Cleaning Technology · Municipal Technology

Scrubmaster B175 R (7180)

Operating Manual

Part number 88-10-3115 - 3922-xx

Valid as from: 04.2018

Introduction

Introduction

Foreword

Dear Customer,

We are certain that the excellent qualities of the machine will justify the faith

you have shown in us by your purchase.

To guarantee safe working with the machine, please read the Safety Notes

chapter before putting it into service.

Your own safety, as well as the safety of others, depends essentially on your

ability to control the vehicle. Please read this original operating manual

before you use the vehicle for the first time, act accordingly and keep these

instructions for future reference or subsequent users. The operating manual

contains all important information for operation, maintenance and care. We

have provided the places in this operating manual concerning your safety with

a danger pictogram. Your authorised Hako dealer is available at all times to

answer further questions about the vehicle or the operating manual.

We would expressly advise you that no legal claims may be asserted based

on the contents of this operating manual. In the case of necessary repair

work, please make sure that only original spare parts are used. Spare parts

must be original spare parts to guarantee safety. We reserve the right to make

changes in the interests of further technical development.

Hako GmbH

23843 Bad Oldesloe, Germany

Hamburger Str. 209-239

Phone +49 4531 806-0

Issue:

Index Book number Change no. Valid as from:

0 88-10-3115 3922-00 04.2018

2 00-7180-00.fm

Introduction

Intended use

Scrubmaster B175 R is a scrubber-drier for the wet cleaning of hard indoor

floor surfaces. This machine is intended for commercial use, e.g. in shopping

centres, swimming pools, shops, airports, schools and hotels. Any use extending beyond this is not intended use. The manufacturer is not liable for any damage resulting from this and the user alone bears the risk. Intended use also

includes compliance with the operating, maintenance and servicing conditions

specified by the manufacturer.

The Scrubmaster B175 R may be used, maintained and repaired only by

persons who are familiar with this work and instructed about the dangers.

The relevant accident prevention regulations as well as the other generally

recognised safety engineering and occupational medical rules must be

complied with.

The machine corresponds by virtue of its design and construction as well as in

the version distributed by us to the usual health and safety requirements of the

EC Directives (see Declaration of Conformity). This declaration loses its validity

in the event of a modification to the machine not authorised by us. The manufacturer is not deemed liable for any damage resulting from unauthorised modifications to the machine.

Notes on warranty

The terms defined in the purchase agreement apply. Claims for compensation

in relation to damage are excluded from the terms of the warranty when the

damage is the result of the failure to observe rules concerning servicing and

maintenance. Maintenance work must be carried out by an authorised Hako

service workshop and confirmed in the “Maintenance Report”, which serves as

a warranty logbook.

The following are excluded from the terms of warranty: wear and tear through

overuse, defective fuses, improper handling and use and unauthorised modifications. Claims under the terms of the warranty are also annulled when damage occurs to the machine resulting from the use of parts or accessories not

explicitly approved of by us or from failure to observe maintenance rules.

00-7180-00.fm 3

Introduction

Acceptance of the machine

Inspect the machine immediately on delivery for signs of transport damage.

You will be compensated for transport damage provided you immediately have

the damage confirmed by the transport company and send in the damage report together with the consignment note to us.

Machine data

Your machine is described clearly by the following data. Please always quote

these data in correspondence or when making a telephone query to your

authorised Hako dealer or our company.

• Machine type

• Manufacturing no.

• Start-up on:

Your nearest authorised Hako dealer:

• Address:

• Telephone:

4 00-7180-00.fm

Table of contents

1 Safety instructions ......................................................... 8

1.1 Warning and danger symbols ......................................... 8

1.2 General safety instructions ............................................. 9

1.3 Operating safety instructions ........................................ 10

1.4 Maintenance instructions .............................................. 11

1.5 Information about special risks ..................................... 12

1.6 Environmental protection instructions and disposal ..... 14

1.7 Labels on the machine ................................................. 15

2 Operation....................................................................... 18

2.1 Overviews ..................................................................... 18

2.1.1 Front view ..................................................................... 19

2.1.2 Rear view ...................................................................... 21

2.1.3 Control panel ................................................................ 22

2.2 Controls and display elements ..................................... 24

2.2.1 Control panel ................................................................ 24

2.3 Multifunction display (MFD) .......................................... 29

2.3.1 Menu guidance ............................................................. 29

2.3.2 Main menu .................................................................... 30

2.3.3 Sub-menu ..................................................................... 36

2.3.4 Controls at the machine ................................................ 40

2.4 Functional description: .................................................. 42

2.4.1 Solution tank ................................................................. 42

2.4.2 Rotating brush and roller brush unit ............................. 43

2.4.3 Side brush unit .............................................................. 43

2.4.4 Wiper ............................................................................ 43

2.4.5 Squeegee ..................................................................... 44

2.4.6 Waste water tank .......................................................... 44

2.4.7 Suction turbine .............................................................. 44

2.4.8 Travel drive ................................................................... 45

2.4.9 Brakes .......................................................................... 45

2.4.10 Batteries ....................................................................... 45

3 Operation....................................................................... 46

3.1 Instruction ..................................................................... 46

3.2 Before putting into service ............................................ 46

3.3 Check list: Before machine start-up .............................. 47

3.3.1 Installing the mains cable ............................................. 47

3.3.2 Driver's seat .................................................................. 48

3.4 Cleaning ....................................................................... 50

88-00-3115-01IVZ.fm 5

Table of contents

3.4.1 Fleet-Recorder (option) ................................................ 51

3.4.2 On-board dosing system (option) ................................. 52

3.4.3 Useful cleaning tips ...................................................... 53

3.4.4 Handling and braking the vehicle ................................. 54

3.4.5 Pushing the machine .................................................... 55

3.4.6 Turning off the machine ................................................ 56

3.4.7 Check list: After cleaning .............................................. 56

3.5 Loading and transporting .............................................. 57

3.6 Service information ....................................................... 58

4 Technical data............................................................... 61

5 Maintenance and Servicing ......................................... 64

5.1 Maintenance certificate ................................................. 65

5.2 Maintenance plan ......................................................... 66

5.3 Battery .......................................................................... 69

5.3.1 Checking the charging state ......................................... 69

5.3.2 Charge the battery ........................................................ 70

5.3.3 Checking the acid level ................................................. 74

5.3.4 Replacing the battery .................................................... 75

5.3.5 Battery plug coding ....................................................... 76

5.3.6 Maintaining drive batteries ............................................ 77

5.3.7 Taking the machine out of service for a long period ..... 77

5.3.8 Disposing of batteries ................................................... 77

5.4 Solution tank ................................................................. 78

5.4.1 Filling the solution tank ................................................. 78

5.4.2 Emptying the solution tank ........................................... 80

5.4.3 Cleaning the solution tank ............................................ 80

5.5 Waste water tank .......................................................... 81

5.5.1 Emptying the waste water tank ..................................... 81

5.5.2 Cleaning the waste water tank ..................................... 82

5.5.3 Cleaning the coarse dirt sieve ...................................... 83

5.5.4 Cleaning the intake sieve ............................................. 83

5.5.5 Checking the seal at the drain valve ............................. 83

5.5.6 Cleaning the fresh water filter ....................................... 84

5.5.7 Checking the seal in the tank cap ................................. 84

5.6 Rotating brush unit ....................................................... 85

5.6.1 Replacing the brushes/pads ......................................... 85

5.6.2 Cleaning the brushes .................................................... 85

5.6.3 Ejecting the brushes/pads ............................................ 86

5.6.4 Coupling the brushes/pads ........................................... 86

5.7 Roller brush unit ........................................................... 87

6 88-00-3115-01IVZ.fm

Table of contents

5.7.1 Emptying the dirt hopper .............................................. 87

5.7.2 Replacing the brushes .................................................. 88

5.7.3 Cleaning the brushes .................................................... 88

5.7.4 Disassembling the brushes .......................................... 88

5.7.5 Installing the brushes .................................................... 88

5.8 Side brush unit (optional) .............................................. 89

5.8.1 Adjusting the side brush ............................................... 89

5.8.2 Changing the side brush ............................................... 90

5.9 Squeegee ..................................................................... 91

5.9.1 Cleaning the squeegee ................................................. 91

5.9.2 Changing the sealing / slot strip ................................... 93

5.9.3 Adjusting the sealing strips ........................................... 94

5.10 Wiper ............................................................................ 96

5.10.1 Changing the wiper rubber ........................................... 96

6 Attachments/options.................................................... 97

6.1 Spray suction tool ......................................................... 97

6.2 Manual suction tool: ...................................................... 98

6.3 Spray nozzle ................................................................. 99

EC Declaration of Conformity ................................. 101

88-00-3115-01IVZ.fm 7

Safety instructions

1 Safety instructions

1.1 Warning and danger symbols

Important tasks concerning the safety of the operator and machine are named

as follows in this operating manual and emphasised by symbols.

Danger

Indication of a direct danger with high risk, in which death or severe

physical injury can occur if it is not avoided.

Warning

Indication of a possible danger with average risk, in which death or

severe physical injury can occur if it is not avoided.

Caution

Indication of a danger with low risk, in which light to medium severe

physical injury or material damage can occur if it is not avoided.

Attention

Attention indicates a hazard that can lead to technical damage when

not observed.

Environmental danger

Environmental danger due to the use of substances from which a

health and environmental risk proceeds.

Note

Indication of information that facilitates more effective and economical use of the machine.

8 01-7180-00.fm

Safety instructions

Note

Before starting up the machine, read the following safety instructions

and act accordingly. Machine operating errors can be avoided and

trouble-free operation can be guaranteed only with precise factual

knowledge.

1.2 General safety instructions

• Apart from the instructions in this operating manual, the general safety and

accident prevention regulations of the legislation must be taken into

account.

• Before the machine is put into service, please carefully read the operating

manual you receive as well as further separate instructions for additional

implements or attachments and observe them in all aspects of your work.

• The machine may be used, maintained and repaired only by persons who

have been instructed by Hako experts.

• The machine is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities or by persons lacking the

required experience and knowledge.

• Children should be supervised to ensure they do not play with the machine.

• The operating manual should always be available at the machine's place of

use and should therefore be stored with the machine.

• Please hand over these documents to the new owner/operator on sale or

rental of the device. Have the hand-over confirmed!

• The labels attached to the machine provide important information for safe

operation. Renew labels that are no longer legible or present.

• Only wheels (wheel tyres) approved by Hako may be used.

• With Hako-AntiBac® machine variants, the plastic inner surface of the fresh

water and waste water tanks contains silver ions in nanoparticle form.

• Spare parts must be original spare parts to guarantee safety.

01-7180-00.fm 9

Safety instructions

1.3 Operating safety instructions

Before putting into service

• Before initially starting up the machine, charge the used battery fully and

appropriately with commissioning charge. Please observe the operating

manual of the charger and the operating manual of the battery manufacturer. Hako assumes no liability for battery damage resulting from insufficient commissioning charge.

• Check the machine for operating safety before every start-up! Eliminate

faults immediately.

• Before starting work, the operator must familiarize himself with all

equipment, operating and actuating elements as well as with their function.

It is too late to do this during operation!

During operation

• Sturdy and slip-proof shoes must be worn when working with the machine.

• Only those surfaces approved by the contractor or its authorised representative for use of the machine may be driven on.

• If the machine is used in areas in which objects may fall down, this is only

permitted if it has a roof which protects the driver.

• When working with the machine, pay special attention to third persons,

especially children.

• When driving over thresholds, raise the brush head.

• Only use detergents suitable for automatic machines (foam retarded) and

observe the application, disposal and warning instructions provided by the

detergent manufacturer.

• The machine is not suitable for removing liquids, dusts or materials that are

dangerous to health, combustible or explosive. It is also prohibited to collect

burning objects, e.g. glowing cigarettes. The collection of wood dust, e.g.

beech and oak dust, is also prohibited – health hazard!

• Excessive quantities of dust must be avoided when working with the side

brush unit!

• The machine is not suitable for collecting large quantities of water, e.g. in

the event of flooding.

• For reasons of safety, the driver's seat is equipped with a seat contact

switch. The machine can only be started when the driver is sitting on the

driver's seat. The function of the seat contact switch must not be bypassed.

• The machine must not be used in potentially explosive atmospheres.

• It is not permitted to transport other people or heavy objects.

• When transporting the machine, raise the squeegee and the brush head.

Adjust your way of driving to local conditions.

10 01-7180-00.fm

Safety instructions

• Drive slowly on wet surfaces, particularly in bends, due to the risk of

skidding.

• Drive slowly into the bend when driving downhill.

• For cleaning, the machine must only be used on a level surface with a

maximum slope of 6 %.

• Transport journeys on slopes of up to 10 % must only take place for a

limited period of time and with special caution.

• Manipulating the switches and protective devices is forbidden.

After operation

• Remove the key when leaving the machine to prevent unauthorised use.

• After use, park the machine in a dry, indoor location with the brush head

and squeegee raised.

1.4 Maintenance instructions

• Daily and weekly maintenance work must be done in accordance with the

maintenance plan by the operating staff. In all other maintenance work,

please contact your nearest Hako service centre.

• The maintenance work and maintenance intervals specified in the

operating manual must be complied with.

• Suitable tools and protective clothing such as gloves and safety goggles must

be used during cleaning and maintenance work.

• Have the machine checked for safe condition by an expert in accordance

with the accident prevention regulations at appropriate intervals (we

recommend at least once yearly).

• Spare parts must at least comply with the technical requirements specified

by the manufacturer. This is guaranteed by original spare parts.

• Turn the machine off and disconnect the battery connector when cleaning

and maintaining the machine and before replacing parts.

• To prevent unauthorised use of the machine, remove the ignition key.

• Cleaning the machine with a high-pressure cleaner or steam jet is not

allowed.

• Application of aggressive and corrosive detergents is not allowed.

• After cleaning, let the machine air dry, e.g. over the weekend.

• Only put the machine into service when all the protective devices are

attached and in protection position.

01-7180-00.fm 11

Safety instructions

1.5 Information about special risks

Electrical system

• If the electrical system is faulty, always turn off the machine, disconnect the

battery and eliminate the fault.

• Work on the electrical system may be done only in accordance with

electrical engineering standards by a specialist trained for this work.

• Regularly inspect/check the electrical system of the machine. Defects such

as loose connections, loose nuts of electrified bolts, electrical components

or damaged cables must be eliminated immediately.

• Only use original fuses with the specified current. If stronger fuses are

used, the electrical system can be destroyed and fires may occur.

Batteries

• Observe the operating manuals and safety instructions provided by the

battery manufacturer.

• Never connect or disconnect batteries when the machine is turned on.

• Make sure the batteries are never fully discharged; recharge them as

quickly as possible.

• Only instructed maintenance personnel must handle and replace batteries.

• Only batteries approved by Hako may be used at the intended position.

• Danger! Make sure that the insulation of the battery cables is not damaged.

The battery cables should not rub against anything. If the insulation is

defective, no longer use the machine and have the battery cables replaced

by the Hako customer service immediately.

• Caution! Always make sure that the batteries are clean and dry to avoid

creeping currents and corrosion damage. Protect the batteries, in

particular, against conductive contamination, e.g. metal dust.

• Risk of short circuits and spark formation! Never place tools or other electrically conductive objects on the battery!

• Do not remove insulating caps and covers, if necessary re-install them after

carrying out work on the battery cables.

• Caution! Explosive gases can develop when charging the batteries.

Avoid smoking, fire or naked light in the vicinity of batteries. Ensure sufficient ventilation when charging the batteries.

• For further safety instructions, see Hako supplementary sheet 88-60-2556

– information for drive batteries.

Power connection and mains plug

• Only connect the machine to an electrical connection installed by an

electrician in accordance with IEC 60364-1.

• We recommend connection to a fused socket with a residual current circuit

breaker (max. 30 mA).

12 01-7180-00.fm

Safety instructions

• We recommend use of splash water protected sockets according to

DIN VDE 0620-1.

• Make sure the socket is dry!

• Only touch the mains plug and the mains cable with dry hands.

• Never insert the mains plug into the socket when the floor is wet or damp.

• Never dip the mains cable or mains plug in water or other liquids or clean it

under running water.

• Damp mains plugs or mains plugs that have become wet must no longer be

used. Water can enter the mains plug. Only qualified electricians must carry

out recommissioning.

• Check the mains cable regularly for damage. If damage is detected, the

machine must no longer be used. Have a qualified electrician replace the

mains cable.

• Make sure that no water or liquid can come into contact with live parts of

the machine. If water has still entered parts, immediately disconnect the

mains plug and have the machine checked by the authorised Hako service.

01-7180-00.fm 13

Safety instructions

1.6 Environmental protection instructions and disposal

If the end of use of the machine or of its components is reached and this is

handed over for scrapping, the components must be correctly disposed of.

Further information about disposal is available through the competent local

authorities and the authorised Hako dealers.

Do not dispose of products with this symbol in domestic waste.

Disposal takes place through local collecting points or the

manufacturer.

Recycle used materials with this symbol according to their labelling and do not dispose of them in domestic waste.

• Observe the applicable laws and local regulations when disposing of dirt,

waste water and detergents, also see the German Water Resources Law

(WHG).

• Used batteries with the recycling symbol contain reusable commodities. In

accordance with the symbol showing the crossed-out garbage bin, these

batteries must not be disposed of in the domestic waste. Return and

recycling have to be arranged with the authorised Hako dealer as required

in § 6 and § 8 of the German battery law (BattG)!

14 01-7180-00.fm

Safety instructions

A

B

Fig. 1:

1

2

3

E

A

C

B

C

D

D

F

E

F

1.7 Labels on the machine

The following safety and instruction labels are affixed to the machine in a

clearly visible and legible manner.

Attention

Renew missing or illegible labels immediately!

01-7180-00.fm 15

Safety instructions

H

Fig. 2:

I

G

I

H

J

G

J

A

16 01-7180-00.fm

Safety instructions

Company logo label Fig. 1/Fig. 2-A

The Hako logo is located at the front on the steering column and at the rear on

the hopper.

Label

– Read and observe the operating manual Fig. 1-B1

– Maximum permissible slope 6 % when cleaning Fig. 1-B2

– Never clean the machine with a high-pressure cleaner Fig. 1-B3

The label is located on the left hand side next to the driver's seat.

Label – Maintenance parts (yellow dot) Fig. 2-C

The yellow dot is located on the cover of the fresh water filter.

Label – Type plate Fig. 2-D

The type plate is located in front of the left front wheel.

Label – Explosive gases Fig. 1-E

The label is in the battery compartment.

Label – 36 V Fig. 1-F

The label is in the battery compartment.

Label – QR code Fig. 2-G

The label is located on the control panel.

Label – Drain waste water Fig. 2-H

The label is located on the drain hose of the waste water tank.

Label – Drain fresh water Fig. 2-I

The label is located on the drain hose of the solution tank.

Label – Keep off! Fig. 2-J

The label is located on the rotating brush or roller brush unit.

01-7180-00.fm 17

Operation

19

21

10

3

Fig. 3:

1718 16 15 14 13

4

9

11

12

8

7

6

5

2 Operation

2.1 Overviews

The description in chapter 2 contains information on the function and handling

of the individual controls on the machine. The controls always have the same

item number in all chapters.

18 02-7180-00.fm

2.1.1 Front view

Item Designation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Steering wheel

Driver's seat

Tray

Flashlight on a pole

Key for electronic system cover

Key for side panelling

Holder for manual suction tool or manual spray suction tool

Drinks holder and storage compartment

Socket for USB connection

Side panelling

Ball cock

Fresh water filter

Wiper

Side brush unit

Collision protection

Working light

Operating brake

Travel drive

Warning device

Operation

02-7180-00.fm 19

Operation

19

32

33

28

Fig. 4:

34

22

20

21

23

24

29

30

31

2527 26

35

36

37

38

39

42

40

20 02-7180-00.fm

2.1.2 Rear view

Item Designation

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Mains cable

Accelerator pedal

On-board dosing system

Brush unit

Wiper

Solution tank

Maintenance opening solution tank

Squeegee water connection

Fresh water drain hose

Squeegee

Suction hose

Drain hose waste water

Waste water tank maintenance opening

Water connection

Spray nozzle

Battery compartment

Battery connector

Coarse dirt sieve

Waste water tank

Intake sieve

Filling opening

Automatic filling unit

Operation

02-7180-00.fm 21

Operation

46

48

51

Fig. 5:

45

47

49

58

53

55

42

59

52 5054

56

57

43 44

2.1.3 Control panel

Item Designation

42

Multifunction display (MFD)

43

Return button

44

Turn-push knob

Button – brush unit

45

Button – squeegee

46

Button – fresh water supply

47

Button – boost function

48

Button – on-board dosing system

49

22 02-7180-00.fm

Button – brush unit and squeegee

50

Button – driving direction selection

51

Button – I-Button Reader, Fleet-Recorder Standard

52

Key switch

53

Button – signal horn

54

Button – speed reduction forwards gear

55

Button – silent operation

56

Button – tool operation

57

Button – pre-sweep suction unit

58

Button – side brush unit

59

Operation

02-7180-00.fm 23

Operation

A

B

2.2 Controls and display elements

2.2.1 Control panel

The individual functions of the buttons on the control panel are described

below. The respective activated functions are visible as corresponding symbols in the multifunction display (MFD).

Key switch Fig. 5-53

The electrical system is switched on and off with the key switch.

• Position 0: The electrical system is switched off. The key can be pulled out.

• Position 1: The electrical system is switched on.

• The software version is displayed for approx. 1 second on the MFD,

followed by the last service code for approx. 3 seconds if necessary. The

operating hours meter is then displayed.

Driving direction selection button Fig. 5-51

The driving direction is selected with this button. The driving direction can be

changed while driving.

• Push the button (A): Forwards gear

• Push the button (B): Reverse gear

Note

A warning signal is output when in reverse gear. The maximum

speed when reversing is half of the maximum speed when driving

forwards.

24 02-7180-00.fm

Operation

Speed reduction button Fig. 5-55

The maximum speed when driving forwards is reduced by approx. 50 % with

this button.

• Push the button: Speed reduction ON

• Push the button again: Speed reduction OFF

Signal horn button Fig. 5-54

The signal horn is switched on and off with this button.

• Push the button: Signal horn ON

• Release the button: Signal horn OFF

Fresh water supply button Fig. 5-47

The fresh water supply is switched on and off with this button.

• Push the button: Fresh water supply ON

• Push the button again: Fresh water supply OFF

Boost function button Fig. 5-48

In order to remove heavy contamination, it is possible to boost the scrubbingvacuuming cleaning program (green button Fig. 5-50) and scrubbing (button

Fig. 5-45) using the boost function.

• Push and hold the button: The highest level of fresh water dosing and the

increased brush pressure are activated simultaneously.

• Release the button: The machine switches back to the operating mode it

was in before the boost function.

02-7180-00.fm 25

Operation

Brush unit button Fig. 5-45

The brush unit is lowered and raised with this button.

• Push the button: The brush unit is lowered. When actuating the accelerator

pedal, the brush drive and the water supply are switched on.

• Push the button again: The brush drive and the water supply are switched

off. The brush unit is raised.

Note

If the accelerator pedal is not actuated, the brush drive and the water

supply are switched off.

Squeegee button Fig. 5-46

The squeegee is lowered/raised and the suction turbine switched on and off

with this button.

• Push the button: The squeegee is lowered and the suction turbine switched

on.

• Push the button again: The squeegee is raised. After an after-run time of

approx. 15 seconds, the suction turbine is switched off.

Note

The squeegee is automatically raised when reversing. The suction

turbine drive remains switched on.

26 02-7180-00.fm

Operation

Button – on-board dosing system Fig. 5-49

The dosing system for the detergent is switched on and off with this button.

• Push the button: Dosing system ON

• Push the button again: Dosing system OFF

Brush unit and squeegee button Fig. 5-50

The brush and suction turbine drive are switched on and off simultaneously

with this button.

• Push the button: The brush unit, the side brush unit and the squeegee are

lowered, and the suction turbine is switched on. The brush drive and the

water supply are switched on when the accelerator pedal is actuated.

• Push the button again: The brush unit and the side brush unit are raised.

The brush drive and the water supply are switched off. The squeegee

continues to run for approx. 15 seconds to absorb residual water.

Button – Side brush unit Fig. 5-59

The side brush unit is switched on and off with this button.

• Push the button: Side brush unit ON

• Push the button again: Side brush unit OFF

02-7180-00.fm 27

Operation

Button – tool operation Fig. 5-57

The following tools can be switched on and off using this button when the

driver is not on the seat:

• Spray nozzle

• Manual suction or spray suction tool

If the machine does not have a particular tool, it is excluded from the switching

order.

• Push the button: Spray nozzle ON

• Push the button twice: Manual suction and spray suction tool ON

• Push the button again: Tool operation OFF

Button – silent operation Fig. 5-56

The suction turbine is switched to silent operation with this button.

• Push the button: Silent operation ON

• Push the button again: Silent operation OFF

I-Button Reader Fleet-Recorder Fig. 5-52

The I-Button Reader is used to activate the functions.

Red illuminated LED or warning sound after switching on the machine request

the activation of the operating data recording system via the I-Button Key.

• Push the I-Button-Key for approx. 2 seconds against the I-Button-Reader.

The red LED goes out. The machine is ready for operation.

28 02-7180-00.fm

Operation

Fig. 6:

A

B

C D

2.3 Multifunction display (MFD)

The functions and indicators of the machine are set and displayed with the

multifunctional display. After the machine is switched on, the operating system

and data are loaded and the start screen Fig. 6-A appears on the display.

After several seconds the view changes, and the main menu Fig. 6-B

appears. By selecting and confirming the soft key Menu selection Fig. 6-C

you are taken to the sub-menu Fig. 6-D.

Note

It is only possible to switch to the sub-menu if the cleaning functions

are switched off!

2.3.1 Menu guidance

The menu is operated with the turn-push knob Fig. 5-44

Menus and sub-menus are selected in the multifunctional display and the individual menu item values are set or changed with the turn-push knob. The following basically applies:

• Turn to select a menu item. The selected menu item is displayed with a

yellow border.

• Push to activate a menu item.

You can jump back to the previous menu using the return button Fig. 5-43.

02-7180-00.fm 29

Operation

Fig. 7:

A

B

C

2.3.2 Main menu

The main menu is divided up into three levels.

• Status level Fig. 7-A

• Function level Fig. 7-B

• Action level Fig. 7-C

Symbols at status level

Symbol Designation Meaning

Time The current time is displayed in hours and

minutes.

Changes can be made to the time in the

sub-menu.

Service alarm

clock

If the service alarm clock Days has elapsed, this

symbol is permanently visible.

Accelerator

pedal in neutral

This symbol appears when the accelerator pedal

is in the neutral position.

position

Speed reduction The symbol is displayed when the machine is

driving at reduced speed.

Parking brake The symbol is displayed when the parking brake

is activated.

30 02-7180-00.fm

Operation

Seat contact The warning symbol lights up if the driver gets

up from the driver's seat during operation. Main

functions, e.g. scrubbing, vacuuming and driving, are no longer possible.

User The symbol indicates the current user setting.

Silent operation The symbol appears when the machine is work-

ing in reduced-noise operation. The symbol also

appears at the Squeegee symbol.

Operating hours

meter

The operating hours in work mode are

displayed.

The operating hours for the individual units can

be called up in the sub-menu.

Service alarm

clock

If the service alarm clock Operating hours has

elapsed, this symbol is permanently visible.

Service indicator The symbol appears if a service case occurred,

but it had already been eliminated automatically

or by operator intervention.

Service indicator The symbol appears if a service case occurs. An

acoustic warning is also output and a four-digit

service code appears on the right next to the

symbol, see section 3.6

02-7180-00.fm 31

Operation

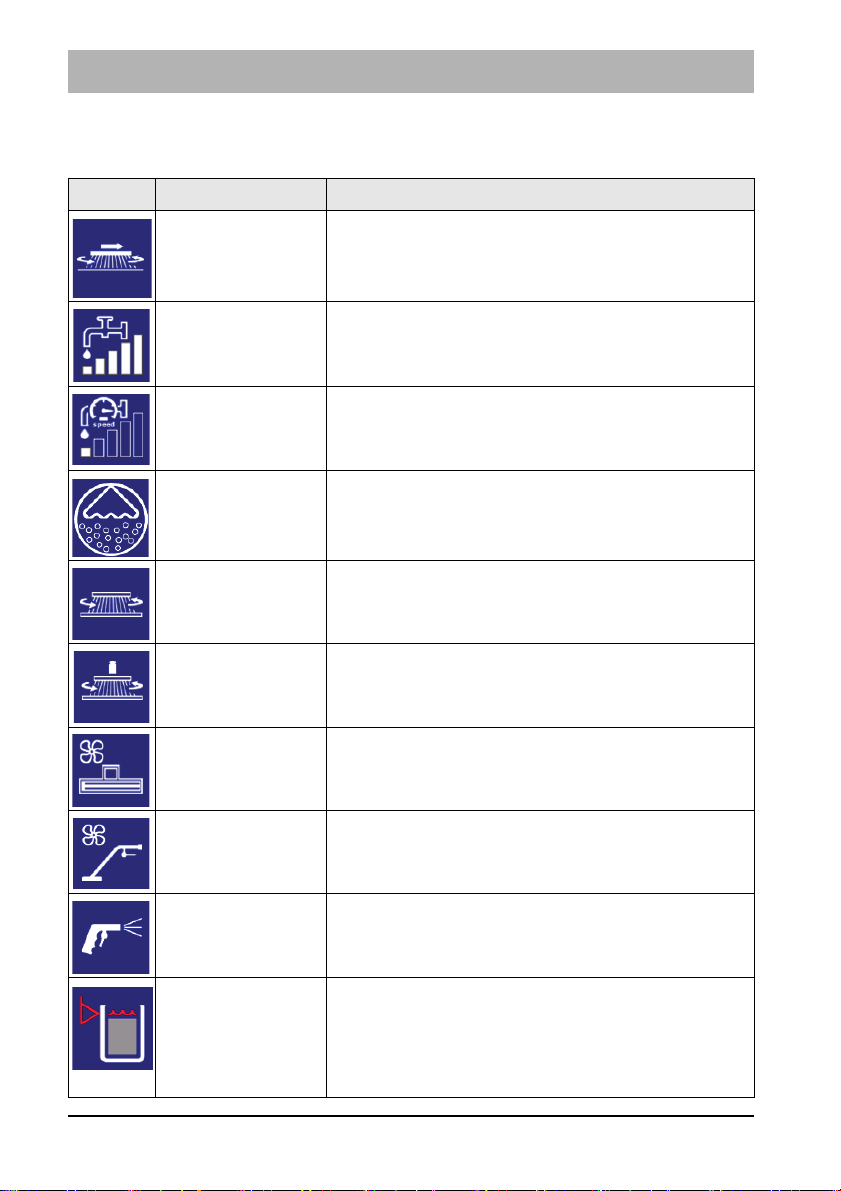

Symbols at function level

All active units are displayed as symbols at function level.

Symbol Designation Meaning

Side brush unit Side brush unit active

Speed-independent water dosing

Speed-dependent water dosing

The selected water dosing is displayed in the

bar diagram.

The selected water dosing is displayed in the

bar diagram.

Water quantity adaptive to driving speed.

On-board dosing

On-board dosing system active

system

Brush unit Brush unit active

Increased brush

pressure

Brush unit operating with increased brush

pressure

Squeegee Squeegee and suction turbines active

Manual suction

Manual suction tool or spray suction tool active

tool/spray suction

tool

Spray nozzle Spray nozzle active

Waste water tank

full warning

symbol

The symbol appears when the waste water tank

is full. An acoustic warning is also output, and

waste water collection is switched off. Empty

the waste water tank immediately, see section

5.5.1.

32 02-7180-00.fm

Symbol Designation Meaning

Solution tank

full

The current filling level of the solution tank is

shown descending in steps of 20 %.

Operation

Warning symbol – solution

tank empty

The symbol appears when the filling level of the

solution tank is approximately 10 litres. A warning

sound is additionally output.

Fill the solution tank immediately, see section 5.4.1

Battery

charging state

The current charge level of the battery is displayed

in steps of 10 %, see section 5.3.1

indicator

Additional symbols

For more information there are additional symbols, which are explained in the

following.

Symbol

Designation

Warning

symbol –

red spanner

Warning

symbol

Meaning

Faults in the functions are signalled by the red spanner. A 4-digit service code is also displayed at the

same time.

If this symbol appears, the unit

• is not installed or

• not configured

Example: On-board metering system not installed.

Symbol OFF If the symbol appears, the function is switched off.

Example: the water supply is switched off.

Function

symbol

displayed in

Interrupted functions are shown in yellow, e.g. if the

accelerator pedal is in the neutral position.

Example: Function interrupted by brush unit.

yellow

Symbol

displayed in

grey

If a symbol appears in grey, the function cannot be

started because the prerequisites for starting have

not been fulfilled.

Example: Switch to sub-menu not possible.

02-7180-00.fm 33

Operation

Fig. 8:

A B GFEDC

H

60

Action level

Settings can be made or actions performed in the action level using soft keys

Fig. 5-A to G.

The soft keys are selected by rotating the turn-push knob (soft key with yellow

border) and confirmed by pressing. An action window opens Fig. 8-H, in

which the actions can be carried out using the turn-push knob.

The following actions are possible:

Soft key Action

Setting

window/

soft key

A

Water

dosing

Depending on the presetting, the action window

appears for speed-dependent or speed-independent

water dosing.

• The water dosing has 5 settings:

• After reaching the highest speed-dependent water

quantity, the speed dependence is deactivated by

turning the turn-push knob clockwise.

B

Brush

pressure

Brush pressure increase ON/OFF

Green background = active

increase

34 02-7180-00.fm

Operation

C

Decoupling the

brushes

D

Coupling

the

brushes

E

Working

light

F

Flashlight

G

Forward

travel

warning

device

Ejecting the brushes, see section 5.6.3

Coupling the brushes, see section 5.6.4

Working light ON/OFF by means of direct selection

using the soft key.

If the working light is switched on, the colour of the

soft key changes from white to green.

Flashlight ON/OFF by means of direct selection

using the soft key.

If the flashlight is switched on, the colour of the soft

key changes from white to green.

The following settings can be selected in the action

window:

• Turn indicator ON/OFF

• Acoustic warning ON/OFF

• Turn indicator and acoustic warning ON/OFF

If the respective function is switched on, the colour

changes from white to green.

02-7180-00.fm 35

Operation

Fig. 9:

B

G

F

E

D

C

A

43

2.3.3 Sub-menu

Configuration can be carried out, operating data read off and the clock/calendar set in the sub-menu. Some sub-menus require additional access rights.

After calling up the sub-menu, the cursor automatically jumps to the operating

hours menu.

To return to the main menu, press

• soft key Home Fig. 9-A or

• the return key on the control panel Fig. 9-43

36 02-7180-00.fm

The following sub-menus can be selected:

Operating hours meter menu Fig. 9-B

• As well as the machine activation time

and work mode, the operating hours of

the individual units are displayed.

• The remaining time until the next

service is displayed in hours/days at

the bottom right. If a service is required,

the spanner appears in red.

Maintenance menu Fig. 9-C

The maintenance menu contains the

following menu items:

•The Maintenance instructions

sub-menu

• Activation/deactivation of speeddependent water dosing

• Activation/deactivation of automatic

squeegee cleaning

The Maintenance instructions sub-menu

opens, in which pictures for daily cleaning

and maintenance are stored.

When this menu is exited, a diskette

appears.

By selecting and confirming the Diskette

symbol, you are confirming that you have

carried out the maintenance.

Operation

Speed-dependent water dosing ON/OFF

Automatic squeegee cleaning ON/OFF,

see section 5.9.1

02-7180-00.fm 37

Operation

Time/date menu Fig. 9-D

User settings menu Fig. 9-E

Time:

• Choice between 12 hour or 24 hour

display

• Set the clock in hours and minutes

Date:

Set the date: day, month and year.

The set values are taken over when the

menu is exited.

The user settings menu contains:

• Selection of:

• Specified settings (1-6)

• User-specific settings (A-C)

• Definition of:

User-specific settings (A-C)

9 settings are available in the selection

menu:

• The specified settings (1-6) contain

predefined standard procedures

• User-specific settings (A-C) contain userdefined function procedures and function

restrictions.

The selected, active user setting is displayed with a number/letter with a green

background.

3 programs (A, B, C) with user-specific settings can be stored in this configuration

menu.

The modification of user profiles requires

additional access rights.

38 02-7180-00.fm

Configuration menu Fig. 9-F

The following settings are made in the configuration menu:

• Activate/deactivate options

• Setting of machine-specific parameters

Making changes to the configuration menu

requires additional access rights.

Service information menu Fig. 9-F

The last 10 items of service information are

displayed in the service information menu.

The operator can perform the following

actions:

• Delete the last service information when

• Obtaining detailed information

Deletion of the last service information

from the display:

Select the Delete symbol with the turnpush knob and press the turn-push knob

for 3 seconds.

The Delete symbol is now no longer visible

and the service code is no longer displayed after starting up the machine.

If the Information symbol appears next to

the service code, detailed information can

be requested.

Select the Information symbol with the

turn-push knob and confirm. Another window opens in which detailed information is

displayed.

Operation

the fault has been remedied

02-7180-00.fm 39

Operation

Fig. 10:

17

20

21

26

28

40

2.3.4 Controls at the machine

Mains cable Fig. 10-20

The mains connection supplies voltage to the on-board charger.

Operating brake Fig. 10-17

When the accelerator pedal is released, the machine comes to a stop due to

the braking effect of the travel drive. If this braking effect is not sufficient, the

operating brake can be applied in addition.

Accelerator pedal Fig. 10-21

The accelerator pedal is used to drive forwards or reverse and continuously

adjust the speed at the same time.

If the accelerator pedal is not actuated, it automatically returns to the zero

position and the machine stops.

Filling opening fresh water Fig. 10-40

The solution tank is filled via the filling opening. If the solution tank is filled

using fast filling, the grey cover can be removed to increase the size of the

filling opening.

Optionally, the solution tank can be filled via the automatic filling unit,

see section 5.4.1.

Fresh water drain hose Fig. 10-28

The solution tank is drained using the drain hose.

Solution tank maintenance opening Fig. 10-26

The cleaning opening is used for cleaning the solution tank.

40 02-7180-00.fm

Operation

Fig. 11:

12

31

10

11

32

Side panelling Fig. 11-10

The trough batteries and the suction turbines are behind the side panelling.

The side panelling can be easily removed using the provided wrench.

Waste water tank maintenance opening Fig. 11-32

The maintenance opening is used to drain the waste water and for cleaning

the tank.

Fresh water filter Fig. 11-12

When supplying water from the solution tank to the brush unit, the fresh water

is cleaned by the filter insert.

Ball cock Fig. 11-11

The ball cock is used to switch the water supply on and off manually in case

the fresh water filter needs to be unscrewed.

Drain hose for waste water Fig. 11-31

The waste water that is collected is drained using the drain hose.

02-7180-00.fm 41

Operation

25

23

Fig. 12:

7

14

40

29

2.4 Functional description:

Scrubmaster B175 R is a ride-on scrubber-drier for wet cleaning hard floor

surfaces. The Scrubmaster B175 R is intended for economical cleaning of

large operational areas.

In cleaning mode, the cleaning solution is supplied from the solution tank to

the rotating brushes in the brush unit. When the machine is moving forwards,

the used waste water is absorbed by the squeegee and conveyed into the

waste water tank.

A seat contact ensures that the machine can only be operated when the operator is sitting on the seat.

2.4.1 Solution tank

The solution tank Fig. 12-25 is filled via the filling opening Fig. 12-40. The

solution tank has a capacity of 175 litres. The current filling level is shown in

the multifunctional display. If the filling level is less than 10 litres in the tank,

the Tank empty symbol appears in the display and an acoustic warning indi-

cates that topping up is required.

42 02-7180-00.fm

Operation

Fig. 13:

A

13

B

2.4.2 Rotating brush and roller brush unit

The brushes in the brush unit Fig. 12-23 are driven by two electric motors.

The brush unit is lowered using the brush unit Fig. 5-45 button. When actuating the accelerator pedal, the brush motors and the water supply are switched

on. The floor is cleaned by the rotating brushes and the supply of cleaning

solution. The brush pressure can be changed in the MFD.

There is an indicator on the brush desk showing the amount of brush wear.

The brushes in the rotating brush unit can be ejected for maintenance purposes by pressing the Brush decoupler Fig. 8-C soft key in the MFD,

see section 5.6.3

2.4.3 Side brush unit

In order to brush up coarse dirt close to walls and beyond the squeegee, a

side brush unit Fig. 12-14 with two side brushes can be fitted at the front.

2.4.4 Wiper

To the right and left of the brush unit there are two wipers which avoid spray

water at the side in the working position and lead the waste water to the centre of the vehicle, where it is easier to vacuum up.

The wipers can be raised if necessary. To do this, raise the wiper at the handle Fig. 13-A and hook the locking hook Fig. 13-B into the bracket above it.

02-7180-00.fm 43

Operation

Fig. 14:

BA

2.4.5 Squeegee

The movable, hinged squeegee Fig. 12-29 is lowered and switched on with

the Squeegee button Fig. 5-46. The squeegee withdraws the waste water

from the floor using a sealing strip. The suction turbine vacuums the waste

water from the floor. If the machine passes through narrow sections, e.g.

checkout areas, the squeegee can be removed by loosening the star-shaped

handle and hooked into the cover Fig. 14-A of the waste water tank. The

squeegee can be swivelled up for maintenance purposes Fig. 14-B.

2.4.6 Waste water tank

The waste water vacuumed by the squeegee is conveyed via a suction hose

Fig. 14-30

from the squeegee into the waste water tank

Fig. 14-38

. A float

switch inside the waste water tank automatically switches the suction turbine off

when the maximum filling level is reached. In this case, a warning symbol illuminates in the MFD. An acoustic warning is output at the same time.

2.4.7 Suction turbine

The suction turbines are on the left-hand side of the machine and are accessible after removing the side panelling. The suction turbines are switched on

and off automatically when the squeegee is lowered and raised.

44 02-7180-00.fm

Operation

2.4.8 Travel drive

The travel drive consists of an electric machine and a gearbox, and fulfils the

functions of driving, braking and steering. Driving and braking are carried out

using the electric machine. Steering is carried out using a connected steering

rod. The gearbox does not require an oil change.

2.4.9 Brakes

The operator slows down the machine by releasing the accelerator pedal.

A greater braking effect is achieved by operating the brake. When the

machine comes to a standstill, the parking brake is automatically applied.

2.4.10 Batteries

The machine variants are equipped with different maintenance-free battery

types.

• Trough battery 36 V/320 Ah PzS, wet

• Trough battery 36 V/280 Ah PzV, maintenance-free

Battery management system (BMS)

The Scrubmaster B175 R is fitted with a BMS. The BMS ensures that the battery system is monitored and secure. The BMS is responsible for:

• determining the battery charging state during operation

• switching off the cleaning functions when the discharge limit has been

reached to protect the battery against total discharge

Attention

When using other batteries which have been approved by Hako, the

BMS must be reset to protect the battery against total discharge.

The settings of the BMS should only be carried out by a workshop

authorised by Hako!

For more information, see section 5.3.1

02-7180-00.fm 45

Operation

3 Operation

3.1 Instruction

Instruction is required before the first start-up. The first-time instruction of the

machine must be provided only by a specialist of your authorised Hako dealer.

This person will be notified immediately after delivery of the machine from the

factory and will contact you to make an instruction appointment.

3.2 Before putting into service

Attention

• Before initially starting up the machine, charge the used batteries

fully and appropriately with commissioning charge. Please

observe the instruction manual of the charging device and the

instruction manual of the battery manufacturer. Hako assumes no

liability for battery damage resulting from insufficient commissioning charge.

• Before the machine is initially put into service, install the countryspecific Hako mains cable.

• Check the machine for operating safety before every start-up!

Eliminate faults immediately.

• Before starting work, the operator must familiarize himself with all

equipment, operating and actuating elements as well as with their

function.

46 03-7180-00.fm

Operation

Fig. 15:

C

B

D

A

3.3 Check list: Before machine start-up

No. Description

1 Checking the parking area for signs of leaks. Cables and tanks must not

show any sign of leaks or damage.

2 Installing the mains cable, see section 3.3.1

3 Mounting the brushes and squeegee, see chapter Maintenance

4 Adjusting the driver's seat, if necessary, see section 3.3.2

5

Checking the battery charge and recharge it as required, see section 5.3.2

6

Emptying the waste water tank and clean it as required, see section 5.5

7 Filling the solution tank (see chapter Maintenance) and add detergent

according to the manufacturer's specifications

3.3.1 Installing the mains cable

1. Loosen the bolts of the cover Fig. 15-A using the supplied socket wrench

and remove the cover.

2. Route the cable of the mains plug Fig. 15-B through the opening in the

bracket Fig. 15-C. Ensure that the side of the strain relief without a latch is

facing the opening.

3. Push strain relief into bracket from below until all latches have engaged.

4. Plug the mains plug Fig. 15-D straight and firmly into the holder.

5. Reinstall the cover using the available screws.

03-7180-00.fm 47

Operation

Fig. 16:

A

3.3.2 Driver's seat

Attention

For reasons of safety, the driver's seat is equipped with a seat contact switch. The function of the seat contact switch must not be

bypassed.

Danger

Do not adjust the driver’s seat while driving. Risk of accident!

• Only adjust the seat if the machine is stationary.

• The driver’s seat must audibly engage after adjustment.

Adjust the driver’s seat in such a way that all controls can be easily reached.

Adjusting the standard driver’s seat

Sit on the driver’s seat and adjust as follows:

Adjust in longitudinal direction

• Push lever Fig. 16-A outwards.

• Move seat forwards or backwards.

• Release lever Fig. 16-A and let the driver's seat engage.

48 03-7180-00.fm

Operation

Fig. 17:

C

A

D

B

Adjusting the driver’s seat comfort

Sit on the driver’s seat and adjust as follows:

Adjust in longitudinal direction

•Push lever Fig. 17-A outwards.

• Move seat forwards or backwards.

• Release lever Fig. 17-A and let the driver's seat engage.

Adjusting the tilt of the backrest

Adjust the tilt of the backrest by turning the handwheel

Fig. 17-B

.

Adjusting the tilt of the armrests

Adjust the tilt of the armrests by turning the wheel Fig. 17-D.

The armrests can be folded up when not in use.

Adjusting the seat suspension

The seat suspension can be continuously adjusted to the weight of the driver

(50–120 kg) by turning the handwheel Fig. 17-C.

• Drivers who weigh less turn the handwheel Fig. 17-C to the left.

• Drivers who weigh more turn the handwheel to the right.

03-7180-00.fm 49

Operation

3.4 Cleaning

Attention

• Before operating the machine, read and observe the safety

instructions in chapter 1.

• The machine can only be put into service when the driver is sitting

on the driver's seat.

• The travel drive can only be started if the accelerator pedal is not

being actuated when the machine is turned on.

No. Description

1 Turn on the machine.

2 Activate the Fleet-Recorder (option)

3 Use the driving direction selection button to select the driving

direction

4 Select the cleaning programme

5 Actuate the accelerator pedal. The brush unit and the water

supply are switched on with the last selected setting.

6 If necessary, switch on the fresh water supply.

7 Set the fresh water quantity in the MFD using soft key Fresh

water dosing.

8 In the event of heavy soiling, increase the brush pressure

using soft key Brush pressure in the MFD or press the Boost

button for 1 minute.

50 03-7180-00.fm

Operation

Fig. 18:

B

C

A

3.4.1 Fleet-Recorder (option)

The Fleet-Recorder records operating times and further operating conditions

of the machine.

Putting into service

1. Turn the machine on with the key switch Fig. 18-A.

• Red LED of the I-Button Reader ON.

2. Press the I-Button Key Fig. 18-A against the I-Button Reader Fig. 18-B for

one to two seconds.

• Red LED OFF.

• Operating data recording system active.

If the machine is not registered with the I-Button Key, the following condition

arises according to the selected option:

Option Display LED Machine function* Data recording

50EC001 Red LED ON Fully functional The operating data

50EC002 Red LED ON Function of the

working tools locked,

transport possible

50EC003 Red LED ON, a

Fully functional

warning sound is

additionally output

after approx. 5 sec.

recording is activated or fully suppressed according

to the presetting.

GPS data is

recorded as

standard.

*deviating machine functions depending on the respective customer configuration possible

Note

A red illuminated LED or acoustic warning is a request for activation

of the operating data recording system via the I-Button Key!

Ending operation

Switch off the machine using the key switch.

03-7180-00.fm 51

Operation

Stage Detergent Mixing ratio

1 0.1 % 1:1000

2 0.2 % 1:500

3 0.3 % 1:333

4 0.4 % 1:250

5 0.5 % 1:200

6 0.6 % 1:167

7 0.7 % 1:143

8 0.8 % 1:125

9 0.9 % 1:111

10 1.0 % 1:100

49

Fig. 19:

F

B

C

E

D

A

3.4.2 On-board dosing system (option)

The on-board dosing system is used for optimum dosing of the detergent.

Attention

Only use detergents suitable for automatic machines (foam

retarded). We recommend use of our detergents and care agents

specifically developed for the machines. These products meet the

requirements of the German Detergent and Detergent Act (WRMG).

I

Putting into service

1. Release quick coupler Fig. 19-A at canister lid by pulling the lower ring of

the coupling upwards. Unscrew lid from filled canister. Screw on lid with

integrated hose Fig. 19-B and fit quick coupling with hose.

2. Turn the machine on with the key switch.

3. Switch on the dosing system using the On-Board Dosing System

Fig. 19-49 switch.

4. Press the quick ventilation switch Fig. 19-C at the dosing pump until detergent is present at the non-return valve.

Setting the mixing ratio

1. Remove the grey cover Fig. 19-D at the dosing pump.

2. Set the mixing ratio according to the detergent being used.

3. Basic setting = 1:700

Set the rotary knob Fig. 19-E between setting 1 and setting 2, see table.

52 03-7180-00.fm

Operation

Maintenance

Check the hose section Fig. 19-F in the hose pump (length approx. 23 mm)

and replace if necessary.

3.4.3 Useful cleaning tips

Sweep the floor before carrying out wet cleaning. This not only enhances the

cleaning effect but also reduces wear of the machine's working tools.

If the floors are really dirty or wax needs to be removed, treat the floor twice.

In the first step, scrub the floor with a detergent suitable for the degree of soiling; the squeegee remains raised for this.

Leave the detergent for approx. 5 to 10 minutes; subsequently scrub the floor

again and work with a lowered squeegee.

Note

• Only use detergents suitable for automatic machines (foam

retarded). We recommend use of our detergents and care agents

specifically developed for the machine. These products meet the

requirements of the German Detergent and Cleaning Agent Act

(WRMG).

• Observe correct dosing of the detergent. Correct dosing saves

money and protects the environment. Strong foam formation is a

sign of excessive dosing and impairs machine operation.

03-7180-00.fm 53

Operation

3.4.4 Handling and braking the vehicle

Note

Set the key switch to ‘0’ to immediately disable all the functions.

Danger

• Danger of tilting over when driving on excessively steep slopes

Transport journeys on slopes of up to 10 % must only take place

for a limited period of time and with special caution.

• Risk of skidding when driving on wet surfaces.

Drive very carefully into the bend when driving downhill.

Observe the following points when driving:

• Driving speed and braking of the machine are controlled via the accelerator

pedal.

• The engine brake is automatically applied when the accelerator pedal is

released. This also applies when ascending or descending.

• Stop the machine: Release the accelerator pedal.

• When the machine is at standstill, the parking brake is activated audibly. It

is no longer possible to push the machine, see section 3.4.5.

Overload protection

In case of an overload, e.g. excessively steep slopes, the drive motor is

switched off after a certain period of time.

• Let the machine cool down for approx. 15 minutes.

• Restart the machine.

54 03-7180-00.fm

3.4.5 Pushing the machine

Fig. 20:

B

A

C

Danger

Risk of accident! When pushing the machine, it does not have any

braking effect.

Only push the machine on a level surface!

After pushing the machine, only re-start it if the lever has been positioned and the cover installed.

Operation

In order to push the machine, carry out the following steps:

1. Loosen the bolts of the cover to the drive using the supplied socket wrench

and remove the cover.

2. Remove the pin Fig. 20-A from the holder and screw it into the ring

Fig. 20-B.

3. In order to unlock the parking brake, pull the pin upwards slightly Fig. 20-C

and simultaneously push the machine.

4. Disassembly is in reverse order.

03-7180-00.fm 55

Operation

3.4.6 Turning off the machine

1. Slowly bring the accelerator pedal to the zero position. The machine slows

down to standstill. A better braking effect is achieved when the machine is

slowed down by applying the brake.

2. When the machine is at standstill, the parking brake is activated audibly.

3. Switch off the cleaning functions.

4. Switch off the machine using the key switch.

Note

Remove the key when leaving the machine to prevent unauthorised

use.

3.4.7 Check list: After cleaning

Environmental danger

Observe the applicable laws and local regulations when disposing of

detergents.

Attention

Do not use a high-pressure cleaner or steam cleaner to clean the

machine.

No. Description

1 Drive to a suitable maintenance location.

2 Switch the machine off and pull out the key.

3 Empty and clean the waste water tank, see section 5.5.2.

4 Check the fresh water filter, see section 5.5.6.

5 Check the sealing strips and suction hose, see chapter Maintenance

and Servicing.

6 Check the functions and settings.

7 Charge the battery, see section 5.3.2.

8 Clean the machine. If the machine is not used over a longer period of

time, the solution tank must be fully emptied.

56 03-7180-00.fm

Operation

Fig. 21:

A

C

B

3.5 Loading and transporting

Attention

• When loading and subsequently transporting the machine to the

work site, the squeegee and brush head must be raised.

• Risk of skidding! Drive very carefully and, if possible, only on dry

ramps.

• To load the machine, reverse it up the ramp at idle speed

(maximum slope 16 %).

Loading

When loading the machine, observe its weight, see Section 4 Technical data.

Transporting

When transported on a vehicle or trailer, the machine must be secured

against tilting and rolling away. To do this, securely lash the machine at both

side Fig. 21-A, at the side Fig. 21-B and the rear Fig. 21-C with tension

straps.

03-7180-00.fm 57

Operation

3.6 Service information

In case problems occur with the machine, a four-digit service code is output in

the display panel in addition to the service indicator (tool key).

Eliminate the cause or note down the service code and inform your authorised

Hako service partner.

If the cause has been eliminated, the fault must be acknowledged via the key

switch OFF/ON.

Service

Fault Cause Remedy

code

1.2.2.1 Brushes/

Electrical defects Notify service partner

Roller stop

1.2.5.1/

1.2.5.2

1.2.6.1/

1.2.6.8

Brushes stop Foreign particles

between brush and

shaft

Brushes stop Foreign particles

block the brush

Inspect the brushes for foreign particles and remove

them if necessary

Inspect the brushes for foreign particles and remove

them if necessary

Brush not positioned

correctly in the holder

Actuate the brush decoupling system, contact

the service partner, if

necessary

1.2.6.3 Brush lift system, brush

and suction

turbine have

been switched

Foreign particles

between brush head

and machine

Brush head stuck Release brush head

Inspect the brush head for

foreign particles and

remove them if necessary

off

1.4.6.1 Squeegee lift

system stops

Overload due to foreign particles

Inspect for foreign particles

and remove them if

necessary

Foreign particles

between squeegee

and machine

Inspect the lift system for

foreign particles and

remove them if necessary

Squeegee jammed Make the squeegee

accessible

1.4.6.3/

1.4.6.4

Suction turbine stops

Foreign particles in

the suction turbine

Notify service partner

Faulty suction turbine

58 03-7180-00.fm

Operation

Service

Fault Cause Remedy

code

1.5.5.1 Fresh water level

not displayed

2.2.5.1 Rotating cylindrical brush stops

3.2.6.6. Service code indicator when turning on the

machine

3.3.1.1 Service interval

expired

3.4.1.2/

3.4.1.3

Driving not

possible

3.4.5.1. Cleaning function

switches off

3.6.6.4. Driving and cleaning not possible

5.8.7.1. Batteries are not

being charged

5.8.7.2 Batteries are not

being charged

Error in the electronics Notify service

partner

Foreign particles block the

brush

Inspect the rotating cylindrical

brush for foreign

particles and

remove them if

necessary

Discharged capacity of the

internal back-up battery of

Notify service

partner

the machine control

See maintenance

plan

Error in the drive control Turn the machine

OFF/ON, contact

the customer service if necessary

Drive wheel becomes

sluggish due to foreign

Remove foreign

particles

particles

Drive motor overheats Let the engine cool

down

Seat permanently loaded Relieve seat

Mains plug not inserted

correctly

Cables on the battery

poles loose or detached

Incorrect type of battery

installed

Insert the mains

plug correctly

Contact the customer service

Install correct

battery

03-7180-00.fm 59

Operation

7.1.5.1 USB connection

not working

Connected consumer

overloaded

Check whether the

consumer is drawing too much power

or there is a shortcircuit in the connected cable.

Internal controller defect Notify service

partner

60 03-7180-00.fm

4 Technical data

Dimensions

Technical data

Name

Length of machine with squeegee

without/with pre-sweep unit

Width of machine without/with

squeegee

Height of machine without/with

driver protection roof

Unit TB 900 TB 1080 WB 850

mm 1890/2670 1890/2670 1890

mm 940/1130 1120/1290 940/1130

mm 1450/2080

Working width

Brush unit mm 900 1080 850

Squeegee mm 1100 1260 1100

Weights

Weight (empty, without batteries) kg 450 455 440

Total weight (ready for use) kg 1010

Permissible total weight kg 1310

1015

1100

Driving performance

Driving speed transportation

(forwards/reverse)

Climbing capacity when cleaning % 6 (2 min)

km/h 8/4

Climbing capacity during transport

journey (ready for operation)

Ramp angle/Slope angle % 16

Turning circle (with squeegee) mm 2960 2970 2960

% 10 (1 min)

Wheels

Wheel diameter mm 305

Specific wheel contact pressure

front/rear

04-7180-00.fm 61

N/mm

2

0.66/0.65

Technical data

Tank contents

Name

Solution tank Litre 175

Waste water tank Litre 175

Unit TB 900 TB 1080 WB 850

Brush head

Brush speed rpm 210 210 850

Min./Max. brush pressure kg 35/70 38/70 29/38

Vacuum system

3

Air quantity 1/2 suction turbine

Vacuum (maximum) mbar approx. 50

m

100/200 200 100/200

/h

Electrical system

Nominal voltage V 36

Nominal output (max.) (P1) W 7470

Power consumption drive motor

(P1) S2-120 min

Power consumption of vacuum motor

(P1) 1/2 suction turbine

Power consumption brush motor

(P1)

W 2335

W 641/1282 1282 641/1282

W 2x936 2x936 2x918

Power consumption water pump

(P1)

Type of protection IPX 3

Protection class III

Wapprox. 67

On-board charger

Rated input/output voltage V 230/36

Nominal output W 1600

Type of protection IPX 3/P20

Protection class I

62 04-7180-00.fm

Noise emission value

Technical data

B175 R WZB B175 R TB

The sound power level (L

wAd

Standard

operation

)

Silent

operation

measured under the customary

conditions of use according to

DIN EN 60335-2-72 is:

dB (A)

85 80 85 80

The sound pressure level (LpA)

(at the ear of the driver) measured under the customary conditions of use according to DIN EN

dB (A)

68 64 68 64

60335-2-72 is:

Measuring uncertainty (KpA)

dB (A)

1.4 1.5 1.6 1.3

Vibration

Under the customary conditions of use, the weighted effective value of the acceleration to which the upper limbs (handarm) are subjected to according to DIN EN ISO 5349 is:

Under the customary conditions of use, the weighted effective value of the acceleration to which the body (feet or seat

surface) is subjected to DIN EN ISO 2631-1 is:

Standard

operation

m/s

m/s

Silent

operation

2

2

≤ 2.5

≤ 0,5

04-7180-00.fm 63

Maintenance and Servicing

5 Maintenance and Servicing

General

The operator is instructed fully on delivery of the machine.

Attention

Before undertaking servicing and maintenance work, read and

observe the safety instructions in chapter 1 of this operating manual!

Compliance with the maintenance work recommended by us gives you the

certainty of always having an operational machine available.

Daily and weekly maintenance and repair work can be undertaken by a driver

trained for this, all further Hako system maintenance work may be undertaken

only by trained and qualified personnel.

Please contact your nearest Hako service centre or authorised Hako dealer.

Any warranty claim is null and void if this is not complied with and damage

results.

Please always state the serial number in all enquiries and spare parts orders,

see section 1.7 – type plate.

Hako system maintenance

The Hako system maintenance specifies in single modules the special technical work to be done and the periods of time for the maintenance activities.

Parts to be replaced for the individual maintenance tasks are determined.

Hako system maintenance:

• Assures the reliable readiness for use of the Hako cleaning machines

(preventive maintenance).

• Minimises operating costs, repair costs, costs for maintenance.

• Assures long life and readiness for use of the machine.

Note

Maintenance parts in the machine are marked with a yellow dot and

yellow areas.

64 05-7180-00.fm

5.1 Maintenance certificate

Maintenance and Servicing

Handover

Equipment

Trial run

Handover to customer

Instruction

performed on:

at _______________ operating hours

Hako system maintenance I

750 operating hours

Workshop stamp

performed on:

at _______________ operating hours

Hako system maintenance II

1500 operating hours

Workshop stamp