Haier HN800TX, XQG50 Instructions For Installation And Operation Manual

AUTOMATIC DRUM

WASHING MACHINE

XQG50-HN800TX

INSTRUCTIONS FOR

INSTALLATION AND

OPERATION

FUNCTION

INTRODUCTION.....................................................

3-4

INSTALLATION...........................................................................

5-7

CLOSE

UP.................................................................................

8-10

USING

INSTRUCTIONS..........................................................

11-15

MAINTENANCE...........................................................................

16

SOLUTION TO

PROBLEMS.................................................17-

18

1

FUNCTION INTRODUCTION

FUNCTION COMPARING TABLE

FUNCTION

MODE

Washing capacity

Programmes

Cotton

Synthetic

Wool

Adjustable thermostat(0 ̄90℃)

Cold wash button

Speed button

Economic button

Spin speed

Power switch

ON/OFF

Rinse

XQG50-HN800TX

5

18

●

●

●

●

●

●

850r/min

●

●

Stainless steel tub

Door-locking device

Power

Power(Wash)

Power(Spin)

Weignt

HX.WX.D

●

●

●

300W

400W

72Kg

850X550X595

2

FUNCTION INTRODUCTION

Characteristics of XQG50-HN800TX

●European and Asia Aesthetic design, elegant and beautiful.

●Three types of wash: rinse, beat and rain effect.

●Changeable washing function: cold wash and hot wash,No soak

●Three types of laundry: cotton, synthetic and wool, with 16

cycles.

●A large washing capacity: 5 kgs.

● Stainless steel tub and drum; painted cabinet with three

layers of

cataphresis, phosphorus and paint.

●Rinse with anti-crease system, care for clothes.

●Super anti-shock design.

3

Installation

Unpacking

levelling and

positioning

Remove the package and check that the machine is

undamaged.

If you have any doubts, do not use the machine and call

on a qualified technician. Keep all packing parts

(plastic bag, foam rubber, screws etc.) out of the

reach of children since they could be dangerous.

Important: The inside of the washing machine which

consists of a floating unit, is fixed with screws and

tabs at the back of the cabinet (Fig.1) during

transport. Before starting the machine remember to

release the floating unit by removing the above screws

and take down the reinforcing iron piece. To prevent

water spray from entering the machine, remember to

close the holes left open by the screws with the plastic

caps provided in the packet containing the owner's

manual. And rescrew the holes where the iron piece is

taken down with the former two screws.Attention:keep

the packing screws and plastic caps in a safe place for

later use. It is important for the machine to be

perfectly level (the angle of inclination on the work

surface must not be more than 2 degrees). For this

reason the machine is fitted with adjustable feet used

for levelling the machine before use (Fig.2). In the

case of flooring with carpeting, remember to check that

the ventilation in the support area is not plugged.

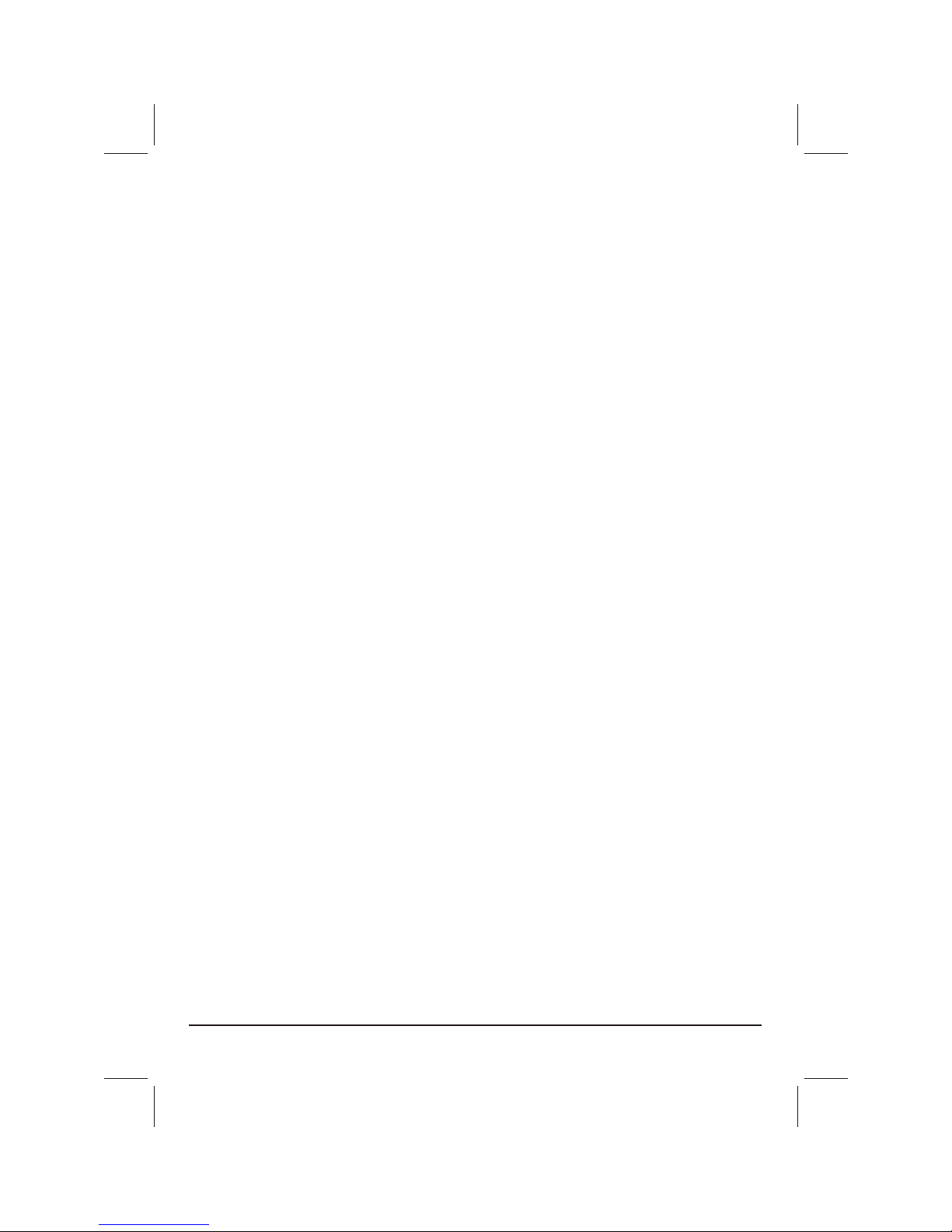

Fig.1

Fig.2

4

Installation

Electric

connection

Connection

of tap and

Loading

Hose

Connect the plug to a socket provided with efficient

earthing. Or use the spare earthing wire supplied

together with the machine and the earthing terminal

located on the left-upper corner of the back of your

machine (Warning: this appliance must be earthed as a

safety measure according to the law). Make sure that the

voltage and frequency available correspond with the

values stated on the data plate located at the back of

the machine (power range:187-242V) and that the

electric system is dimensioned to withstand the maximum

current shown on the data plate. If the socket the

machine is connected to does not correspond with the

plug, replace the plug with a suitable one and avoid

using adaptors or shunts since they could cause

overheating and burn out.The spare eathing wire is

absolutely not allowed to be connected to water

pipe,heating pipe or other kinds of pipes.

Connect the inlet hose to a cold water tap with a 3/4

gas threaded opening, and fit the filter and the rubber

gasket supplied with the washing machine. Check that it

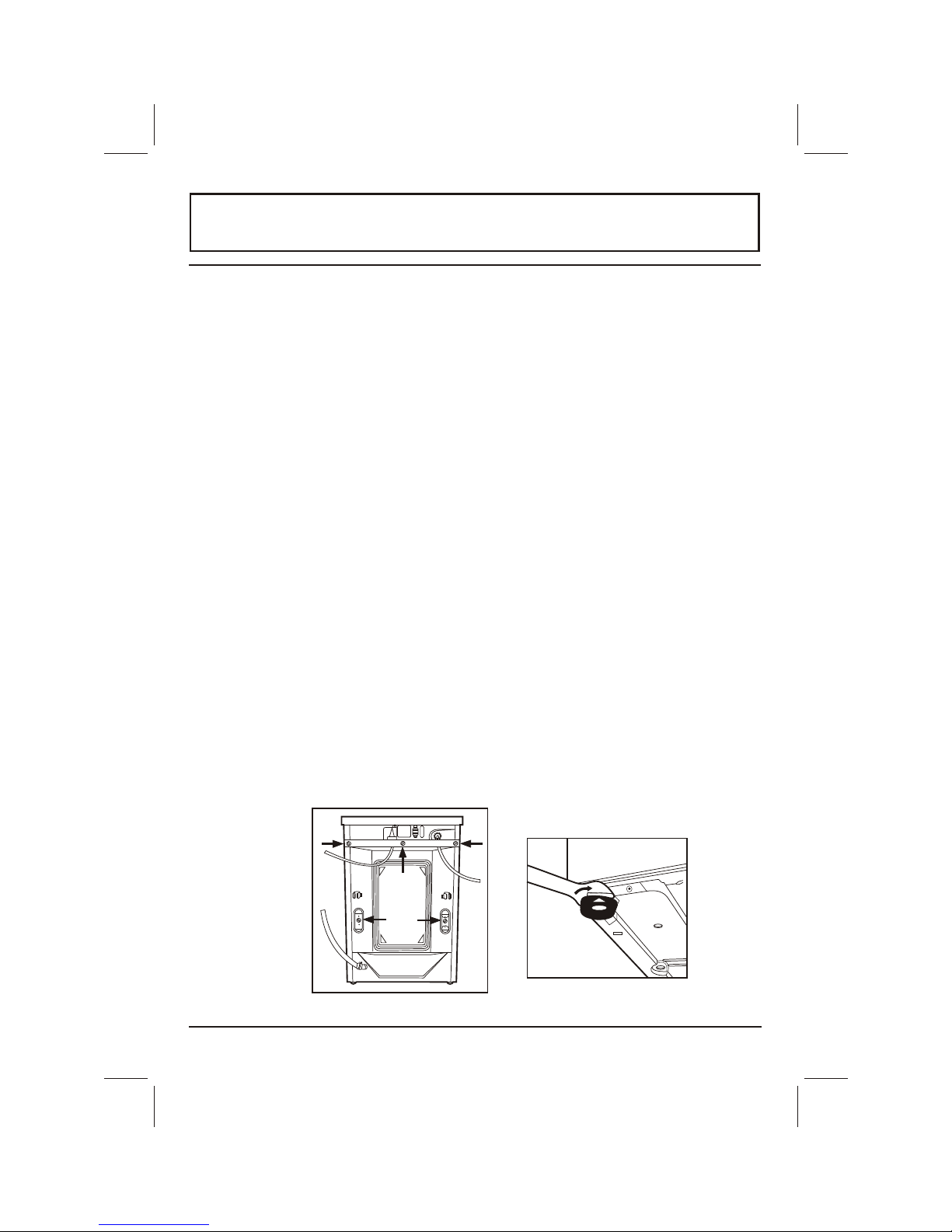

is tightly screwed to the tap (Fig. 3).

If the water piping is new or has not been used for a

long time, before making the connection, let the water

run until it is clear and free from impurities.

This step is necessary to ensure that the incoming

water does not clog and possibly damage the machine.

Fig. 3

5

Installation

Connection of

the Drain Hose

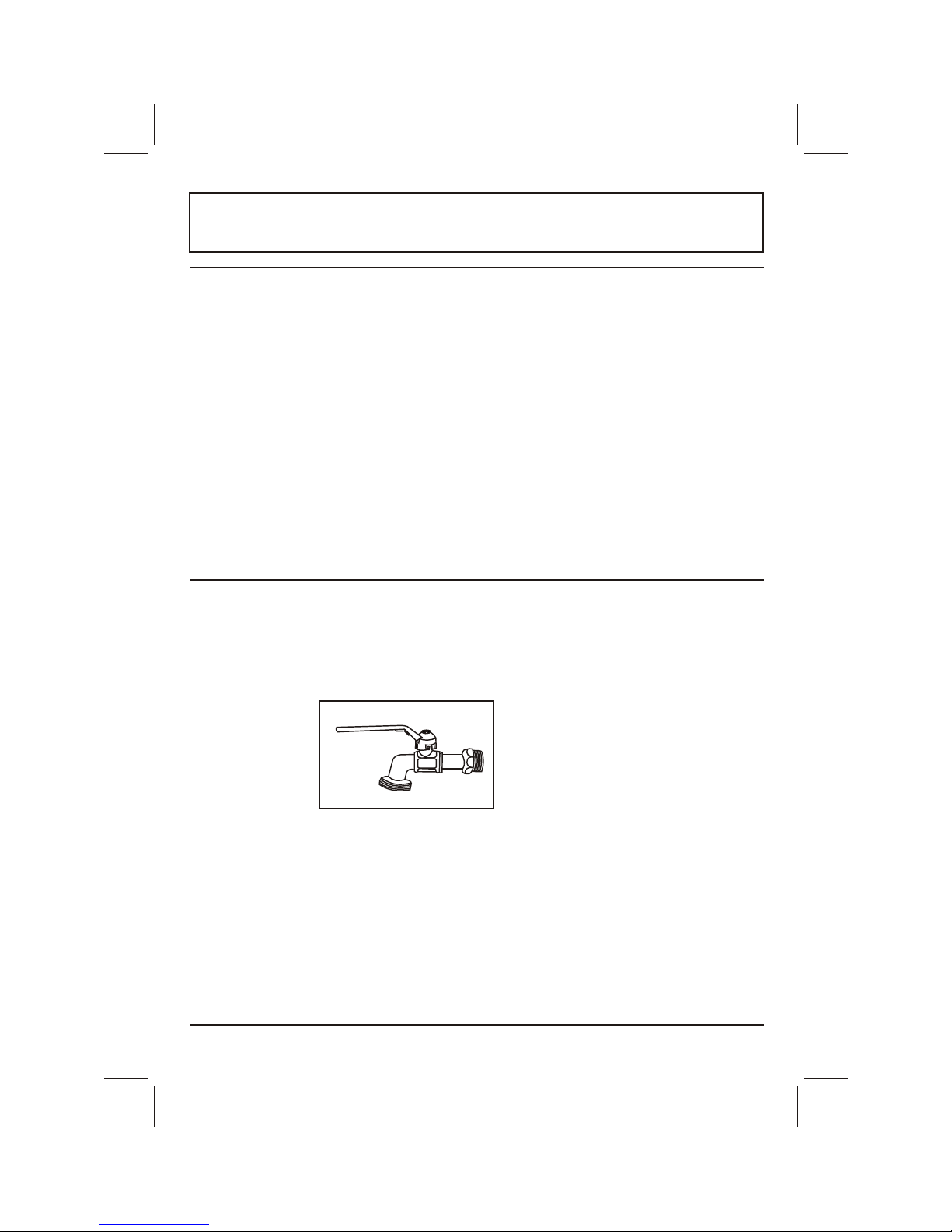

Connect the drain hose to a drain duct (with

internal diameter of at least 4 cm.) or place it

for drainage into a sink or a tub, ensuring that

there are no kinks or bends. The free end must be

at a height of between 80 and 100 cm. Should it be

necessary to fix the end of the hose at a height

of less than 80 cm from the floor, the hose must

be fixed in the appropriate hook on the upper

part of the back panel (Fig.4) or use the

supplied support to fix the drain hose.(Fig.5)

Fig.4

Connecting

WaterSupply

Fig.5

Insert stainless steel screen washers into end

of each supply hose and attach that end of supply

hose to your 3/4" water tap spigot.Be sure that

you match up cold water to "C" and hot to

"H".Note:Home Centers also have"Y" connectors

and "Couplings" which enable you to connect the

machine to your sinks faucet.

6

Loading...

Loading...