Halsey Taylor OVLER-EE-1F Installation Manual

OVLER-EE * 1F, OVLSR-EE * 1F, OVLSER-EE * 1F, OVLESR-EE * 1F

Halsey Taylor Owners Manual

Refrigerated Fountains

OVL-ER OVL-SR OVL-SER

OVL-ESR

Installer

To assure you install this model easily and correctly, PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After installation,

leave these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO WATER LINES

IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY OCCUR AWAY FROM THE

BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK INTO A FOUNTAIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN INCREASE IN THE METAL CONTENT OF THE WATER.

THIS CONDITION IS AVOIDABLE BY USING THE PROPER MATERIALS AS INDICATED. ANY DRAIN FITTINGS

PROVIDED BY THE INSTALLER SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE FOUNTAIN

FROM THE BUILDING PLUMBING SYSTEM.

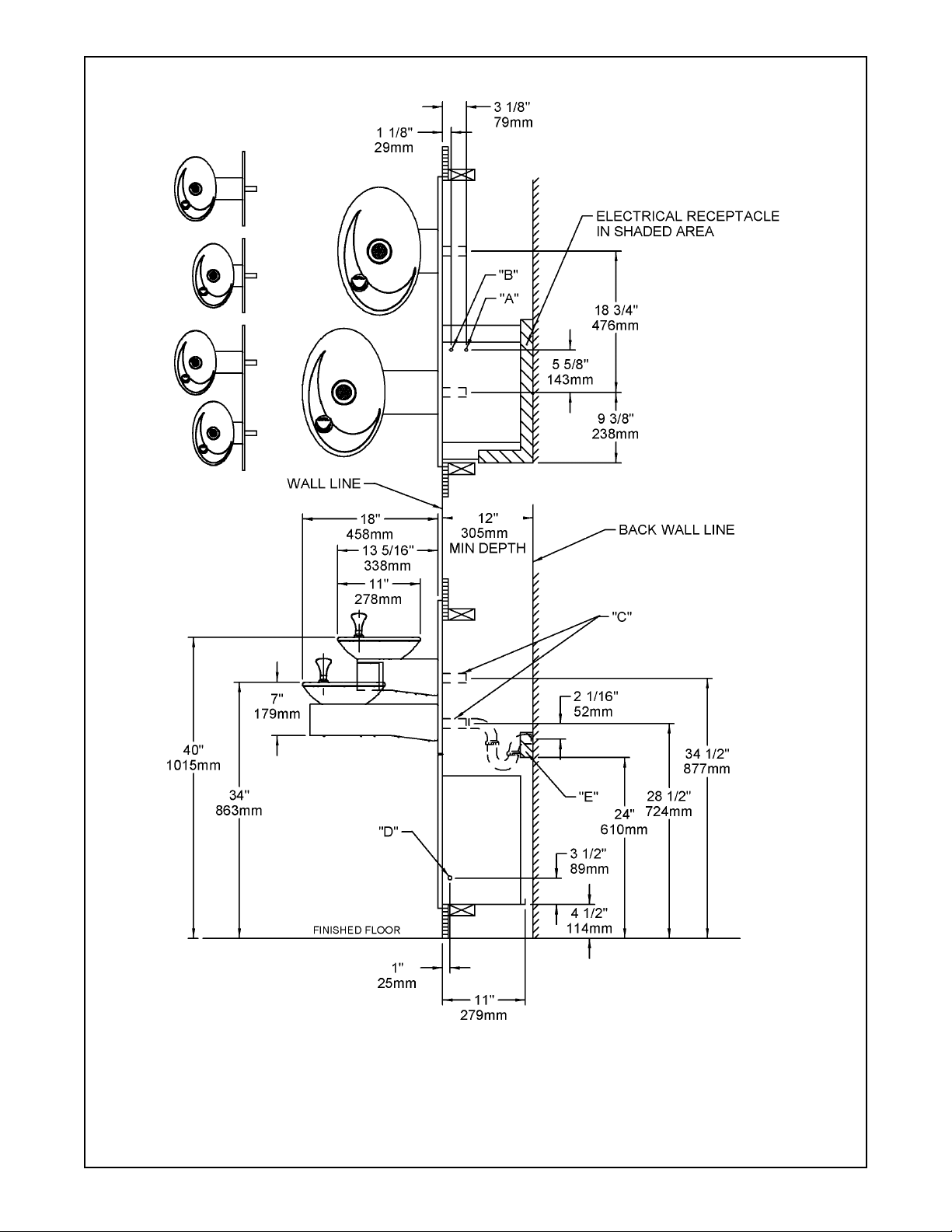

1/4" O.D. TUBE

WATER INLET

TO COOLER

FIG. 1

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS

SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

FIG. 2

PAGE 1 97447C - (Rev. J - 07/01)

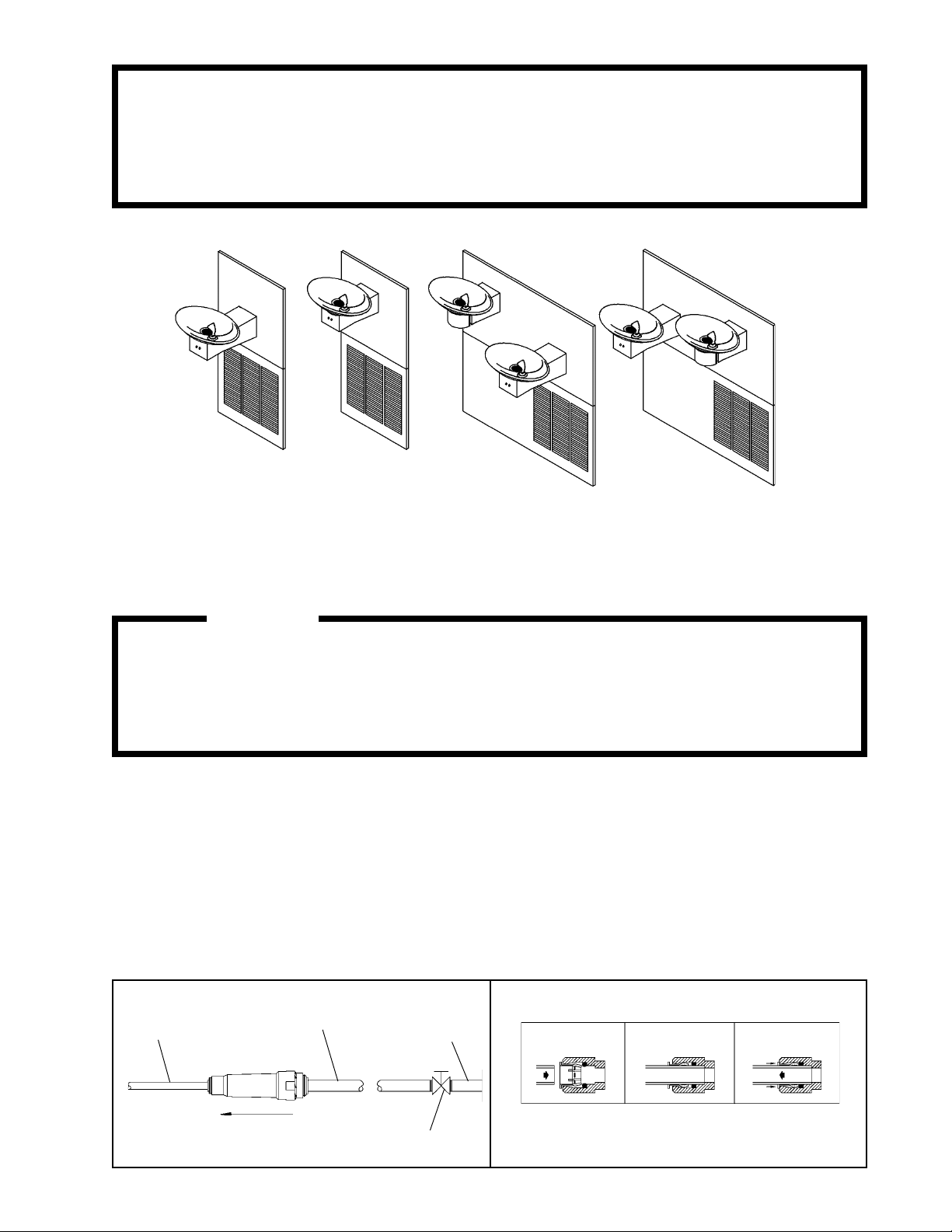

MODEL OVLER-EE

MODEL OVLSR-EE

MODEL OVLESR-EE

OVLER-EE * 1F, OVLSR-EE * 1F, OVLSER-EE * 1F, OVLESR-EE * 1F

MODEL OVLSER-EE SHOWN

LEGEND:

A = 3/8" O.D. UNPLATED COPPER TUBE CONNECT (CHILLER WATER OUTLET)

B = 3/8" O.D. UNPLATED COPPER TUBE CONNECT (CHILLER WATER INLET) SHUT OFF VALVE BY OTHERS

C = 1-1/4" O.D. WASTE TUBE (ELBOW AND TRAP NOT PROVIDED)

D = ELECTRICAL INLET

E = ELECTRICAL OUTLET LOCATION. ADDITIONAL UL/CSA LISTED GROUNDED OUTLET (BY OTHERS) REQUIRED FOR

115 VOLT, 60Hz.

FIG. 3

PAGE 297447C - (Rev. J - 07/01)

OVLER-EE * 1F, OVLSR-EE * 1F, OVLSER-EE * 1F, OVLESR-EE * 1F

INSTALLATION INSTRUCTIONS

1. Install mounting frame. See mounting frame instructions.

2. These products are designed to operate on 20-105 PSIG supply line pressure. If inlet pressure is above 105 PSIG, a pressure

regulator must be installed in the supply line. Any damage caused by reason of connecting these products to supply line pressures

lower than 20 PSIG or higher than 105 PSIG is not covered by warranty.

3. Install remote chiller. Remove front panel of chiller. Slide chiller onto the shelf and position it to the left within the guides on the shelf.

4. Make water supply connections. Install a shut-off valve and union connection to building water supply (valve and union not provided).

Turn on the water supply and flush the line thoroughly.

5. OVLER-EE, OVLSR-EE MODELS: (Ref. Fig. 5) Make connection between remote chiller and building supply line. Remove the 3/8" x 1/4"

union (item 44) from the chiller inlet tube and install the 3/8" x 3/8" union (item 49) on the chiller outlet tube. Install the strainer (item 39)

on the chiller inlet tube. Install a 3/8" O.D unplated copper water line between the valve and the cooler. Remove all burrs from the

outside of the water line. Insert the 3/8" water line into the inlet side of the strainer by pushing it in until it reaches a positive stop,

approximately 3/4" (19mm). See Figures 1 and 2. DO NOT SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-

RINGS MAY RESULT.

OVLSER-EE: (Ref. Fig. 6) Make connection between remote chiller and building supply line. Remove the 3/8" x 1/4" union (item 44) from

the chiller inlet tube and install it on the water inlet line of the upper fountain. Install the strainer (item 39) on the chiller inlet tube. Install a

3/8" O.D unplated copper water line between the valve and the cooler. Remove all burrs from the outside of the water line. Insert the

3/8" water line into the inlet side of the strainer by pushing it in until it reaches a positive stop, approximately 3/4" (19mm). See Figures 1

and 2. DO NOT SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE TO THE O-RINGS MAY RESULT.

6. OVLER-EE, OVLSR-EE: Make connection between remote chiller and solenoid valve assy. Insert end of 3/8" O.D. tube (provided) into

union on chiller outlet and the other end into the 3/8" x 1/4" union. Next insert end of 1/4"O.D. tube (provided) into union and the other

end into the straight fitting on solenoid valve assy.

OVLSER-EE: Make connection between remote chiller and solenoid valve assy. Install the 3/8" tee (provided) on the chiller outlet tube.

Insert end of 3/8" O.D. tube (provided) into outlet of the 3/8" tee and the other end into the 3/8" x 1/4" union. Next insert end of 1/4" O.D.

tube (provided) into union and the other end into the straight fitting on solenoid valve assy.

7. Hang the upper panel on the mounting frame hanger. Align holes in the panel with holes in the mounting frame. Be sure that panel is

engaged with hanger at top of frame before releasing it.

8. Install fountains. Remove bottom cover plates on underside of fountains and save the screws. Mount the fountains to the upper panel

and the wall frame with (4) 5/16" x 3/4" (19mm) long bolts and nuts (provided). Tighten securely.

9. OVLER-EE, OVLSR-EE: Connect solenoid valve assy to regulator holder in fountain by installing 1/4" O.D. tube (provided).

OLVSER-EE: Connect solenoid valve assy and regulator holder in fountain with sensor by installing 1/4" O.D. tube (provided). Connect

fountain with push button to chiller by inserting 3/8" O.D. tube (provided) into remaining outlet of the 3/8" tee and the other end into the

3/8" x 1/4" union that was removed from the chiller inlet. Insert 1/4" O.D. tube (provided) into end of union and the other end into the

regulator holder of push button fountain.

10. Remove elbow from end of p-trap and attach it to drain tube. Re-attach elbow to p-trap and cut waste tube to required length using

plumbing hardware and trap as a guide.

11. Connect power cord of sensor to solenoid valve by running it through the back panel and connecting it as shown in Fig. 7. Connec

tors may be connected to either terminal on solenoid valve. Attach ground wire to solenoid valve bracket with green ground screw.

12. Attach solenoid valve assy. to the underside of cross member of mounting frame on electric eye unit. See Figure 4.

13. Turn on water supply. Release air from tank by interrupting infrared beam; steady stream of water assures all air is removed. The

sensor has a 30 second maximum ON time. It may be necessary to step away from beam a few times to allow chiller tank to fill.

Check for leaks.

14. Make electrical connections to chiller and replace front panel. See chiller instructions.

15. Check stream height from bubbler. Adjust stream height by adjusting the screw on the regulator (item 40).

Clockwise adjustment will raise stream height and counter-clockwise will lower stream height. If needed, adjust push arm/regulator

clearance by turning phillips head screw on regulator bracket assy., Pushbar units only (item 48, fig. 10). For best adjustment a

stream height of 1-1/2"

(38mm) above the projector is recommended. (See fig. 12).

16. Mount lower panel. Loosen the (2) #10-24 x 5/8" (16mm) screws at frame bottom lip. Slide upper tongue of lower panel under lower

edge of already installed upper panel. Tighten previously loosened screws securely.

17. Replace bottom cover plate to fountain basin using screws provided. Tighten securely.

PAGE 3 97447C - (Rev. J - 07/01)

Loading...

Loading...