Halsey taylor Hrf-sbpxb User Manual

HRF-EBP*B HRF-SBP*B HRF-SEBP*B HRF-ESBP*B

Halsey Taylor Owners Manual

Non-Refrigerated Fountains with Back Panel

Installer

T o assure you install this model easily and correctly ,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE ST ARTING THE

INST ALLATION. CHECK YOUR INSTALLA TION FOR COMPLIANCE WITH

PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After installation, leave

these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WA TER LINES IS A COMMON PROCEDURE. THIS GROUNDING MA Y BE IN THE BUILDING OR MA Y

OCCUR A WA Y FROM THE BUILDING . THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNT AIN, CREA TING AN ELECTROLYSIS WHICH CAUSES A METALLIC T ASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS A VOIDABLE BY USING

THE PROPER MA TERIALS AS INDICA TED. ANY DRAIN FITTINGS PROVIDED BY THE INST ALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALL Y ISOLA TE THE FOUNT AIN FROM THE BUILDING

PLUMBING SYSTEM.

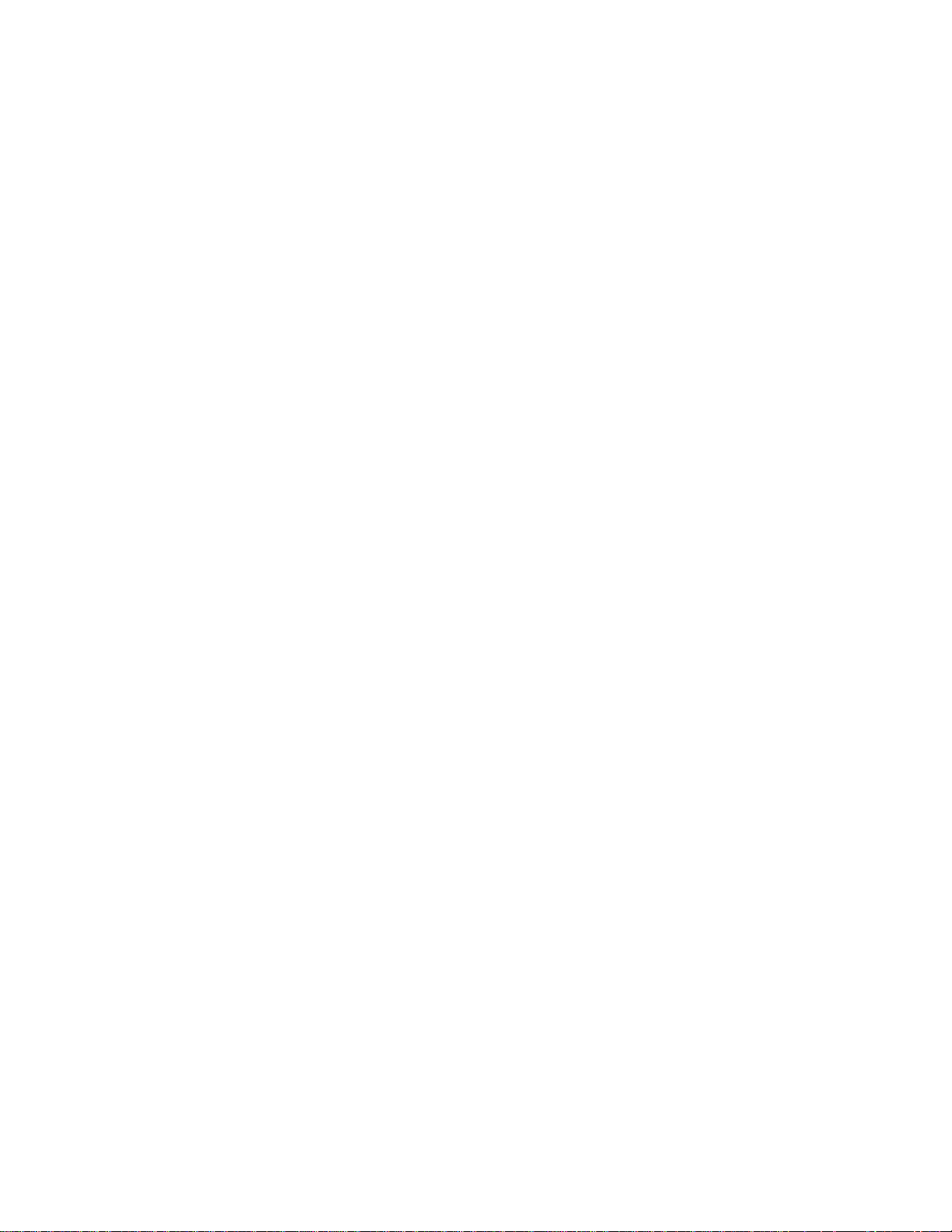

1/4" O.D. TUBE

WATER INLET

TO COOLER

FIG. 1

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WATER SUPPL Y

NOTE: WA TER FLOW

DIRECTION

BUILDING WA TER INLET

SERVICE STOP

(NOT FURNISHED)

OPERA TION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

FIG. 2

PAGE 1 97640C (Rev. L - 4/09)

TUBE IS

SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

HRF-EBP*B HRF-SBP*B HRF-SEBP*B HRF-ESBP*B

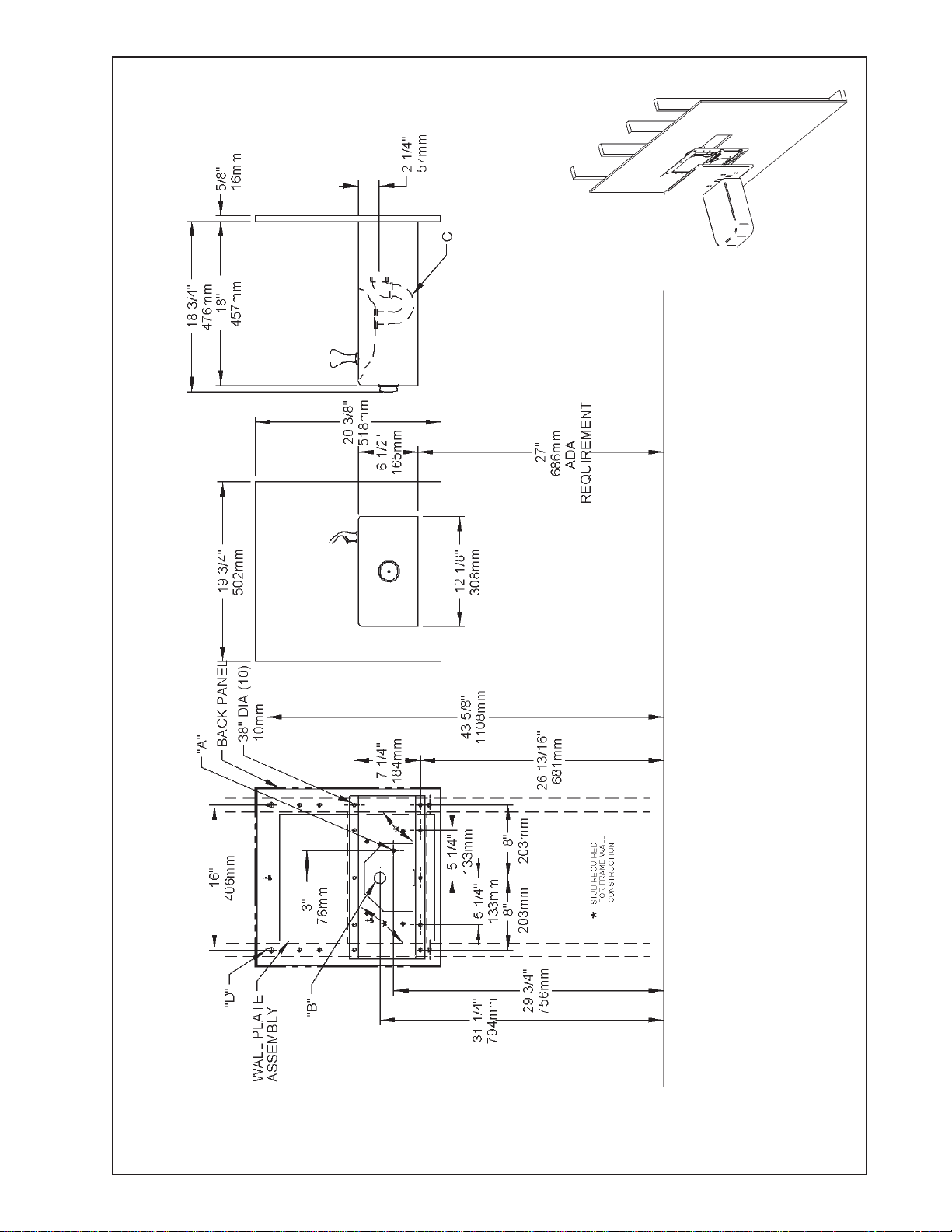

1. Fountains using the MPW Mounting Plate refer to Fig's. 4,6,8, or 10 for hanger bracket

location and rough-in dimensions.

NOTE: Review separate installation instructions for details of the MPW Mounting Plate.

Fountains using the Wall Plate Assy. refer to Fig's. 3,5,7, or 9 for rough-in dimensions.

2. Shown dimensions pertain to installation location (framing must support up to 150 lbs. weight

for single fountain and 300 lbs. for dual fountains). These dimensions are required for compliance

with ANSI S t andard A1 17.0.

3. Install rough-in plumbing as shown in Fig’s. 3,4,5,6,7,8,9, or 10. W aste line should extend a

minimum of 2" (51mm) thru the back panel. Run supply water inlet line thru back panel.

Install a service stop (not provided). T urn on supply water and flush thoroughly.

4. Installing back panel.

Ftn. w/MPW Mounting Plate: Refer to Fig. 12 for placement of braces onto back panel.

Place the upper edge of the panel above hanger bracket. Slide the panel down until it engages

the hanger bracket. Be sure back panel is firmly engaged before releasing it.

Ftn. w/Wall Plate Assy.: Place the upper edge of the panel above mounting plate on the

wall. Slide the panel down until it engages the hanger. Be sure back p anel is firmly engaged

before releasing it.

5. Remove bottom access panel from fountain basin and save the screws.

Ftn. w/Back Panel: Install the fountain to the back panel and wall using (4) 5/16" x 2.00" long

lag bolts and washers (NOT PROVIDED).

Ftn. w/MPW Mounting Plate: Install the fountain to the back panel and wall using (4) 5/16 “ x

6” long threaded rods, washers, and nuts (provided). T ighten securely.

Ftn. w/Wall Plate Assy .: Inst all the fountain to the back panel and wall using

(4) 5/16" x 3/4" long bolts and washers (provided) thru holes in back panel. T ighten securely.

6. Cut waste tube to required length using plumbing hardware and trap (provided) as a

guide. Install hardware and trap. T ighten securely.

7. Make water supply connections from service stop to the fountain strainer. Insert the

water inlet line into the inlet side of strainer until it reaches a positive stop - about 3/4"

(See Fig. 2). Turn on water supply and check for leaks. Newly inst alled water supply line

should be insulated after leak check is completed. DO NOT SOLDER TUBES INSERTED

INTO THE STRAINER AS DAMAGE TO THE O-RINGS MAY RESULT.

8. Check stream height from bubbler. Stream height is factory set at 45-50 PSI. If supply

pressure varies greatly from this, adjust the screw on regulator, item 9 by using a small

screwdriver through the small hole in the push button item 5 (See Fig. 1 1).

Clockwise adjustment will raise stream height and counter-clockwise will lower stream

height. For best adjustment stream height should be approximately 1-1/2" (38mm) above

the bubbler guard. (See Figure 13)

9. These products are designed to operate on 20-105 PSIG supply line pressure. If

inlet pressure is above 105 PSIG, a pressure regulator must be installed in the supply

line. Any damage caused by reason of connecting these products to supply line

pressure lower than 20 PSIG or higher than 105 PSIG is not covered by warranty .

10. Replace bottom access panel to fountain basin using screws provided. Tighten securely.

PAGE 297640C (Rev. L - 4/09)

HRF-EBP*B HRF-SBP*B HRF-SEBP*B HRF-ESBP*B

FINISHED FLOOR

FIG. 3

ROUGH-IN FOR HRF-EBP WITH W ALL PLA TE ASSY.

LEGEND:

A = Recommended Water Supply Location 3/8" O.D. Unplated Copper

Tube Connect, S tubbed 1-1/2" (38mm) From W all. Shut Off By Others

B = Recommended Location For Waste Outlet 1-1/4" O.D. Drain Stubbed

6-5/8" (35mm) From The Wall

C = 1-1/4" Trap Furnished

D = 3/8" (10mm) DIA. Slots For Mounting Hanger Bracket T o W all

PAGE 3 97640C (Rev. L - 4/09)

HRF-EBP*B HRF-SBP*B HRF-SEBP*B HRF-ESBP*B

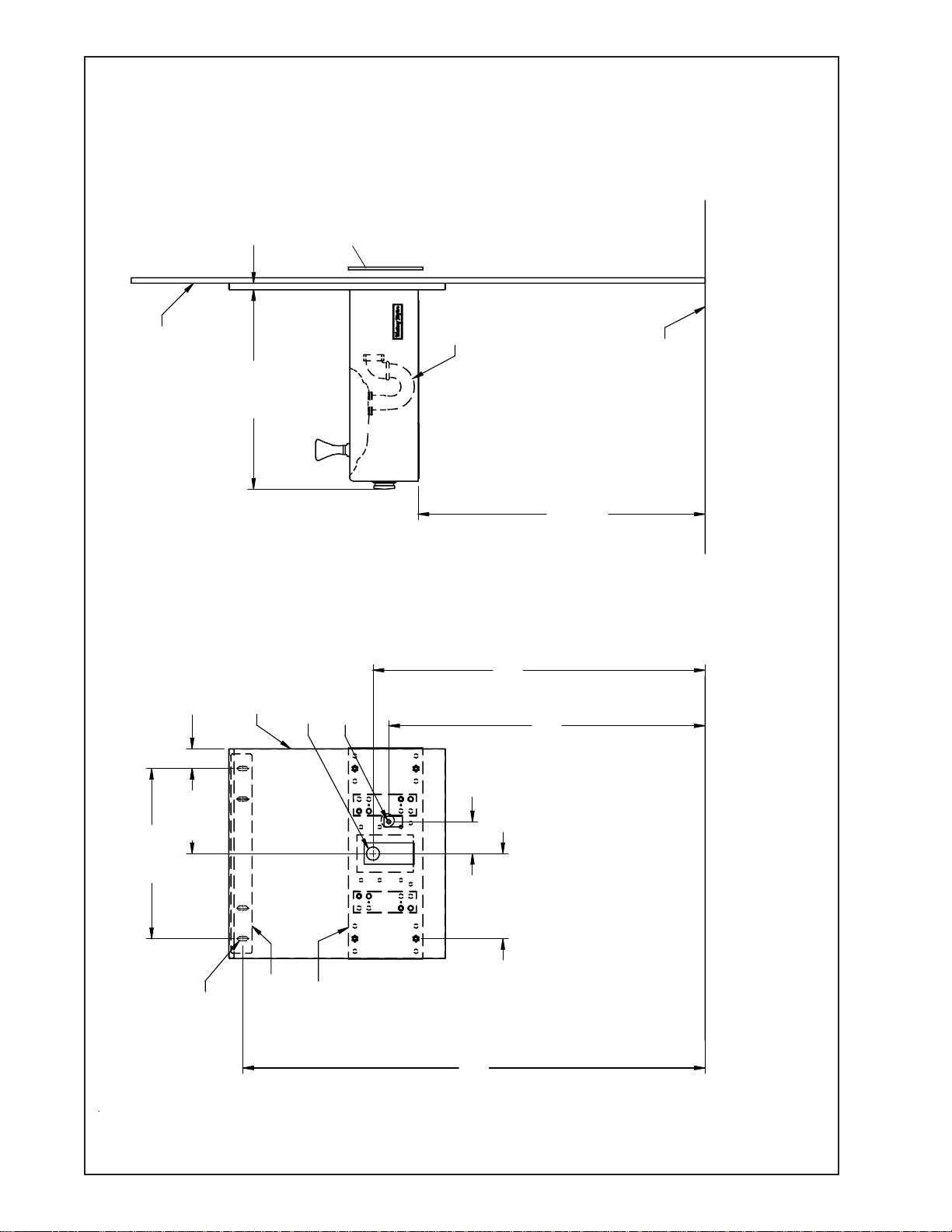

5/8"

16mm

MPW101 MTG. PLT.

REF. SEPARATE

INSTALLATION

INSTRUCTIONS

FOR DETAILS

C

18 3/4"

FINISHED WALL

476mm

FINISHED FLOOR

ROUGH-IN FOR HRF-EBP WITH MPW101 MOUNTING PLA TE

ADA

27"

686mm

REQUIREMENT

FIG. 4

31 1/4"

76mm

8"

203mm

794mm

29 3/4"

756mm

1 7/8"

48mm

BACK PANEL

B

A

3"

8"

203mm

16"

406mm

D

HANGER

BRACKET

MPW101

MTG. PLT.

43 1/2"

1105mm

LEGEND:

A = Recommended Water Supply Location 3/8" O.D. Unplated Copper

Tube Connect, S tubbed 1-1/2" (38mm) From W all. Shut Off By Others

B = Recommended Location For Waste Outlet 1-1/4" O.D. Drain Stubbed

6-5/8" (35mm) From The Wall

C = 1-1/4" Trap Furnished

D = 3/8" (10mm) DIA. Slots For Mounting Hanger Bracket T o W all

PAGE 497640C (Rev. L - 4/09)

Loading...

Loading...