Operation and

MANUAL P/N 029

-

0020

-69-

0, REV B,

2002 HALE PRODUCTS, INC.,

Maintenance Manual for

Hale Booster Pumps

AP

CBP

2CBP

ECO NO REV CHANGED FROM BY DATE APVD

02-0301 A RELEASED SAG 10/15/02 MAL

DRAWN BY: SAG ISSUE DATE:

CHECKED BY: PRW 10/15/02

HALE PRODUCTS, INC. • A Unit of IDEX Corporation • 700 Spring Mill Avenue • Conshohocken, PA 19428 • TEL: 610-825-6300 • FAX: 610-825-6440

MANUAL P/N 029-0020-53-0, REV A

Hale Products cannot assume responsibility for product failure resulting from improper maintenance

or operation. Hale Products is responsible only to the limits stated in the product warranty. Product

specifications contained in this material are subject to change without notice.

HALE PRODUCTS, INC

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

COPYRIGHT ©

NOT TO BE REPRODUCED OR USED TO

MAKE OTHER DRAWINGS OR MACHINERY

9615

Booster

Contents

SECTION I: INTRODUCTION ....................................................................I-1

Overview............................................................................................................................................................. I-1

Principals Of Operation......................................................................................................................... I-1

Centrifugal Force .................................................................................................................................. I-1

Pump Stages ........................................................................................................................................ I-2

Two-Stage Booster Pump ..................................................................................................................... I-3

Components of a Booster Pump........................................................................................................................ I-3

Pump Body........................................................................................................................................... I-3

Impeller and Shaft Assembly ................................................................................................................ I-3

Mechanical Seal .................................................................................................................................. I-4

Gearbox ................................................................................................................................................ I-4

Pump Drives ......................................................................................................................................... I-4

Accessories....................................................................................................................................................... I-5

Auxiliary Cooling (Overheat Protection) ................................................................................................ I-5

Priming Systems.................................................................................................................................. I-5

Priming the Pump................................................................................................................................. I-5

Priming Valves ...................................................................................................................................... I-6

Pressure Control.................................................................................................................................. I-6

Thermal Relief Valveb (TRV).................................................................................................................. I-7

Anodes ................................................................................................................................................. I-7

Explanation of Terms ......................................................................................................................................... I-8

SECTION II OPERATING PROCEDURES ................................................2-1

Stationary Pumping Operations ........................................................................................................................ 2-1

Pumping From a Hydrant

(General Operation) ....................................................................................................................... 2-1

Draft limiting factors............................................................................................................................. 2-2

Pumping from Draft .............................................................................................................................. 2-2

Pump and Roll Operation.................................................................................................................................. 2-4

Relief Valve Procedures .................................................................................................................................... 2-4

TPM /P35 Relief Valve Procedures .................................................................................................... 2-4

Process of Cavitation ........................................................................................................................................ 2-5

Warning Signs of Cavitation: Discharge and Gauges.......................................................................... 2-6

Discharge Pressure ............................................................................................................................. 2-6

Vacuum Compound Gauge .................................................................................................................. 2-6

How to Prevent Cavitation .................................................................................................................... 2-6

During Operations:............................................................................................................................... 2-6

Preventive Measures:........................................................................................................................... 2-6

Post Operation procedure ................................................................................................................................. 2-8

SECTION III PREVENTIVE MAINTENANCE ............................................3-1

Overview............................................................................................................................................................ 3-1

Post-Operation Maintenance Procedures ......................................................................................................... 3-1

Weekly Maintenance ........................................................................................................................................ 3-1

Relief Valve Testing .............................................................................................................................. 3-1

Valve Maintenance............................................................................................................................... 3-2

Verify all Gauges are in Working Order. ............................................................................................... 3-2

Inspect Water and Foam Tanks........................................................................................................... 3-2

Monthly Maintenance ....................................................................................................................................... 3-3

Gearbox Lubrication............................................................................................................................. 3-3

Priming System Test (Dry Vacuum Test)

(Refer to NFPA 1901 or NFPA 1911) .............................................................................................. 3-3

Annual Pump Maintenance............................................................................................................................... 3-4

Booster

Replace Gearbox Oil ........................................................................................................................... 3-4

Tank to Pump Flow Rate Test.............................................................................................................. 3-4

Performance Testing Overview ............................................................................................................. 3-5

Worn Clearance Rings and Impeller Hubs ........................................................................................... 3-8

Extreme Conditions Maintenance Guidelines ................................................................................................... 3-8

SECTION IV: TROUBLESHOOTING .......................................................4-1

SECTION V MAINTENANCE AND REPAIR...............................................5-1

Overview............................................................................................................................................................ 5-1

General Repair Guidelines ................................................................................................................................ 5-1

Cleaning and Inspection Guidelines ..................................................................................................... 5-1

Recommended Cleaners...................................................................................................................... 5-3

Pump Components ........................................................................................................................................... 5-3

Pump and Gearbox Assembly ............................................................................................................. 5-3

Remove the Pump from the Apparatus................................................................................................. 5-3

AP Pump Disassembly ....................................................................................................................... 5-5

AP Pump Body.................................................................................................................................... 5-5

Remove AP Pump Body ...................................................................................................................... 5-5

Install the Pump body.......................................................................................................................... 5-5

AP IMPELLER AND MECHANICAL SEAL .......................................................................................... 5-5

Remove AP Impeller............................................................................................................................. 5-5

Remove AP Mechanical Seal.............................................................................................................. 5-6

Reinstall AP Mechanical Seal.............................................................................................................. 5-6

Reinstall the AP Impeller...................................................................................................................... 5-6

REMOVE AP PUMP HEAD................................................................................................................. 5-6

REINSTALL AP PUMP HEAD.............................................................................................................. 5-7

AP Gearbox......................................................................................................................................... 5-8

Disassemble AP Gearbox.................................................................................................................... 5-8

Reassemble and Reinstall AP Gearbox ............................................................................................... 5-8

CBP Pump Repair ...........................................................................................................................................5-11

CBP Pump Body ................................................................................................................................5-11

Remove CBP Pump Body...................................................................................................................5-11

Reinstall CBP Pump Body ................................................................................................................5-11

CBP IMPELLER AND MECHANICAL SEAL....................................................................................... 5-11

Remove CBP Impeller .........................................................................................................................5-11

Reinstall CBP Impeller....................................................................................................................... 5-12

REMOVE CBP MECHANICAL SEAL ................................................................................................ 5-12

Reinstall CBP Mechanical Seal........................................................................................................ 5-12

CBP PUMP HEAD ............................................................................................................................ 5-12

REMOVE CBP PUMP HEAD............................................................................................................ 5-12

Reinstall CBP Pump Head................................................................................................................. 5-13

CBP GEARBOX................................................................................................................................. 5-13

Remove and Disassemble CBP Gearbox........................................................................................... 5-13

Reassemble and Reinstall CBP Gearbox .......................................................................................... 5-14

2CBP Pump Repair ........................................................................................................................................ 5-16

Disassemble the 2CBP Pump from the Gearbox Assembly ............................................................ 5-16

Reassemble Pump to Gearbox.......................................................................................................... 5-16

Disassemble the 2CBP Gearbox ....................................................................................................... 5-18

Reassemble and Reinstall 2CBP Gearbox ........................................................................................ 5-19

Booster

SECTION VI: PARTS LISTS ......................................................................6-1

AP Pump ............................................................................................................................................. 6-2

CBP Pump ........................................................................................................................................... 6-5

2CBP Pump ......................................................................................................................................... 6-8

Hydraulic Adapter ........................................................................................................................................... 6-12

Tachometer Option.......................................................................................................................................... 6-13

Booster Pumps

SECTION I:

INTRODUCTION

OVERVIEW

Hale Products currently has 3 models of booster

pumps in production:

o AP

o CBP

o 2CBP

Unless otherwise indicated, these procedures

will apply to all models of Hale booster pumps:

Any variations in operations and maintenance of

the different models will be addressed within the

context of this manual.

Hale booster pumps are the favorite of fire

fighters throughout the world. Booster pumps

can be used as initial attack pumps or as

auxiliary pumps in conjunction with the

apparatus main pump. Covering a range of

capacities from 20 Gallons Per Minute (GPM)

(76 Liters per Minute, LPM) to 500 GPM (1,893

LPM), Hale booster pumps offer the versatility,

dependability, reliability, and ease of operation

so necessary to effective fire fighting.

Hale Booster Pumps are of a compact size and

lightweight design for easy mounting on the

apparatus chassis. The pump is coupled to the

gearbox and the apparatus builder need only

supply the transmission PTO (power takeoff)

and connecting shaft.

Principles Of Operation

shows an amount of water has been placed at

the center of a disk. The disk is rotated and

the water is thrown outward from the center to

the edge of the disk. The velocity at which the

water travels from the center directly relates to

the diameter of the disk and the speed of

rotation. When water is confined in a closed

container (such as the pump body), the velocity

is converted to pressure; pressure is therefore,

dependant on the speed of rotation.

Figure 1-1: Centrifugal force

from a rotating disk

There are three inter-related factors that

regulate the performance of a centrifugal pump:

o Speed (RPM): If the speed of rotation

increases with the flow held constant, the water

pressure increases.

o Pressure: Pressure is usually measured

in pounds per square inch (PSI) or (BAR). If

pressure changes and speed is constant, the

flow will change inversely. That is, if pressure

increases, flow decreases.

This section reviews the principles of operation

of Hale booster pumps and provides a

description of the pump components.

Centrifugal Force

Hale booster pumps are centrifugal pumps that

operate on the principle that centrifugal force is

created by a rapidly spinning disk. Figure 1-1

Introduction

o Flow: Flow is usually measured in the

number of gallons of water per minute (GPM)

or liters per minute (LPM) that a pump can

deliver when supplied from draft. If the

pressure is held constant, the flow will increase

with an increase in the speed of rotation.

Sec I-1

Booster Pumps

The centrifugal pump is preferred by the fire

protection service due to its ability to fully utilize

any positive inlet pressure, reducing the strain

on the pump.

For example, if the required discharge pressure

is 120 PSI (8 BAR), and the inlet pressure is 45

PSI (3 BAR), the pump must only produce the

difference in pressure of 75 PSI (5 BAR). This

contributes to low engine and pump speeds

which reduces wear on the pump. Another

important benefit is the centrifugal pump has

basically only two moving parts; the impeller

and the shaft.

Pump Stages

The number of impellers on a common shaft

determines the number of pump stages. Hale

single-stage booster pumps use a single

impeller to develop the required volume and

pressure. Two stage pumps have two impellers

on a common shaft.

During operation water enters the suction eye of

the impeller. The rotating impeller vanes

develop discharge pressure and direct the water

to the discharge opening. The cutwater is a

wedge that divides the water between the volute

(pump body) and the pump discharge.

Sec I- 2

Figure 1-3: Single-stage Water Flow

There are three models of Hale booster pumps.

(The anticipated use determines which model is

selected.) The AP and CBP booster pumps are

single stage and provide initial attack pump

performance per NFPA 1901 standards. The

2CBP is a two-stage series operation pump, is

used as a high-pressure booster pump.

The available Booster Pump Models and their

flow capacities are shown in Table 1-1.Figure 1-2: Pump Stages

Model Type Capacity Pressure

100 to 700 GPM (379 to

AP

Single-Stage High

Volume Attack Pump

2650 LPM) NFPA1901 Rated

@250 to 500 GPM (946 to

100 to 350 PSI

(7 to 24 BAR)

1893 LPM)

CBP

2CBP

Single-Stage High

Volume

Attack/Booster Pump

Two-Stage High

Pressure Booster

Pump

50 to 400 GPM (189 to 1514

LPM) NFPA1901 Rated

@250 GPM (946 LPM)

20 to 100 GPM (76 to 379

LPM)

100 to 400 PSI

(7 to 28 BAR)

300 to 1000 PSI

(21 to 69 BAR)

Table 1-1: Booster Pump Models and Capacities

Introduction

Booster Pumps

Two-Stage Booster Pump

The Hale Two-Stage Booster Pump (2CBP)

has two impellers connected in series for highpressure operation. The output of the first

impeller is supplied to the intake of the second

impeller. This second impeller adds additional

pressure and directs the water to the discharge.

Since the two-stage booster pump only

operates in series, the final water pressure is

the inlet pressure plus the pressure added by

both impellers. The volume of water delivered

at the discharge, however, is the same. Figure

1-4 shows the flow of water through a Hale

2CBP booster pump.

Figure 1-5: Parts of the Hale Booster Pump

Figure 1-4: 2-Stage waterflow

(Top half of 2CBP shown only.)

COMPONENTS OF A BOOSTER

PUMP

Booster pumps are made up of:

o Pump Body

o Impeller and Shaft Assembly

o Mechanical Seal

o Gearbox

Figure 1-5 shows these basic parts of a Hale

booster pump. These parts are briefly

described in the following section.

Pump Body

The Hale single-stage booster pump body is a

single-piece casting. Service of the impeller,

clearance rings, and mechanical seal is

accomplished by removing the pump body from

the pump head and gearbox.

The pump body is constructed from fine grain

cast iron. For areas where salt water is

commonly used, a bronze version of the booster

pump is available.

Impeller and Shaft Assembly

The impeller provides velocity to the water. The

impeller is made of high quality bronze and is

mounted on a stainless steel shaft that is

rotated by the gearbox. Water enters the

rotating impeller at the intake (or eye). The

vanes guide water from the inlet to the

discharge. Vanes curve away from the direction

of rotation so water moves toward the outer

edge (see Figure 1-2). The shrouds form the

sides of the impeller and keep the water

Introduction

Sec I-3

Booster Pumps

confined to increase acceleration and pressure.

The discharging tube is widest at the pump

outlet. The increasing discharge path, known

as the volute, collects the fast moving water and

converts the water's velocity into pressure.

Mechanical Seal

The mechanical seal is common to all Hale

booster pumps. Shown in figure 1-6, a

stationary seat is in constant contact with a

rotating seal ring to prevent leakage. The

sealing diaphragm is made of a rubber

elastomer specifically designed for hightemperature operations.

Figure 1-6: Mechanical Seal

engine, and the torque rating of the

transmission PTO.

Pump Drives

There are four common types of booster pump

drives used on fire fighting apparatus:

1. The most common drive is the PTO mounted

on the truck transmission or four-wheel drive

transfer case which allows for pump and roll

operation.

2. A stand-alone drive with separate engine

(auxiliary engine).

3. The truck chassis engine crankshaft (frontengine PTO).

4. Hydraulic Motor

Hale booster pumps are built to produce the

volumes and pressures shown on their

respective performance curves. However, the

volumes and pressures safely obtainable are

dependent on the torque capacity of the

apparatus transmission or transfer case, power

takeoff and the pump drive line. In most cases,

the torque rating of the PTO determines

maximum pump performance.

If a pump is operated without water for

extended periods, or without discharging water,

it may overheat. This may damage the

mechanical seal or the drive mechanism.

Gearbox

The gearbox is typically constructed of fine

grain alloy cast iron. Inside the gearbox (Figure

1-5) a gear set and input drive shaft made of

heat-treated nickel steel, transfers engine power

to the impeller. Hale offers a variety of pump

gear ratios to accommodate a wide range of

end-user and apparatus manufacturer

requirements based on the pump's intended

use, horsepower and speed rating of the

Sec I- 4

The apparatus builder can give various pump

performance spots that will define the torque

limit of the PTO in terms of GPM and PSI.

When pumping continuously, care should be

taken not to overheat the apparatus' PTO,

transmission or transfer case.

HALE Power Takeoff Pumps

Hale booster pumps are available for either

engine rotation or opposite engine rotation PTO

operation. Additionally, the pump can be

configured to discharge in a variety of positions.

Since some PTOs match engine rotation and

some turn opposite of the engine rotation, each

pump model can be built to match the rotation

of the PTO.

Introduction

Booster Pumps

NOTE: Please refer to Hale Bulletin #886 for

further assistance in selecting the correct

booster pump PTO.

ACCESSORIES

In addition to the basic parts of Hale booster

pumps described above, the following items are

available to enhance operation:

o Cooling Systems

o Priming Systems

o Pressure Control Devices

o Anodes

Auxiliary Cooling (Overheat Protection)

A cooler is available to protect the gearbox, the

apparatus engine, and the pump.

The gearbox cooler (see Figure 1-7), circulates

pump water to transfer heat from the gearbox oil

to the pump discharge. It is standard equipment

on pumps with a capacity of 750 GPM or greater

and optional equipment on all other pumps.

Priming Systems

Priming the Pump

Priming pumps are used to evacuate air in the

suction hose and the pump. The vacuum

created allows atmospheric pressure to push

water from the static source through the suction

hose and into the pump. Hale booster pumps

use Rotary Vane Positive Displacement type

pumps for priming.

A priming pump draws air out of the pump body

and discharge piping allowing water to enter.

Shown in figure 1-8, the priming pump has a

rotor mounted off-center (eccentric) to the

pump body housing. The vanes in the rotor

slide in grooves and are held against the body

housing by centrifugal force. As a vane turns

toward the discharge, it recedes into the rotor

compressing the air. As the rotor continues

past the discharge, the vane advances outward

from the groove and against the body housing.

During this cycle, the space between the rotor

and housing case fills with air. The vanes,

acting as wipers, force air out of the discharge,

creating a vacuum in

the main pump

allowing atmospheric

pressure to push

water into the hose

and suction side of

the pump.

ESP Priming

Pump

Figue 1-7. This AP pump shows

the optional gearbox cooler (This

option available on CBP, and

2CBP too.)

Introduction

Figure 1-8: Rotary Vane Priming Pump

Sec I-5

The Hale ESP-series

priming pump is an

environmentally

friendly primer that

does not require a

separate lubricant

reservoir. The vanes

and pump body are

self lubricating for

maintenance free operation.

A Hale priming pump has a single control to

open the priming valve between the booster

pump and the priming pump, and start the

priming motor.

Priming Valves

Booster Pumps

Figure 1 -10: PVG Priming Valve

2. The Hale PVG Priming Valve (Figure 1 -

10) is mounted on the pump operator’s

panel. The PVG is a combination valve and

switch. When the handle on the PVG is

pulled out, the valve opens and the switch

energizes the primer motor. Pushing the

handle de-energizes the motor and closes

the valve.

Hale priming valves open when the priming

pump is operated to allow the air to escape from

the pump. There are two priming valves

available:

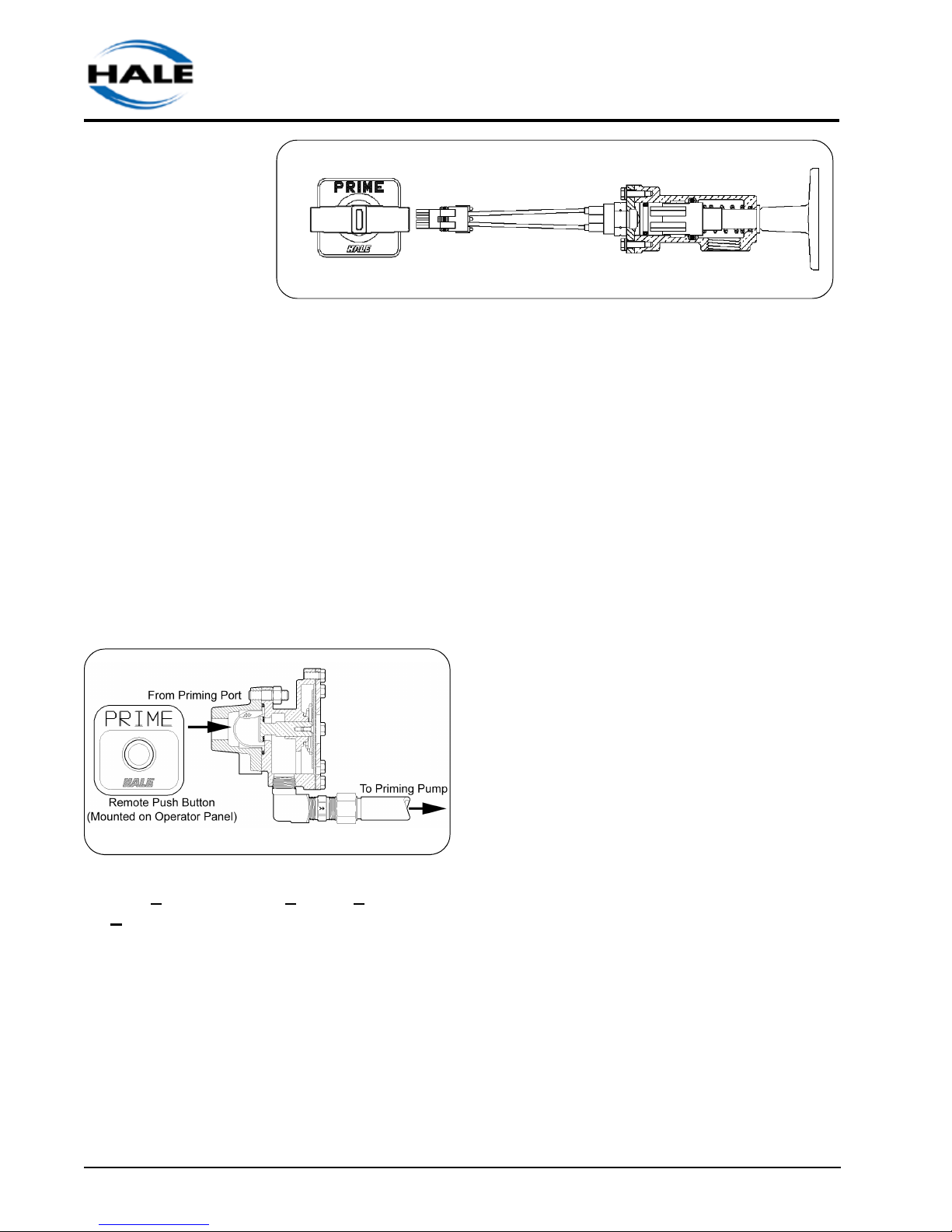

Figure 1 -9 : SPVR Priming Valve

1. Hale Semi-Automatic Priming Valve for

Remote Mounting (SPVR) A hose is

connected from the SPVR to the priming tap

on the booster pump body. When the SPVR

is installed, a single push-button on the

operator’s panel starts the priming pump

motor. When a vacuum is created, the

SPVR opens. Releasing the push-button

stops the priming pump and the SPVR

closes. Figure 1-9

Pressure Control

The P Series relief valve system is a bronze,

variable-pressure setting relief valve that

prevents undue pressure per the requirements

of NFPA Standard 1901. An indicator light on

the operator control panel signals when the

valve is open.

The P Relief Valve System

The P relief valve system consists of a panel

mounted control valve (PM) and, depending on

the pressure rating of the pump, a P30, or P35

relief valve mounted in the discharge piping and

plumbed back to the pump suction. Valve

connections are either flanged or Victaulic tm.

Both are shown in figure 1-12.

How the Relief System Works:

A bleeder line mounted in the pump discharge

pressure tap provides pressure to the

diaphragm in the PM control valve. The

handwheel on the PM control either increases

or decreases the spring tension on the

diaphragm. The seat of the P-series relief valve

is kept closed by pump discharge pressure.

Sec I- 6

As pump pressure increases, more pressure is

Introduction

Booster Pumps

applied to the diaphragm in the PM Control

valve. As the pressure on the diaphragm

increases beyond the set point, the stem will

move off its seat, allowing pump pressure to

push on the piston in the relief valve. The

pressure on the piston will cause the relief valve

seat to lift

allowing

excess

pressure to

dump back to

the pump

suction. After

the pressure

equalizes, the

piston returns

to the closed

position.

Figure 1-11: TRV-L

The amber

indicator light on the PM control illuminates

when the relief valve is open.

Thermal Relief Valveb (TRV)

The Thermal Relief Valve (see Figure 1-11)

protects the pump from overheating. The

optional TRV unit can be attached to the

discharge piping either by flange mounting or 11/4" NPT threaded connection (38 mm for the

TRVM). The valve monitors the temperature of

the water in the pump. When the temperature

exceeds 120o F (48.9o C), the valve

automatically opens and depending on the

installation, discharges a small amount of water

either to the ground or into the water tank

allowing cooler water to enter. After the

temperature returns to a safe level, the valve

closes. The TRV will flow up to 1-2 GPM (3-7

LPM).

TRV-L Kit

The TRV-L kit includes a chrome panel placard

with a warning lamp, lamp test button, and a

preassembled wiring harness. The light

illuminates whenever the TRV is open and

discharging water. An optional buzzer provides

audible warning. The buzzer mounts on the

operator panel.

Anodes

The Hale Anode System

helps prevent damage

caused by galvanic corrosion

in the pump. Galvanic action

pits the pump and pump

shaft material. The popularity

of non-corrosive water tanks

and piping has increased this

type of corrosion in today’s

fire pumps. The Hale Anode

System is a sacrificial metal, which helps

prevent corrosion. The anode will fit on any

Hale truck mounted pump, regardless of age or

model. It is designed to be easily installed

requiring four bolts and a gasket. Total time to

install is just fifteen minutes, yet it will provide

years of protection for the pump. The Anode kit

is designed for installation in the standard Hale

115 series flange opening. On fabricated

manifolds and similar applications, the installer

is to provide 1-1/4 NPT openings and install

anodes directly. It is recommended that one

anode be installed on the suction side and one

on the discharge side.

Figure 1-13:

Hale Anode

Figure 1-12:

Introduction

Sec I-7

Booster Pumps

EXPLANATION OF TERMS

Atmospheric Pressure

Static air pressure. Air pressure is 14 pounds

per square inch at sea level. Pressure increases

below sea level and decreases above sea level.

The weather also effects air pressure. Air in a

high pressure area compresses and warms as it

descends. The warming inhibits the formation of

clouds, meaning the sky is normally sunny in

high-pressure areas. But haze and fog still

might form. Just the opposite occurs within an

area of low atmospheric pressure. Atmospheric

pressure effects a pumps ability to pump from

draft. Higher pressures will increase a pumps

performance, while lower pressures can cause

a noticeable decrease in lift.

Cavitation

The sudden formation and collapse of lowpressure bubbles in liquids by means of

mechanical forces, such as those resulting from

rotation of a pump impeller.

Priming Pump

An auxiliary positive displacement pump which

pumps air out of the booster pump creating a

vacuum in order to prime the pump. The

priming pump is a rotary vane type, electric

motor driven. Once the main pump is primed

and pumping, the priming pump is shut off.

Relief Valve

An automatic valve which, when activated by

the relief valve control will hold the pump

pressure to no more than 30 PSI when the

pump discharge is gated or closed. The valve

maintains a set pressure by diverting the pump

discharge flow into the pump suction.

Relief Valve Control (PM)

A hand adjustment valve. When set to the

desired pressure, the relief valve will maintain

the desired pump discharge pressure and limit

a pressure increase to no more than 30 PSI (2

BAR).

Dead Heading

Operating a pump without any discharge. Lack

of flow causes temperatures to rise inside the

pump.

Impeller

The working part of centrifugal pumps which

imparts energy (motion) to the water.

Essentially, an impeller consists of two discs

separated by curved vanes. The vanes force

the water to rotate between the discs and is

thrown outward at high velocity. The water from

the impeller discharges into a diverging

passage known as a volute, converting the high

velocity energy of the water into pressure.

Volute

The increasing discharge path of the pump, its

function is to collect the water from the impeller

and depending on its design can either increase

pressure and decrease velocity or increase

velocity and decrease pressure.

Sec I- 8

Introduction

Booster Pumps

SECTION II OPERATING

PROCEDURES

This section supplies information and

procedures for the operation of Hale booster

pumps. Included in this section are procedures

for pumping from an on-board tank, a hydrant,

from draft, and post-operation procedures.

Unless otherwise indicated, these instructions

apply to all Hale booster pumps.

THE PROCEDURES IN THIS SECTION ARE

GENERAL OPERATING PROCEDURES. THEY

DO NOT REPLACE LOCAL PROCEDURES OR

POLICIES, NOR DO THEY REPLACE THE

RECOMMENDATIONS AND PROCEDURES

PROVIDED IN THE TRUCK MANUAL.

STATIONARY PUMPING OPERATIONS

Pumping From a Hydrant

(General Operation)

1. Position the truck for the best hydrant hookup

and discharge hose layout.

REFER TO DEPARTMENT PROCEDURES

FOR SETTING WHEEL CHOCKS AND LAYING

OUT SUCTION AND DISCHARGE HOSES.

ALL VALVES, DRAIN COCKS, AND CAPS

SHOULD BE CLOSED.

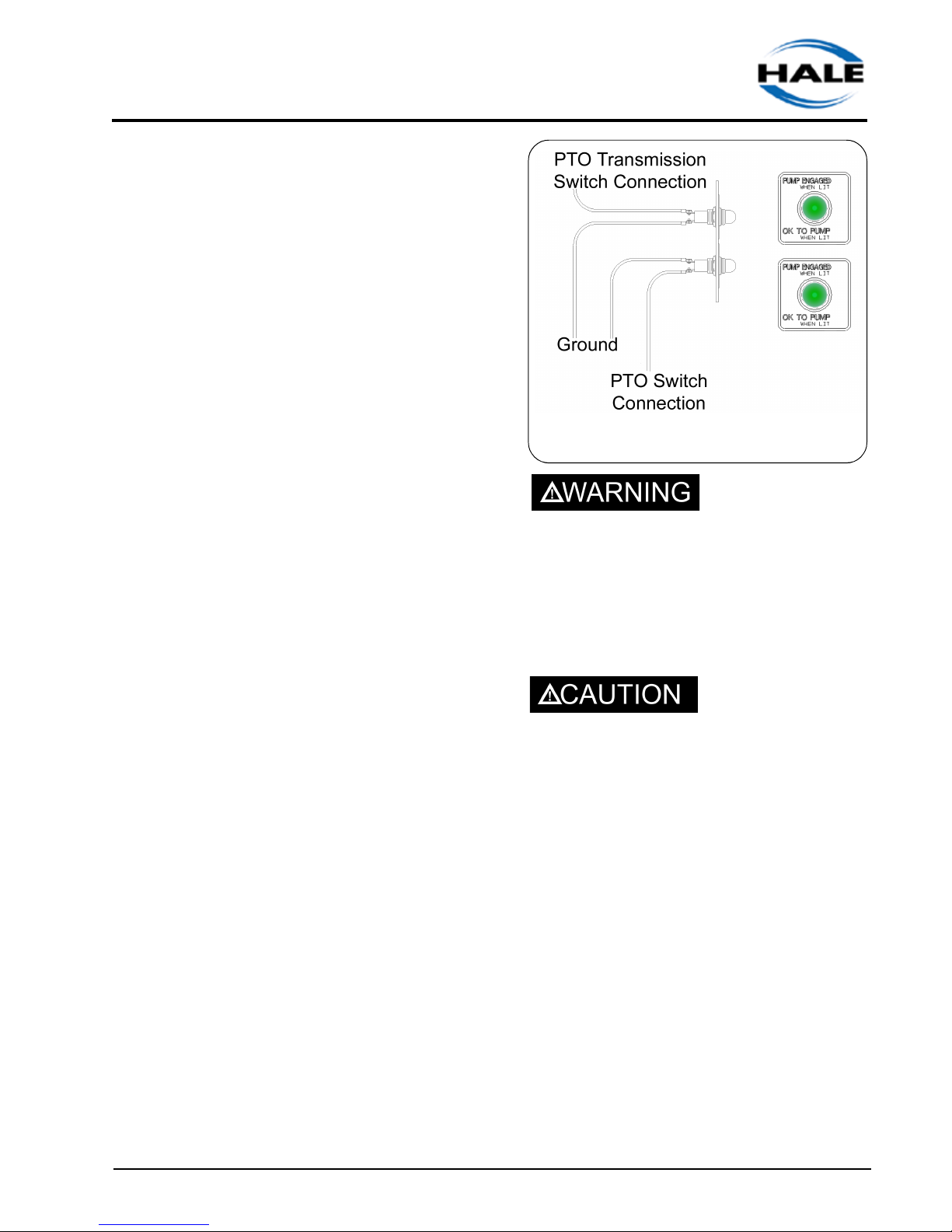

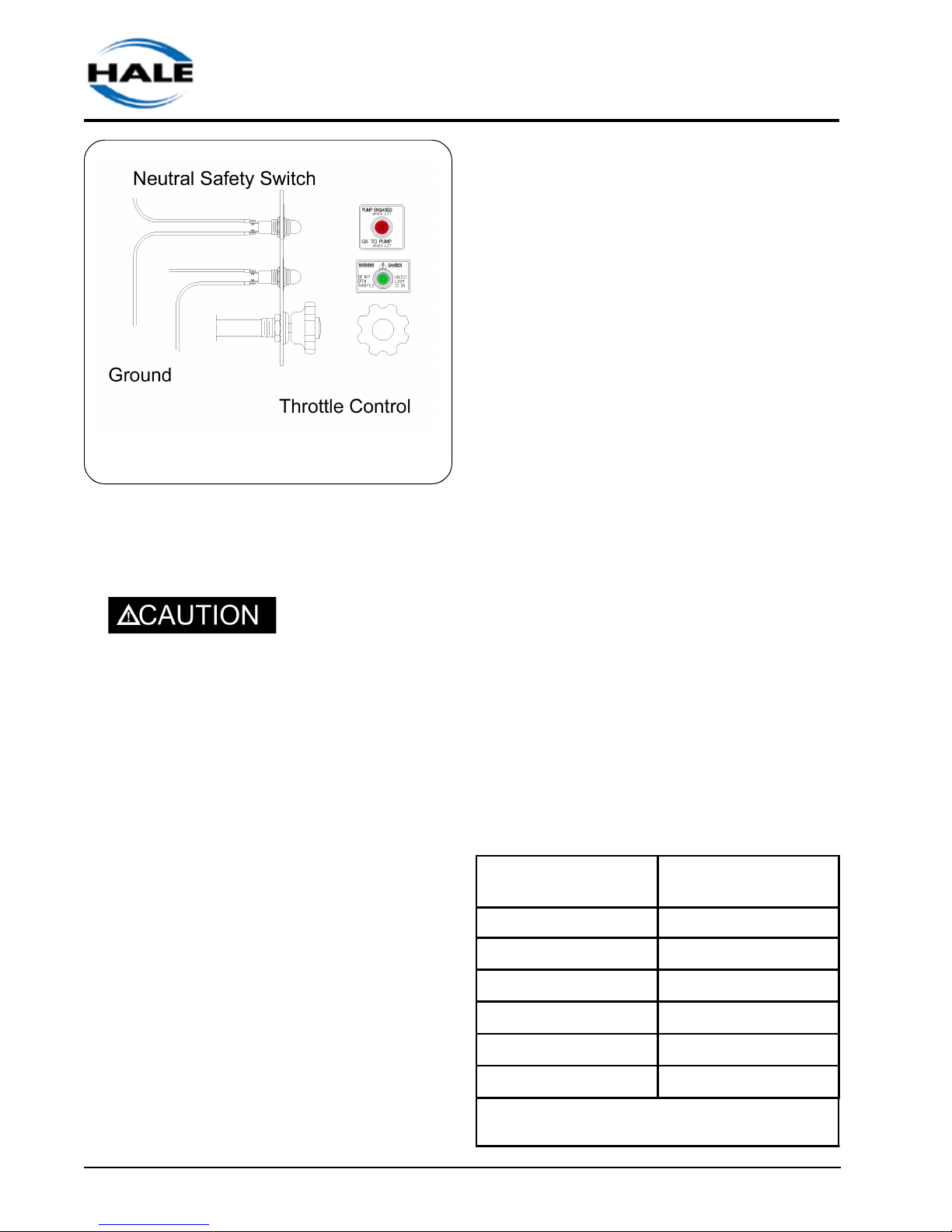

Figure 2-1: Driver's Compartment

Indicator Lights

DO NOT LEAVE THE CAB OR ATTEMPT TO

PUMP UNTIL ALL "OK TO PUMP" LIGHTS IN

THE CAB ARE ILLUMINATED. (Figure 2-1).

6. Exit the driving compartment only after all the

above steps are completed.

DO NOT OPEN THE THROTTLE UNLESS

THE GREEN INDICATOR LIGHT IS ON

(Figure 2-2).

7. Verify the pump panel shift indicator light is

on and that all hose connections are complete.

2. Bring the truck to a complete stop before

attempting to shift from "road" to "pump".

3. Apply the truck parking brake.

4. Shift the truck transmission to the NEUTRAL

position.

5. Engage the pump PTO switch.

Operating Procedures

8. Open the hydrant. Bleed off the air from the

suction hose.

9. Open the suction valve.

10. If necessary to eliminate air pockets, prime

the pump; see Pumping From Draft for

instructions.

Sec II- 1

Figure 2-2: Pump Operator's Panel

11. Advance the engine throttle gradually until

the master discharge gauge indicates the

desired pressure.

DO NOT REDUCE THE PRESSURE ON

THE INTAKE GAUGE BELOW ZERO;

SERIOUS DAMAGE TO THE WATER MAIN

COULD RESULT.

The master intake gauge reading must be

maintained at 5 PSI (.3 BAR), minimum. If the

gauge shows a vacuum the pump is attempting

to draw more water than the hydrant can

supply. When this occurs, reduce the pump flow

to increase the pressure.

As the throttle is opened, the pressure gauge

reading increases with the engine speed. If the

engine speed increases without an increase in

pressure, the pump is beginning to cavitate.

Close the throttle slowly until the pressure

begins to drop, and the engine returns to an idle.

Booster Pumps

13. If the pump overheats and it is not equipped

with a Hale TRV valve, open the valve to

access the bypass line, if it is furnished, or

open the valve to the booster tank (both

suction and discharge sides) to circulate

water.

14. After completion of pumping operations,

gradually reduce the pump pressure until the

engine is at idle speed. Disengage the PTO.

DRAFT LIMITING F ACT ORS

The effect of raised water temperatures when

pumping from a positive pressure source

(hydrant) is negligible on fire pump

performance. But when pumping from draft,

elevated water temperature does have a limiting

effect. Water temperatures above 95o F (35o C)

will cause a noticeable decrease in lift when

drafting. Another factor that can limit lift when

drafting is barometric pressures below 29 In of

Hg. It is important to be aware of environmental

conditions when drafting.

PUMPING FROM DRAFT

1. Get as close to the water source as possible.

The pump can draw 100% of its rated capacity with less than a 10 foot vertical lift. As the

lift increases to above 10 feet, the pump

Water Temperature

Fo (C)

60° (16°) NFPA Baseline

70° (21°)

80° (27°)

90° (32°)

Lift Loss

Head Ft (Meters)

.3 (.09)

.6 (.18)

1.1 (.335)

12. Set the automatic relief valve according to

department policy. If no department policy

exists, refer to the Relief Valve Procedures

later in this section.

Sec II- 2

100° (38°)

110° (43°)

Table 2-1 : Additional Losses Beyond

Baseline NFPA Rating

1.7 (.52)

2.5 (.76)

Operating Procedures

Booster Pumps

capacity will be reduced.

2. Bring the truck to a complete stop.

3. Apply the truck parking brake.

4. Shift the truck transmission to the NEUTRAL

position.

REFER TO DEPARTMENT PROCEDURES

ON SETTING WHEEL CHOCKS AND HOSES.

ALL VALVES, DRAIN COCKS, AND CAPS

SHOULD BE CLOSED.

5. Engage pump PTO.

DO NOT LEAVE THE CAB OR ATTEMPT

TO PUMP UNTIL ALL THE INDICATOR

LIGHTS IN THE CAB ARE ON.

6. Exit the driving compartment only after all the

above steps are completed and the indicator

lights in the cab and on the panel are on.

DO NOT ADVANCE THE THROTTLE

UNLESS THE "OK TO PUMP" INDICATOR

LIGHT IS ON.

Running the engine at speeds higher than

1200 RPM during priming is not recommended since it will not improve priming

operation and may cause damage to the

pump.

IF THE DISCHARGE GAUGE READING DOES

NOT INCREASE, THE INTAKE GAUGE

READING DOES NOT FALL BELOW ZERO,

OR THE PRIMING PUMP DOES NOT

DISCHARGE WATER TO THE GROUND IN 30

TO 45 SECONDS, DO NOT CONTINUE TO

RUN THE PRIMING PUMP. STOP THE PUMP

AND CHECK FOR AIR LEAKS OR POSSIBLE

PUMP TROUBLE.

10. Gradually open the discharge valve until

water emerges in a steady stream. Then

open the other discharge valves to the

desired setting.

11. Open the engine throttle gradually until the

desired pressure or flow is reached.

As the throttle is opened, increase the pressure

gauge reading with engine speed. If the engine

speed increases without an increase in

pressure, the pump is nearing cavitation.

Cavitation will be discussed in detail later.

Reduce the flow from the pump to maintain

pressure or reduce the pressure (throttle) to

maintain flow.

7. Verify the pump panel shift indicator light is

on.

8. Activate the priming pump by pulling the

control handle located on the pump panel.

9. Monitor the intake and discharge master

gauges. The pump is primed when the

intake indication reading falls below zero,

and the discharge pressure starts to increase. Water may also be heard discharging to the ground.

Operating Procedures

13. If a pump shutdown is desired while pumping

from draft, reduce the engine speed to idle,

and close the discharge valves. To resume

pumping, open the throttle and discharge

valves.

14. Set the automatic relief valve according to

department policy. Refer to the Relief Valve

Procedures later in this section.

15. If the pump overheats and is not equipped

with the Hale TRV valve, open the valve to

access the pump auxiliary cooling system, or

Sec II- 3

Booster Pumps

slightly open the drain line.

16. After completing pumping procedures,

gradually reduce the engine RPM to idle

speed and disengage the PTO.

PUMP AND ROLL OPERATION

Hale booster pumps are primarily driven by a

transmission mounted Power-Take-Off (PTO)

unit.

During pump and roll operation, it is necessary

to slow the forward motion of the apparatus to

the PTO manufacturer's recommended

engagement speed.

The following outlines a general pump and roll

procedure:

1. Slow the apparatus to safe PTO engagement

speed as recommended by the PTO manufacturer.

Note: Most PTOs must be engaged while the

apparatus is stopped. Only a "Hot Shift" PTO

can be engaged while the apparatus is rolling.

2. Engage the PTO.

RELIEF VAL VE PROCEDURES

TPM /P35 Relief Valve Procedures

These procedures cover the Hale TPM Relief

Valve System. Be sure to select the correct

procedure, for the equipment on the truck.

1. Set the pressure indicator on the PMD

control valve to a position slightly above the

normal operating pressure (even before

water starts to flow).

2. After normal operating pressure has been

achieved (as indicated on the master pressure gauge while the pump is discharging

water), slowly move the adjusting hand

wheel counterclockwise until the relief valve

opens, and the amber indicator light comes

on.

3. Turn the hand wheel slowly clockwise until

the indicator light goes out. The relief valve

will operate at the set pressure.

4. When the pump is not in operation, turn the

hand wheel clockwise back to a position

slightly above the normal operating pressure.

3. Verify the PUMP ENGAGED light is illuminated.

4. Open the valve between the tank and pump

suction.

5. Observe pump discharge pressure and verify

the pump pressure increases.

6. Prime the pump if necessary.

7. Open the discharge valves and commence

operations.

Sec II- 4

Figure 2-3 PMD Relief

Valve Control

Operating Procedures

Booster Pumps

More complete and detailed information can

be found in the relief valve manual.

THE PRESSURE INDICATOR ON THE

PANEL IS ONLY A ROUGH INDICATION

OF TPM SETTING. ALWAYS USE THE

ABOVE PROCEDURE TO PROPERLY SET

THE TPM RELIEF VALVE SYSTEM.

CAVITATION

Cavitation can occur while pumping from draft,

in relay, or from a hydrant. The operator must be

aware of the warning signs and correct the

situation, or serious damage to the pump and

impeller will occur.

Cavitation can damage the impeller and other

sensitive components, impair pump

performance, and reduce flow capacity. The

damage done during any one period of

cavitation is not great, but the effects are

cumulative. Implosions occurring during

cavitation break away or erode tiny pieces of

metal from the internal parts and the pump

casing. When enough metal has been chipped

away, the impeller becomes unbalanced

causing a strain and vibration on bearings,

bushings and shafts.

Process of Cavitation

1. When increased discharge demand exceeds

the intake, bubbles form in the low-pressure

region (eye) of the impeller.

2. The pressure of the water in the pump drops

as it flows from the suction flange through

the suction nozzle and into the impeller.

3. As flow from the pump increases, the

vacuum at the impeller increases. As the

vacuum increases, the boiling point of water

in that vacuum decreases until it reaches a

point near the impeller eye where it boils and

vaporizes.

4. Once the vapor pockets, or bubbles, enter

the impeller, the process begins to reverse

itself. As the vapor reaches the discharge

side of the pump, it is subjected to a high

positive pressure and condenses back to a

liquid.

The way to eliminate cavitation is to increase the

flow to the pump, decrease the amount of water

being discharged from the pump, or reduce the

pressure in the pump by decreasing engine

speed.

Cavitation

Cavitation occurs when a centrifugal pump is

attempting to discharge more water than it is

receiving. It is often referred to as “the pump

running away from the supply."

Operating Procedures

Figure 2-4 Low Pressure Regions

5. The sudden change from vapor to liquid

generates a shock effect that damages the

impeller and pump housing. Usually there

are thousands of tiny vapor pockets

(bubbles) rather than a few large ones. It is

the collapsing (or implosion) of these

bubbles that causes the characteristic sound

of cavitation that has been described as

rocks tumbling in the pump.

Sec II- 5

Booster Pumps

Warning Signs of Cavitation: Discharge

and Gauges

Discharge Pressure

In a properly functioning pump, an increase in

RPM will increase the discharge pressure and

volume. An increase in engine RPM that does

not cause an increase in the pump discharge

pressure, is the most reliable indication that a

pump is approaching cavitation.

Vacuum Compound Gauge

The operator should not depend entirely on the

vacuum (compound) gauge to indicate when a

pump is nearing cavitation: The vacuum gauge

is usually tapped into the intake chamber

several inches away from the leading edge of

the impeller eye where the greatest amount of

vacuum occurs. The vacuum gauge does not

take into account ambient temperature nor

atmospheric pressure and is not accurate near

zero on the vacuum scale.

illustrates the amount of lift loss as

temperatures rise. If there is a marked loss

of suction capacity, the pump may be near

cavitation.

NOTE: When water reaches 95° F( 35 C),

the operator is likely to notice a marked

decrease in lift.

o Monitor barometric pressure. NFPA

standards sets a baseline of 29.9”Hg. See

Table 2-2.

o Location: The higher the elevation above

sea level, the lower the atmospheric

pressure and less lift. See Table 2-3.

o Open the throttle gradually and watch the

Barometric Reading

in (mb)

29.9 (1012.53) NFPA Baselines

29.7 (1005.76) .2 (.06)

Lift-loss in Head Feet

(meters)

How to Prevent Cavitation

A soft sleeve has an advantage over a hard

sleeve when pumping from a hydrant because it

will partially collapse providing an immediate

indication to the operator that cavitation is

imminent. A hard sleeve indicates problems only

at the intake gauge which is not the best or most

reliable indicator.

Monitoring current operating conditions,

knowing the capabilities of the equipment, and

regular inspection are the best protection

against cavitation.

During Operations:

o Do not increase the pump speed beyond the

speed at which the pressure ceases to rise.

o Monitor the water temperature baseline per

NFPA standards is 60° F (16 C). Table 2-1

29.5 (999) .5 (.15)

29.3 (992.21) .7 (.21)

29.1 (985.444) .9 (.27)

28.9 (978.67) 1.1 (.33)

28.7 (971.89) 1.4 (.43)

Table 2-2 : Lift-Loss from Barometric Pressure

pressure gauge and the tachometer, if

equipped. An increase in engine RPM

without a corresponding increase in

pressure indicates cavitation.

o Use a hard suction hose when pumping from

draft and soft suction hose when pumping

from hydrant.

Preventive Measures:

o Regularly inspect discharge and suction

hoses to check for air leaks: these can also

Sec II- 6

Operating Procedures

Booster Pumps

Elevation

Feet (Meters)

Lift-Loss in Feet

(Meters)

2,000 (609) NFPA Baseline

3,000 (914) 1.1 (0.33)

4,000 (1219) 2.2 (0.67)

5,000 (1524) 3.3 (1)

6,000 (1828) 4.4 (1.34)

7,000 (2133) 5.5 (1.67)

8,000 (2438) 6.6 (2.01)

9,000 (2743) 7.7 (2.35)

10,000 (3048) 8.8 (2.68)

Table 2-3: Lift Loss from Elevation

cause cavitation.

o Consider the size of the suction hose: Table

2-4 shows the NFPA pre-selected hose

sizes for each pump-rating capacity. Using

the appropriate-sized hose will minimize the

occurrence of cavitation.

Hose

Diameters

(mm)

FLOWS GPM

(LPM)

250

350

500

750

1000

1250

1500

1750

2000

2500

Table 2-4: Hose Sizes for Pump-Rating Capacity

3"

(76)4"(102)

5.2

(19.7)

2.5

(9.5)

5.0

(19)

11.4

(43)

4 ½"

(114)5"(127)6"(152)

3.6

(51.5)

8.0

(30)

14.5

(55)

Lift Loss

(17.8)

4.7

8.5

(32)

13

(49)

1.9

(7.2)

3.4

(12.9)

5.2

(19.6)

7.6

(28.7)

10.4

(39.4)

Dual

6"

1.9

(7.2)

2.6

(9.8)

3.4

(12.9)

5.2

(19.6)

o Consider the piping within the truck: Further

suction losses may result from additional

suction piping added to the fire pump during

assembly by the manufacturer.

o Follow the maintenance and inspection

procedures.

o Cavitation can occur with large nozzle tips.

Solve this problem by reducing flow.

o Cavitation can also occur when air enters the

pump. The pump may be primed, however,

air leaks can cause rough operation and an

increase of engine speed without an increase in pressure or flow. If an air leak is

suspected, discontinue pumping and refer to

Section IV.

Operating Procedures

Sec II- 7

POST OPERATION PROCEDURE

o Return the engine to idle.

o Slowly close all valves.

o Place the transmission in neutral or park.

o Slowly shift from "pump" to "road" to disen-

gage the pump.

o Drain the pump (especially important in

freezing weather):

a. Open the discharge valves, remove

suction tube caps, and discharge valve caps.

b. Open the pump body drain cocks or Hale

multiple drain valve. If a multiple drain valve

is used, all pump drain lines should be

connected to this valve.

Booster Pumps

c. After the pump is completely drained,

replace all caps and close all valves,

o If sea water, dirty water, alkaline water

or foam solution, has been used, flush the pump

with clean water.

o Remove the wheel chocks only when

preparing to leave the scene.

o Fill out the pump run log, indicating total

pumping time and total out-of-station time.

o Report all pump, vehicle and equipment

malfunctions, and irregularities to the proper

authority.

o Know and follow all local procedures.

Sec II- 8

Operating Procedures

Booster Pumps

SECTION III PREVENTIVE

MAINTENANCE

OVERVIEW

Hale Booster Pumps require very little care and

maintenance. However, the little required is

important. Preventive maintenance tasks take

little time to accomplish and consist of leak

testing, lubrication and cleaning. The

procedures supplied in this section are for

normal use and conditions.

This section provides recommended actions to

be completed after each use, weekly, monthly

and annually basis.

Post-Operation Maintenance Procedures

Flush Pump

1. Inspect the suction hose and rubber washers

as well as the washers in the suction tube

caps. Remove any foreign matter from the

hose and coupling. Replace worn, damaged, or dry washers.

2. Verify all discharge valves, drain valves and

drain cocks are closed.

o Checking and cleaning the intake strainers

o Checking any auxiliary engine.

o Verifying all gauges are in working order.

o Operating pump controls.

o Inspecting water and foam tanks.

o Checking roof and bumper turrets

o Checking auxiliary fire suppression equip-

ment

Relief Valve Testing

When the relief valve is not in operation, keep

the hand wheel set above the normal operating

pressure.

1. Set up to pump from the

onboard water tank with

the discharge flow back to

the water tank.

2. Turn the relief valve hand

wheel clockwise to the

stop to prevent the relief

valve from operating.

Figure 3-1

3. Tighten the suction caps.

Weekly Maintenance

Weekly maintenance consists of:

o Testing the relief valve system

o Testing the priming system

o Testing the pump shift warning indicator

lights

o Valve Maintenance

Preventive Maintenance

3. Bring the pump pressure

up to 150 PSI (10 BAR) as

indicated on the master

pressure gauge per

normal operating procedures.

4. Turn the relief valve hand wheel counterclockwise until the relief valve opens. The

relief valve is open when the amber indicator

light is lit and the pressure begins to drop.

5. Turn the relief valve hand wheel clockwise

then counterclockwise a few times to ensure

that the hand wheel turns freely. Observe

the pressure gauge and indicator light for

Figure 3-1

PM Valve Control

Sec III- 1

Loading...

Loading...