Halsey T aylor Owners Manual

Replacement Kit P/N 92776C

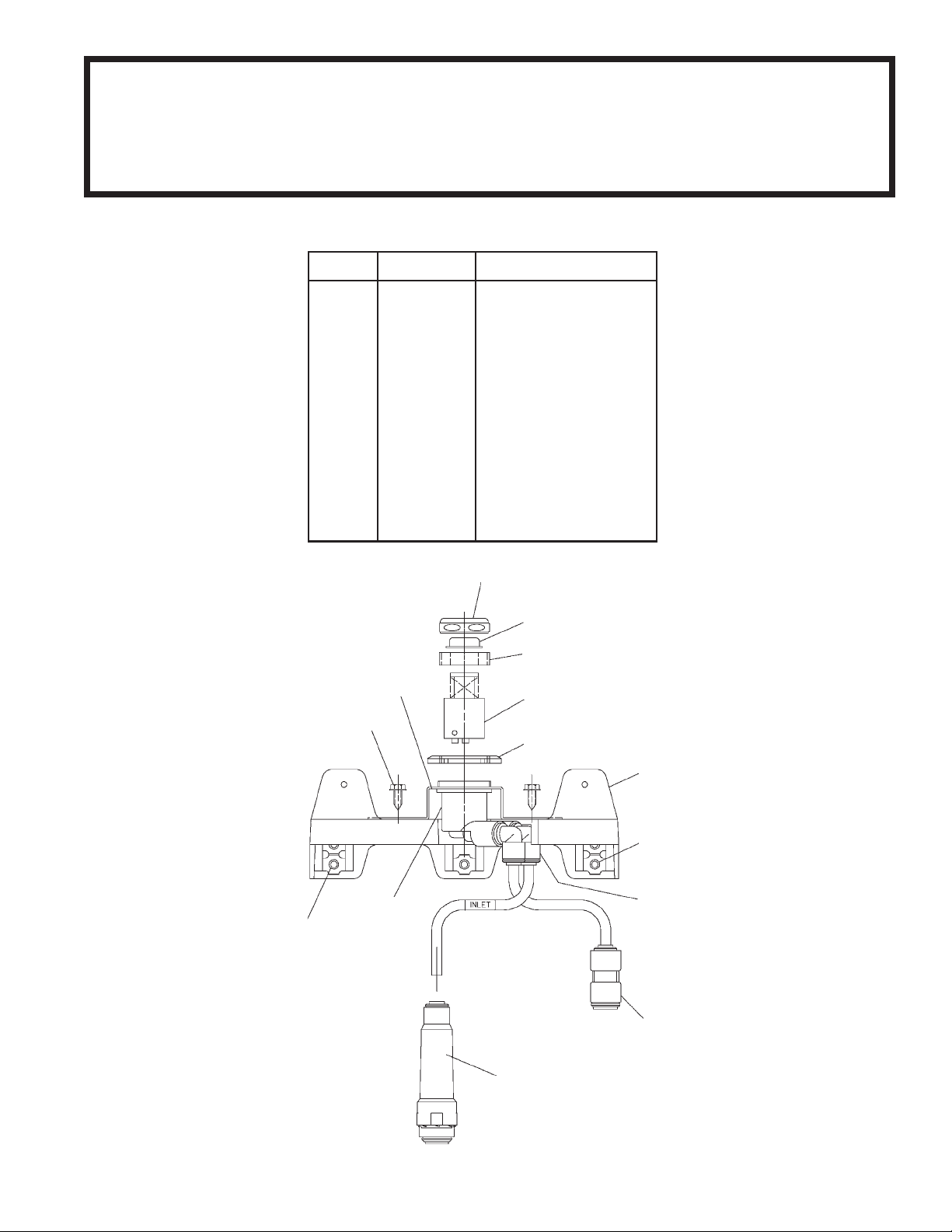

ITEMIZED PARTS LIST

ITEM NO. P ART NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

NS

NS

NS

NS

40116C

40048C

15005C

61314C

40045C

51576C

401475143730

70817C

70745C

55996C

50986C

70002C

23004C

51544C

100322740560

111516043890

60291C

DESCRIPTION

Nut - Cover

Button

Nut-Retaining

Regulator

Nut - Hex

Bracket - Valve and Push Bar

Clip - Speed Strip

Elbow - 1/4" to 1/4"

Union - 3/8" to 1/4"

Strainer

Holder - Regulator

Screw - #10 x .50 HHSM

Bracket - Regulator Mtg.

Bubbler

Gasket - Black

Pin - Cotter 1/8" x 3"

Screen - SS

1

2

3

13

4

12

5

6

7

11

8

7

10

9

97218C (Rev. B - 12/07)PAGE 1

COOLER

WASTE

LINE

BUMPER SCREWS

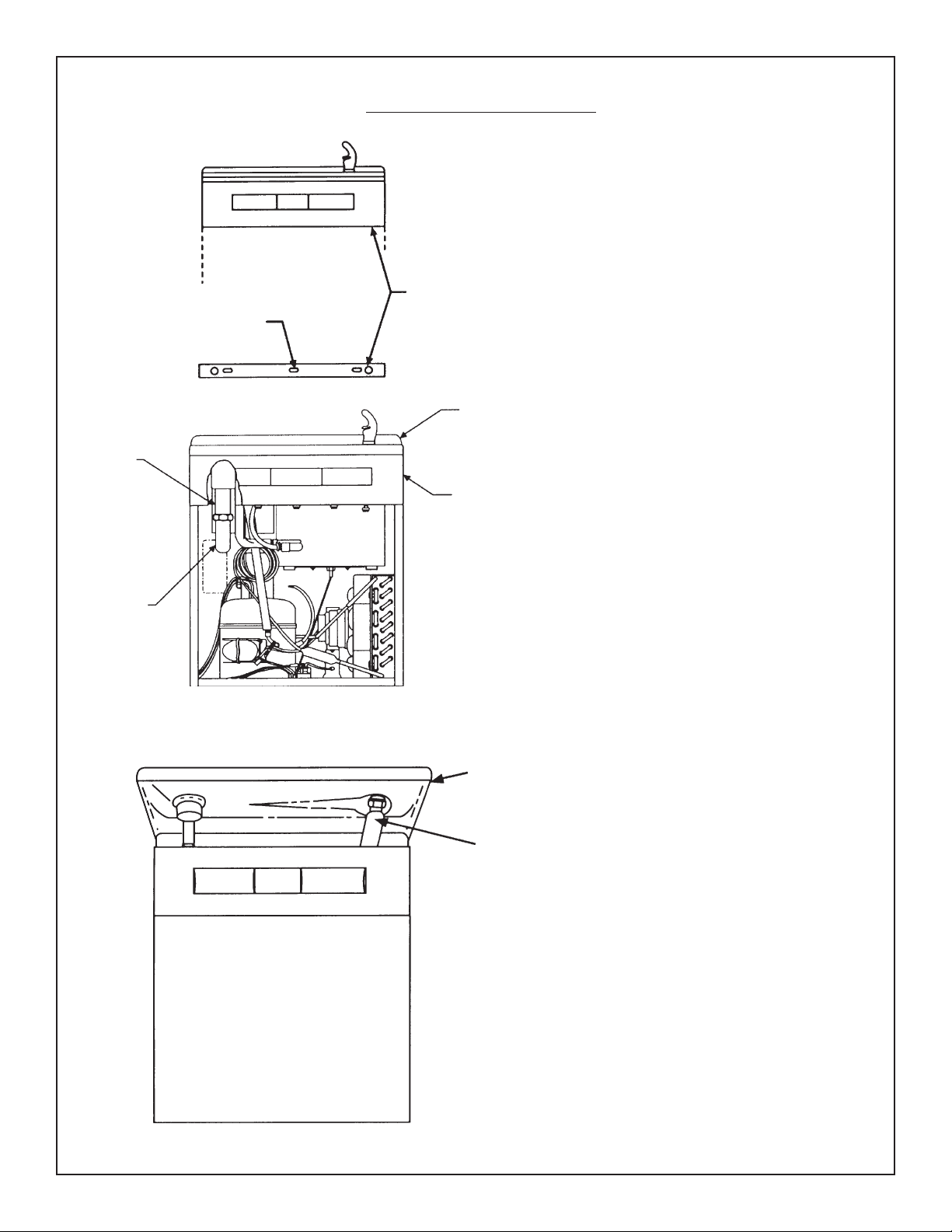

Removal of Existing V alve

Remove two (2) bumper screws and two (2)

screws mounting front panel at bottom using a

5/16" and 1/4" socket or nut driver or a regular

slotted screwdriver. Loosen the (2) screws holding the front panel at the top. Remove the front

panel and set aside

FRONT P ANEL

SCREWS

RECEPTOR

SMALL

SIDE

PANELS

Loosen (2) screws on upper front panel using a

5/16" socket or nut driver. Remove upper front

panel. Unplug the water cooler from electrical

outlet. Shut off water supply.

TRAP

RECEPTOR

FLEX

COPPER

TUBE

For additional access to water valve connections.

Remove the eight (8) receptor mounting screws,

disconnect the waste line from P-trap and unscrew

the projector. Lift the receptor . NOTE: Extreme care

must be taken not to kink the flexible copper line

which supplies the projector.

97218C (Rev. B - 12/07) PAGE 2

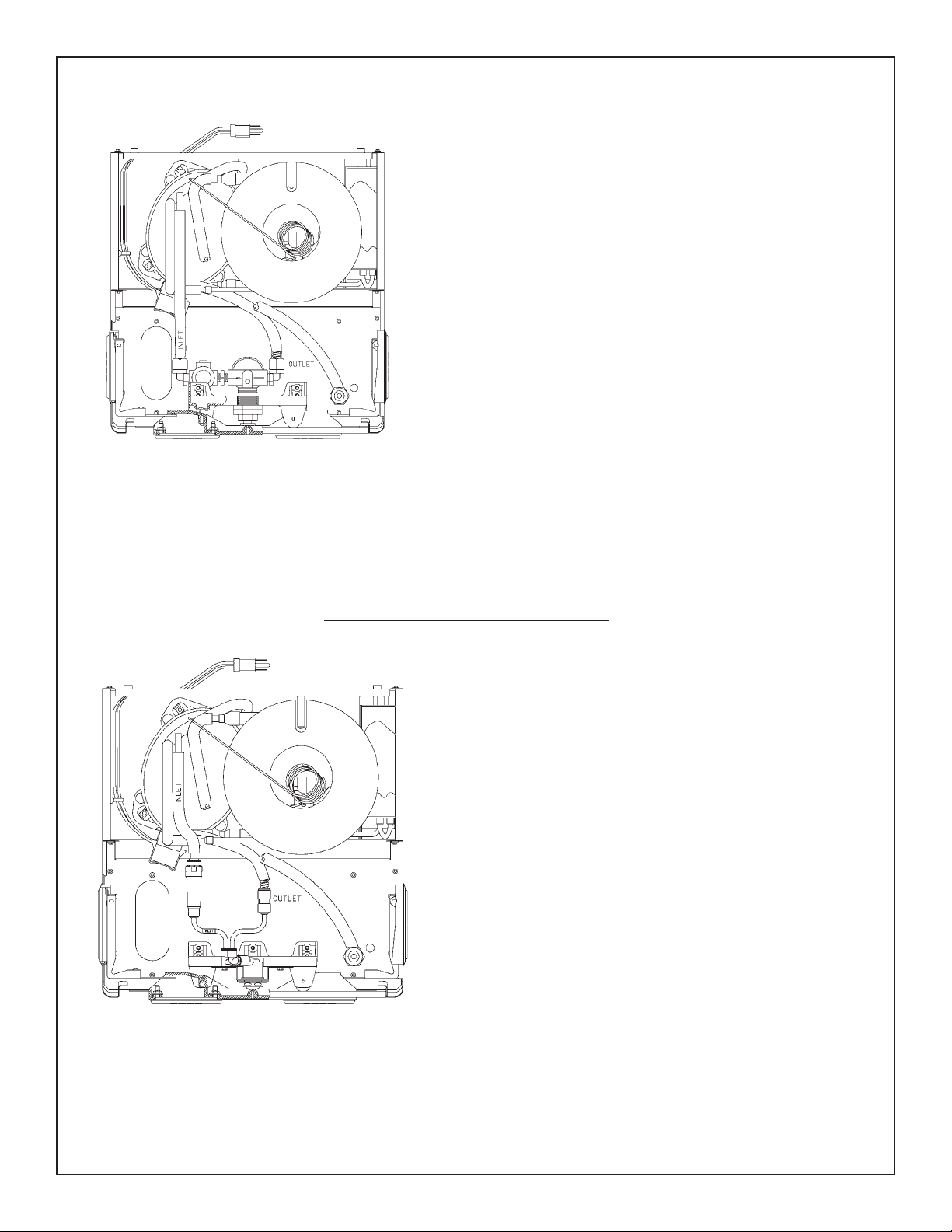

Top view of cooler

w/basin removed

Remove (5) screws holding the black plastic regulator bracket

using a 5/16" socket or nut driver.

Disconnect water inlet and outlet lines from existing water valve.

Remove regulator with bracket from the water cooler. Remove

cotter pins from bracket and remove front push bar.

If the water lines on the unit were connected to the valve with black

compression fittings:

-Remove and discard the "o"-ring and black plastic spacer

-DO NOT ATTEMPT to remove the grab ring and connection nut.

Attempting to remove the grab ring can damage, nick or scratch,

the sealing area on the tube end.

If the water lines on the unit were connected to the valve with brass

flare fittings:

-Cut the tubing as close to the flare as possible with a tube

cutter. NOTE: Only use a tube cutter to cut the tubing so the end

is square. Other tools, for example a hacksaw, could leave an

excessive burr.

-Discard the cutoff end and flare nut.

-De-burr the tube ends before assembling to the new valve

assembly.

Top view of cooler

w/basin removed

Installation Of New Valve Assembly

Connect water inlet line, from building supply to

strainer on replacement valve assembly.

Connect chiller line to super speed fitting.

97218C (Rev. B - 12/07)PAGE 3

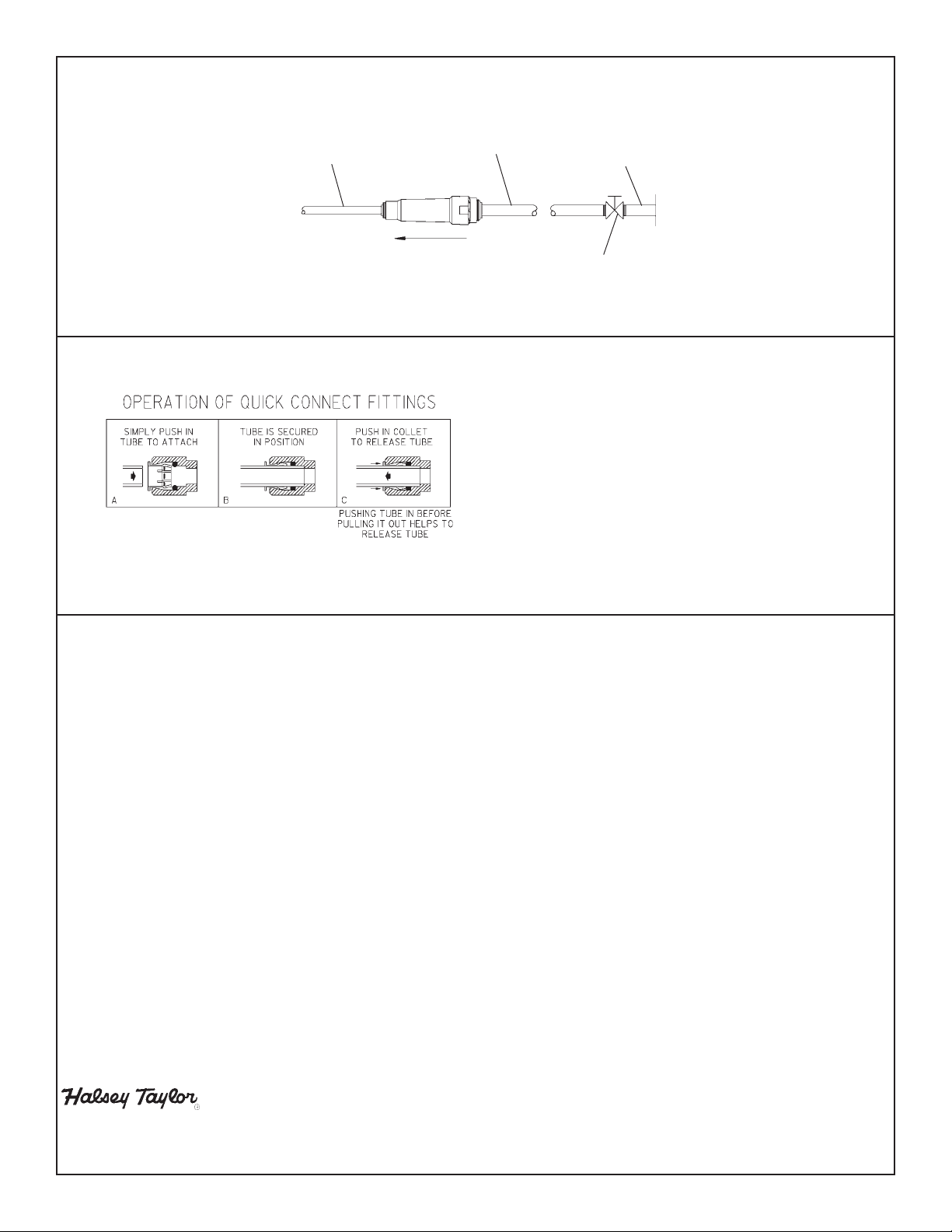

1/4" O.D. TUBE

WATER INLET

TO COOLER

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WA TER SUPPLY

BUILDING WATER INLET

NOTE: WA TER FLOW

DIRECTION

SERVICE STOP

(NOT FURNISHED)

1. Push tubing into fitting until it reaches positive

stop (approximately 3/4 inches). DO NOT SOLDER

TUBES INSERTED INTO THE STRAINER AS

DAMAGE TO THE O-RINGS MA Y RESUL T .

2. To remove tubing from fitting, relieve water

pressure, push in on gray collar while pulling

out on tubing.

Turn on water supply and check for leaks. Install new projector and reposition receptor and drain tube to "P"-trap.

Adjust water flow. Flow is adjusted by removing cover and button on valve bracket, a clockwise adjustment to

screwdriver slot increases the stream height. Reassemble cover and button. NOTE: Flow must be adjusted before

push bar is installed. Install push bar on to new valve bracket. Add speed clip strip to valve bracket assembly,

(row of 4 - (1) each side). Install valve bracket into unit. Reattach receptor and reconnect wate tube to "P"-trap.

Connect power cord to electrical outlet. Reassemble panels and kickplate to unit.

2222 CAMDEN COURT

OAK BROOK, IL 60523

630.574.3500

PRINTED IN U.S.A.

FOR PAR TS, CONT ACT YOUR LOCAL DISTRIBUT OR OR CALL 1.800.323.0620

97218C (Rev. B - 12/07) PAGE 4

Loading...

Loading...