Halsey Taylor HTERQ-D Installation Manual

HTERQ*D HTSRQ*D HTESRQ*J HTSERQ*J

HALSEY TAYLOR OWNERS MANUAL

Classic

Refrigerated Fountains with Back Panel

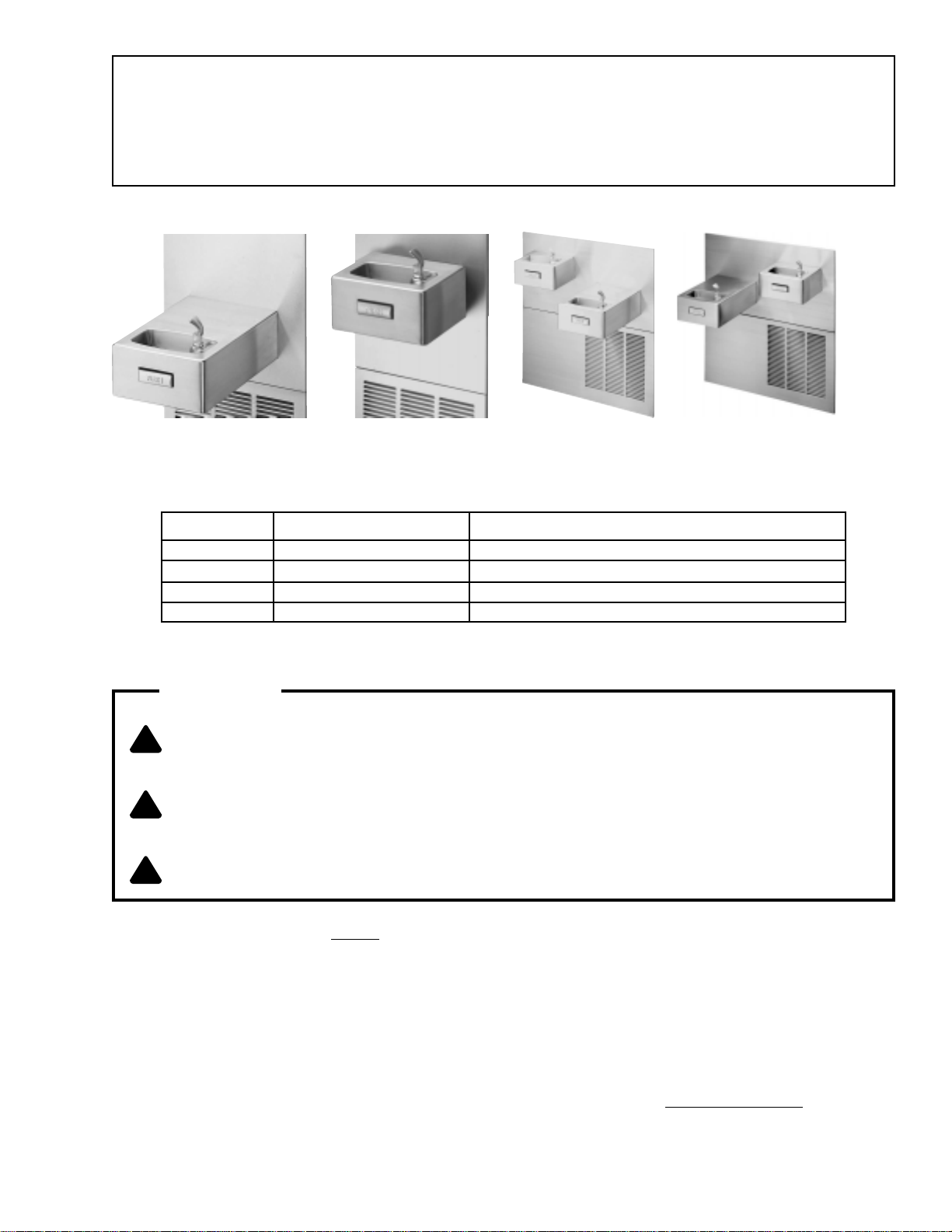

Figure 1 HTER-Q Figure 2 HTSR-Q Figure 3 HTSER-Q Figure 4 HTESR-Q

TM

Series Barrier-Free Water Coolers

Figure

1

2

3

4

Model

HTER-Q

HTSR-Q

HTSER-Q

HTESR-Q

Classic

Classic

Classic

Classic

Description

TM

Series - Extended Reach

TM

Series - Standard Reach

TM

Series - Dual Installation

TM

Series - Dual Installation

INSTALLER

!

CAUTION:

!

WARNING:

!

WARNING:

NOTE: It is common practice to ground electrical hardware such as telephones, computers and other devices

to available water lines. This can, however, cause electrical feedback in the plumbing circuit, which

results in an electrolysis effect occurring in the fountain. This may result in water which has a metallic

taste to it or has a noticeable increase in the metallic content of the water.

Review these instructions before beginning installation. Be sure that installation

conforms to all plumbing, electrical and other applicable codes.

When installation is complete, ensure these instructions are left in the plastic bag

provided inside the installed unit for future reference.

Service to be performed by authorized service personnel only.

When inspecting plumbing circuit, remember the line may be grounded some distance from the

installation, and may occur outside the building or area in which the unit is being installed.

This condition can be avoided (in most cases) by using recommended materials during installation. Any

drain fittings provided by the installer should be made of plastic which will electronically isolate the

fountain from the remainder of the buildings plumbing circuits.

97792C - 10/01

1

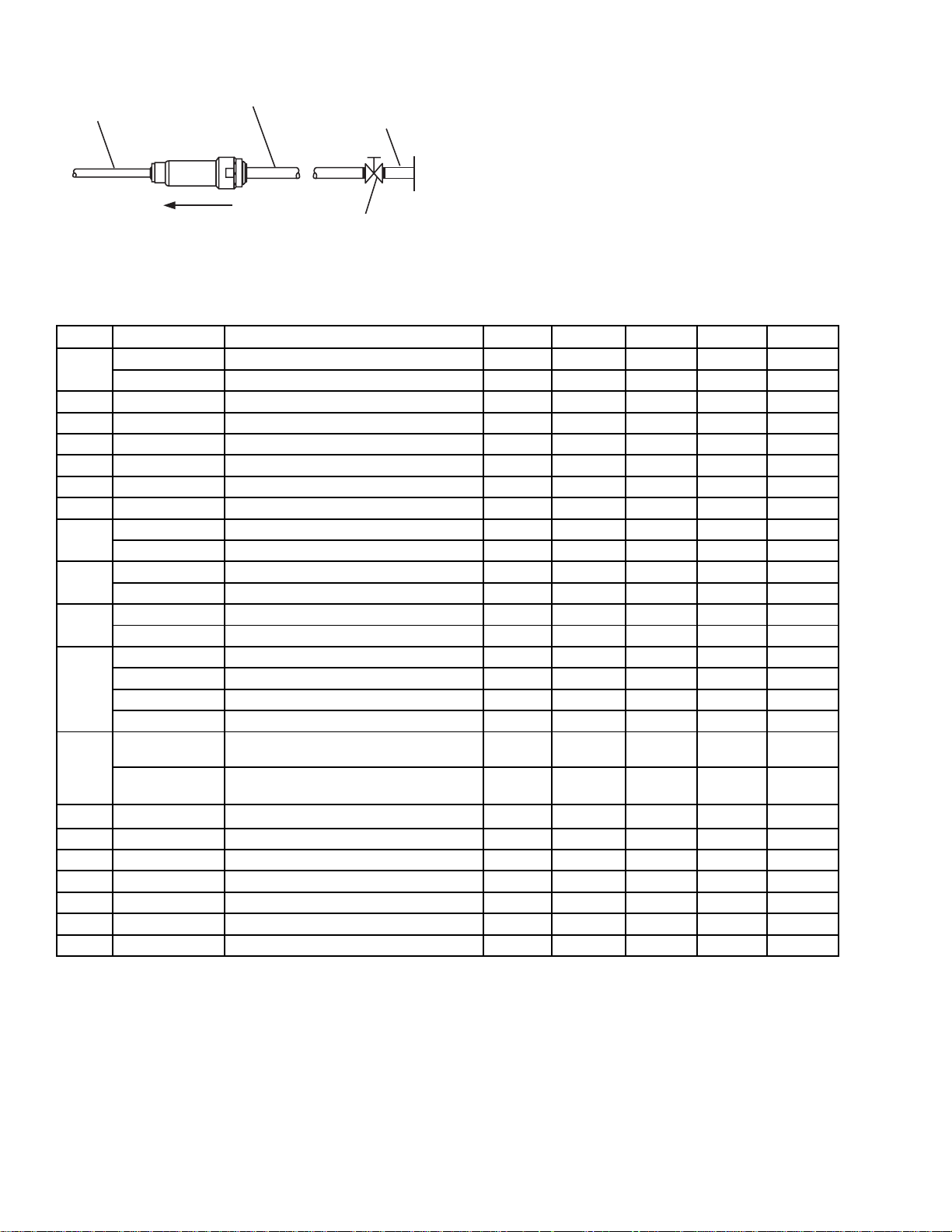

1/4" O.D. TUBE

WATER INLET

TO COOLER

NOTE: WATER FLOW

DIRECTION

Figure 5 Water Supply Connections

HTERQ*D HTSRQ*D HTESRQ*J HTSERQ*J

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

Installation Package

The components for installation are packed in three

separate boxes, regardless of the type of unit being

installed. The boxes contain the following:

Box No. 1: Wall Frame(s)

Box No. 2: Remote Chiller, SJ8-Q

Box No. 3: Fountain(s), Arm(s) and Panels

Additional materials, as noted in the Parts List, are also

shipped in these boxes.

Parts List

Ite m Part No. Description HTER-Q HTSR-Q HTSER-Q HTESR-Q See Fig.

1

2 66318C Tube Assembly Bubbler 1 1 2 2 18

3 10080C Nipple Bubbler (Included w/item 2) 1 1 2 2 4 100322740560 Gasket Bubbler 2 2 4 4 18

5 160270508640 Strainer Plate 1 1 2 4 18

6 161637308640 Drain Plug 1 1 2 2 18

7 100147140560 Gasket Drain 1 1 2 2 18

8

9

10

11

12

13 56121C Elbow Drain 1 1 1 1 18

14 75588C Nut 1-1/4 Slip Joint 1 1 2 2 18

15 55996C Strainer 1 1 2 2 19, 20

16 70745C Union 3/8 x 1/4 Tube 1 1 1 1 19, 20

17 70852C Tee 3/8 - - 1 1 20

18 70870C Union 3/8 1 1 - - 19

N-S 70055C Nut Speed 1 1 1 1 -

51546C Bubbler Satin 1 1 2 2 18

Bubbler Easy FlexTM (Option) 1 1 2 2 18

66346C Tube Waste (HTER-Q) 1 - 1 1 18

66343C Tube Waste (HTSR-Q) - 1 1 1 18

26868C Basin Stainless Steel (HTER-Q) 1 - 1 1 18

26870C Basin Stainless Steel (HTSR-Q) - 1 1 1 18

23001C Cover Bottom (HTER-Q) 1 - 1 1 18

23002C Cover Bottom (HTSR-Q) - 1 1 1 18

26837C Upper Panel Stainless Steel (HTER-Q) 1 - - - 14, 18

26835C Upper Panel Stainless Steel (HTSR-Q) - 1 - - 14, 18

26839C Upper Panel Stainless Steel (HTSER-Q) - - 1 - 14, 18

27028C Upper Panel Stainless Steel (HTESR-Q) - - - 1 14, 18

26833C Lower Panel Stainless Steel

(HTER-Q/HTSR-Q)

27026C Lower Panel Stainless Steel

(HTSER-Q/HTESR-Q)

1 1 - - 16, 18

- - 1 1 16, 18

Number Required

NOTE: N-S means Not Shown.

97792C - 10/01

2

HTERQ*D HTSRQ*D HTESRQ*J HTSERQ*J

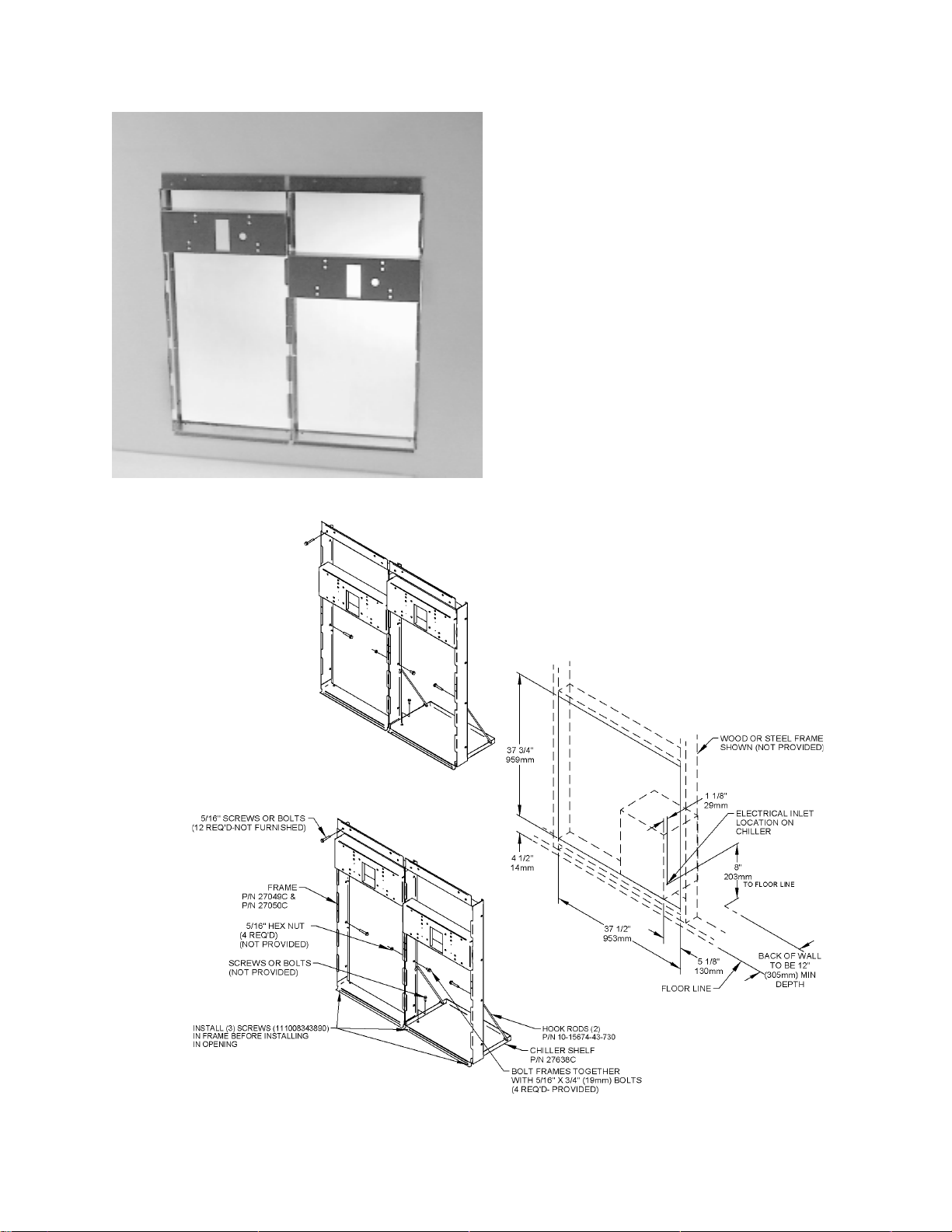

Figure 6 HTSER-Q Rough-In

Models

HTSER-Q HTESR-Q

1. Cut a rectangular wall opening 37-1/2 (953 mm) W x

37-3/4 H (959 mm) and 4-1/2 (114 mm) above the

floor line (see Figure 7). The dimensions are required

to obtain proper rim and bubbler heights for

compliance with ANSI standard A117.1.

2. Reinforce the wall opening on all sides to adequately

support the water fountain. This reinforcement must

support up to 150 lbs. static load and provide a

means for securing the frame assembly in place.

NOTE: Building construction must allow for

adequate air flow on both sides and top of

remote chiller unit a minimum of 4 (102

mm) is required.

3. Install plumbing and electrical rough-ins. A junction

box for a (3) wire, 10 amp branch circuit is provided on

the inside of the chiller. (Standard 120 Volts, 60 Hz,

and single phase.)

4. Remove frames and related hardware from

packaging. Release the two shelf rods by cutting

cable ties. Attach the two frames together through the

upright supports with (4) 5/16 x 3/4 (19 mm) long

bolts and nuts (not provided). Tighten securely.

REVERSED CONFIGURATION:

HIGHER UNIT ON THE RIGHT

MAKE SURE FRAME CONFIGURATION MATCHES

THE COOLER TO BE INSTALLED

STANDARD CONFIGURATION:

HIGHER UNIT ON THE LEFT

Figure 7 Rough-In Assembly

Dual-Station Mounting Frames

97792C - 10/01

3

Loading...

Loading...