Halsey Taylor HTHB-HAC-RF-NF User Manual

Satisfying Thirsts Since 1912

Model HTHB-HAC-RF-NF

HAC Retro Fit

Hydroboost® Bottle Filler

MODEL:

HTHB-HAC-RF-NF

GENERAL

Bottle lling station designed to retro-t existing

HAC pushbar activated models. Applicable on 115V

models only. Rated for indoor use. Supplied with

basin to insure proper t and allow for easy

installation. Ideal for use in sports and tness centers,

educational and healthcare facilities, airports, ofce

buildings and any other commercial buildings.

HYDROBOOST® RETRO-FIT BOTTLE FILLING STATION

Sensor-activated enhanced with user interface

graphics. Quick ll rate is 1.5 gallons per minute on

refrigerated model and 1.1 gallons per minute on

non-refrigerated model. Laminar ow provides a clean

ll to minimize splashing and easy maintenance.

Equipped with an automatic 20-second shut-off timer.

SILVER ION ANTI-MICROBIAL PROTECTION

Key plastic components are integrated with silver ion

anti-microbial protection to inhibit growth of mold and

mildew.

GREEN COUNTER™

Visually displays count of plastic bottles saved from

landlls. (Based on 20 oz. bottles for refrigerated

models)

Bottle Filler Retro-Fit

for HAC models

*Rated for Indoor Use Only

HTHB-HAC-RF-NF

SUGGESTED SPECIFICATION

Unit shall include a bottle lling station that retrots onto

a cooler. Model HTHB-HAC-RF-NF shall retro-t existing

115V pushbar activated HAC models. Shall include

basin to ensure proper t and function. Bottle ller shall include

electronic sensor for no-touch activation with automatic

20-second shut-off timer. Shall include a Green Counter™

displaying the count of plastic bottles saved from the

landll. Shall include anti-microbial protected components

to prevent mold and mildew. Shall comply with ADA

guidelines for visual and motion disabilities. The

manufacturer shall certify the unit to meet the

requirements of NSF/ANSI 61 and 372, UL 399 and

CAN/CSA 22.2 No. 120.

CAPACITIES CHART

Model

No.

HTHB-HAC-RF - - - - - 1.0 32 120

NOTE: Continued product improvement makes specication sheets subject to change without notice.

** With projector service and tap water at 80°F

t

UL 399 and ASHRAE (previously ARI 1010) compliant

Protected by Halsey Taylor’s Limited Warranty.

Warranty details available at halseytaylor.com.

GPH Capacity Cooled to 50°F** Base

Ambient Air Temp

70°F 80°F 90°F

HALSEY TAYLOR, 2222 Camden Court, OakBrook, IL 60523

t

100°F

halseytaylor.com

Rate

Cap.

F.L.

Amps

Shipping

Weight

lb.

SPEC00218 09/2014

Rated

Usage

Watt

Model HTHB-HAC-RF-NF

HAC Retro Fit

Hydroboost® Bottle Filler

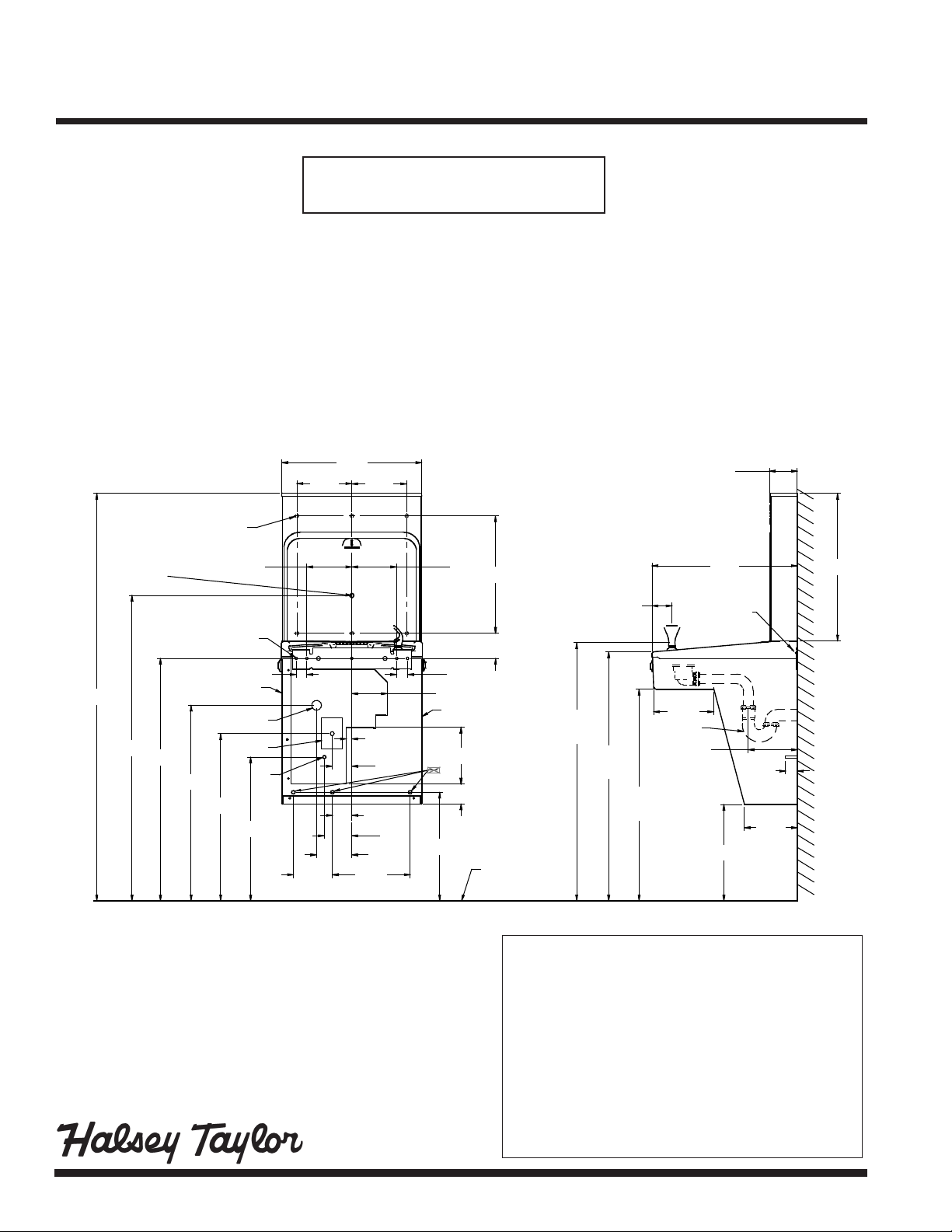

OPERATING PRESSURES

Supply water - 105 psi maximum

Minimum 40 psi supply line pressure required

in special circumstances where both sides of

bi-level are in use simultaneously to ensure

adequate stream height. Use of water lter in

this situation is not recommended.

FRONT VIEW SIDE VIEW

7/16"

O

11mm

MOUNTING HOLES

(6)

5 3/4"

21 3/8"

543mm

146mm

1 3/8"

35mm

18 3/8"

467mm

E

B

D

A

52 1/16"

1323mm

ACTIVATION

SENSOR

39 1/16"

991mm

5/16" (8mm) DIA. (5 HOLES)

31"

787mm

25"

635mm

NOTE: A service stop (not included) must be installed at

the water inlet line.

NOTE: P-Trap (not supplied) to be installed per local

building code.

SINGLE COOLER

17 7/8"

454mm

178mm

5"

127mm

7"

C

L

178mm

11/16"

18mm

2 7/16"

63mm

4 1/2"

114mm

10"

254mm

7"

2 1/2"

64mm

3 1/2"

89mm

4 9/16"

116mm

F

13 7/8"

352mm

146mm

1 3/8"

35mm

E

7 1/4"

185mm

2 9/16"

65mm

5 3/4"

15"

381mm

3 3/16"

82mm

FINISHED FLOOR

33"

838mm

ORIFICE

HEIGHT

ELECTRICAL

Hydroboost® station equipped with electric cord

and three-prong molded rubber plug for use with

15-amp minimum receptacle. Rated at 115 volt,

60 Hz, single phase.

3 9/16"

90mm

18 1/2"

471mm

2 5/8"

31 13/16"

808mm

RIM

HEIGHT

67mm

27"

686mm

ADA

REQUIREMENT

8"

203mm

159mm

6 1/4"

HANGER BRACKET

C

12 5/16"

313mm

1 1/2"

38mm

6 3/4"

172mm

18 7/8"

479mm

REDUCE HEIGHT BY 3” FOR INSTALLATION OF CHILDRENS ADA COOLER

LEGEND:

A = Recommended Water Supply location. Shut-off Valve (not furnished) to accept

3/8” O.D. unplated copper tube. Up to 3” (76mm) maximum out from wall.

B = Recommended Waste Outlet location. To accommodate 1-1/4” nominal drain.

Drain stub 2” (51mm) out from wall.

C = 1-1/4” Trap (not furnished).

D = Electrical Supply (3) Wire Recessed Box Duplex Outlet.

E = Insure proper ventilation by maintaining 6” (152mm) minimum clearance from cabinet

louvers to wall.

F = 7/16” (11mm) Bolt Holes for fastening to wall.

**New Installations Must Use Ground Fault Circuit Interrupter (GFCI).

®

Page 2

Job Name: ____________________________________

Model: _____________________________ Qty. ______

Contact: ______________________________________

Approval Signature: _____________________________

Notes:

Printed in the U.S.A.

Loading...

Loading...