HT-E *C & HT-S*C

Halsey Taylor Owners Manual

Non-Refrigerated Fountains

Installer

To assure you install this model easily and correctly,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE

INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH

PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After installation, leave

these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WATER LINES IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY

OCCUR AWAY FROM THE BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNTAIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS AVOIDABLE BY USING

THE PROPER MATERIALS AS INDICATED. ANY DRAIN FITTINGS PROVIDED BY THE INSTALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE FOUNTAIN FROM THE BUILDING

PLUMBING SYSTEM.

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

FIG. 1

PAGE 1

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS

SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

FIG. 2

97088C (Rev. E - 3/04)

97088C (Rev. E - 3/04)

PAGE 2

HT-E *C & HT-S*C

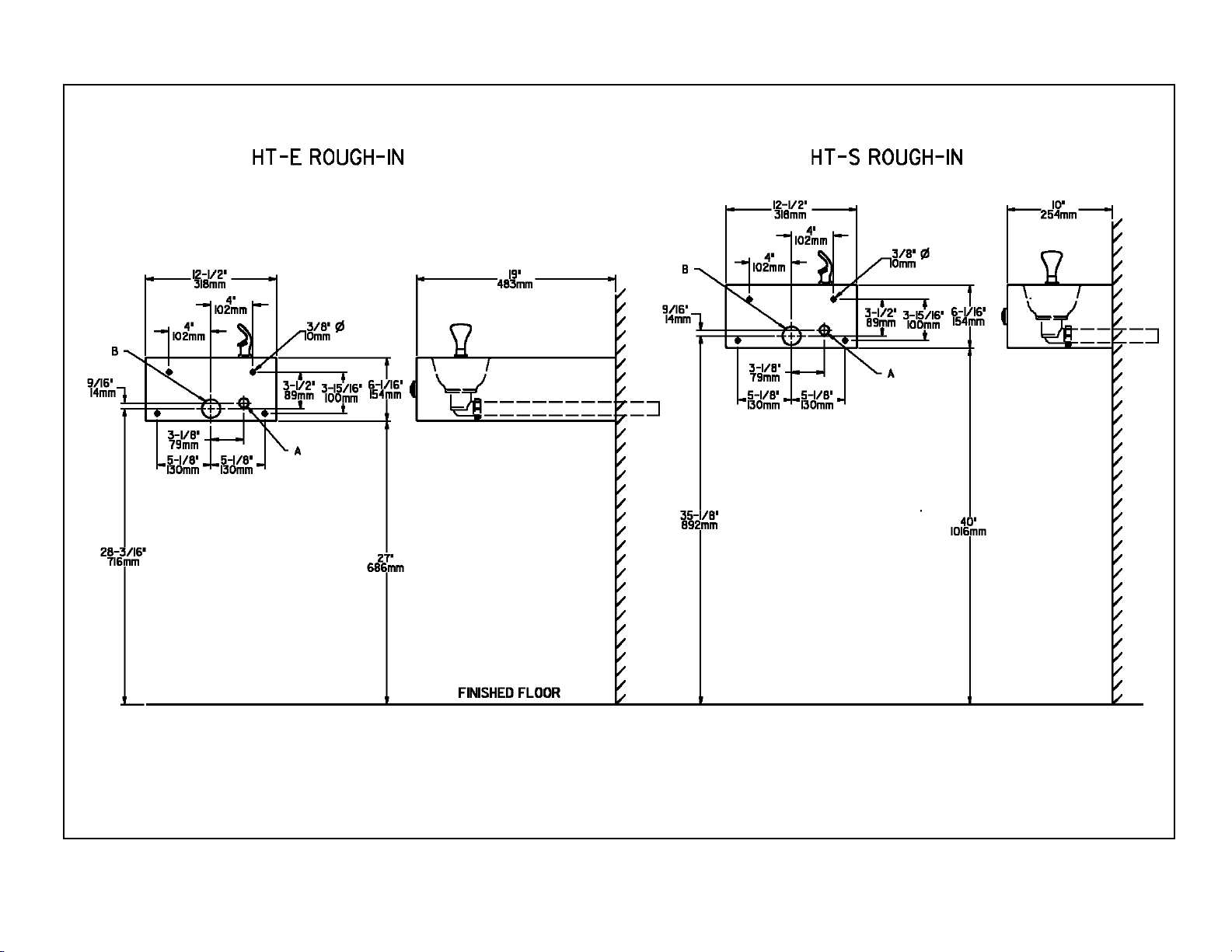

LEGEND:

A = 3/8" O.D UNPLATED COPPER TUBE CONNECT (WATER SUPPLY)

B = 1-1/4" O.D. WASTE TUBE (ELBOW AND TRAP NOT PROVIDED)

FIG. 3

HT-E *C & HT-S*C

ITEM NO. PART NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

26936C

26935C

27237C

75517C

70378C

75555C

70856C

55859C

101514331640

111411743620

40045C

15005C

61313C

50986C

50198C

55899C

27073C

DESCRIPTION

Pivot Lever Assembly

Mounting Bracket Assy

Pushbar Bracket

Lever Rod

Pushbar Rod

Spring Clip

Screw - #10-24 x .38 PHMS

Pushbar - Side & Front

Push Bar Insert

Nut - 1/4, Self Thread

Hex Nut - Reg.

Regulator Retaining Nut

Regulator

Regulator Holder

Snap Bushing

Pad - Window Fill

Backing Plate

FIG. 4

1. Wall should already be framed for the fountain using the positioning dimensions shown in

Fig.3. Shown dimensions pertain to installation location (framing must support up to 150 lbs.

weight). These dimensions are required for compliance with ANSI Standard A117.0.

2. Install rough-in plumbing as shown in Fig.3. Waste line should extend a minimum of 2" (51mm)

thru the back panel. Run supply water inlet line thru back panel. Install a service stop (not pro

vided). Turn on supply water and flush thoroughly.

3. Remove bottom access panel from fountain basin and save the screws. Install the fountain to the

back panel and wall using (4) 5/16" x 2" lag bolts and washers (not provided) thru holes in back

panel. Tighten securely.

4. Cut waste tube to required length using plumbing hardware and trap (not provided) as a guide.

Install hardware and trap. Tighten securely.

5. Make water supply connections from service stop to the fountain strainer (See Fig.1). Turn on

water supply and check for leaks. Newly installed water supply line should be insulated after leak

check is completed. DO NOT SOLDER TUBES INSERTED INTO THE STRAINER AS DAMAGE

TO THE O-RINGS MAY RESULT.

6. Check stream height from bubbler. Stream height is factory set at 45-50 PSI. If supply pressure

varies greatly from this, adjust screw on regulator (Item 13). Clockwise adjustment will raise stream

height and counter-clockwise adjustment will lower stream height. For best adjustment stream

height should be approximately 1-1/2" (38mm) above the bubbler guard. (See Fig's 4 & 5).

7. Water Valve Mechanism - ADJUSTMENT PROCEDURE:

- Turn adjustment screw (Item #7) counter-clockwise until water flow from bubbler starts.

- Turn adjustment screw clockwise until water flow stops, then turn an additional 1/2 turn.

8. Replace bottom access panel to fountain basin using screws provided. Tighten securely.

PAGE 3

97088C (Rev. E - 3/04)

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

NS

NS

NS

PART NO.

51546C

66318C

10080C

100322740560

160270508640

161637308640

100147140560

66346C

66343C

55884C

75588C

28316C

28317C

23001C

23002C

75589C

70055C

55996C

112627543890

HT-E *C & HT-S*C

PARTS LIST

DESCRIPTION

Bubbler - Satin

Tube Assy - Bubbler

Nipple - Bubbler (included with Item 2)

Gasket - Bubbler (2 Reqd)

Strainer Plate - Chrome

Drain Plug - Chrome

Gasket - Drain

Tube - Drain (HT - E1)

Tube - Drain (HT - S1)

Elbow - Drain

Nut - Slip Joint

Basin - Stainless Steel (HT - E1)

Basin - Stainless Steel (HT - S1)

Cover - Bottom (HT - E1)

Cover - Bottom (HT - S1)

Gasket

Nut - Speed

Strainer (See Fig. 1)

Screw 10-24 x 1/2 PHTC

Fig. 5

MODEL HT-ER SHOWN

SEE PUSH BAR

MECHANISM

(PAGE 3, FIG. 4)

1, 3

24

5, 6, 7

11

8

1210, 139

2222 CAMDEN COURT

OAK BROOK, IL 60523

630.574.3500

PRINTED IN U.S.A.

97088C (Rev. E - 3/04)

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

PAGE 4

Loading...

Loading...