Foil 1

Hakomatic B 1100

(7580.02)(7580.35)

Hakomatic B 1050

(7580.12/22)(7580.16/26)(7580.15)

Service-Handbuch

Service Booklet

Hako GmbH . Technisches Produktmanagement . D-23840 Bad Oldesloe . Stand 04/2012

Vertraulich – nur für den internen Gebrauch . For internal use only!

Schulung/Training

Fehlersuche/Trouble Shooting

Einstelldaten/Adjustments

Foil 2

Contents

1 Remarks 5

2 General 7

2.1 Settings 8

2.2 Brief Description 11

2.2.1 Switch Off Suction/Recovery Tank Filled Up 14

2.2.2 Initial Position Of Machine/Release, Lock Functions 15

3 Check Settings For Machine Type, TSG And Options,

Display And Delete Last Error 18

3.1 Check And Set Machine Type 23

3.2 Check And Set Options 24

3.3 Check And Set TSG 25

3.4 TSG Error 3211 28

3.5 View And Delete Last Appeared Error In The Display 29

4 Programming Different Cleaning Function Procedures Depending On

Accelerator Position (Check And Set) 30

4.1 Programme Functions 32

Foil 3

Contents

5 Specific Customer Settings (Display Of Last Error And Selection Of

Water Stage, Cleaning Agent, SWA, Side Brush, Filter) PPV 37

5.1 PPV1 40

5.2 PPV2 41

5.3 PPV3 42

5.4 PPV4 43

5.5 PPV5 (B 1100 only) 44

5.6 PPV6 (B 1100 only) 45

5.7 PPV7 (B 1100 only) 46

5.8 PPV8 (B 1100 only) 47

6 Setting Of Modules 48

6.1 Module 1 49

6.2 Module 3 50

7 Settings Of CAN Operator Panels (B 1100 only) 51

8 Water Pump 52

8.1. Water Amounts 52

8.2 Standstill Detection for Water Pump 54

Foil 4

Contents

9 Drive Controllers 55

9.1 SEVCON Controller (Diagnostic LED) 55

9.1.1 Signal Measurement On Controller (SEVCON) 58

9.2 ATECH / ZAPI Controller 63

9.2.1 Automatic Monitoring Of Components 65

9.2.2 Error Messages Displayed Via LED 66

9.2.3 Explanations For Displayed Error Messages 67

9.3 Drive Motor Hakomatic B1050 (Amer) 84

9.3.1 Tyre replacement 84

9.3.2 Check / replacement of carbon brushes 88

9.3.3 Diagnostic LED for drive control unit (Italsea) 89

10 Error Table With Information On Service Display 91

11 Notes 113

Foil 5

This document is structured so as to allow and seek continuous extension. You thus

receive the documents with the annotation that more or revised pages are to follow in

future.

This decision has been taken to allow adding modifications made to the machine

equally to the documents as revisions.

Beyond that this document may be improved upon your advice and proposals. I would

thus be grateful to receiving your feedback.

1. Remarks

Foil 6

Caution :

• Before working at the machine, disconnect voltage supply (pull battery plug)

except for the purpose of voltage and current measurement.

• When replacing stripe fuses, only loosen screws. Do not remove them completely

- short-circuit hazard.

Make sure to fully and evenly insert new blade fuses under the screws.

• After each repair proceed to starting and service current measurement to allow

detection of eventual defects.

• When working at the machine, comply with the general safety and accident

prevention regulations as provided by law.

1. Remarks

Foil 7

The Hakomatic B 1100 and the Hakomatic B1050 are equipped with a service indication

in the hourmeter display. Upon switching the key switch ON, a 4-digit code describing

the software version (e.g. 3.018), is displayed for about 3 seconds, followed by another

4-digit code signalling the last error which again is followed by the hourmeter indication.

Upon launch of the Hakomatic B1050, software version has updated to 4.020.

With the software revision 4.026 the Hakomatic B1100 TB 1230 was introduced.

As soon as a malfunction occurs, the red LED signalling a defect lights up and a warning

buzzer sounds. The current error code appears (as 4-digit alpha-numeric code in the

service display) with blinking dots between the digits. When all these criteria are met,

the error is a current one!

There is NO error code, containing a “0”.

Find the error codes listed in a table in chapter 11.

This document uses the following abbreviations:

TSG - low discharge signal sender

SWA - dirty water recycling

2. General

Foil 8

Settings on the control electronics/panel which have to be set and checked on

each machine:

In contrast to the Hakomatic B1100, scope of performance of the Hakomatic B1050 is

reduced and does not feature all the options available in the Hakomatic B1100. The

Hakomatic B1050PB (Plate Brush aggregate) has the side scrub unit optionally

available only; the Hakomatic B1050CB (Cylindrical Brush aggregate) has the side

broom unit optionally available, while the pre-sweeper, dirty water recycling and

cleaning agent dosage (99756402) options are available and settable for the

Hakomatic B1100 only. The B1050 PB 1230 doesn´t have any options adjustable via

the control moduls of the machine control system.

The Hakomatic B1100 PB1230 is equipped with the pre-sweep unit generally.

Machine type

TSG (low discharge signal sender - also called LDS)

Options

Delete display of last error after repair

Programme variants depending on the accelerator position

2.1 Settings

Foil 9

Settings which may be set via operator panel according to customer

requirements:

Display of last (remedied) error upon switching machine ON

Selection of water stage upon start of cleaning

Cleaning agent ON in addition to switching water ON (B1100 &

B1100 PB 1230 only)

Switching over to SWA upon switching water ON (B1100 only)

Side brush additionally ON in addition to switching ON scrubbing (B1100 and

B1050 PB only)

Side broom additionally ON in addition to switching ON scrubbing (B1050CB)

Filter shaking (B1100 only & B1100 PB 1230 )

Filter suction ON in addition to sweeping ON (B1100 only & B1100 PB 1230 )

Automatic filter shaking after sweeping (B1100 only & B1100 PB 1230 )

2.1 Settings

Foil 10

Settings at Module 1:

Dip-switch for electronic circuit-breakers

Settings at Module 3:

Dip-switch for electronic circuit-breakers and module coding

Settings at the additional operator panels (B1100 only):

Dip-switch for operator panel coding

2.1 Settings

Foil 11

Machine control is effectuated via the following electronics:

Control electronics

Module 1

Module 3 (for pre-sweeper, side broom and side brush, 3rd brush options)

Operator panel

Cleaning agent dosage /SWA operator panel (B1100 only)

Pre sweeper operator panel (B1100 only)

Cleaning agent module (optional, B1100 only)

Auxiliary voltage module (36V/24V transformer)

Voltage to the electronics is supplied by the auxiliary voltage module which transforms

36 Volts to 24 Volts. As the electronics are the same as integrated in the B910 and B

750R machines, the 24V electronics have to be transformed for use in the B 1100 and

B1050 machines. Components such as the motors and pumps, however, are still 36V

components.

The 24V voltage supply must not, even under load, fall below 23V since otherwise, supply

of the modules 1 and 3 would be insufficient and cause a CAN error (4000 error code).

2.2 Brief Description

Foil 12

The control electronics covers all control and monitoring functions in the machine

except for drive control.

Operation of drive controller is independent from the other electronics and only the

release signal and the signal for speed reduction are transmitted via control

electronics to drive controller. Beyond that, a signal is transmitted from drive controller

to control electronics for forward and reverse ride.

Upon occurrence of a defect on the drive controller, an error code is not output since

this controller has its own diagnostic indicator (see chapter 10).

The buttons for scrubbing, suction, scrubbing and suction and the green Hako button

for combined cleaning may be switched arbitrarily such that the selected function is

activated. Pre-sweeper/side broom and /or side brush function can be activated or de-

activated disregarding of the selected cleaning mode, if present in the machine.

The remaining functional buttons (water, brush ground pressure) allow activating or

de-activating the related functions in addition to the cleaning procedure without effect

on the running function.

2.2 Brief Description

Foil 13

The machine is equipped with a seat switch. Activation of this switch is required before

switching key switch on since otherwise sweeping and scrubbing functions (even in

combination) are locked. If the seat switch is not activated, suction can only be

activated for the „Hand suction hose“ option.

A reset of the machine after it was deactivated by the seat contact switch, is realized

by switching off and on again with the key switch.

Constant activation of the seat switch is also required. Leaving the seat while key

switch is ON causes locking of the functions.

The seat contact switch is 3 seconds delayed.

At the Hakomatic B1050 machines the sequence of switching on the machine (key

switch, seat contact switch), has no influence to the ability of function of the machine.

It is equally required to release parking brake to enable cleaning functions and drive

control is released.

To switch on the “TOOL”-function of the B1050 machines, it is necessary to activate

the brake of the machine.

2.2 Brief Description

Foil 14

The suction function is either stopped by the operator via button actuation or

automatically upon the „recovery tank filled up“ signal.

Switching off by operator:

Squeegee is lifted up

Suction motors switch off delayed (15 seconds)

Switching off after tank filled up:

The switch signalling „recovery tank filled up“ opens as soon as the tank is filled

If switch is open for 3 seconds or longer (spill protection) squeegee will be lifted

and the suction motors switch off with a delay of 15 seconds.

2.2.1 Switch Off Suction /

Recovery Tank Filled Up

Foil 15

When turned ON and the seat switch closed, all units of the machine are set to „initial

position“.

This means that the control electronic triggers all units (lifting elements and motors).

Lifting elements will be lifting up as long as they are not switched off by the microswitch controlling the upper limit position and integrated in the lifting element.

This means that the outputs for the lifting elements are powered for approx. 6 sec

every time the machine is switched on. During this time a voltage can be measured at

the outputs for the lifting elements.

Motors are off and the cleaning unit LED indication in the operator panel extinguishes.

The drive controller is transmitted the release signal.

Should the seat switch not be activated, the motors will also be turned off - for safety

reasons - but the lifting elements will not be lifting and the travel drive controller will

not be released either.

The only exception: water suction by hand hose (B1100).

2.2.2 Initial Position/Release,

Lock Functions

Foil 16

Before operation of the pre-sweeper (B1100 & B1100 PB 1230 only), the hood is to be

closed and the dirt hopper correctly inserted. The hood and the dirt hopper are

monitored each by a switch (NC switch) being serially connected. As soon as the

switch opens, the LED in the standard operator panel lights to signal „open hood“ and

the pre-sweeper function is disabled. Since both switches are serially connected, this

LED equally lights if the switch signalling „no dirt hopper inserted“ opens. In case of

faulty function, check the switch and all cable connections and connectors.

Another safety request is effected by the thermal switch of the broom motor. If this

switch opens, the pre-sweeper function will be disabled and an error code appears.

After engaging the parking brake, all cleaning functions will be disabled and the red

LED „brake engaged“ lights. This switch is an NC switch as well and it is thus

required, in case of faulty function, to check the switch, all cable connections and

connectors.

2.2.2 Initial Position/Release,

Lock Functions

Foil 17

Activation of the „Brushes“ function causes lowering of the brush head to the so-called

central position. The lifting element does not attain the lower limit position before

cleaning with increased ground pressure. The brush head lifting element thus has 3

micro-switches integrated, one each for the upper, the central and the lower limit

position.

Extracting the side brush unit is possible only after the brush head had lowered or in

other words: if the central position micro-switch does not switch, the „brush lowering

completed“ signal is missing and the side brush does not swing out. This signal

depends on the central position micro-switch only such that swinging out of side brush

is possible as well for cleaning with increased brush ground pressure. Since on its way

down to the lower limit position the central position micro-switch had been triggered

even if no fault occurred during cleaning with increased ground pressure.

2.2.2 Initial Position/Release,

Lock Functions

Foil 18

Check settings for machine type, TSG and options; display and delete last error

The settings described in this step are to be checked and modified if required.

Proceed to check and adjustment in particular after electronics replacement.

3. Machine Type Settings

Foil 19

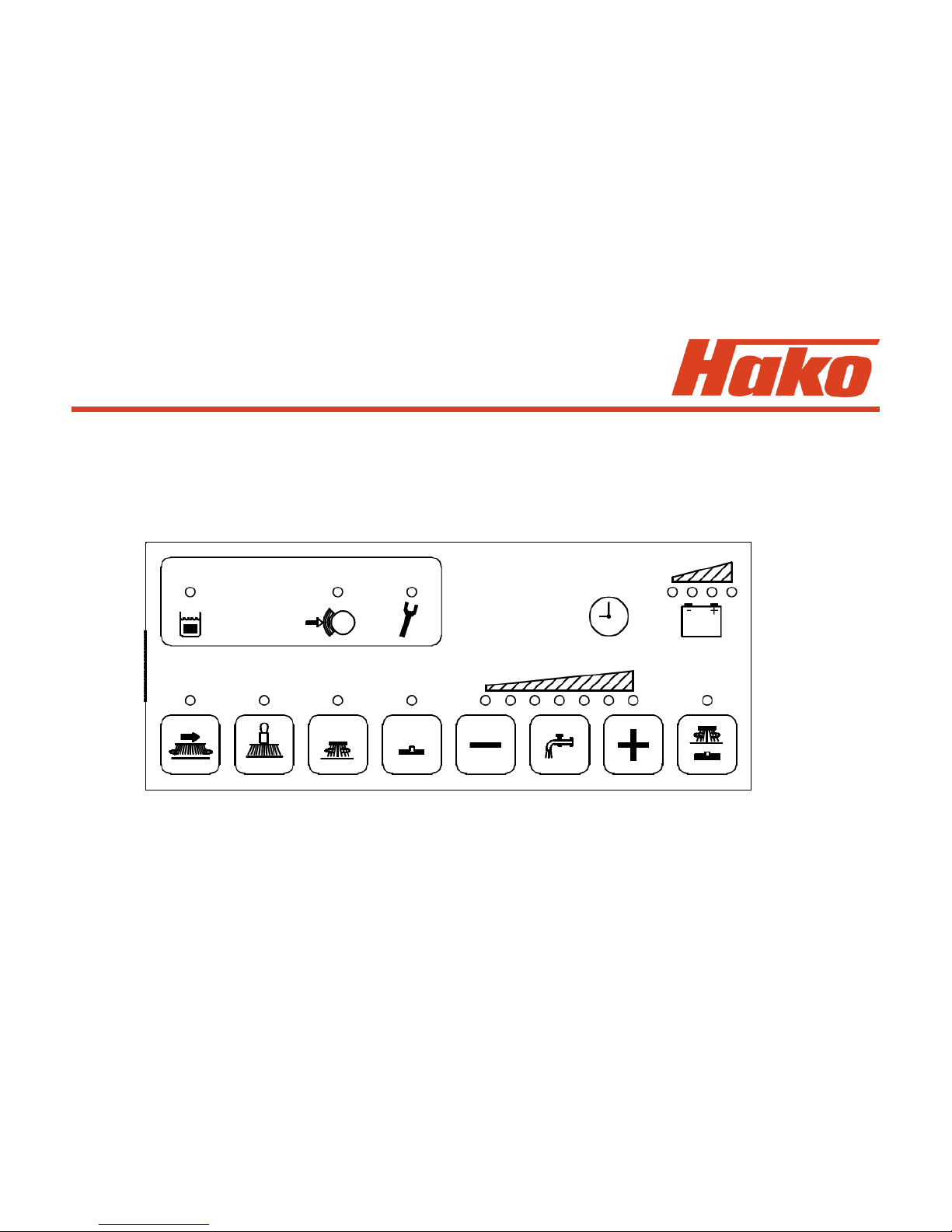

The picture shows the Hakomatic B1050 operator panel. Position of the programming

buttons is identical to those of the Hakomatic B1100. Only the icons differ due to the

different functional scope of this machine.

3. Machine Type Settings

B1050 PB & CB & PB 1230

Foil 20

Entry into programming

1. Switch off machine by key switch

2. Simultaneously press "G" and "H" and hold depressed, then switch on key switch

3. Hold depressed both buttons as long as the software version is displayed then

release buttons

Display of set machine type then appears automatically. Use the “N” button to proceed

to display of set options and display of TSG setting or then to display of last

(remedied) error. Use the “L” button to return to previous display.

Quit programme any time by switching OFF the key switch.

3. Machine Type Settings

Foil 21

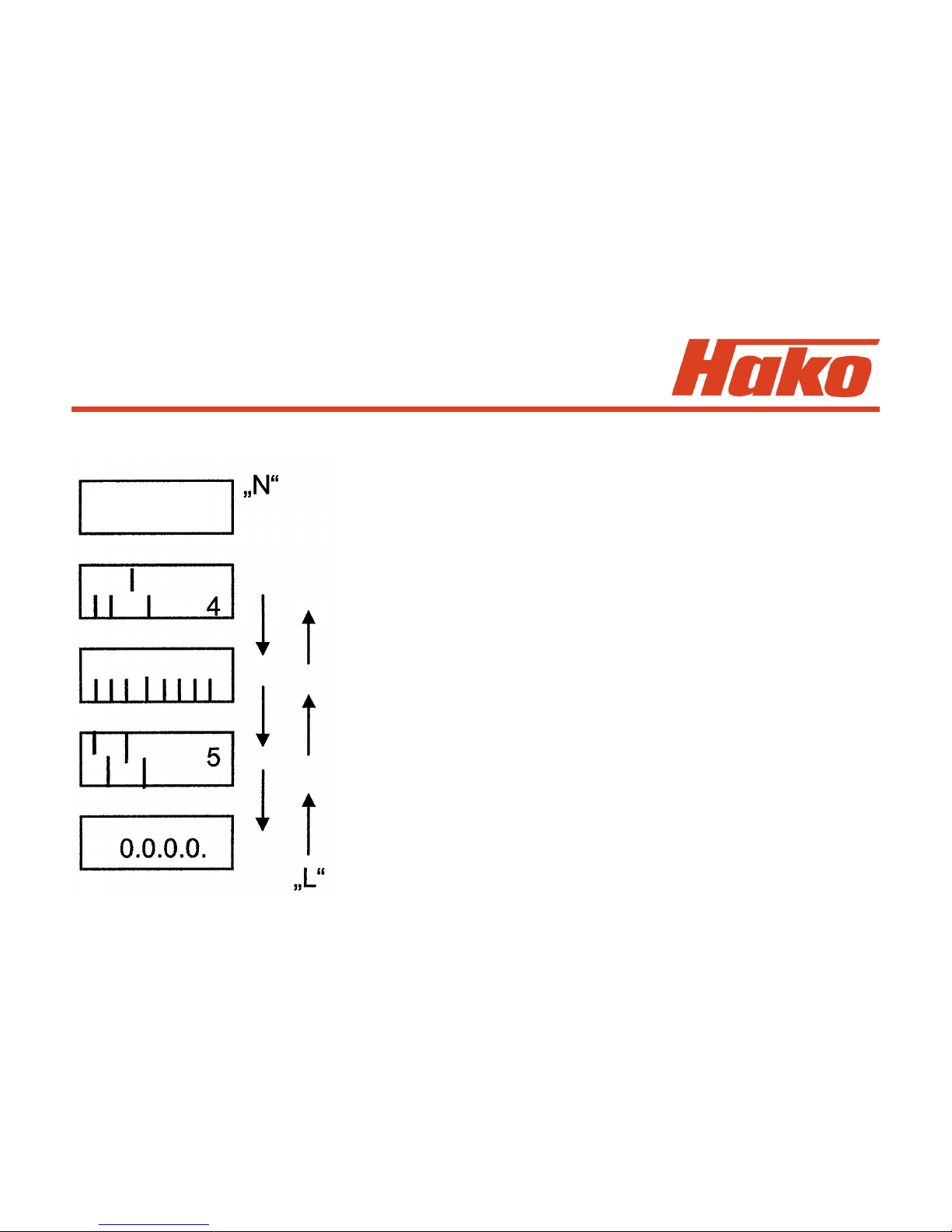

3. Machine Type Settings

Software version, automatic change to next

display

Set machine: 4 means B 1100; 11 means B 1050

13 means B1050 PB 1230;

14 means B1100 PB 1230

Set options

TSG setting

Display last error and reset

4020

Foil 22

3. Machine Type Settings

Control electronics

A1.X2

B

C

A

B1100 B1050 PB/CB B1050PB 1230

B1100-PB 1230

Foil 23

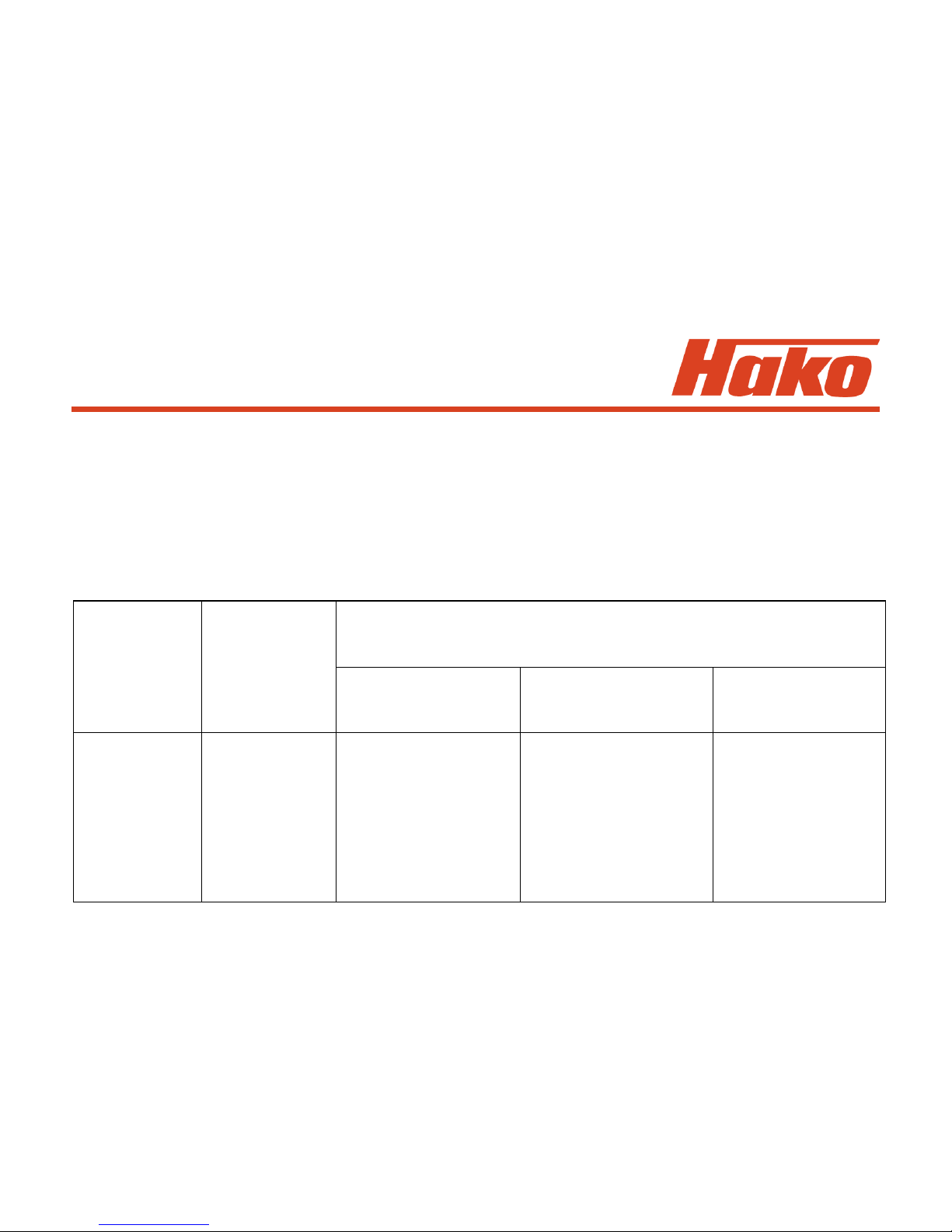

3.1 Check And Set

Machine Type

1. Make sure to have the correct machine type set. Use the Dip switch A on the

control electronics for setting (see foil 22)

2. For the B1100 machine, the bars no. 1, 2, 4 are to set in bottom and the bar no. 3 in

top position. This setting is a prerequisite for display of the cipher 4.

For the B1100 PB1230 machine, the bars no. 2, 3, 4 are to set in top and the bar 1

in bottom position. This setting is a prerequisite for display of the cipher 14.

For the B1050 machine, the bar no. 3 is to set in bottom and the bars 1, 2 and 4 in

top position. This setting is a prerequisite for display of the cipher 11.

For the B1050 TB 1230 machine, the bar no. 2 is to set in bottom and the bars

1, 3 and 4 in top position. This setting is a prerequisite for display of the cipher 13.

3. If other ciphers appear, modify combination at the Dip switch.

B 1100 1: OFF B 1100 1: OFF B 1050 1: ON B 1050 1: ON

2: OFF PB1230 2: ON PB / CB 2: ON PB 1230 2: OFF

3: ON 3: ON 3: OFF 3: ON

4: OFF 4: ON 4: ON 4: ON

Foil 24

3.2 Check And Set

Options

1. Setting each option in the machine is required at the Dip switch B (see p. 22)

on the control electronics.

2. The Dip switches are assigned as follows:

1: Cleaning agent dosage (B1100 &B1100PB 1230) (set = “ON”)

2: SWA (B1100 only) (set = “ON”)

3: Side brush (B1100 & B1050PB) (set = “ON”)

4: Tool (B1100 suction only) (set to “OFF”)

Tool (B1100 PB1230 & B1050PB / CB (set = “ON”)

and B1050 PB 1230 Spraying and suction)

5: Pre-sweeper (B1100 & B1050CB* (set = “ON”)

and B1100PB1230)

6: Cylindrical brush deck (B1050 only) (set = “ON”)

7 - 8: not assigned, i.e. “OFF”

* - for the B1050CB the side broom is activated.

3. An option is set if the Dip switch is set to ON.

Foil 25

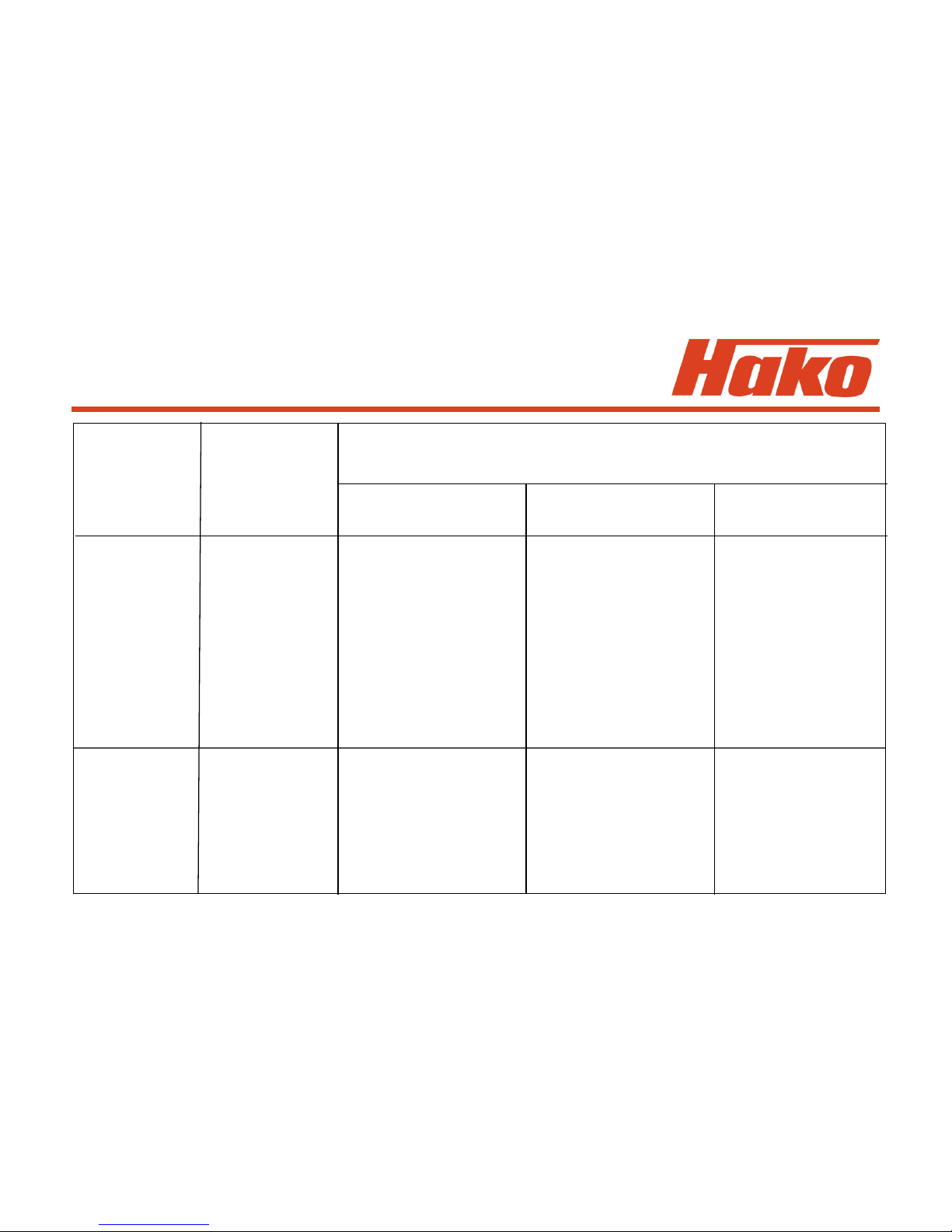

3.3 Check And Set

TSG

1. The TSG has to be set in any case to the correct battery type.

2. When fitting other battery types, modify TSG setting as described below by

using Dip switch C on the control electronics

(see p. 22)

3. Dip switch 4 is to set to 36 V (OFF).

Set the TSG according to the following table. (No. 5 - PzS - is the default setting)

Foil 26

3.3 Check And Set

TSG

“1” means ON; “0” means OFF

The addition “foreign” indicates batteries which are not delivered by Hako.

Reset voltage for the TSG: approx. 38.5V.

This voltage is required to reset the TSG capacity to 100%.

Caution: as far as maintenance-free gel batteries are concerned, the difference

between Sonnenschein and Deta is no longer made and setting depends on the

battery type. Setting 6 for GIV batteries and setting 7 for PzV batteries, irrespective

of the manufacturer. (For historical reasons, the designations Sonnenschein and

Deta remain in the documents).

The adjustments 0 and 1 (GiS USA) are for the use with US manufactured batteries

only.

Foil 27

3.3 Check And Set

TSG

GiS and GiV are Grid plate batteries,

PzS and PzV are Tubular plate batteries,

GiV and PzV are maintenance free batteries

in Gel-Technologie,

GiS and PzS are vented, low maintenance batteries with liquid electrolyte.

For block batteries the following short terms are also used:

GiS = FF

GiV = GF-Y; GF-V

PzS = FT

Trough batteries are available as following types:

EPzS and EPzV

Foil 28

3.4 TSG Error 3211

TSG - Remarks on the error 3211

The controller receives data from the TSG module in serial form and transmission of a telegram

takes one second. The 3211 error occurs when two telegrams with the same contents are not

received within 5 seconds and this equally is the case if there is no transmission at all.

Apart from an actual defect of the TSG the following causes are possible for this error message:

No voltage supplied to the TSG (MK controller: A1:X2.1 + 4)

TSG is in auto test mode: battery DIP switch set to off-off-off or on-off-off (1-2-3) -

from Software revision 4.020 on, this adjustments are used for US-american

batteries

After occurrence of the 3211 error it is also possible to use the LED of the TSG to detect

functioning of data transmission since the TSG bar lights as soon as two telegrams with the same

contents have been successfully transmitted within 5 seconds. In all other cases, the bar does not

light.

Folie 29

3.5 View And Delete

Last Error

View

1. Press “N” button three times; then a 4-digit error code with blinking dots appears

(last error occurred and remedied)

2. Quit programme by switching OFF key switch (do not switch OFF key switch

when proceeding to point “Delete”)

Delete

1. Press “O” button and hold depressed as long as the display changes to 0.0.0.0.

2. Release button, switch key switch OFF and on again

3. The software version appears then and changes to normal hourmeter display

4. It is possible at any time and as described under “View” to read out the last

occurred error from the memory and view it since the error code is saved there

5. Quit programme by switching OFF key switch

Foil 30

4. Programming

Different Procedures

Programming of different procedures of cleaning functions depending on

the direction switch (check and set)

(For setting of the B 1050, it is the position of buttons which is decisive and not the

icon on the operator panel)

Foil 31

4. Programming

Different Procedures

Check

1. Switch off machine by key switch

2. Simultaneously press "N" and "O" buttons and hold depressed, then switch on

key switch

3. Hold both buttons depressed as long as the software version appears in the

display then release both buttons

4. Viewing the different programmes is possible by pressing the button “L” (down)

or the button “N” (up).

5. The active programme is marked by a dash in front of the cipher

6. Quit programme by switching OFF key switch (do not switch OFF key switch

when proceeding to point “Set”)

Set

1. Use the “L” or “N” button to select the desired programme

2. Press the “O” button and hold depressed until the dash appears in front of the

cipher. The programme then is saved and active

3. Quit programme by switching OFF key switch

Foil 32

4.1 Programme Functions

Precondition for functioning of the following programmes is that “Brushes” and/or

“Suction" and/or “Sweep” are ON. All programmes allow normal cleaning and suction

in ‘forward' accelerator position; for the 'Neutral' and 'Reverse‘ accelerator positions,

however, differences apply and are listed in the following table.

Programme Accelerator Function according to

code position/ accelerator position/direction switch

Direction Brush head Squeegee Broom

switch + Water (B1100 only)

Neutral Brushes and Suction remains Broom remains

water ON ON ON

1

Reverse Brushes and

water ON Lift squeegee Broom remains

ON

Foil 33

4.1 Programme Functions

Programme Accelerator Function according to

code position/ accelerator position/direction switch

Direction Brush head Squeegee Broom

switch + Water (B1100 only)

Neutral Brushes and Lift squeegee Broom remains

water ON ON

2

Reverse Brushes and Lift squeegee Broom remains

water ON ON

Neutral Brushes and Suction remains Broom remains

water OFF ON ON

3

Reverse Brushes and Lift squeegee Broom remains

water ON ON

Foil 34

4.1 Programme Functions

Programme Accelerator Function according to

code position/ accelerator position/direction switch

Direction Brush head Squeegee Broom

switch + Water (B1100 only)

Neutral Brushes and Lift squeegee Broom off and

water OFF, lifted up

lift brush

head

4

Reverse Brushes and Lift squeegee Broom off and

water OFF, lifted up

lift brush

head

Neutral Brushes and Lift squeegee Broom remains

water OFF ON

5

Reverse Brushes and Lift squeegee Broom remains

water ON ON

Foil 35

4.1 Programme Functions

Programme Accelerator Function according to

code position/ accelerator position/direction switch

Direction Brush head Squeegee Broom

switch + Water (B1100 only)

Neutral Brushes and Lift squeegee Broom OFF and

water OFF, (delay lifted up

of 1 second for

6 brushes to avoid

(B 1100 only) the brushes from

& B1100 being switched OFF

PB 1230) when changing

from forward to

reverse ride)

Reverse Brushes and Lift squeegee Broom OFF and

water ON lifted up

Foil 36

4.1 Programme Functions

When the selected function of water supply, brush or suction function or the green

Hakomatic button is switched off by changed accelerator position, the function-related

LED blinks.

“ON” always means ‘switched ON’ and ‘lowered‘.

“OFF” only means ‘switched OFF’, ‘lifted’ is additionally indicated

Foil 37

5. Specific Customer

Settings

(Display of last error and selection of water stage, cleaning agent, SWA,

side brush, filter)

The settings described in this step can be modified according to customer

requirements. Factory settings need not be adopted.

For setting of the B 1050, it is the position of buttons which is decisive and not the

icon on the operator panel.

Foil 38

5. Specific Customer

Settings

Entry into programming

1. Switch off machine by key switch

2. Simultaneously press ”G" and "O" buttons and hold depressed, then switch on

key switch

3. Hold both buttons depressed as long as the software version appears in the

display, then release both buttons

Then the programmed settings for the following points are displayed automatically:

Display of last (remedied) error upon switching ON: yes / no

Water stage at start of cleaning: last selected stage/ always medium stage

Switch on cleaning agent together with switching ON water: yes / no (B 1100 & B1100 PB1230)

Water stage for Scrubbing and suction: last selected stage/ always medium stage

(B1050PB / B1050CB / B1050 PB 1230)

Switch over to SWA upon water ON: clear water / SWA (B 1100 only)

Switch on side brush/side broom together with switching ON scrubbing: yes / no (B1050PB/CB)

Switch on side brush together with switching ON scrubbing: yes / no (B 1100 only)

Filter shaking: in interval / as long as button is depressed (B 1100 & B1100 PB 1230)

Switch on filter suction together with switching ON sweeping: yes / no (B 1100 & B1100 PB 1230)

Automatic filter shaking after sweeping: yes / no (B 1100 & B1100 PB 1230)

Foil 39

5. Specific Customer

Settings

(this is the Factory setting for the B1100)

Currently programmed setting

Filter (B 1100 only)

Side brush

SWA (B 1100 only)/Side broom/-brush with scrubbing

Cleaning agent (B 1100 only)/water stage at scrub/suct

Water stage

Error display

Foil 40

5.1 PPV1 (Display Of Last Error)

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = Error code (of the remedied error) will be displayed for 3 seconds

after switching on

Down = OFF = Error code (of the remedied error) will not be displayed

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

Foil 41

5.2 PPV2 (Water stage Upon

Start of cleaning)

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = last selected stage is set

Down = OFF = always the medium stage is set

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

Foil 42

5.3 PPV3 (Cleaning Agent /

Waterstage)

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

B1100 Up = ON = Cleaning agent is equally switched on

& B1100 PB 1230 Down = OFF = Cleaning agent is not switched on

B1050 Up = ON = Water stage for Scrubbing and suction: last

selected stage

Down = OFF = always the medium stage is set

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

Foil 43

5.4 PPV4 (Switch Over to SWA /

Side broom - side brush)

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

B1100 Up = ON = Switching to dirty water recycling (SWA)

Down = OFF = Switching to clear water

B1050 Up = ON = Switching on side broom / brush together

(not B1050 PB 1230) with scrubbing

Down = OFF = don´t switch on side broom / brush

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

Foil 44

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = side brush is equally switched on

Down = OFF = side brush is not switched on

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

5.5 PPV5 (Side Brush Upon

Switching On Scrubbing)

(B1100 only)

Foil 45

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = Filter shaking as long as button is depressed

Down = OFF = Filter shaking after switching on by button 3 times in intervals

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

5.6 PPV6 (Filter Shaking)

(B 1100 & B1100 PB 1230)

Foil 46

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = Filter suction is equally switched on

Down = OFF = Filter suction is not switched on

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

5.7 PPV7 (Filter Suction Upon

Switching On Sweeping

Mode) (B 1100 & B1100 PB 1230)

Foil 47

1. Select desired setting by “L” and “N” buttons

2. The corresponding bar starts blinking

3. Use “M” button to move the bar up and down

Up = ON = after a minimum of 2 minutes of sweeping, shaking is automatically

switched on upon end of sweeping

Down = OFF = shaking is not automatically switched on upon end of sweeping

4. Save setting by pressing the green button (“O” button) as long as the dot appears

at the bottom right of the display

5.8 PPV8 (Automatic Filter Shaking

After Sweeping)

(B 1100 & B1100 PB 1230)

Foil 48

6. Settings On Module

The settings on the modules have an influence on load values of the electronic

circuit-breakers and the module coding.

Foil 49

6.1 Module 1

As they have an influence on the load value of the electronic circuit breakers for the

brush head and squeegee lifting elements, the Dip switch settings have to be correct

on Module 1.

Dip switch setting:

1: OFF

2: OFF

Circuit-breaker values:

Brush head: 5.7 A

Squeegee: 5.7 A

Foil 50

6.2 Module 3

As they have an influence on the module coding and the load value of the electronic

circuit breakers for the pre-sweeper / side broom / side brush lifting elements,

the Dip switch settings have to be correct on Module 3.

Modul 3 Code A (pre-sweeper B 1100 &): Modul 3 Code C (3rd Brush):

(B 1100 PB 1230) (B 1050 TB 1230 & B1100 PB 1230)

(Side broom B 1050 CB only)

1: OFF 1: OFF

2: OFF 2: ON

3: OFF 3: OFF

4: OFF 4: OFF

electr. C-b.: 5.7 A electr. C-b: not required

Modul 3 Code D (Side brush):

(B1100 und B 1050 TB)

1: ON

2: ON

3: OFF

4: ON

electr. C-b: 1.9 A

Foil 51

7. Operator Panel Settings

(B 1100 only)

The Code A and B operator panels (pre-sweeper / side brush and Cleaning agent /

SWA) have to be correctly set - i.e. coded - on the Dip switch.

These operator panel are available only in the Hakomatic B1100 & B1100 PB 1230.

They are located under the right-hand operator panel of the machine.

Code A (Pre-sweeper/Side brush; A2 ): Code B (Cleaning agent / SWA; A10):

1: OFF 1: ON

2: OFF 2: OFF

Foil 52

8. Water Pump

8.1 Water Amounts

For checking function of the water pump, voltage for each of the stages can be

measured at Module 1 (A5:X2:6+7).

When using a True RMS device, having water in the tank and ensuring that suction

turbine is OFF, the values from the following table shall be obtained:

When using other than the indicated measuring devices, values may vary since

measured voltage is pulsed. Beyond that the value depends on battery voltage.

Here, measurement was done with charged battery presenting three green LED

lighting in the battery indication.

The voltage values in the table are given for the Hakomatic B1100 and B1050PB only.

Beyond that, evaluation of the actually delivered water amount is to be

preferred since voltage values only indicate whether water pump control is

operable or not.

Foil 53

8. Water Pump

without

Sidebrush

with

Sidebrush

Stage 1: xx V ca. 1,3 l/min ca. 2,7 l/min ca. 1,3 l/min ca. 1,0 l/min

Stage 2: ca. 5,7 V ca. 2,2 l/min ca. 3,3 l/min ca. 2,2 l/min ca. 1,0 l/min

Stage 3: ca. 7,4 V ca. 2,9 l/min ca. 3,9 l/min ca. 2,9 l/min ca. 1,0 l/min

Stage 4: ca. 8,9 V ca. 3,6 l/min ca. 4,4 l/min ca. 3,6 l/min ca. 1,0 l/min

Stage 5: ca. 12,0 V ca. 4,7 l/min ca. 5,5 l/min ca. 3,9 l/min ca. 1,0 l/min

Stage 6: ca. 14,7 V ca. 5,7 l/min ca. 6,4 l/min ca. 4,1 l/min ca. 1,0 l/min

Stage 7: ca. 20,0 V ca. 7,5 l/min ca. 8,2 l/min ca. 4,4 l/min ca. 1,0 l/min

Hakomatic B1100 / B1050PB

Hakomatic

B1050CB

Option Tool

Hakomatic B1050

Foil 54

8.2 Standstill Detection For

Water Pump

Automatic standstill detection for water pump:

The electronics offer a possibility for water pump protection if delivery of pump is

blocked.

When the pump takes in water from the tank but cannot deliver it to the brushes,

a pressure builds up downstream the pump. Without protection by the electronics,

the pump would continue delivery against this pressure and could be damaged.

The electronics detects interruption of free delivery of the pump and automatically

switches off the pump for 2 seconds.

After these 2 seconds, pump is briefly switched on with simultaneous measurement

whether delivery then is free or whether water supply to brushes is still blocked.

When delivery of the pump is free, the selected stage remains ON; if counter-pressure

is still present, the pump again is switched OFF for 2 seconds. This procedure is

repeated until fault will be remedied.

Foil 55

9. Drive Controller

The light-emitting diodes (LED) are directly located on the electronics

LED indication Malfunction Remark

OFF Drive controller Voltage supply interrupted

without function Check fuses and wiring

ON Drive controller is Drive controller function

operable okay

2 signals Wrong start sequence Check accelerator and direction

switch as well as cabling

3 signals Output transistors Check wiring to drive motor;

do not connect or check carbon brushes;

no connection to if okay but error still present

drive motor replace drive controller

9.1 SEVCON Controller (Diagnostic LED)

Foil 56

9.1 SEVCON Controller

LED indication Malfunction Remark

4 signals Output transistors do Check wiring to drive motor

not connect or no and drive motor.

connection to drive motor Check direction switch and

direction contactors on drive

controller; if okay but signals

still present, replace drive

controller

5 signals Output transistors 160 A fuse blown, check

defective release signal from control

electronic; Check direction

switch and direction contactors

on drive controller; if okay but

signals still present, replace

replace drive controller

Foil 57

9.1 SEVCON Controller

LED indication Malfunction Remark

6 signals Accelerator or cable Check accelerator and wiring,

connection interrupted plugged connection eventually

loose; check direction switch

and drive potentiometer

switch

7 signals Battery voltage in- Measure voltage, check

sufficient, less than connections

13 Volts

8 signals Temperature of drive Is travel drive smooth?

electronics exceeded Is parking brake setting

(70 °C and higher) okay? Longer uphill rides?

Max. operating current

approx. 45 A

Foil 58

9.1.1 Signal Measurement at the

Drive Controller (SEVCON)

During test of the drive controller, the following points should be checked since

faultless operation of the drive controller is not possible without the described

signals applying accordingly.

The drive controller is designated by A6 in the circuit diagram and is supplied with

36 V even though some of the signals are 24-Volts signals.

The drive controller is a pulse controller activating the motor by the pulsed voltage.

In case of full throttle forward ride, battery voltage always applies at the motor.

1. Is F51-160A fuse okay?

2. Is battery voltage applying at drive controller?

3. Is battery minus connected at drive controller?

4. Is battery voltage applying at A6-X51:2 after switching key switch ON?

Foil 59

9.1.1 Signal Measurement at the

Drive Controller (SEVCON)

5. Cabling between accelerator potentiometer and drive controller okay?

Voltage measurement:

Green at A6-X51:8 (approx. 8.6V)

Red at A6-X51:9 (0-5V depending on potentiometer position)

Yellow at A6-X51:3 (approx. 0V)

Measured to battery minus

Resistance measurement (with machine switched off and

potentiometer disconnected):

Between green and red: approx. 5.7 kW Reducing to approx. 1.8 kW upon actuation

Between yellow and red: approx. 1.8 kW Increasing to approx. 5.7 kW upon actuation

Between yellow and green: approx. 4 kW Unchanged upon actuation

Caution: The potentiometer has a nominal value of 4 kW 20%. This means:

Due to the 20% tolerance, values may vary between 3.2 kW and 4.8 kW.

Depending on these tolerances, the measured values may increase or reduce

by up to 0.8 kW.

Foil 60

9.1.1 Signal Measurement at the

Drive Controller (SEVCON)

6. Is connection between A6:X51:3 and A1:X4:3&4 okay? Is battery minus equally

connected to A1:X4:3&4?

7. Is battery minus applying at A1:X3:1 after closing of key switch and seat contact

switch? Battery minus equally at S54:1? Is connection between A1:X3:1

and S54:1 okay? Only when battery minus is applying to S54 potentiometer

switch, the closed direction contactors can control the potentiometer switch and

the S53 direction switch.

8. Connection between direction switch and drive controller okay?

S53:B2 to A6-X51:4 (forward)

S53:B4 to A6-X51:5 (reverse)

9. Connection between direction switch and A1 control unit okay?

S53:A2 to A1:X8:4

S53:A4 to A1:X8:2

10. Are 24V applying at A1:X8:4 with “reverse” ride being selected?

Foil 61

9.1.1 Signal Measurement at the

Drive Controller (SEVCON)

11. Are 24V applying at A1:X8:2 after “forward” ride selected?

12. Is jumper in A1:X8 between Pin 1 and 3 and 5 okay?

13. Do switches S53 (direction) and S54 (potentiometer) operate faultlessly?

14. Is battery minus applying at A6-X51:4 with “forward” ride being selected

(potentiometer switch has to close)?

15. Is battery minus applying at A6-X51:5 with “reverse” ride being selected

(potentiometer switch has to close)?

16. Is battery minus no longer applying at A6-X51:11 with “reverse” ride being selected

(signal for speed reduction)?

Foil 62

9.1.1 Signal Measurement at the

Drive Controller (SEVCON)

17. Is cabling between drive controller and drive motor okay? Please check each

cable and their contacts. Do two wires contact via crimping > short-circuit?

18. Do direction contactors switch? Eventually proceed to activate each of them

directly.

19. Test with diagnostic device (general diagnostic devise and not that specific one for

drive controller as in the old version)

Foil 63

9.2 ZAPI Controller

The ZAPI controller has a diagnostic input. Unless not expressly indicated in the service

documents, modification of the default values and parameters is not admitted.

Contactor arrangement

A = Connector for contactor control and control inputs

B = Connector for console or alarm LED

Foil 64

9.2 ZAPI Controller

Description of control connections of the ZAPI controller

A1 RV1 Speed reduction 1; active if no positive voltage is applying

A2 IRE Emergency inversion acc. to Europ. standard; active if a pos. voltage is applying

A3 MT Tiller micro switch; active if a pos. voltage is applying

A4 NT2 Activation of neg. direction contactor forward ride (auto-stop),

Bypass contactor, general contactor or electric brake (standard)

A5 CH connected + (from key switch)

A6 IRZ Emergency inversion ("ZAPI standard"); active if no positive voltage is applying

A7 RV2 Speed reduction 2; active if no positive voltage is applying

A8 PT Activation positive for all contactors and micro-switches

A9 MA Micro-switch forward ride; active if a pos. voltage is applying

A10 MI Micro-switch reverse ride; active if a pos. voltage is applying

A11 NT1 Activation negative direction contactor reverse ride (auto-stop)

or both direction contactors (standard)

A12 NPOT Potentiometer negative

A13 CPOT Potentiometer arm

A14 PPOT Potentiometer positive (13V; output impedance 82Ohm)

Foil 65

9.2.1 ZAPI Controller

9.2.1 Automatic Monitoring of the Components

The micro-processor effectuates evaluation of basic controller functions.

This evaluation concerns:

•Check upon switching key switch ON:

Watch Dog, current sensor, power MOS FET, contactor activation (contactor driver),

direction switch, potentiometer connections, EEPROM)

•Check in standstill:

Watch Dog, current, power MOS FET, contactor activation (contactor driver), potentiometer

connections)

•Check during ride:

Watch Dog, current, power MOS FET, contactor activation (contactor driver), potentiometer

connections), closing and opening of contactors

•Permanent Monitoring:

Temperature, battery voltage

Eventual error messages are indicated by a blinking LED on connector B (section 2). The

number of blinks indicates the error type.

Foil 66

9.2.2 ZAPI Controller

9.2.2 Error Codes Displayed Via The LED

No. Blinks Message State* Remark

1) 1 WATCH-DOG A Error on electronics

2/3/4/5) 1 EEPROM A Error on electronics (EEprom)

6) 2 INCORRECT START B Direction actuated upon switching ON (or incorrect connection of IR)

7) 3 VMN LOW B MOSFET short-circuited

8) 3 VMN HIGH B Diodes short-circuited or direction contactor stuck

9) 4 VACC NOT OK B Potentiometer defective

10) 5 I=0 EVER A No current flow detectable during ride

11) 5 HIGH CURRENT A Current flow in rest mode

12) 6 PEDAL WIRE KO B Potentiometer wiring defective

13) 7 TEMPERATURE C Temperature > 76°C

15) 8 DRIVER 1 KO A NT1 driver short-circuited

16) 8 DRIVER 1 SIC KO A Contactor coil on NT1 short-circuited

17) 8 DRIVER 2 KO A NT2 driver short-circuited

18) 8 DRIVER 2 SIC KO A Contactor coil on NT2 short-circuited

19) 8 DRIVER SHORTED B Driver short-circuited (NT1)

20) 8 CONTACTOR OPEN B Contactor does not close

21) 9 POSITION HANDLE B Tiller micro-switch not actuated

22) 9 INVERSION B Deadman bounce key (IR) actuated or incorrectly wired

23) 9 FORW.+BACKW. B Both directions simultaneously actuated

24) Perman. light BATTERY C Battery discharge too important

* A = switch off system, remedy fault and switch on again

B = remedy fault and actuate direction again

C = display of state and eventual software-controlled measures

Foil 67

9.2.3 ZAPI Controller

1) WATCH-DOG

Test during rest state as well as during ride; internal self-test of hard- and software; replace controller

in case of fault alarm!

2) EEPROM PAR. KO

Error in the memory area containing values of the setting parameters. System switches off. If error

still persists after having switched key switch OFF and ON again, replace logic! If error disappears,

mind that the saved parameter values are deleted. (—> initial setting)

3) EEPROM CONF. KO

Error in the memory area containing the controller configuration data. If error still persists after having

switched key switch OFF and ON again, replace logic! If error disappears, mind that the saved

configuration is deleted. (—> initial setting)

9.2.3 Explanations On Displayed Error Messages

Foil 68

9.2.3 ZAPI Controller

4) EEPROM DATA KO

Data of the memory area controlling the hourmeter counter are corrupted. If alarm disappears after

having switched key switch OFF and ON again, mind that the hourmeter counter is reset to zero then.

5) EEPROM OFF LINE

Error in the non-volatile memory containing those values of the hourmeter counter concerning the

programmable parameters and the saved alarms. If error still persists after having switched key

switch OFF and ON again, replace controller!

Foil 69

9.2.3 ZAPI Controller

6) INCORRECT START

Corrupted order of sequence of start conditions. The system only starts if, depending on SAFETY

SWITCH programming, the following order is observed :

- Key switch - tiller micro-switch - direction switch (HANDLE)

- Key switch - direction switch (FREE)

- Key switch + seat switch - direction switch (SEAT)

Possible causes:

a) Direction or tiller micro-switch stuck.

b) Operator did not observe sequence.

c) Incorrect wiring.

If no external fault can be detected, replace controller!

Foil 70

9.2.3 ZAPI Controller

7) VMN LOW

Test in rest state and during ride up to VMN synchronised for 80%;

Voltage at VMN terminal normally equals 50% Vbatt if contactors are open. If this voltage is

insufficient (< 30% VBatt), an alarm will be output. Possible causes:

a) Main contactor (if available) does not close or is not connected at all

b) Short-circuit between VMN and -Batt terminals (metal particle or other)

(disconnect cable at VMN terminal, switch on, fault disappears)

c) Power MOSFET short-circuited or permanently activated by the logic;

disconnect cable at VMN terminal, switch on, fault persists, replace controller

d) Bypass contactor (if available) stuck or opens too slowly

Foil 71

9.2.3 ZAPI Controller

8) VMN HIGH

Test in rest state;

Voltage at VMN terminal normally equals 50% Vbatt if contactors are open. If this voltage is

excessive (> 70% VBatt), an alarm will be output. Possible causes :

a) One of the direction contactors is permanently closed due to mechanical blocking

or permanent activation (incorrect wiring of contactor coil)

b) Short-circuit between field and anchor coil of the motor

(disconnect cable at VMN terminal, switch on, Fault disappears, repair motor)

c) Incorrectly connected motor cable (check field and anchor wiring)

d) Power element of controller defective (suppressor or brake diodes short-circuited)

disconnect cable from VMN terminal, switch on, fault persists, replace controller

Foil 72

9.2.3 ZAPI Controller

9) VACC NOT OK

Test in rest state;

An alarm is displayed if the potentiometer voltage is higher than 1V, related to the saved minimum

value.

Possible causes:

a) One of the wires at the potentiometer or inductive sensor is broken.

b) Potentiometer or inductive sensor ist defective.

10) I=0 EVER

Test during ride;

If, during ride, the current does not exceed a determined minimum value, the error message appears

and the system switches off.

Possible causes :

a) Resistance of the motor is excessive due to motor defect or faulty carbon brush

contact

b) Current sensor is defective (replace controller)

Foil 73

9.2.3 ZAPI Controller

11) HIGH CURRENT

Test in rest state - contactor open;

If measured current is >50A, an alarm will be output and the system switches off. Current sensor is

defective (replace controller!)

12) PEDAL WIRE KO

If no voltage can be measured at the Pin NPOT (A12), to which the negative potentiometer terminal

is connected, an alarm is output. Possible causes:

a) Wire at PPOT (A14) terminal broken

b) Wire at NPOT (A12) terminal broken

c) Potentiometer defective (infinite resistance)

d) Potentiometer resistance >47 kOhm

Foil 74

9.2.3 ZAPI Controller

13) TEMPERATURE

This message indicates that temperatures has exceeded 76°C.

Maximum current is reduced by steps down to zero with a temperature of 86°C. Possible causes:

a) If the alarm is output directly after switching the system ON with a cold controller,

temperature monitoring is not working correctly (replace controller!)

b) If the alarm is output shortly after start of operation, heat is insufficiently

dissipated (check installation and fastening screws)

14) NO FULL COND.

Test at full speed;

If, at full speed, voltage at the VMN terminal is > 1/3 VBatt, this is an indication for a faulty diagnostic

circuit and the system switches off.

If the error persists, replace controller (logic unit).

Foil 75

9.2.3 ZAPI Controller

15) DRIVER 1 KO

If voltage at the NT1 terminal (A11) does not correspond to the desired value, an alarm is output and

the system switches off.

Possible causes:

a) Wire at the NT1 terminal (A11) broken or coil of the direction contactor

for reverse ride is defective.

b) Internal driver MOSFET short-circuited (replace controller!)

16) DRIVER 1 SIC KO

If current load at the contactor driver which activates the NT1 output (A11) is excessive, an alarm is

output and the system switches off.

Possible causes :

a) Short-circuit of the wire at NT1 terminal (A11) to +Batt

b) Coil of the connected contactor short-circuited or current consumption > 5A

Foil 76

9.2.3 ZAPI Controller

17) DRIVER 2 KO

If voltage at the NT2 terminal (A4) does not correspond to the desired value, an alarm is output and

the system switches off.

Possible causes:

a) Wire at the NT2 terminal (A4) broken or coil of the direction contactor

for forward ride is defective.

b) Internal driver MOSFET short-circuited (replace controller!)

18) DRIVER 2 SIC KO

If current load at the contactor driver which activates the NT2 output (A4) is excessive, an alarm is

output and the system switches off.

Possible causes :

a) Short-circuit of the wire at NT2 terminal (A4) to +Batt

b) Coil of the connected contactor short-circuited or current consumption > 5A

Foil 77

9.2.3 ZAPI Controller

19) DRIVER SHORTED (only with H0 STANDARD TRACT.)

If voltage at the NT1 terminal (A11) does not correspond to the desired value, an alarm is output and

the system switches off.

Possible causes:

a) Wire at the NT1 terminal (A11) broken or coil of the direction contactor

for forward or reverse ride is defective.

b) Internal driver MOSFET short-circuited (replace controller!)

20) CONTACTOR OPEN

Test upon actuation of a direction;

– It is checked whether the selected direction contactor closes by measuring the value of the VMN.

If this value is not correct, an alarm is output.

Proceed to the following instructions for remedy:

Foil 78

9.2.3 ZAPI Controller

When does error

occur?

1st test result 2nd test Result Error

Yes --> --> A1

Yes B1

No C1

Yes --> --> A2

Yes B2

No C2

Yes --> --> A3

Yes B3

No C3

In forward direction

only

Forward direction contactor

closes for 0.3 seconds and

then opens

No

For 0.3 seconds, a voltage

applies to the coil of the

forward direction contactor

In reverse direction

only

Reverse direction contactor

closes for 0.3 seconds and

then opens

No

For 0.3 seconds, a voltage

applies to the coil of the

reverse direction contactor

In both directions

Forward or reverse

direction contactor (as

actuated) closes for 0.3

seconds and then opens

No

For 0.3 seconds, a voltage

applies to the coil of the

forward or reverse direction

contactor (as actuated)

Folie 79

9.2.3 ZAPI Controller

A1 The NO contact of the forward direction contactor (TA) or the NC contact of the

reverse direction contactor (TI) is soiled or stuck.

Clean contacts or replace contactor group if required.

Clean NO contact of the forward

direction contactor (TA)

Clean NC contact of the reverse

direction contactor (TI)

Foil 80

9.2.3 ZAPI Controller

A2 The NC contact of the forward direction contactor (TA) or the NO contact of the

reverse direction contactor (TI) is soiled or stuck.

Clean contacts or replace contactor group if required.

Clean NC contact of the forward

direction contactor (TA)

Clean NO contact of the reverse

direction contactor (TI)

Foil 81

9.2.3 ZAPI Controller

A3 Connection to motor interrupted:

- Carbon brushes without contact to collector (Fig. 1)

- Connecting cable of carbon brush broken (Fig. 2)

- Motor winding defective or motor cable broken

- Inverted motor connection

Foil 82

9.2.3 ZAPI Controller

B1 The forward direction contactor is correctly activated but does not close.

- contactor coil defective, measure resistance by ohmmeter

- contact is mechanically blocked

- nominal voltage of contactor coil is higher than the battery voltage

B2 The reverse direction contactor is correctly activated but does not close.

- contactor coil defective, measure resistance by ohmmeter

- contact is mechanically blocked

- nominal voltage of contactor coil is higher than the battery voltage

B3 The forward or reverse direction contactor is correctly activated but does not close.

- coils of contactors are defective, measure resistance by ohmmeter

- contacts are mechanically blocked

- nominal voltage of contactor coils is higher than the battery voltage

C1 No voltage at the coil of the forward direction contactor. Check connector and cable of the

contactor coil to plus supply and to Pin A4 (NT2).

C2 No voltage at the coil of the reverse direction contactor. Check connector and cable of the

contactor coil to plus supply and to Pin A11 (NT1).

C3 No voltage at the coils of the forward and reverse direction contactors. Check connectors

and cables of the contactor coils to plus supply and to Pin A4 (NT2) and A11 (NT1).

Are the items C1, C2, C3 without fault, replace logic.

Foil 83

9.2.3 ZAPI Controller

21) POSITION HANDLE

If, upon switching ON, the tiller micro-switch has already been actuated, an error is output (only if

SAFETY SWITCH is programmed to HANDLE). Possible causes:

a) Tiller micro-switch stuck

b) Incorrect operation

22) INVERSION

If, upon switching ON, the emergency inversion switch (deadman) has been pressed, an alarm is

output. Possible causes:

a) Micro-switch for emergency inversion stuck

b) Incorrect operation

c) Incorrect wiring or programming

23) FORW - BACK

Fault is displayed if two directions are simultaneously active. Possible causes:

a) Wiring defective.

b) Direction micro-switch stuck. If none of the causes applies, replace logic!

24) BATTERY

Battery discharged, i.e. voltage has fallen below 60% of nominal voltage. An alarm is output. The

system switches off but may be restarted. In that case, maximum current will be reduced to 50% of

the programmed maximum current value.

Foil 84

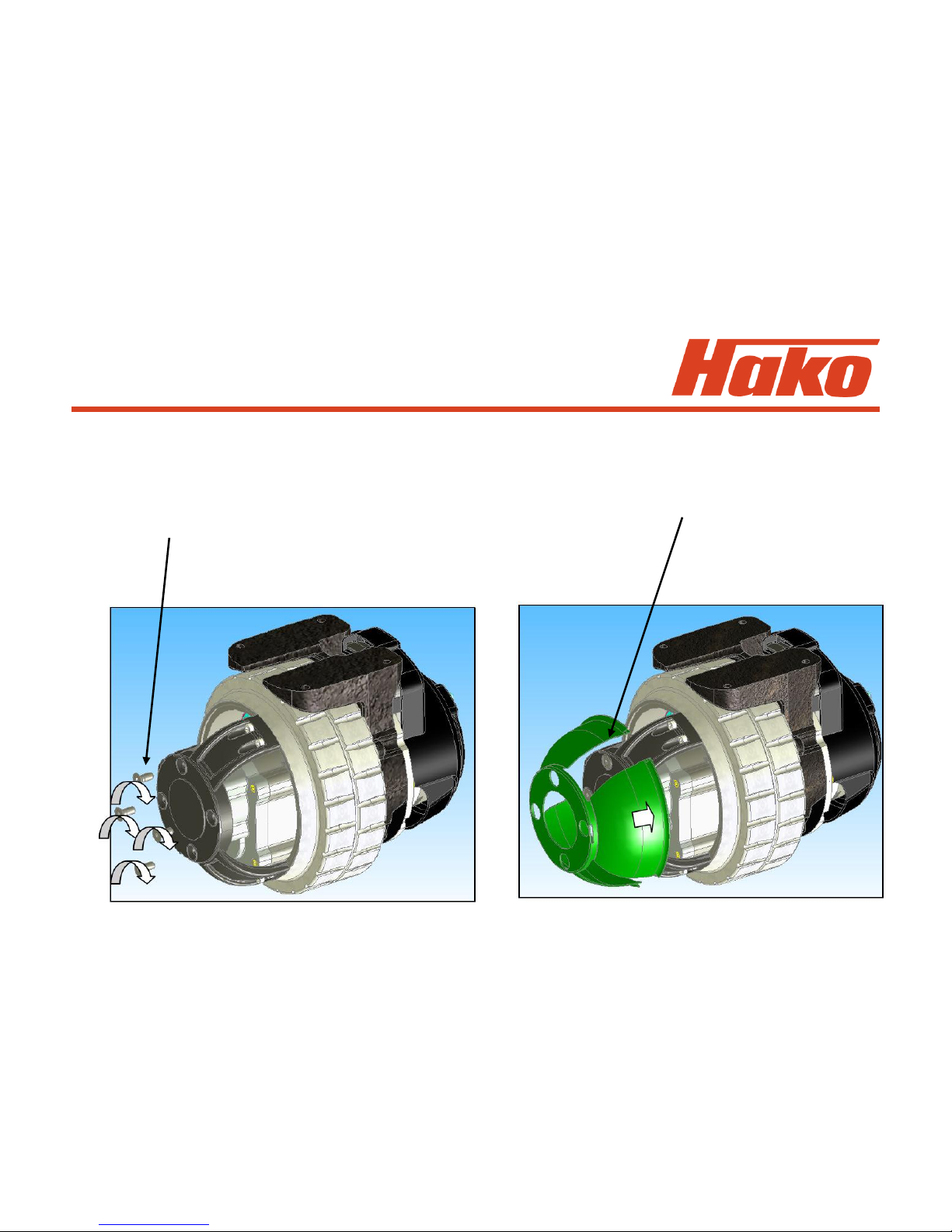

9.3 Drive Motor B1050 (Amer)

9.3.1 Tyre replacement

Unscrew the 4 screws of the hub

Warning! Lift up the machine so that the

tyre is not touching the ground

Screw the 4 pullers two by two (at 180°) in

the bracket until the hub is removed (Tool

PN 03502210)

Warning! Remove the 4 pullers

after this operation

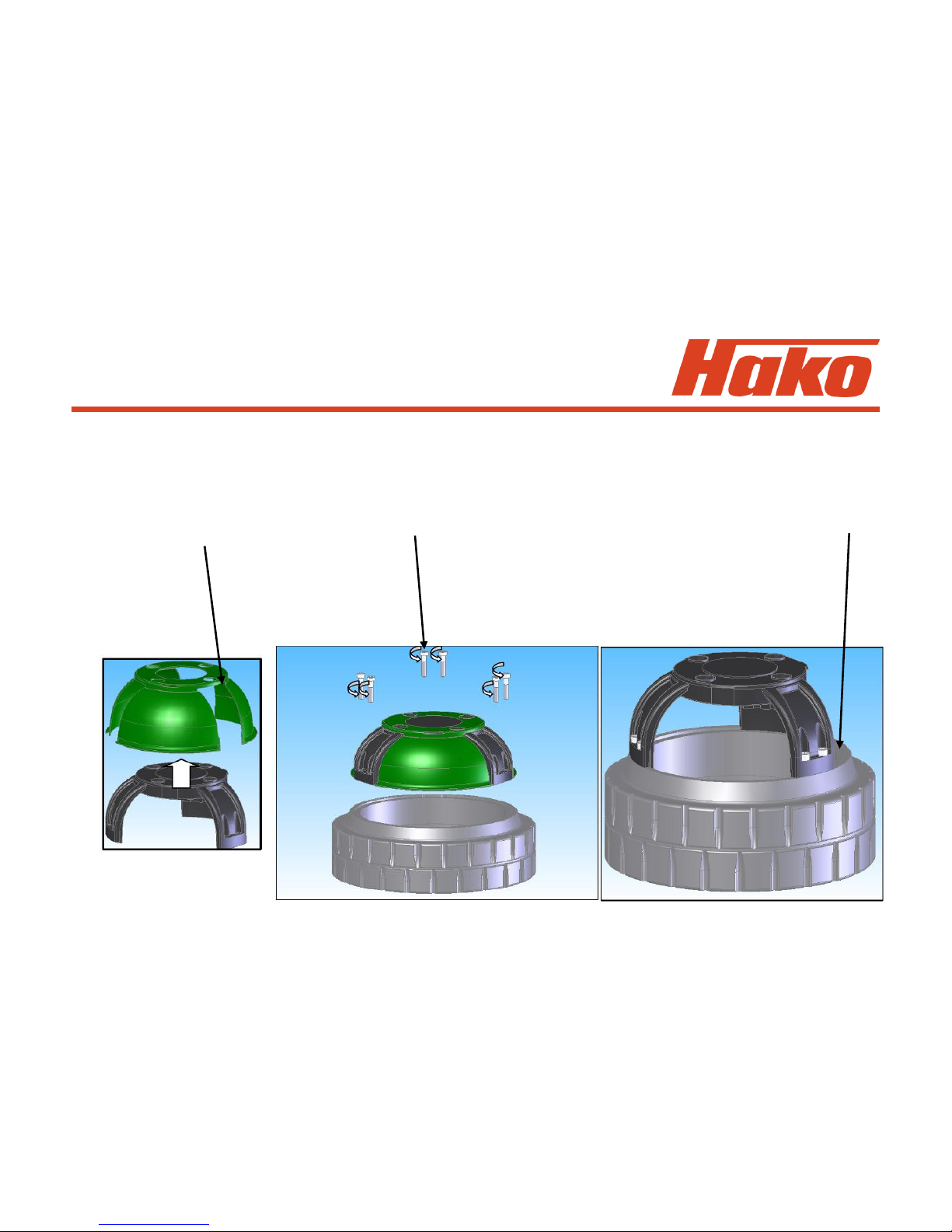

Foil 85

9.3 Drive Motor B1050 (Amer)

Remove the

plastic hub cover

Unscrew the 6 screws M6x30

tightening torque 16Nm ±10%

Replace the old tyre and re-assemble

the new tyre with the hub without the

plastic hub cover

Torque screw 16 Nm ± 10%

Foil 86

9.3 Drive Motor B1050 (Amer)

Install the wheel on the MTR11 by using

a plastic mallet

Warning! Check the radial position of the

hub with the inner disc during the

mounting

Tire puller kit (Tool PN 03502210)

Foil 87

9.3 Drive Motor B1050 (Amer)

Screw the 4 screws M8x20

tightening torque screw 22 Nm ±10%

Mount the plastic cover hub manualy

Foil 88

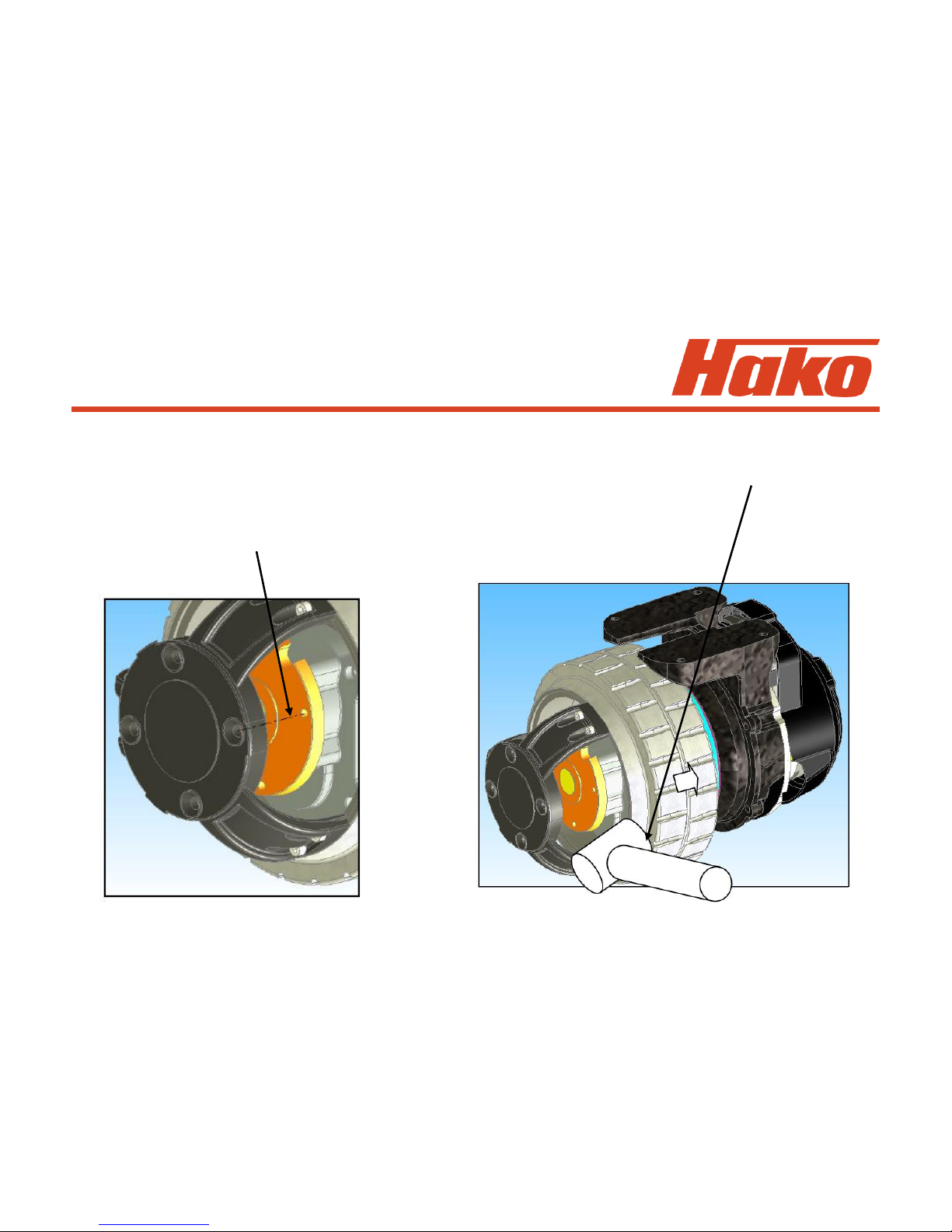

9.3.2 Drive Motor B1050 (Amer)

Check (every 1000 hours) and replacement (max. 1500 hours) of the

carbon brushes

•the wear out limit of the carbon brushes is 12 mm

Unscrew the 2 nuts.

After remove the terminal board cover.

Remove the 4 screws M6x20.

tightening torque 9.5Nm -10% +20%

Then remove the motor.

Replace the carbon brushes.

Foil 89

9.3.3 Diagnostic LED for Drive

control unit (Italsea)

Display / Flashes Alarm What To Do

Alarm A7

OVERCURRENT

Alarm A8

Power fuse/Relais

Power fuse or main

contactor damaged

Over-current: short circuit

Controller detects a failure on the external power

fuse or power connections. If controller repeats

this alarm and the power connections are ok,

replace it

Check the motor´s wires: if ok, and the controller

repeats this alarm, replace the controller

Alarm A6

POWER STAGE

Alarm A5

Over temperature

Alarm A4

Reference OUT of neutral

Move the potentiometer to neutral position or if it

is in neutral position yet, calibrate the speed

reference.

Thermal protection

Controllers power stage

damaged

replace the controller

Wait a few minutes and check the motor current

Potentiometer out of neutral

position at power-on

Alarm A3

Potentiometer Fault

Check the potentiometer and it´s wiring

Alarm A1

FORWARD switch ON

Alarm A2

BACHWARD switch ON

Forward switch closed at

power-on

Backward switch closed at

power on

Potentiometer fault

Put the speed reference to zero and open the

Forward switch

Put the speed reference to zero and open the

Backward switch

Foil 90

9.3.3 Diagnostic LED for Drive

control unit (Italsea)

Display / Flashes Alarm What To Do

Alarm A16

Forward and Backward

switch on

Both direction switches on

Check the direction switches and / or their

connections

Check the field output connections / wirings. If ok

replace controller

E²PROM fail

Check the settings: if the controller repeats this

alarm, replace it.

Alarm A14

E2PROM FAIL

Alarm A15

Field Fault

Check the input switch: this alarm will reset by

power-off. Input voltage at -A6:J2.6

Disable switch ON

Alarm A12

Disable ON

Alarm A13

KEY-OFF

Key-Off sequence detected

Check the key switch connections.

Input voltage at -A6:J2.15

Battery voltage higher than 45V: check the battery

Check the Motor working current

Armature: I

max

50A

Field: I

max

12A

Overload protection

(armature or field)

Alarm A11

Overload Current

Alarm A10

Overvoltage

Overvoltage

Alarm A9

Undervoltage

Undervoltage

Check battery charging level

Foil 91

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

1.2.5.2. Thermal switch Wire broken since NC activation?

Brush motor Measure operating current (approx. 12 A

1); 2); 3); 4); 5) for a motor when operated without in-

creased pressure and on Fama Famin)

Motor overload due to unfavourable floor-

brush-combination and/or permanent

ride with increased ground pressure?

1.2.5.5. Thermal switch Wire broken since NC activation?

3rd Brush motor Measure operating current (approx. 12 A

(Modul3 Code C) for a motor when operated without in-

4) ; 5) creased pressure and on Fama Famin)

Motor overload due to unfavourable floor-

brush-combination and/or permanent

ride with increased ground pressure?

Foil 92

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

1.2.6.1. Blocking protection Check 35 A fuse

Brush motor Measure operating current (approx. 12 A

(right and left) for a motor when operated without in-

1); 2); 3); 4); 5) creased pressure and on Fama Famin)

Motor overload due to unfavourable floor-

brush-combination and/or permanent

ride with increased ground pressure?

1.2.6.2. Blocking protection Check 35 A fuse

3rd Brush motor Measure operating current (approx. 12 A

(Modul3 Code C) for a motor when operated without in-

4); 5) creased pressure and on Fama Famin)

Motor overload due to unfavourable floor-

brush-combination and/or permanent

ride with increased ground pressure?

Foil 93

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

1.2.6.3. Electronic circuit-breaker Jammed? Lifting element stopped by

Brush lifting element limit stop before being switched off by

1); 2); 3); 4); 5) micro-switch? Check coding of

Module 1 Measure operating current

(approx. 3.5A max. during lifting)

1.3.5.1. Thermal switch Jammed? Permanent contact to border

Side brush during ride? Wire broken since NC

1); 2) activation? Check 35 A fuse; Measure

operating current (approx. 8 A max.)

1.3.6.1. Blocking protection Jammed? Permanent contact to border

Side brush during ride? Wire broken since NC

1); 2) activation? Check 35 A fuse; Measure

operating current (approx. 8 A max.)

Foil 94

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

1.3.6.2. Blocking protection Jammed? Lifting element stopped by

Lifting element limit stop before being switched off by

Side brush micro-switch? Check coding of

1); 2) Module 3 Code D Measure

operating current

(approx. 1.2A max. during lifting)

1.4.6.1. Electronic circuit-breaker Jammed? Lifting element stopped by

Lifting element limit stop before being switched off by

Squeegee micro-switch? Check coding of

1); 2); 3); 4); 5) Module 1 Measure operating current

(approx. 3.2A max. during lifting)

Foil 95

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

2.2.5.1. Thermal switch Thermal switch of Broom or Side brush

Broom (and thermal motor opened or cabling faulty?

switch Side brush Jammed? Measure operating current

Motor if new version (approx. 9.5 A max. on Fama Famin for

is fitted) broom motor) Wrong sweeping track

1); 5) width? Unfavourable floor-brush-

combination?

At machines equipped with the new side

brush version (Kit 105-736, side brush

motor PN 105-733): Is side brush setting

okay? Jammed? Measure operating

voltage (max. 2.5 A after approx.

10 minutes run) and approx. 100-110 rpm

Foil 96

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

2.2.6.1. Blocking protection Jammed? Check 35 A fuse

broom Measure operating current (approx. 9.5 A

1); 5) on Fama Famin floor), Sweeping track

adjustment (30 mm - 50 mm)

Unfavourable floor-broom combination?

2.2.6.2. Blocking protection Jammed? Does lifting element moves up

lifting element broom to dead stop before being switched off

1); 5) by micro switch? Check module coding

module 3 Code A switch S4 to OFF

Measure operating current

(approx. 3.3 A when lifting)

Foil 97

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

2.3.5.1. Thermal switch side Side broom setting okay?

broom left / right Jammed? Measure operating current

1); 3); 5) (max. 2.5 A after approx. 10 minutes run)

2.3.6.1. Blocking protection Side broom setting okay?

L-h side broom Jammed? Measure operating current

1); 3); 5) (max. 2.5 A after approx. 10 minutes run)

and approx. 100-110 rpm

2.3.6.2. Blocking protection Side broom setting okay?

R-h side broom Jammed? Measure operating current

1); 3); 5) (max. 2.5 A after approx. 10 minutes run)

and approx. 100-110 rpm

Foil 98

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

2.3.6.4. Blocking protection Jammed? Does lifting element moves up

lifting element side to dead stop before being switched off

broom by micro switch?

3)

3.1.6.1. Fuse Check 10 A / 80 V fuse. If code for

Module 1 blocking protection of lifting element for

1); 2); 3); 4); 5) brush or squeegee is indicated, check

these, check water pump; with SWA

equally check K2 and water pump (SWA)

check 35A fuse; measure operating

current of suction turbines

(approx. 19.5 A max. for one Motor)

Foil 99

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

3.1.6.2. Fuse Check all fuses F1(10 A / 80 V)

Module 3 Code A and F4-F7, check motors for filter

( for pre-sweeper) suction (F6 = 20A/80V),

1); 3); 5) shaking (F7 = 20A/80V), r-h (F4)

and l-h side broom (F5)

Caution: If old version of side broom

motor (PN 51-237) is still installed, the

F4 and F5 fuses are 20A/80V.

If new version of side brush motor

(PN 105-733) is already installed, the

F4 and F5 fuses are 10A/80V

Foil 100

10. Error Table With Information

On Service Display

Error code in Malfunction Remark

the display

3.1.6.5. Fuse Check all fuses F1(10 A / 80 V)

Module 3 Code C and F4-F7 (5A/80V)

( for 3rd brush)

4); 5)

Loading...

Loading...