head assembly to side of

chiller (See Figure 11). Make connections between

filter and building supply line (3/8” O.D. tube not provided). Inlet port is marked on the chiller (1/4” O. D. copper

tube). Install a 1/4” x 1/4” union (provided) on the marked chiller inlet port. Insert the 1/4” poly tubing (provided)

into the fitting on filter and connect the union to the chiller. DO NOT SOLDER TUBES INSERTED INTO THE

UNION/TEE AS DAMAGE TO THE O-RINGS MA Y RESUL T .(See Figure 11)

RC12A Models – Make connections between precooler and building supply line. Install the in-line strainer

(provided with chiller) by pushing it in until it reaches a positive stop, approximately 3/4” (19mm) on the precooler

inlet tube. Connect building supply line to strainer. DO NOT SOLDER TUBES INSERTED INTO THE STRAINER AS

DAMAGE TO THE O-RINGS MA Y RESUL T . (See Fig. 10)

Make connections between precooler and remote chiller. Inlet port is marked on the chiller (1/4” O.D. copper

tube). Bend the copper tube (provided) at an appropriate length from chiller and install a 1/4” x 3/8” union (provided) on the marked chiller inlet port. Insert the precooler outlet tube into the union. DO NOT SOLDER TUBES

INSERTED INTO THE UNION AS DAMAGE T O THE O-RINGS MA Y RESUL T . (See Fig. 10)

Make connections between remote chiller outlet tube and fountain. Outlet port is marked on the chiller (1/4”O.D.

copper tube). Install a 1/4” x 1/4” union (provided) on the marked chiller outlet port. Insert the 1/4” poly tubing

coming from the fountain into the union. Turn on the water supply and check for leaks. DO NOT SOLDER

TUBES INSERTED INTO THE UNION AS DAMAGE TO THE O-RINGS MA Y RESULT. (See Fig. 10)

10. GF Model Only . Make connections between remote chiller outlet tube and fount ain. Outlet port is marked on

the chiller (1/4” O.D. copper tube). Install a 1/4” x 1/4” tee (provided) on the marked chiller outlet port. Insert the 1/4”

poly tubing coming from the fountain into the tee. Connect glass filler line to outlet on tee. Install a 1/4” x 3/8” union

(provided) on the glass filler outlet line. Insert a piece of 1/4” poly tubing from the tee to the union. Turn on the

water supply and check for leaks. DO NOT SOLDER TUBES INSERTED INTO THE UNION/TEE AS DAMAGE TO THE

O-RINGS MA Y RESUL T. (See Fig. 9)

10. Open service stop and operate push button to purge air. Check thoroughly for leaks.

97884C (Rev. B - 3/08)

PAGE 4

Loading...

Loading...