XPB90-99VGS

Twin-tub washing machine with pump

Service Manual

XPB90-99VGS(MALTA)

XPB90-99VS(AUSTRILIA)

Features

High head , unique shape

Large capacity , capable of more washing

Unique cascade current

Separating water and electricity , wide voltage range design

Enclosed base frame , mute design

Spray rinsing and spinning saving water and time

Haier Group

Special No.: SMXPB90-99VGS-02

Edition: 2003.01.12

CONTENTS

1.Contents 1

2. 1

Product code illumination and series introduction

3.

Features 2

4. 3

Specifications

5. Safety precautions 4

6. 5

Warning and cautions

7. Net dimension 6

8. 6

Installation and accessory parts

9. Parts and functions 10

10. Program list of wash timer 10

11. Maintenance service and trouble shooting 11

12. Wiring diagram 14

13. Exploded view 15

14. List of parts 17

PRODUCT CODE ILLUMINATION AND SERIES INTRODUCTION

X P B 90 - 99 V G S ( )

ABC D E

A:Washing machine

B:Ordinarily

C:Pulsator washing machine

D:Decuple of Capacity

E:Apperance code

F:Series

G:Twin-tub

H:Country

F

GH

1

High head , unique shape

Large capacity , capable of more washing

Unique cascade current

Separating water and electricity , wide voltage range design

Enclosed base frame , mute design

Spray rinsing and spinning saving water and time

With pump, drain up

With caster , move easily

Soak washing , more clean (XPB90-99VGS(AUSTRILIA))

FEATURES

2

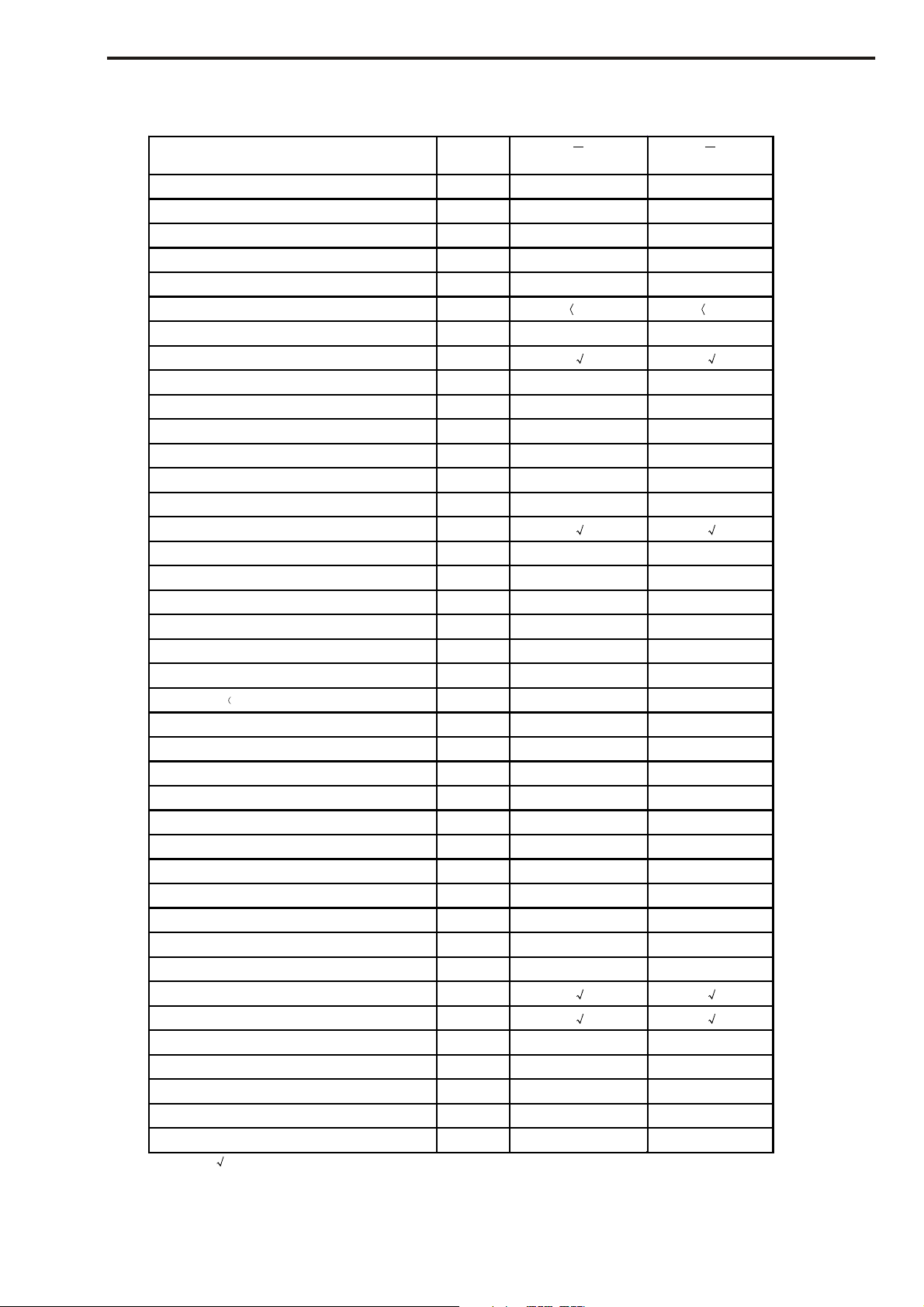

SPECIFICATIONS

Model

Features for use

Wash capacity kg 9 9

Spin capacity kg 7.8 7.8

Level/Volume L 83/68/49 83/68/49

Preset H

Residual dampness %

Contral model

controller

Normal computerized

Fuzzy computerized

Frequency conversion

Service features

Programs

Short cycle

Inlet heating select

Heating selection

Spinning cycle (selector) 860 860

Spinning cycle (variable)

Start/Pause

Automatic balancing

Aesthetics

Cabinet m aterial P=Plastic/Z=Zincking/C=Cold )

Rolled stainless steel

Inner drum (stainl. steel=s / plastic=p)

Drain type drain up drain up

Door (glass=g / plastic=p) P P

Adjustable feet

Technical data

Voltage/frequency V/Hz 230-240V/50Hz 220-240V/50Hz

Wash power W 560 560

Spin power W 325 325

Special function

Air-Bubble

Feet wheel

Water fall current

Dimensions (measurements)

Height / built under cm 98.6 98.6

Width cm 87.6 87.6

Depth / with open door cm 50 50

Net weight kg 45 45

NOTES: "

" FOR AVALIABLE, " " FOR NOT AVALIABLE , "-"FOR BE APPLICABLE

XPB90

99VGS

(AUSTRILIA)

100 100

ZZ

PP

XPB90 99VGS

(MALTA)

3

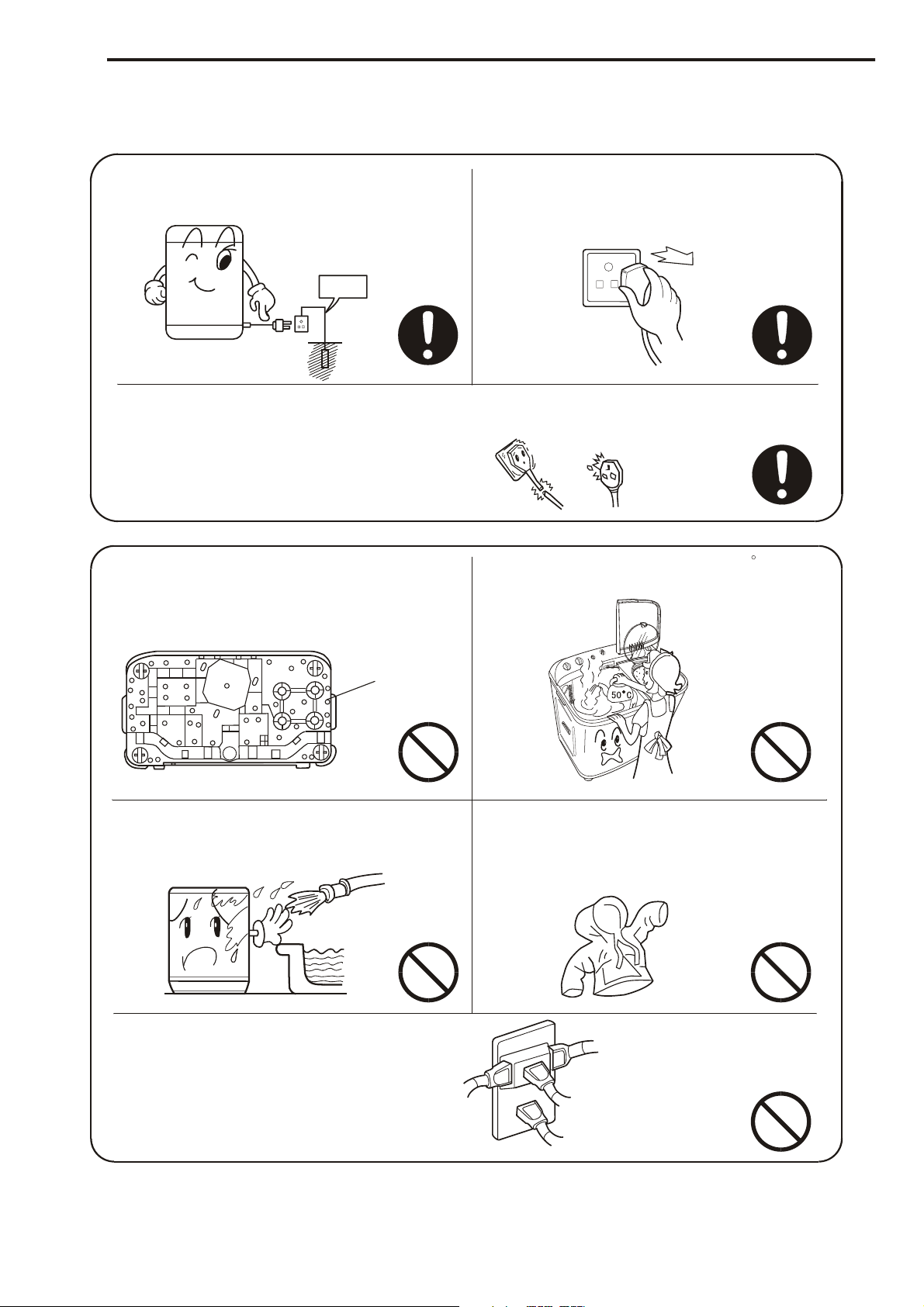

SAFETY PRECAUTIONS

Be sure to use three-pins receptacle.

Earth the earthing terminal of the

receptacle reliably.

Be sure to pull the plug off when there's

power failure, or the machine is being

moved, cleaned or when it is idle.

Earth

If the power cord is bad, to avoid risk it is required to replace it by the technicians

of our special shop or the after-sale service department. Keep the pin of the power

plug clean.

In case the washing machine is installed

Do not use water hotter than 50 C .

on ground with carpet , do not block the

ventilation hole with carpet.

Ventilation hole at

the bottom of the

washing machine

Do not put the machine at damp place

like the bathroom . Never wash it with

water.

Do not share one receptacle with other

electric appliances. Do not use it in

case that the power plug is damaged

or the inserting into the receptacle is

loose.

Do not wash water-proof laundries such

as the raincoat, bicycle shelter etc. To

avoid abnormal vibration during spinning.

4

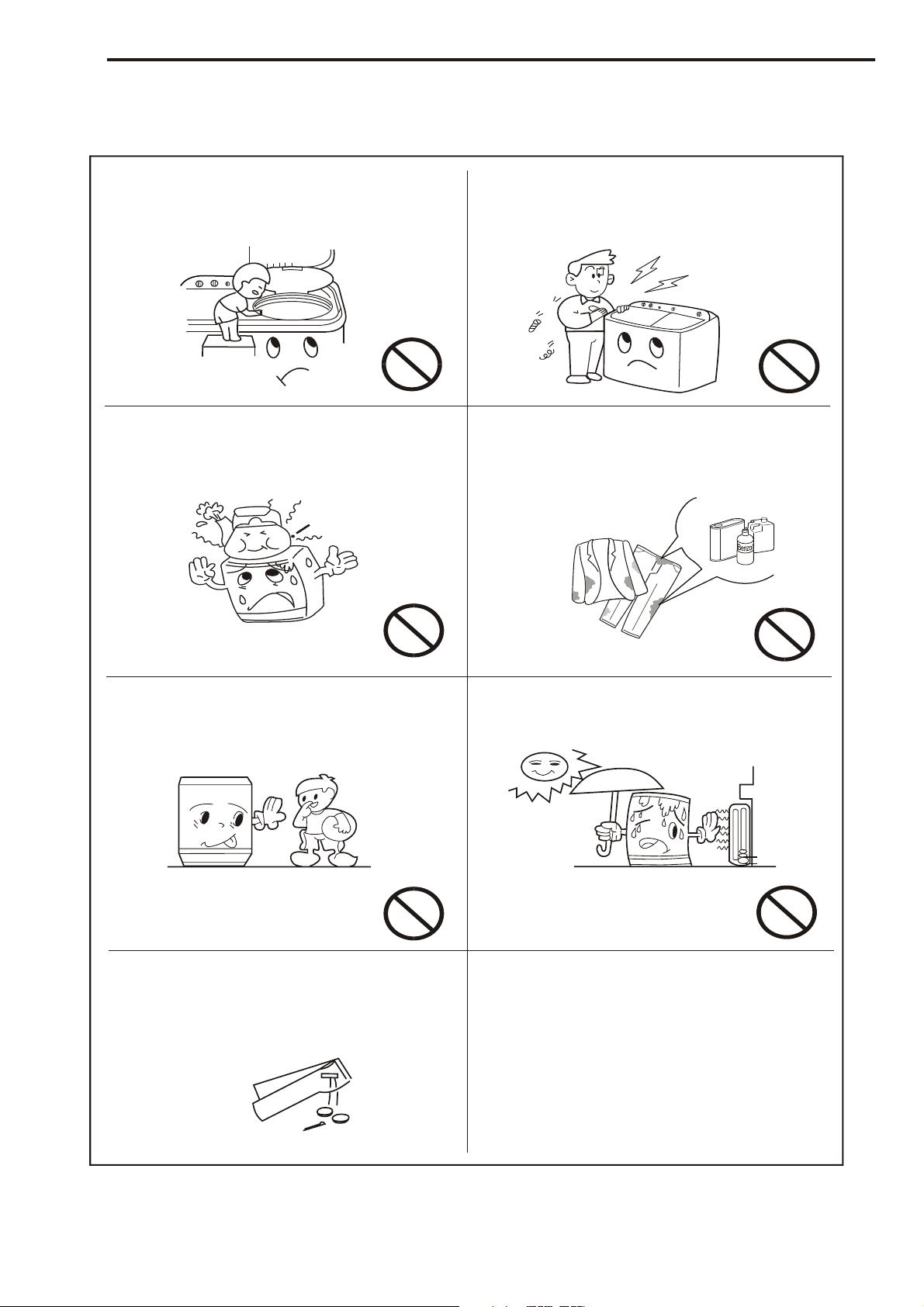

WARNING AND CAUTIONS

Do not stretch hands into the working

machine. It is dangerous even if the

rotation is slow. Take special care of

the children.

Do not put any hot or heavy items

( such as the kettle with hot water )

on the washing machine.

Do not decompose, repair or alter the

machine by yourself.

Do not wash laundries with volatile

materials (such as thinner, petrol etc.).

l

Petro

Thinner

Handicapped or children without care

shall not use the machine.

To prevent your laundries and washing

machine from damage , be sure to take

out of the foreign materials from your

pocket , such as coins, buttons, sand

or hair pins etc.

Keep the machine away from direct

sunlight and heat source like the

heater.

Before washing, please check if the

water tap is open, and if the water inlet

pipe is connected properly.

It is suggested to use low-foaming

washing powder

5

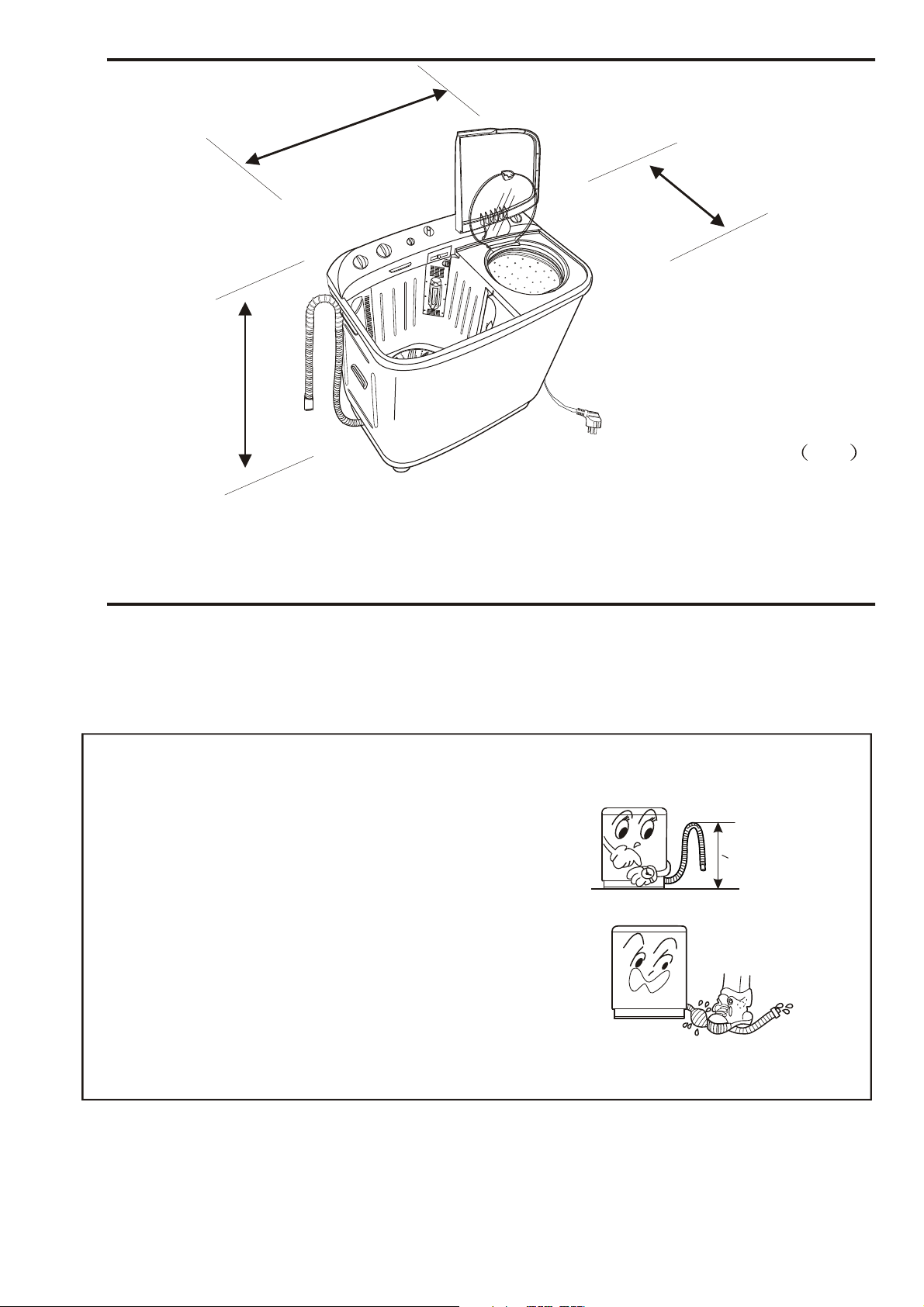

986

NET DIMENSION

876

500

Unit mm

INSTALLATION AND ACCESSORY PARTS

Usage of the drain hose

The drainage shall be smooth with the drain hose.

1 put the drain hose up to the suitable position.

2 do not tramp or squeeze the drain hose.

<1.2m

6

INSTALLATION AND ACCESSORY PARTS

How to change the direction of the drain hoses

Figure 1 indicates the ex factory installation

position of the drain hose.

Soft item

Extend the drain hose from the side of spin tub

Put soft items on the ground. Lean the machine

down gently with the front surface facing the

ground. Take off the drain hose from the cabinet.

Dismantle the drain hose fixing clamp and take

the hose out of the fixing groove.

(See to Figure 2).

Drain hose fixing clamp

Back

Front

Figure 1

Soft item

Embed the drain hose into the groove along the side

of the spin tub in the order of (1)~(3), heading for the

side of the spin tub. (See to Figure 3).

Extend to the

spin tub side

Embed the drain hose into the groove with

hands. Take care not to damage the drain

hose in fastening the fixing clamp.

Extend the drain hose from the rear side

Dismantle the drain hose fixing clamp.

Take out the drain hose from the fixing groove.

Extend it from the rear side as per the direction

of the arrow. (When the drain hose is extended

from the rear side, it can be hung on the point

for drain hose at the two sides of the cabinet.)

(See to Figure 4).

Figure 2

Embed into the

groove in turn

Figure 3

Figure 4

7

INSTALLATION AND ACCESSORY PARTS

Points of Attention in After-sales Service

Be sure to switch off the power during dismantling or repair.

Be sure to use insulated wiring terminals and insulation box in connection of the wires, and

crimp and fix to proper position with suitable tools.

In welding connections with electric iron, be sure to twist the wires before welding, and insulate

with insulation tapes.

In welding the wires with electric iron, be sure not to touch the resin part and insulation part of

each switch.

The inlay connection wires and terminals shall not be loose or drop.

Do not make the wires touch the moving parts like the belt, pulley of the motor, brake bar etc.

Do not make the wires touch the sharp edges and high-temperature area.

In case that there are metal parts with the wires, do not make the wires touch the metal parts.

Insulation materials are needed between them.

After assembly, the washing machine shall act normally. Check if it leaks and if the sound and

vibration are normal.

Dismantling and installation of the control panel component

Loosen the fastening screws. Pull towards the direction indicated

in the figure to dismantle the control panel. In installation the

beard shall lock into the installation hole of the water reception

groove and the spin tub frame. (Figure 5)

Dismantling and installation of the spin tub frame component

Dismantle the control panel component. Loosen

the two fastening screws at the rear of the spin

tub frame to dismantle the component.

Dismantling and installation of

the spin tub

Dismantle the spin tub frame component.

Loosen the fastening screw of the spin tub

shaft. The spin tub then can be taken out.

In installation, be sure to inlay the bulge of

the inner lining of the brake wheel into the

groove of the spin tub shaft. (Figure 6)

Figure 5

Spin tub shaft

Bearing seat

Oilite bearing

Inner lining of

the bearing seat

Fastening screw

Inner lining of the

brake wheel

Fastening screw of

the brake wheel

Brake wheel

Spin motor shaft

Figure 6

8

INSTALLATION AND ACCESSORY PARTS

Adjust the tension of the belt

Loosen the fastening screw at the back of the

base frame. Move the shift fixing gasket along

the direction indicated in the figure to adjust

the tension of the belt. After adjusting, fasten

the screw. (Figure 7)

Dismantling and installation of the base frame

Dismantle the back cover. Loosen the wires.Loosen the fastening screw

of the spin tub shaft. Separate the shaft from the brake wheel. Loosen

the brake hook. Take off the brake cable frame from the installation groove

of the twin-tub.Take off the V-belt. Take out the drain hose from the groove

of the base frame. Loosen the fastening screw between the base frame

and the cabinet to dismantle the base frame component.

Figure 7

Dismantling and installation of the bearing seat

Once the bearing seat is taken off, it can not be utilized again. Therefore do not dismantle

it as far as possible. In case that it has to be replaced, please dismantle it as per following

sequence, then install a new bearing seat.

a. Dismantle the spin tub as per Clause .4. Then pull out the bearing seat.

b. Cut off the inner lining claw inside the bearing seat with cutting pliers and take it out.

c. Install the new bearing seat and inner lining.

d. The bearing seat is an inlay component. Be sure to aim the claw of the inner lining

at the hole of the tub then push it in. Please use suitable tools and add even pressure

around the tub.

e. After inlay the bearing seat, check if the claw is installed to proper position from the

out side of the twin-tub (Figure 8).

Right

Wrong

Figure 8

9

Water inlet

Inlet selection

Buzzer

Current change

Wash timer

Control panel

Cascade outer

Filter frame

PARTS AND FUNTIONS

Spin tub outer cover

Spin tube inner cover

Spin timer

Spin tub frame

Spin tub

Lint filter

Pulasor

Wash tub

Drain hose

DIAGRAM LIST OF XPB90-99VGS(MALTA)

0 310

15min 2min

a

S1

b

17s 12s

a1

a

a2

S2

b

a3

a

b1

a4

b2

S3

b3

b

b4

Cabinet

Power cord

Base frame

PROGRAM LIST OF WASH TIMER

S2 strong S3 standard

symbol time limit S symbol time limit S

6

1.8

1.8

1.5

0.8

0.6

1.5

6

0.8

0.6

a1 On a3 On

a2 Off a4 Off

b1 On b3 On

b2 Off b4 Off

b

a

4.5

1

0.8

3.3

0.5

0.8

4.5

1

0.8

3.3

0.5

0.8

S2(S3)

a

10

S1

Wash timer

b

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Insert the power plug , but the machine does not work

Wash part

Check if the wash timer is opened ?

YES

Check if the power source is available

YES

Check if the contact between the plug

and receptacle is good

YES

Check if the power supply

cord is good

YES

NO

NO

NO

NO

Open the wash timer

Switch on the power

Replace the plug

or receptacle

Replace with new power

supply cord

Check if the capacitor

is good

Replace the capacitor

Check if the lead connection-peg is good

YES

Check if the fuse is good

YES

Poor contact or inferior

inside of the wash timer

YES

Replace the wash timer

NO

NO

NONO

Insect the lead well again

Replace the fuse

Check if the motor is good

NONO

Replace the motor

11

Spin part

MAINTENANCE SERVICE AND TROUBLE SHOOTING

Check if the spin timer is opened ?

YES

NO

Open the spin timer

Check if the power source is available

YES

Check if the contact between the plug

and receptacle is good

YES

Check if the power supply

cord is good

YES

Check if the lead connection-peg is good

YES

NO

NO

NO

NO

Switch on the power

Replace the plug

or receptacle

Replace with new power

supply cord

Insect the lead well again

Check if the capacitor

is good

NO

Replace the capacitor

Check if the fuse is good

YES

Check if the microswitch is closed

YES

Check if the motor is good

YES

Check if the brake system is detached?

NO

NO

NOYES

NO

Replace the fuse

Repair the microswitch,

make it closed

Replace the motor

Repair the brake system

12

MAINTENANCE SERVICE AND TROUBLE SHOOTING

There is metal rubbing noise in braking

If the brake arm has brake block ?

The washing noise is too large

Is the motor noise large?

NO

Is the motor fastened tightly?

YES

Is the belt too loose or too tight?

NO

NO

YES

NO

YES

Add the brake or

replace the brake arm

Replace the motor

Fasten the motor tightly

Adjust the tension of the belt

Is the radiating pulley loose?

YES

Fasten the radiating pulley

NO

Is the pulsator rubbing the

bottom of the twin-tub?

YES

Adjust the gap between the

pulsator and the twin-tub

The pulsator only rotates towards one direction

First check if the inlay connection is OK . If so please replace the wash timer.

Poor contact inside of the wash timer

YES

Replace the wash timer

NO

Adjust the connection to

right position

13

WIRING DIAGRAM

There is overload protector installed in the motor. In case that the motor is overload or meets

breakdown in working, the protector will act and stop the motor. When the breakdown is

removed, the motor will resume normal working.

Actual Circuit Diagram

Drain switch

Brown

Drain

Pump

White

Control

panel

Cabinet

Wash timer

Yellow

Red

Red

Wash

Motor

Brown Brown

Gray

Yellow

Spin timer

Microswitch

Orange Orange

Fuse

Brown

Blue

Purple

Yellow

Red

Capacitor

Gray

Purple

Blue

Purple

Gray

Buzzer

Spin

Motor

Gray

14

Blue

EXPLODED VIEW

20

12

14

30

31

34

38

10

1

9

11

37

39

27

142

29

235

8

13

17

18

16

73

81

85

68

86

70

46

69

78

87

88

80

78

83

84

79

71

72

4

135

7

136

62

61

60

40

82

67

66

129

65

64

63

41

74

76

77

78

81

59

140

141

32

33

35

36

47

133

42

43

44

89

15

90

45

Carton box

58

15

52

28

53

54

56

21

Manual

EXPLODED VIEW

92

91

23

121

111

122

112

137

138

24

110

93

118

119

99

117

94

109

26

100

101

116

95

102

103

23

96

104

105

106

107

108

139

97

98

75

130

128

55

49

131

132

120

114

113

112

134

25

22

92

123

124

125

126

127

57

106

104

106

115

19

50

51

104

105

48

16

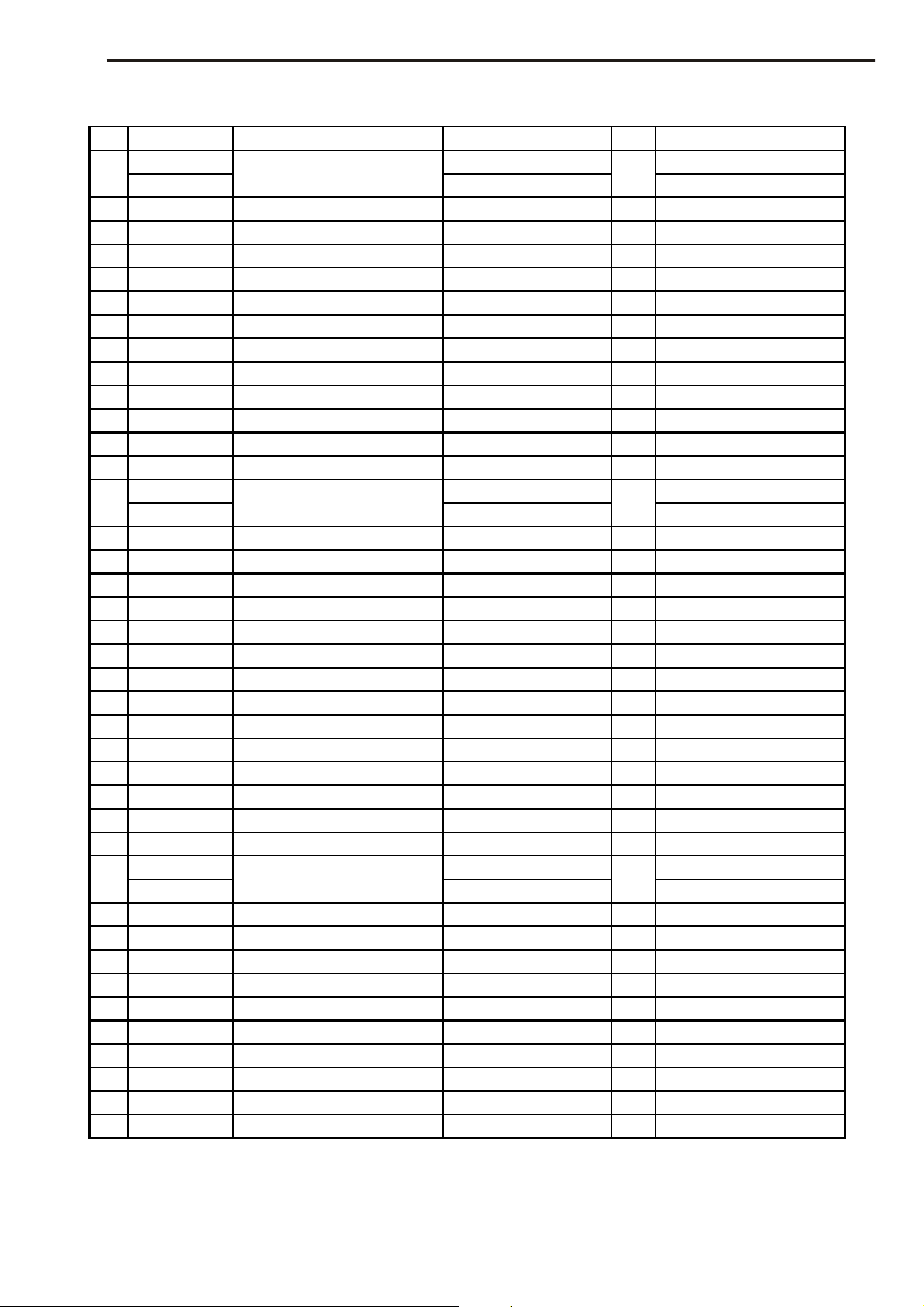

No Parts Code Parts Name Model QTY Remark

1 0030200363 Wash tub cover All-purpose 1

2 00330603049 Kick spring All-purpose 1

3 0030200365 Spin tub cover All-purpose 1

4 00330901529 Notice label All-purpose 1

5 00330029022 Brake pullback component All-purpose 1 *

6 00330503500 Microswitch All-purpose 1 *

7 00330810009 Tapping screw All-purpose 3

8 00330043004 Spin tub frame component All-purpose 1

9 00330015008 Water channel A component All-purpose 2

10 00330810009 Tapping screw All-purpose 2

11 00330015009 Guide slot A components All-purpose 2

12 00330019010

13 00333101049 Filter frame All-purpose 1

14 00330015011 Guide slot B component All-purpose 1

15 0030802452 spin tub component All-purpose 1

16 0030201873 Lint filter All-purpose 1 *

17 00330810009 Tapping screw All-purpose 3

18 00333101147 Flat valve cover All-purpose 1

19 00330014038 Damping spring component All-purpose 4 *

20 00330203010 Small block All-purpose 3

0030502281

0030502950 XPB90-99VGS( MALTA)

21

22 0030801588 Brake panel A component All-purpose 1

23 00330812061 Bolt A component All-purpose 2

24 00330104001 Anti-deformation strip All-purpose 1

25 00330802095 Tapping screw All-purpose 7

26 0034200060 Capacitor All-purpose 4 *

27 0030600056 Pulsator fixing screw All-purpose 1

0030502282

0030502943 XPB90-99VGS( MALTA)

28

29 00333101124 Pulsator All-purpose 1

30 00330303028 Pulsator cover All-purpose 1

31 00333101069 Twin-tub All-purpose 1

32 00330602060 Water channel block All-purpose 1

33 00330602061 Water channel block A All-purpose 2

34 00330810009 Tapping screw All-purpose 12

35 00330067005

36 00330802062 Tapping screw All-purpose 4

37 00330603011

38 00330810009 Tapping screw All-purpose 1

39 00330109030

40 00330029023

41 00330106004 Long overflow pipe All-purpose 1

Water channel B component All-purpose 1

XPB90-99VS(AUSTRILIA)

mannual 1

XPB90-99VS(AUSTRILIA)

Packing box 1

Damping clutch

Locating lever

Pullback band pulley

Drain pullback band component

All-purpose 1 *

All-purpose 1

All-purpose 1

All-purpose 1

LIST OF PARTS

Notes: the components marked with * in the remarks columns are damageable parts.

17

No Parts Code Parts Name Model QTY Remark

42 00330107085 Overflow pipe All-purpose 1

43 00333101030 Valve body All-purpose 1

44 00330203007 Valve plug All-purpose 1

45 00333101140 Valve rod All-purpose 1 *

46 0030501168 Warning label All-purpose 1

47 00330605502 Drain hose clamp All-purpose 2

48 0030800456 Outer drain hose component All-purpose 1 *

49 00333101072 Base frame All-purpose 1 Sea grey

50 0030200752 Tightening mat All-purpose 4

51 00330802017 Tapping screw All-purpose 4

52 00330603061 Valve spring All-purpose 1

53 00333101031 Valve cover A All-purpose 1

54 00330810009 Tapping screw All-purpose 4

55 00330812069 Nut All-purpose 3

56 00330106005 Safeguard bag All-purpose 1

00330502020

00330502530 XPB90-99VS(AUSTRILIA)

57 1

Ground wire parts

XPB90-99VGS( MALTA)

58 0030801662 Bearing seat component A All-purpose 1 *

59 0030803377 Accessories

XPB90-99VGS( MALTA) 1

60 00330101092 Water filli ng guide slot All-purpose 1

61 00333101067 Water channel All-purpose 1

62 00330109028 Gliding block All-purpose 1

63 00330810009 Tapping screw All-purpose 2

64 00330111532 Water filli ng control handle All-purpose 1

65 00330104003 Stabling block All-purpose 2

66 00330101095

Connecting rod

All-purpose 1

67 00330603505 Small pullback spring All-purpose 1

68 00330101096 Expansion gasket All-purpose 1

69 00330502145 Wires module All-purpose 1

00330501009 Other-purpose

00330501018

Wash timer 1 *70

XPB90-99VS(AUSTRILIA)

71 00330906195 Excess filling label All-purpose 1

00330111293 Other-purpose

0030200950

72

0030502284 XPB90-99VS(AUSTRILIA)

0030502940 XPB90-99VGS( MALTA)

73

Wash shelf

Print control panel

XPB90-99VS(AUSTRILIA)

1

1

74 00330111538 Knob All-purpose 3 *

75 00330602017 Outer drain hose clamp All-purpose 1

76 0030600001 Tapping screw All-purpose 3

00330111294 Other-purpose

0030200951

Spin shelf 177

XPB90-99VS(AUSTRILIA)

78 00330802005 Tapping screw All-purpose 10

79 00330501013 Spin timer All-purpose 1 *

LIST OF PARTS

Notes: the components marked with * in the remarks columns are damageable parts.

18

No Parts Code Parts Name Model QTY Remark

00330111295 Other-purpose

0030200952

81 00330802005 Tapping screw All-purpose 5

82 00330312502

83 00330513517 Buzzer All-purpose 1 *

84 00330802025 Tapping screw All-purpose 2

85 00330109018 Selector cam All-purpose 1

86 00330802025 Tapping screw All-purpose 1

87 00330906500 Water filli ng label All-purpose 1

88 00330810009 Tapping screw All-purpose 3

89 00330802500 Tapping screw All-purpose 2

90 00333101041 Drain hose fixing clamp All-purpose 1

91 0030600001 Tapping screw All-purpose 5

92 00330829001 long locking band All-purpose 2

0030502283

0030502942 XPB90-99VGS( MALTA)

93

94 00333101562 Power cord hook All-purpose 2

95 00330802500 Tapping screw All-purpose 2

96 00330101854 Back cover All-purpose 1

97 00330802500 Tapping screw All-purpose 9

98 00330028011

99 00330101655 Wire holder All-purpose 1

100 00330802007 Tapping screw All-purpose 1

101 00330101894 Cabinet handle All-purpose 2

102 00330103501 Fixing pin All-purpose 1

103 00330308502 Power cord fixing clamp All-purpose 1

104 00330804001 Screw All-purpose 3

105 00330804003 Gasket All-purpose 2

106 00330806003 Notched gasket All-purpose 3

107 00330804002 Nut All-purpose 2

0030400126

00330802133 XPB90-99VGS( MALTA)

108

109 00330308049 Cabinet All-purpose 1

110 00330802500 Tapping screw All-purpose 2

111 0030400237 Capacitor cord Other-purpose 1

112 00330301023 Capacitor fastening ring All-purpose 2

113 00330205021 Damping gasket, lower All-purpose 3

114 00330205020 Damping gasket, upper All-purpose 3

115 00330603013 Pullback spring All-purpose 1

116 00330047001 Brake wheel component All-purpose 1 *

117 00330812048 Fixing screw All-purpose 1 *

118 00330812043 Screw All-purpose 3

Buzzer shelf 80

Positioning spring

Nameplate 1

Brake strand cord component All-purpose 1

Power cord 1

XPB90-99VS(AUSTRILIA)

All-purpose 1

XPB90-99VS(AUSTRILIA)

XPB90-99VS(AUSTRILIA)

1

LIST OF PARTS

Notes: the components marked with * in the remarks columns are damageable parts.

19

No Parts Code Parts Name Model QTY Remark

119 00330820004 Spring gasket All-purpose 3

120 00330812070 Bolt All-purpose 3

121 00330401016 Radiating pulley All-purpose 1 50Hz

122 00330011021 V-belt All-purpose 1 *50Hz

123 00330812071 Screw All-purpose 3

124 0034000189 Spin motor All-purpose 1 *240V~50Hz

125 00333101008 Motor insulation seat All-purpose 3

126 00330802017 Tapping screw All-purpose 4

127 00330301130 Motor fixing plate All-purpose 1

128 0034000188 Wash motor All-purpose 1 *240V~50Hz

129 00330111285 Hinge seat All-purpose

130 0034000121 Drain pump All-purpose 1

131 00330302033 Drain pump seat All-purpose 1

132 00330206502 Damping seat All-purpose 4

133 00330107108 Inner drain pipe All-purpose 1

134 00330812514 Tapping screw All-purpose 3

135 00330503060 Drain switch All-purpose 1

136 00330802052 Tapping screw All-purpose 2

137 00330506522 Disturbance controller All-purpose 1

138 00330205001 Rubber band All-purpose 3

139 0030400029

140 0030801995 Water inlet pipe XPB90-99VS(AUSTRILIA) 1

141 00330107106

142 00330303505 Tooth gasket All-purpose 1

Dist urbanc e controller power cor d All-purpose 1

Gland XPB90-99VS(AUSTRILIA) 1

LIST OF PARTS

Notes: the components marked with * in the remarks columns are damageable parts.

20

Sincere Forever

Haier Group

Tel: 86-532-8938356

Web site: http: //www.haier.com

Loading...

Loading...