Page 1

Manual of Weekly Timer

YCS-A001

Contents

Safety Precautions------------------------------------1-2

Function Introduction--------------------------------3-4

System Outline----------------------------------------5-8

Operation instruction--------------------------------9-12

Maintenance--------------------------------------------13

Appearance/Dimension/Interface--------------------14

Installation and Debugging------------------------14-17

Performance Parameter and Fittings-----------------18

User's Self-provide Parts ------------------------------18

Detector--------------------------------------------------19

Central Controller---------------------------------------20

No.0010573289

Please read this operation manual carefully before using the appliance.

Keep this manual in a safe place.

Page 2

Safety Precautions

The following lists four kinds of safety precautions and recommendations:

Warning:Improper use may cause death or serious injury, etc. serious

consequences.

Notice:Improper use may cause body injury or unit damage; in some cases,

it may cause serious consequences.

*

Any contents marked with this "Prohibition" symbol are the actions

must be prohibited. Otherwise, it may cause unit damage or

endanger the body safety of user.

Any contents marked with this "Force" symbol are the actions

*

must be force done. Otherwise, it may cause unit damage or

endanger the body safety of user.

The following safety precautions must be observed.

These safety precautions should be kept in hand to consult it when needs.

If the air conditioner is resold to a new customer, this manual also should be

given to him.

Warning

The installation work shall be done by a qualified person and what the

manual specified. If installation is not proper, water leakage, electric shock,

fire and other accidents will occur.

If finding abnormal phenomenon (e.g. smell of fire), please cut the

power immediately and contact our after-sale service staffs for the solvent.

In this case, if you still use the unit, it will be damaged and

electric shock or fire accident may be caused.

Power

off

1

Page 3

Safety Precautions

Warning

Please let the after-saleservice staffs do the job when the manual must

be removed, reseted. Imporper installation may cause water leakage,

electric shock and fire accident.

Do not alteration the manual by yourself, the improperty

alteration may cause electric shock and fire accident.

When needing repairing, please contact our after-saleservice staffs to

do it. Imporper repairing may cause electric

shock and fire accident.

The power supply : 220VAC

Notice

Do not put or use any flammable spray liquid near the

manual. Otherwise, electric shock may occur.

Do not operate the manual with wet hands. Do not

use water to clean the manual. Otherwise, electric shock may occur.

Do not press the manual and switch with acuminate object. Otherwise,

electric shock may occur.

Cleaning

Turn off the power supply switch before cleaning or abnormality occur

Do not use the thinner, benzine, or chemical dishcloth

cleaning the manual . Otherwise, discolourment or

coating desquamation may occur.

If it is very dirty, dissolve neutral deter gent in the lukewarm water and

make the colth wet with the water. After wiping, clean off the detergent

using clean water. Clean with soft and dry dishcloth.

2

Page 4

Function Introduction

The weekly timer is a special functional part for Haier Commercial Air Conditioner's remote

monitoring system-group control function network (hereinafter abbreviated as group control network)

and the user's optional part. Remote central controller (hereinafter abbreviated as central controller)

achieves the coding and display of control data by its keystroke and LCD screen; connected to

bus and executes the control to the air conditioner's basic functions by detector. Remote detector

(hereinafter abbreviated as detector) is used to transform the standard digital interface to realize

the communication of bus code sub-address; connected directly to air conditioner to execute local

operation and collection to the control information and working information of air conditioner and

to transmit the control and information data. Network air conditioner (hereinafter abbreviated as

air conditioner) means the air conditioner, which indoor PCB possesses remote control interface.

Only the network air conditioner can cooperate with detector, central controller and weekly timer,

etc. parts to form the remote monitoring system-group control network and fulfill data exchange

and monitoring function.

The function level of weekly timer and the central controller is the same. It can be checked

by detector and displayed by LCD screen the trouble state and timing setting of air conditioner. It

also can set the timing settings of the air conditioner within a week by keystroke input cooperating

with LCD display. Weekly timer can be either used together with central controller or used

independently (the detector is the essential part). Additionally, the weekly timer is equipped with

24-hour real-time clock system to unify the clocks in the group control network (the clocks in group

control network and air conditioner are respectively independent and do not interfere with each

other). The brief introductions are as follows:

1.Communication Function

PROGRAM

NO.

1 2 3 4 5 6 7

SET 1 ON OFF

SET 2 ON OFF

1 2 3 4 5 6 7

NO.

Hour

Min.

Time

ON/OFF

Number

HolidayProgram

Cancel

Confirm

Week

3

Page 5

Function Introduction

Communication with the detector of the group control network.t

Executing communication with detector by RS-485 bus (A, B). The weekly timer sends

a control command and communicates according to unified address; the execution of

the command is delayed. The weekly timer can simultaneously monitors the trouble

information sent from detector.

2.LCD function:

The LCD can display the weekly timing settings of the air conditioner (7 days a

week and each day can set max two times of timer on and timer off),

The LCD can display the trouble code information of the air conditioner with trouble,The

LCD can display the current time of the clock and weekday's information,

The LCD can display holiday setting, which is used to temporarily cancel the On

function of the air conditioner.

3.Keystroke input function:

The keys used in normal state to adjust and confirm the clock and weekdaystime, Confirm, Cancel,

The key used for enter and quit from timing setting program state-program.

The keys used to switch programmed contents-Date, Hour, Minute.

The keys used to adjust the program contents-- ,

The keys used to whether accept the programmed contents or not-tConfirm, Cancel.

The key used in normal state to temporarily cancel the special date timing functionHoliday.

4.Unit number setting function:

In order to rich the control function of Haier Commercial Air Conditioner's remote

monitoring system and be able to set multiple controllers combined use to fulfill the

combination of multiple functions, the weekly timer is configured with two dial-code

switches used to set the controller's addresses (the controller's addresses cannot be

repeated in the same control network).

4

Page 6

System Outline

The weekly timer has its independent own power supply. Its communication interface

is RS-485 interface, and the two-core screw fixed terminals (A, B) is connected with

shielded twisted pair communication bus and set the address number different from those

of other controllers.

1. Use weekly timer to realize weekly timing function:

The detector is connected with one air conditioner by the 4-core screw fixed terminals

A+ and A- of air conditioner interface, then accordingly set the dial-code switch of the

detector in single unit working mode; the address number setting shall be performed

according the planned program, for specific setting and corresponding address, please

refer to the dial-code switch setting in detector's operation manual; use weekly timer to

fulfill weekly timing function, the system needs to be connected with weekly timer; each

detector and weekly timer is connected with shielded twisted pair communication bus

by the 2-core screw fixed terminals (A and B) of its RS-485 interface; the communication

bus must be shielded and grounded, and the resistors in its two ends shall be suited.

View of the instrumentation

Resetting

Indoor unit

Outdoor unit

interface

Air Conditoner HMI

PROGRAM

1 2 3 4 5 6 7

SET 1 ON OFF

SET 2 ON OFF

1 2 3 4 5 6 7

NO.

NO.

Number

HolidayProgram

Hour

Cancel

Min.

Confirm

Week

Time

ON/OFF

Power cord

Power on/off

5

Page 7

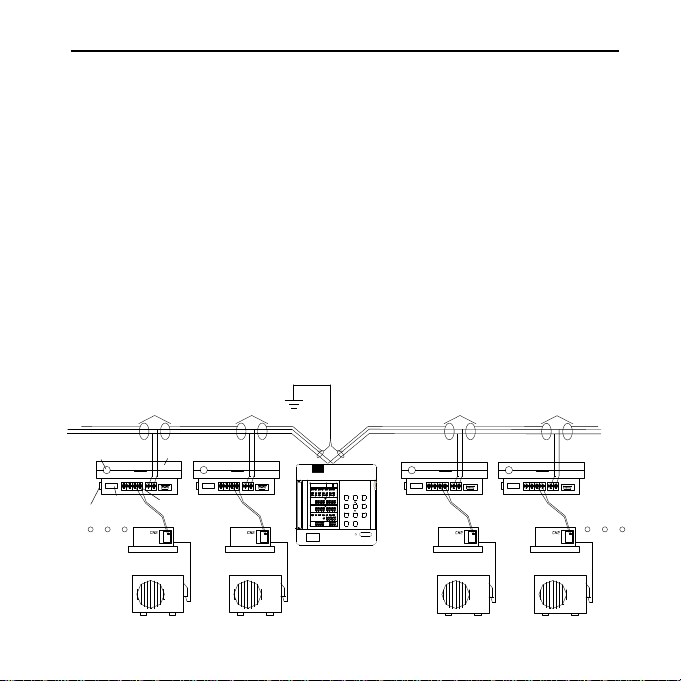

System Outline

2. Use weekly timer to realize two units auto-changeover function:

The detector is connected with two same model air conditioners by the 4-core

screw fixed terminals of air conditioner interface; then accordingly set the dial-code

switch of the detector in double units working mode, and the double units switch time

is default 24 hours; the address number setting shall be performed according the planned

program, for specific setting and corresponding address, please refer to the dial-code

switch setting in detector's operation manual; use weekly timer to fulfill double units

switch weekly timing function, the system needs to be connected with weekly timer;

each detector and weekly timer is connected with shielded twisted pair communication

bus by the 2-core screw fixed terminals (A and B) of its RS-485 interface; the

communication bus must be shielded and grounded, and the resistors in its two ends

shall be suited.

PROGRAM

NO.

1 2 3 4 5 6 7

Number

HolidayProgram

SET 1 ON OFF

Hour

Cancel

SET 2 ON OFF

Min.

Confirm

1 2 3 4 5 6 7

Week

Time

NO.

ON/OFF

6

Page 8

System Outline

3. Use central controller + weekly timer to realize the group control function +

weekly timing function:

The detector is connected with one set of air conditioner by the 4-core screw fixed

terminals A+ and A- of air conditioner interface, then accordingly set the dial-code switch

of the detector in single unit working mode; the address number setting shall be performed

according the planned program, for specific setting and corresponding address, please

refer to the dial-code switch setting in detector's operation manual; use group controller

and weekly timer to fulfill the group control function with weekly timing function, the

system needs to be connected with group controller and weekly timer; each detector,

group controller and weekly timer is connected with shielded twisted pair communication

bus by the 2-core screw fixed terminals (A and B) of its RS-485 interface; the

communication bus must be shielded and grounded, and the resistors in its two ends

shall be suited.

RS-232

A RS485 B

PROGRAM

NO.

1 2 3 4 5 6 7

Number

HolidayProgram

SET 1 ON OFF

Hour

Cancel

SET 2 ON OFF

Min.

Confirm

1 2 3 4 5 6 7

Week

Time

NO.

ON/OFF

7

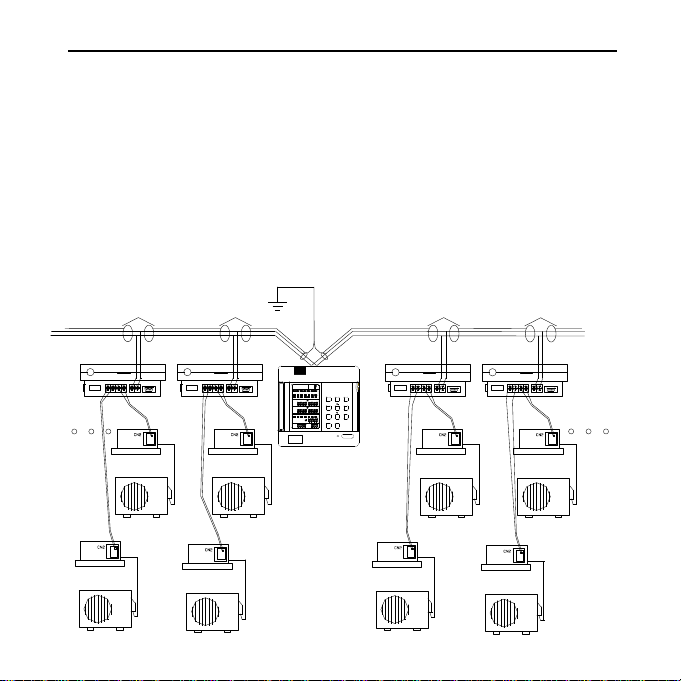

Page 9

System Outline

4. Use central controller and weekly timer to realize auto-changeover + group

control + weekly timing function:

The detector is connected with two same model air conditioners by the 4-core

screw fixed terminals of air conditioner interface; then accordingly set the dial-code

switch of the detector in double units working mode, and the double units switch

time is default 24 hours; the address number setting shall be performed according

the planned program, for specific setting and corresponding address, please refer

to the dial-code switch setting in detector's operation manual; use central controller

and weekly timer to fulfill double units switch group control function with weekly

timing function, the system needs to be connected with central controller and weekly

timer; each detector, central controller and weekly timer is connected with shielded

twisted pair communication bus by the 2-core screw fixed terminals (A and B) of

its RS-485 interface; the communication bus must be shielded and grounded, and

the resistors in its two ends shall be suited.

RS-232

A RS485 B

PROGRAM

NO.

1 2 3 4 5 6 7

Number

HolidayProgram

SET 1 ON OFF

Hour

Cancel

SET 2 ON OFF

Min.

Confirm

1 2 3 4 5 6 7

Week

Time

NO.

ON/OFF

8

Page 10

Operation Instruction

Instruction:

1 - PROGRAM-the display

shows the weekly timer timing

setting state, and in setting state,

the timing information can be

adjusted.

2 - No:8-timing group number:

when it is not set timing, there

is no timing group number; after

setting timing, it will

automatically form a group

number according to each kind

of setting combination, so that

in the sequent timing setting, it

can execute instant setting by

using timing group number.

3 - Setting state and holiday functional area-1 (MON), 2 (TUE), 3 (WED), 4 (THU), 5

(FRI), 6 (SAT), 7 (SUN) are used to indicate the 7 days in a week; the symbol of this

part will display after powered on; after set the corresponding weekday's timing function,

the ON symbol under the corresponding symbol will display, if not set timing, there will

be no display; if not set Holiday function, the OFF symbol on the upside of the indicating

symbol will not display, after set Holiday function, the OFF will display and at the same

time temporarily the previous timing setting and turn off the air conditioner.

4 - No. 1 group and No.2 group timing setting display area-when entering timing setting

state, the contents of timing will flash; choose Date, Hour and Minute to perform increase

and decrease adjustment by the adjusting key.

2

1

3

4

5

6

PROGRAM

NO.

1 2 3 4 5 6 7

SET 1 ON OFF

SET 2 ON OFF

1 2 3 4 5 6 7

NO.

Hour

Min.

Time

ON/OFF

Number

HolidayProgram

Cancel

Confirm

Week

9

7

8

9

14

16

10

15

17

11

13

12

18

Page 11

Operation Instruction

5 - Time display area-including display the weekday, hour and minute; before setting

timing function, please calibrate the current clock.

6 - Unit number trouble code display area-when the air conditioner in the control network

has trouble, the corresponding unit number and the trouble code will display in this area.

7 - Program

Enter or exit the timing setting in normal condition,

8 - Holiday

Close the units and invalid for timing in no affect on the timing setting condition.

9 - Number

Group setting and timing setting (take one day as a standard unit)

10 - Hour

Timing setting condition and time setting condition ,select the adjustment

11 - Min.

Timing setting condition and time setting condition ,select the adjustment

12 - Time

Enter and exit the at present date and time condition in normal condition

13 - Week

Timing setting condition and time setting condition ,select the adjustment

14 -

Timing setting condition and time setting condition , increase the setting parameters

15 -

Timing setting condition and time setting condition , decrease the setting parameters

16 - Cancel

Cancel the present setting before confirm the parameter.

17 - Confirm

Confirm the parameter.

18 - ON/OFF

Open/close the unit.

10

Page 12

Operation Instruction

1. Time adjusting function:

When powered on for the first time or after a long period of time

Press the Time key to enter time adjusting function;

(1)Continuously press Week key can adjust the current

date (weekday);

(2)Press Hour key/Min. key to choose the contents to be

adjusted, then use Increase key /Decrease key to adjust

time;

(3)Press Confirm key to confirm the above adjustment.

After confirming and the time works in the adjusted time;

or press Cancel key to cancel the adjustment and resuem

the previous state.

2. Timing data setting

(1)Press Program key to enter timing data setting state;

(2)Press Week key to choose the program setting date;

(3)Press Hour key/Min. key to choose the contents to

be adjusted, then use Increase key /Decrease key to

adjust time;

(4)After finishing data setting, press Confirm key to

confirm the setting and simultaneously switch to the

next timing section; or press Cancel key to cancel the

setting and resume the previous state; the weekly timer

can set two groups of Timer On/Off per day;

Number

HolidayProgram

Hour

Min.

Time

Hour

Min.

Time

Cancel

2

Confirm

3

4

Week

1

Number

HolidayProgram

1

Cancel

4

3

Confirm

5

Week

2

11

Page 13

Operation Instruction

(5)After finishing the data setting for a whole day, the controller will automatically

distribute a time number. In the sequent setting, if use the same timing setting data,

only choose the date to be set and choose the Number key, then press Confirm key;

Press Program key again to quit from the timing data setting state.

3. Holiday setting function:

(1)Press Holiday key to enter holiday setting function state;

(2)Press Week key to choose the date to set as holiday;

(3)Press Confirm key to confirm the set holiday function,

and simultaneously OFF will display on the top of the current

date;

(4)If set multi-days as holiday, repeat the above operation

till it is complied with requirements;

Holiday setting function is only valid in timing setting

function.

Hour

Min.

Time

Number

HolidayProgram

1

Cancel

Confirm

Week

2

3

12

Page 14

Maintenance

Weekly timer can display the malfunction unit number having trouble (the same as

detector setting address number) and the following trouble code. The corresponding

meaning of the trouble code are as the follow table show (including air conditioner

trouble and group control network trouble):

D4 D3 D2 D1 D0

0 0 0 0 0

0 0 0 0 1

0 0 0 1 0

0 0 0 1 1

0 0 1 0 0

0 0 1 0 1

0 0 1 1 0

0 0 1 1 1

0 1 0 0 0

0 1 0 0 1

0 1 0 1 0

0 1 0 1 1

0 1 1 0 0

0 1 1 0 1

0 1 1 1 0

0 1 1 1 1

1 0 0 0 0

1 0 0 0 1

1 0 0 1 0

1 0 0 1 1

1 0 1 0 0

1 0 1 0 1

1 0 1 1 0

1 0 1 1 1

1 1 0 0 0

1 1 0 0 1

1 1 0 1 0

1 1 0 1 1

1 1 1 0 0

1 1 1 0 1

1 1 1 1 0

1 1 1 1 1

Code

Meaning

No trouble(working normally)

1

Indoor ambient temperature sensor abnormal

2

Indoor pipe temperature sensor abnormal

3

Indoor heating overload protection

4

Indoor cooling freezing (overload) protection

5

Indoor unit and outdoor unit communication abnormal

6

Panel (wire controller) and indoor unit communication trouble (air conditioner

displays, central control displays 30)

7

Module abnormal (PFC protection-DC)

No load

8

Compressor overheat

9

CT current abnormal

10

Outdoor ambient temperature abnormal

11

Outdoor heat exchanger (pipe temperature) sensor abnormal

12

Power supply excess/lack voltage protection

13

High pressure protection

14

---Outdoor evaporator sensor abnormal

15

---Cooling overload

16

EEPROM abnormal

17

Outdoor return air sensor abnormal

18

Compressor sensor abnormal

19

---Indoor evaporator sensor abnormal

20

Drainage system abnormal

21

Power supply 3-phase abnormal (lack phase or wrong phase)

22

Humidity sensor abnormal

23

Indoor fan motor abnormal (fan motor over-current, fan motor IPM protection,

24

fan motor Hall components abnormal)

Outdoor fan motor abnormal (fan motor over-current, fan motor IPM protection,

25

fan motor Hall components abnormal)

Low pressure protection

26

---Electronic expansion valve abnormal

27

---Dust removing filter needs to be cleaned

28

Refrigerant is insufficient

29

Detector and air conditioner communication abnormal

30

Abnormal communication with the bus of detector

31

13

Page 15

Appearance/Dimension/Interface

RS-485

B A

12VDC

O

PROGRAM

NO.

1 2 3 4 5 6 7

SET 1 ON OFF

SET 2 ON OFF

1 2 3 4 5 6 7

NO.

Number

HolidayProgram

Hour

Cancel

Min.

Confirm

Week

Time

ON.

1 2 3 4

Installation and Debugging

1. The long-distance monitoring system group control network (hereinafter abbreviated

as group control network) of Haier Commercial Air Conditioner must establish, from

its design plan, installation and debugging to after-sale-service, a complete set of

documents (group control network programming, installation record, debugging record

and repair and maintenance record) and keep in the archives for future use.

2. The programming of group control network needs to finish the following works in

advance, including: (1) Composition of group control network system and control

number; (2) Choose the model of air conditioner, installation position, power distribution

and wiring treatment and connection with detector;

14

Page 16

Installation and Debugging

(3) Installation position of detector, address and unit number distribution, power

distribution and wiring treatment, connection with group control bus; (4) Installation

and wiring of group control bus, bus length limitation, the matched resistors at the two

ends of bus, the shielded layer of bus shall be single-point grounded; (5) Installation

position of central controller, address unit number distribution, power distribution and

wiring treatment.

3. The programming principle of group control network: (1) Detector is the essential

part; in order to guarantee proper response speed and reliable communication, the number

of detector equipped on the central controller shall not exceed 64; (2) The air conditioner

must be network air conditioner, and the installation must be performed according to

the attached operation and installation manual; in test run, cancel the air conditioner's

Power Failure Resume function; (3) It is recommended do not use the double units switch

function of the detector in the big load circumstance, that is it must be equipped with

group control network double units switch function, which requires the model of the

used air conditioners must be the same and the installation space is half of the general

installation space; (4) The installation position of the detector shall not be too far from

the air conditioner and shall not exceed the length of the connecting wire; (5) The detector

address unit number must be strictly distributed in the increasing sequence and set the

successive unit number; (6) Detector power distribution: the wiring shall not be too close

to the communication wire or pass through the same wire channel; no other special

requirements; (7) Connection of detector and group control bus: it is not allowed to

connect additional branch wire to the group control bus; (8) The shielded wire of detector's

air conditioner communication wire is short connected with the shielded wire of detector's

central controller communication wire; (9) The wiring of group control bus shall not be

too near the connecting wire or pass through the same wire channel; the rest can refer

to the wiring requirements of the storied building's auto control system; (10) The total

length of group control bus limits in 1000m; (11) At the ends of the bus and between A

bus and B bus shall respectively connect a 100 metal film precise resistor; address unit

number of central controller and weekly timer shall not be repeated;

15

Page 17

Installation and Debugging

(12) The bus shielded wire is single-point grounded. It is recommended to arrange it

in the middle part of the bus and near central controller or weekly timer; (13) The

installation position of central controller or (and) weekly timer arrange in the middle

part of the bus in principle and near the communication bus shielded grounding wire;

(14) The address unit number of central controller is set as default; the address unit

number of weekly timer is set as default; the central controller unit No. can't the same

as that of the weekly timer. (15) The central controller is in its own separate wiring

circuit; the wiring circuit and the communication circuit shall not be too close or pass

the same channel; no other special requirements; (16) The weekly timer uses 12VDC

power supply, which can be directly connected from the neighboring detector or

connected with other DC12V power supply; (17) Weekly timer can cooperatively use

together with central controller as a controller, or use weekly timer separately as the

only controller.

4. The wiring and installation of group control network will be done synchronously

together with the installation and debugging of network air conditioner. Please perform

test run before installation.

5. Connection of detector and air conditioner: The working mode and address unit

number of detector shall be performed strictly in line with the planned programming;

detector executes wire communication with at most two sets of air conditioners by the

air conditioner interface 4-core screw fixed terminals (A+, A-, B+, B-); the connection

of detector and air conditioner shall use the same wire; the inserted terminal at one

end of the wire is connected with the remote control interface on the air conditioner

PCB, the core wire at the other end of the wire is respectively connected with A+, A(B+, B-); the connection has polarity: generally the white wire connects A+/B+, black

wire/red wire connects A-/B-; in debugging, if the detector cannot work normally, it

can be checked by exchange between + pole and + pole. In powered on debugging, it

can also use the operation state displayed by the operation light (green LBD) to determine

whether the air conditioner communication interface is normal.

16

Page 18

Installation and Debugging

6. After finishing the wiring work of communication bus, perform the connection between

detector bus and communication bus: multiple detectors are parallel connected with

communication bus; all the A interfaces (including central controller or weekly timer)

are in the same bus; all the B interfaces (including central controller or weekly timer)

are in the other same bus; A interface wire and B interface wire at the end of the

communication bus is respectively connected a 100 metal film precise resistor; the

communication bus shielded wire is single point grounded in the middle part; the total

length of communication bus is limited in 1000m.

7. After finishing installation and connection of detector, perform central controller or

weekly timer connection with communication bus: central controller or weekly timer

connects with communication bus by RS-485 interface 2-core screw fixed terminals (A,

B); the connecting position is in the middle part of communication bus and near the

grounded point of its shielded wire.

8. Powered on debug: after powered on, the central controller will circularly monitor

the detectors and air conditioners in the communication bus. After searching a period

of time, the unit number shall expectedly display. If abnormal, perform check and debug.

9. After finishing debugging of central controller, powered on weekly timer. If at this

time appears disorderly communication, please check the address setting of weekly timer

and central controller. If communication normal, perform clock calibration and timing

setting. After the timing function achieves, finally perform Holiday function checking.

10. After debugging, record the debugging process, and after training the personnel,

deliver the engineering.

11. Setting of central controller's dial-code switch: if the dial-code switch is in OFF

position, indicates 0; if in ON position,

indicates 1. For the address number

setting, please refer to the

following table:

Note: D1, D2 not used

No.

D3, D4

1

2

3

4

17

0 0

0 1

1 0

1 1

Address

FFH

FEH

FDH

FCH

Page 19

Performance Parameter and Fittings

Power supply

Power consumption

Max dimension

Weight

Fittings

1PH DC12V / AC220V

2W

120x120x68

520g

Power supply connecting wire

User's Self-provide Parts

User's self-provide parts:

Group control bus: Recommend to use UL2547 type or equivalent

type twisted-pair shielded wire, and the specification is no less than

AWG20 (UL2547-202).

18

Page 20

Detector

1. Remote detector:

2. Group Control Detector:

power

R

YCJ-A002

Double/Single

9600/1200

S2

LED2yellow

SMG

LED3green

S1

INC

S3

SWITCHENTER

S5

EMERGENCY

DEC

S4

RD EMGYW GR

air conditioner

interface

YCJ-A002 sketch

open the cover

from here

-

+

LED1red

Choosing the detector type:

Remote detector is applicable to the environment with high electromagnetic disturbance,

and can operate and monitor by connecting to computer and air conditioner;

The cost of group control detector is low and applicable to the environment with low

electromagnetic disturbance. It can only form group control network and is economical.

19

Page 21

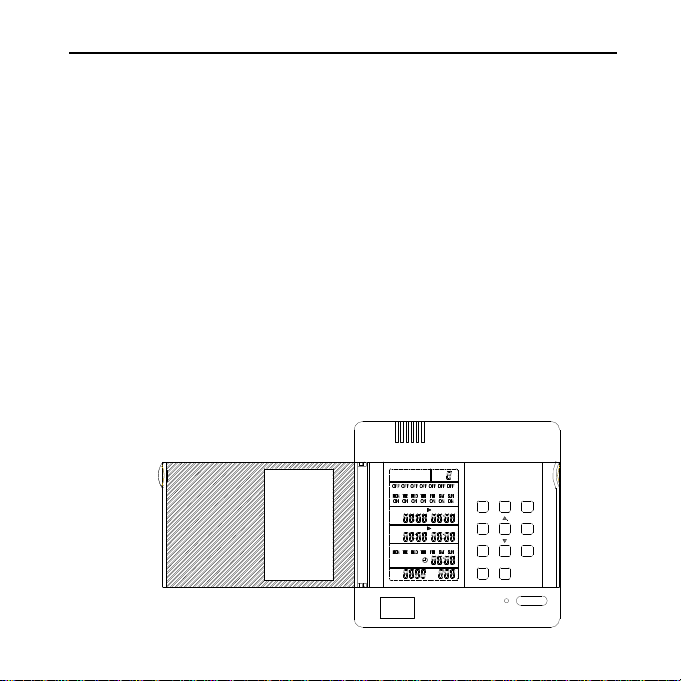

Central Controller

Central Controller

180mm

MONITER

SET

SELECT

UNIT

ON

OFF

LOCK

AUTO

MODE FAN

Total on/Total off

TEMP

TEMP.

TIME

ROOM

TEMP

TIME TIMER

CENTRAL

TIMER ON

EVERY DAY

TIMER OFF

REMOTE

CENTRAL

REMOTE

CONFIRM

120mm

(Fig.1)

64.4mm

As illustrated:

(Fig.2)

(Figure 1 is the front view and Figure 2 is the side view) The central

controller is 180mm long, 120mm wide and 64.4 mm thick.

20

Loading...

Loading...