Halsey Taylor HTHB-8 Installation Manual

HTHB-8*, HTHB-LR*, HTHB-8*-2, HTHB-8*-3, HTHB-LR*-2

HTHB-8-NF*, HTHB-LR-NF*, HTHB-8-NF*-2, HTHB-8-NF*-3, HTHB-LR-NF*-2

Installation/Care/Use Manual

Hydroboost In Wall Bottle Filling Station

HTHB-8* HTHB_LR*

HTHB-8-NR* HTHB_LR-NR*

Installer

To assure you install this model easily and correctly,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE

INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH

PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After installation,

leave these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WATER LINES IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY

OCCUR AWAY FROM THE BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNTAIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS AVOIDABLE BY USING

THE PROPER MATERIALS AS INDICATED. ANY DRAIN FITTINGS PROVIDED BY THE INSTALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE FOUNTAIN FROM THE BUILDING

PLUMBING SYSTEM. WE SUGGEST THAT THE BOTTLE FILLER BE PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI)

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER

INLET

SERVICE STOP

(NOT FURNISHED)

FIG. 2FIG. 1

Page 1 98558C (Rev. H - 11/13)

HTHB-8*, HTHB-LR*, HTHB-8*-2, HTHB-8*-3, HTHB-LR*-2

HTHB-8-NF*, HTHB-LR-NF*, HTHB-8-NF*-2, HTHB-8-NF*-3, HTHB-LR-NF*-2

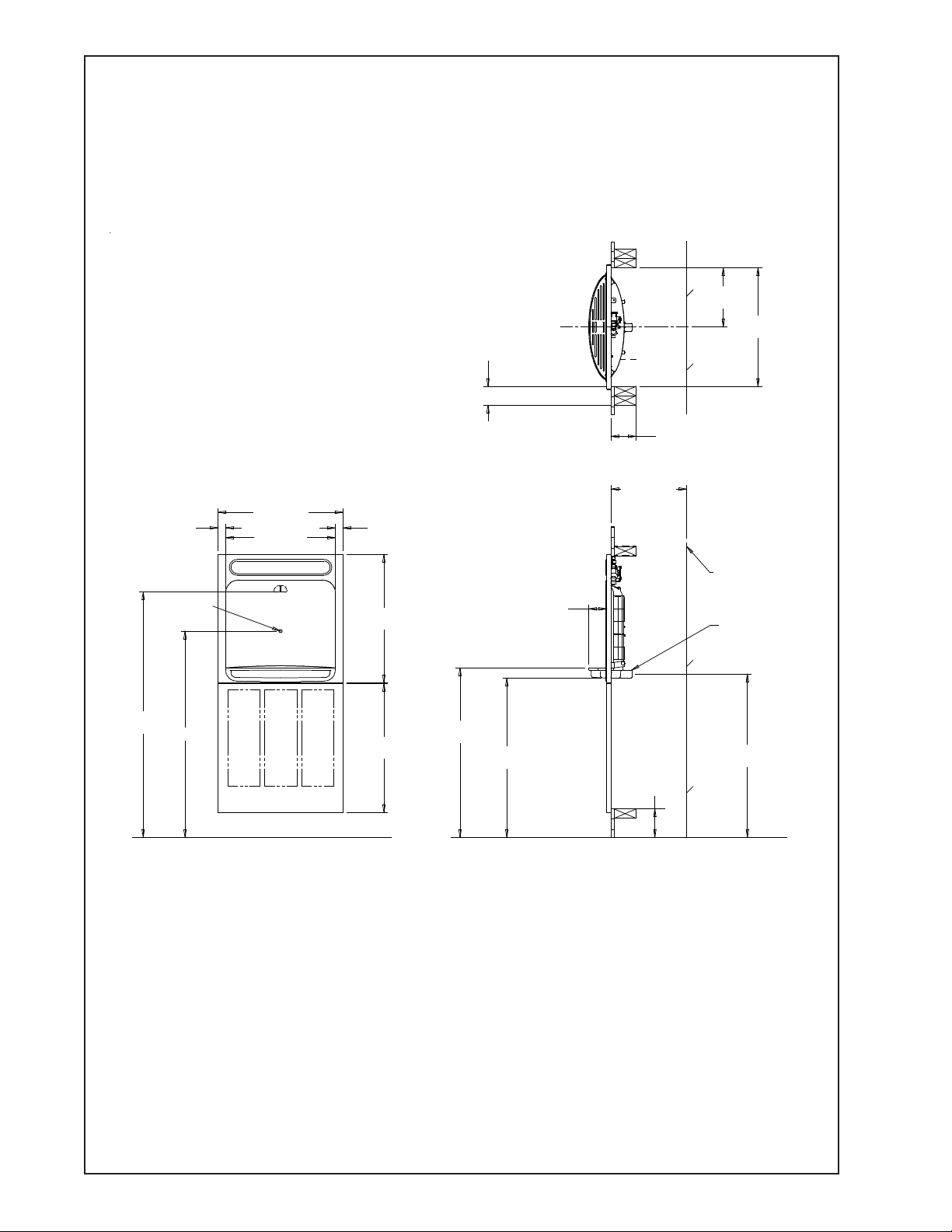

HTHB-8*, HTHB-LR*, HTHB-8-NR*, HTHB-LR-NR* ROUGH IN

9 3/8"

( 238mm )

DOUBLE STUD OR 3" (76mm)

BETWEEN MOUNTING FRAMES

IF PLACED NEXT TO ANOTHER

FOUNTAIN OR WALL

4"

( 102mm )

18 3/4"

( 476mm )

1 3/16"

( 30mm )

ACTIVATION

SENSOR

38 7/8"

( 987mm )

32.673

19 3/4"

( 502mm )

17 3/8"

( 441mm )

FINISHED FLOOR

1 3/16"

( 30mm )

20 3/8"

( 518mm )

20 7/16"

( 519mm )

27"

( 681mm )

2 7/8"

( 73mm )

25 1/4"

( 641mm )

FINISHED FLOOR

12"

( 305mm )

MINIMUM

DEPTH

4 1/2"

( 114mm)

BACK WALL LINE

1-1/4" (32MM)

WASTE TUBE

FURNISHED

25 7/8"

( 657mm )

FIG. 3

98558C (Rev. H - 11/14) Page 2

HTHB-8*, HTHB-LR*, HTHB-8*-2, HTHB-8*-3, HTHB-LR*-2

HTHB-8-NF*, HTHB-LR-NF*, HTHB-8-NF*-2, HTHB-8-NF*-3, HTHB-LR-NF*-2

INSTALLATION INSTRUCTIONS

1. Install mounting frame. See mounting frame instructions.

2. Install remote chiller. See chiller instructions.

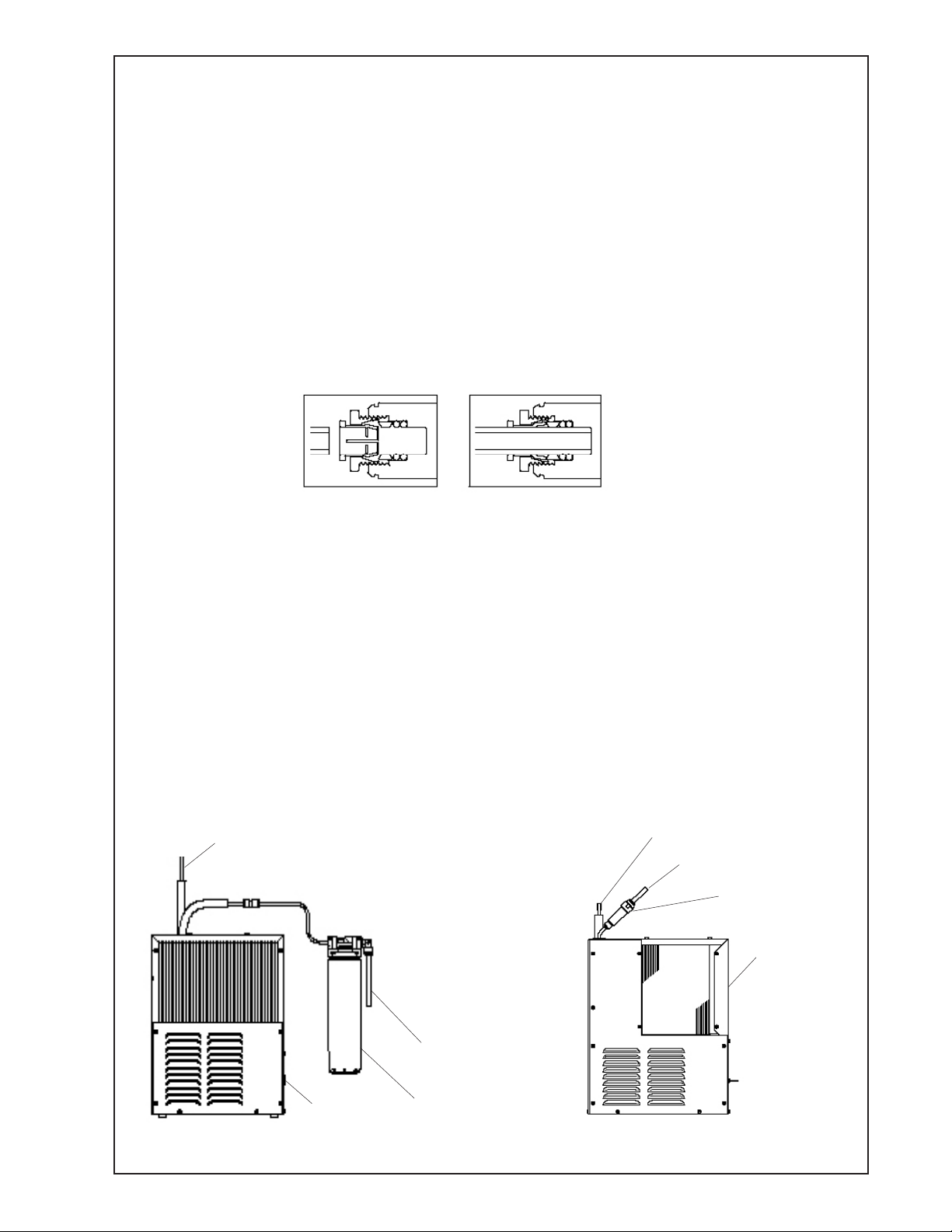

3. EWF3000 WATERSENTRY PLUS FILTER INSTALLATION

(Filtered units only. For non ltered units proceed to step 4b)

NOTICE: Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the system.

1)These lter kits must be installed in compliance with all state and local laws

and regulations governing the installation and use of this product. Maximum

inlet water temperature 100°F (38°C).

2) See lter instructions for lter assembly. Insert 3/8" elbow tting into the

inlet side of lter head, insert 1/4" polytube or 1/4" x 90° elbow into outlet

of lter head prior to mounting the lter head assembly into the remote chiller.

3) Mount lter head to the side of the remote chiller using the lter mounting bracket and screws supplied.

CAUTION: If supply pressure will ever exceed 100 psi, install a pressure

regulator to limit the inlet pressure to the lter to 100 psi or below.

DO NOT ATTACH HOT WATER LINE TO FILTER. To make connections on the

lter head, loosen locknut. Push the tube end past both o-rings to a positive

stop in the lter head recess - approx. 1", locknut may have to be backed out a

little more. Screw the locknut hand tight to seal (See Fig. 5). Ends of tubing

must be cut square and free of burrs and sharp ends that could cut or nick the o-rings.

NOTE: SCREW THE LOCK-

NUT HAND TIGHT TO SEAL

FIG. 5

4a. Make water supply connections for Fltered units. Install a shut-off valve and union connection to building water supply (valve

and union not provided). Turn on the water supply and ush the line thoroughly.

4b. Make water supply connections for Non Fltered units. Install a shut-off valve and union connection to building water supply

(valve and union not provided). Turn on the water supply and ush the line thoroughly. install the in-line strainer between the

valve and the cooler. The in-line strainer is not installed on ltered units.

5. (Filtered units only. For non ltered units proceed to step 7)

Make connection between lter head and building supply line. Insert the 3/8" water line into the inlet side of the lter head by

pushing it in until it reaches a positive stop, approximately 3/4" (19mm). Install two 1/4" x 1/4" unions (provided) on the chiller.

One on the inlet tube, and the other on the outlet tube.

6. Make connection between the lter head and the remote chiller. Insert end of 1/4" O.D. poly tubing from the lter head (pro-

vided) into union on chiller inlet.

7. Mount the upper panel to the mounting frame, aligning holes in the hinge brackets with holes in the mounting frame (three

places). Mount with adequate size screws (not provided). Close the door and verify that the lock brackets on the side and

bottom of the panel align with the slots on the mounting frame. Also verify that the panel is hanging high enough that it covers

the top of the mounting frame. If adjustments need to be made, open the door and loosen the three screws on the hinge and

adjust accordingly and then retighten the screws.

8. Connect water line from the water station by inserting the 1/4" O.D. poly tubing into the union on the chiller outlet.

9. Close the upper door and attach the drain ttings to drain tube. Re-attach elbow to p-trap and cut waste tube to required

length using plumbing hardware and trap as a guide.

PLUMBING DIAGRAM

FIG. 6

TO BOTTLE FILLER

TO BOTTLE FILLER

INLET

STRAINER

CHILLER

CHILLER

INLET

FILTER

NON FILTEREDFILTERED

Page 3 98558C (Rev. H - 11/13)

Loading...

Loading...