Haier XQJ60-31 Service Manual

Computerized Automatic Washing Machine

·þÎñÊÖ²

SERVICE MANUAL

Models XQJ60-31

Edition: 2006.07.08

Special No.: HWM5TL

Features:

Top-head model,nice and elegant

Soak wash the wash result is more better

Eccentric plusator better effect

3.Names

of th

e

Parts................................................................3

4.Usage

o

f

Operati

ng

Knobs............................................................4

5.Product

Briefs

and

Major

Features..................................................5

..

..

.......7

7.Tr

ouble sh

ooting

.........................................................................13

8.Exploded

9.

view

of

the

compone

nts

...................................19

1.Table of

...........................................................1

2.Circuit Diagram

Contents

Specifications

Key Points in Installation, Adjustment and Disassembly

Components List

1

Programs

Safety

specifications

Large About 50L 3.5~4.5kg

Medium About 44L 2.0~3.5kg

Small About 35L 1.0~2.0kg

Model

Rated voltage * rated frequency

Rated wash/spin capacity

Water level and quantity

of different wash capacity

Water level W

ater quantity Wash capacity

HWM5TL

230-240V~ 50Hz

5.0kg (weight of standard dry cloth)

Standard water consumption About 150L (Large water level, NORMAL program)

Water inlet pressure 0.03Mpa~0

.78M

pa

Washing method Agitater current

Weight About 37kg

Water inlet pipe component, bottom plate,

tapping screws, user's manual,

Accessories

300W

450W

Ratedpowerconsumption

in spinning

Ratedpowerconsumption

in washing

Full auto

Manual

5A (interception

on

the

whole

circuit)

Motor With auto-resetthermalprotectiondevice

Capacitor with safeguardfunction

F r ee s election on w as hing pr ocedur es (ex cept QU ICK )

Power source

fuse

Table Of Specifications

HEAVY, NORMAL,GENTLE,QUICK WASH

2

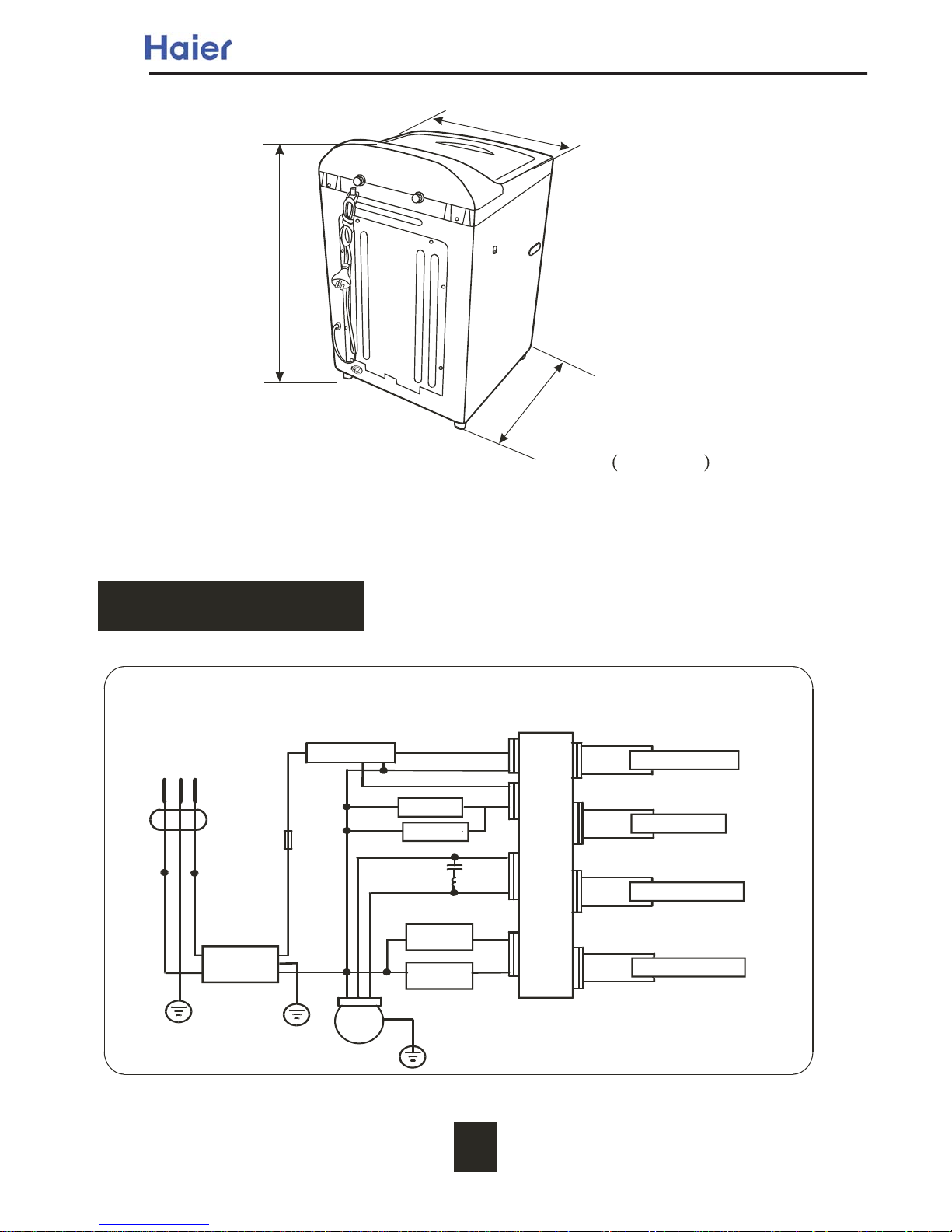

Overall Dimension Sketch

Circuit Diagr am

The

capacitor

coil

Lis

usedtoprotect

the

circuit,please

do

not

dismantle

it

Power switch

Fuse

Stop switch

Hot

wa

ter

inlet va

lve

Retractor

Macro-active switch

Red

Motor

Computer P r ogr am Contr ol l er

Blue

Orange

940

540

5

6

0

Unit:mm

C

L

5A

White

Tem

perature

s

ensor

Black

R/W

Red/Blue

Gray

Drain

Pump

Coldwate

r

inletva

lve

Blue

Blue

Water levelsensor

Pink

Orange

Purple

R/W

R/W

Pink

Gray

Gray

Blue

Blue

B lue/Whi te

Brown/White

Brown

Blue

Brown

Disturbance

Controller

Motor

Blue/White

Brown/White

Brown

Blue

Brown

Fuse

Blue

Drain pump

Retractor

Blue

Red/white

Gray

Gray

Temp eratu re

sensor

White Red

Gray

Blue

Orange

Powerswitch

Orange

Orange Orange

Gray

Red/Blue

Black

ColdWater

inletvalve

Hot Water

inletvalve

Pink

Waterlevel

Sensor

Stop switch

Macro-active

switch

R/W

R/W

Pink

Purple

Top lid

adjustable foot seam

The Actual Circuit Diag ram

Outer switch

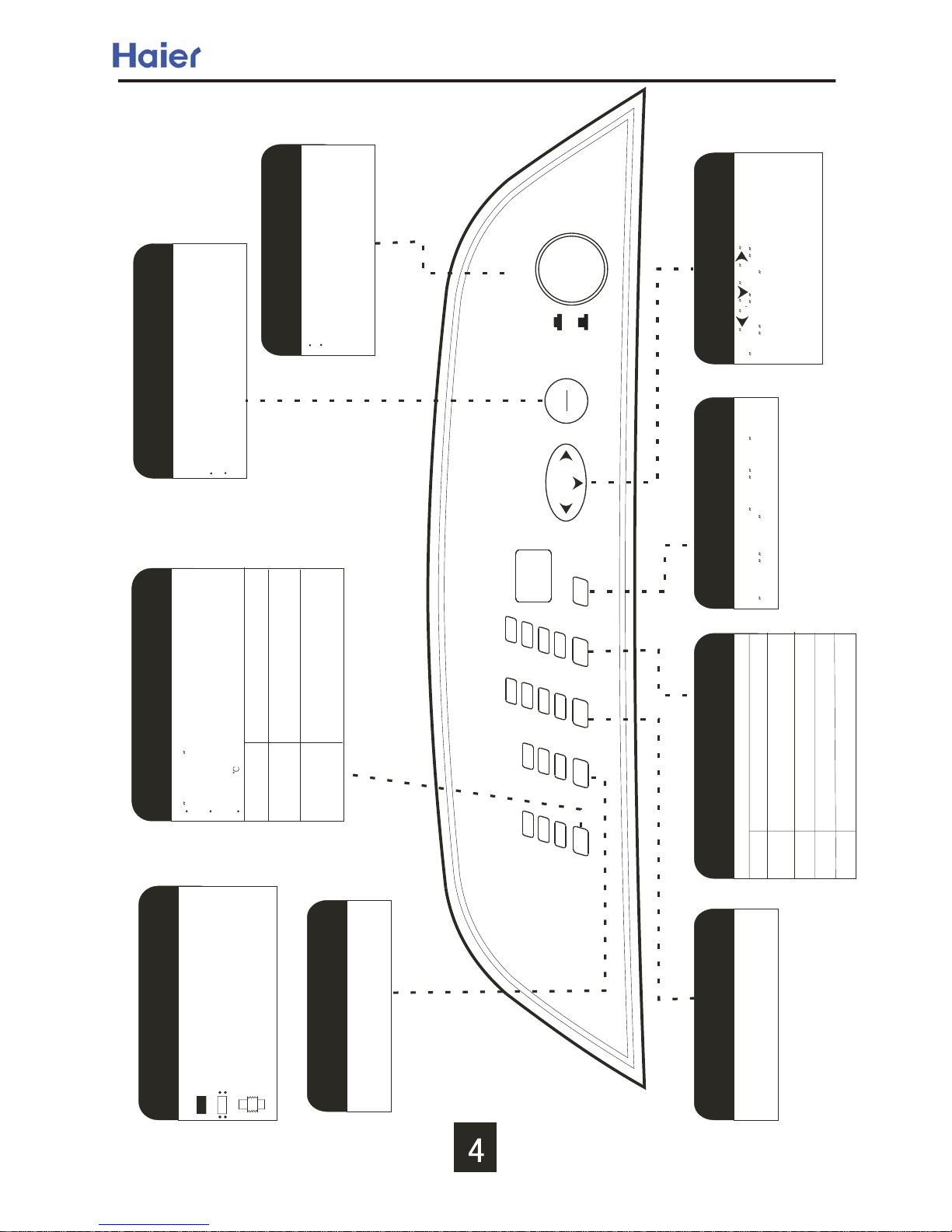

Names of the par ts

Detergent box

Inner tubInner tubInner tub

Cabinet

Hight Pulsator

Co

ntr

ol

pa

nel s

ea

t

Adjustable foot

Back faceplate

Control panel film

Power switch

Power cord

Fixed foot

Wa

te

r

abs

o

r

pt ion

g

asket

Cold Water inlet

valve

Hook

Handle

Back cover

Drain hose bushing

Hot Water inlet

valve

Contr ol panel s eat

C

L

Disturbance

Controller

LARGE

ME DI U M

LITTLE

WAT ER

LEVEL

SOAK

WAS H

RINSE

SPIN

PROCESS

HEAVY

NORMAL

GE NT L E

QU I CK WA S H

WASH CYCLE

HOT/COLD

WARM/COLD

COLD / COLD

TEMP

SELECT

SELECT

START

PAUS E

T I ME R E MA I N I NG

TIMERON

DEL AY S TA RT

POWER S WIT CH

ON

OF F

"T empselect" button

Cool water valveis set automatically when

washer is started.

P ush down thebutton, threety pes of water inlet

can be sel ected cold/col d, warm/w arm, hot/ cold.

P ay attention to thewater in drumnot being

over 50 .

Cold/Cold

Warm/Warm

Hot/cold

No r equi rement on wat er temperat ur e

T emper atur e of war m water i s h igh

and need to mix w ith s ome cool wat er

T emper atur e of war m wate r i s s ui table

or hi gher wat er temperat ure i n the

dr um is ex pected.

"Start/Pause" button

After s witch onthe power, push it once to start the

washing machine

I n operat ing, pu sh th e butt on to paus e th e oper ati ng.

I n pus hin g, pus h the bu tton to r es ume oper atin g.

Power switch button

P ush thebutton once to switch on thepower.

W hen the power i s on, pus h the button once

to cut off the power .

Water level selection button

P ush the button to select or adjus t

diff eren t water l evel.

P r ocedur e select ion button

P us h the button to s elect one or more pr ograms

fr om so ak, w as h r ins e and s pin .

Programbutton

S elect followingfour automaticprograms with thebutton

Program

Normal

Heavy

Quick

Gentle

A pplicabl e cir cums t ances

Washingthebigger,thicker or

heavier dirty laundries

Common washing

W ash ing the wool en tex til es or un derw ear

Quick washi ngof thel ight dirty laundries

Delay start button

P ush the button to select the reser ve

washing time among 4 hour 8 hour

12 hour 24 hour

Facti on sel ect but t on

Push or toselect

w as h cy cl e pr oces s wa ter

lev el t emp sel ect four

function.

I ndicat or made and meani ng

T he i ndi cator i s o ff, i ndicat ing th at the pr ogr am

or mode is n ot sel ected

T hei ndicator is flashing, indicating the running

pr ogram

T heindicator is on,indicatingthe programor

mode s electe d and about t o ru n

Usage of the Operation Knobs

Product Briefs and Major Features

<1>Product Briefs

(1) Computersequencer

It

adopts

pouring

seal with

polyurethane

on thesurface.The

light-emitting

diode

is

sealed

with

insulationbushing toavoid humidity.To avoid splashing,the

bottom

of the

control

panel

seat

wherethe

computer

plate

is installed

adopts

enclosed

structure,

and

the

surface

of

the

operation

componentsofthe

front

control

boardiscoated

with

control

panel

film.

(2) Structure of the top lid

intergrated

top

lid

structure.

(3) Power transmission system

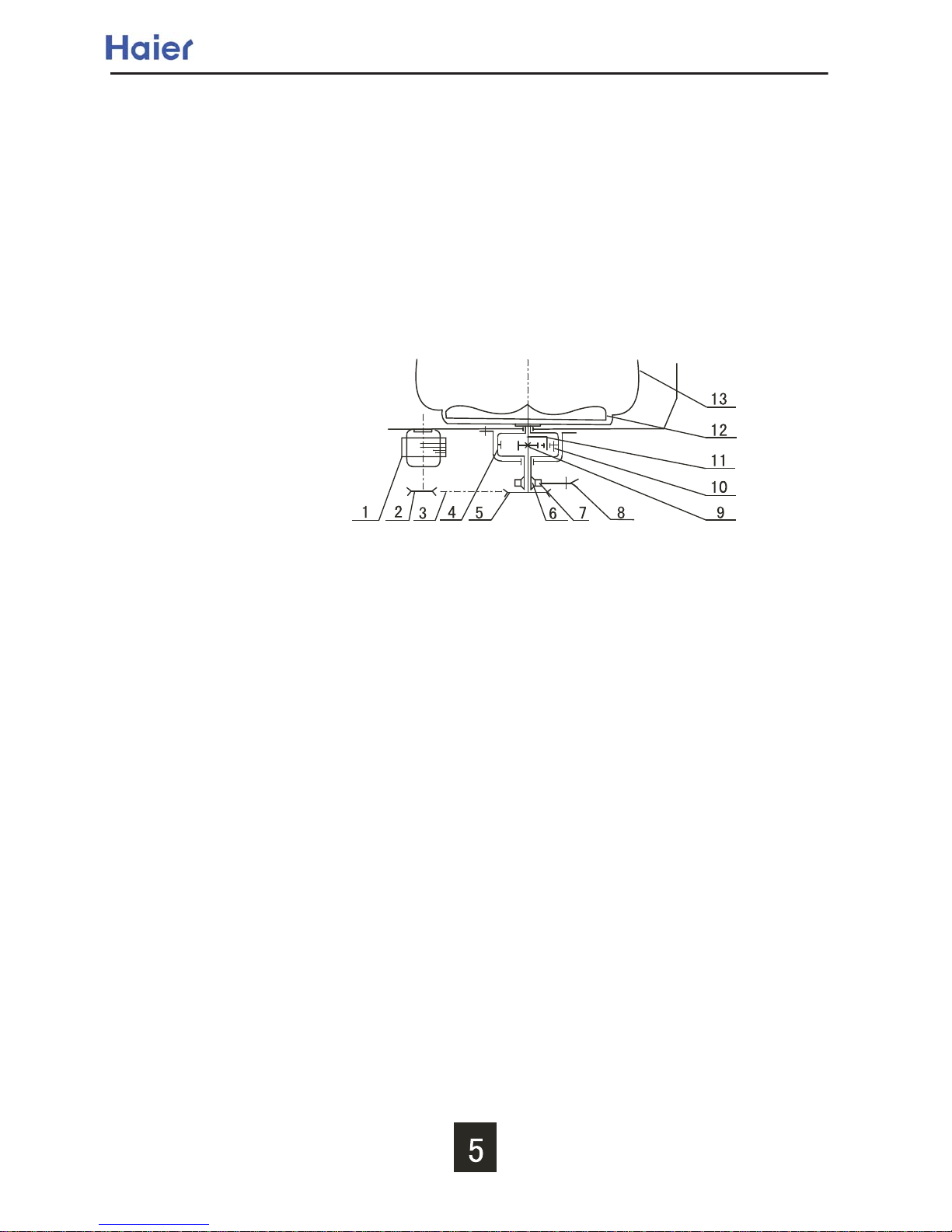

During washing, the rotation of Motor 1 is transferred to Follower 5 from Drive Wheel 2 through

Belt 3. Meanwhile, Ratchet 7 will be braked by Pawl 8 through the actionforce of the spring, and

the movement will be transferred to Center Gear 9, and then be retarded and transferred to

Tie-rod 10 through a planetary gear mechanismconsisting of Center Gear 9, Planet Gear 10 and

Spin Shaft 4 (inner gear), then Tie-rod 10 is connectedto Pulsator 12 via a spline shaft.Therefore,

Pulsator 12 will movealong with the clockwise andcounterclockwise rotation of the Motor 1.

During spinning, the rotation of Motor 1 is transferred to Follower 5 from Drive Wheel 2 through

Belt 3. Meanwhile, Pawl 8 will leave Ratchet 7 by the actionof the puller. Clutch Reed 6is twisted

tightly on the down part of Spin Shaft 4. The Spin tub 13 is connectedto Spin shaft 4 with flange.

The movement of Motor 1 will be retarded by V-belt, and then transferred to Spin shaft 4 and

make the Spin tub 13 to spin.

(4) Damping system

In installing the damping component, please note that the hangers at the motor side are

different from those of the other side. The motor side shall use the yellow spring. The other shall

use white spring.

Loading...

Loading...