Halsey Taylor HTV8EEMVP-1C Installation Manual

HTV8EEMVP*1C HTV8EEMVP*2C HTV8EEMVP*3C HTVDEEMVP*1C

OWNERS MANUAL

HTVEE-MVP Series Barrier-Free Water Coolers

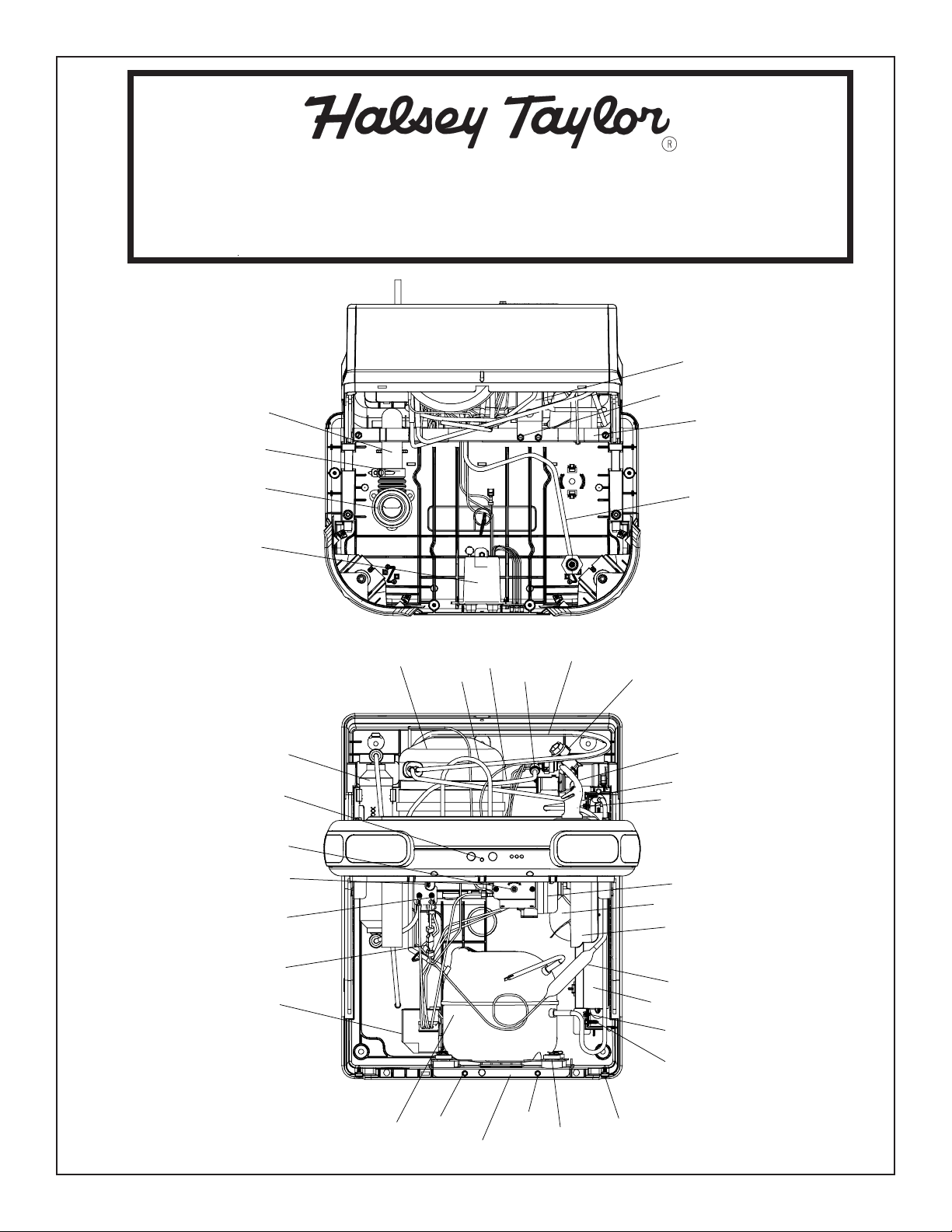

8

49

43

53

6

36

24 or 25

39, 40

(A) - See. Fig. 10

4, 17

26

4

45, 57

47

30

28

30

44

21

29

56

27

16, 50, 51

13

37

15, 20

18, 19, 23

Fig. 1

NOTE: Non-refrigerated units do not include all

electrical and refrigeration components shown above.

Other components and rough-in are the same as

shown.

22

46

48

27

56

54

PAGE 1 98495C (Rev. C - 7/09)

54

7

2, 3, 5

55, 58

HTV8EEMVP*1C HTV8EEMVP*2C HTV8EEMVP*3C HTVDEEMVP*1C

**

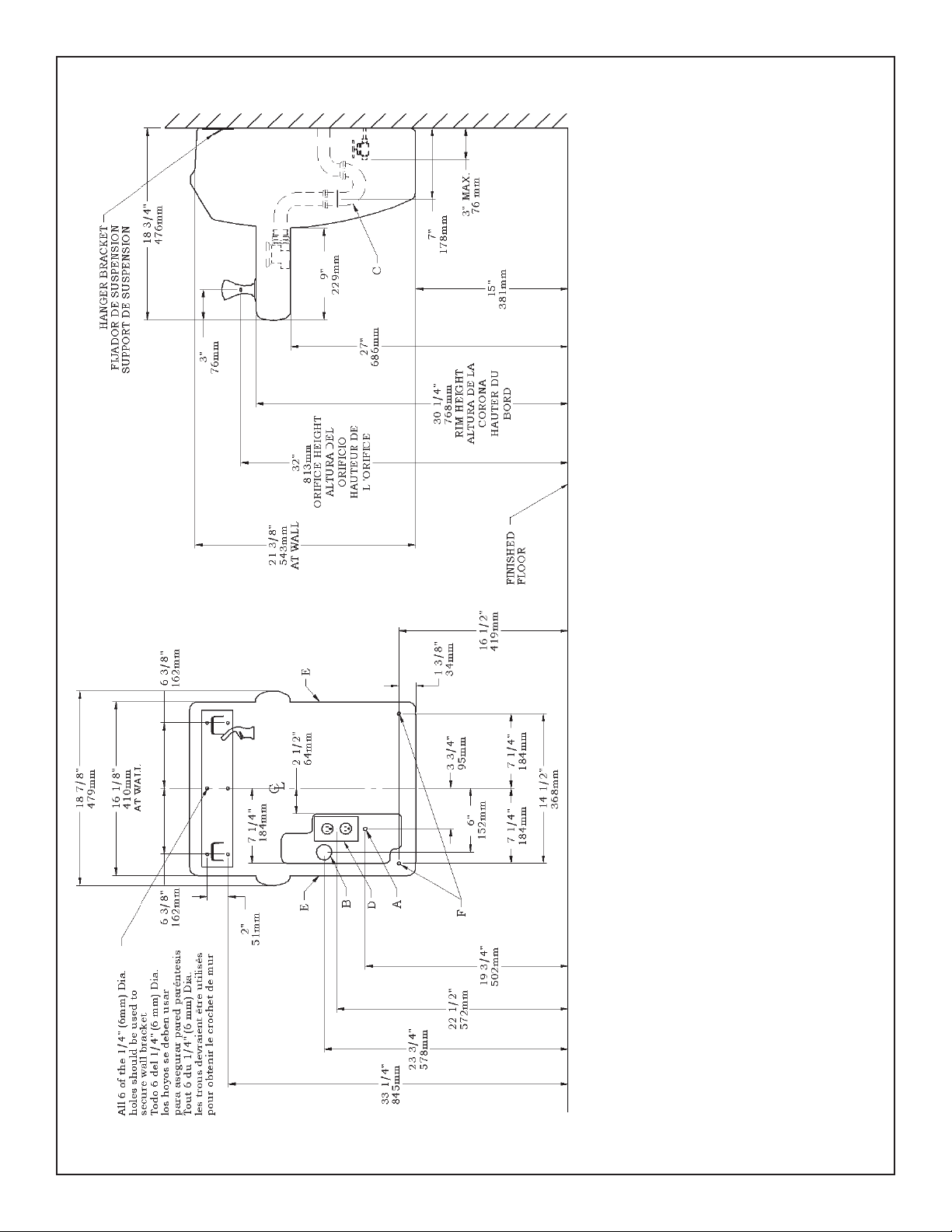

NOTE: Halsey Taylor’s recommended orifice

mounting height for children 38” to 46” tall

(approx. four through seven years old) is 23”

from the finished floor.

*

Reduce height by 3” (76mm) for

installation of childrens ADA cooler.

Reduzca la altura por 3” (76 mm) para

la instalación de childrens ADA más fresco.

*ADA REQUIREMENT

*REQUISITO DE A.D.A.

*EXIGENCE ADA

Réduire la hauteur par 3 (76 mm) pour

l’installation de childrens ADA plus frais.

When replacing a Model “HAC” with a new unit Model “HTV”,

installer must cut 1-1/2 inches from length of cooler waste line

before connecting to trap (see installation instruction No.6)

Cuando reemplace un Modelo “HAC” con una unidad nueva

Modelo “HTV” el instalador deberá cortar 1½ pulgadas del

largo del tubo de desagüe del enfriador antes de conectar el

purgador (vea las instrucciones de instalación No. 6)

En remplaçant un modèle “HAC” avec un nouveau modèle

“HTV”, l’installateur doit couper 1 1/2 pouce de longueur de la

canalisation résiduaire du refroidisseur avant de le raccorder

au siphon (voir instruction d’installation no. 6)

Fig. 2

PAGE 298495C (Rev. C - 7/09)

COPPER TUBE.

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION. SHUT OFF VALVE (NOT FURNISHED) TO ACCEPT 3/8” O.D. UNPLATED

La UBICACION RECOMENDADA de ABASTECIMIENTO DE AGUA. APAGUE V ALVULA (no AMUEBLADO) ACEPTAR 3/8 O. D.

UBICACIÓN RECOMENDADA P ARA EL DRENAJE DE SALIDA DE AGUA, DE 1¼” DE DIÁMETRO.

EMPLACEMENT RECOMMANDÉ POUR LE DRAIN DE D.E. 1-1/4" DE SORTIE D’EAU.

El TUBO del COBRE de UNPLATED

L’EMPLACEMENT DE PROVISION D’EAU RECOMMANDE. ETEINDRE LA SOUPAPE (P AS FOURNI) ACCEPTER 3/8 O.D. LE TUBE DE

CUIVRE DE UNPLATED.

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/4” O.D. DRAIN

C = 1-1/4 TRAP NOT FURNISHED**

PURGADOR DE 1¼ NO PROPORCIONADO**

SIPHON 1-1/4 NON FOURNI**

CAJA RECESIV A DE ALAMBRES (3) DE SUMINISTRO ELÉCTRICO

BOÎTE ENCASTRÉE D’ALIMENTATION ÉLECTRIQUE (3) FILS

ASEGURE UNA VENTILACIÓN ADECUADA MANTENIENDO UN ESPACIO E 6" (152 mm) (MÍN.) DE HOLGURA ENTRE LA REJILLA DE

VENTILACIÓN DEL MUEBLE Y LA PARED

ASSUREZ-VOUS UNE BONNE VENTILATION EN GARDANT 6" (152 mm) (MIN.) ENTRE LES ÉVENTS DE L’ENCEINTE ET LE MUR.

AGUJEROS DE LAS TUERCAS DE 5/16 PARA SUJETAR LA UNIDAD A LA PARED

TROUS D’ÉCROUS 5/16 POUR FIXER L’APP AREIL AU MUR

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

F = 5/16 BOLT HOLES FOR FASTENING UNIT TO WALL

HTV8EEMVP*1C HTV8EEMVP*2C HTV8EEMVP*3C HTVDEEMVP*1C

HANGER BRACKET & TRAP INST ALLATION

1) Remove the hanger bracket fastened to back of the

cooler by removing one (1) screw.

2) Mount the hanger bracket as shown in Fig. 2 & Fig 3.

NOTE: Hanger Bracket MUST be supported securely.

Add fixture support carrier if wall will not provide

adequate support. Anchor hanger securely to wall

using all six (6) 1/4 in. dia. mounting holes.

IMPORTANT:

7 in. (178mm) dimension from wall to centerline

of trap must be maintained for proper fit.

INSTALLATION OF COOLER

3) Hang the cooler on the hanger bracket. Be certain the

hanger bracket is engaged properly in the slots on the

cooler back as shown in Figure 3.

4) Remove the two (2) screws holding the bottom cover

at the bottom of cooler. (Shown in Fig. 12) Remove the

bottom cover by pulling straight down and set aside.

5) Connect water inlet line--See Note 4 of General Inst.

6) Install trap. Remove the slip nut and gasket from the

trap and install them on the cooler waste line making

sure that the end of the waste line fits into the trap.

Assemble the slip nut and gasket to the trap and tighten

securely.

IMPORTANT: If it is necessary to cut the wasteline, loosen

the clamp (Item 53) at the drain fitting (Item 36)

and remove. Check for leaks after re-assembly.

8) Plug in electrical power and re-install bottom cover. Unit

must have electrical power to have water flow.

HANGER BRACKET (Item 10)

COOLER BACK

Fig. 3

ST ART UP

Also See General Instructions

9) Stream height is factory set at 35 PSI. If supply pressure

varies greatly from this, adjust screw located on upper

side of frame (Item 32). See Fig. 3. CW adjustment

will raise stream and CCW adjustment will lower stream.

For best adjustment, stream should be 1-1/2” above

bubbler hood. (See Fig. 4)

NOTE: If continuous flow occurs at the end of the

compressor cycle, turn cold control (Item 17)

counterclockwise 1/4 turn.

CAUTION: PLASTIC COMPONENTS

Any service of this unit that requires use of a torch,

care should be taken not to melt any of the plastic

components. To keep flame away from plastic, the

use of a shield may be required.

CLEANING:

Warm, soapy water or mild household cleaning products

can be used to clean the exterior panels of the HTV

series coolers. Use of harsh chemicals or petroleum

based cleaners WILL VOID THE WARRANTY.

CORRECT STREAM

HEIGHT

Fig. 4

IMPORT ANT:

When installing cooler, do not solder 3/8” copper inlet tube

while inserted into union fitting as damage to o-ring and

plastic will result.

PAGE 3 98495C (Rev. C - 7/09)

Loading...

Loading...