HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

OWNERS MANUAL

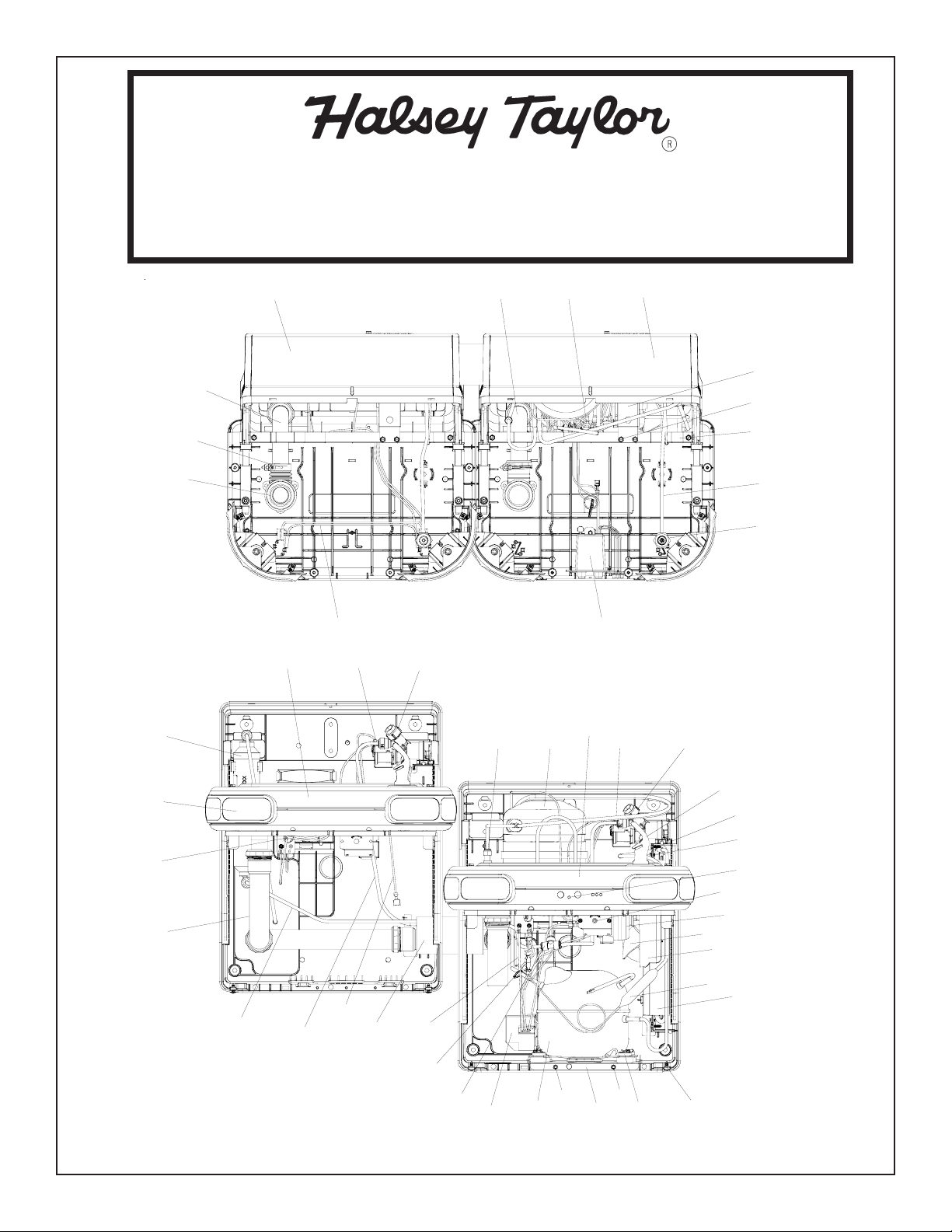

HTVBLEE-MVP Series Barrier-Free Water Coolers

49

41

62

56

43 53

24

34

17

23, 36, 51

64

69

54, 68 23, 36, 51

12

44

27

52

8

58

6

35

1, 47

40

22, 29

31

Fig. 1

35

35

28

45, 46

77

21, 29

33

67

30

(A) - See. Fig. 10

4, 16

15, 59, 60

13

42

55

57

63

18,

20,

26

PAGE 1 98496C (Rev. C - 7/09)

25

65

65

2, 3, 5

7

66, 70

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

Reduzca la altura por 3” (76 mm) para

la instalación de childrens ADA más fresco.

Reduce height by 3” (76mm) for

*ADA REQUIREMENT

*REQUISITO DE A.D.A.

*EXIGENCE ADA

installation of childrens ADA cooler.

Réduire la hauteur par 3 (76 mm) pour

l’installation de childrens ADA plus frais.

NOTE: Halsey Taylor’s recommended orifice

mounting height for children 38” to 46” tall

(approx. four through seven years old) is 23”

from the finished floor.

Fig. 2

PAGE 298496C (Rev. C - 7/09)

COPPER TUBE.

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WATER SUPPLY LOCATION. SHUT OFF VALVE (NOT FURNISHED) TO ACCEPT 3/8” O.D. UNPLATED

La UBICACION RECOMENDADA de ABASTECIMIENTO DE AGUA. APAGUE V ALVULA (no AMUEBLADO) ACEPTAR 3/8 O. D.

UBICACIÓN RECOMENDADA P ARA EL DRENAJE DE SALIDA DE AGUA, DE 1¼” DE DIÁMETRO.

EMPLACEMENT RECOMMANDÉ POUR LE DRAIN DE D.E. 1-1/4" DE SORTIE D’EAU.

El TUBO del COBRE de UNPLATED

L’EMPLACEMENT DE PROVISION D’EAU RECOMMANDE. ETEINDRE LA SOUPAPE (P AS FOURNI) ACCEPTER 3/8 O.D. LE TUBE DE

CUIVRE DE UNPLATED.

B = RECOMMENDED LOCATION FOR WASTE OUTLET 1-1/4” O.D. DRAIN

C = 1-1/2 TRAP NOT FURNISHED**

PURGADOR DE 1-1/2 NO PROPORCIONADO**

SIPHON 1-1/2 NON FOURNI**

CAJA RECESIV A DE ALAMBRES (3) DE SUMINISTRO ELÉCTRICO

BOÎTE ENCASTRÉE D’ALIMENTATION ÉLECTRIQUE (3) FILS

ASEGURE UNA VENTILACIÓN ADECUADA MANTENIENDO UN ESPACIO E 6" (152 mm) (MÍN.) DE HOLGURA ENTRE LA REJILLA DE

VENTILACIÓN DEL MUEBLE Y LA PARED

ASSUREZ-VOUS UNE BONNE VENTILATION EN GARDANT 6" (152 mm) (MIN.) ENTRE LES ÉVENTS DE L’ENCEINTE ET LE MUR.

AGUJEROS DE LAS TUERCAS DE 5/16 PARA SUJETAR LA UNIDAD A LA PARED

TROUS D’ÉCROUS 5/16 POUR FIXER L’APP AREIL AU MUR

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

F = 5/16 BOLT HOLES FOR FASTENING UNIT TO WALL

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

HANGER BRACKET & TRAP INST ALLATION

1) Remove the hanger bracket fastened to back of the

cooler by removing one (1) screw.

2) Mount the hanger bracket as shown in Fig. 2 & Fig 3.

NOTE: Hanger Bracket MUST be supported securely.

Add fixture support carrier if wall will not provide

adequate support. Anchor hanger securely to wall

using all six (6) 1/4 in. dia. mounting holes.

IMPORTANT:

7 in. (178mm) dimension from wall to centerline

of trap must be maintained for proper fit.

INSTALLATION OF COOLER

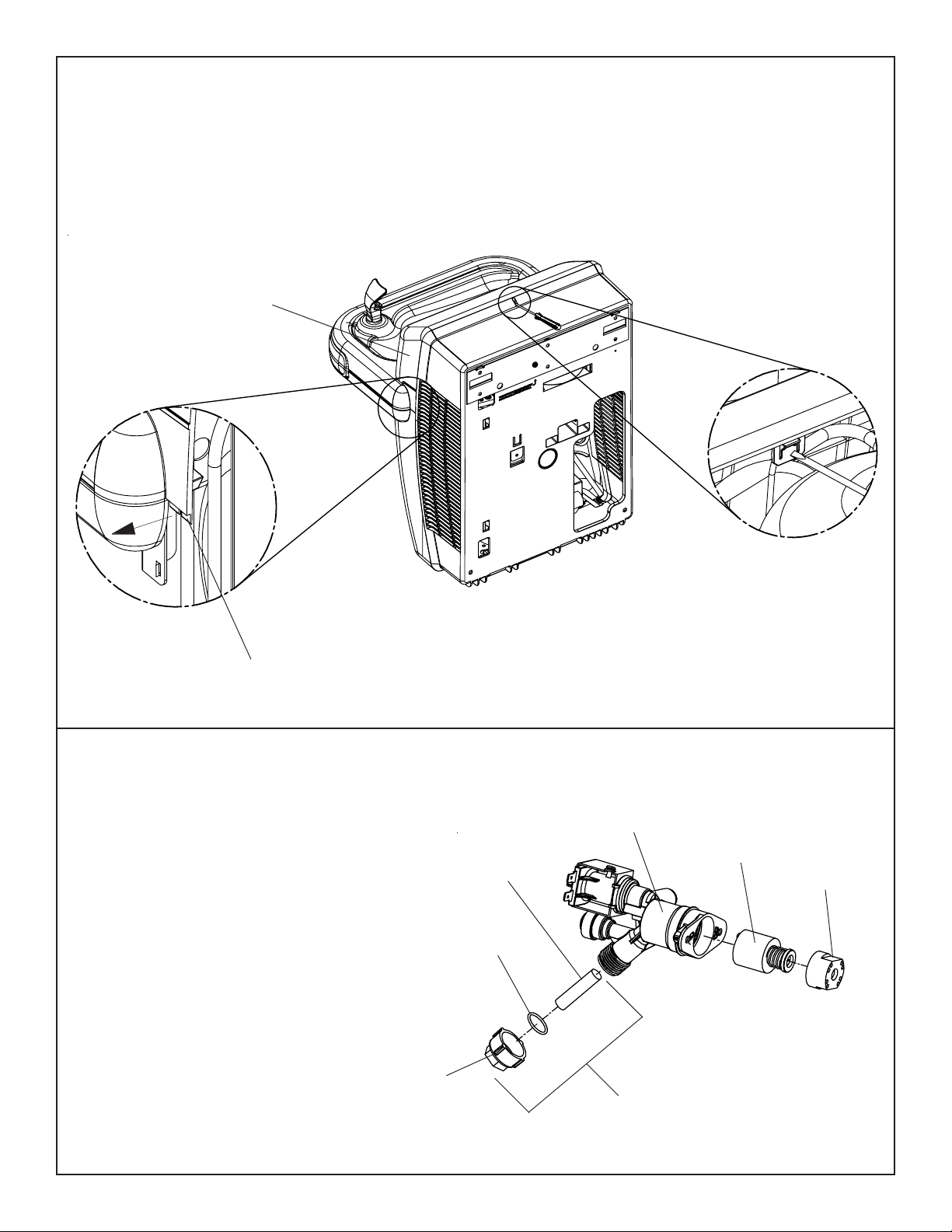

3) Hang the cooler on the hanger bracket. Be certain the

hanger bracket is engaged properly in the slots on the

cooler back as shown in Figure 3.

4) Remove the two (2) screws holding the bottom cover

at the bottom of cooler. (Shown in Fig. 16) Remove the

bottom cover by pulling straight down and set aside.

5) Connect water inlet line--See Note 4 of General Inst.

6) Install trap. Remove the slip nut and gasket from the

trap and install them on the cooler waste line making

sure that the end of the waste line fits into the trap.

Assemble the slip nut and gasket to the trap and tighten

securely.

IMPORTANT: If it is necessary to cut the wasteline, loosen

the clamp (Item 62) at the drain fitting (Item 41)

and remove. Check for leaks after re-assembly.

8) Plug in electrical power and re-install bottom cover. Unit

must have electrical power to have water flow.

HANGER BRACKET (Item 10)

COOLER BACK

Fig. 3

ST ART UP

Also See General Instructions

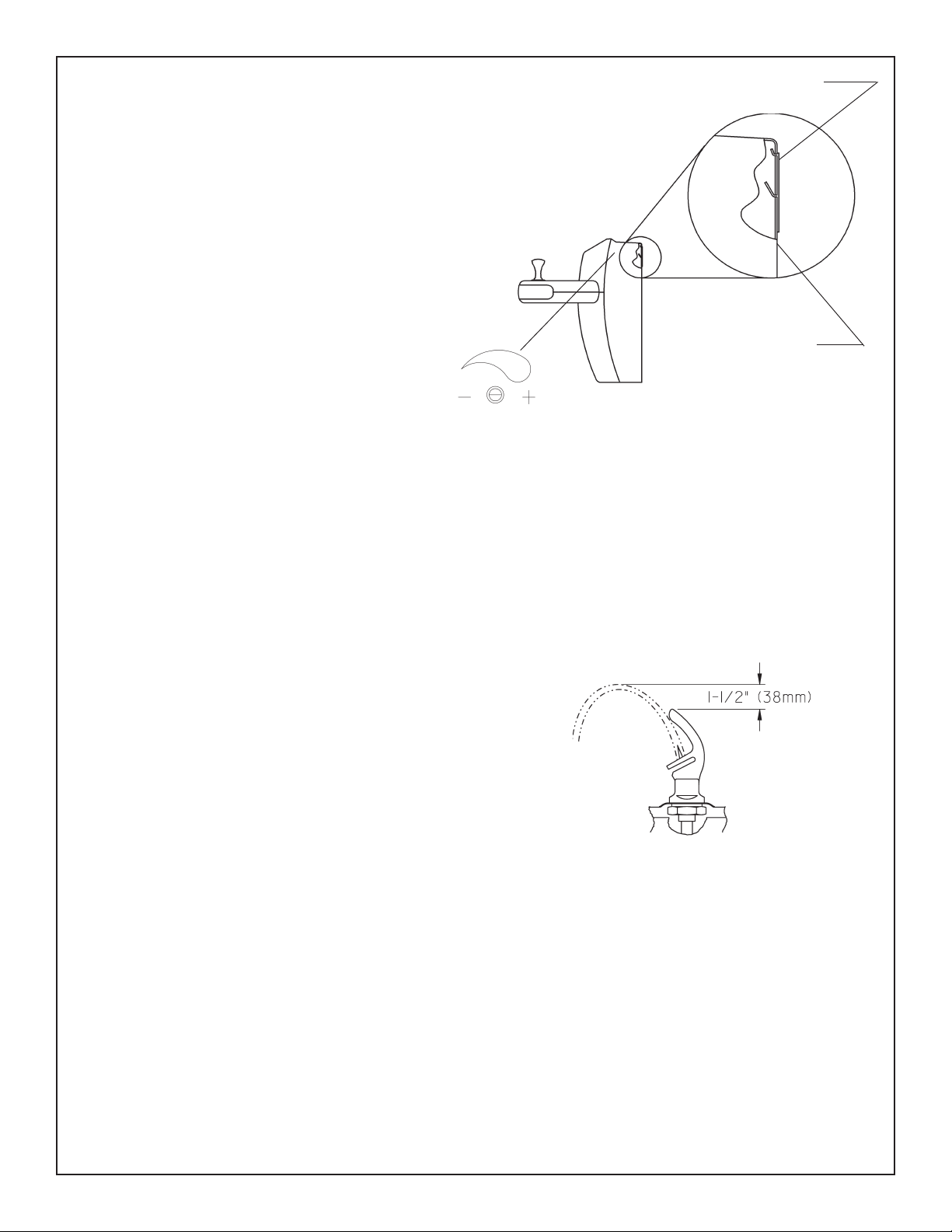

9) Stream height is factory set at 35 PSI. If supply pressure

varies greatly from this, adjust screw located on upper

side of frame (Item 43 or 44). See Fig. 3. CW adjustment

will raise stream and CCW adjustment will lower stream.

For best adjustment, stream should be 1-1/2” above

bubbler hood. (See Fig. 4)

NOTE: If continuous flow occurs at the end of the

compressor cycle, turn cold control (Item 16)

counterclockwise 1/4 turn.

CAUTION: PLASTIC COMPONENTS

Any service of this unit that requires use of a torch,

care should be taken not to melt any of the plastic

components. To keep flame away from plastic, the

use of a shield may be required.

CLEANING:

Warm, soapy water or mild household cleaning products

can be used to clean the exterior panels of the HTV

series coolers. Use of harsh chemicals or petroleum

based cleaners WILL VOID THE WARRANTY.

CORRECT STREAM

HEIGHT

Fig. 4

IMPORT ANT:

When installing cooler, do not solder 3/8” copper inlet tube

while inserted into union fitting as damage to o-ring and

plastic will result.

PAGE 3 98496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

Top Cover Removal

Please remove bottom cover before removing top cover. To remove top cover

(Item 37), use a small screwdriver to release the snap for the top cover as shown

in Fig. 5. Then pull the small tabs on each side of the top cover outward slightly

and slide upward to remove.

FIG. 5

37

Small tabs

Cleaning the strainer

To clean the strainer, unscrew the cap of the

solenoid valve. Remove screen and rinse

thoroughly with water. Insert screen back

into solenoid valve and screw cap on. Make

sure the o-ring is placed properly.

Retén anular

Joint Torique

Cap

Tapa

Bouchon

Screen

Malla

Ecran

O-ring

FIG. 6

23

51

36

76

PAGE 498496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

Removing the basin

To remove the basin (Item 12 or 34), remove two screws (Item 58) on top of the basin

(Shown in Fig. 7). Then remove the four screws (Item 71) located underneath the

dispenser bottom (Item 39 or 50) as shown in Fig. 7. Finally pull polytube (Item 35)

out of bubbler nipple (Item 47) as shown in Fig. 8. and remove the basin.

FIG. 7

58

58

12 or 34

71

FIG. 8

1

35

33

47

See figure below for

Operation of Quick

Connect Fittings

FIG. 9

Filter Installation Detail

(Some parts hidden for clarity)

48, 65

49

PAGE 5 98496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

SENSOR RANGE ADJUSTMENT: (A)

The electronic sensor used in this cooler is factory pre-set for a “visual” range of

36 inches (914 mm). If actual range varies greatly from this or a different setting

is desired, follow the range adjustment procedure below:

- Using a small tip screwdriver, locate range adjustment screw through the

small hole between the sensor lenses (A). Turn this screw clockwise to

increase range and counterclockwise to decrease range.

CAUTION: Complete range of sensor (24-46 inches/610-1168mm) is only one

turn of the adjusting screw.

SENSOR CONTROL: If sensor fails to operate valve mechanism or operates

erratically, check the following.

A. Ensure there are no obstructions within a 40 inch (1016mm) radius in front

of cooler.

B. Check wire connections at the solenoid valve and sensor.

CAUTION: Make sure unit is unplugged before checking any wiring.

C. Ensure proper operation of solenoid valve. If there is an audible clicking

sound yet no water flows,look for an obstruction in the valve itself or

elsewhere in the water supply line.

65

FIG. 10

32

Green

Yellow

50

9

27

11

74

Red

(A)

PAGE 698496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

SENSOR WITH FILTER LIFE INDICATOR: (B)

The electronic sensor includes LED filter status indicators that are factory preset to monitor filter life. The sensor monitors the “ON” time

of the water valve solenoid and keeps track of total time water is dispensed. There are (3) LED’s and indicates the following:

Once power is applied to the water cooler, if all three LED’s flash then the Green LED aluminates, this indicates that there is some filter

usage memory stored. When the Green LED comes on only, this indicates that the filter life is at absolute 0% of filter life. NOTE: You

may have some very minimal filter life in memory upon receiving water cooler due to factory functional testing.

NOTE: The filter status will be retained until reset (see resetting filter monitor). The filter monitor will retain its memory even

during a loss of power.

Green LED (Good) indicates that the filter is operating within 0% - 80% of its life.

Yellow LED indicates that the filter is operating within 80% - 100% of its life.

Red LED (Replace) indicates that the filter needs to be replaced since it has reached end of filter life.

RESETTING FILTER LIFE INDICATOR: (C)

In order to reset the filter life indicator status LED’s, you must remove the finishing plug (Item 75) underneath the front dispenser. With a

straight blade screw driver or pen, reach inside opening and depress the reset button located on the back of the sensor as seen on

a minimum of 1 second. (You may need a flashlight). Reinstall finishing plug and the Green LED should be illuminated indicating that the

visual filter monitor has been reset.

(B)

(C) for

FIG. 11

(C) - Reset Button

75

PAGE 7 98496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

Switch Activation Detail

FIG. 12

40

19

Closed switch

40

19

Open switch

PAGE 898496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

FIG. 13

73

72

73

40

Pushbar Replacement

Please remove the basin before removing the pushbars.

Remove screw (Item 73) that holds pushbars in place. Then

simply slide the pushbars upward and remove. Do not discard the

small springs or screws. When replacing pushbars do not over

tighten screws, because the pushbars need to move freely.

See Figures 13 & 14 for proper spring placement.

FIG. 14

72

PAGE 9 98496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

See

Fig. 10

40

73

12

58

62

53

33

1

1

46

73 40

58

FIG. 15

58

37

10

58

44

41

50

71

75

71

71

Bottom Cover Removal

To access the refrigeration system and plumbing

connections, remove two screws (Item 66) to remove

bottom cover (Item 38).

32, 36, 51

71

61

6

61

58

38

70

66

70

66

PAGE 1098496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

FIG. 16

28

CONNECTS TO

SENSOR ON

REFRIG. SIDE UNIT

HTVD8BL-MVP - 115V

SOLENOID

17

VALVE

PURPLE

JUMPER

SMOOTH

(LINE)

RIBBED

(NEUTRAL)

WIRING DIAGRAM

GND

GREEN

FIG. 17

COMPRESSOR

BLACK

LED PCB

RED

WHITE

GREEN

WHT

BLK

SENSOR

RED

OVERLOAD

3

1

2

C

S

M

6

5

3

2

1

RELAY

FAN

SOLENOID

COLD CONTROL

SMOOTH (LINE)

RIBBED

(NEUTRAL)

MALE TERMINAL ON

WHITE SHORT LEAD

ON POWERCORD

YELLOW

PURPLE JUMPER

GRND

VALVE

GREEN

14 (Black Jumper Wire)

GND

CONNECTS TO SENSOR

ON LESS REFRIG. UNIT

WIRING DIAGRAM

HTV8BLEE-MVP - 115V

FIG. 18

28

CONNECTS TO

SENSOR TO

REFRIG. SIDE UNIT

SMOOTH LEAD

TO "L" TERMINAL

ON POWER INLET

17

PURPLE

JUMPER

GREEN LEAD TO

GROUND TERMINAL

ON POWER INLET

SOLENOID

VALVE

RIBBED LEAD

TO "N" TERMINAL

ON POWER INLET

GND

GREEN

FIG. 19

OVERLOAD

COMPRESSOR

RELAY

BLACK

LED PCB

RED

WHITE

GREEN

WHT

BLK

SENSOR

RED

SOLENOID

3

1

2

C

S

M

6

5

3

2

1

FAN

RIBBED LEAD

TO "N" TERMINAL

ON POWER INLET

GREEN LEAD TO

"GROUND" TERMINAL

ON POWER INLET

COLD CONTROL

YELLOW

PURPLE

GND

CONNECTS TO SENSOR

VALVE

GREEN

ON LESS REFRIG. UNIT

14 (Black Jumper Wire)

MALE TERMINAL ON

WHITE SHORT LEAD

ON POWERCORD

GND

SMOOTH LEAD

TO "L" TERMINAL

ON POWER INLET

WIRING DIAGRAM

HTVD8BL-MVP - 220V-50/60Hz

WIRING DIAGRAM

HTV8BLEE-MVP - 220V-50/60Hz

PAGE 11 98496C (Rev. C - 7/09)

HTV8BLEEMVP*1C HTV8BLEEMVP*2C HVT8BLEEMVP*3C HTVDBLMVP*1C HTVDBLMVP*2C HTVDBLMVP*3C

PARTS LIST

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

*

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

*REPLACE WITH SAME COMPRESSOR USED IN ORIGINAL ASSEMBL Y.

NOTE: All correspondence pertaining to any of the above water coolers or orders

for repair parts MUST include Model No. and Serial No. of cooler, name and part

number of replacement part.

PART NO.

100322740560

100806740570

101516143550

111411443890

19037000

28237C

28238C

28239C

28246C

28266C

28803C

28836C

30646C

30873C

31490C

31513C

33133000

35768C

35948C

35959C

36285C

35980C

36247C

36279C

36094C

36158C

36263C

36265C

38397000

38417001

45875C

75717C

51544C

55001122

56092C

56082C

56098C

56102C

56106C

56110C

56118C

56122C

56128C

56132C

56154C

56155C

56159C

56190C

56191C

56291C

66654C

66661C

45893C

66700C

66703C

45893C

66762C

70002C

70009C

70018C

75718C

70444C

70682C

70683C

75722C

75532C

75533C

75568C

75583C

75599C

75663C

75621C

75625C

75715C

75716C

98169C

36090C

DESCRIPTION

Gasket - Bubbler (upper and lower)

Grommet - Compressor Mtg.

Stud - Compressor Mtg.

Screw - #8 -36 x .38 Tri-Lobed

Clip - Compressor Mtg.

Support Brace

Compressor Base

Bracket - Fan Motor

Bracket - EE

Hanger Bracket

Bracket - Mtg.

Basin - (Filter Monitor Unit)

Fan Blade

Jumper Wire - Black

Fan Motor

Cold Control

Adapter Tab

Cover - Relay

Switch Electrical

Relay

Power Cord (Refrig. Unit)

Power Cord (Less Refrig. Unit)

Solenoid Valve

Wiring Harness

Compressor Serv. Pak EMI 70

Overload

Sensor - EE (Filter Monitor)

Jumper Wire (Purple)

Bushing - Strain Relief

Screw - #8-18 x .37 HHSM

Waste Line Assy.

Rivet - Push In

Bubbler - Chrome

Tubing - Poly (Cut To length)

Dispenser Bottom (Less Refrig. Unit)

Dispenser Bottom (Refrig. Unit)

Waste Line (Less Refrig. Unit)

Screw - #10 x 1/2” Lg. HHSM

Screw - #8-18 Flat hd. Torx Drive

Screw - #10-16 x .63” THSM

Kit - Replacement Cap/Screen/O-Ring

Basin

Regulator Nut

Top Cover

Bottom Cover

Pushbar

Fitting - Drain

Fan Shroud

Frame (Less Refrig. Unit)

Frame (Refrig. Unit)

Bushing

Drain Cover

Nipple - Bubbler

Bracket - Filter Mounting

Filter Assembly

Regulator

Heat Exchanger

Waste Line (Refrig. Unit)

Evaporator Assembly

Drier

Condenser

Screw - Fan Motor

Hex Nut

Clamp - Drain Gasket

Fitting - Tee 1/4”

Fitting - Union 1/4”

Screw - #8-18 HH Self Tap

Screw - #8 x .63 HHSM

Screw #12 x 1.50” HHSM

Fitting - Elbow 5/16” x 1/4”

Clip - Tinnerman

Screw - #10 x .50 HHSM

Spring - Pushbar

Screw - HTV Pushbar

Rivet - Push In Ratcheting

Finishing Plug

Ground Wire - Green

ITEM NO.

15

20

21

22

23

25

*

26

78

NS

ITEM NO.

15

20

21

22

23

25

*

26

78

NS

FIG. 20

220V-50Hz PARTS LIST

PART NO.

31431C

36050C

36066C

36067C

36248C

36085C

36195C

35826C

28350C

220V-60Hz PARTS LIST

PART NO.

31431C

36050C

36066C

36067C

36248C

36092C

36174C

35826C

28350C

78 (220V)

DESCRIPTION

Fan Motor

Relay

Power Cord (Refrig. Unit)

Power Cord (Less Refrig. Unit)

Solenoid Valve

Compressor Serv. Pak

Overload

Power Inlet

Bracket - Power Inlet

DESCRIPTION

Fan Motor

Relay

Power Cord (Refrig. Unit)

Power Cord (Less Refrig. Unit)

Solenoid Valve

Compressor Serv. Pak

Overload

Power Inlet

Bracket - Power Inlet

2222 CAMDEN COURT

OAK BROOK, IL 60523

630.574.3500

FOR PARTS CONTACT YOUR LOCAL DISTRIBUTOR OR VISIT OUR WEBSITE WWW.HALSEYTAYLOR.COM

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

PAGE 1298496C (Rev. C - 7/09)

PRINTED IN U.S.A.

Loading...

Loading...