HAC8EEBLQ*1F , HAC8EEBLRQ*1F

HALSEY TA YLOR OWNERS MANUAL

USES HFC-134A REFRIGERANT

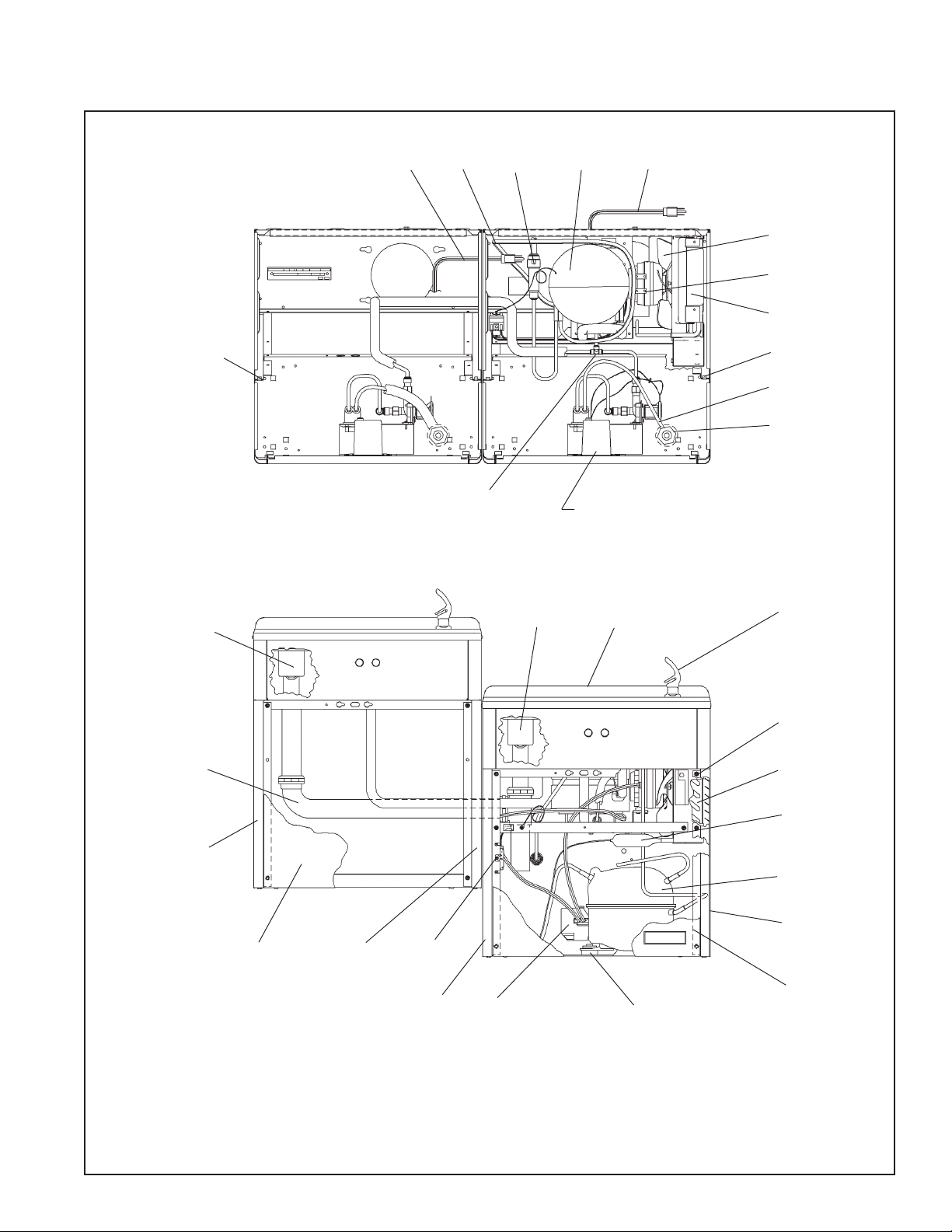

25

59

43

60

57

54

See Fig. 3 (on Page 3)

For Electric Eye Mechanism

18

19,20

21,22

23

25

24

26

45,46,47,48,

49,58,52

55

16

14

15

53

17

44

40,41,42

50,51

36,37,38

27,28

35

29

30

39

13

14

Page 1

98145C (3/05)

HAC8EEBLQ*1F , HAC8EEBLRQ*1F

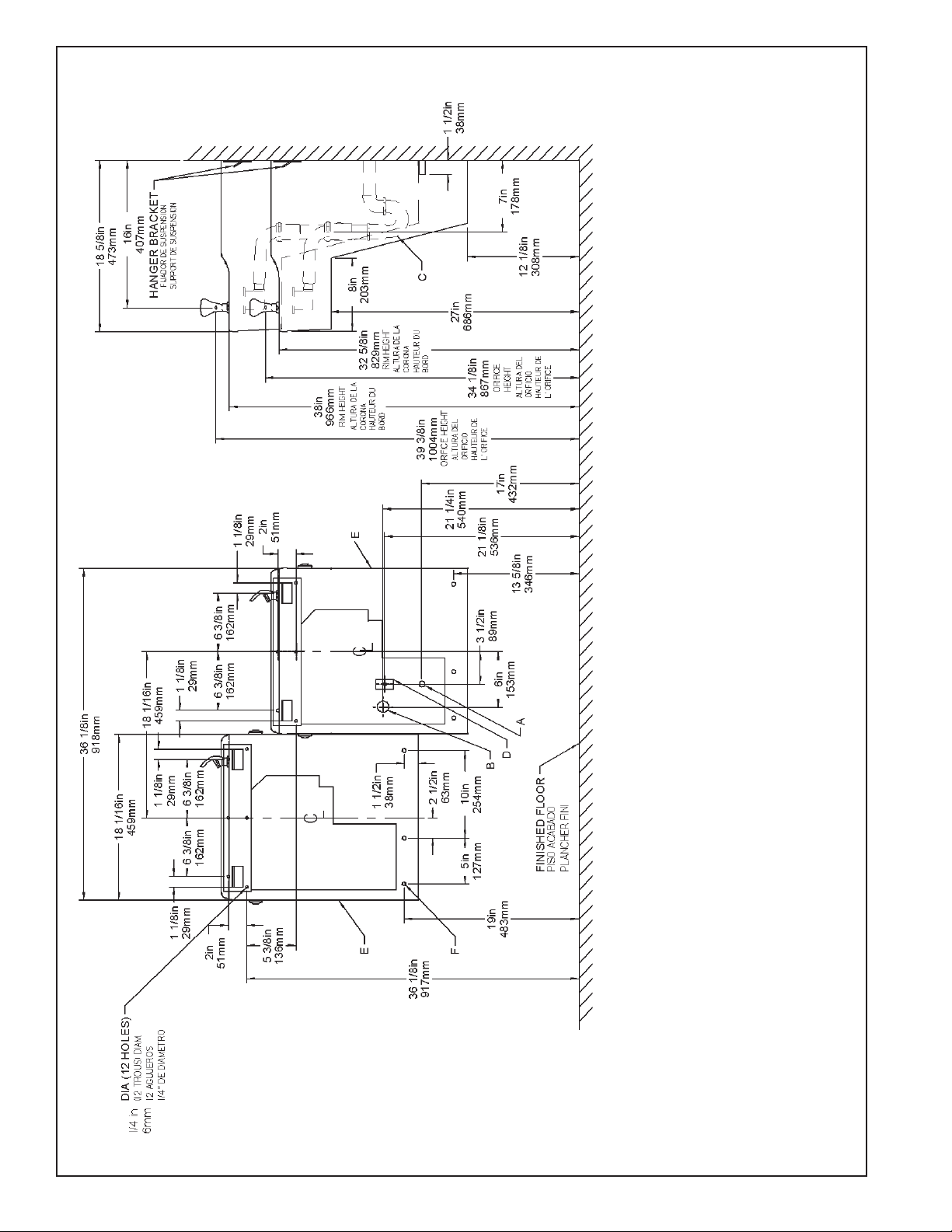

cooler waste line before connecting to trap (see installation instruction No.7)

1½ pulgadas del largo del tubo de desagüe del enfriador antes de conectar el purgador (vea las

instrucciones de instalación No. 7)

de longueur de la canalisation résiduaire du refroidisseur avant de le raccorder au siphon (voir

*ADA REQUIREMENT

*REQUISITO DE A.D.A.

*EXIGENCE ADA

**When replacing a Model “BFC” with a new unit Model “HAC”, installer must cut 1-1/2 inches from length of

**Cuando reemplace un Modelo “BFC” con una unidad nueva Modelo “HAC” el instalador deberá cortar

instruction d’installation no. 7)

**En remplaçant un modèle “BFC” avec un nouveau modèle “HAC”, l’installateur doit couper 1 1/2 pouce

98145C (3/05)

FIG. 2

Page 2

OFF BY OTHERS

DE LA LLA VE DE P ASO EN LA PARED COLOCADA POR TERCEROS.

TUYAUTERIE DE 1-1/2 PO. (38 mm) DEPUIS LE ROBINET D'ARRÊT FOURNI P AR D'AUTRES.

UBICACIÓN RECOMENDADA P ARA EL DRENAJE DE SALIDA DE AGUA, DE 1-1/2” DE DIÁMETRO.

SE RECOMIENDA UBICAR EL TUBO COR TO DE CONEXIÓN AL TUBO DE COBRE SIN CHAP AR DE 3/8" DE DIÁM. EXT. A 1-1/2" (38 mm) FUERA

LEGEND/LEYENDA/LÉGENDE

A = RECOMMENDED WA TER SUPPLY LOCATION 3/8 O.D. UNPLA TED COPPER TUBE CONNECT STUB 1-1/2 IN. (38 mm) OUT FROM WALL SHUT

EMPLACEMENT RECOMMANDÉ POUR LE DRAIN DE D.E. 1-1/2" DE SORTIE D’EAU.

EMPLACEMENT RECOMMANDÉ D'ALIMENTA TION EN EAU P AR TUBE EN CUIVRE NON PLAQUÉ DE 3/8 PO. (9,5 mm) D.E. CONNECT ANT UNE

B = RECOMMENDED LOCATION FOR W ASTE OUTLET 1-1/2” O.D. DRAIN

C = 1-1/2 TRAP NOT FURNISHED**

PURGADOR DE 1-1/2 NO PROPORCIONADO**

SIPHON 1-1/2 NON FOURNI**

CAJA RECESIV A DE ALAMBRES (3) DE SUMINISTRO ELÉCTRICO

BOÎTE ENCASTRÉE D’ALIMENTA TION ÉLECTRIQUE (3) FILS

ASEGURE UNA VENTILACIÓN ADECUADA MANTENIENDO UN ESP ACIO E 6" (152 mm) (MÍN.) DE HOLGURA ENTRE LA REJILLA DE

VENTILACIÓN DEL MUEBLE Y LA P ARED

ASSUREZ-VOUS UNE BONNE VENTILATION EN GARDANT 6" (152 mm) (MIN.) ENTRE LES ÉVENTS DE L ’ENCEINTE ET LE MUR.

AGUJEROS DE LAS TUERCAS DE 7/16 PARA SUJET AR LA UNIDAD A LA P ARED

TROUS D’ÉCROUS 7/16 POUR FIXER L’APP AREIL AU MUR

D = ELECTRICAL SUPPLY (3) WIRE RECESSED BOX

E = INSURE PROPER VENTILATION BY MAINTAINING 6" (152 mm) (MIN.) CLEARANCE FROM CABINET LOUVERS TO WALL.

F = 7/16 BOLT HOLES FOR FASTENING UNIT TO WALL

HAC8EEBLQ*1F , HAC8EEBLRQ*1F

PUSH BAR MECHANISM

RANGE

ADJUSTMENT

SCREW

33

3

6

32

7

32

11

Sensor Control: If sensor fails to operate valve mechanism or operates erratically,

check the following.

a. Ensure there are no obstructions within a 40-inch radius from front of cooler.

b. Check wire connections at solenoid valve and sensor.

CAUTION: Make sure unit is unpluged before checking any wiring.

c. Ensure proper operation of solenoid valve. If there is an audible clicking sound yet

no water flows, look for an obstruction in the valve itself or elsewhere in the water

supply line.

NOTE: WATER FLOW DIRECTION

34

31

10

8

9

35

9

1

5

32

4

56

2

12

Sensor Range Adjustment: The electronic sensor used in this cooler is factory pre-

set for a "visual" range of 36 inches. If actual range varies greatly from this, or a

different setting is desired, follow the range adjustment procedure below:

a. Remove front panel of cooler.

b.Using a small tip screwdriver, rotate range adjustment screw clockwise to increase

range and counter-clockwise to decrease range. (See Fig. 3).

CAUTION: Complete range of sensor (24-46 inches) is only one turn of the

adjusting screw.

c. Replace the front panel.

FIG. 3

ALL SERVICE TO BE PERFORMED BY AN

AUTHORIZED SERVICE PERSON

CAUTION: To preserve the quality and keep this AZTEC GOLD

finish clean and spot free, clean this surface with only mild

detergent or window cleaner and polish with a soft cloth.

DO NOT use any abrasive cleaners or harsh chemicals.

They WILL damage the finish!

1) Remove hanger bracket fastened to back of cooler by removing

one (1) screw.

2) Mount the hanger bracket and trap as shown in Figure 2.

NOTE: Hanger Bracket MUST be supported securely. Add fixture sup-

port carrier if wall will not provide adequate support.

IMPORTANT:

y 7 in. (178mm) dimension from wall to centerline of trap must be

maintained for proper fit.

y Anchor hanger securely to wall using all six (6) 1/4 in. dia. mounting

holes.

3) Install straight valve for 3/8" O.D. tube.

4) Hang the cooler on the hanger bracket. Be certain the hanger bracket

is engaged properly in the slots on the cooler back as shown in Fig.

4.

5) Loosen the two (2) screws holding the lower front panel at the bottom of cooler base and two (2) screws at the top. Remove the front

panel and set aside.

6) Connect water inlet line--See Note 4 of General Instructions.

7) Remove the slip nut and gasket from the trap and install them on the

cooler waste line making sure that the end of the waste line fits into

the trap. Assemble the slip nut and gasket to the trap and

tighten securely. Plug both power cords into duplex receptacle.

8) Stream height is factory set at 45-50 PSI. If supply pressure varies

greatly from this, readjust stream height to approximately 1-1/2"

(38mm) above the bubbler guard by turning adjustment screw, accessible by removing front panel,Item No.7 (see Fig.3 & 5).

9) Replace the front panel and secure by retightening four (4)

screws.

IMPORTANT

HANGER BRACKETS & TRAP

INSTALLATION

INSTALLATION OF COOLER

START UP

Also See General Instructions

HANGER BRACKET

FIJADOR DE SUSPENSIÓN

SUPPORT DE SUSPENSION

COOLER BACK

SUPPORT DE SUSPENSION

ARRIÈRE DU REFROIDISSEUR

CORRECT STREAM HEIGHT

FIG. 4

FIG. 5

Page 3

98145C (3/05)

HAC8EEBLQ*1F , HAC8EEBLRQ*1F

ITEM

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

ITEMIZED P ARTS LIST

PART NO

22897C

26729C

36028C

31272C

See Color T able

See Color T able

See Color T able

70817C

75507C

56082C

70644C

75497C

See Color T able

See Color T able

See Color T able

See Color T able

See Color T able

31483C

30664C

70018C

31490C

70009C

56237C

56092C

75524C

56159C

51544C

45396C

55905C

100322740560

66743C

66703C

61314C

70864C

Panel - Bottom Dispenser

Bracket - Valve Mounting

Sensor - Clear (115V)

Solenoid Valve (1 15V)

Panel - Right Side

Panel - Left Side

Panel - Front

Elbow 1/4 Stem x 1/4 O.D.

Fitting 1/4 NPTF x 1/4 O.D.

Nut - Regulator

Screw #6-32 x 1/2" Lg. PHMS

Screw #10 x 1/2" Lg. PHSM

Panel - Right Rear (Refrig. Unit)

Panel - Front Lower

Panel - Right Rear (Left Unit)

Panel - Left Rear (Left Unit)

Panel - Left Rear (Refrig. Unit)

Power Cord

Fan Blade

Hex Nut - Fan Blade

Fan Motor

Screw - (Fan Motor)

Shroud - Fan

Tubing - Poly (Cut To Length)

Clip (Front and Rear Panels)

Nipple - Bubbler

Bubbler - Chrome

Bubbler - Aztec Gold

Bubbler - Flexible (Optional)

Gasket - Bubbler (upper and lower)

Condenser

Drier

Regulator

Screw #8 x 5/8" Lg. Torx/Slot

DESCRIPTION

ITEMIZED P ARTS LIST

ITEM

NO

33

34

35

36

37

38

39*

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

NS

PART NO

40045C

50986C

70002C

101516143550

100806740570

19037000

36094C

35959C

35768C

36158C

66576C

45351C

56121C

75588C

100147140560

102639931640

45413C

160270508640

45400C

28152C

27594C

75634C

75605C

75589C

31513C

66534C

40022C

See Color T able

55996C

45485C

31376C

70682C

400660943730

Hex Nut

Holder - Regulator

Screw #10 x 1/2" Lg. HHSM

Stud - Compressor Mtg.

Grommet - Compressor Mtg.

Clip - Compressor Mtg.

Compressor Serv. Pak EMI 70 HNR

Relay

Cover - Relay

Overload

Heat Exchanger

Waste Line Assembly

Fitting - Elbow 1-1/4

Nut - Slip Joint 1-1/4

Gasket - Drain

Drain Plug - Chrome

Drain Plug - Aztec Gold

Strainer Plate - Chrome

Strainer Plate - Aztec Gold

Basin - Stainless Steel

Basin - Aztec Gold

Screw - Basin Mtg. - Stainless Steel

Screw - Basin Mtg. - Aztec Gold

Gasket

Cold Control

Evaporator Assembly

Waste Line Assembly

Cover - Dispenser Bottom

Strainer

Waste Line Assembly

Power Cord

Fitting - Tee 1/4

Hanger Bracket

*REPLACE WITH SAME COMPRESSOR USED IN ORIGINAL ASSEMBL Y.

NOTE: All correspondence pertaining to any of the above water coolers

or orders for repair parts MUST include Model No. and Serial No. of cooler ,

name and part number of replacement part.

DESCRIPTION

PANEL

COLOR

Platinum Vinyl

Almond Vinyl

Aztec Gold

Stainless Steel

Item No. 5

Part No.

22820C

23016C

27899C

22822C

Item No. 6

Part No.

22812C

23009C

27897C

22814C

COLOR T ABLE

Item No. 7

Part No.

23135C

23162C

27907C

23137C

Item No. 13

Part No.

22860C

22968C

27911C

22862C

Item No. 14

Part No.

22844C

22954C

27905C

22955C

WIRING DIAGRAM

This Drawing is merely for illustrating the

components of the electrical system.

Item No. 15

Part No.

26806C

26772C

27903C

26776C

Item No. 16

Part No.

22852C

22961C

27909C

22854C

Item No. 17

Part No.

26798C

26765C

27901C

26800C

Item No. 56

Part No.

55931C

55931C

55930C

55931C

2222 CAMDEN COURT

OAK BROOK, IL 60523

630.574.3500

PRINTED IN U.S.A.

98145C (3/05)

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR VISIT OUR WEBSITE WWW.HALSEYTAYLOR.COM

Page 4

Loading...

Loading...