Page 1

YCZ-A001

Air conditioner central controller

Contents:

1.Safety precautions ------------------------1

2.Brief description on functions ----------2

3.System general information--------------3

4.Installation and debugging---------------4

5.Installation manual for wire

controller---------------------------------5-9

6.Outside view and dimensions of

the central controller--------------------10

7.Description and function of keys

on the controller--------------------------11

8.Operational guide -------------------12-19

9.Failure diagnosis-------------------------20

10.Installation procedure -----------------21

11.Installation and debugging--------22-24

12.Model of monitor/detector----------- 25

13.Performance parameters

and spare parts--------------------------26

To ensure safe and correct operation of the central controller, please read

this operational instruction manual carefully before using for thoroughly

understanding the information therein.

Please keep this manual appropriately.

No.

0010570688

MONI TOR

SET

UNIT

AUTO

TEMP

ROOM

TEMP

CENTRAL

REMOTE

TIMER ON

EVERY DAY

SELECT

ON

OFF

MODE

FAN SPEED

TEMP.

TIME

TIME TIMER

CENTRAL

REMOTE

CONFI RM

LOCK

TIMER OFF

Total on/Total off

Page 2

1

Safety Precautions

Below are four kinds of safety precautions and suggestions:

WARNING:

Improper use may result in severe consequences of death or serious

injures.

Improper use may result in injures or machine damages; in some

cases may cause serious consequences

CAUTION:

: It must be strictly prohibited where marked with Prohibited ,

otherwise may result in machine damages or endanger the user

personal safety.

: It must be strictly followed where marked with To be followed ,

otherwise may result in machine damages or endanger the user

personal safety.

Instructions: This information can ensure correct operation of the machine.

Be sure to follow the following important safety precautions.

These precautions should be at hand to be checked at any time when needed.

If air conditioner is transferred to a new user, this manual should be as well

transferred to the new user.

WARNING

Entrusting Installation

Installation should be entrusted to after

service staff; self-installation

may result in electric shock, fire

and the similar because of improper

installation.

If any abnormal phenomena are found

(e.g. smell of burning),

please stop running and cut off

power supply, and contact after service

staff to find out treatment method.

If keep using under this

situation, may result in

accident of electric and fire.

Power

of f

When intend to move and reset controller,

ask after service staff for responsibility.

Improper installation may result in electric

shock and fire.

Absolutely not to alter without authorization.

Improper alteration may result in accident

of electric shock, fire and the similar.

When repair needed, ask after service staff

to handle it.

Improper maintenance and

repair may result in electric

shock and fire.

Not be allowed to spray flammable spraying agent directly to controller.

Otherwise may result in fire.

Not be allowed to operate switch with damp hands, and not to spray controller

with water.

Otherwise may result in electric shock.

Not be allowed to press switch with matter having sharp tip.

Otherwise may result in malfunction or electric shock.

Maintenance

When maintenance or abnormity appeared, be sure to cut off manual operation power.

It will cause color change or paint-fading if wipe appearance of operation

portion with gasoline, thinner or chemical wiping cloth; be careful.

If operation portion is heavily soiled, shall immerse cloth in diluted

neutral detergent, and wipe that portion after wring the cloth, and wipe

cleanly with dry cloth.

Page 3

2

Brief description on functions

The remote central controller (hereunder as central controller ) is a necessary part at the option of the user for Haier commercial air conditioner remote

monitoring system group control functional network . A remote control monitor(or dector) is used to transform standard digital interface and realize bus code address communication.Connecting the air conditioner directly,it undertakes

local processing and gathering of air conditioner control and operation information,transmitting control and information data to the central controller.A network air conditioner (hereunder as air conditioner ) is defined as an air conditioner having an indoor computer board with remote control interface, only which

could combine with parts such as the monitors and central controller to form a

remote monitoring system

group control network , fulfilling the function of

data exchange and monitoring .

The central controller could consult through the monitors as well as display

through the LCD the main work status of the air conditioner. With it the work

status of main functions of the air conditioner could be set through key input

and LCD display . It can also monitor the basic working status of all air

conditioners in the network . In addition, the central controller is equipped with

a 24 hours real-time clock system for centrally control the clocks in the network .

Brief descriptions are given as follows :

1. Communication function

Communicate with the monitors in the group control network

To communicate with the monitors through the RS-485 bus (A, B). The

central controller sends commands to and receives response from the monitor;

communication by address enables sending and receiving control information,

work information and fault information between the monitors and the central

controller.

2. LCD display function:

The LCD could display the fundamental status of air conditioning units (are

the units existing? On/off? Fault? Are units group selected? Cursor and the

current unit no.);

The LCD can display the working status of the air conditioning unit with the

current number (mode, fan speed, temperature setting, room temperature,timer,

error code, central/remote control status);

The working status of the central controller (monitor/set status, panel locking

status, signaling status).

3. Key input function:

The keys for moving the current unit number cursor and for group selection:

, ,

, , SELECT;

The keys for setting working status of the air conditioning unit and control

conditions: ON/OFF, MODE, FAN SPEED, TEMP TIME

/

, CLOCK,

TIMER, CENTRAL/REMOTE, SET;

The key for locking key function of the central controller: LOCK.

4. Unit number setting function:

To enrich the control functions of Haier commercial air conditioner remote monitoring system, multiple controllers could be set to work together for a combination

of multiple functions. For this, the central controller is provided with a two-digital

switch for setting controller address.

Page 4

3

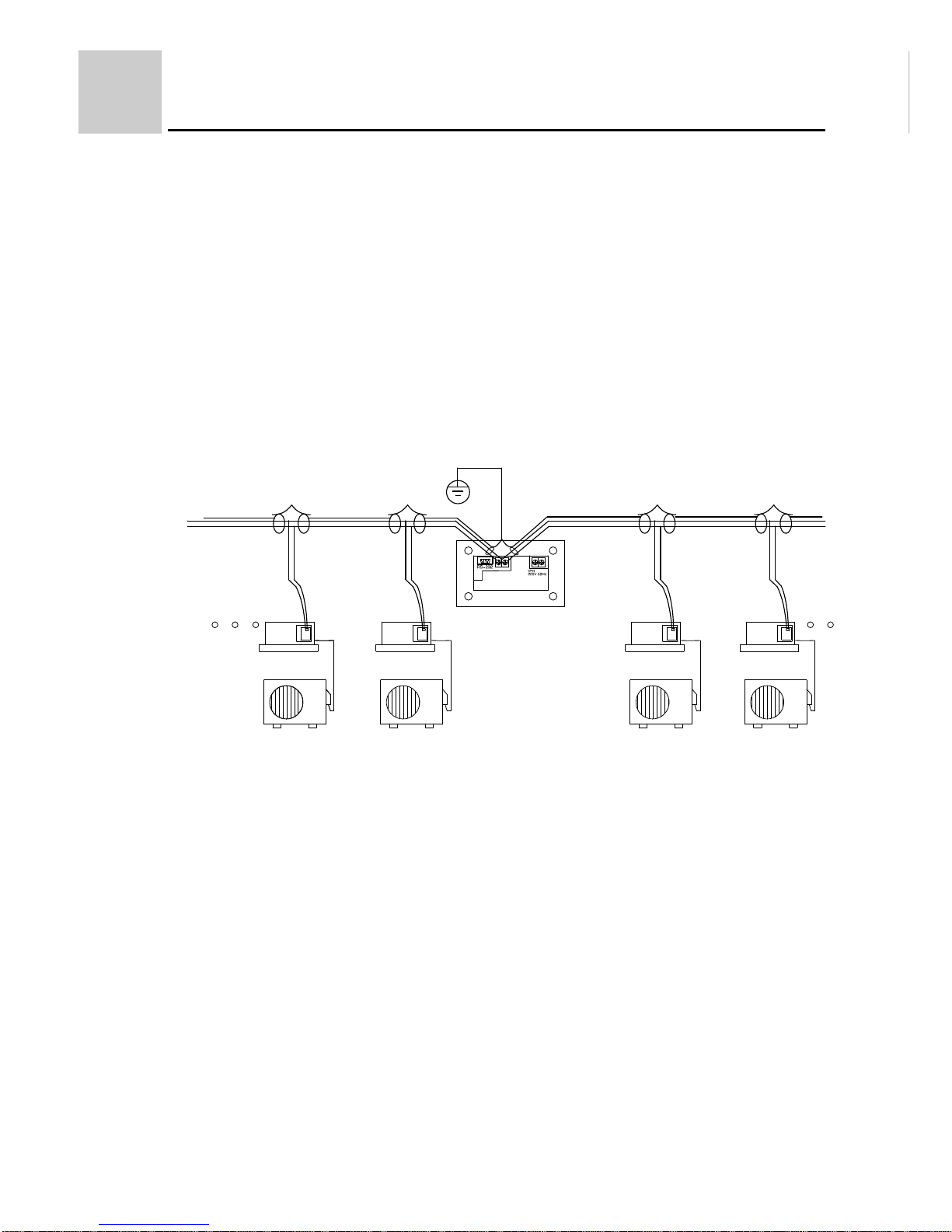

(Fig.2)

(Fig.1)

System general information

1. Realizing group control function with the central controller

A monitor is connected with an air conditioner through A+, A- of the 4-wire screw

terminals on the interface for air conditioner, meanwhile the monitor dial switch

shall be set as single unit working mode and the address unit number shall be set

according to the planed scheme, see "Setting of the Dial Switch" for detailed setting

and corresponding addresses. For realizing group control function through the

central controller, the system still needs to connect the monitors. Each monitor shall

be connected with the twin twisted shielded communicating bus through the twowire screw terminals (A, B) on the RS-485 interface. For the communicating bus, it

is required to be shield grounded and the resistances on two sides shall be matched.

2.Realizing double unit switch-over group control function with the central

controller

A monitor is connected with two air conditioners with the same model through the

4-wire screw terminals on the interface for air conditioner, meanwhile the monitor

dial switch shall be set as double unit switch-over working mode with the default

switch-over time of 24 hours, and the address unit number shall be set according to

the planed scheme, see Setting of the Dial Switch

for detailed setting and corresponding addresses. For realizing double unit switch-over group control function

through the central controller, the system still needs to connect the monitors. Each

monitor shall be connected with the twin twisted shielded communicating bus

through the two-wire screw terminals (A, B) on the RS-485 interface. For the communicating bus, it is required to be shield grounded and the resistances on two sides

shall be matched.

RS-485 bus Upper A Lower B

Rear view of the

central controller

View of the monitor

interface

Power cord

Power on/off

Indoor unit

Outdoor unit

A RS-485 B

RS-485 bus Upper A Lower B

Page 5

4

Installation and debugging

(Fig.3)

3. For some newly-developed models, such as A******BEA, A******BIA,

A******ERA, in indoor PCB , we set the stanard connector data transforma-

tion function of the detector. They can connect the central controller directly

through the RS-485 communication protocol. The detailed information

refers to the operation manual with the unit.

For the above models, have no double unitswitch-over group control function.

If you want the timing function, the weekly timer YCS-A001 is necessary,

and is used together with YCZ-A001. The address seeting of weekly timer

needs to be adjusted, please refer to the operation manual with the unit.

The detailed information refers to the operation manual with the unit.

RS-485 bus Upper A Lower B

Rear view of the

central controller

Indoor unit

Outdoor unit

RS-485

Page 6

5

(Fig.4)

Installation manual for wire controller

The communication wiring is 4 meter long; if the actual length is more

than it, please distribute wiring according to below table:

2. Communication wiring:

The wired controller is equipped with special communication wiring in the accessories.

3-core terminal (Polar wire) is connected with the terminal A, B, C of wired controller

respectively.

1. Wiring connections of wired controller:

There are three methods to connection wired controller and the indoor units:

A.One wired controller can control max. up to 16 sets of indoor units, and 3 pieces of

polar wire must connect the wired controller and the master unit (the indoor unit

connected with wired controller directly), the others connect with the master unit through

2 pieces of polar wire.

B. One wired controller controls one indoor unit, and the indoor unit connects with

the wired controller through 3 pieces of polar wire.

C. Two wired controllers control one indoor unit. The wired controller connected with

indoor unit is called master one, the other is called slave one. Master wired controller

and indoor unit; master and slave wired controllers are all connected through 3 pieces

of polar wire.

*One side of the shielded sheet of communication wire must be earthed.

Communication wiring length(m) Dimensions of wiring

< 100 0.3mm2x3-core shielded wire

100 and <200 0.5mm2x3-core shielded wire

A B C

Wired controller

Control wiring of wired

controller, polar.

1 2 3

1 2 3 1 2 3

1 2 3

1 2 3

Indoor 16Indoor 15Indoor NIndoor 2Indoor 1

Wired controller Wired controller Wired controller Wired controller Wired controller

(master unit)

1 2 3

Indoor 1

Wired controller

A B C

Wired controller

Polar wire

1 2 3

Indoor 1

Wired controller

A B C

Wired controller

Polar wire

A B C

Wired controller

Polar wire

A

B

C

Page 7

Cut off Cut oonnected

SW0-1 Master unit Slave unit

Note

6

Installation manual for wire controller

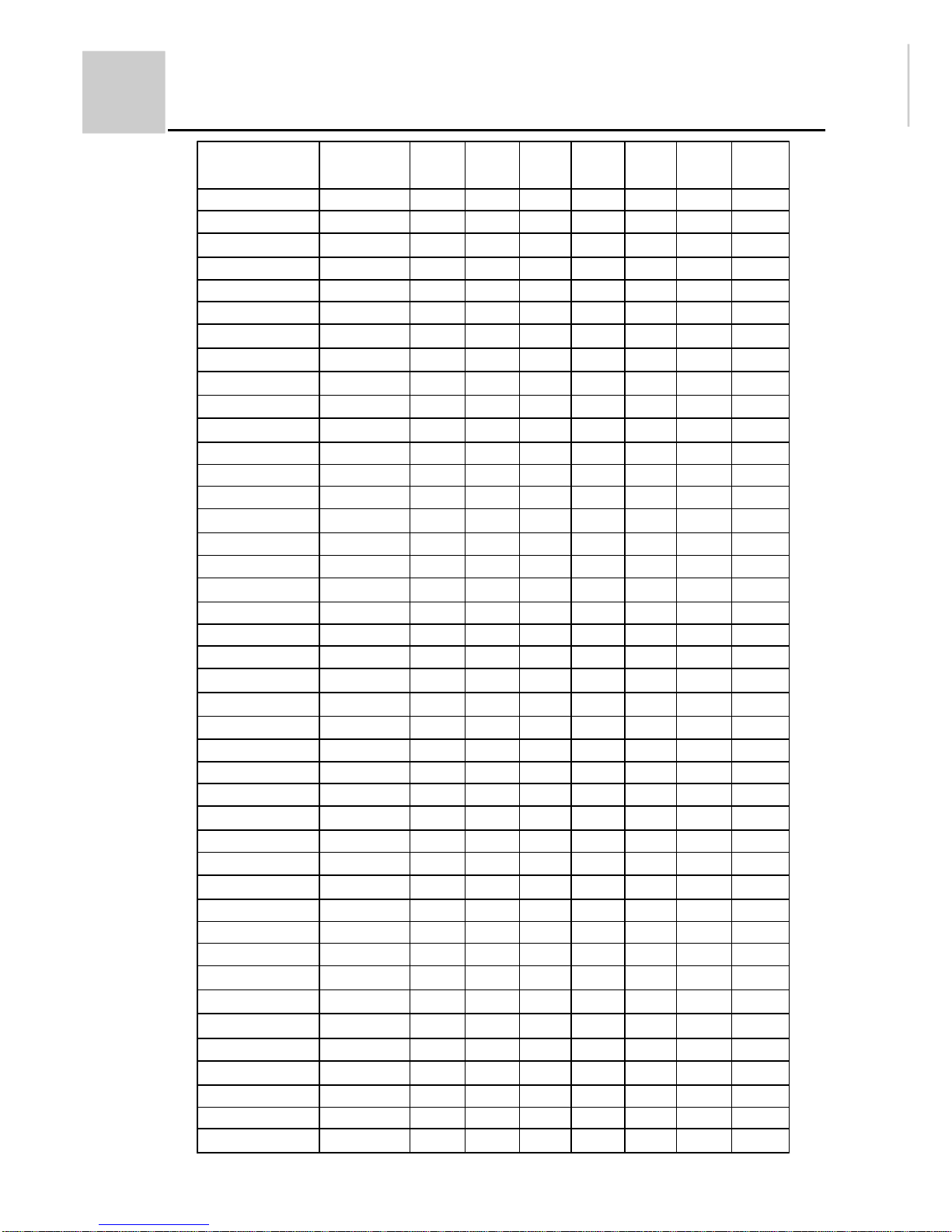

3.Setting address method:

The dip switch of indoor unit usually marked with "SW" or "BM", you can refer the

below table to set address:

If you use central controller , the clip switch will be used simultaneously.

Wiring request in central control type: port A-B is connected with indoor port refer to

A-B through 2-core shield wire. Requirements:

1.Port A connects with port A of all indoor units.

2.Port B connects with port B of all indoor units.

Refer to the Figure 3 to wiring.

The address setting can be realized by the dip switch, which used to set address in

indoor PCB. Please refer the indoor unit circuit diagram to find the dip switch.

If you use the group control function, there should be a master unit and 15 sets of

slave units.Refer to the operation manual with the unit to set the master unit or the slave

units.

The indoor PCB is matched with this wired controller (YR-E12)which can be set

according to below table:

When the wired controller controls several indoor units, there is only one Master unit,

and other can be set as Slave unit.

The detailed information manual with the unit to set the master unit or the slave units.

The wired controller must be used with cooperation with indoor unit. When wired control

type is selected, the function of indoor unit must be adjusted (after power cut off).

Indoor unit address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SW1-4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

SW1-3

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

SW1-2

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

SW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Page 8

7

Installation manual for wire controller

Address on central

controller

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Indoor unit

address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

SW2-3

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SW2-2

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SW2-1

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SW1-4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

SW1-3

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

SW1-2

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

SW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Page 9

8

Installation manual for wire controller

SW2-1

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

SW1-4

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

SW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Address on central

controller

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

Indoor unit

address

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

SW2-3

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SW2-2

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SW1-3

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

SW1-2

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

Page 10

9

Installation manual for wire controller

Address on central

controller

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

Indoor unit

address

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

--------

SW2-3

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SW2-2

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SW1-3

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

SW1-2

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

SW1-1

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

SW2-1

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SW1-4

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

Page 11

10

180mm

(Fig.5)

MONI TOR

SET

UNIT

AUTO

TEMP

ROOM

TEMP

CENTRAL

REMOTE

TIMER ON

EVERY DAY

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFIRM

LOCK

TIMER OFF

(Fig.6)

FAN SPEED

Outside view and dimensions of the central

controller

As illustrated:

(Figure 5 is the front view and Figure 6

is the side view) The central controller

is 180mm long, 120mm wide and 64.4 mm

thick.

64. 4mm

Total on/Total off

Page 12

11

MONI T0R

SET

UNIT

AUTO

TEMP

ROOM

TEMP

CENTRAL

REMOTE

TIMER ON

EVERY DAY

SELECT

ON

OFF

MODE

TEMP.

TIME

TIME TI MER

CENTRAL

REMOTE

CONFIRM

LOCK

TIMER OFF

FAN SPEED

Description and function of keys on the

controller

Display of operation mode

and signal emitting

LOCK display

Display of current unit number

Location of the indicating cursor

Display of MONITOR/SET

Generally indicating MONITOR . When

setting ON/OFF or other items, it changes

from MONITOR

into SET .

Display of the connected units

Flashing

indicates the cursor for current unit

or that the monitor and air conditioner are in

group selection status.

Lighted

indicates the monitor for the unit

has been linked into the network, otherwise not

linked.

Lighted

indicates the unit is in "on" mode, otherwise in

"off" mode.

Flashing

indicates fault.

Flashing

of the current unit

indicates the cursor, flashing

of non-current unit indicates the

unit is in group selection status.

Direction keys

Up

Down

Left

Right

Used to select the current unit

number

SELECT key

To determine the selected unit

number during group selection,

the

of the corresponding

unit number flashes at the same

time.

LOCK key

This key can be used to lock the

keys and LCD display.

ON/OFF key

Used to select unit on/off.

MODE key

Used to select running mode.

Display of fan speed and

louver

Total on/ Total off indicator

Total on/ Total off key

Display of temperature setting

FAN SPEED key

To select the fan speed.

Note: 1 In MONI

mode, pressing SEL, MODE, FAN SPEED, TEMP TIME keys

may change the MONITOR

mode into SET

mode. If SET

key or other keys

hasn t been pressed within 10s, it will automatically return to MONI

mode.

2 The button with blue background button film can send the control command.

3 The response condition of the Mode button, TEMP betton and FAN SPEED button is

that the unit is at ON state.

TEMP/TIME keys

Used to set a desired room

temperature, clock and time.

CLOCK key

Used to unitarily set the clock.

TIMER key

To select timer mode:

TIMER ON/TIMER OFF

/blank

CONFIRM key

Used to confirm the function

settings and send to the air

conditioner corresponding to

the selected unit number.

CENTRAL/

REMOTE key

To select central

or remote control

method.

Display of

self-check code

Display of time setting

Display of CENT/REM

Display of room

temperature

Total on/Total off

Page 13

12

TEMP

REMOTE

UNI T

ROOM

TEMP

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFIRM

LOCK

FAN SPEED

Operational guide

Total on and Total off

Pressing the Total on and Total off

key could turn on or off all connected indoor

units.

1. Press the Total on and Total off

key to send all on/all off instruction.

There is indication for signaling and the working status changes.

In all on status, pressing this key could turn all indoor units off and the

indicator turns off.

In all off status, pressing this key could get all indoor units entering on

and operation mode, and the indicator turns on.

Note:

1. After a single unit is turned on, this key enters all on mode, led is on.

2. The default operation mode is AUTO mode. If the remote control

monitor connecting with the air conditioner hasn t power failure

resumption function, the air conditioner will operate in the mode

memorized by the remote control monitor.

3. Total ON/OFF function: the air conditioner will make time-delay

control in turns, in the precess, the current air conditioner state

information may be flash, but it is normal.

Total on/Total off

MONI TOR

1

Page 14

13

SET

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFI RM

LOCK

FAN SPEED

Operational guide

Unit selection and group

selection control

The central controller provides three control modes:

1.Unitary control mode: See Total on/Total off Unitarily Control Function .

2.Unit selection control mode:

1 The cursor flashes at

of the current unit. Using the direction keys

may change the flashing location of the cursor and the current

unit number (the cursor will flash even if the unit does not exist.). The

controller takes the current unit with the flashing cursor as unit selection

mode;

2 After completion of selection, parameters of mode, fan speed, temperature

and timer could be changed;

3 After setting the parameters, press CONFIRM

key to send the settings

to the air conditioner and thus the unit selection control is completed.

4 After step , directly press the ON/OFF

key and CENTRAL/REMOTE

key, the requirement settings could also be transmitted to the air conditioner

and then the unit selection control is completed.

Within 10s if no parameter (mode, fan speed, temperature) setting keys

haven t be pressed or the CONFIRM

key hasn t be pressed to send instruction

to the air conditioner, the time-out control will automatically cancel the

just made settings, and the system will automatically restore central control

and cyclic monitor status.

Remarks:

Total on/Total off

4

3

2

2

2

Page 15

14

SET

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFI RM

LOCK

FAN SPEED

Operational guide

Unit selection and group

selection control

3.Group selection control mode:

1 Move the cursor to the unit to be group selected and press SELECT

key

to enter group selection mode. Then use the

keys to move the

cursor to the next unit number to be selected and press SELECT

key again.

Repeat until selection is completed. After group selection is fulfilled, set

the working status of the central controller;

Keep the cursor at a unit already group selected and press SELECT

key

again,the original selection will be canceled; afterwards the current unit

display condition will not change because the cursor keep flashing, whereas

after removing the cursor you ll find the result of group selection or canceling

of group selection;

2 After completion of selection, parameters of mode, fan speed, temperature

and timer etc. could be changed;

3 After parameter setting, press SET

key sending the desired settings to the

air conditioner and thus the group selection control is completed.

4 After step , directly press the ON/OFF

key and CENTRAL/REMOTE

key, therequirement settings could also be transmitted to the air conditioner

and then the group selection control is completed.

Remarks

:

1.Within 10s if no parameter (mode, fan speed, temperature) setting keys

haven t be pressed or the CONFIRM

key hasn t be pressed to send

instruction to the air conditioner, the time-out control will automatically

cancel the just made settings, and the system will automatically restore

central control and cyclic monitor status.

2.During group selection, the first selected air conditioner will be defined as

the first unit, which will be taken as the control reference, i.e. if no mode

has been set, after pressing CONFIRM

key, all air conditioners under

group selection control will operate in the same mode as that of the first

air conditioner.

Total on/Total off

4

2

2

2

Page 16

15

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFIRM

LOCK

FAN SPEED

Operational guide

Turn on/turn off

Using the ON/OFF key:

1.Carry out unit selection or group selection to select the units to be controlled;

Press ON/OFF

key to send control orders;

2.If the units are in on status before unit or group selection, pressing this key

will send turning off order to get units stop;

3.If the units are in off status before unit or group selection, pressing this key

will send turning on order to get units start.

MONI TOR

Total on/Total off

Page 17

16

Operational guide

AUTO, COOL, DRY, HEAT,

FAN SPEED, TEMP, CLOCK

1. Conduct unit selection or group selection to select the units to be controlled.

2. Operation mode

Press MODE

key to select the operation mode. Each pressing will change

the working mode in the following sequence:

Select the working mode you desire.

3. Fan speed shift

Press FAN SPEED

key to select fan speed. Each pressing will change the fan

speed in the following sequence.

Select the desired fan speed.

AUTO

COOL

DRY

HEAT

AUTO

4.Temperature setting

Press TEMP TIME

key.

Each pressing will increase the temperature by 1

.

Each pressing will decrease the temperature by 1 .

The temperature could be set at your desire between 16

and 30 , which will

be displayed by the LCD.

Note: These keys will also be used in clock setting and timer setting. See the related

description for details.

5.Setting confirmation

In CONFIRM

mode, pressing CONFIRM

key to send control orders to air

conditioners, after which the central controller will change into cyclic monitoring

status.

Note: Within 10s if no parameter (mode, fan speed, temperature) setting keys haven t

be pressed or the CONFIRM

key hasn t be pressed to send instruction to the air

conditioner, the time-out control will automatically cancel the just made settings, and

the central controller will restore cyclic monitoring status.

SET

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TIME

TIME

TIMER

CENTRAL

REMOTE

CONFIRM

LOCK

FAN SPEED

Total on/Total off

4

5

Page 18

17

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME TI MER

CENTRAL

REMOTE

CONFIRM

LOCK

FAN SPEED

Operational guide

Clock setting

To adjust the settings and unify the system clocks

1. Press

Time

key

Each pressing of the TEMP TIME

key, the time setting will increase

by 1 min; keep pressing will increase the value rapidly.

Each pressing of the TEMP TIME

key, the time setting will decrease

by 1 min, keep pressing will decrease the value rapidly.

2. In CONFIRM

mode, press the CONFIRM

key to send control orders for

controlling the air conditioner central control system. After confirmation of

sending orders, the central controller will change to cyclic monitoring status.

1 Within 10s if the CONFIRM

key hasn t been pressed to confirm order

sending, the time-out control will automatically cancel the just made settings,

and the central controller will restore cyclic monitoring status.

2 The centrol controller will uniform the clock auto matically once every day.

Note:

Total on/Total off

SET

Page 19

18

Operational guide

Timer Function

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TI ME

TI ME

TI MER

CENTRAL

RETOME

CONFI RM

LOCK

FAN SPEED

TIMER ON

Total on/Total off

EVERY DAY

TIMER OFF

MONI TOR

The timing function:

1. The timing set of central controller will be performal by the detector. Because

of the large time tolerance, we recommend that you use the weekly time

YCS-A001 to realise the daily management.

2. The central controller will set TIMER ON, and meanwhile the TIMER OFF

time will be 0 o'clock as default.

3. The central controller will set TIMER OFF, and meanwhile the TIMER ON

time will be 0 o'clock as default.

4.TIMER ON/OFF, TIMER ON and TIMER OFF- once being set, they will be

performed in turns every day.

5. If you want to cancel the timing function, when LCD screen displays TIMER

on and TIMER OFF are all 0 o'clock, press "SET/CONFIRM" button to cancel it.

6. Press TIMER buttom, LCD displays the following in turn: TIMER ON

TIMER OFF TIMER ON/OFF TIMER ON/OFF everyday TIMER

ON/OFF are 0 o'clock.

7. If you want to set timing function, select the TIMER ON clock and the

TIMER OFF clock, and then press "SET/CONFIRM".

8. After the power is off, the clock needs to be set again.

Page 20

19

SELECT

ON

OFF

MODE

TEMP.

TIME

TIME

TIMER

CENTRAL

REMOTE

CONFI RM

LOCK

UNI T

TEMP

ROOM

TEMP

REMOTE

SELECT

ON

OFF

MODE

TEMP.

TIME

TIME

TIMER

CENTRAL

REMOTE

CONFIRM

LOCK

UNI T

TEMP

ROOM

TEMP

REMOTE

FAN SPEED

FAN SPEED

Operational guide

Central/Remote setting, keypad locking,

setting confirmation and reset function

1.Central/remote setting function is applicable only

for those air conditioners with wire remote controller

or panel, but not for models with wireless remote

controller. It deals with management of air condi-

tioners inside the central control system. Once the

air conditioner has been set as central status, it

could be controlled only through the remote control

interface.

Carry out unit selection or group selection procedure to select the units to be

controlled.

Press CENTRAL/REMOTE

key.

If the unit is in remote mode before selection, pressing this key will send

orders getting the unit in central mode;

If the unit is in central mode before selection, pressing this key will send

orders enabling the unit in remote status.

In central status, the air conditioner does not accept instructions from the

wire controller but only those from the central controller; whereas in remote

mode, the air conditioner accepts orders from both the wire controller and the

central controller.

2.Locking, setting confirmation and reset function setting method

Central controller keypad locking:

This function is used to control if the keypad of

the central controller is valid, avoiding random

operation by unrelated persons.

Keep pressing LOCK

key until the key

symbol is displayed, which means the

keypad (other keys) is locked;

Keep pressing LOCK

key again for a while,

the key symbol disappears, it indicates the keypad could be regularly used;

CONFIRM

key:

It is used to confirm the settings of air conditioner running mode, fan speed,

temperature and timer. This key is invalid in monitor status.

Reset key:

It is installed inside the central controller for reset operation. In case the

central controller operation is invalid or dead for a long time (not including

over long control time, and self-locking of the keypad), press reset key to

restart the central controller. The location of the reset key is as shown in the

following figure:

Open the controller at the two clasps located at the top front side of the central

controller, then you can see the reset key as shown in the figure. Pressing this

key could restore the controller to normal conditions.

Total on/Total off

MONI TOR

Total on/Total off

MONI TOR

3. Master/Slave controller set:

When the central controller is powered on, the controller with the default

address FFH is the Master controller .

In the group control network, there's only one Master central controller. The

Slave controller will display " ", when being powered on, In the operation,

you can change over between Master controller and Slave controller by the

button. The setting of Master/Slave controller please refers to the address

setting section.

Page 21

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Failure diagnosis

Upon abnormal operation:

Please read the User s Manual

attached with the indoor unit before asking for

repairing. You may contact the after-sales technicians after careful checkup.

When faults arise, the symbol

appears along with the error code.

The central controller faults corresponding to error codes are given in the

following list (including air conditioner faults and group control network faults):

Code

Meaning

None (normal operation)

Fault with indoor ambient temperature sensor

Fault with indoor tube temperature sensor

Indoor heating overload protection

Indoor cooling icing (overload) protection

Indoor & outdoor communication error

Communication fault between panel (wire controller) and indoor unit

(air conditioner indication, central controller shows 30)

Module fault (PFC protection

DC)

No load

Compressor overheating

Abnormal CT current

Fault with outdoor ambient temperature sensor

Fault with outdoor heat exchanger (tube temperature) sensor

Protection of supply overvoltage or undervoltage

High voltage protection

--- Fault with outdoor evaporator sensor

--- Cooling overload

EEPROM fault

Fault with outdoor return gas sensor

Fault with compressor sensor

--- Fault with indoor evaporator sensor

Drain system failure

Power supply 3-phase fault (phase lack or mistake)

Humidity sensor malfunction

Indoor fan failure (fan overcurernt, fan IPM protection, fan Holtz .

element fault)

Blank

Low voltage protection

--- Electronic expansion valve failure

--- Dust remover screen needs cleaning

Insufficient refrigerant

Abnormal communication between monitor and air conditioner or exterior alarm

input singal.

Abnormal communication between monitor and bus or temperature cut off abnormal.

Outdoor fan failure (fan overcurernt, fan IPM protection, fan Holtz

.

element fault)

Page 22

21

1PH , 220-240V~, 50Hz

91. 5mm

Installation procedure

1. Wire connecting

A B

Power supply

To connect the process

control monitor/detector

2. Installation method

A wiring box cover must be used.

The central controller shall be installed into the installation box built in the

wall fastening with 4 screws (as shown).

Rear view

Note: Please confirm the supply voltage of AC220-240V and correct wiring. In

application environment with intense electromagnetic interference, the central

controller should be shielded, while the connecting wire between the monitor

and the central controller should be shielded twin twisted wire.

Page 23

Installation and debugging

22

1. It must form a complete set of documents (project layout for group control

net, installation and construction records for group control net, debugging

records for group control net, maintenance and repair records for group

control net) for group control net of Haier commercial air conditioner long

distance system (hereinafter for short as: group control net) from layout

design, installation, debugging to after service, and file all for future

reference.

2. Layout design of group control net shall be finished in advance, including:

(1) compositions of group control net system and quantities controlled;

(2) selection type of air conditioner, installation place, power distribution and

wiring manner and connection to detector;

(3) installation place of detector, allocation of unit address code, power distri-

bution and wiring manner and connection to group control bus;

(4) installation and wiring of group control bus, length limitation of bus,

resistance matching of two ends of bus, and single point earth of bus shield-

ing layer;

(5) installation place of central controller, allocation of unit address code, power

distribution and wiring manner.

3. Principles of layout design of group control net:

(1) detector is essential part, to keep proper responding speed and communication

reliability, detector quantities carried by one central controller shall not more

than 64;

(2) air conditioner must be a net air conditioner, installation must strictly follow

the installation and operation instructions shipped with the unit, and confirm

that power blackout compensation function of local air conditioner has been

cancelled when debugging;

(3) suggest that do not use two-unit switchover function of detector in the case

of high load, i.e. suggest that do not use one detector to load two air condi-

tioners when detector forming group control net, otherwise temperature

difference control may be affected. If it is necessary to install two-unit switch-

over function for group control net, air conditioners with same type and half

installation distance of that of normal installation are required;

(4) installation place of detector shall not too far away from air conditioner, not

exceed the wiring length;

(5) unit address code of detector shall be strictly allocated in a sequence from

small one to big one, and set continuous unit number;

(6) for power distribution of detector, the power distribution line and commu-

nication line shall not be too close from each other or in the same wiring

channel, and no other special requirements;

Page 24

23

Installation and debugging

close from each other or in the same wiring channel, and others may refer

to wiring requirements of building autocontrol system;

(10) limit the total length of group control bus to 1000 meters; optional due

to the site operation.

(11) at both ends between Bus A and Bus B connect a metallic membrane

precision resistance of 100ohm respectively;

(12) single point earth for bus shielding line, suggest to be arranged in the middle

of communication bus, close to central controller;

(13) in principle, installation place of central controller shall be arranged in the

middle of communication bus, close to shielding earth line of communi-

cation bus;

(14) unit address codes of central controller adopt the default settings;

(15) central controller has its own power distribution line, the power distribution

line and communication line shall not be too close from each other or in

the same wiring channel, and no other special requirements.

4. Installation and construction of wiring of group control net shall be processed

together with installation and debugging of net air conditioner, pay attention to

commissioning before installation.

5. Connection between detector and air conditioner: detector working mode and

unit address code shall be strictly set according to planned layout; detector

makes wire communication with at most two air conditioners (A, B) through

4-post screw-fixing terminal at air conditioner interface (A

+, A-

, B+, B-); con-

nection between detector and air conditioner use uniform wiring; use uniform

wiring for connection between detector and air conditioner, one plug in type

terminal of wiring connected to long distance control interface on the computer

board of air conditioner, and cores of another terminal respectively connected

to A+ and A- (B+ and B-); connection has polarity, and generally white wire

connected to A+/B+ and black/red wire connected to A-/B-; if detector cannot

work normally when debugging, then can check and remove malfunction by

changing positive and negative polarity. During debugging also can judge

whether communication interface to air conditioner is normal according to the

running status indicated by operation indicator (green LED).

(7) for connection between detector and group control bus, not allowed to

connect branch line from the group control bus;

(8) shielding line of communication line between detector and air conditioner

and the shielding line of communication bus between detector and central

controller shall be shorted;

(9) wiring and power distribution line of the group control bus shall not be too

Page 25

24

Installation and debugging

6. Connect detector and communication bus after finish the wiring of communi-

cation bus: connect several detectors to communication bus in parallel, all

terminal port A (including central controller) on one bus, and all terminal

port B (including central controller) on another bus, at both ends of the com-

munication bus - A terminal port line and B terminal port line shall paralleling

connect a metal membrane precision resistance of 100ohm respectively. Earth

one point of the shielding line of communication bus, which is at the middle

position of the communication bus, and the total length of communication bus

shall be limited within 1000m.

7. Connect central controller and communication bus after finish installation and

connection of detector: central controller is connected to communication bus

through the 2-post screw-fixing terminal (A and B) of interface RS-485,

locating in the middle of the communication bus, with position close to the

earth point of the shielding line of communication bus.

8. Power on and debugging: after power on, central controller periodically

monitors the detector and air conditioner groups on the communication bus,

and after inquiring for a period of time the unit number shall display as expected,

check and debug if having any difference.

9. Set the dialing switch of detector: OFF means 0 and ON means 1see the table

below for detail setting check list.

No.

1

2

3

4

D3 D4

0 0

0 1

1 0

1 1

Address

FFH

FEH

FDH

FCH

Bit 1 and 2 are pre-set.

Funct i on

Master

Sl ave

Sl ave

Sl ave

The default set when out of factory:

1.OFF 2. OFF 3.OFF 4. OFF

Page 26

25

1 - unit A signal groundwire

2 - unit A signal wire

3 - unit B signal groundwire

4 - unit B signal wire

5 - centralized controlling interface B

6 - centralized controlling interface A

7 - 12VDC power for the detector

8 - power indicator light(red),also as

fault indicator

9 - communicate indicator light(yellow)

10 - charactron,display setting address

and switching time between two units.

11 - run indicator light(green)

12 - installation hole

13 -binary switch,set single/double and baudrate

14 - keys,include:Inc,Dec,switch,enter,

emergency

YCJ-A002 sketch

air conditioner

interface

1

2 3

4

5

6

7

problem about the arranging of the connecting line

between air conditioner and its upper unit:

holes prepared for passing line behind the detector

can be used--for those installation project who have

already buried the pass line.To those who haven't

prepared pass line,the thinner part on the top of the

detector shell could be opened with tools for passing

line.

power

red yellow

green emergency

power

communicate

run

Double/Single

9600/1200

SMG

S1

S2

S3

S4

S5

INC

DEC

SWITCH ENTER

EMERGENCY

LED1red

LED2yellow

LED3green

8

9

10

11 12

13

14

+

-

YCJ-A002

open the

cover from

here

Model of monitor/detector

1. Remote control detector

2.Group control detector

57

B- B+ A- A+

B RS-485 A

RS- 232

138

57

Page 27

26

1PH AC220-240V 50Hz

3W

180X120X64.4mm

0.39kg

1.

Performance parameters and spare parts

Power supply

Power consumption

Maximum dimension

Weight

Spare parts

no

Note: The company focuses on technological innovation and reserves right to

modify the parameters without further notification.

2. User self-provided parts:

Performance parameters and spare parts

a. Power cord: copper core wire with the conductor diameter not less than

1.0mm2, the plug is not less than 5A250V.

b. Group control bus: Recommended type: UL2547 or equivalent model twin

twisted shielded wire, the specification not lower than AWG20 (UL2547-202).

c. Installation mechanical box for the central controller: 4 holes installation

location dimension: 91.5*86 bilaterally symmetric in the whole, vertically

symmetric with the upper variation of 2 (the hole is 15+ apart from the upper

edge and 19 apart from the lower edge). See the dimensions shown in the

figure on Page 15.

Page 28

This document was created with Win2PDF available at http://www.daneprairie.com.

The unregistered version of Win2PDF is for evaluation or non-commercial use only.

Loading...

Loading...