Page 1

®

SMD HOT TWEEZER

Instruction Manual

Thank you for purchasing the HAKKO 950 SMD Hot Tweezer.

Please read this manual before operating the HAKKO 950.

Store the manual in a safe, easily accessible place for future reference.

CAUTION

The HAKKO 950 cannot function by itself. It must

•

be connected to a HAKKO station. Specific

information can be found in the instruction manual

for your particular HAKKO station.

Before operating the HAKKO 950 for the first

•

time,be sure to calibrate the station.

Do not set the tip temperature to over 400 C/752 F.

•

Table of Contents

Packing List/Applicable Models/

Specifications

Precautions

Names of Parts

Setting up the HAKKO 950

Replacing the Tip/Tip selection

Operating Instructions

Troubleshooting Guide

Checking for breakage of the heating element,

cord assembly and tip to ground resistance

Maintenance/Tip Care and Use

Parts List

Tweezer/Iron Holder/Tips

Wiring Diagram

…………………………………………1

……………………………………………2

………………………………………3

………………………3,4

……………………5

………………………………6

………………………………7

……………………10

……………………………………11,12,13

………………………………………14

…8,9

Page 2

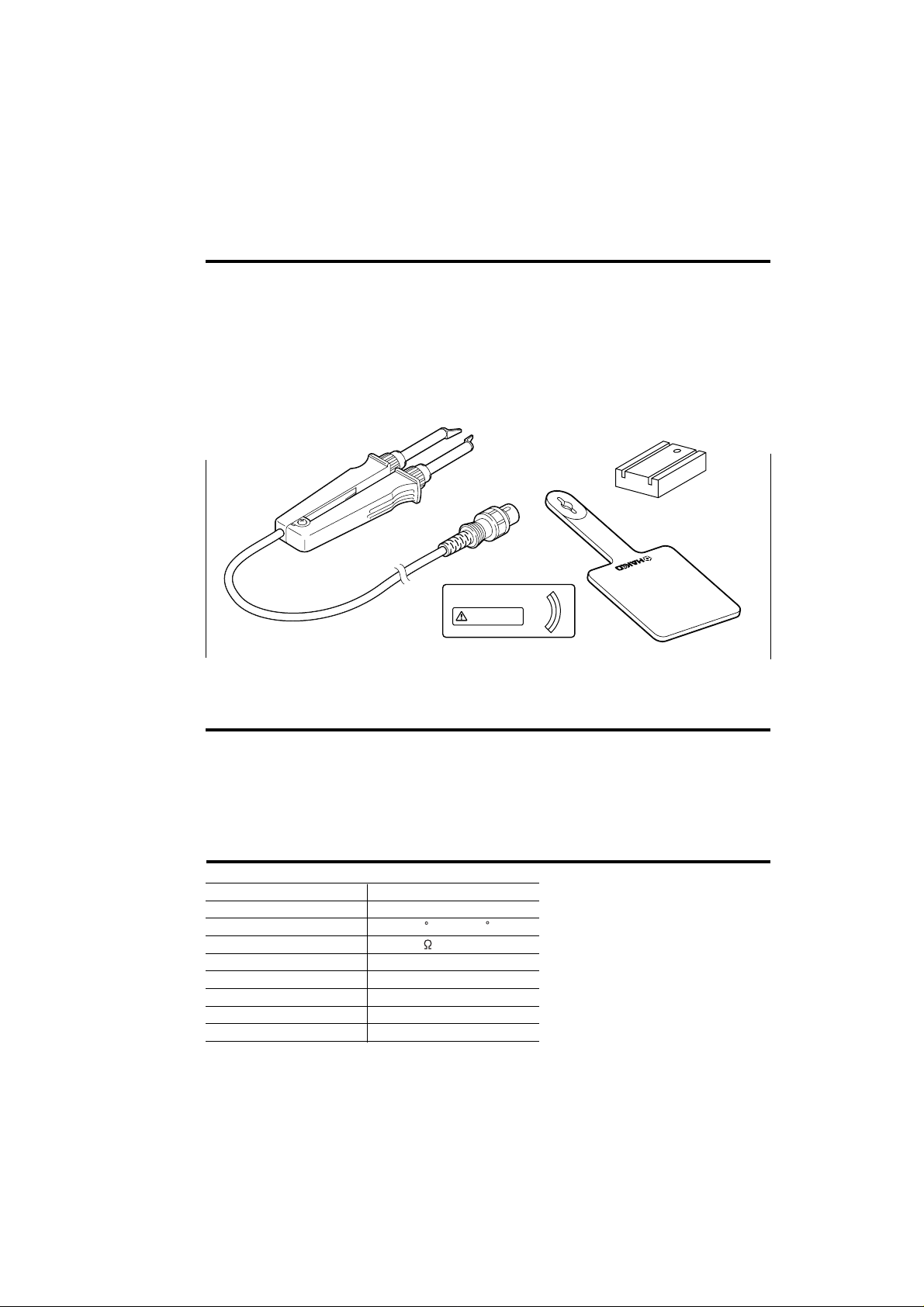

Packing List

Please check the contents of the HAKKO 950 package and confirm that all the items listed

below are included.

Tweezer

Caution Sticker

Heat Resistance Pad

Tip Alignment Tool

Instruction Manual

Tweezer

……………………………………… 1

………………………………1

…………………………1

…………………………1

…………………………1

Tip Alignment Tool

Do not operate this station

over 400 C with HAKKO 950.

Caution Sticker

Heat Resistance Pad

Applicable Models

In order to function, the HAKKO 950 must be connected to one of the

following HAKKO stations: HAKKO 700, 701, 702, 926, 927, 928,

936, 937, 939.

Specifications

Name HAKKO 950

Power Consumption

*Specifications and design subject to change without notice.

1

50W

200-400 C/392-752 FTemperature Range

Under 2Tip to Ground Resistance

Under 2mV (TYP.0.6mV)Tip to Ground Potential

Ceramic HeaterHeating Element

1.2m (4 ft.)Cord Assembly

186mm (7.3 in.)Total Length (w/o Cord)

93g (0.2 lbs.)Weight (w/o Cord)

Page 3

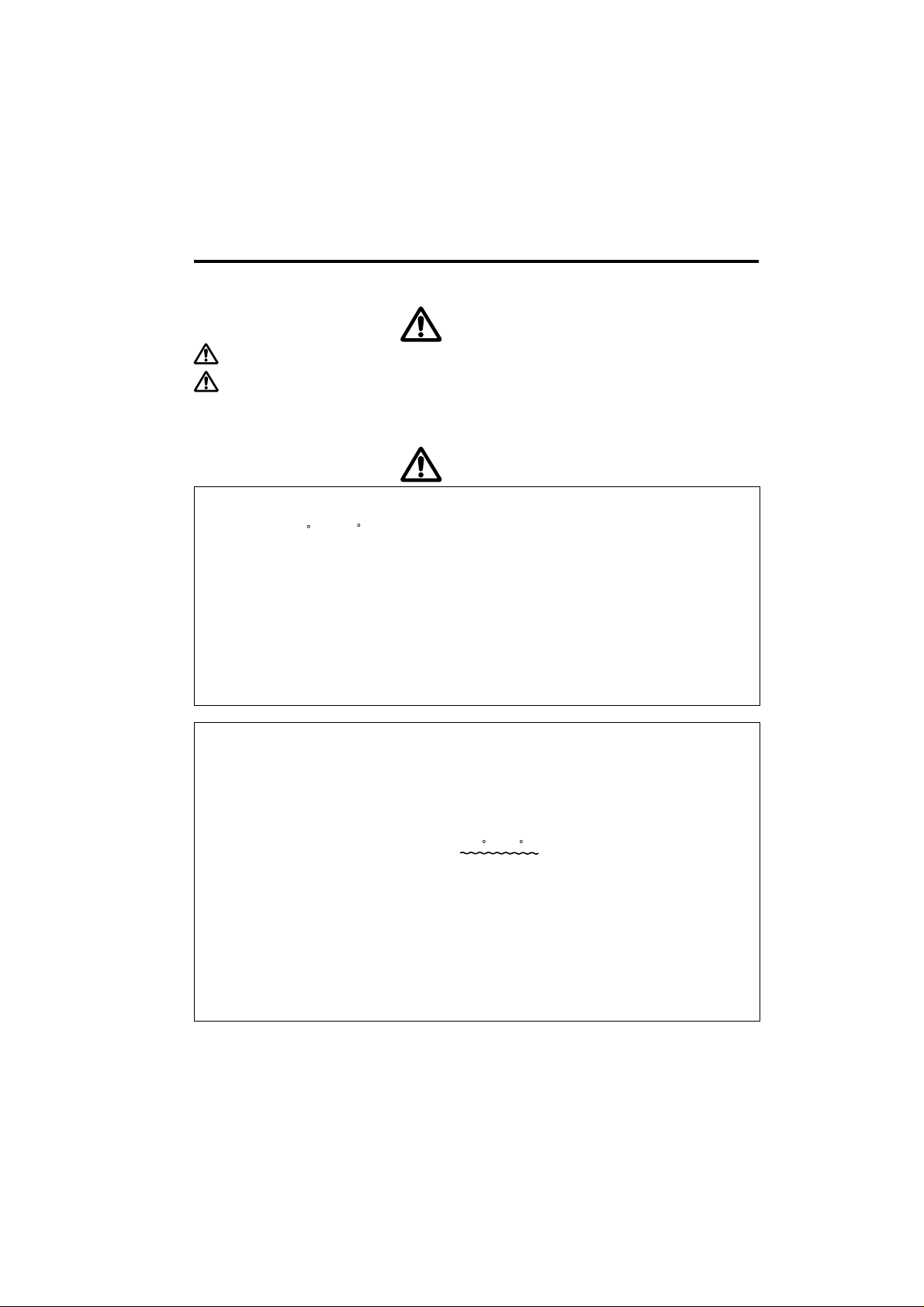

Precautions

In this instruction manual, “warning” and “caution” are defined as follows.

WARNING

WARNING: Misuse may potentially cause death of, or serious injury to, the user.

CAUTION : Misuse may potentially cause injury to the user or physical damage

to the objects involved.

For your own safety, be sure to comply with these precautions.

CAUTION

When the power is on, the tip temperature is between 200 C/392

F and 400 C/752 F. Since mishandling may lead to burns or fire,

be sure to comply with the following precautions.

Do not touch the metallic parts near the Tip.

•

Do not use the product near flammable items.

•

Advise other people in the work area that the unit can reach a very high temperature and

•

should be considered potentially dangerous.

Turn off the power while taking breaks and when finished using the unit.

•

Before replacing parts or storing the unit, turn off the power and allow the unit to cool to

•

room temperature.

To prevent damage to the unit and ensure a safe working

environment, be sure to comply with the following precautions.

Do not use the unit for applications other than those specifically described in the

•

instruction manual.

Before using the HAKKO 950 for the first time, calibrate the tip temperature.

•

Do not set the tip temperature to over 400 C/752 F.

•

Do not rap the HAKKO 950 against the work bench to shake off residual solder, or

•

otherwise subject the iron to severe shocks.

Do not modify the unit.

•

Use only genuine HAKKO replacement parts.

•

Do not wet the unit or use the unit when your hands are wet.

•

The operating process will produce smoke. Make sure the area is well ventilated.

•

Pull on the plug to disconnect the HAKKO 950 from the station outlet. Do not pull the

•

cord.

While using the unit, don’t do anything which may cause bodily harm or physical damage.

•

2

Page 4

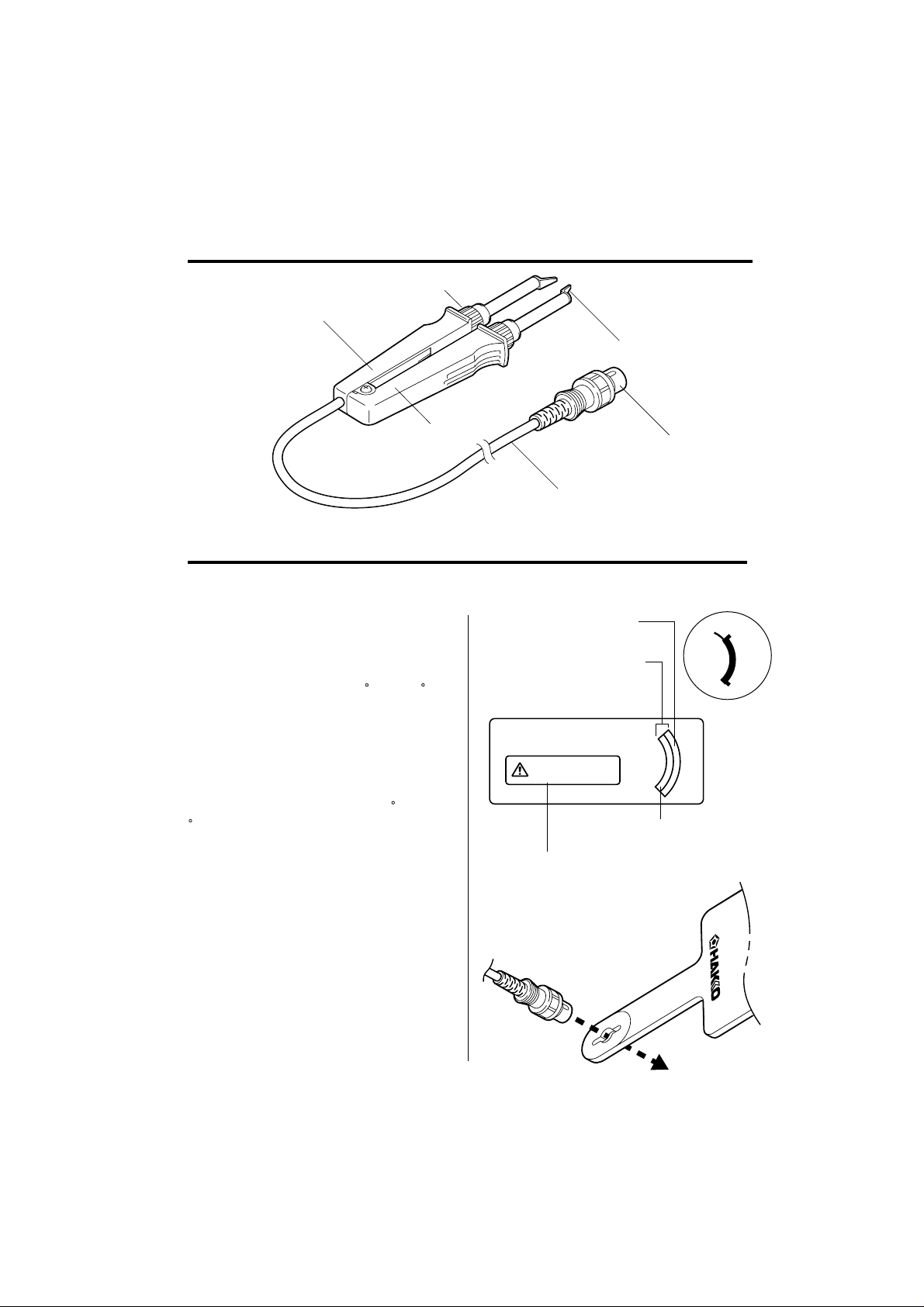

Names of Parts

Nipple

Handle B

Tip

Handle A

Cord Assembly

Setting up the HAKKO 950

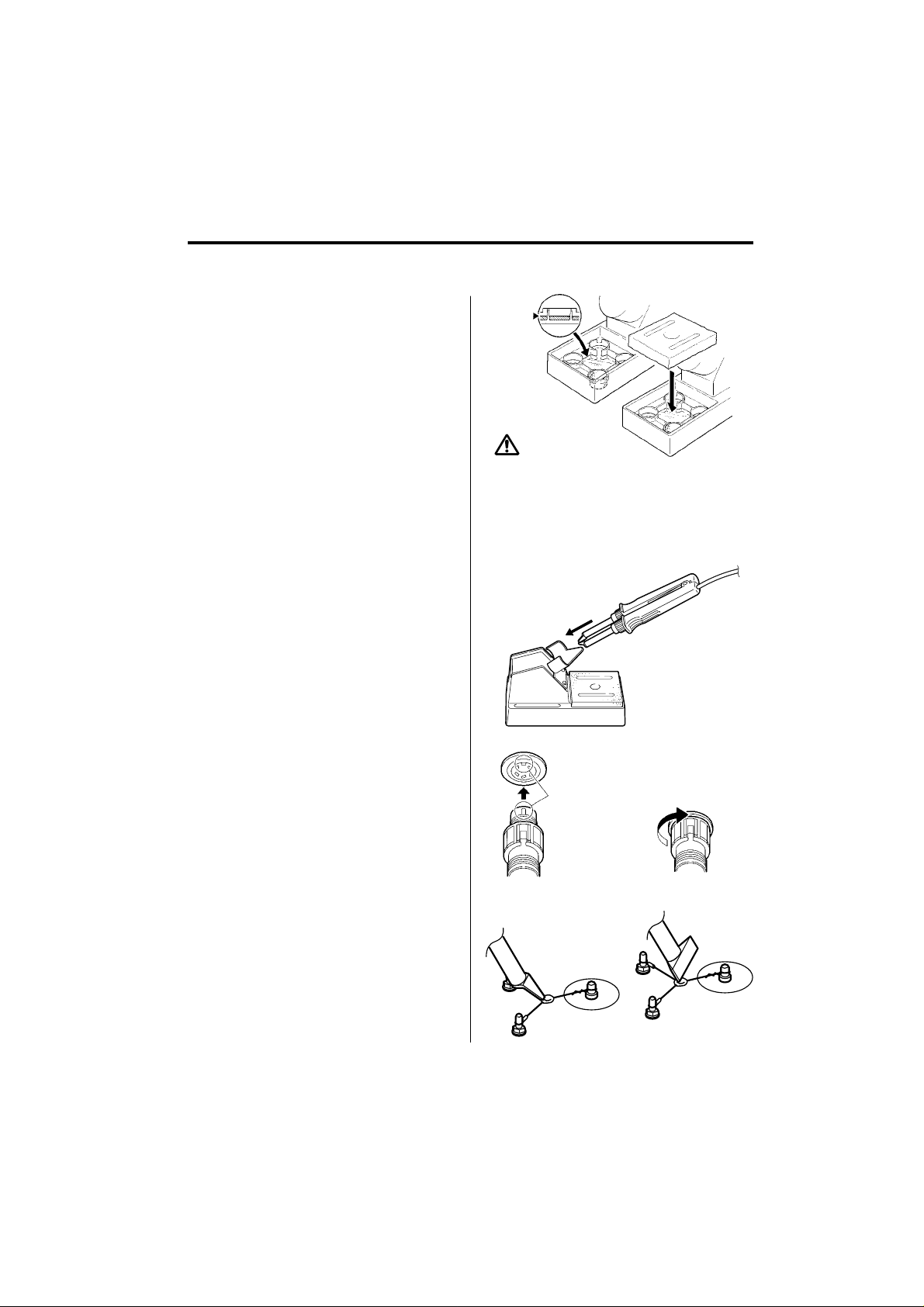

1. Affix the caution

sticker to the station.

The HAKKO 950 cannot be used at

temperatures above 400 C (752 F).

Higher temperatures may damage

the station. Be sure to affix the caution sticker to the station.

When using the HAKKO 950 SMD

Hot Tweezer, do not operate this sta-

tion at temperatures over 400 C (752

F).

For HAKKO 700,702

Dial type sticker only

Place the sticker above

the temperature

indicator lines.

Do not operate this station

over 400¡C with HAKKO 950.

Put the sticker in a visible area

such as the front or top panel

of the station.

Plug

400

450

480

For HAKKO 926,936

928,701

2. Install the Heat

Resistance Pad

Insert the cord plug through the hole

in the Heat Pad. The Heat Pad is

used when the soldering tip is

replaced.

3

Page 5

3. Iron holder

(Optional, part no. C1313)

An optional iron holder (part no.

C1313) is available for use with the

HAKKO 950.

Dampen the small cleaning sponge

1.

with water and squeeze it dry.

Place it in one of the 4 openings in

the iron holder base.

Add water to approximately the

2.

level shown in illustration. The

small sponge will absorb water to

keep the larger sponge above it

wet at all times.

Note: The large sponge may be

used separately (without the small

sponge and water)

3.

Dampen the large cleaning sponge

and place it on the iron holder

base.

4. Connections

Connect the Plug to the receptacle.

1.

Place the HAKKO 950 in the iron

2.

holder.

Plug the power cord into the power

3.

supply. Be sure to ground the unit.

CAUTION

The sponge is compressed. It will swell when

moistened with water. Before using the unit,

dampen the sponge with water and squeeze it

dry.

Always use a damp sponge to clean the tip.

Never wipe the tip clean on a dry sponge as

this can damage the tip.

@Receptacle

Align the grooves and pins,

and push straight in.

5. Calibration

Before operating the HAKKO 950, be

sure to calibrate the station using a

tip thermometer (HAKKO 191 Thermometer or 192 Soldering Tester.

When calibrating the tip for removing

SOP´s, place the edge of the tip on

the measuring point of the HAKKO

191 or 192, See sketch.).

Please refer to the instruction manual

for your station.

Turn clockwise firmly.

Tip/SOP

Tip/CHIP

4

Page 6

Replacing the Tip/Tip selection

Replacing the Tip

CAUTION

Be sure to turn off the power switch before

replacing the tip.

Loosen the nipple by turning it

1.

counterclockwise. It is not necessary to pull it out completely.

When the tip is heated, grasp the

2.

pipe part using the heat resistance

pad of the tip and pull.

Insert the new tip as far as it will

3.

go, and align it so that it is parallel

to the other tip.

Tighten nipple to fix the tip in

4.

place.

Tip Selection (Refer to P13)

The tip temperature will vary according to the shape of the tip. The preferred method of adjustment uses a tip

thermometer. (See your station's

instruction manual.) Less accurate

methods include adjusting the temperature control knob and calibrating

with a room thermometer.

CAUTION

Use only genuine HAKKO 950 replacement tips.

5

CHIP

SOP

Part No.

A13791L

A13782L

A13808L

A138110L

A138213L

A138318L

A138420L

A138525L

Dial Type Station

Difference From

CHIP 2L

0

0

0

0

-5 C (-9 F)

-5 C (-9 F)

-5 C (-9 F)

Digital Type Station

Compensation

Value

+4 C (+7 F)

+4 C (+7 F)

+4 C (+7 F)

+4 C (+7 F)

+4 C (+7 F)

0

0

0

SOP tip only

Use the tip alignment tool to

easily align the two tips in parallel.

CAUTION

The tip is very hot. If handled improperly,

it can cause serious burns.

Do not hold onto the heat resistance pad for

a long period.

1. Dial type station

Example: When using an SOP 25L tip at

a temperature of 400 C (750 F), the difference between this tip and CHIP 2L is -5 C

(-9 F).

Set the temperature control knob to 405 C

(759 F).

2. Digital type station

Digital type stations can be calibrated with a room thermometer. Refer

to the compensation value chart

below.

Specific instructions can be found in

your station's instruction manual.

Page 7

Operating Instructions

1. Set the Temperature

CAUTION

Never set the temperature to any value over

400˚C (752˚F). Doing so may damage the

station.

Set the temperature according to the

type of work to be done.

2. Apply solder or flux.

If there is insufficient solder on the

PWB, or the soldered area is too

small, apply solder or flux to the

PWB. Solder may also be applied to

the tip.

3. Melt the solder

Place the tip on the soldered part and

melt the solder. Confirm that the

solder is fully melted. See sketch `A´.

4.

Remove the componen

After confirming that the solder is fully

melted, lightly squeeze the tweezer to

grasp the component and lift to

remove the component. See sketch

`B´.

t

CAUTION

Very high tip temperatures may damage the

printed circuit board, possibly causing the

printed pattern to become detached. HAKKO

recommends setting the tip temperature to

300˚C (572˚F) for all normal work, and raising it

only when a specific job requires a higher

temperature. Using the lowest possible

effective temperature not only helps protect

parts that are sensitive to heat, it also helps

protect the tip from deterioration caused by

heat.

A

CAUTION

(For users of the HAKKO 937 Soldering Station)

The HAKKO 950 contains a sensor—attached to the heating element in

handle B—to detect the tip temperature. The HAKKO 937 Soldering Station’s heater error function will not

operate if the heating element in handle A is broken.

B

6

Page 8

Troubleshooting Guide

English

More information can be found in your station’s instruction manual.

Problem 1.

WARNING

The tip does not heat up.

Problem 2.

The tip heats up intermittently.

Problem 3.

The tip is not wet.

Disconnect the power plug before servicing.

Failure to do so may result in electric shock.

Check 1. Is the cord assembly

broken ?

• Refer to ‘Checking for breakage in the

cord assembly.’

Check 2. Is the Heating Element

broken?

• Refer to ‘Checking for breakage in the

heating element.’

Check 1

Check 3. Is the tip temperature too

high?

• Set an appropriate temperature.

Check 4. Is the tip clean?

• Refer to ‘Tip Care and Use’

Problem 4.

The tip temperature is too low.

Problem 5.

The tip can not be pulled off.

Problem 6.

The tip doesn't hold the

desired temperature.

7

Check 5.

• Refer to ‘Inspect and clean the tip’

Check 6. Is the iron calibrated

correctly?

• Recalibrate.

Check 7. Is the tip seized?

Is the tip swollen because

of deterioration?

•

Replace the tip and the heating element.

Check 6 above.

Is the tip coated with oxide?

Page 9

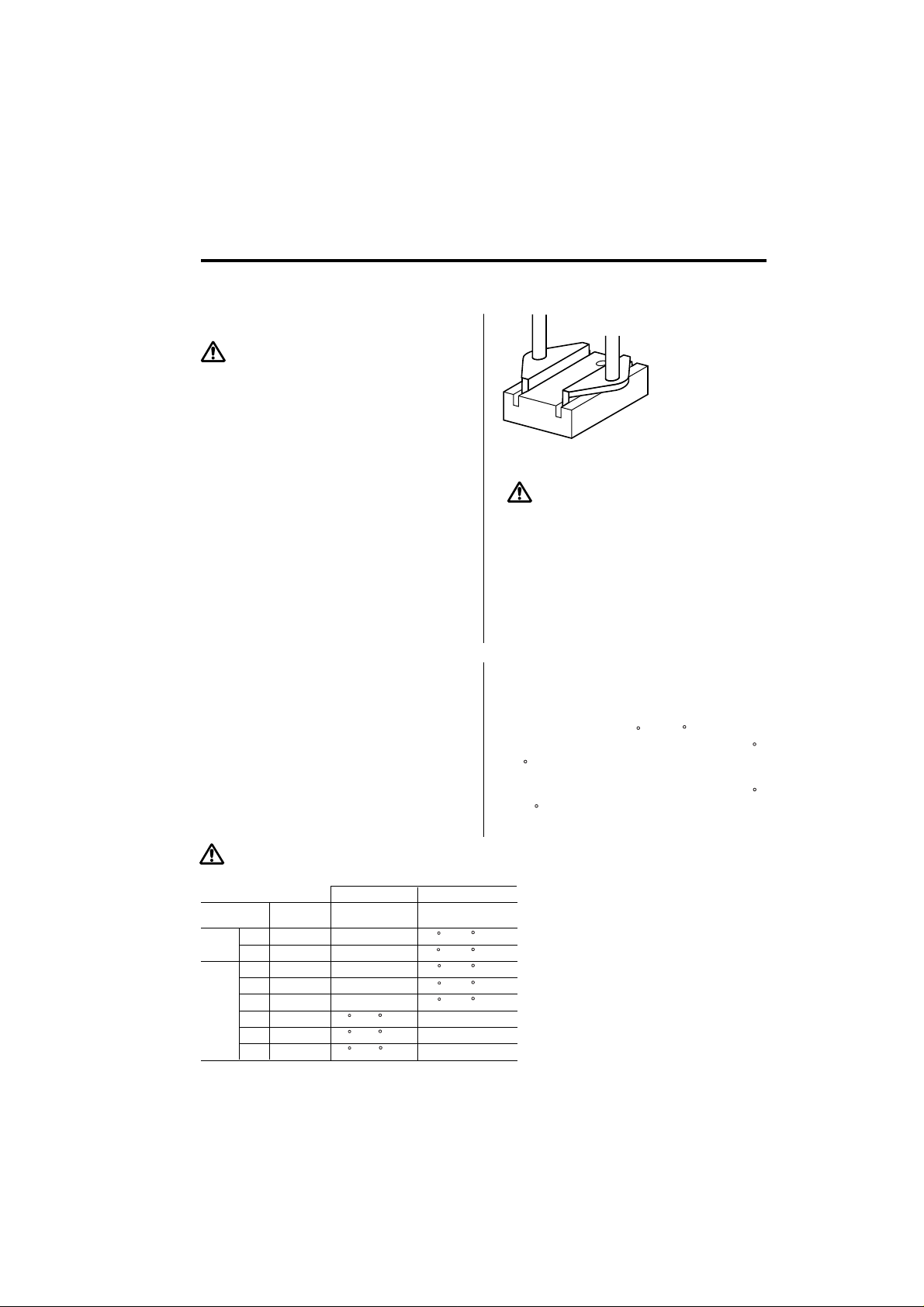

Checking for breakage of the heating element,

cord assembly, and tip to ground resistance

Disconnect the plug and measure the

resistance between the connecting

plug pins as follows.

If the values of 'a' and 'b' are outside

the ranges shown in the chart,

replace the heating element (sensor)

and/or cord assembly.

1.

Broken heating element

CAUTION

Be sure to measure the resistance of the heating element in both handles A and B. If one of

the heating elements is found to be broken,

replace both heating elements.

Disassembling the HAKKO 950

(Refer to P11,12)

1. Loosen the nipple by turning it

counterclockwise.

2. Pull out the tip.

3. Remove the screw.

4. Remove the strut pin, and

detach handles A and B.

CAUTION

Do not lose the tension spring.

5. Remove the self-tapping screw

and the handle cover.

6. Pull out the PWB and the heating

element.

a Between pins 4&5

(Heating Element)

b Between pins 1&2

(Sensor)

c Between pin 3&Tip

3

4

5

1

Heating Element (Red)

Sensor (Blue)

2.5 - 4.5 (Normal)

43 - 58

Under 2

2

S

(Normal)

H1

H2

H2

S

H1

Measure when the heating element is

at room temperature.

1.Resistance value of heating element (RED) 2.5 - 4.5

2.Resistance value of sensor (BLUE)

43-58 @If the resistance value is not

normal, replace the heating element.

(Refer to the instructions included

with the replacement part.)

8

Page 10

2. Broken Cord

There are two methods of testing the

cord.

CAUTION

The LED heater lamp will flicker even with a

normal cord if the temperature reaches 400˚C

(752˚F).

3. Checking the tip to

ground resistance

1.

Turn the unit ON and set the temperature to 400˚C(752˚F). Then

wiggle and kink the iron cord at

various locations along its length,

including the strain relief area.

If the LED heater lamp flickers,

then the cord needs to be

replaced.

2.

Check the resistance between the

pin of the plug and the wire on the

terminal in the handle B.

Pin 1: Red

Pin 2: Blue

Pin 3: Green

Pin 4: White

Pin 5: Black

The value should be 0 . If it is

greater than 0 or is , the cord

should be replaced.

If the value of ‘c’ (between pin 3 & tip)

is over the above value 2 as

measured with a tester, remove the

oxidization film by lightly rubbing with

sand-paper or steel wool the points

shown below.

9

Page 11

Maintenance

Inspect and Clean the Tip

CAUTION

Never file the Tip to remove oxide.

Tip Care and Use

1.

Set the temperature to 250 C (482

F).

2.

When the temperature stabilizes,

clean the tip with the cleaning

sponge and check the condition of

the tip.

3.

If there is black oxide on the solderplated portion of the tip, apply new

solder (containing flux) and wipe

the tip on the cleaning sponge.

Repeat until the oxide is completely

removed. Coat with new solder.

4.

If the tip is deformed or heavily

eroded, replace it with a new one.

•Tip T emperature

•Cleaning

•When Not in Use

•After Use

High operating temperatures can degrade

the tip. Use the lowest possible operating

temperature.

Clean the tip regularly with a cleaning

sponge, as oxides and carbides from the

solder and flux can form impurities on the

tip. These impurities can result in defective joints or reduce the tip's heat conductivity.

Never leave the HAKKO 950 sitting at

high temperature for long periods of time,

as the tip's solder plating will become covered with oxide, which can greatly reduce

the tip's heat conductivity.

Wipe the tip clean and coat the tip with

fresh solder. This helps prevent tip oxidation.

10

Page 12

Parts List (Tweezer/Iron Holder)

Note: Spare or repair parts do not include mounting

screws, if they are not listed on the description.

Screws must be ordered separately.

14

13

13

15

16

16

8

Tapping Screw

M 3 x 8 (2)

5

9

6

Pan Head Screw

M 3 x 14 (1)

Spring Washer

M 3 (1)

3

10

4

Item No. Part No. Part Name Description

1 Tip See P.13

2 A1377 Heating Element 24V-50W (25W x 2)

3 B2289 Nipple

4 B2290 Terminal

5 B2295 Tension Spring

6 B2292 Handle A

7 B2294 Handle B

8 B2291 Handle Cover A

9 B2293 Handle Cover B

10 B2296 Strut Pin

11 B2297 Cord Asse'y

12 B2032 Grounding Spring

13 C1313 Iron Holder With Cleaning Sponge

14 A1386 Cleaning Sponge

15 B2300 Heat Resistance Pad

16 B2301 Tip Alignment Tool

11

11

2

1

1

5

2

12

4

Hexagon Nut

M 3 (1)

7

11

3

1

12

Page 13

Parts List (Tips)

Part No.

A1379

CHIP

A1378 Tip/CHIP 2L

SOP

A1380 Tip/SOP 8L

A1381 Tip/SOP 10L

A1382 Tip/SOP 13L

A1383 Tip/SOP 18L

A1384 Tip/SOP 20L

A1385 Tip/SOP 25L

Part Name

Tip/CHIP 1L

Size A Shape

1mm (0.04 in.)

2mm (0.08 in.)

A

8mm (0.31 in.)

10mm (0.39 in.)

13mm (0.51 in.)

18mm (0.71 in.)

20mm (0.79 in.)

25mm (0.98 in.)

A

13

Page 14

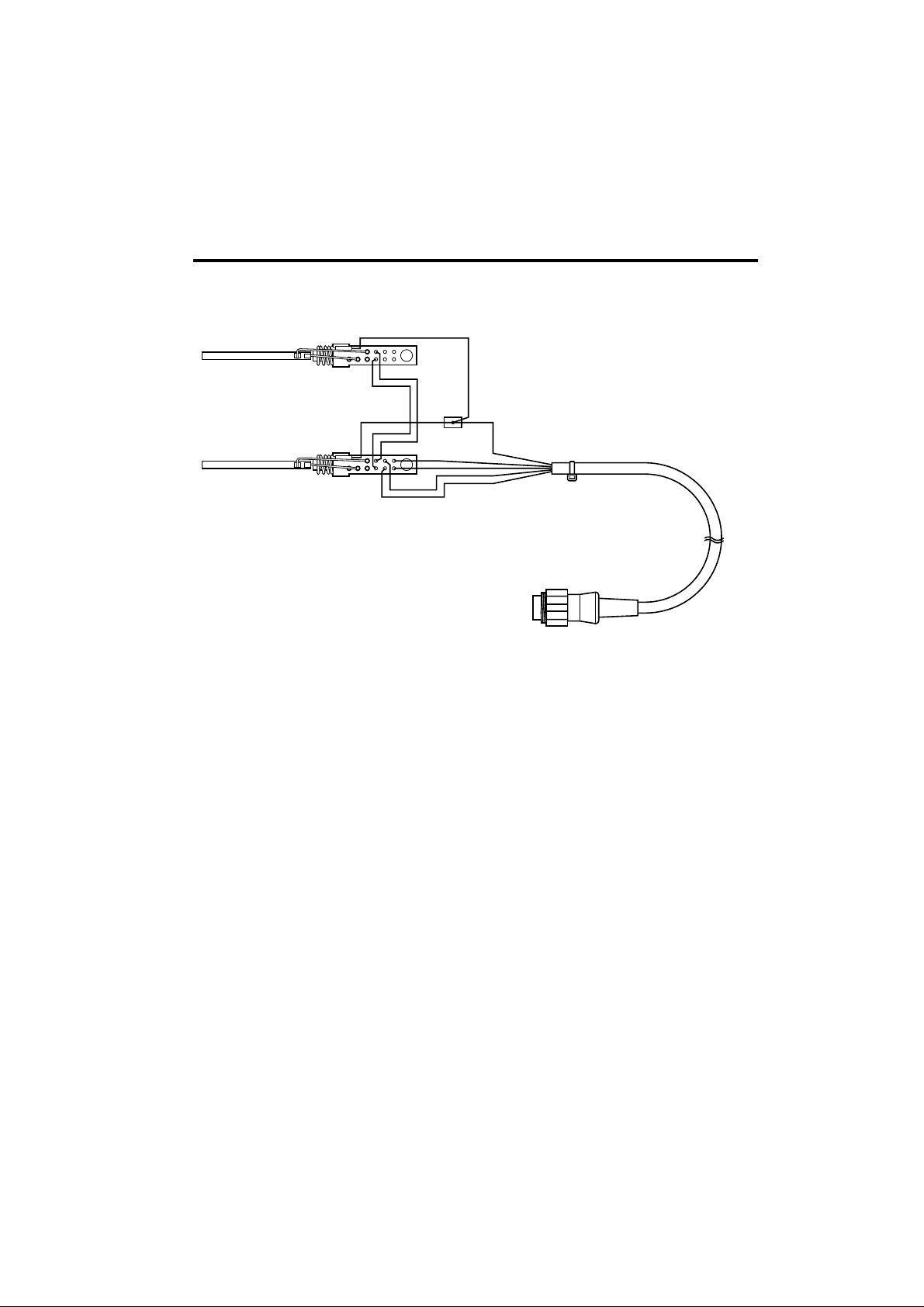

Wiring Diagram

14

Page 15

®

HEAD OFFICE

4-5, SHIOKUSA 2-CHOME, NANIWA-KU, OSAKA, 556 JAPAN

TEL: (06) 561-3225 FAX: (06) 561-8466

TLX: HAKKOOSA J65274

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

25072 ANZA DR. SANTA CLARITA, CA 91355, U.S.A.

TEL: (805) 294-0090 FAX: (805) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

S'PORE: HAKKO PRODUCTS PTE., LTD.

1, GENTING LINK #02-04, PERFECT INDUSTRIAL

BUILDING, SINGAPORE 349518

TEL: 7482277 FAX: 7440033

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

ROOM 804 EASTERN HARBOUR CENTRE,

28 HOI CHAK STREET, QUARRY BAY, HONG KONG.

TEL: 2811-5588 FAX: 2590-0217

PHILIPPINES: HAKKO PHILS TRADING CO., INC.

NO. 415 WINDSOR TOWER CONDOMINIUM,

163 LEGASPI ST., LEGASPI VILLAGE MAKATI,

METRO MANILA, PHILIPPINES

TEL: 2-817-07-12 FAX: 2-810-76-49

MALAYSIA: HAKKO PRODUCTS SDN BHD

MALAYSIA HEAD OFFICE: PETALING JAYA

LOT 35/1 THE HIGHWAY CENTRE JALAN 51/205 46050

PETALING JAYA WEST MALAYSIA

TEL: 03-7941333 FAX: 03-7911232

PENANG BRANCH: TEL: 04-644 6669 FAX: 04-644 8628

JOHORE BAHRU BRANCH: TEL: 07-236 7766 FAX: 07-237 4655

May. ’97~

Page 16

Page 17

Loading...

Loading...