This fountain is certified to

NSF/ANSI 61.

GENERAL

Two face-mounted 14 gauge heavy duty

fountains, one-piece, non-corrosive stainless

steel number 300 series with brushed satin

finish and one piece vandal resistant drain.

Larger seamless drawn contour-formed basins

with softly rounded corners and edges reduce

splatter, insures proper drainage and prevents

standing waste water. Designed to be easily

accessible to both physically challenged and

able-bodied individuals. Ideally suited for

installation in public areas. Model meets state

and federal requirements as defined by the

Americans with Disabilities Act. Barrier walls

required or apron installation to meet 27" cane

touch prerequisite.

BUBBLER

Vandal resistant bubbler is one-piece chrome

plated, with integral hood guard design to

prevent contamination from other users,

airborn deposits and tampering.

PUSHBUTTON ACTUATION MECHANISM

Self-closing, vandal-resistant pushbutton does

not require grasping or twisting.

PANELS

Backpanel constructed of stainless steel,

No. 300 series with satin finish. Solid 14 gauge

heavy duty stainless steel underplate and

vandal resistant pinned torx screws. 1/4" thick

heavy duty stainless steel mounting backplate

on fountain arm.

AUTOMATIC STREAM HEIGHT REGULATOR

Self-closing assembly is located inside unit to

prevent tampering and can be adjusted from

front pushbutton. Unit resists corrosion and

liming. A constant stream height is automatically

maintained under line pressures that vary from

20 to 105 psi.

INLET STRAINER

Easily cleaned in-line strainer screen traps

particles of 140 microns or larger before they

enter the waterway.

WATER INLET

3/8" O.D. Tubing

DRAIN OUTLET

1-1/4" tube outlet for 1-1/4" slip joint connection.

SUGGESTED SPECIFICATIONS

Both fountains shall include pushbutton on the

front. Both shall include contour-formed basins

to eliminate splashing and standing water, and

shall have rounded corners and edges. Each

projector shall be chrome-plated vandalresistant type with integral hood guard and

anti-squirt feature. Fountain shall comply with

ANSI 117:1 and ADA for visual and motion

disabilities. The manufacturer shall certify the

unit to meet the requirements of NSF/ANSI 61,

and the Safe Drinking Water Act.

Note: Continued product improvement makes

specifications subject to change without notice.

See Halsey Taylor website for most current

spec sheet.

Standard Finish is Stainless Steel

Optional Accessories (extra cost)

■■

Cane Touch Apron

■■

Water Filter (2 recommended)

Each HDFFBLEBP consists of 1 carton

as follows:

Fountain, Panel and Misc. Parts

Service stop not included.

Shipping weight: 80 lbs.

HALSEY TAYLOR, 2222 CAMDEN COURT, OAK BROOK, ILLINOIS 60523

B20 / 6-2008

MODEL HDFFBLREBP

Barrier-Free Fountain

Heavy Duty

Contour

™

Bi-Level

halseytaylor.com

JOB NAME:

ENGINEER/CONTRACTOR NAME:

APPROVAL:

DATE:

Printed in the U.S.A.

HDFFBLREBP

Heavy Duty

Contour

™

Barrier-Free

Bi-Level Fountain

(CONTINUED)

MOUNTING INSTRUCTIONS

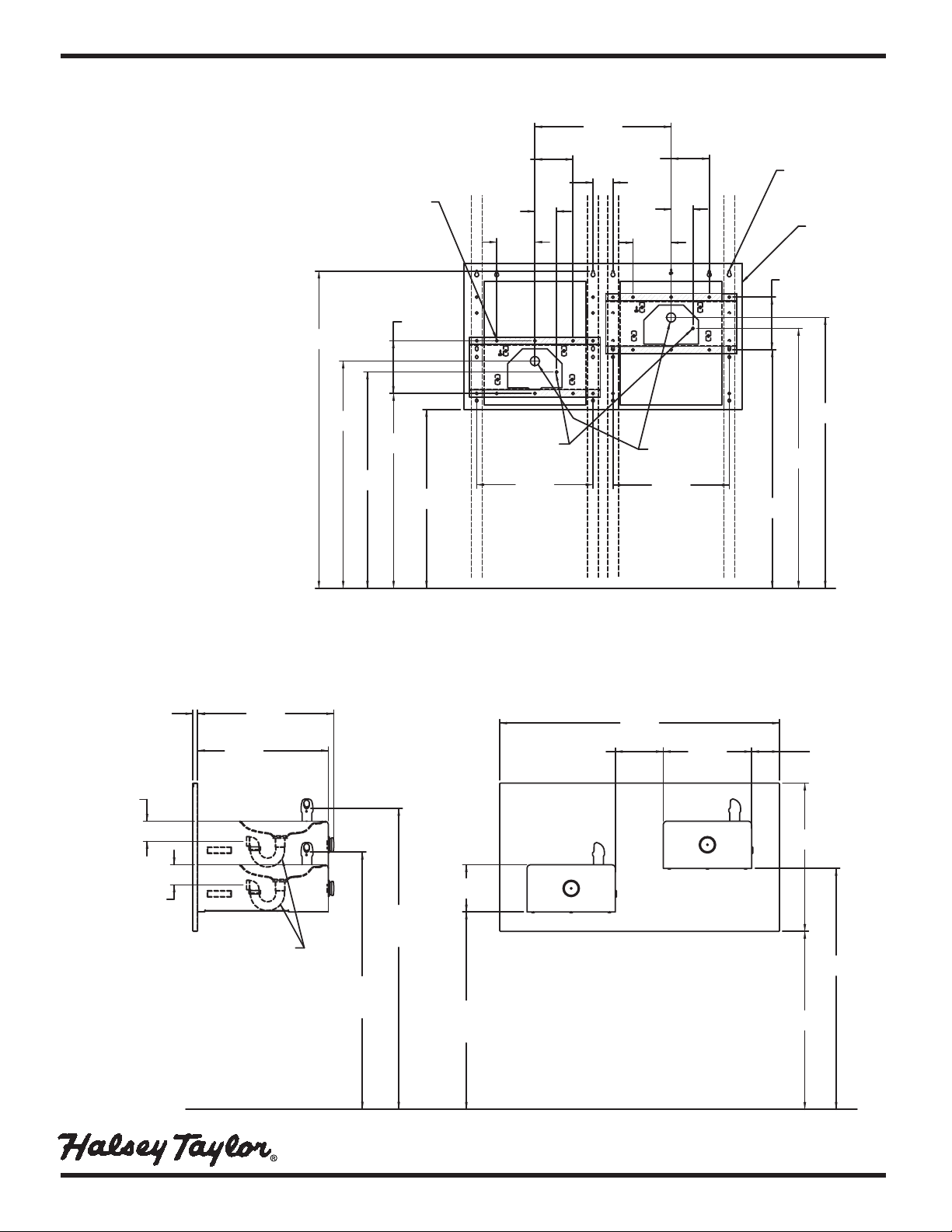

Refer to diagrams for rough-in of

plumbing. Mount wall plate assembly

to wall per the installation instructions.

Hang fountain panel over the wall

plate assembly. Attach fountains to

wall plate assembly. Water service line

and waste line are to be assembled as

required. Final check for leaks and

correct functions of fountain should be

made. (For details see the installation

instructions.)

CAUTION — Fountain must be

securely bolted to wall.

OPERATING PRESSURES:

Supply water - 105 psi maximum

Installation requires trap to be

installed in wall. A service supply

stop must be installed at the

fountain inlet line. Trap and service

stop not included.

NOTE: For wall support required

locations see installation

instructions provided with

panel and fountains.

1-1/4" TRAP

FURNISHED

27"

686mm

ADA

REQUIREMENT

6 1/2"

165mm

33 1/8"

842mm

20 3/8"

518mm

24 1/2"

622mm

3 13/16"

98mm

12 1/8"

309mm

6 5/8"

168mm

38 1/2"

978mm

35 3/8"

899mm

ORIFICE

HEIGHT

41 3/8"

1051mm

ORIFICE

HEIGHT

2 3/4"

71mm

2 3/4"

71mm

18"

457mm

5/8"

16mm

18 3/4"

476mm

3/8" WATER

SUPPLY

1-1/4" DRAIN

1/4" DIA. HOLES FOR

MOUNTING PLATE

TO WALL

3/8" DIA. HOLES FOR

MOUNTING PLATE TO WALL

WALL PLATE

ASSEMBLY

24 9/16"

625mm

26 13/16"

681mm

29 3/4"

756mm

31 1/4"

794mm

43 5/8"

1108mm

7 1/4"

184mm

16"

406mm

16"

406mm

32 13/16"

833mm

35 3/4"

908mm

37 1/4"

946mm

7 1/4"

184mm

5 1/4"

133mm

5 1/4"

133mm

2 3/4"

70mm

3"

76mm

3"

76mm

5 1/4"

133mm

5 1/4"

133mm

18 3/4"

476mm

WALL LAYOUT

SIDE VIEWFRONT VIEW

Note: Reinforce the wall in the shaded areas.

Loading...

Loading...