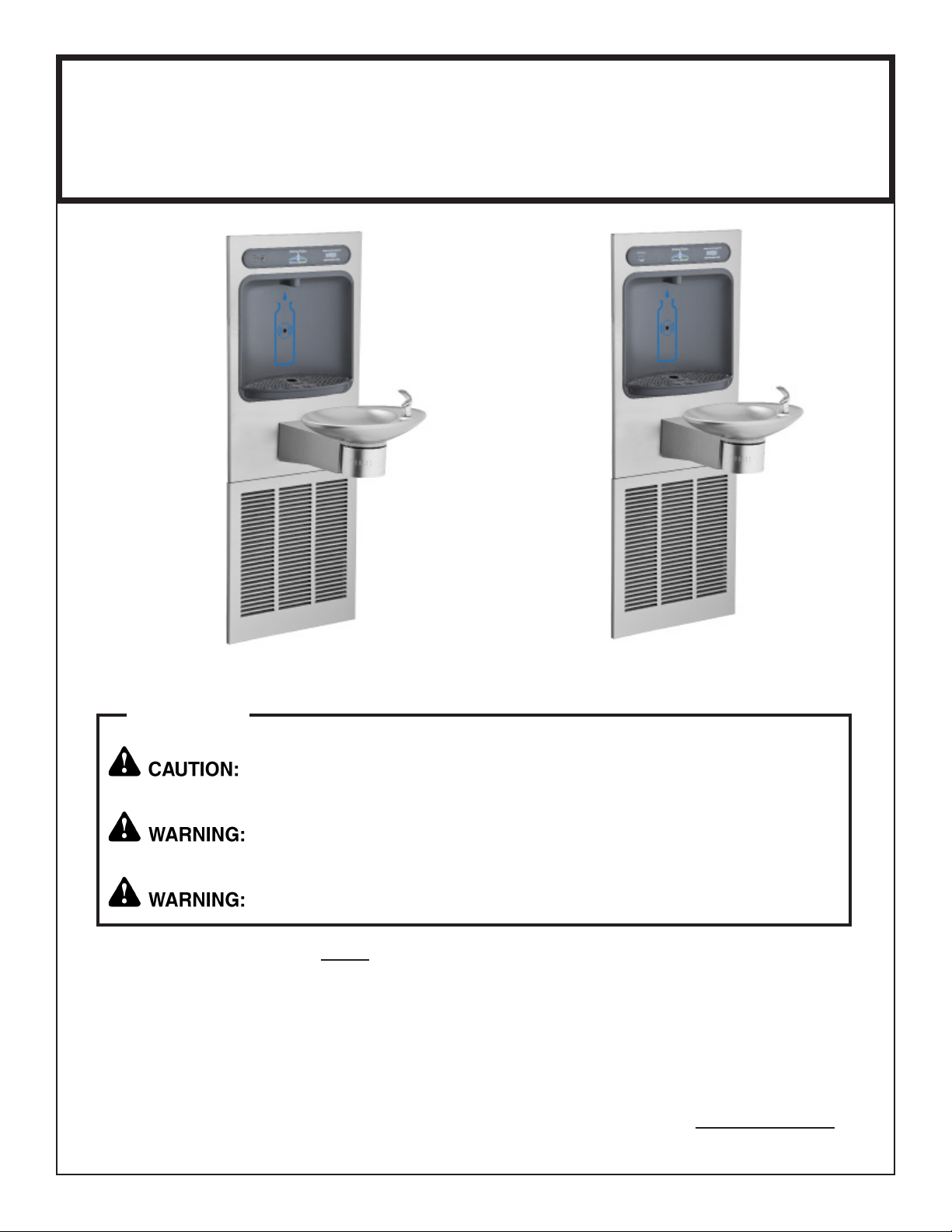

Halsey taylor Hthbwf-ovler-i, Hthb-ovler-i User Manual

OVLERWSI_NF OVLERWSI_WF

Halsey Taylor Owners Manual

OVL™ Fountains with Dual-Stream Bubbler

and HydroBoost® Bottle Filler

™

HTHB-OVLER-I

HTHBWF-OVLER-I

INSTALLER

Review these instructions before beginning installation. Be sure that installation

conforms to all plumbing, electrical and other applicable codes.

When installation is complete, ensure these instructions are left in the plastic bag

provided inside the installed unit for future reference.

Service to be performed by authorized service personnel only.

NOTE: It is common practice to ground electrical hardware such as telephones, computers and other devices

to available water lines. This can, however, cause electrical feedback in the plumbing circuit, which

results in an “electrolysis” effect occurring in the fountain. This may result in water which has a

metallic taste to it or has a noticeable increase in the metallic content of the water.

When inspecting plumbing circuit, remember the line may be grounded some distance from the

installation, and may occur outside the building or area in which the unit is being installed.

This condition can be avoided (in most cases) by using recommended materials during installation.

Any drain ttings provided by the installer should be made of plastic which will electronically isolate

the fountain from the remainder of the building’s plumbing circuits.

Page 1

1000002450 (Rev. F - 03/19)

OVLERWSI_NF OVLERWSI_WF

38 1/2"

978mm

37 1/4"

946mm

28 1/2"

724mm

8"

203mm

8" 203mm MINIMUM

FOR DRAIN CONNECTION

AND ACCESS TO

BOTTLE FILLER

ELECTRICALS

BOTTLE FILLER

DRAIN (TRAP REQUIRED

SUPPLIED BY INSTALLER)

JUNCTION BOX

LOCATION

1-1/4" (32mm)

WASTE TUBE

FURNISHED

1/4" O.D. COPPER

TUBE, COLD WATER

OUTLET

4 1/2"

114mm

11"

279mm

5/8"

16mm

455mm

17 15/16"

7"

179mm

1 1/2"

38mm

Models HTHB-OVLER-I / HTHBWF-OVLER-I

ACTIVATION

SENSOR

9 7/8"

251mm

19 3/4"

502mm

INLET

1 1/8"

29mm

ELECTRICAL

3/8" O.D. COPPER

ON CHILLER. SHUT

TUBE WATER INLET

OFF VALVE BY OTHERS

27"

ADA

686mm

REQUIREMENT

44"

1118mm

**NEW INSTALLATIONS MUST USE GROUND FAULT CIRCUIT INTERRUPTER *GFCI)

1000002450 (Rev. F - 03/19)

881mm

34 11/16"

Figure 1 - Rough-in Dimensions

Page 2

FINISHED FLOOR

20 1/2"

520mm

OVLERWSI_NF OVLERWSI_WF

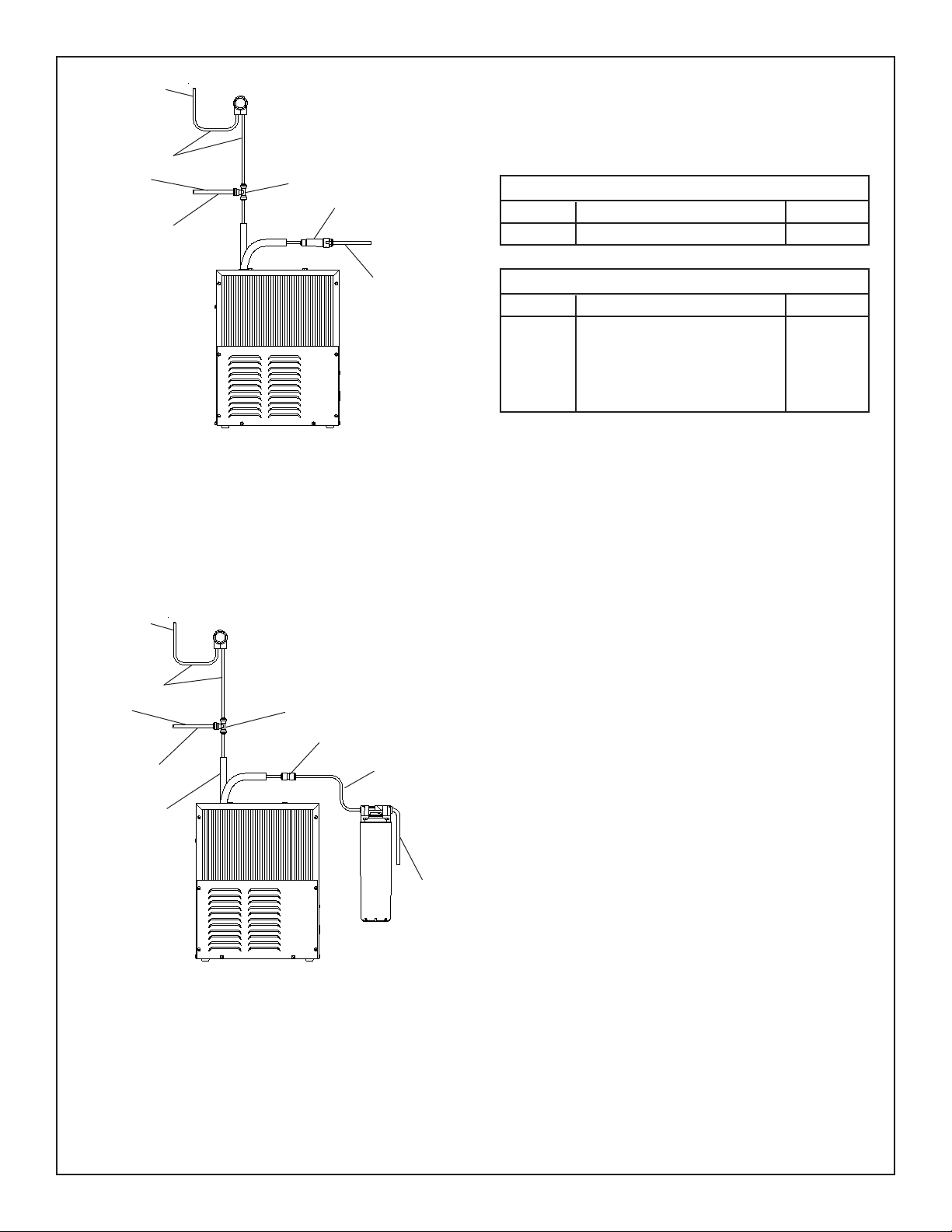

TO BUBBLER

12

TO BOTTLE

FILLER

28

27

Figure 2 - HTHB-OVLER-I Tube Routing

14

CHILLER

INLET

REQUIRED TOOLS AND MATERIALS

These tables show special tools and/or additional materials

(not provided) which are necessary to complete installation

of these units:

Special Tools

Item

Description

NONE

Additional Materials Not Included

Item

1

Unplated copper inlet pipe

2

Service Stop/Shut-off Valve

3

90° 1-1/4” Drain Line

4

1-1/4” Tee Drain Line

1. Make water supply connections (Fig. 11). Install a shut-off valve

and union connection to building water supply (valve and union

not provided). Turn on water supply and ush the line thoroughly.

Caution: DO NOT SOLDER tubes inserted into the

strainer or lter head as damage to the o-rings may result.

Description

Quantity

Quantity

1

1

1

1

TO BUBBLER

TO BOTTLE

FILLER

CHILLER

OUTLET

12

27

25

28

12

WATER

INLET

Figure 3 - HTHBWF-OVLER-I Tube Routing

2. Install mounting frame (instructions supplied with mounting

frame.

3. (For HTHB-OVLER-I) Install the strainer on the inlet tube of the

chiller. Install 1/4” x 1/4” x 3/8” tee on outlet tube of the chiller per

(Fig. 2).

4. (For HTHBWF-OVLER-I) Install the lter head to the bracket

then install bracket to side of chiller (Fig. 13). Next install lter to

lter head and plumb from lter outlet to the chiller inlet with 1/4”

poly tubing and 1/4” x 1/4” union per (Fig. 3).

4a. Install chiller on shelf, install 1/4” X 1/4” x 3/8” Tee on chiller

outlet tube. With the back panel standing close to the frame,

connect the 3/8” poly tube coming from the bottle ller to the tee

(Fig. 3).

Note: Building construction must allow for adequate

air ow on both sides, top & back of chiller. A minimum

of 4” (102 mm) on both sides & top is required. See

chiller installation for additional instructions.

5. Hang main panel on mounting frame hanger. Make sure the

power cord, reset switch wire & poly tube, do not get pinched

between the panel & mounting frame. Ensure the panel engages

at the top. Align fountain holes with mounting frame holes.

6. Remove protective coating from main panel.

7. Install reset switch for bottle ller (Fig. 4). Snap the switch into

position after locating wires through slot. Wrap up the excess

cord.

Page 3

1000002450 (Rev. F - 03/19)

Loading...

Loading...