Instruction Manual

Sweepmaster P650 (6403.10)

Sweepmaster B650 (6403.20)

2

Introduction

Preface

Dear Customer,

We are certain that the excellent qualities of the vehicle will justify the faith

you have shown in us through your purchase.

Your safety, and that of others, basically lies in your ability to control and operate the vehicle. Before using the

equipment for the first time, read this

original manual thoroughly, act according to the information contained and

keep it in a safe place for future reference or subsequent owners. Please

read the Chapter "Safety Information"

prior to starting the vehicle to ensure it

is operated and used safely.

The instruction manual contains all the

most important information regarding

operation, maintenance and service.

Throughout this instruction manual, sections which concern safety are indicated by corresponding warning symbols.

Should you have any questions in respect of the vehicle or instruction manual, your authorized Hako dealer is

available to provide help at any time.

Please be expressly advised that you

cannot base any legal claims on the information contained in this manual. Ensure only original spare parts are used

should any repairs be necessary. Only

such original spare parts warrant that

the equipment is reliably ready to use at

all times. Subject to modification as required by technical advancement.

Valid as of: April 2014

Hako GmbH

D-23843 Bad Oldesloe

Hamburger Str. 209-239

Phone ++49 (0) 4531 8060

Proper use

The Sweepmaster is a manually operated sweeper for industrial/commercial

use and serves to clean up dry and wet

waste from indoor and outdoor areas

such as production plants, warehouses,

car parks, parking blocks, pedestrian

precincts, market squares, railway stations and filling stations. The Sweepmaster can clean all types of industrial

floor, concrete, asphalt and tar, paving

and interlocking stone paving. It is not

permitted for use on public roads with

motor traffic. The Sweepmaster B650

can be upgraded with a carpet kit so it

can also be used to clean dry waste

from carpets.

Any use beyond this is regarded as improper use. The manufacturer is not

considered liable for any damage resulting from improper use; the user is

solely responsible for all the risks.

Intended use also includes maintaining

and observing the operating, maintenance and repair conditions prescribed

by the manufacturer.

Introduction

3

The Sweepmaster may only be operated, serviced and repaired by personnel

who are familiar with the work involved

and are aware of the risks. The applicable accident prevention laws must be

observed and any generally accepted

health and safety directives must be

maintained.

Based on the conception, design and

construction of the model introduced

onto the market by us, the machine

complies with the applicable basic safety and health requirements stipulated in

the EC directives (refer to the Declaration of Conformity). The EC Declaration

of Conformity is no longer considered

valid in the event of modifications to the

machine not authorized by us. The

manufacturer is not deemed liable for

any damage resulting from unauthorized modifications to the machine

Notes on warranty

The terms defined in the purchase

agreement apply. Claims for compensation related to damage are excluded

from the terms of warranty when the

damage is the result of failure to observe regulations concerning service

and maintenance. Maintenance work

must be performed by authorized Hako

service centers and confirmed in the

“Maintenance Report” which serves as

a warranty logbook.

The following are excluded from the

terms of warranty: wear and tear

through overuse, defective fuses, improper handling and use or unauthorized modifications. Claims under the

terms of warranty are also annulled

when damage occurs to the vehicle resulting from the use of parts or accessories not explicitly approved by us or

from failure to observe maintenance

regulations.

Acceptance of the machine

Inspect the vehicle immediately on delivery for signs of transport damage.

Replacement will be made when confirmation is provided immediately by the

freight carrier with regard to the damage and the damage report is sent to

our authorized sales partner together

with the consignment note.

Introduction

4

Disposing of the machine

Render the machine inoperable. It must

not represent a source of risks to children. Dispose of the machine in accordance with the applicable local

regulations. For further information on

disposal and recycling, contact the authorized Hako dealer where you purchased the machine.

Used batteries with the recycling symbol contain reusable commodities. The

heavy metals contained simultaneously

represent a serious risk to health and to

the environment. Never open batteries

or damage them. Never touch, inhale or

swallow any material inside batteries.

Health hazard! Never allow batteries to

pollute the environment. Risk of contaminating the ground and water! In accordance with the symbol with the

crossed out bin, these batteries must

not be disposed of in domestic waste.

The return and recycling of old batteries

must be agreed on with your authorized

Hako dealer in accordance with the Battery Law § 6 and § 8 (BattG).

Introduction

5

Introduction . . . . . . . . . . . . . 2

Preface . . . . . . . . . . . . . . . . . . 2

Proper use . . . . . . . . . . . . . . . 2

Notes on warranty . . . . . . . . . 3

Acceptance of the machine . . 3

Disposing of the machine . . . . 4

1 Safety Information . . . . . . . . 7

1.1 Safety and warning symbols . 7

1.2 General information . . . . . . . . 8

1.3 Operating information. . . . . . . 8

1.4 Maintenance information . . . . 9

1.5 Particular risks . . . . . . . . . . . 10

1.6 Environmental protection . . . 11

1.7 Labels on the machine . . . . . 12

2 Starting Up . . . . . . . . . . . . . 16

2.1 Before starting up for the first

time. . . . . . . . . . . . . . . . . . . . 16

2.1.1 Unpacking . . . . . . . . . . . . . . 16

2.1.2 Refueling the machine

(only Sweepmaster P650) . . 17

2.1.3 Checking the oil level

(only Sweepmaster P650) . . 17

2.1.4 Connecting the battery

(only Sweepmaster B650) . . 17

2.1.5 Initial battery charge

(only Sweepmaster B650) . . 17

2.1.6 Instruction. . . . . . . . . . . . . . . 18

2.2 Before starting up each day . 18

3 Operation . . . . . . . . . . . . . . 19

3.1 Method of operation . . . . . . . 19

3.2 Operating and indicator

elements. . . . . . . . . . . . . . . . 20

3.2.1 Operating elements . . . . . . . 20

3.2.2 Operating panel . . . . . . . . . . 24

3.3 Operation . . . . . . . . . . . . . . . 26

3.3.1 Switching on. . . . . . . . . . . . . 26

3.3.2 Accelerating . . . . . . . . . . . . . 27

3.3.3 Stopping . . . . . . . . . . . . . . . . 27

3.3.4 Vacuumsweeping. . . . . . . . . 27

3.3.5 Switching off. . . . . . . . . . . . . 28

3.3.6 After finishing work. . . . . . . . 29

3.3.7 Loading and transportation . 29

3.4 Function faults . . . . . . . . . . . 30

3.5 Options. . . . . . . . . . . . . . . . . 30

4 Technical Data . . . . . . . . . . 31

5 Maintenance and

Service . . . . . . . . . . . . . . . . 33

5.1 Hako system maintenance. . 33

5.2 Maintenance report . . . . . . . 34

5.3 Maintenance Plan . . . . . . . . 35

5.4 Engine . . . . . . . . . . . . . . . . . 38

5.4.1 Checking the engine oil level 39

5.4.2 Refilling engine oil . . . . . . . . 39

5.4.3 Changing/Draining the engine

oil change. . . . . . . . . . . . . . . 39

5.4.4 Oil sensor . . . . . . . . . . . . . . . 40

5.4.5 Disassembling the air filter . . 40

5.4.6 Cleaning the air filter . . . . . . 40

5.4.7 Installing the air filter . . . . . . 40

5.5 Battery system . . . . . . . . . . . 41

5.5.1 Charging battery. . . . . . . . . . 42

5.5.2 Total discharge signal transduc-

er (TSG) . . . . . . . . . . . . . . . . 42

5.5.3 Servicing the drive batteries. 42

5.5.4 Removing battery . . . . . . . . . 42

5.5.5 Inserting batteries. . . . . . . . . 43

5.5.6 Disposing of batteries. . . . . . 43

5.6 Drives . . . . . . . . . . . . . . . . . . 44

5.6.1 Adjusting the drive belt. . . . . 45

5.7 Side brush . . . . . . . . . . . . . . 47

5.7.1 Side brush wear, readjustment

48

5.7.2 Changing the side brush . . . 48

5.8 Rotary brush. . . . . . . . . . . . . 49

5.8.1 Cleaning the brush space . . 50

5.8.2 Changing the rotary brush . . 50

5.8.3 Setting the sweeping pattern 51

5.8.4 Changing the sealing strips . 51

5.9 Dirt hopper . . . . . . . . . . . . . . 54

5.9.1 Removing the dirt hopper. . . 55

Table of Content

6

5.9.2 Emptying the dirt hopper . . . 55

5.9.3 Inserting the dirt hopper . . . . 55

5.9.4 Changing the seals . . . . . . . 55

5.10 Dust vacuum . . . . . . . . . . . . 56

5.10.1 Clearing dust deposits from panel air filter during operation. . 57

5.10.2 Removing the panel air filter 57

5.10.3 Cleaning the panel air filter thor-

oughly. . . . . . . . . . . . . . . . . . 57

5.10.4 Replacing the sealing strips . 57

5.10.5 Inserting panel air filters . . . . 58

5.10.6 Checking the suction turbine 58

5.10.7 Checking the filter system for

leaks. . . . . . . . . . . . . . . . . . . 58

5.11 Special equipment . . . . . . . . 59

EC Declaration of Conformity

60

Table of Content

7

Safety Information

1 Safety Information

1.1 Safety and warning symbols

The following warning symbols appear

in the instruction manual in those

sections in which your safety, the safety

of the machine and environment could

be affected:

Symbol Damage to... Definition

Safety information persons

or property

Safety symbol to indicate dangerous situations arising

through failure to follow instructions or prescribed work

procedures precisely or through ignoring them

altogether.

Note the machine Important information on handling the machine to

maintain its functioning ability.

Risk to environment the environment Risks to the environment through using substances

which represent a risk to health and the environment.

8

Safety Information

1.2 General information

• In addition to the information

provided in this instruction manual, all

the legally applicable health and

safety provisions must be observed.

• Before starting up the machine for

the first time, read the instruction

manual supplied with it thoroughly as

well as any separate manuals

provided with additional or

attachment devices and observe all

the information during work.

• The equipment may only be

operated, serviced and repaired by

personnel trained by Hako technical

experts.

• This vehicle is not intended to be

used by persons (including children)

with limited physical or mental capabilities or persons without sufficient

experience and ability.

• Particular attention should be paid to

the information regarding safety.

Technical expertise is the key to

preventing errors when operating the

machine and ensuring trouble-free

operation.

• The instruction manual must always

be kept at the operating location of

the machine and, as a result, should

kept in a safe place on the

equipment.

• If the equipment is sold or rented out,

these documents should be

transferred to the new owner/

operator. The transfer should be

confirmed!

• The warning labels attached to the

machine provide important

information concerning safe

operation.

Illegible or missing labels must be

replaced by new ones.

• For reasons of safety, always use

original spare parts.

1.3 Operating information

• The machine is not suitable for

clearing up fluids, dust or

substances which represent a health

hazard, are inflammable or

explosive. No burning items may be

cleared up, e.g. glowing cigarettes.

In addition, it is forbidden to clean up

wood dust, e.g. beech and oak dust

- health hazard!

• When the machine is in

vacuumsweeping mode, it must not

be driven through puddles of water.

• Before starting the machine up for

the first time, the battery to be used

must be fully charged, properly, by

implementing the initial battery

charge routine (only

Sweepmaster B650). Hako

assumes no liability for damage to

the battery caused by a fault when

the battery is charged for the first

time.

• The machine together with the

working equipment must be checked

in terms of proper condition and

operational safety each time prior to

use. Clear any faults immediately!

The machine must not be used when

not in a sound condition.

9

Safety Information

• Only start the machine when the

hood is closed and locked and the

lever of the shaking device has been

pushed in.

• Before starting work, the operator

must be fully familiar with all

adjustment, operating and control

elements as well as their respective

function! It is too late to do this when

the machine is actually in operation!

• Always wear heavy duty, non-slip

footwear when working with the

machine.

• The machine may only be used on

those surfaces which have been

approved by the contractor or person

appointed by him.

• The manner of driving must be

adapted to the local conditions.

• It is forbidden to use the machine in

potentially explosive atmospheres.

• Do not let the engine run indoors!

Risk of poisoning (only

Sweepmaster P650)! Ensure

sufficient ventilation when working

indoors.

• When using the machine, it is

essential to pay attention to third

parties, especially children.

• Pay attention to hot parts of the

engine, risk of burns.

• It is prohibited to transport

passengers.

• Accelerate the machine immediately

after switching on the rotary brush,

otherwise imprints of the brush could

be produced on the floor.

• Never leave the machine unattended

as long as the engine is running.

• Remove the ignition key to prevent

unauthorized use of the machine.

• Never leave batteries in a

discharged state but recharge them

as soon as possible (only

Sweepmaster B650).

• When transporting the machine,

switch the engine off and raise the

side brush.

• The Sweepmaster can be used on

surfaces with a maximum gradient of

2%.

• Steps or curbs up to a maximum of

4 cm can be driven over.

• It is forbidden to manipulate switches

and safety equipment.

1.4 Maintenance information

• The maintenance work and

maintenance intervals prescribed in

the instruction manual must be

adhered to.

• Operating personnel must complete

the necessary daily and weekly

maintenance work. All other

maintenance work must be

completed at your nearest Hako

service center.

• The machine must be inspected by a

recognized technical expert in

respect of operational safety, within

the terms of the applicable accident

prevention laws, at reasonable

intervals (we recommend at least

once a year) and following

modification or repairs.

• Spare parts must comply with the

minimum technical requirements

stipulated by the manufacturer! This

is ensured by the use of original

spare parts.

• The machine must be switched off

prior to cleaning or servicing it or to

replacing parts.

10

Safety Information

• Suitable tools must be used for

cleaning and maintenance work.

• When working with the hood raised,

it must be opened up fully to prevent

it from accidentally dropping or

slamming shut.

• When working on the electrical

system, always disconnect the

battery cable (only

Sweepmaster B650).

• Battery may only be handled and

changed by properly skilled

maintenance personnel (only

Sweepmaster B650).

• Pay attention that the insulation of

the charger cable is not damaged

and cannot be damaged during the

charging process. The cable must

not chafe against anything. In the

case of defective insulation, do not

use the on-board charger (only

Sweepmaster B650).

• Check the exhaust system at regular

intervals (only Sweepmaster P650).

• It is not permitted to clean the

machine with a pressure washer or

steam blaster.

• It is not permitted to use aggressive

and corrosive cleaning agents.

• Allow the machine to dry properly

after being cleaned, e.g. over the

weekend.

• Do not carry out any welding, drilling,

sawing or grinding work on the frame

sections. Damaged parts may only

be changed at an authorized Hako

service center.

1.5 Particular risks

Refueling

(only Sweepmaster P650)

• Take the utmost care when handling

fuel: Increased risk of fire! Never

refuel near open flames or

incendiary sparks! Never smoke

when refueling!

• Never refuel indoors!

• Before refueling, switch off the

engine and remove the ignition key.

• Wipe up spilled fuel immediately!

Batteries (only Sweepmaster B650)

• To prevent creeping currents,

always keep the batteries clean and

dry, protect from soiling such as by

metal dust.

• Never lay any metallic objects or

tools on batteries. Risk of short

circuit and deflagration!

• When charging the batteries, there

must be sufficient ventilation in the

charging area. Otherwise, there is a

risk of explosion!

• Batteries must not be connected or

disconnected when conducting

electricity.

• Wash your hands thoroughly after

working on batteries.

Information on the power plug

• Only take hold of the power plug and

power cable when your hands are

dry.

• Never insert the power plug in the

socket if the base is wet or damp.

• Never immerse the power cable or

power plug in water or other fluids

clean them in running water. Risk of

electric shock!

• Dry any power plugs and power cables which have become damp with

a dry cloth before connecting them in

power sockets.

• Pay attention that the power socket

is dry.

• We recommended the use of splashproof power sockets complying with

DIN VDE 0620-1.

• Pay attention that no water or fluids

can get on to live machine parts. If

water should penetrate to such

11

Safety Information

parts, disconnect the power plug immediately and have the vehicle

checked at an authorized Hako service center.

• The power connection cable must be

inspected for signs of damage at

regular intervals. If damage is detected, the cable must be replace prior to further use.

Health hazard

• The shaking device for cleaning the

panel air filter may only be actuated

when the dirt hoppers are in the

machine and have been raised.

• It is forbidden to eat, drink and

smoke in battery charging rooms.

Safety equipment

• Never operate the Sweepmaster

without the hood being closed and

locked (safety equipment)!

• Do not open the hood when the

engine is running!

12

Safety Information

1.6 Environmental protection

• Sufficient factual knowledge is

required in order to use substances

which could represent a risk to

health and the environment, e.g oil

and lubricants.

• Observe the applicable laws and

local regulations when disposing of

waste and cleaning agents, also

refer to the Water Resources Act.

• Observe the applicable laws and

local regulations when disposing of

waste oil (only Sweepmaster P650).

• Used batteries with the recycling

symbol must not be disposed of in

household waste, refer to Section

Disposing of batteries.

13

Safety Information

1.7 Labels on the machine

The following safety and warning labels

are attached to the machine where

easily legible.

Missing or illegible labels must

be replaced immediately.

Choke (Fig. 1/1)

(only Sweepmaster P650)

Lock, dirt hopper

(Fig. 1/2)

Company logo (Fig. 1/3)

Fig. 1

2

1

3

14

Safety Information

Fig. 2

1

6

3

5

4

2

7

15

Safety Information

Bypass flap (Fig. 2/1)

Only use maintenance-free batteries

(Fig. 2/2)

(only Sweepmaster B650)

Wear compensator for rotary brush

(Fig. 2/3)

Rating plate (Fig. 2/4)

Wear compensator for side brush

(Fig. 2/5)

Oil label (Fig. 2/6)

(only Sweepmaster P650)

Engine oil, only use SAE 15 W 40 .

12 V label (Fig. 2/7)

(only Sweepmaster B650)

12 V

16

Safety Information

Fig. 3

Shaking device (Fig. 3/1)

Type of machine (Fig. 3/2)

Sweepmaster P650

Sweepmaster B650

Lower/Raise side brush (Fig. 3/3)

Read and observe the instruction

manual (Fig. 3/4)

Gradient (Fig. 3/5)

3

1

4

2

5

17

Starting Up

2Starting Up

2.1 Before starting up for the first

time

2.1.1 Unpacking

Remove the packaging, open the

fastening straps and take the

Sweepmaster from the pallet. For

reasons of packaging, the handlebar of

the Sweepmaster is pivoted forwards.

First of all, pivot the handlebar to its

operating position.

Pivoting the handlebar to its

operating position

1. Loosen the wing bolts (Fig. 4/1) on

the right and left sides of the

handlebar (Fig. 4/2) a few

revolutions until the handlebar

(Fig. 4/2) can be straightened up.

2. Pivot the handlebar (Fig. 4/2)

towards the rear and set it to a height

convenient for the user.

3. Tighten the wing bolts (Fig. 4/1) on

the right and left sides of the

handlebar (Fig. 4/2).

Fig. 4

1

2

18

Starting Up

2.1.2 Refueling the machine

(only Sweepmaster P650)

Unscrew the fuel tank cap

(Fig. 7/5) and fill approx. 2.5 l gasoline.

Screw the fuel tank cap back on.

Only refuel the machine when

the engine has cooled down.

Otherwise, any spilled

gasoline can evaporate if it

lands on hot machine parts.

Health hazard through inhaling

vapors!

Refueling must not be carried

out in closed rooms.

Refueling may only be carried

out when the engine is

switched off! Remove the

ignition key.

It is forbidden to smoke or use

fire when refueling or working

on or near components

containing fuel.

Wipe up any spilled fuel!

Wipe up spilled fuel with a cloth

and dispose of the cloth

according to the applicable

environmental laws.

2.1.3 Checking the oil level

(only Sweepmaster P650)

Engine oil is filled at the factory. As a

precaution, however, check the oil level

again on site, refer to Section 5.4.1.

2.1.4 Connecting the battery

(only Sweepmaster B650)

Before starting up for the first time,

connect the positive cable of the device

as illustrated in Figure 5 to the positive

pole (Fig. 5/1) of the battery in the

device.

2.1.5 Initial battery charge

(only Sweepmaster B650)

Before starting up the machine for the

first time, the batteries used must be

fully charged by completing the initial

battery charge, refer to Section 5.5.1.

Hako assumes no liability for damage to

the battery resulting from failing to carry

out the initial battery charge properly.

Risk of explosion! When

charging the battery, there

must be sufficient ventilation in

the charging area.

Fig. 5

1

19

Starting Up

2.1.6 Instruction

Operators must receive instruction

before putting the machine into service.

Only technicians from your local,

authorized Hako dealer are allowed to

provide initial instruction on how to use

the machine. The manufacturing plant

notifies the dealer immediately after

delivering the machine and the dealer

will contact you to arrange a date for

providing the initial instruction.

2.2 Before starting up each day

Carry out the following checks before

starting the machine:

1. Check the parking space for signs of

leaks.

2. Only Sweepmaster P650: Check the

engine oil level with the dipstick and

refill, if necessary; refer to Section

5.4.2.

3. Only Sweepmaster P650: Check the

fuel supply and refill fuel, if

necessary, refer to refer to

paragraph 2.1.2.

4. Only Sweepmaster B650: Check the

charge status of the battery and

recharge, if necessary.

5. Check the fill level of the dirt hopper

and empty them, if necessary.

6. Check the levels of wear on the

rotary brush and side brush.

7. Check the ergonomic position of the

handlebar and readjust it, if

necessary.

20

Operation

3Operation

3.1 Method of operation

The Sweepmaster is a manually

operated sweeper machine with a drive

for the dry cleaning of hard floors and

carpets.

The side brush (Fig. 6/4), located on the

right-hand side of the machine, sweeps

the dirt away from corners and edges

into the path of the rotary brush

(Fig. 6/3). The rotary brush (Fig. 6/3)

sweeps the dirt into the dirt hopper

(Fig. 6/2) using the overhead throw

method. The particulate matter

(depicted gray in Fig. 6) is forced

against the panel air filter (Fig. 6/1) by

the suction turbine (Fig. 6/5) and filtered

out there. Only dust-free air is fed back

into the ambient air.

Fig. 6

1 Panel air filter

2 Dirt hoppers

3 Rotary brush

4 Side brushes

5 Suction turbine

Sweepmaster P650

The Sweepmaster P650 is equipped

with a gasoline engine and is filled with

approx. 2.5 l gasoline.

Sweepmaster B650

To charge the battery, the

Sweepmaster B650 is equipped with a

corresponding, fully automatic onboard charger. To protect the battery

against total discharge, the

Sweepmaster B650 is provided with a

total discharge signal transducer (TSG)

which indicates the battery status

during the charging process and

discharging.

4321

5

21

Operation

3.2 Operating and indicator

elements

3.2.1 Operating elements

1 Side brush lever

2Hood

3 Hood lock

4 Bypass flap

5 Fuel tank cap

(only Sweepmaster P650)

6 Choke

(only Sweepmaster P650)

7 Recoil starter

(only Sweepmaster P650)

Fig. 7

1

3

4

2

5

6

7

22

Operation

Side brush lever (Fig. 7/1)

Use the lever to lower or raise the side

brush.

Lever forward: Side brush is lowered.

Lever to rear: Side brush is raised.

Hood with lock

(Fig. 7/2)

Only operate the machine with

the hood closed!

The hood should only be opened for

maintenance and repair work. In this

case, unlock the lock (Fig. 7/3) using a

square wrench and pivot the hood up.

Bypass flap (Fig. 7/4)

On opening the bypass flap, the

vacuum operation is interrupted. If

necessary, open up the bypass flap by

hand.

Vacuuming should be

interrupted when wet waste

could be vacuumed up.

Fuel tank cap (Fig. 7/5)

Only for Sweepmaster P650 with

gasoline engine. The fuel tank cap

closes the fuel tank.

Choke (Fig. 7/6)

Only for Sweepmaster P650 with

gasoline engine. The choke must be

pulled out before cold starting the

engine.

Recoil starter (Fig. 7/7)

Only for Sweepmaster P650 with

gasoline engine. The engine is then

started by pulling the recoil starter after

having set the key switch to Position 1

beforehand.

23

Operation

1 Drive bar

2 Handlebar

3 Operating panel

4 Wing bolt for handlebar

5 Charger cable

6 Shaking device lever

7 Dirt hopper

8 Dirt hopper lock

Fig. 8

1

2

3

7

4

5

8

6

24

Operation

Drive bar (Fig. 8/1)

The drive bar serves to activate and

deactivate the wheel drive. The drive

bar must be pulled up towards the

handlebar with the fingers so that the

wheel drive operates and the machine

moves forward. If the drive bar is

released, the machine stops (safety

circuit).

Handlebar (Fig. 8/2)

The machine is guide/steered via the

handlebar.

Release the drive bar when

turning sharp corners.

The two wing bolts (Fig. 8/4) serve to

adjust the handlebar to an optimal

position for the user.

Operating panel (Fig. 8/3)

Refer to Section 3.2.2.

Charger cable (Fig. 8/5)

The charger cable of the

Sweepmaster B650 is located in the

recess which also contains the shaking

device lever.

Shaking device lever (Fig. 8/6)

To clean the panel air filter, pull the

shaking device lever out then push

back in again; repeat this several times.

Dirt hopper lock (Fig. 8/8)

To remove the dirt hopper, move the

locking lever to the right (when facing

the front) and, at the same time pivot

the handlebar forwards. The frame of

the dirt hoppers is lowered as a result

so that the hopper can be removed

towards the rear. To lock the hopper,

pull the handlebar to the rear until the

lock audibly engages.

25

Operation

3.2.2 Operating panel

Sweepmaster P650

Fig. 9

1 Key switch

Key switch (Fig. 9/1)

The key switch serves to secure the

machine against unauthorized use.

Key switch positions

Position 0: Off

Position 1: On (engine ready to start)

1

26

Operation

Sweepmaster B650

1 Key switch

2 Charge control indicator

3 Battery discharge status indicator

Key switch (Fig. 10/1)

The key switch serves to switch the

drive motor on and off and secure the

machine against unauthorized use.

Key switch positions

Position 0: Off

Position 1: On (engine on)

Charge control indicator (Fig. 10/2)

During the charging process, the

machine electronics indicates the

charge status via four green LEDs.

The Sweepmaster B650 can

only be charged when the key

switch is in Position 0.

As the charge level increases, it is

indicated by the LEDs which light up

progressively from left to right.

Fig. 10

1

2

3

27

Operation

Flashing or individually lit LEDs

indicate an error status, also

refer to the charger instruction

manual.

Battery discharge status (Fig. 10/3)

During operation, the machine

electronics indicates the discharge

status of the battery by means of a red

LED (left) and three green LEDs (right).

When all three green LEDs light up, the

batteries are fully charged. As the

batteries become progressively

discharges, the LEDs go out in

succession from right to left. When the

last green LED goes out, the red LED

starts to flash (early warning of

imminent shutdown). After a certain

time, the red LED lights up continuously

indicating the "battery empty" status.

Shortly afterwards, the drive motor is

automatically switched off to protect the

battery from a total discharge.

The machine should only be restarted

when the battery have been charged.

3.3 Operation

The Sweepmaster must not be

used in domestic or office

areas.

Practice all the operating steps

in a training area and only use

the machine in the areas

specified for deployment when

you are familiar with all the

operations.

3.3.1 Switching on

The motor must not be started

when the hood is open! Risk of

injury through belt drive and

rotating fan!

Sweepmaster P650

Before starting the

Sweepmaster P650, pay

attention to the following:

1. Set the key switch (Fig. 10/1) to

Position 1.

2. Pull out the choke (Fig. 7/6) in the

case of a cold start.

3. Pull the recoil starter cord (Fig. 7/7)

until the starter clutch perceptibly

engages (slight resistance) and then

pull the starter cord (Fig. 7/7) hard

and fast to start the engine.

4. Release the starter cord (Fig. 7/7)

and let it recoil back into the housing.

5. Then push the choke (Fig. 7/6) back

in, slowly.

If the engine does not start

immediately, use the starter

cord again exactly as

described above.

The engine and sweeping functions are

activated.

Sweepmaster B650

Set the key switch to Position 1.

28

Operation

3.3.2 Accelerating

When the engine is running:

1. Use your fingers to pull the drive bar

(Fig. 11/1) against the handlebar

(Fig. 11/2).

2. Steer the machine with the

handlebar (Fig. 11/2) in the required

direction.

Fig. 11

3.3.3 Stopping

1. Release the drive bar (Fig. 11/1).

The machine decelerates and

comes to a stop.

Do not park the machine on

carpets while the engine is

running. Risk of fire through

the flooring overheating due to

the rotating rotary brush!

Exception: The machine is

equipped with a carpet kit

(option) which automatically

switches the rotary brush off

when stopping the machine.

3.3.4 Vacuumsweeping

Ensure sufficient ventilation

when sweeping indoors!

It is forbidden to sweep up

dust which represents a health

hazard!

1. Check the machine,

refer to paragraph 2.2.

2. Open the bypass flap if damp waste

is to be cleared up.

3. Switch the machine on,

refer to paragraph 3.3.1.

The engine and sweeping functions

are activated.

Drive away immediately after

switching on the machine

otherwise it is possible that

marks will be produced on the

floor by the rotating rotary

brush.

12

29

Operation

4. Lower the side brush: Move the lever

(Fig. 7/1) forwards.

5. Accelerating: pull the drive bar up,

refer to paragraph 3.3.2.

6. Drive to the ground surface to be

cleaned.

Steps and curbs up to a height

of 4 cm can be driven over,

carefully. When driving over

thresholds, release the drive

bar and tip the machine back a

little so that the front roller can

negotiate the step.

7. Operate the shaking device

occasionally, refer to paragraph

”Operating the shaking device”.

8. Check the contents of the dirt hopper

regularly and empty as necessary,

refer to paragraph ”Emptying the dirt

hopper”.

Do not overload the dirt

hopper! This can affect the

stopping distance. Caution,

particularly when sweeping up

dirt such as metallic chippings!

Tip out the dirt hopper from a

low height when emptying to

prevent dust swirling around! If

necessary, pay attention to the

wind direction and evade any

clouds of dust! Health hazard!

3.3.5 Switching off

Turn the key switch to Position 0.

Remove the ignition key when

leaving the machine to prevent

unauthorized use.

30

Operation

3.3.6 After finishing work

1. Operate the shaking device.

2. Empty the dirt hopper.

3. Check the brush area for any

residual waste and remove it if

necessary, refer to Section

“Cleaning the brush space“.

4. Clean the machine, if necessary.

Warning - do not clean

electrical components with

liquids! Risk of electric shock!

It is not permitted to clean the

machine with a pressure

washer or steam blaster.

Operating the shaking device

Push and pull the lever (Fig. 8/6) in and

out several times in succession to clean

dust from the panel air filter.

Only operate the shaking

device when the engine is

switched off.

Emptying the dirt hopper

1. Move the locking lever (Fig. 8/8) to

the right (looking to the front) and, at

the same time, tip the handlebar

(Fig. 8/2) to the front.

2. Remove the dirt hopper (Fig. 12/2)

from the machine and empty it.

Carry the dirt hopper

(Fig. 12/2) by the handles

(Fig. 12/1).

Fig. 12

Observe the applicable laws

and local regulations when

disposing of waste.

3.3.7 Loading and transportation

When loading the machine and

transporting it to its area of

deployment, the side brush

must be raised.

Loading

When loading the machine, take its

weight into account, refer to Section

‘‘Technical Data‘‘.

Transp orti ng

The machine must be properly

secured. It must not slip or tip

during transportation! Risk of

injury!

When transporting on a vehicle or

trailer, the machine must be secured

against rolling away: Lash down the

machine securely at the front and rear.

21

31

Operation

• Secure the machine at the front with

a strap which must be fed through

the two openings (Fig. 13/1) near the

front wheel (Fig. 13/2).

• At the rear, thread a strap around the

bottom ends of the handlebar and fix

the strap to the transporter.

Fig. 13

3.4 Function faults

• If the machine is overloaded, the

engine speed drops.

Set the key switch to Position 0.

Check the side brush, rotary brush

and brush area for residual waste

and remove the waste, if necessary.

Ensure that there is sufficient fuel in

the tank (only Sweepmaster P650)

or that the battery is sufficiently

charged (only Sweepmaster B650).

Start the machine. If the fault occurs

again, contact a Hako service

center.

If the machine cannot be

switched off, pay attention to

the rotating fan when you

disconnect the cable or pull out

the spark plug connector! Risk

of injury!

3.5 Options

The basic machine can be upgraded by

adding further components. The order

and spare parts numbers for these

components are provided in brackets.

• Carpet kit (6460)

By fitting the carpet kit on the

Sweepmaster B650, the machine is

converted for clearing up dry waste

from carpets.

Please refer to the spare parts

catalogue on our internet site

at www.hako.com for

accessories, such as rotary

brushes, side brushes etc.

2

1

1

32

Technical Data

4 Technical Data

Machine length cm 110

Machine height (handlebar folded forward) cm 72

Machine width (including side brush) cm 69

Working width (with / without side brush) cm 71 / 51

Rotary brush width cm 51

Rotary brush diameter cm 25

Side brush diameter cm 40

Theoretical area coverage (with / without side brush) m²/h 3525 / 2525

Sweeping speed kph 5

Dirt hopper volume Liter 35

Load capacity, dirt hopper (Maximum 25 Kg!) kg 25

Filter surface m² 1,5

Power output (Sweepmaster P650 / Sweepmaster B650) kW 3.3 / 0.75

Weight, ready to use (Sweepmaster P650 / Sweepmaster B650) kg 102 / 122

Climbing capacity %2

Ambient temperature

Sweepmaster P650

Sweepmaster B650

ºC

ºC

-10 to +40

0 to +40

33

Technical Data

Noise emission values

Sweepmaster P650 Sweepmaster B650

The sound pressure level (LpA) (at the ear of the operator) measured according to DIN IEC 60335-2-72 under normal working

conditions is: dB (A) 77 66

Measurement inaccuracy (KpA): dB (A) 2 2

The sound power level (LwAd) measured according to DIN EN

60335-2-72 under normal working conditions is: dB (A) 92 84

Vibration values

The weighted, effective value of the acceleration, established in

accordance with ISO 5349-1, to which the upper limbs (handarm) are exposed under normal working conditions is:

m/s² < 2,5 < 2,5

The weighted, effective value of the acceleration, established in

accordance with ISO 2631-1 to which the body (feet-seat surface) is exposed under normal working conditions is: m/s² < 0,5 < 0,5

34

Maintenance and Service

5 Maintenance and

Service

General information

It is essential to pay attention

to the information in Chapter

"Safety Information" before

completing any service or

maintenance work!

By adhering to the maintenance work

recommended by us, you can be sure

that the machine is always ready to be

put into operation. Maintenance and

repair work necessary on a daily and

weekly basis can be carried out by an

operator trained to complete the work,

all other Hako system maintenance

may only be completed by personnel

who are correspondingly qualified and

trained. Please contact your nearest

Hako service center or authorized Hako

dealer. Failure to observe this annuls

any rights to claims under the terms of

guarantee in respect of resulting

damage or consequential damage.

Always specify the serial number in the

case of inquiries and spare parts

orders, refer to section 1.7 - Rating

plate.

5.1 Hako system maintenance

The Hako system maintenance:

• ensures that the Hako machine is

always ready for operation

(preventive maintenance),

• minimizes operating costs,

maintenance and repair costs,

• ensures the machine has a long

service life.

Hako system maintenance is arranged

into individual modules explaining the

special technical work to be carried out

and prescribes the intervals at which

the work should be performed. Parts to

be replaced for the individual

maintenance tasks are defined and

provided in spare parts kits.

Hako system maintenance,

customer

Work to be carried out by the customer

according to the service and

maintenance instructions in the

instruction manual (daily and weekly).

The driver/operator receives proper

instruction when the machine is

delivered.

Hako one-off system maintenance

After the first four weeks or the first 20

operating hours.

Hako system maintenance I

Six-monthly.

To be completed by skilled personnel

from an authorized Hako service center

according to the machine-specific

system maintenance with spare parts

kit.

Hako system maintenance II

Annually.

To be completed by skilled personnel

from an authorized Hako service center

according to the machine-specific

system maintenance with spare parts

kit - including safety check.

35

Maintenance and Service

5.2 Maintenance report

Handover

Upgrading

Test drive

Handover to customer

Instruction

completed on:

at _________________ operating hours

Hako system maintenance

after 4 weeks

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance I

six-monthly

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance II/S

annually

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance I

six-monthly

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance II/S

annually

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance I

six-monthly

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance II/S

annually

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance I

six-monthly

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance II/S

annually

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance I

six-monthly

Workshop Stamp

completed on:

at _________________ operating hours

Hako system maintenance II/S

annually

Workshop Stamp

completed on:

at _________________ operating hours

36

Maintenance and Service

5.3 Maintenance Plan

Hako system maintenance,

customer

The following maintenance work must

be completed by the customer. The

maintenance intervals must be

observed.

Activity

Interval

Daily Weekly

Check the battery charge, recharge if necessary (only Sweepmaster B650) oo

Check the engine oil level, refill engine oil if necessary

(only Sweepmaster P650)

oo

Empty the dirt hoppers oo

Clean the brush space oo

Clean the panel air filter in the dust vacuum using the shaking device, check it for

damage and replace if necessary

oo

Check the rotary brush and side brush; clean or replace as necessary oo

Check sealing strips (2 side aprons, 1 rear apron) for wear and clearance,

replace if necessary

o

Clean the air filter (only Sweepmaster P650) o

Check the function of the suction turbine o

Check the filter system (panel air filter) for leaks o

Check the seals on the dirt hopper o

Check the dirt hopper lock o

Check the sweeping pattern; readjust, if necessary o

Test drive and function test o

37

Maintenance and Service

Hako one-off system maintenance

After the first four weeks or the first 20

operating hours the

Sweepmaster P650 must be subject to

an engine oil change at an

authorized Hako service center.

Hako system maintenance I

The following maintenance work must

be completed by an authorized Hako

service center.

Activity

Once

after the first 4 weeks

or after 20 operating hours

Engine oil change (only Sweepmaster P650) o

Activity

Interval

Six-monthly

All the maintenance work in accordance with the weekly Hako system maintenance

customer

o

Check the drive belt for signs of wear and its tension,

replace or readjust as necessary

o

Engine oil change (only Sweepmaster P650) o

or every 100 operating hours

Change the air filter (only Sweepmaster P650) o

Check the condition of the tires o

Test drive and function test o

38

Maintenance and Service

Hako system maintenance II

The following maintenance work

must be completed annually at an

authorized Hako service center.

Activity

Interval

Annually

All maintenance work in accordance with Hako system maintenance I o

Check the function of the operating panel o

Check thew function of the on-board charger (only Sweepmaster B650) o

Check the Bowden cables for signs of wear; change, if necessary o

Check the suction turbine for signs of wear; change, if necessary o

Check the rotary brush bearing in terms of play and for signs of wear; change, if

necessary

o

Check the steering castor in respect of its running surface and bearing play; change,

if necessary

o

Check the rear wheels for bearing clearance and signs of wear of the running

surface; replace the wheel bearings and rear wheels, if necessary

o

Change the spark plug o

Clean the drive motor from carbon dust, check the carbon brushes run smoothly and

for signs of wear; change the carbon brushes, if necessary

o

Test drive and function test o

39

Maintenance and Service

5.4 Engine

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently! Remove the

ignition key.

1 Spark plug cable

2 Screw plug with dipstick and oil fill-

ing neck

3 Oil drain bolt

4 Vessel for engine oil change

(not part of scope of delivery)

5 Fastening nut

for air filter cover

6 Air filter cover

7Air filter

8 Fastening nut for air filter

9 Threaded pin

10 Oil sensor

Fig. 14

2

4

6

7

8

9

5

3

1

5

6

10

40

Maintenance and Service

5.4.1 Checking the engine oil level

1. Park the machine on a level piece of

ground.

2. Leave it to stand still for a time.

Do not check the engine oil

level directly after the machine

has been in operation.

3. Open the hood.

4. Clean the area around the oil filling

neck (Fig. 14/2).

5. Unscrew the screw plug with dipstick

(Fig. 14/2) counterclockwise and

check the oil level. The oil level must

be in the range between H and L.

6. If the oil level is near the L mark or

below, refill engine oil, refer to

paragraph 5.4.2.

7. If the oil level is considerably above

the H mark, drain off some engine

oil, refer to paragraph 5.4.3.

8. Screw the screw plug with dipstick

(Fig. 14/2) back in, clockwise.

9. Close the hood.

5.4.2 Refilling engine oil

Only use SAE 15 W 40 engine

oil. The engine has a max.

volume of approx. 0.6 l engine

oil.

1. Park the machine on a level piece of

ground.

2. Leave it to stand still for a time.

3. Open the hood.

4. Clean the area around the oil filling

neck (Fig. 14/2).

5. Turn the screw plug with dipstick

(Fig. 14/2) counterclockwise to

remove it.

6. Pour the oil (SAE 15 W 40) slowly in

the oil filling neck.

7. Check the new engine oil level, refer

to paragraph 5.4.1.

8. Top up with more engine oil, if

necessary, and check the engine oil

level again.

9. Screw the screw plug with dipstick

(Fig. 14/2) back in, clockwise.

10.Close the hood.

5.4.3 Changing/Draining the engine

oil change

Change the oil when the

engine is warm but switched

off.

1. Open the hood.

2. Position an appropriate collecting

vessel (Fig. 14/4) under the oil drain

bolt (Fig. 14/3).

3. Unscrew the oil drain bolt

(Fig. 14/3) and collect the escaping

oil in the vessel (Fig. 14/4).

4. Clean the oil drain bolt (Fig. 14/3)

with a clean cloth.

5. Remove the collecting vessel

(Fig. 14/4) and dispose of the waste

oil.

Observe the applicable laws

and local regulations when

disposing of waste oil and oily

cloths.

6. Screw the oil drain bolt (Fig. 14/3)

back in.

7. Fill up with engine oil SAE 15 W 40,

refer to paragraph 5.4.2.

41

Maintenance and Service

5.4.4 Oil sensor

The oil sensor (Fig. 14/10) installed

serves as a safety feature to protect the

engine from damage due to insufficient

oil.

In the event of insufficient oil, the

engine stops or cannot be started.

Check the engine oil level!

5.4.5 Disassembling the air filter

1. Open the hood.

2. Unscrew the fastening nut

(Fig. 14/5) securing the air filter

cover (Fig. 14/6).

3. Remove the air filter cover

(Fig. 14/6).

4. Unscrew the fastening nut

(Fig. 14/8) securing the air filter.

5. Pull the air filter (Fig. 14/7) from the

threaded pin (Fig. 14/9).

5.4.6 Cleaning the air filter

1. Disassemble the air filter,

refer to paragraph 5.4.5.

2. Beat the air filter lightly on a level,

solid surface.

3. If necessary, vacuum the air filter

carefully using a vacuum cleaner.

Do not damage the filter ribs!

4. If the air filter cannot be cleaned

sufficiently, replace the old air filter

with a new one.

5.4.7 Installing the air filter

1. Install the cleaned or new air filter

(Fig. 14/7) on the threaded pin

(Fig. 14/9).

2. Fix the air filter (Fig. 14/7) by

screwing the fastening nut

(Fig. 14/8) for the air filter on the

threaded pin (Fig. 14/9).

3. Replace the air filter cover

(Fig. 14/6).

4. Screw the fastening nut (Fig. 14/5)

for the air filter cover (Fig. 14/6) on

the threaded pin (Fig. 14/9).

5. Close the hood.

42

Maintenance and Service

5.5 Battery system

Only Sweepmaster B650.

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently!

Only batteries approved by

Hako may be used.

Batteries may only be handled

and changed by properly

skilled maintenance

personnel.

Only maintenance-free

batteries may be used.

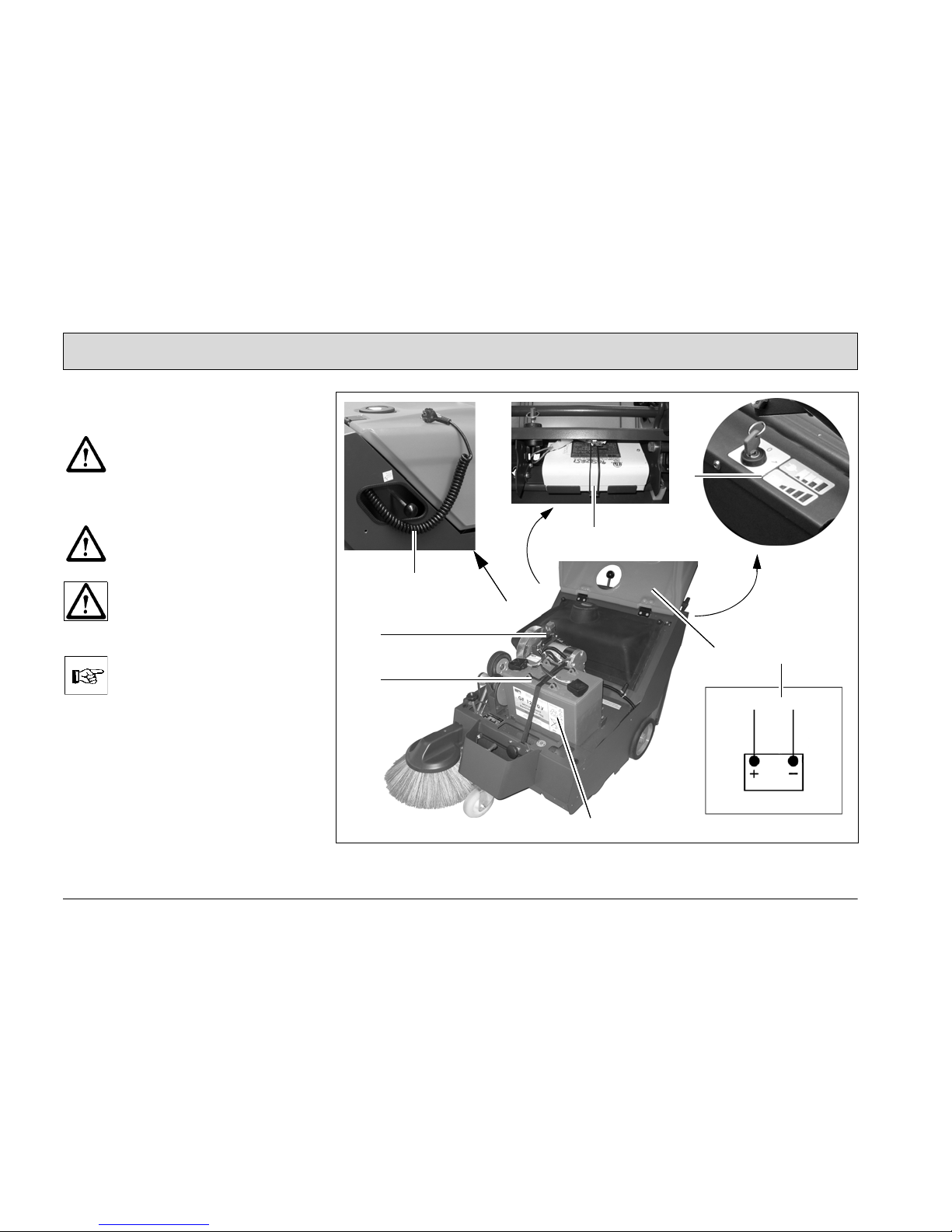

1 Charger cable

2 On-board charger

(housing disassembled)

3 Operating panel

4 Connection diagram

5Hood

6 Block battery

7 Handle

8 Fuses

Fig. 15

1

3

2

54

6

7

8

43

Maintenance and Service

5.5.1 Charging battery

Before starting the machine up

for the first time, the battery to

be used must be fully charged,

properly, by implementing the

initial battery charge routine.

Hako assumes no liability for

damage to the battery caused

by a fault when the battery is

charged for the first time.

During operation, the battery discharge

indicator in the operating panel

(Fig. 15/3) indicates the discharge

status of the battery, refer to Section

3.2.2, Section ”Battery discharge status

(Fig. 10/3)”. The battery must be

charged immediately the red LED lights

up. The battery (Fig. 15/6) is recharged

using the integrated on-board charger

(Fig. 15/2):

1. Set the key switch to Position 0.

The battery cannot be charged

in Position 1.

2. Remove the charger cable

(Fig. 15/1) from the recess on the

right-hand side of the machine.

3. Plug the charger cable

(Fig. 15/1) in a 230 V power outlet.

While the battery is charging, the

charge control indicator lights up in the

operating panel (Fig. 15/3), refer to

Section 3.2.2, Section "Charge control

indicator (Fig. 10/2)".

When the charging process

has been completed,

disconnect the plug from the

power outlet and return safely

to the recess.

5.5.2 Total discharge signal

transducer (TSG)

The machine is equipped with a total

discharge signal transducer to protect

the battery against total discharge. The

total discharge signal transducer is

integrated in the electronics.

5.5.3 Servicing the drive batteries

Never leave discharged batteries lying

around; recharge them immediately!

Notes on servicing drive

batteries is also provided in

supplementary sheet

88-60-2556 "Information on

Drive Batteries“.

5.5.4 Removing battery

Before the Sweepmaster B650

is tipped for any reason, the

battery must be removed!

1. Unlock the hood (Fig. 15/5) using a

square wrench and open the hood

(Fig. 15/5).

Ensure the engine has

stopped before opening the

hood. Risk of injury through

belt drive and rotating fan!

2. Disconnect the negative cable from

the battery (Fig. 15/6).

3. Disconnect the positive cable from

the battery (Fig. 15/6).

4. Release the retaining strap.

44

Maintenance and Service

5. Take hold of the battery (Fig. 15/6)

by their handles (Fig. 15/7) and lift

them out.

5.5.5 Inserting batteries

Only the special, maintenancefree batteries approved by

Hako may be installed at the

prescribed position.

1. Unlock the hood (Fig. 15/5) using a

square wrench and open the hood

(Fig. 15/5).

Ensure the engine has

stopped before opening the

hood. Risk of injury through

belt drive and rotating fan!

2. Take hold of the battery (Fig. 15/6)

by their handles (Fig. 15/7) and

install them at their prescribed

positions in the machine, refer to

Figure 15.

3. Secure the battery using the

retaining straps.

4. Connect the battery (Fig. 15/6) in

accordance with the connection

diagram (Fig. 15/4).

5. Connect the positive cable of the

machine to the battery (Fig. 15/6)

installed in the machine.

6. Connect the negative cable of the

machine to the battery (Fig. 15/6)

installed in the machine, refer to

Section 2.1.4.

Sparks could be produced

when connecting the battery!

7. Close the hood (Fig. 15/5) so that it

audibly locks.

5.5.6 Disposing of batteries

Used batteries with the recycling

symbol contain reusable commodities.

However, the heavy metals contained

also represent a major risk to human

health and to the environment. Never

open or damage batteries. Never touch,

inhale or swallow the content matter of

batteries. Health hazard! Do not allow

batteries to pollute the environment.

There is a risk of contaminating the

ground and water! In accordance with

the symbol with the crossed out bin,

these batteries must not be disposed of

in domestic waste. The return and

recycling of old batteries must be

agreed on with the authorized Hako

dealer in accordance with the Battery

Act §6 and §8.

45

Maintenance and Service

5.6 Drives

1 Suction turbine fan

2 Belt drive for rotary brush

and machine drive

3 Drive shaft (for rotary brush, side

brush and machine drive)

4 Belt drive for side brush

and rotary brush

5 Tension pulley for rotary brush drive

6 Friction wheel crank

7 Screw connection,

friction wheel bearing

8 Belt drive for machine drive

9 Friction wheel

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently!

Ensure the engine has

stopped before opening the

hood. Risk of injury through

running belt drives

(Fig. 16/2+4+8) and rotating

fan (Fig. 16/1)!

Fig. 16

1 2

9

8

5

4

3

6

7

46

Maintenance and Service

5.6.1 Adjusting the drive belt

If you notice that the rear wheel shaft is

no longer driven properly, it is possible

that the tension of the drive belts

(Fig. 16/2+8) is no longer sufficient or

the running surface of the friction wheel

(Fig. 16/9) is worn (distance between

wheel and running surface > 1mm).

1. Loosen the screw connection

(Fig. 16/7) in the friction wheel crank

(Fig. 16/6).

2. Tension the belt (Fig. 16/8) which

leads to the rear wheel shaft by

moving the friction wheel crank

(Fig. 16/6) in the slot using an

appropriate tool.

The friction wheel (Fig. 16/9)

thereby lies against the drive

shaft (Fig. 16/3).

3. Tighten the screw connection

(Fig. 16/7) in the friction wheel crank

(Fig. 16/6).

4. Check the belt tension with an

appropriate measuring instrument

(belt tension 95±5 Hz).

Fig. 17

1 Bowden cable

2 Tension spring

3 Adjusting nuts for Bowden cable

4 Hexagon nut

5Eye bolt

1

2

3

451 2

47

Maintenance and Service

5. Turn the hexagon nut (Fig. 17/4) so

far on the eye bolt (Fig. 17/5) until

the tension spring (Fig. 17/2)

tensions and the friction wheel

retracts 1-2 mm from the drive shaft

(Fig. 16/3).

6. Turn the hexagon nuts (Fig. 17/4)

one revolution further.

7. Complete any fine adjustment using

the Bowden cable adjusting nuts

(Fig. 17/3) on the handlebar: turn the

adjusting nuts (Fig. 17/3) so that the

distance between friction wheel and

drive shaft is between 0.4 and 1 mm.

48

Maintenance and Service

5.7 Side brush

1 Side brush control knob

(underneath the hood)

2Hood

3 Screws, plastic housing

4 Plastic housing

5 Side brush

6 Hexagon head bolt

7Washer

8 Side brush holder

9 Hexagon nut

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently!

Fig. 18

4

3

5

6

7

8

9

1

2

49

Maintenance and Service

5.7.1 Side brush wear,

readjustment

1. Unlock the hood (Fig. 18/2) using a

square wrench and open the hood

(Fig. 18/2).

Ensure the engine has

stopped before opening the

hood (Fig. 18/2). Risk of injury

through belt drive and rotating

fan!

2. Turn the side brush control knob

(Fig. 18/1) to adjust the height of the

side brush.

3. Close the hood (Fig. 18/2) so that it

audibly locks.

5.7.2 Changing the side brush

Check the side brush (Fig. 18/5) weekly

and change in the case of wear.

1. Switch the machine off and tip it

back, refer to Figure 19.

Before tipping the

Sweepmaster B650, the

battery must be removed, refer

to Section 5.5.4!

Before the Sweepmaster can

be tipped back, the handlebar

must be adjusted to a vertical

position.

Fig. 19

2. Remove the screws

(Fig. 18/3) from the plastic housing

(Fig. 18/4) and remove the plastic

housing (Fig. 18/4).

3. Remove the hexagon head bolts

(Fig. 18/6), the washers (Fig. 18/7)

and hexagon nuts (Fig. 18/9).

4. Pull the old side brush (Fig. 18/5)

from the side brush holder (Fig. 18/

8).

5. Install the new side brush (Fig. 18/5)

on the side brush holder (Fig. 18/8).

6. Fix the side brush (Fig. 18/5) with the

hexagon head bolts (Fig. 18/6),

washers (Fig. 18/7) and hexagon

nuts (Fig. 18/9) to the side brush

holder (Fig. 18/8).

7. Assemble the plastic housing

(Fig. 18/4) and fix it in place with the

screws (Fig. 18/3).

50

Maintenance and Service

5.8 Rotary brush

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently! Remove the

ignition key.

1 Rotary brush

2 Rotary brush segment

3 Bore holes

4Screw

5 Rotary brush shaft

6 Guide pin

7 Seal, dirt hoppers

Fig. 20

5

1

7

3

2

2

4

6

51

Maintenance and Service

5.8.1 Cleaning the brush space

The brush space with the rotary brush

(Fig. 20/1) and seals for the dirt hopper

(Fig. 20/7) must be checked daily for

signs of dirt and cleaned as necessary.

Only Sweepmaster B650:

Tapes winding around the

rotary brush leads shutdown

due to overloading!

1. Remove the dirt hopper, refer to

Section 5.9.1.

2. Check the brush space - the area

between the rotary brush, panel air

filter and dirt hopper - for residual

waste and damage.

3. Remove any foreign bodies.

4. Clean the brush space, firstly with a

hand brush and then with water. Dry

the brush space.

5. Change defective dirt hopper seals,

refer to Section 5.9.4.

5.8.2 Changing the rotary brush

The rotary brush (Fig. 20/1) must be

checked weekly and changed in the

case of wear. A new rotary brush has a

diameter of 25 cm. When a rotary brush

has a diameter of only 20 cm, it must be

replaced with a new one.

The rotary brush (Fig. 20/1) is

comprised of two rotary brush

segments (Fig. 20/2) which are fixed to

the rotary brush shaft

(Fig. 20/5) by the screws (Fig. 20/4).

Pay attention that the bristle pattern on

the rotary brush (Fig. 20/1) is always

arranged in a V-shape in the direction of

driving so that the dirt is guided to the

center of the rotary brush.

1. Tip the machine to the rear.

Before tipping the

Sweepmaster B650, the

battery must be removed, refer

to Section 5.5.4!

Before the Sweepmaster can

be tipped back, the handlebar

must be adjusted to a vertical

position.

2. First of all, disassemble the two

adjacent rotary brush segments

(Fig. 20/2): Loosen the screws

(Fig. 20/4) and remove the rotary

brush segments (Fig. 20/2).

3. Then turn the rotary brush shaft

(Fig. 20/5) 180º by hand and

disassemble the two remaining

rotary brush segments (Fig. 20/2).

4. Assemble four new rotary brush

segments (Fig. 20/2) in the reverse

sequence. When doing so, pay

attention that the rotary brush

segments (Fig. 20/2) are installed on

the guide pins (Fig. 20/6) of the

rotary brush shaft (Fig. 20/5) and

screw to facing rotary brush

segments

(Fig. 20/2) firmly to each other.

5. Tip the machine back up again.

52

Maintenance and Service

6. Install the battery again in the

Sweepmaster B650, refer to Section

5.5.4.

7. After changing the rotary brush

(Fig. 20/1), readjust the sweeping

pattern as necessary.

5.8.3 Setting the sweeping pattern

In the case of brush wear, and after

changing the rotary brush (Fig. 20/1),

the sweeping pattern must be

readjusted.

1. Push the machine onto a dusty

surface when the engine is switched

off.

2. Switch the machine on, refer to

paragraph 3.3.1, and allow the rotary

brush to rotate for a short time while

at a standstill.

3. Switch the machine off,

refer to paragraph 3.3.5.

4. Tip the machine up at the front a little

and pull the machine back a short

way.

5. Examine the sweeping pattern

(brush stroke) produced on the dusty

ground: The width of the sweeping

pattern must be approx. 5 cm. The

borders of the sweeping pattern

must be parallel.

Fig. 21

1 Rotary brush height control knob

6. Open the hood.

7. Adjust the height of the rotary brush

by means of the control knob

(Fig. 21/1).

8. Close the hood.

9. Repeat steps 1 to 8 until the

adjustment is correct.

5.8.4 Changing the sealing strips

The rotary brush is surrounded by four

sealing strips: a front apron, two rear

aprons (front and rear) and two side

aprons. The four sealing strips must be

checked weekly and changed in the

case of wear.

1. Tip the machine to the rear.

Before tipping the

Sweepmaster B650, the

batteries must be removed,

refer to Section 5.5.4!

Before the Sweepmaster can

be tipped back, the handlebar

must be adjusted to a vertical

position.

1

53

Maintenance and Service

1 Side apron, left

2 Screw connection

side aprons

3 Rear apron

(back rear apron)

4 Screw connection

rear apron

5 Side apron, right

Fig. 22

52

3

4

A

1

2

54

Maintenance and Service

Changing the side aprons

2. Unscrew the screw connections

(Fig. 22/2) in the side aprons

(Fig. 22/1+5).

3. Change the sealing strips and adjust

the side aprons (Fig. 22/1+5): There

must be approx. 1 - 2 mm clearance

to the floor.

4. Screw the screw connections

(Fig. 22/2) back in the side aprons

(Fig. 22/1+5). Also screw the ground

of the wing nut at Position A

(Fig. 22/A).

Changing the rear aprons

5. Remove the dirt hopper, refer to

Section 5.9.1.

6. Unscrew the screw connections

(Fig. 22/4) in the rear aprons

(Fig. 23/1+2).

7. Change the sealing strip and adjust

the rear apron (Fig. 22/3): The

clearance of the rear apron

(Fig. 23/2) from the ground must be

1 - 2 mm.

8. Screw the screw connections

(Fig. 22/4) back in the rear aprons

(Fig. 23/1+2).

Fig. 23

1 Front rear apron

2 Back rear apron

1

2

55

Maintenance and Service

5.9 Dirt hopper

1 Seal for dirt hopper

2 Handle for dirt hopper

3 Dirt hopper

4 Handlebar

5 Locking lever for dirt hopper

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently!

Fig. 24

3

2

4

5

1

56

Maintenance and Service

5.9.1 Removing the dirt hopper

1. Switch the machine off and move the

lever (Fig. 24/5) for locking the dirt

hopper to the right (looking in drive

direction) and, at the same time,

pivot the handlebar (Fig. 24/4)

forwards. The frame (Fig. 25/2) of

the dirt hopper is lowered.

The engine must be at a

standstill before the dirt hopper

(Fig. 24/3) is removed. Risk of

injury through swirling waste

and dust!

2. Hold the dirt hopper (Fig. 24/3) by

the handle (Fig. 24/2) and pull it to

the rear and out of the machine

Fig. 25

5.9.2 Emptying the dirt hopper

Check the fill level of the dirt hopper

(Fig. 24/3) regularly and empty it

regularly and as necessary.

Observe the applicable

national laws and local

regulations when disposing of

waste.

5.9.3 Inserting the dirt hopper

1. Insert the dirt hopper (Fig. 24/3)

back in the machine from the rear

until they perceptibly engage in the

frame (Fig. 25/2).

2. Pivot the handlebar (Fig. 24/4)

towards the rear until the lever

(Fig. 24/5) for locking the dirt

hoppers audibly engages.

5.9.4 Changing the seals

Check the dirt hopper seals (Fig. 25/1)

for wear on a weekly basis and change

the seals as necessary.

1. Remove the dirt hopper,

refer to paragraph 5.9.1.

2. Pull the seals (Fig. 25/1) from the

edges.

3. Press new seals (Fig. 25/1) on the

edges.

4. Insert the dirt hopper,

refer to paragraph 5.9.3.

2

1

57

Maintenance and Service

5.10 Dust vacuum

1 Knurled screws

2 Sealing strip

3Fan

4 Threaded pin

(for top filter cover lock)

5 Panel air filter

6 Bottom filter cover lock

7Hood

8 Filter cover

9 Shaking device lever

Before starting any

maintenance and repair work,

set the key switch to Position 0

to prevent starting the machine

inadvertently!

Fig. 26

12

4

5

4

6

6

8

9

7

3

3

58

Maintenance and Service

5.10.1 Clearing dust deposits from

panel air filter during

operation

Clean the panel air filter (Fig. 24/5) in

the dust vacuum regularly and as

necessary using the shaking device:

1. When the engine is switched off,

pull/push the lever (Fig. 24/9) of the

shaking device quickly, several

times.

5.10.2 Removing the panel air filter

1. Unlock the hood (Fig. 24/7) using a

square wrench and open the hood

(Fig. 24/7).

Ensure the engine has

stopped before opening the

hood (Fig. 24/7). Risk of injury

through belt drive and rotating

fan(Fig. 24/3)!

2. Release the top filter cover locks:

Unscrew the knurled screws

(Fig. 24/1) from the threaded pins

(Fig. 24/4).

3. Release the bottom filter cover locks:

Pivot the hinged locks (Fig. 24/6)

outwards.

4. Remove the filter cover (Fig. 24/8).

5. Remove the panel air filter

(Fig. 24/5).

5.10.3 Cleaning the panel air filter

thoroughly

Do not inhale the dust. Health

hazard! Wear an appropriate

dust mask.

1. Drop the panel air filter (Fig. 24/5) a

few times from a small height onto a

level, solid surface. Be careful not to

damage the filter ribs!

The ground must not have any

surface irregularities. Do not

drop the panel air filter

(Fig. 24/5) onto the ground at a

slant.

Never install panel air filters

(Fig. 24/5) which have

damaged filter ribs!

5.10.4 Replacing the sealing strips

If the panel air filter (Fig. 24/5) is

removed, check the self-adhesive

sealing strips (Fig. 24/2) for signs of

damage. Damaged sealing strips

(Fig. 24/2) must be replaced:

1. Pull off the damaged sealing strips

(Fig. 24/2).

2. Clean any residual adhesive from

the surfaces on which the sealing

strips (Fig. 24/2) must be adhered.

3. Adhere the new sealing strips

(Fig. 24/2).

59

Maintenance and Service

5.10.5 Inserting panel air filters

1. Insert the thoroughly cleaned or new

panel air filter (Fig. 24/5) from the

correct side in the filter support

frame.

Pay attention to the labeling on

the side of the panel air filter

(Fig. 24/5)!

2. Replace the filter cover (Fig. 24/8).

3. Close the bottom filter cover locks:

Pivot the hinged locks (Fig. 24/6)

over the edge of the filter cover

(Fig. 24/8).

4. Close the top filter cover locks:

Screw the knurled screws (Fig. 24/1)

on the threaded pins (Fig. 24/4).

5. Close the hood (Fig. 24/7) so that it

audibly locks.

5.10.6 Checking the suction turbine

1. Switch the machine on,

refer to paragraph 3.3.1.

2. Clean a dusty surface for test

purposes, refer to paragraph 3.3.4.

3. Switch the machine off,

refer to paragraph 3.3.5.

4. Remove the dirt hopper, refer to

Section 5.9.1.

5. Check whether dust has

accumulated on the inner side of the

panel air filter (Fig. 24/5).

6. If you have the impression that the

suction turbine does not work or dust

escapes from the machine, contact a

Hako service center.

Do not open the hood

(Fig. 24/7) when the engine is

running. Risk of injury through

belt drive and rotating

fan(Fig. 24/3)!

5.10.7 Checking the filter system for

leaks

Do not open the hood (Fig. 24/

7) when the engine is running.