Page 1

Compressed Air Foam System

Installation / Operation Manual

Class1 ◆ A Unit of IDEX Corporation

607 NW 27th Avenue

Telephone: 352-629-5020

Web..........www.class1.com

◆ Ocala, FL 34475 U.S.A.

◆ FAX: 352-629-3569

Manual p/n: 029-0020-85-0

Page 2

APPARATUS INFORMATION

ENGINE ______________________________________________

TRANSMISSION _______________________________________

MAXIMUM CAFS ENGINE RPM ___________________________

CAFS ENGINE SPEED RANGE ___________________________

NOTICE !

Class1 cannot assume responsibility for product failure resulting from improper

maintenance or operation. Class1 is responsible only to the limits stated in the

product warranty. Product specifications contained in this manual are subject to

change without notice.

All Class1 products are quality components -- ruggedly designed, accurately

machined, precision inspected, carefully assembled and thoroughly tested. In

order to maintain the high quality of your unit, and to keep it in a ready condition, it

is important to follow the instructions on care and operation. Proper use and good

preventive maintenance will lengthen the life of your unit.

ALWAYS INCLUDE THE UNIT SERIAL NUMBER

IN YOUR CORRESPONDENCE.

ECO NO REV CHANGE FROM BY DATE APVD

0000 A INITIAL RELEASE LwH 02/00/2006

Manual p/n: 029-0020-85-0, Rev. -A

Printed in U.S.A.

Class 1

A Unit of IDEX Corporation

Ocala, FL 34475 USA

DRAWN BY LwH ISSUE DATE COPYRIGHT ©

CHECKED BY 02/00/2006

NOT TO BE REPRODUCED OR USED TO

MAKE OTHER DRAWINGS OR MACHINERY.

© Class 1 2006

All Rights Reserved

Page 3

Table of Contents ❑

Contents Page

CAFSAttack Air Bottle System

1 Safety precautions ................................................................................................... 7

1.1 General Guidelines............................................................................................................. 7

1.2 Air Bottle Cylinders.......................................................................................................... 12

Brief Overview ..................................................................................................................................12

SCBA Fill Station ..............................................................................................................................14

1.3 Air Filter Element.............................................................................................................. 14

1.4 Emergency Shut-Down .................................................................................................... 14

2 Introduction........................................................................................................... 15

2.1 Overview ........................................................................................................................... 15

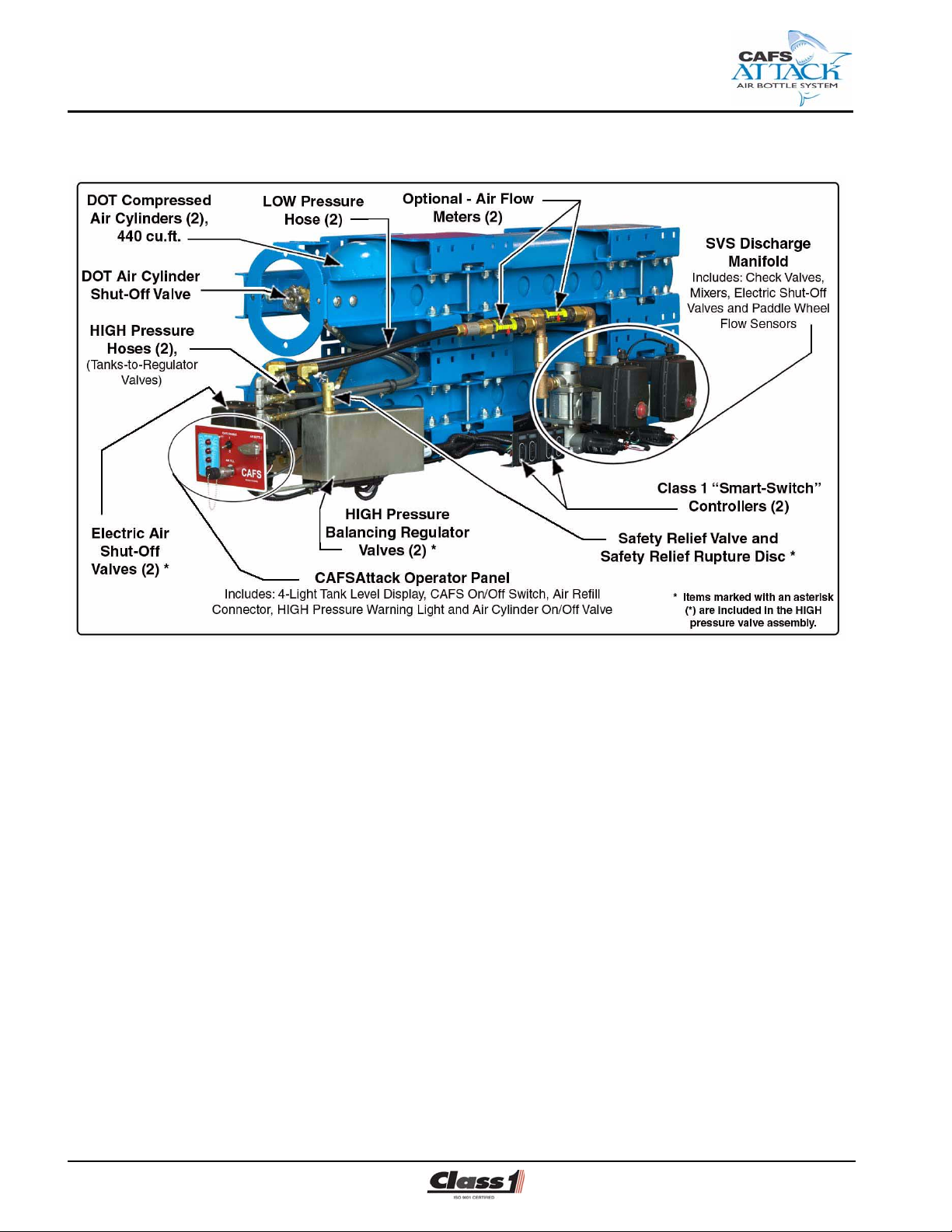

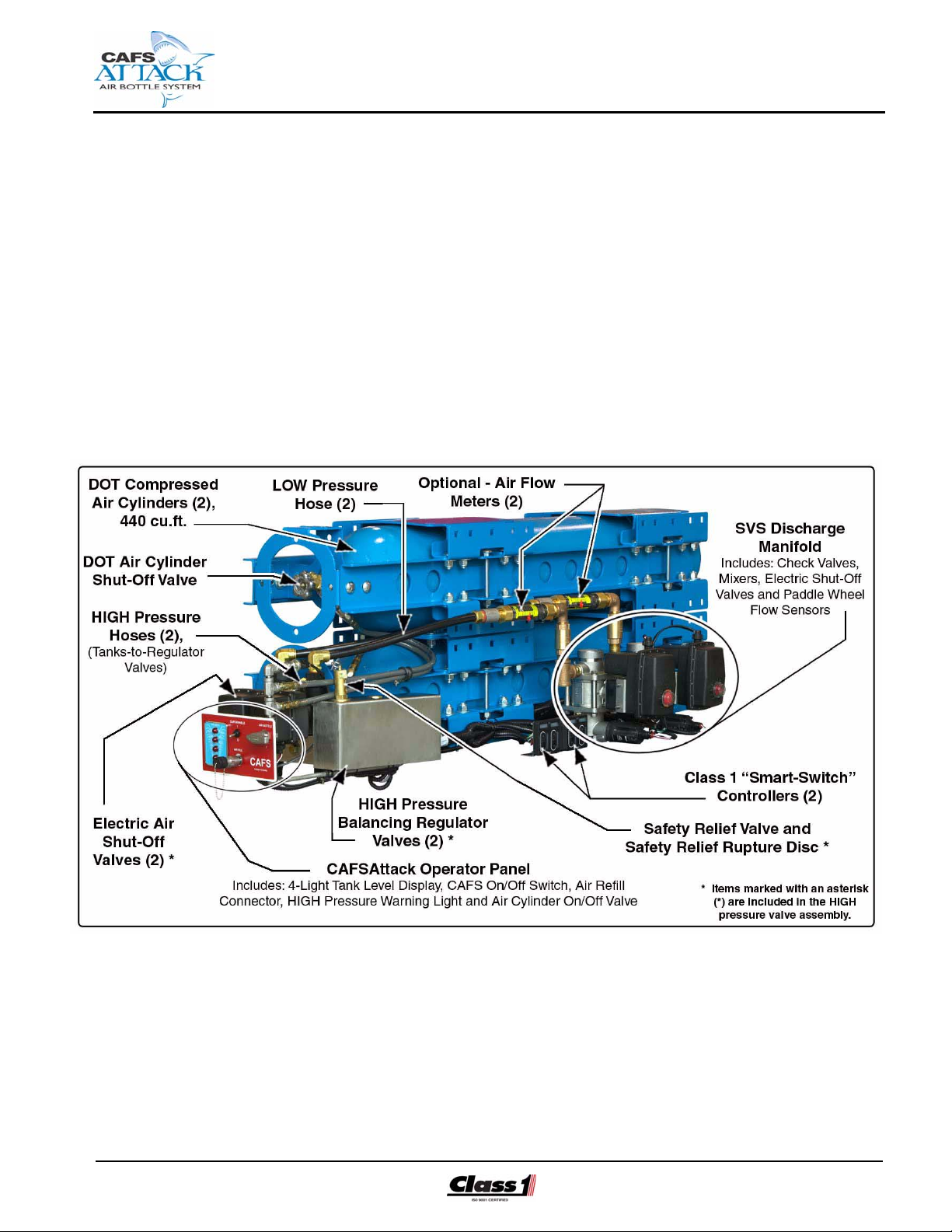

Figure 2-1: CAFSAttack System Overview.........................................................................16

2.2 Smart-Switch Controller (SPC) ....................................................................................... 18

OPEN Button, Discharge Valve........................................................................................................18

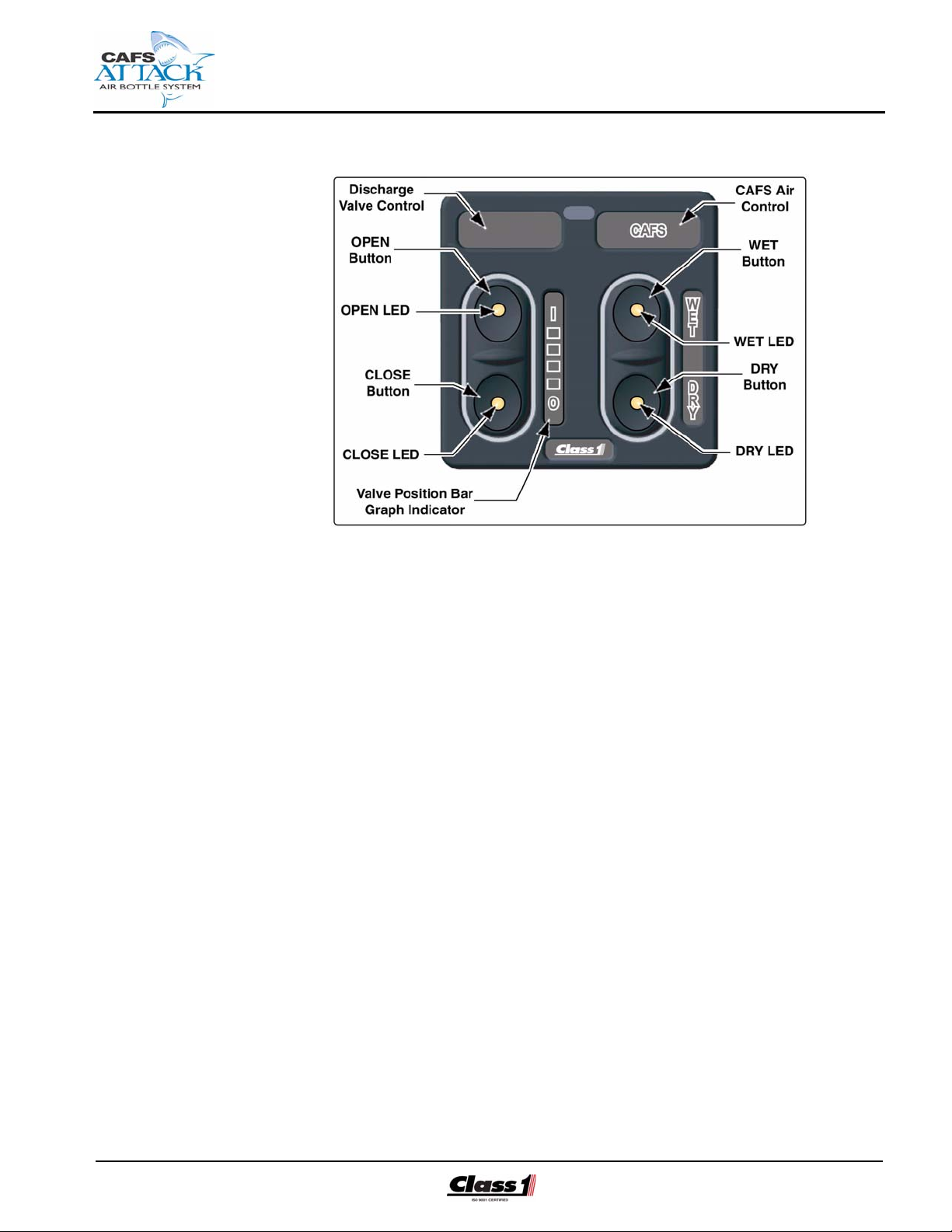

Figure 2-2: Smart-Switch Controller - SPC......................................................................... 19

CLOSE Button, Discharge Valve......................................................................................................19

LED Indicator Array (Bar Graph) ...................................................................................................... 19

WET (+) Button.................................................................................................................................19

Press and Release..................................................................................................................... 19

Press and Hold...........................................................................................................................20

LED Indicator .............................................................................................................................20

DRY ( - ) Button ................................................................................................................................ 20

Press and Release..................................................................................................................... 20

Press and Hold...........................................................................................................................20

LED Indicator .............................................................................................................................20

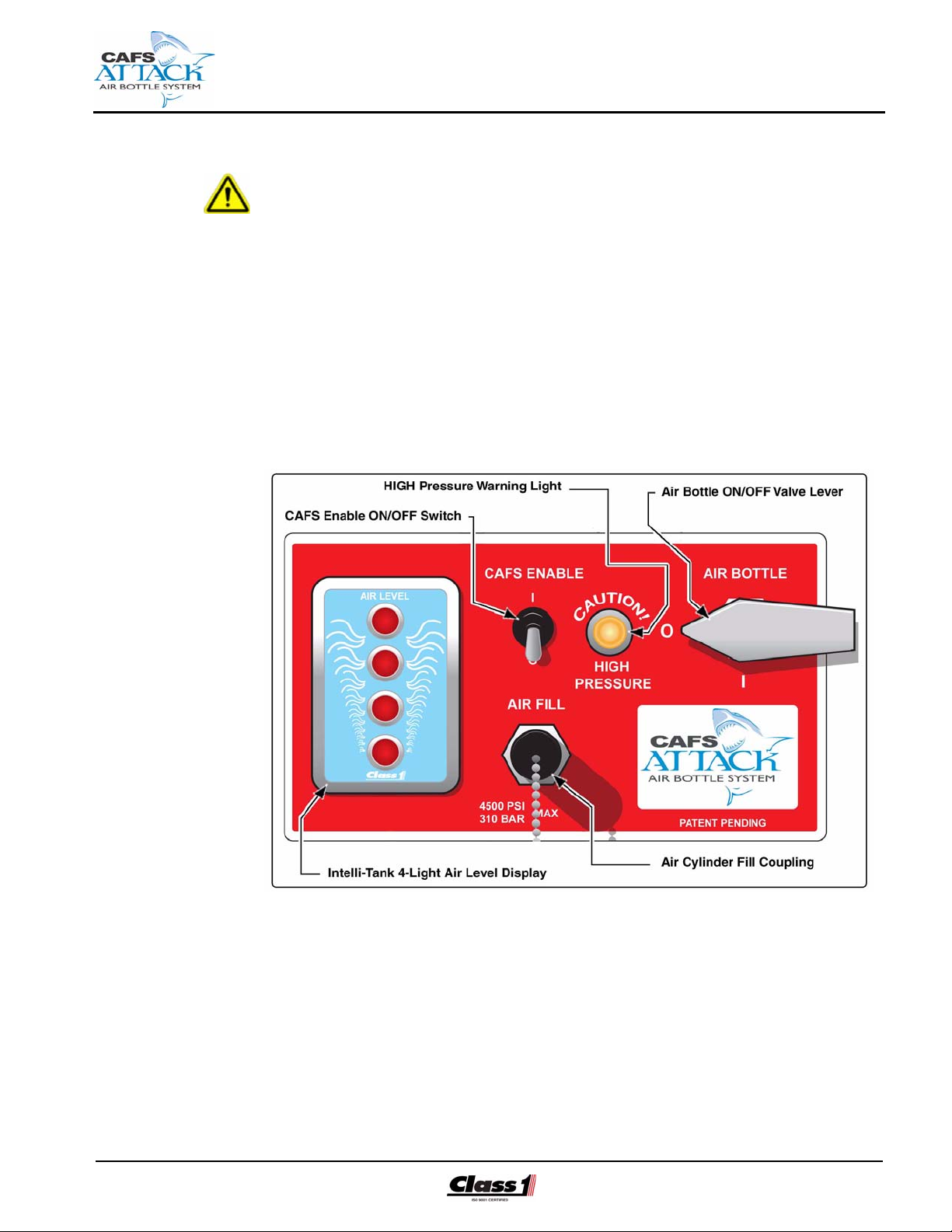

2.3 CAFSAttack Operator Control Panel.............................................................................. 21

Figure 2-3: CAFSAttack Operator Control Panel ................................................................21

CAFS Enable ON/OFF Switch..........................................................................................................21

HIGH Pressure Indicator...................................................................................................................22

Air Bottle OPEN/CLOSE Valve.........................................................................................................22

Intelli-Tank Air Level Indicator ..........................................................................................................22

Air Bottle FILL Coupling....................................................................................................................22

3 Receiving and inspection ...................................................................................... 23

3.1 Receiving .......................................................................................................................... 23

Items Furnished................................................................................................................................23

Items Required, by Builder/Installer..................................................................................................23

CAFSAttack Air Bottle System Installer / Operator’s Guide

p/n: 209-0020-85-0

3

Page 4

❑ Table of Contents

Contents - continued Page

3.1 Receiving - continued

Unpacking......................................................................................................................................... 24

Lifting The System............................................................................................................................ 24

4 Installation - Retrofit Full Size Pumper..............................................................25

4.1 General.............................................................................................................................. 25

Figure 4-1: CAFSAttack System Overview......................................................................... 25

4.2 DOT Air Bottle Cylinder Assembly................................................................................. 26

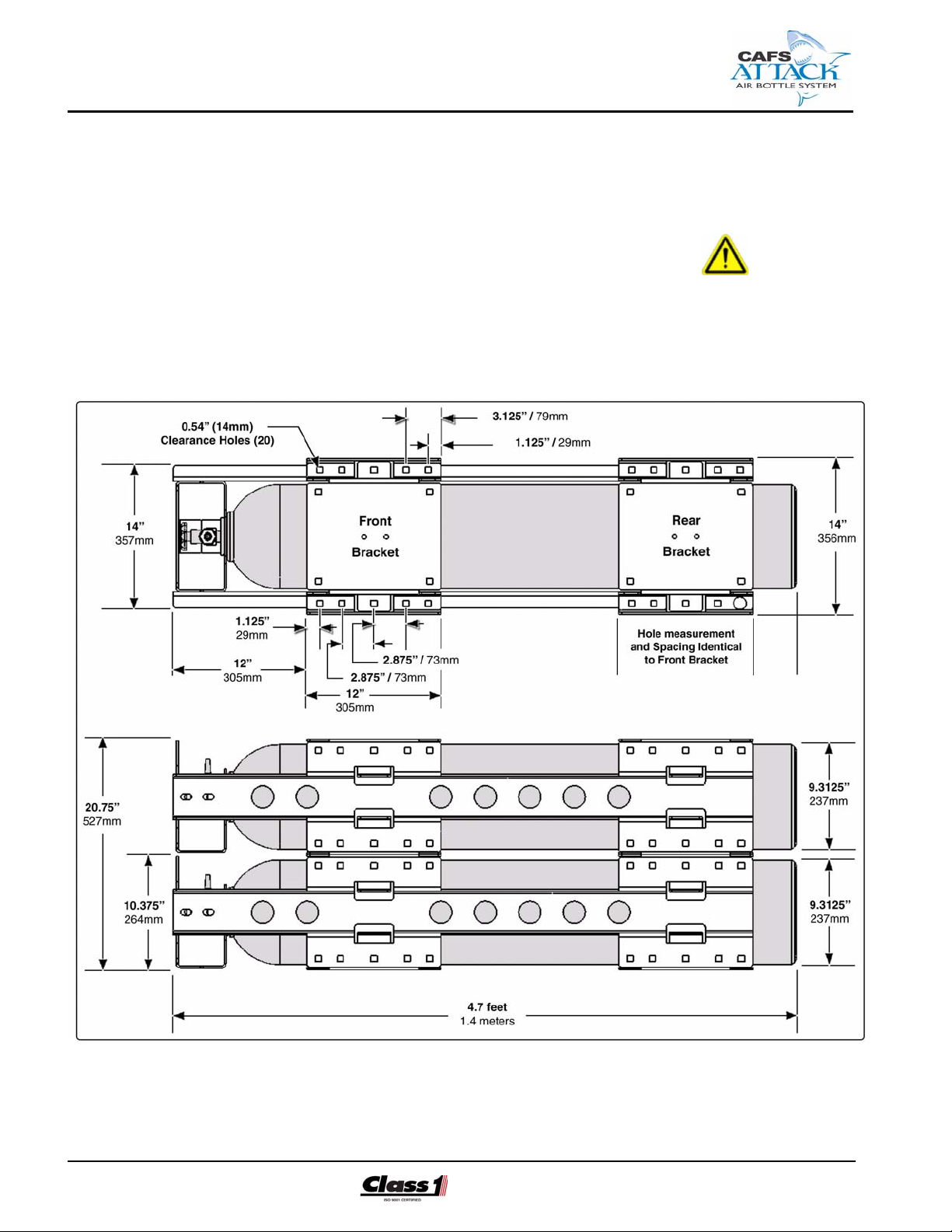

Figure 4-2: DOT Air Bottle Cylinder Assembly Layout Dimensions.................................... 26

4.3 Pressure Balancing Valve Assembly............................................................................. 27

Figure 4-3: Pressure Balancing (Regulator) Valve Assembly Layout.................................28

4.4 Foam Pump Installation .................................................................................................. 28

4.5 CAFSAttack Operator Panel Layout............................................................................... 29

Figure 4-4: Operator’s Panel Layout Dimensions............................................................... 29

4.6 SVS Discharge Manifold ................................................................................................ 30

Figure 4-5: Typical CAFSAttack SVS Discharge Manifold Assembly.................................30

4.7 Plumbing........................................................................................................................... 31

CAFSAttack Operator’s Control Panel .............................................................................................32

Figure 4-6: Typical HIGH Air Pressure Connections.......................................................... 32

Figure 4-7: 4,500 PSI HIGH Pressure Balancing Regulator and Dome Connections ........ 34

Figure 4-8: Pump-to-Balancer Valve Dome Connection .................................................... 34

Intake Air Pressure Gauge Layout Option ........................................................................................ 35

Figure 4-9: Typical Intake Air Pressure Gauge Layout....................................................... 35

Low Pressure CAFS Connect (2) ..................................................................................................... 35

Figure 4-10: Typical LOW Pressure CAFS Air Connections .............................................. 36

Air Discharge Moisture Drain............................................................................................................ 37

Figure 4-11: Typical Discharge Drain................................................................................. 37

Table 4-12: Tubing Size vs. Color ......................................................................................37

CAFS Air LOW Pressure Gauge Layout Option ...............................................................................38

Figure 4-13: CAFS Air LOW Pressure Layout Option ........................................................ 38

4.8 Electrical ........................................................................................................................... 38

Smart-Switch Controller - SPC (S1 and S2)..................................................................................... 40

Figure 4-14: Smart-Switch Controller Panel Cutout ........................................................... 40

Figure 4-15: SPC Connector, Back View ........................................................................... 40

CAFSAttack Main Wire Harness....................................................................................................... 41

Figure 4-16: Primary CAFS Wire Harness .........................................................................41

Primary Power and Ground ..............................................................................................................42

RFI / EMI .......................................................................................................................................... 43

Figure 4-17: Extra Cable Storage....................................................................................... 43

4

CAFSAttack Air Bottle S ystem Installer / Operator’s Guide

p/n: 209-0020-85-0

Page 5

Table of Contents ❑

Contents - continued Page

4.8 Electrical - continued

Flow Sensor Connections (FM1 and FM2) .......................................................................................43

Air Supply Valve, Electric Motor (MV2).............................................................................................43

Discharge Valve, Electric Motor (MV1).............................................................................................44

On/Off Switch (SA3), Operator Control Panel .................................................................................. 44

Figure 4-18: On/Off Switch Connection..............................................................................44

4.9 Installation and Delivery Check List...............................................................................45

4.10 Start Up Check List .......................................................................................................... 46

Electrical ........................................................................................................................................... 46

Air and Water.................................................................................................................................... 46

4.11 System Installer Start-Up................................................................................................. 48

Initial System Power Check..............................................................................................................48

System Operation Check..................................................................................................................48

For FoamLogix...........................................................................................................................48

For CAFSAttack ......................................................................................................................... 49

5 Preset calibration .................................................................................................. 51

5a.1 Smart-Switch calibration ................................................................................................. 51

Figure 5-1: Smart-Switch Calibration Overview..................................................................51

To calibrate a WET consistency... ....................................................................................................52

To calibrate a DRY consistency........................................................................................................53

5a Basic operation ...................................................................................................... 54

5a.1 Starting CAFSAttack ........................................................................................................ 54

5a.2 Shutting-down CAFSAttack ............................................................................................ 56

5a.3 Emergency Shut-Down .................................................................................................... 56

6 Routine maintenance ............................................................................................ 57

6.1 Maintenance Procedures.................................................................................................57

After each use...................................................................................................................................57

Monthly .............................................................................................................................................57

Every Two (2) Months.......................................................................................................................57

Annually ............................................................................................................................................58

6.2 Replace Filter Element..................................................................................................... 58

Figure 6-1: Filter Pressure Contamination Gauge ..............................................................58

6.3 Relieving HIGH PRessure................................................................................................ 59

Figure 6-2: Relieving HIGH Pressure .................................................................................59

CAFSAttack Air Bottle System Installer / Operator’s Guide

p/n: 209-0020-85-0

5

Page 6

❑ Table of Contents

Contents - continued Page

Appendix B: Foam Concentrate Compatibility..................................................61

Reference......................................................................................................................................... 63

Express Warranty .................................................................................65

Class 1..............................................................................................................................................66

7 Drawing / Manual Package ..................................................................................67

Drawings........................................................................................................................................... 68

Manuals............................................................................................................................................68

6

CAFSAttack Air Bottle S ystem Installer / Operator’s Guide

p/n: 209-0020-85-0

Page 7

1 Safety precautions

THE CLASS1 CAFSATTACK™ AIR BOTTLE COMPRESSED AIR FOAM

SYSTEM IS DESIGNED FOR OPTIMUM OPERATOR SAFETY. FOR ADDED

PROTECTION, PLEASE FOLLOW THE SAFETY GUIDELINES LISTED IN THIS

SECTION AND ADHERE TO ALL WARNING, DANGER, CAUTION AND

IMPORTANT NOTES FOUND WITHIN THIS MANUAL.

THIS SECTION ON SAFETY MUST BE CAREFULLY READ, UNDERSTOOD

AND ADHERED TO STRICTLY BY ALL INSTALLERS AND OPERATORS

BEFORE ATTEMPTING TO INSTALL OR OPERATE THE CAFSATTACK

AIR BOTTLE SYSTEM.

WHEN DEVELOPING DEPARTMENTAL APPARATUS OPERATING PROCEDURES, INCORPORATE THE WARNINGS AND CAUTIONS AS WRITTEN.

Safety Precautions ❑

IMPORTANT !

CAFSAttack is a trademark of Class1. All other brand and product names are the

trademarks of their respective holders.

1.1 GENERAL GUIDELINES

NOTICE !

THE PROCEDURES IN THIS MANUAL ARE GENERAL INSTALLATION AND

OPERATING PROCEDURES. THEY DO NOT REPLACE THE PROCEDURES,

POLICIES OR GUIDELINES ESTABLISHED BY THE AUTHORITY HAVING

JURISDICTION, NOR DO THEY REPLACE THE RECOMMENDATIONS AND

PROCEDURES PROVIDED IN THE APPARATUS MANUFACTURER'S

MANUAL.

REFER TO THE PROCEDURES PROVIDED BY THE AUTHORITY HAVING

JURISDICTION ON SETTING WHEEL CHOCKS (TO PREVENT ANY MOVEMENT OF THE APPARATUS), AS WELL AS LAYOUT AND CONNECTION OF

HOSES, VALVES AND DRAIN COCKS.

Read all instructions thoroughly before beginning

any installation and operation process.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

❑ Use care when removing the CAFSAttack system from its packaging

(skid) to prevent personal injury and/or damage to the system, especially

the external system connections.

7

Page 8

❑ Safety Precautions

THE CAFSATTACK AIR BOTTLE (H-CYLINDER) ASSEMBLY IS HEAVY AND

BULKY, WEIGHING OVER 500 LBS. (227 KGS.). ALWAYS REFER TO YOUR

BILL OF LADING FOR THE ACTUAL WEIGHT.

USE PROPER LIFTING SUPPORT DEVICES (OVERHEAD CRANE, STRAPS /

CHAINS, ETC.) CAPABLE OF HANDLING THE LOAD WHEN MOVING OR

INSTALLING THE ASSEMBLY. ATTACH LIFTING APPARATUS TO THE CYLINDER FRAME ONLY. DO NOT ATTACH STRAPS AROUND THE CYLINDERS.,

ESPECIALLY AT THE SHUT-OFF VALVE AREA. ALSO SEE FIGURE 4-2:

“DOT AIR BOTTLE CYLINDER ASSEMBLY LAYOUT DIMENSIONS” ON PAGE

26.

❑ Installation, maintenance and repairs should be performed by a trained

and qualified installer, or your authorized Class1 service representative.

Be sure the installer has sufficient knowledge, experience and the proper

tools before attempting any installation. DO NOT permit untrained personnel to install, use or maintain the CAFSAttack system.

WARNING !

Installation, use or repairs performed by persons not properly trained

may cause equipment failure that could result in serious bodily injury,

sickness or death.

❑ The installer is responsible for observing all instructions and safety

precautions in his or her daily routine as dictated by regional safety

ordinances or departmental procedures.

❑ Periodic inspection and scheduled maintenance of the equipment is

required for continued safe operation. A separate label is affixed to the

operator’s panel indicating the test date stamped on the cylinders and

the date the cylinders next require testing.

❑ Read and follow the precautions on all compressed gas cylinder labels.

❑ The frequency of servicing is the responsibility of the end-user based

upon the application.

❑ Never allow problems or lack of maintenance to go unreported.

❑ DO NOT permanently remove or alter any guarding or insulating devices,

labels, plates or instruction plates, or attempt to operate the system

when these items are removed. Various labels and/or instruction plates

are also located on the apparatus operator’s panel.

Make sure all access/service panels, covers, labels and plates are

installed, closed and latched tight, where applicable.

❑ DO NOT remove or alter any hydraulic or pneumatic connections, electri-

cal devices, etc. DO NOT tamper with or disconnect safety features. DO

NOT add or remove structural parts. Doing so voids the CAFSAttack

warranty.

8

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 9

Safety Precautions ❑

Any of the preceding could effect system capacity and/or safe operation

of the system and is a serious safety violation which could cause personal injury or death, could weaken the construction of the system or

could affect safe operation of the CAFSAttack Air Bottle System.

WARNING !

NO MODIFICATIONS OR ADDITIONS MAY BE MADE TO THE CAFSATTACK

AIR BOTTLE SYSTEM WITHOUT PRIOR WRITTEN PERMISSION FROM:

Class1

A Unit of IDEX Corporation

607 NW 27th Avenue

Ocala, FL 34475 U.S.A.

Telephone ......352-629-5020

Fax................. 352-629-3569

Web:...............www.class1.com

❑ Nozzle selection – Class1 does not recommend any specific type or

brand of nozzle for use with the CAFSAttack system.

Each fire department must conduct its own evaluation to ensure an

appropriate nozzle choice for the various types of hazards encounter.

Each fire department must develop associated operational procedures

and guidelines. Class1 does not recommend or claim suitability or fitness for any given nozzle brand or style.

WARNING !

ONCE A NOZZLE HAS BEEN SELECTED IT IS IMPERATIVE TO PROVIDE

AMPLE TRAINING IN THE USE OF THE NOZZLE.

OPEN CAFS NOZZLES “SLOWLY” AND MAKE SURE THE NOZZLE IS

SECURED AGAINST REACTION FORCES.

❑ Inspect the pressure balancing regulator valves and interconnecting

components (HIGH pressure side) for leaks before each use.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

WARNING !

BE SURE TO WEAR SAFETY GLASSES WHEN SERVICING THE HIGH

PRESSURE SYSTEM OR WHEN REMOVING AND/OR INSTALLING HIGH

PRESSURE PARTS.

9

Page 10

❑ Safety Precautions

Also see Tescom “Safety, Installation and Operation Precautions” guide

lines, located at the back of this manual.

If a balancing regulator valve or other component in the system shows

signs of a leak or malfunction, the CAFSAttack system must be removed

from service immediately and repaired and tested before retuning to

service.

ONCE THE AIR CYLINDERS ARE FULLY CHARGED AND THE SYSTEM IS

ENERGIZED, ALL HIGH PRESSURE LINES BETWEEN THE CYLINDER SHUTOFF VALVES AND THE PRESSURE BALANCING REGULATOR VALVES,

INCLUDING THE AIR FILTER, ARE EXPOSED TO HIGH PRESSURES (4,500

PSI / 310 BAR).

DO NOT PERFORM ANY SERVICE TO THE HIGH PRESSURE SIDE UNTIL THE

SYSTEM PRESSURE IS RELIEVED. SEE SECTION “6.3 RELIEVING HIGH

PRESSURE,” ON PAGE 59 FOR ADDITTIONAL INFORMATION.

DANGER !

❑ DO NOT operate the system with just air and water. Shut off the air sup-

ply whenever the foam tank is empty.

CAUTION !

COLD WEATHER ENVIRONMENTS CAN CAUSE SOME COMPONENTS TO

FREEZE AND RESTRICT AIR FLOW. COMPONENTS MUST BE THAWED

BEFORE CONTINUING CAFS OPERATION.

❑ NEVER fully empty the air-bottle cylinders. Always maintain a positive

pressure (approximately 50 to 100 PSI / 4 to 7 BAR) within the cylinders.

Positive pressure ensures against moisture and/or dirt contamination in

the tanks, which could also flow back and contaminate the SCBA

recharging cylinders.

Failure to comply could result in serious bodily injury, sickness or

death.

❑ To prevent electrical shock always disconnect the primary power source

before attempting to service any part of the CAFSAttack system.

❑ All electrical systems have the potential to cause sparks during service.

Take the necessary precautions to eliminate explosive or hazardous

environments during any installation and/or service.

10

❑ To prevent system damage or electrical shock, the main power supply

wire must be the last connection made to the CAFSAttack system.

❑ The CAFSAttack system is designed for use on negative (-) ground,

direct current, electrical systems only.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 11

Safety Precautions ❑

❑ Always disconnect the power cable, ground straps, electrical wires and

control cables from the smart-switch control unit or other CAFSAttack

system equipment before electric arc welding at any point on the apparatus. Failure to do so could result in a power surge through the unit that

could cause irreparable damage.

❑ Before connecting the cord sets and wiring harnesses, inspect the seal

washer in the female connectors. If the seal washer is missing or damaged water can enter the connector causing pin and terminal corrosion.

This could cause possible system failure.

❑ DO NOT operate or fill (recharge) the air system at pressures higher than

the maximum rated system pressure of 4,500 PSI (310 BAR), as stated

on the WARNING placard located near the air cylinders.

If the “Rupture Disk” has ruptured due to over pressurization, the reason

for the rupture mst be determined and the cylinders must be visually

inspected and re-hydrostatic tested as stated in regulation 49 CFR

178.37. Failure to comply and re-certify the cylinders could lead to catastrophic failure resulting in serious bodily injury, sickness or death.

❑ DO NOT operate the CAFS system at pressures above 150 PSI (10

BAR), as stated on the WARNING placard on the operator’s panel.

❑ Use only piping or tubing, hose and fittings which are rated at or above

the maximum pressure rating at which the CAFSAttack system operates.

Also see heading “Air Bottle Cylinders” on page 12.

❑ Relieve all system pressure, then drain all foam concentrate and water

from the system before servicing any of its component parts.

❑ DO NOT mount a radio transmitter or transmitter cables in direct or close

contact with the CAFSAttack smart-switch controllers. Direct contact

could cause electrical interference and disrupt controller operations.

❑ DO NOT connect the CAFSAttack main power lead to small leads that

are supplying some other device, such as a light bar or siren. The

CAFSAttack requires ?? AMP minimum current.

❑ When operating the CAFSAttack and the Hale FoamLogix in Simulated

Flow Mode an outlet for the foam concentrate must be provided to prevent excessive pressure buildup in the discharge piping or hoses.

❑ Foam tank “low level” sensors must be utilized to protect the foam pro-

portioner from dry running. Failure to use “low level” sensors voids the

warranty.

❑ Make sure the foam tank and foam concentrate suction hoses are clean

before making the final connection to the foam pump. If necessary, flush

the tank and hoses prior to making any connections.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

❑ Also review your specific FoamLogix Installation and Operation Manual

(FoamLogix Model 2.1A, Hale p/n: 029-0020-74-0; FoamLogix Model 3.3

and 5.0, Hale p/n: 029-0020-68-0) for additional safety information.

11

Page 12

❑ Safety Precautions

1.2 AIR BOTTLE CYLINDERS

The CAFSAttack system uses HIGH pressure, compressed air storage cylinders (4,500 PSI / 310 BAR) which are in compliance with NFPA 1989

“Standard on Breathing Air Quality for Fire and Emergency Services Respiratory Protection.” For NFPA 1901 compliance, when a breathing air system

or a utility air system is mounted on fire apparatus the following requirements must apply:

CAUTION !

INSTALLATION OF THE CAFSATTACK SYSTEM MUST MEET NFPA #1901,

CHAPTER 25 “AIR SYSTEMS” REGULATIONS, INCLUDING ALL

SUBSEQUENT CHAPTERS OR REGULATIONS, I.E., “ASME” AND/OR “DOT”

AS STATED IN NFPA 1901 REGULATION. A SAMPLE LISTING FROM CHAPTER 25 “AIR SYSTEMS REGULATIONS” THAT APPLY AND MUST BE

ADHERED FOLLOWS:

CHAPTER # ........................... TITLE

25.2 ........................................ Provisions Applying to All Air Systems

25.2.5 ..................................... Assembly and Installation Practices

25.2.5.2 .................................. Hot Surface

25.2.5.4 .................................. Locking Devices

25.2.7 ..................................... General Piping Installation

25.2.8 ..................................... Flexible Hose

25.2.9 ..................................... Operator’s Panel and Controls

25.2.‘0 .................................... Maintainability

25.2.11 ................................... Labels and Plates

25.2.12 ................................... Documentation

25.2.13 ................................... Training and Instructions

25.5 ........................................ Air Storage Systems

25.5.1 ..................................... Transportable Air Tanks

25.5.7 ..................................... Air Tank Mounting

25.5.8 ..................................... Air Tank Valve Control and Monitoring

25.7 ........................................ Air Supply Regulation

25.11 ...................................... Air Hose

25.14 ...................................... Testing

12

Brief Overview

❑ Air tanks must comply with regulation 49 CFR 178.37, “Specification

3AAA and 3AAAX Seamless Steel Cylinders” or 29 CFR 1910.169, “Air

Receivers.”

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 13

Safety Precautions ❑

Also review and adhere to regulation NFPA 55: “Standard for the Storage, Use and Handling of Compressed Gases and Cryogenic Fluids in

Portable and Stationary Containers, Cylinders, and Tanks.”

CAUTION !

THE AIR CYLINDERS MUST BE FILLED WITH “BREATHING AIR” QUALITY

AIR. HOWEVER, THIS AIR IS “NOT SUITABLE” FOR BREATHING AIR APPLICATIONS (SCBA). OPEN AND CLOSE AIR CYLINDER VALVES “SLOWLY.”

ALWAYS “CLOSE” THE AIR VALVE WHEN THE CAFSATTACK SYSTEM IS

NOT IN USE.

❑ The air system must be designed and constructed to withstand the

stresses, vibrations and other conditions found when mounted on a fire

apparatus and being used in mobile service.

❑ Air tanks must be mounted in an arrangement that will hold the tanks in

all types of mobile use. Protective devices must be provided to protect

the air tanks, valves and associated piping and/or hoses from damage as

a result of accidental impact.

❑ Each DOT cylinder, valve, hose and/or tubing must successfully with-

stand a “Hydrostatic Test” as stated in regulation 49 CFR 178.37.

The Hydrostatic Test must be performed at least once every five (5)

years.

Failure to successfully meet the test criteria as stated in regulation 49

CFR 178.13 indicates a system failure. The CAFSAttack system must

be removed from operation immediately and repaired and re-tested

before retuning to service.

❑ Valving used on transportable air tanks must be of the ASME type on

ASME cylinders and of the DOT type on DOT cylinders, or equal, for the

rated system pressure.

❑ The air system must be designed so that it can be stored and operated in

environments with relative humidity up to and including 100% (percent).

❑ Surfaces over 142° F (61° C) must be covered with a thermal insulating

material or must be mechanically guarded to protect the operator. If covering or guarding the surface affects the operation of the component, a

label must be provided that states “CAUTION!: Hot Surfaces When

Operating.”

❑ The air tanks must be located away from any heat-producing devices,

such as the generator engine or exhaust.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

❑ Locking devices - All screws, pins, bolts or other fasteners whose failure

could create a hazardous condition for personnel or equipment must be

equipped with locking devices. Safety wire, self-locking nuts, cotter pins,

lock washers and liquid-locking compounds are acceptable.

13

Page 14

❑ Safety Precautions

❑ All materials used in the air system must be corrosion resistant or treated

to resist corrosion unless the finished product is in continual contact with

a noncorrosive lubricant.

All pneumatic fittings, tubing and hoses must also be rated for the maximum allowable working system pressure.

❑ Flexible hose must be installed to prevent cuts, abrasions, exposure to

damage, excessive temperatures, damage from loose equipment and

excessive bending.

SCBA Fill Station

THE CAFSATTACK SYSTEM IS NOT DESIGNED OR INTENDED TO BE USED

AS A “SCBA FILL STATION.” THE CAFSATTACK SYSTEM MUST NOT BE

USED FOR OTHER THAN ITS INTENDED USE. DO NOT FILL SCBA BOTTLES

USING THE CAFSATTACK AIR CYLINDERS AS YOUR AIR SOURCE.

DANGER !

1.3 AIR FILTER ELEMENT

A visual differential pressure indicator enables the operator to read contaminated build up before the element is plugged, and includes an automatic

reset.

DANGER !

THE FILTER IS LOCATED IN THE SYSTEM HIGH PRESSURE LINE. YOU

MUST FIRST BLEED-OFF THE HIGH PRESSURE BEFORE ATTEMPTING TO

CHANGE AND/OR CLEAN THE FILTER ELEMENT. TO RELIEVE (BLEED-OFF)

THE SYSTEM HIGH PRESSURE, SEE SECTION 6.3 “RELIEVING HIGH PRESSURE” ON PAGE 59.

1.4 EMERGENCY SHUT-DOWN

1. Manually shut-off the air supply to the system - turn the CAFSAttack air

bottle valve, on the operator’s control panel, to the CLOSE position (O).

2. Set the CAFS ENABLE switch, on the operator’s control panel, to OFF (O).

3. Close the air bottle shut-off valves for each cylinder.

4. Also see heading “Emergency Shut-Down” on page 56.

14

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 15

2Introduction

2.1 OVERVIEW

The CAFSAttack Air Bottle Compressed Air Foam Pumping System is

designed for installation on new or for retrofit onto existing fire apparatus.

The CAFSAttack system must be considered an additional option on a fire

fighting apparatus and must not impair the operation of the basic system.

The performance of the original fire fighting system, as well as personal

safety, must not be compromised.

CAFSAttack offers accurate push-button, compressed air foam from a

stored air supply using Class1 “Smart-Switch” electronic technology. The

Class1 Smart-Switch provides enhanced fire fighter safety, performance

and ease of use. Two 200 cfm capacity pressure “balancing regulator”

valves “balance” water and air pressures.

Description ❑

Dual compressed air foam discharges provide variable foam consistancies. For example, one line can generate a “WET” quick draining foam blanket; while the second line could discharge “DRY,” shaving cream-like foam

for exposure protection.

The CAFSAttack DOT high pressure compressed air bottle cylinders are in

compliance with NFPA 1989 “Standard on Breathing Air Quality for Fire and

Emergency Services Respiratory Protection” regulations.

The CAFSAttack system is shipped in modular assembly form, completely

tested and ready for installation on full size municipal, forestry and skid

units. (See Figure 2-1: “CAFSAttack System Overview,” on page 16.)

The CAFSAttack System includes the following modular assemblies:

❑ Dual DOT high pressure (4,500 PSI / 310 BAR) compressed air bottle

cylinders (H-cylinder type) having a capacity of over 440 cubic feet

of storage, fully assembled as a complete unit.

❑ Dual HIGH pressure (4,500 PSI / 310 BAR and 1,000 PSI / 69 BAR)

valve assembly

● The first high-to-low air pressure “balancing” regulator valve (4,500

PSI) is direct acting and dome loaded to provide constant discharge

pressure - 200 cfm capacity. The second valve (1,000 PSI) is also

direct acting and reduces pressure to 1,000 PSI for best overall

performance.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

15

Page 16

❑ Description

Figure 2-1: CAFSAttack System Overview

❑ HIGH pressure valve assembly - continued

● Tee-type air filter - used to remove any particulate contaminates from

the system. A multi-layered glass fiber element produces high efficiency silt-control filtration and provides for extended service intervals

and reduced maintenance cost.

A visual pressure indicator enables the operator to read contaminated

build up before the element is plugged, with an automatic reset.

● Two electrically-controlled open/close air shut-off valves.

● Pressure safety relief valve, set at 165 PSI (11.4 BAR).

● Pressure safety relief Rupture Disc, set at 350 PSI (24 BAR).

● Check valves to ensure separation of water, foam solution, foam con-

centrate and air.

❑ Discharge Manifold

● Two electrically-controlled shut-off valves, with valve position

indicator.

See separate SVS manual provided (Hale p/n: 209-0020-90-0) for

additional valve information.

16

● Mixing chambers.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 17

Description ❑

● Paddle wheel flow sensors.

❑ CAFSAttack operator control panel

● Two Class1 “Smart-Switch” Controllers with LED bar graph array.

● Inteli-Tank high pressure air tank level indicator - four (4) RED indica-

tors lights, indicates cylinder tank charge remaining.

● On/Off CAFSAttack air enable switch, to activate the CAFSAttack

system.

● Amber HIGH pressure warning light, illuminates at pressures above

150 PSI (10 BAR).

● Quick connect high pressure air cylinder refill connection for an SCBA

Breathing Air High Pressure 4,500 PSI (310 BAR) Compressor System. SCBA station not included.

● Main air bottle open/close valve - introduces HIGH pressure air into

the system.

❑ HIGH pressure hose (2) - air bottle cylinders-to-pressure valves.

❑ LOW pressure hose (2) - high pressure air shut-off valves-to-SVS dis-

charge valves.

❑ FoamLogix foam pump, Model 2.1A - standard (not shown)

See separate manual for description, installation and operation of FoamLogix Electronic Foam Proportioning System (Hale p/n: 029-0020-74-0).

❑ CAFSAttack Installer / Operation Manual, Hale p/n:209-0020-85-0

Additional options, such as; FoamLogix Models 3.3 or 5.0, for higher foam

solution applications or the use of Class “B” type foams are available to further meet customer requirements.

IMPORTANT!

COMPONENTS ARE INSTALLED WHERE REQUIRED, PER CUSTOMER

ORDER AND/OR OPERATIONAL REQUIREMENTS. NOT ALL INSTRUCTIONS

HEREIN ARE INCLUSIVE. THEY ARE GENERAL GUIDELINES ONLY. INDIVIDUAL CHASSIS CONFIGURATION, BUILDER PRACTICES, ETC. DICTATE

WHEN AND WHERE COMPONENTS ARE INSTALLED.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Using accepted assembly procedures, the CAFSAttack air cylinders may be

mounted on the apparatus in an arrangement that secures the cylinders in

all types of mobile use and where they are least susceptible to accidental

impact.

Once the cylinders are in place, the interconnecting valving, pressure

gauges, pneumatic lines and related components must be installed.

17

Page 18

❑ Description

Since the system is of the modular design, a minimum number of pneumatic

and electrical connections are required.

Mounting the FoamLogix 2.1A, 3.3 or 5.0 System includes installation of

the foam pump and motor assembly, in-line strainer and valve assembly and

low tank sensor. Refer to the following manual, based on the specific model

FoamLogix included with your system:

❑ FoamLogix Model 2.1A Installation and Operation Manual,

Hale p/n: 029-0020-74-0

❑ FoamLogix Model 3.3 and 5.0 Installation and Operation Manual,

Hale p/n: 029-0020-68-0

The CAFSAttack smar t-switches and air pressure level indicator are to be

mounted on the apparatus pump operator’s panel.

Once the major components are installed, see separate headings for pneumatic plumbing and electrical hookup instructions.

❑ Plumbing - see 4.7 “Plumbing” on page 31.

❑ Electrical - see 4.8 “Electrical” on page 38.

WARNING !

WHILE INSTALLING A CAFSATTACK SYSTEM MAKE SURE ALL SAFETY

REGULATIONS AND INSTRUCTIONS ARE FOLLOWED TO PROVIDE A SAFE

INSTALLATION. THOROUGHLY REVIEW SECTION 1 “SAFETY PRECAUTIONS” BEGINNING ON PAGE 7.

2.2 SMART-SWITCH CONTROLLER (SPC)

The “Smart-Switch” Panel Controller (SPC) is the primary controller for both

compressed air injection and discharge valve control. The SPC allows the

operator to inject air and control the consistency of the discharged finished

foam. (See Figure 2-2: “Smart-Switch Controller - SPC,” on page 19.)

OPEN Button, Discharge Valve

18

(See Figure 2-2: “Smart-Switch Controller - SPC,” on page 19.)

The OPEN button opens the water discharge valve to increase water or

foam solution (making a wetter solution). Holding the button pressed opens

the valve until the internal limit switch activates, indicating the fully OPENED

position.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 19

Description ❑

Figure 2-2: Smart-Switch Controller - SPC

The OPEN button LED is ON steady during operation and flashes during

setup.

CLOSE Button, Discharge Valve

The CLOSE button closes the water discharge valve to decrease the water

or foam solution (making a dryer solution). Holding the button pressed

closes the valve until the internal limit switch activates, indicating the fully

CLOSED position. The CLOSE button LED is ON steady during operation

and flashes during setup.

LED Indicator Array (Bar Graph)

The OPEN / CLOSE bar graph LED indicator array illuminates from the bottom (O - fully closed) to the top (I - fully opened). It sequentially indicates

the approximate open / close position of the valve.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

WET (+) Button

Press and Release

Pressing and RELEASING the WET button sets and maintains the air injection rate at the Preset 2 * value, producing a WET foam concentrate.

19

Page 20

❑ Description

Pressing the WET button also immediately activates the FoamLogix controller in preparation for foam injection. When the system detects water is flowing, the appropriate air valve is opened.

Press and Hold

Press and HOLD the WET button for about ten (10) seconds to store a new

WET CAFS consistency at Preset 2. The entire display blinks once when

the setting is stored. Use the OPEN and CLOSE buttons to adjust the airto-foam solution ratio, thus the foam consistency.

LED Indicator

The WET button LED FLASHES when in the WET position and is ON

steady if the CAFS system is active and air is flowing into the corresponding

discharge.

DRY ( - ) Button

(See Figure 2-2: “Smart-Switch Controller - SPC,” on page 19.)

Press and Release

Pressing and RELEASING the DRY button sets and maintains the air injection rate at the Preset 1 * value, producing a DRY foam concentrate. Press-

ing the DRY button also immediately activates the FoamLogix controller in

preparation for foam injection.

When the system detects water is flowing, the appropriate air valve is

opened.

Press and Hold

Press and HOLD the DRY button for ten (10) seconds to store a new DRY

CAFS consistency at Preset 1. The entire display blinks once when the setting is stored. Use the OPEN and CLOSE buttons to adjust the air-to-foam

solution ratio, thus the foam consistency.

LED Indicator

The DRY button LED FLASHES when in the DRY position and is ON

steady if the CAFS system is active and air is flowing into the corresponding

discharge.

* Presets 1 and 2 are an established value by the end user and the installer/builder at

the time of installation to produce the required CAFS discharge. This assures the

correct DRY and WET consistency ever time the appropriate CAFS button is pressed.

20

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 21

Description ❑

IMPORTANT !

THE DUAL DISCHARGES AND SMART-SWITCH CONTROLLERS OFFER SEPARATE CONTROL FOR EACH DISCHARGE, I.E., ONE DISCHARGE CAN BE

SET FOR WET CAFS WHILE THE OTHER IS SET FOR DRY CAFS.

2.3 CAFSATTACK OPERATOR CONTROL PANEL

The CAFSAttack Operator Control Panel provides the means to enable

(turn ON) the CAFSAttack system and to supply, monitor and charge the air

pressure in the two DOT air cylinders. (See Figure 2-3: CAFSAttack Operator Control Panel.)

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Figure 2-3: CAFSAttack Operator Control Panel

The CAFSAttack operator control panel is a complete assembly. It must be

installed in a convenient location on the apparatus operator’s control panel.

CAFS Enable ON/OFF Switch

The CAFS Enable On/Off Switch allows the electrical power to the

CAFSAttack system components (0 = OFF; I = ON).

21

Page 22

❑ Description

HIGH Pressure Indicator

Also see Figure 2-3: “CAFSAttack Operator Control Panel” on page 21.

The HIGH pressure indicator (YELLOW) illuminates when the water/air

pressure is greater than 150 PSI (10 BAR). Pressure in excess of 160 PSI

(11 BAR) is discharged through the safety relief valve.

Air Bottle OPEN/CLOSE Valve

This open/close shut-off valve introduces HIGH air pressure to the system

(0 = CLOSED; I = OPEN).

Intelli-Tank Air Level Indicator

The 4-light air level indicator visually shows the air remaining in the HIGH

pressure air cylinders (bottles). See separate manual, located at the back

of this manual, for additional information.

CAUTION !

SYSTEM MAXIMUM PRESSURE MUST NOT EXCEED 4,500 PSI (311 BAR).

ALSO SEE HEADING “AIR BOTTLE CYLINDERS” ON PAGE 12.

Air Bottle FILL Coupling

The air FILL coupling allows charging of the 4,500 PSI (310 BAR) HIGH

pressure cylinders with a SCBA compressor system.

DANGER !

THE CAFSATTACK AIR BOTTLE FOAM PUMP SYSTEM IS NOT DESIGNED

OR INTENDED TO BE USED AS A “SCBA FILL STATION.” THE CAFSATTACK SYSTEM MUST NOT BE USED FOR OTHER THAN ITS INTENDED

USE.

22

DO NOT FILL SCBA BOTTLES USING THE CAFSATTACK AIR CYLINDERS AS

YOUR AIR SOURCE.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 23

3 Receiving and inspection

3.1 RECEIVING

Before shipping from Class1 the CAFSAttack Compressed Air Foam Pumping System is factory inspected and tested. However, we recommend that

you:

1. Inspect the packaging for any signs of physical damage during shipment. Note

any apparent damage on the bill of lading and request the delivery agent to

sign it. Report the damage to Class1, Ocala, FL. and the shipping company.

2. Verify that the system configuration and options match your purchase order.

Report any discrepancies to Class1.

Receiving and Inspection ❑

Class1

A Unit of IDEX Corporation

607 NW 27th Avenue

Ocala, FL 34475 U.S.A.

Telephone . 352-629-5020

Fax ............ 352-629-3569

Web:.......... www.class1.com

Items Furnished

The CAFSAttack system is shipped with all OEM required connections

tagged for easy identification. For a listing of items furnished, see Section

2.1 “Overview,” beginning on page 15.

Also included are the necessary labeling, plates and instruction plates

which must be installed in their appropriate locations to ensure proper personal and system operating safety.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Items Required, by Builder/Installer

The following items are a sampling of what might be required to complete

the installation, connecting the system to your apparatus. The items

required vary depending on your system configuration. Also see the FoamLogix Model 2.1A, 3.3 or 5.0 Manual for additional information.

23

Page 24

❑ Receiving and Inspection

❑ Appropriate air injection hose, 1/4” (6 mm), up 6,000 PSI (414 BAR)

❑ Appropriate discharge hose or piping, 1/4” (6 mm), up ??? PSI (???

BAR)

❑ Appropriate electrical wire, Type SXL, GXL or TXL

❑ Appropriate DOT air injection tube, 3/8” (9.5 mm)

❑ Appropriate LOW pressure drain and HIGH pressure tubing / hose, rec-

ommended - 3/8” (10 mm), up 6,000 PSI (414 BAR)

Unpacking

The CAFSAttack system is shipped partially assembled on two skids. One

skid contains the CAFSAttack air bottle cylinder module assembly. The

second skid contains the FoamLogix Pump Unit along with all supplied

loose items.

Use care when removing the CAFSAttack from its packaging (skid) to prevent injury and/or damage to the system, especially the external system

connections.

IMPORTANT!

EXERCISE CARE DURING UNPACKING AND INSTALLATION TO ENSURE

THAT THE IDENTIFICATION TAGS ARE NOT REMOVED BEFORE THE CONNECTIONS ARE MADE.

DO NOT REMOVE OR ALTER ANY HYDRAULIC OR PNEUMATIC CONNECTIONS WITHOUT WRITTEN APPROVAL FROM CLASS1. ALSO REVIEW SECTION 1 “SAFETY PRECAUTIONS” BEGINNING ON PAGE 7.

Lifting The System

WARNING!

THE CAFSATTACK AIR BOTTLE (H-CYLINDER TYPE) ASSEMBLY IS HEAVY

AND BULKY, WEIGHING OVER 500 LBS. (227 KGS.). SEE BILL OF LADING

FOR ACTUAL WEIGHT. USE PROPER LIFTING SUPPORT DEVICES (OVERHEAD CRANE, STRAPS/CHAINS, ETC.) CAPABLE OF HANDLING THE LOAD

WHEN MOVING OR INSTALLING THE SYSTEM. ATTACH LIFTING APPARATUS TO THE CYLINDER FRAME ONLY. DO NOT ATTACH STRAPS AROUND

THE CYLINDERS, ESPECIALLY THE SHUT-OFF VALVE AREA. ALSO SEE

FIGURE 4-2: “DOT AIR BOTTLE CYLINDER ASSEMBLY LAYOUT DIMENSIONS” ON PAGE 26.

24

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 25

Installer Installation ❑

4 Installation - Retrofit Full Size Pumper

4.1 GENERAL

Since most truck configurations are not the same, this section serves only

as a general guide for installation.

When installing the CAFSAttack system use the best accepted practices for

mounting. Review previous Section 3 “Receiving and inspection,” beginning

on page 23. Also see Figure 4-1: “CAFSAttack System Overview.”

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Figure 4-1: CAFSAttack System Overview

25

Page 26

❑ Installer Installation

4.2 DOT AIR BOTTLE CYLINDER ASSEMBLY

DANGER !

ALWAYS TREAT COMPRESSED AIR CYLINDERS WITH RESPECT. THEY

CONTAIN VERY HIGH PRESSURES (UP TO 4,500 PSI / 310 BAR). READ THE

MSDS AND FOLLOW PROPER PROCEDURES WHEN HANDLING AND USING

THESE CYLINDERS. ALWAYS FOLLOW THE RECOMMENDED SAFETY

PROCEDURES.

26

Figure 4-2: DOT Air Bottle Cylinder Assembly Layout Dimensions

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 27

Installer Installation ❑

IMPORTANT!

(SEE FIGURE 4-2: “DOT AIR BOTTLE CYLINDER ASSEMBLY LAYOUT DIMENSIONS,” ON PAGE 26.)

WHEN DETERMINING THE LOCATION FOR THE AIR BOTTLE CYLINDER

ASSEMBLY (WITH THE HIGH PRESSURE VALVE ASSEMBLY), IT IS RECOMMENDED TO INSTALL THE SYSTEM “ABOVE” THE PUMP WITH DOWNWARD

SLOPPING LINES TO PROMOTE POSITIVE DRAINAGE.

KEEP IN MIND PIPING RUNS, CABLE ROUTING, VISIBILITY, REQUIRED

OPERATOR ACCESS TO VALVE SHUT-OFFS AND OTHER INTERFERENCES

THAT COULD HINDER OR INTERFERE WITH PROPER SYSTEM

PERFORMANCE.

ALSO ENSURE THE ASSEMBLY IS INSTALLED IN AN AREA AFFORDING PROTECTION FROM ROAD DEBRIS AND EXCESSIVE HEAT BUILDUP AND WITH

THE LEAST EXPOSURE TO ACCIDENTAL IMPACT.

Drill the corresponding mounting holes and use minimum 5/8”, Grade 8

bolts with flat washers and lock nuts to bolt-down the air cylinder bracketry.

(See Figure 4-2: “DOT Air Bottle Cylinder Assembly Layout Dimensions,” on

page 26.)

An installation diagram is also located at the back of this manual to assist

with overall dimensions and clearances required for the various mounting

configurations. See Contents for a listing of the drawings.

For plumbing requirements, proceed to heading 4.7 “Plumbing” on page 31.

For electrical requirements, proceed to heading 4.8 “Electrical” on page 38.

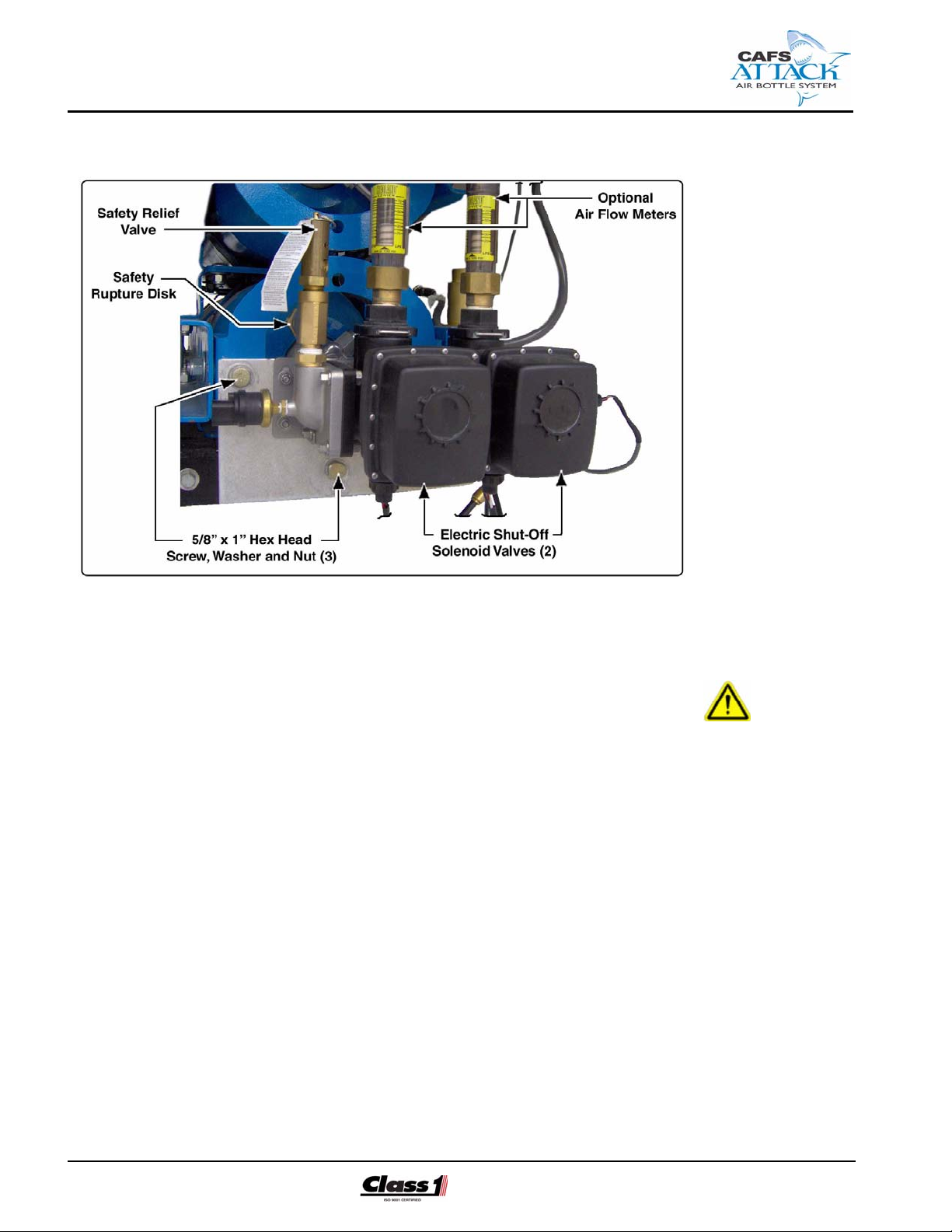

4.3 PRESSURE BALANCING VALVE ASSEMBLY

The high pressure balancing regulator valve assembly is pre-mounted to

the front of the air cylinder tank assembly. The module is mounted using

three 5/8”, Grade 8 bolts with flat washers and lock nuts. (See Figure 4-3:

“Pressure Balancing (Regulator) Valve Assembly Layout,” on page 28.)

Additionally, there must be room for the WARNING ! placards as provided.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

IMPORTANT !

SHOULD IT BE REQUIRED TO RELOCATE THIS ASSEMBLY, IT IS RECOMMENDED TO INSTALL THE PRESSURE BALANCING VALVE ASSEMBLY

“ABOVE” THE PUMP WITH DOWNWARD SLOPING LINES TO INSURE POSITIVE DRAINAGE.

27

Page 28

❑ Installer Installation

Figure 4-3: Pressure Balancing (Regulator) Valve Assembly Layout

WARNING !

EXERCISE CARE NOT TO DAMAGE OR TWIST INTERCONNECTING HIGH

PRESSURE PNEUMATIC PIPING OR ACCIDENTALLY LOOSEN FITTING CONNECTIONS DURING ASSEMBLY. REMEMBER, THE SYSTEM MUST BE

HYDROSTATIC TESTED BEFORE USE AND SHIPPING TO THE CUSTOMER.

4.4 FOAM PUMP INSTALLATION

Detailed foam pump installation instructions are found in the FoamLogix

Electronic Foam Proportioner Installation and Operation Manual, packaged

with the FoamLogix assembly. Refer to the specific model FoamLogix system included with your CAFSAttack system.

❑ FoamLogix Model 2.1A Installation and Operation Manual,

Hale p/n: 029-0020-74-0

❑ FoamLogix Model 3.3 and 5.0 Installation and Operation Manual,

Hale p/n: 029-0020-68-0

28

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 29

Installer Installation ❑

Note: For CAFSAttack systems, the main cable harness included with the Foam-

Logix system differs from what is shown in the FoamLogix manual. For an overview of the replacement cable used with CAFSAttack, see Section 7, “Drawing /

Manual Package” on page 67.

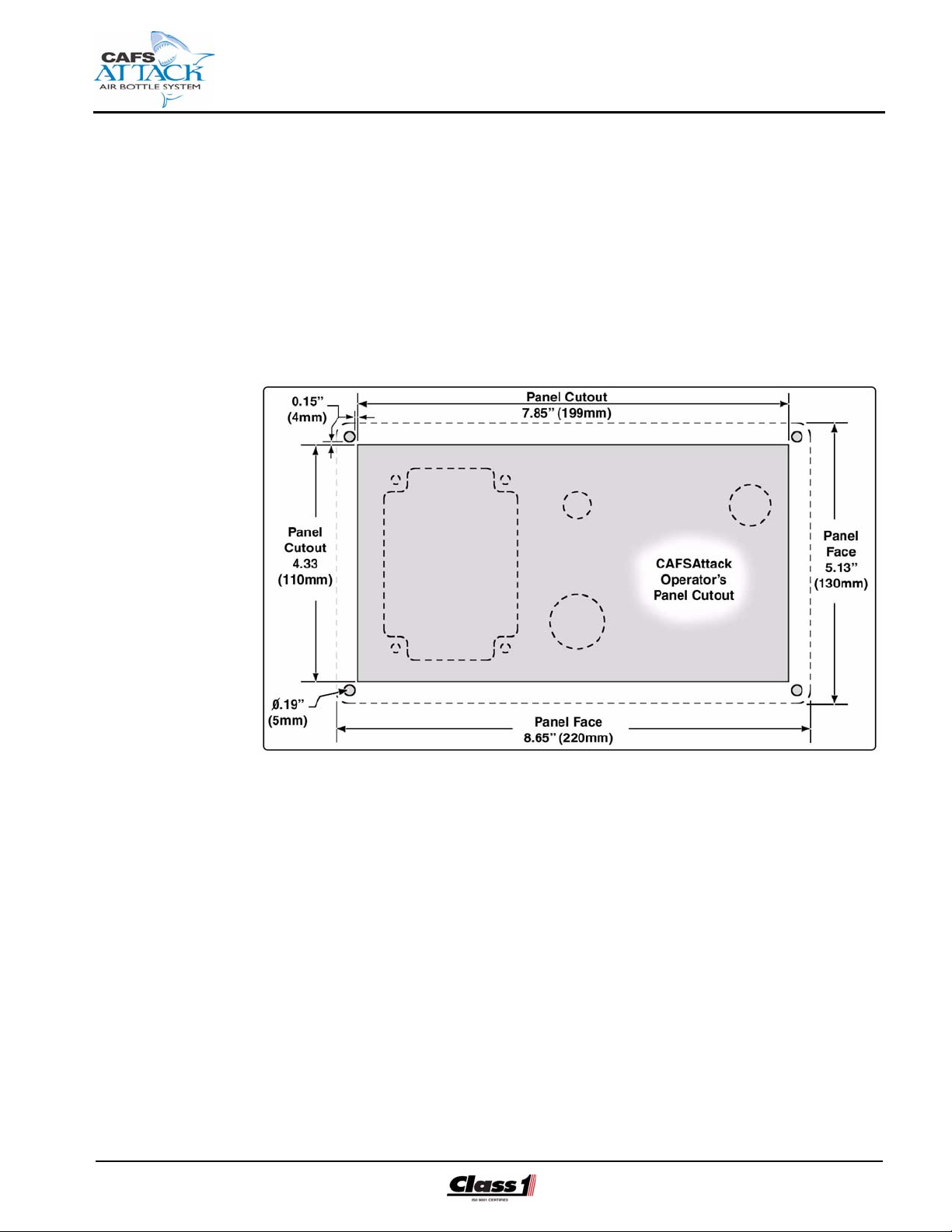

4.5 CAFSATTACK OPERATOR PANEL LAYOUT

(See Figure 4-4: “Operator’s Panel Layout Dimensions.”)

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Figure 4-4: Operator’s Panel Layout Dimensions

The following components are pre-mounted on the CAFSAttack operator’s

panel assembly:

❑ Inteli-Tank high pressure air level indicator - four (4) RED indicator lights

❑ HIGH pressure WARNING ! indicator light (YELLOW)

❑ On/Off air enable switch

❑ HIGH pressure shut-off valve and handle

❑ Quick-connect HIGH pressure air cylinder refill connection

Also see Figure 2-3: “CAFSAttack Operator Control Panel” on page 21.

1. Determine the location on the apparatus operator’s control panel for the

CAFSAttack operator’s panel assembly, with placard. This assembly

must be located at the main pump operator’s position in close proximity

to the FoamLogix system controls.

29

Page 30

❑ Installer Installation

2. Consideration must be given for routing the HIGH pressure tubing /

hoses and electrical harnesses. Make certain there is sufficient room

behind the assembly. If necessary, order a longer or shorter harness to

suit the location demands.

3. Modify the apparatus operator’s control panel to accept the CAFSAttack

operator’s panel and placard. (See Figure 4-4: “Operator’s Panel Layout

Dimensions.”) Use #10-24 screws and hardware to secure the panel the

apparatus control panel.

4. For plumbing, proceed to heading 4.7 “Plumbing” on page 31. For electrical, proceed to heading 4.8 “Electrical” on page 38.

4.6 SVS DISCHARGE MANIFOLD

30

Figure 4-5: Typical CAFSAttack SVS Discharge Manifold Assembly

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 31

Installer Installation ❑

The following components are pre-mounted on the SVS discharge manifold

assembly. (See Figure 4-5: “Typical CAFSAttack SVS Discharge Manifold

Assembly,” on page 30.)

❑ Electrically-operated Hale SVS valves, with valve position indicator.

See separate manual for description, installation and operation of the

SVS valves - Torrent SVS Valve Installation Operation and Maintenance

Manual, Hale p/n: 029-0020-90-0.

❑ Mixing chambers, includes one 2.0” (51 mm) mixer insert.

❑ Paddle wheel flow sensors (2).

1. The SVS Hale pre-manufactured, flange-mounted stainless steel discharge manifold is assembled and fully tested before leaving the factory.

When properly mounted, the flow sensor is on the side of the manifold

with one of the drain ports located at the bottom.

2. The flow sensor should point upwards slightly to allow drainage of water

and sediment. (See Figure 4-5: “Typical CAFSAttack SVS Discharge

Manifold Assembly,” on page 30.)

3. Mount the SVS discharge manifold assembly to the pump manifold discharge port using the gasket and hardware provided.

4. Apply a small amount of grease to the gasket before final installation,

then firmly tighten the four 7/16”-14 mounting bolts and torque to 33

ft.lbs. (45 N-m).

Note: The CAFS discharge connection from the SVS discharge manifold assembly is 2” (51 mm) Victaulic.

4.7 PLUMBING

IMPORTANT !

WHEN PLANING INTERCONNECTING PLUMBING LINES MAKE SURE THEY

ARE ROUTED BY THEIR SHORTEST MOST DIRECT ROUTE, STABILIZED

AGAINST EXCESSIVE VIBRATION AND ROUTED TO AVOID INTERFERENCE

WITH THE APPARATUS OPERATORS.

CONNECTING ENDS OF HYDRAULIC TUBING, IF USED, MUST BE FLARED.

USE THREAD SEALING COMPOUND, FOR EXAMPLE, LOCTITE PST OR

EQUIVALENT, ON ALL PLUMBING CONNECTIONS.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

A system block diagram is provided at the end of this manual.

31

Page 32

❑ Installer Installation

CAFSAttack Operator’s Control Panel

Figure 4-6: Typical HIGH Air Pressure Connections

WARNING !

THE CYLINDER PRESSURE LINES OPERATE AT PRESSURES UP TO 4,500

PSI (310 BAR). ALL FITTINGS, TUBING, ETC. SHOULD BE THE FLARED

TYPE AND MUST BE RATED FOR THE MAXIMUM SYSTEM OPERATING

PRESSURE.

IF HOSE IS REQUIRED, USE 3/8” (10MM) MINIMUM TO 1/2” (13MM), WIRE

REINFORCED HOSE, SUCH AS AEROQUIP FC350-16 FOR MAXIMUM AIR

FLOW.

1. A HIGH pressure air hose line (one each) must be plumbed from each DOT

air cylinder shut-off valve connection to the CAFSAttack operator panel shutoff valve inlet port. (See Figure 4-6: “Typical HIGH Air Pressure Connections.”)

32

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 33

Installer Installation ❑

It is preferred to run 3/8” (10 mm) high pressure tubing with flared ends for

connection to the appropriate fittings. Also see WARNING ! on page 32.

2. Ensure the hose or tubing is adequately secured against stresses, vibrations

and other conditions incident to being mounted on a fire apparatus and being

used in mobile service.

3. All materials used in the air system must be corrosion resistant or treated to

resist corrosion unless the finished product is in continual contact with a

noncorrosive lubricant.

4. Flexible hose must be installed to prevent cuts, abrasions, exposure to damage,

excessive temperatures, damage from loose equipment and excessive bending.

5. The installer/builder must provide the necessary plumbing hardware, i.e.,

fittings, tubing, etc. and make certain they conform to the maximum system

operating pressure of 4,500 psi (310 Bar).

6. Use a suitable sealing compound (for example, Loctite PST or equivalent) on

all fitting threads prior to installation.

7. Plumb a high pressure hose or hard tubing line from the outlet port of the

operator panel shut-off valve to the 3/4” (19 mm) fitting, reduced to 1/4” (6 mm)

tube fitting, at the IN port of the 4,500 PSI high pressure balancing regulator

valve. See WARNING ! on page 32. Also see Figure 4-7: “4,500 PSI HIGH

Pressure Balancing Regulator and Dome Connections” on page 34.

WARNING !

DO NOT TIGHTEN FITTINGS, GAGES, OR COMPONENTS WHILE IN A PRESSURIZED SYSTEM.

NEVER TURN THE REGULATOR OR VALVE BODY. INSTEAD HOLD THE

REGULATOR OR VALVE BODY AND TURN THE FITTING NUT.

IF A REGULATOR OR VALVE LEAKS OR MALFUNCTIONS, REMOVE IT FROM

SERVICE IMMEDIATELY.

8. An additional port must also be added for the tank level display air supply

pressure transducer. (See Figure 4-6: “Typical HIGH Air Pressure Connections,” on page 32.)

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

33

Page 34

❑ Installer Installation

Figure 4-7: 4,500 PSI HIGH Pressure Balancing Regulator and Dome Connections

9. Plumb a 3/8”

(9.5 mm) tubing

line between the

bottom or dome

port on the balancing regulator valve

to the pump discharge for waterto-air operating

pressure balance.

(See Figure 4-8:

“Pump-to-Balancer Valve Dome

Connection.”)

Figure 4-8: Pump-to-Balancer Valve Dome Connection

34

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 35

Installer Installation ❑

Intake Air Pressure Gauge Layout Option

An “optional” high pressure gauge is available, Class1 p/n: ??, to provide

accurate intake air pressure monitoring (up to 7,500 PSI / 517 BAR) during

system operation and cylinder tank refill. (See Figure 4-9: “Typical Intake

Air Pressure Gauge Layout.”)

Figure 4-9: Typical Intake Air Pressure Gauge Layout

The gauge should be mounted in the area of the CAFSAttack operator’s

panel (tank refill connector) and plumbed before the air supply shut-off valve

intake. Provisions must also be made for the pressure transducer.

Also see WARNING ! note beginning on page 32. Use a suitable sealing

compound (for example, Loctite PST) on the fitting threads.

Low Pressure CAFS Connect (2)

A LOW or CAFS air pressure hose line (one each) and injection check

valves (one each) must be plumbed from each electrically-operated shut-off

valve connection to the CAFSAttack discharge manifold air intake port.

(See Figure 4-10: “Typical LOW Pressure CAFS Air Connections,” on page

36.)

1. The installer/builder must provide the necessary plumbing hose and hardware,

i.e., 3/4” (19 mm) fittings, tubing, etc. and make certain they conform to the

maximum CAFS system operating pressure of 150 PSI (10 BAR).

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

35

Page 36

❑ Installer Installation

Figure 4-10: Typical LOW Pressure CAFS Air Connections

WARNING !

THE LOW PRESSURE CAFS LINES OPERATE AT PRESSURES OF APPROXIMATELY 150 PSI (10 BAR). ALL FITTINGS, TUBING, ETC. USED MUST BE

RATED FOR THE MAXIMUM CAFS SYSTEM DISCHARGE OPERATING

PRESSURE.

LOW PRESSURE LINES MUST ALSO BE ADEQUATE FOR OPERATING

TEMPERATURES FROM -30° F TO +140° F (-34° C TO +60° C).

2. Provisions must be made to include a check valve in each line to prevent water

/ foam solution from back-flowing and contaminating the air lines.

For best performance, the check valves (2) must be mounted right after the

main HIGH pressure shut-off valves. (See Figure 4-10: “Typical LOW Pressure

CAFS Air Connections.”)

36

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 37

Installer Installation ❑

3. A method for discharge draining / flushing (possible tee fitting) must also be

provided. (See heading “ Air Discharge Moisture Drain” on page 37.)

4. Use a suitable sealing compound (for example, Loctite PST) on all fitting

threads.

Air Discharge Moisture Drain

(See Figure 4-11: “Typical Discharge Drain.”)

The installer/

builder must supply individual

moisture drain

lines and valving

(3/4” / 9.5 mm),

along with all necessary DOT

approved tubing

(3/8” / 10 mm)

from the low pressure air inject

hose lines to prevent freezing in

cold weather.

When designing

the drain system

care must be

taken to prevent

Figure 4-11: Typical Discharge Drain

contamination of the air and water system with foam and vise versa. Use

appropriate check valves in the drain lines. Also see Figure 4-10: “Typical

LOW Pressure CAFS Air Connections” on page 36.

All Hale supplied tubing conforms to the color scheme

listed in Table 4-12: “Tubing

Size vs. Color.”

Use a suitable sealing com-

Line Size Color Use

1/4” (6.4mm) Black Air

1/4” (6.4mm) Green Air

1/4” (6.4mm) Red Air

pound (for example, Loctite

PST) on all fitting threads.

3/8” (9.5mm) Blue TPM

3/8” (9.5mm) Orange Manifold Drain

3/8” (9.5mm) Yellow Main Pump Drain

Table 4-12: Tubing Size vs. Color

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

37

Page 38

❑ Installer Installation

CAFS Air LOW Pressure Gauge Layout Option

An “optional” numeric-display, low or CAFS air pressure gauge is available,

Class1 p/n: 91220001, to show the air pressure being delivered to the foam

discharge manifolds. (See Figure 4-13: “CAFS Air LOW Pressure Layout

Option,” on page 38.)

The gauge should be mounted in the area of the CAFSAttack operator’s

panel and plumbed in the system after the pressure balancing regulator

valve. Use 1/4” (6 mm) DOT approved tubing and 1/4” brass fittings.

Figure 4-13: CAFS Air LOW Pressure Layout Option

Use a suitable sealing compound (for example, Loctite PST) on all fitting

threads.

4.8 ELECTRICAL

A system electrical diagram is provided at the end of this manual. Refer to

this diagram for proper installation of the electrical components.

The Class1 CAFSAttack system is designed to be installed with a minimum

of electrical connections. A main harness cable assembly is provided with

each system to enable the flow sensor, electric valve motors and transducer

connections.

The system installer must supply primary power and ground wiring. Also

see Figure 4-16: “Primary CAFS Wire Harness” on page 41.

38

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 39

Installer Installation ❑

CAUTION !

❑ Review the “Safety” section of this manual, beginning on page 7, in

its entirety before proceeding with electrical connections.

❑ To prevent system damage or electrical shock the main power sup-

ply wire must be the last connection made.

❑ The cables provided with each CAFSAttack system contain

shielded assemblies.

NEVER attempt to shorten or lengthen these shielded cables.

If necessary order longer or shorter cables from Class1 to suit your

particular installation.

❑ The cables are indexed so they connect to the correct receptacle

one way only. The cables shipped with each CAFSAttack system

are tested at the factory with the specific unit. When making cable

connections DO NOT force mismatched connections as damage

can result, causing improper system operation.

❑ The system can only perform when the electrical connections are

sound.

Make sure each electrical connection is correct.

❑ Class1 CAFSAttack systems are designed for use on direct current,

negative (–) ground apparatus electrical systems only.

❑ Do not mount a radio transmitter or transmitter cables in direct or

close contact with the CAFSAttack unit.

❑ Before connecting cables, inspect the O-ring seal in the female con-

nector. If the seal washer is missing or damaged, water can enter

causing corrosion, resulting in possible system failure.

❑ Be careful when inserting connector halves to avoid bent pins or

pushed-back pins that do not make contact.

❑ The ground strap must be attached to the chassis frame. Ground-

ing to the body IS NOT acceptable.

❑ Always disconnect the power cable, ground straps, electrical wires

and cables from the control unit or other Hale FoamLogix equipment before electric arc welding at any point on the apparatus.

Failure to do so could result in a power surge through the unit that

could cause irreparable damage.

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

❑ There are no user serviceable parts inside CAFSAttack system

electrical/electronic components. Opening of these components

(motor distribution box, smart-switch controller or control unit)

voids the warranty.

39

Page 40

❑ Installer Installation

Smart-Switch Controller - SPC (S1 and S2)

For the suggested panel installation and cutout dimensions see Figure 414: “Smart-Switch Controller Panel Cutout” on page 40.

Determine a location on the apparatus pump operator panel for the smartswitch controllers (2). Consideration must be given for routing the interconnecting cable from the controller to the foam discharge assembly and the

high pressure transducer assembly.

40

Figure 4-14: Smart-Switch Controller Panel Cutout

Once the SPC controllers are mounted on the

pump operator panel, attach the 10 pin AMP

connector on the cable assembly to the back of

the controller. (See Figure 4-15: “SPC Connector, Back View.”) Also see Figure 4-16: “Primary

CAFS Wire Harness” on page 41.

Notes: Ensure that the panel where the control

units are mounted has an adequate ground. For

stainless steel and vinyl coated panels a ground

strap, 1/2” (13 mm) wide, must be attached from

one of the four screws securing the controllers in

place to the frame of the apparatus to ensure adequate grounding.

Figure 4-15: SPC Connec-

tor, Back View

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 41

Installer Installation ❑

Add a service loop to avoid strain on the wires or connectors during body

and frame flex. Also see Figure 4-17: “Extra Cable Storage” on page 43.

CAFSAttack Main Wire Harness

The system installer must provide an extension main power and ground

wire cable for the Class1 CAFSAttack system. (See heading “ Primary

Power and Ground” on page 42.) Also see Figure 4-16: “Primary CAFS

Wire Harness.”

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Figure 4-16: Primary CAFS Wire Harness

Before connecting the cable harness, Class1 p/n: 112757, inspect the Oring seals of the female connectors. If a seal washer is missing or damaged, water can enter the connector causing pin and terminal corrosion,

resulting in possible system failure.

IMPORTANT !

THE POWER MUST BE FUSED FOR 12 VDC (OR OPTIONAL 24 VDC), MINIMUM 20 AMP. CIRCUIT TO MEET NFPA SPECIFICATIONS. USE MINIMUM 16

AWG TYPE SXL OR GXL (SAE J1128) WIRE.

DO NOT CONNECT POWER SUPPLY HARNESS TO A “LOAD SHEDDING

SYSTEM.

41

Page 42

❑ Installer Installation

WHEN PLANING CABLE RUNS MAKE SURE THE WIRES ARE ROUTED BY

THEIR SHORTEST MOST DIRECT ROUTE, STABILIZED AGAINST EXCESSIVE

VIBRATION AND ROUTED TO AVOID INTERFERENCE WITH THE APPARATUS

OPERATORS.

For complete cable design of the standard harness (Class1 p/n: 112757)

and for the Triple Discharge Option harness (Class1 p/n: 114810), also see

Section 8, heading “Drawing / Manual Package” on page 67.

Primary Power and Ground

PREVENT CORROSION OF POWER AND GROUND CONNECTIONS BY SEALING THESE CONNECTIONS WITH SILICONE SEALANT.

IMPORTANT - continued !

CAUTION !

DO NOT CONNECT THE MAIN POWER LEAD TO SMALL LEADS THAT ARE

SUPPLYING SOME OTHER DEVICE, SUCH AS A LIGHT BAR OR SIREN. THE

CAFSATTACK SYSTEM REQUIRES ?? AMP MINIMUM CURRENT.

USE MINIMUM 14 AWG TYPE SXL/GXL (SAE J1128) WIRE.

Primary electrical power must be supplied directly from the battery, the battery master disconnect switch or solenoids to the CAFSAttack harness,

connector #13.

❑ RED................... Power

❑ BLACK .............. Ground

The primary power connection must be made so that power is supplied to

the CAFSAttack system when the main apparatus electrical system is energized. This ensures immediate operation when the operator places the

apparatus in PUMP mode, and to prevent battery power drain when the

apparatus is not running.

Be sure the CAFSAttack system is grounded to the chassis.

When making the ground connections make sure lugs are soldered to the

strap ends for trouble free connections. Seal all connection against

corrosion.

42

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

Page 43

Installer Installation ❑

RFI / EMI

A 100% electrically shielded main cable harness is provided with the Class1

CAFSAttack system to eliminate the potential problem of RFI / EMI.

Proper installation of system components and cables, along with

proper grounding, limits radio interference caused by the CAFSAttack

system. Additionally, make sure

radio cables and hardware are not

located in the immediate area

where the CAFSAttack system is

mounted.

Making round coils of extra control

and flow sensor cables in the pump

compartment can act as an

antenna. While the control and

flow sensor cables cannot be shortened, various lengths of cable are available to minimize the “extra” cable in

the apparatus. (See Figure 4-17: “Extra Cable Storage.”)

Figure 4-17: Extra Cable Storage

When routing control and flow sensor cables take care to avoid routing them

next to antenna wires, radio power lines and radio components.

When there is extra cable, double the cable back on itself and secure with

plastic wire ties in a flat bundle instead of making a round coil. (See Figure

4-17: “Extra Cable Storage,” on page 43.)

Flow Sensor Connections (FM1 and FM2)

The main cable harness (connectors #1 and #7) connect to the 3-pin connector on the flow sensors. (See Figure 4-16: “Primary CAFS Wire Harness,” on page 41.)

NEVER attempt to shorten or lengthen these shielded cables. If necessary

order longer or shorter cables from Class1 to suit your particular installation

needs. Wire used is minimum 18 AWG type SXL/GXL (SAE J1128) Wire.

Air Supply Valve, Electric Motor (MV2)

Connect the main cable harness (connectors #2 and #8) to the 3-pin connectors on the air supply electric motors. (See Figure 4-16: “Primary CAFS

Wire Harness,” on page 41.)

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

43

Page 44

❑ Installer Installation

NEVER attempt to shorten or lengthen these shielded cables. If necessary

order longer or shorter cables from Class1 to suit your particular installation

needs. Wire used is minimum 18 AWG type SXL/GXL (SAE J1128) Wire.

Discharge Valve, Electric Motor (MV1)

Connect the main cable harness (connectors #3 and #9) to the ?-pin con-

nectors on the discharge air valve electric motors. (See Figure 4-16: “Primary CAFS Wire Harness,” on page 41.)

NEVER attempt to shorten or lengthen these shielded cables. If necessary