Halsey Taylor HTHB-OVLSEBP-I User Manual

Satisfying Thirsts Since 1912

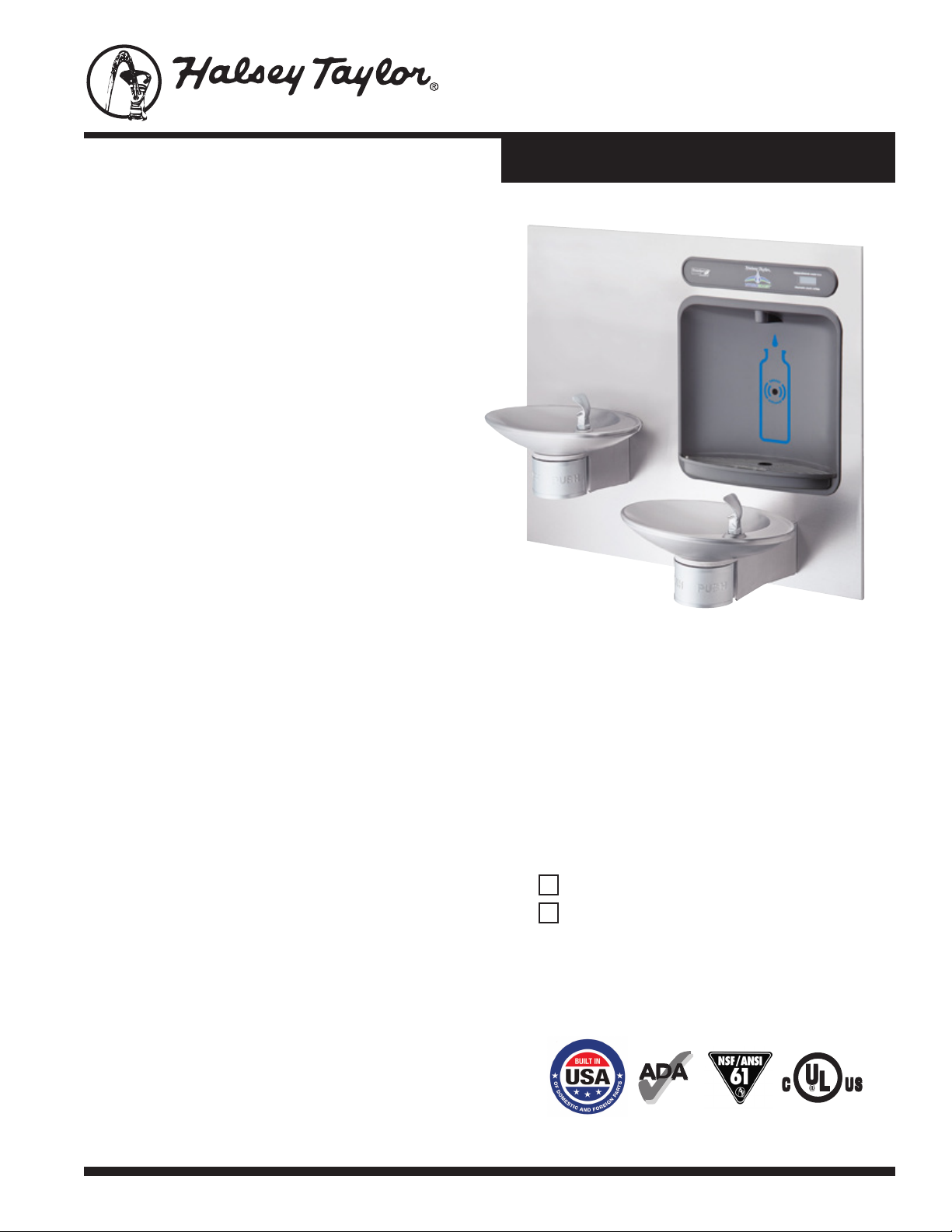

OVL-II™ Series Bi-Level

Wall Mount Fountain

Barrier-Free with HydroBoost

®

MODEL: HTHB-OVLSEBP-I

GENERAL

Complete water station including HydroBoost® bottle lling station and OVL-II™ style water fountain. Two face-mounted fountains,

one-piece, non-corrosive stainless steel number 300 series with

brushed satin nish. Contour-formed basins with softly rounded

corners and edges reduces splatter, insures proper drainage and

prevents standing waste water. Designed to be easily accessible

to both physically challenged and able-bodied individuals. Ideally

suited for installation in public areas. Model meets state and fed-

eral requirements as dened by the Americans with Disabilities Act.

HYDROBOOST® BOTTLE FILLING STATION

Sensor-activated enhanced with user interface graphics. Quick ll

rate is 1.5 gallons per minute. Laminar ow provides a clean ll with

minimal splash and easy maintenance. Equipped with an automatic

20-second shut-off timer. Key plastic components are integrated with

silver ion anti-microbial protection to inhibit growth of mold and mildew.

SILVER ION ANTI-MICROBIAL PROTECTION

Key plastic components are integrated with silver ion anti-microbial

protection to inhibit growth of mold and mildew.

GREEN COUNTER™

Visually displays count of plastic bottles saved from landfills.

(Based on 20 oz. bottles for refrigerated models).

DOUBLE BUBBLER™

Features an exclusive one-piece, chrome plated twostream mound-building bubbler with non-removable anti-squirt

feature. It’s integral hood insures a satisfying drink of water.

PUSHBUTTON ACTUATION MECHANISM

Self-closing, vandal-resistant pushbutton does not require grasping or

twisting.

PANEL

Constructed of stainless steel, No. 300 Series with satin nish.

AUTOMATIC STREAM HEIGHT REGULATOR

Self-closing assembly is located inside unit to prevent tampering.

Unit resists corrosion and liming. A constant stream height is automatically maintained under line pressures that vary from 20 to 105 psi.

OVL Fountain With Bottle Filler

Rated for Indoor Use Only

SUGGESTED SPECIFICATIONS

Unit shall include bi-level contoured fountains with integral bottle lling

station constructed of stainless steel and ABS plastic. Bottle ller shall

include electronic sensor for no-touch activation with automatic 20-sec-

ond shut-off timer. Shall provide 1.5 gpm ow rate with laminar ow to

minimize splashing. Shall include anti-microbial protected plastic components to inhibit mold and mildew. Fountains shall include front pushbutton

activation. Shall have contoured fountain basins to minimize splashing

and standing water and include rounded edges. Each projector shall be

two-stream, mound-building type with integral hood guard and anti-squirt

feature. Shall comply with ANSI 117:1 and ADA guidelines for visual and

motion disabilities. The manufacturer shall certify the unit to meet the requirements of NSF/ANSI 61 and 372, UL 399 and CAN/CSA 22.2 No. 120.

INLET STRAINER

Easily cleaned in-line strainer screen traps particles of

140 microns or larger before they enter the waterway.

WATER INLET

3/8” O.D. Tubing.

DRAIN OUTLET

1-1/2” tube outlet for 1-1/2” slip joint connection. (P-Trap not included.)

Note: Continued product improvement makes specication

subject to change without notice. See Halsey Taylor website

for most current spec Sheet.

www.halseytaylor.com

HALSEY TAYLOR, 2222 Camden Court, OakBrook, IL 60523

Optional Accessories (Extra Cost)

Cane Touch Apron (Item #HTOVLAPR)

Access Panel (Item #ACCESS12X38-5)

Each HTHB-OVLSEBP-I consists of 2 cartons as follows:

Fountain, Panel and Misc. Parts; Mounting Frame.

Service stop not included. Total shipping weight: 120 lbs.

SPEC00051 09/2014

Model HTHB-OVLSEBP-I

OVL-II™ Series Bi-Level

Wall Mount Fountain

Barrier-Free with HydroBoost

(continued)

®

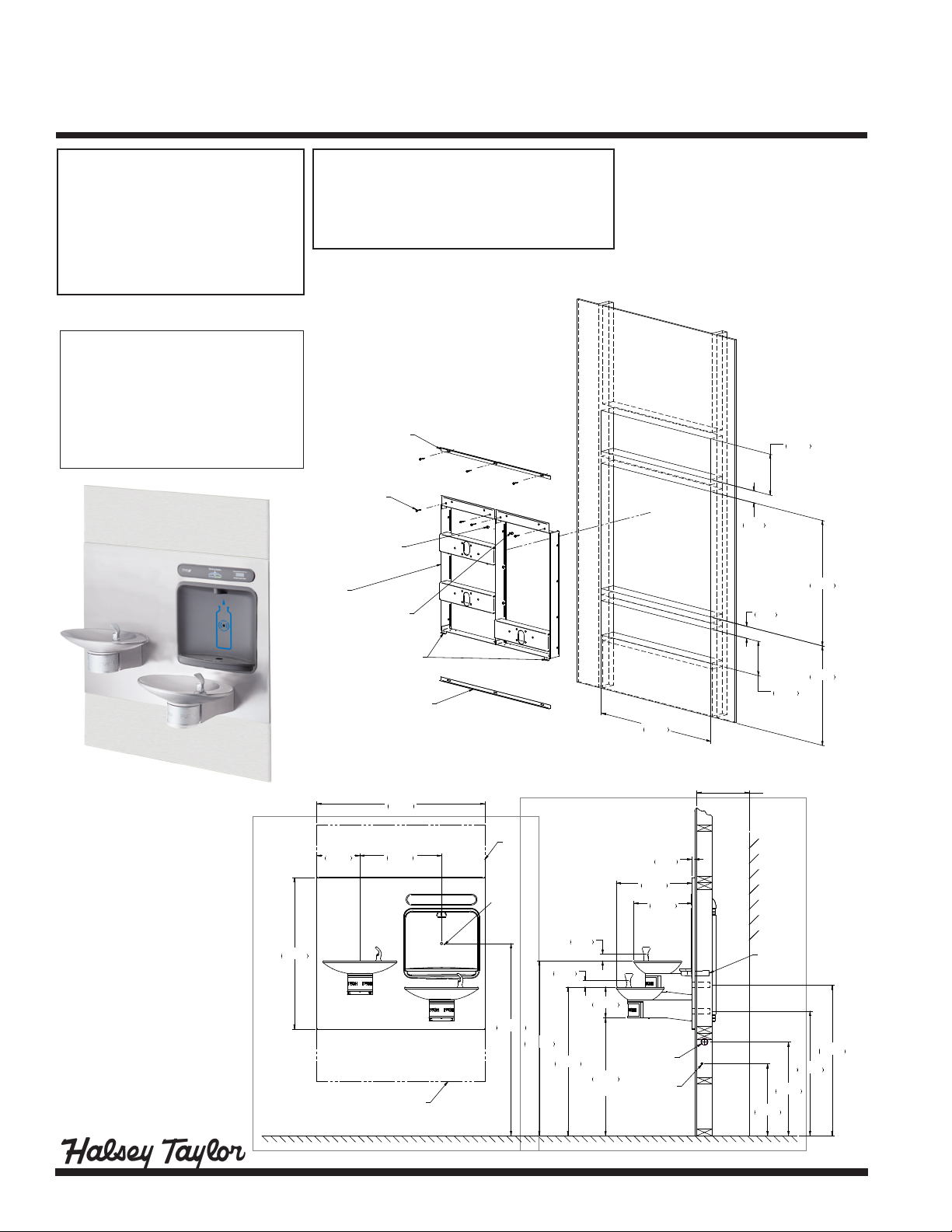

Refer to diagrams for rough-in of plumbing. Install mounting frame into wall per the

installation instructions. Hang fountain

panel over the wall plate assembly. Attach fountains to wall plate assembly. Water

service line and waste line are to be assembled

as required. Final check for leaks and correct functions of fountain should be made.

(For details see the installation instructions.)

CAUTION - Fountain must be securely bolted

to wall.

MOUNTING INSTRUCTIONS:

Job Name: ______________________________

Date: __________________ Qty. ____________

Contact Info (Name, Phone, Email): __________

________________________________________

________________________________________

Approval: _______________________________

NOTE: A service stop (not included) must be installed at

the fountain inlet line.

NOTE: P-Trap (not supplied) to be installed per local

building code.

NOTE: For wall support required locations see installation

instructions provided with panel and fountains.

WALL LAYOUT

OPTIONAL BRACKET

FOR ACCESS PANEL

5/16" SCREWS OR BOLTS

(20 REQ'D - NOT PROVIDED)

5/16" HEX NUT

(4 REQ'D - PROVIDED)

P/N 111577343890

FRAME

BOLT FRAMES TOGETHER

WITH 5/16" X 3/4" (19mm) BOLTS

(4 REQ'D - PROVIDED)

P/N 111577243890

INSTALL (2) SCREWS

(P/N 111008343890) IN FRAME

BEFORE INSTALLING IN OPENING

OPTIONAL BRACKET

FOR ACCESS PANEL

FRONT VIEW

OPERATING PRESSURES:

Supply water - 105 psi maximum

Minimum 40 psi supply line pressure required in special

circumstances where both sides of bi-level are in use

simultaneously to ensure adequate stream height. Use

of water lter in this situation is not recommended.

ELECTRICAL

Hydroboost® station equipped with electric cord and

three-prong molded rubber plug for use with 15amp minimum receptacle. For the cooling unit, a

junction box for a (3) wire, 10 amp branch circuit is

provided. Rated at 115 volt, 60 Hz, single phase.

10 1/4"

260mm

OPTIONAL FOR

ACCESS PANEL

3"

76mm

31 3/4"

806mm

3"

76mm

25"

635mm

8 5/8"

219mm

OPTIONAL FOR

ACCESS PANEL

37 1/2"

952mm

Shown with two optional access

panels installed

34 5/8"

879mm

FINISHED FLOOR

®

9 7/8"

251mm

38 1/2"

978mm

18 11/16"

475mm

OPTIONAL ACCESS

PANEL

OPTIONAL ACCESS

PANEL

Activation

Sensor

44"

1118mm

40"

1017mm

1 1/2"

38mm

34"

864mm

1 1/2"

38mm

7"

179mm

27"

686mm

REQUIREMENT

ADA

SIDE VIEW

5/8"

16mm

17 5/16"

440mm

13 5/16"

338mm

1-1/2" IPS

WASTE LINE

3/8" IPS

SUPPLY

8" (203mm) MINIMUM

12" (305mm) RECOMMENDED

FOR DRAIN CONNECTION

AND ACCESS TO

BOTTLE FILLER

ELECTRICALS

BOTTLE FILLER

DRAIN

34 1/2"

876mm

28 1/2"

724mm

21 1/2"

546mm

16 1/2"

419mm

Printed in the U.S.A.

Loading...

Loading...