Haier PGT2.0-2 Installation Manual

1

Haier flat panel solar collector

Installation manual

Model: PGT2.0-2

Prepared by: Qingdao economic and technology development zone Haier water

heater company

Prepared date: 2009.02.18

2

CONTENTS

Ⅰ、Haier solar panel performance parameter 3

1、technical specification 3

2、pressure falloff curve 3

3、installation angle 4

4、solar panel dimension 4

Ⅱ、heat-conducting medium for solar heating system 5

Ⅲ、lightning conductor 8

Ⅳ、solar panel installation manual 9

A、installation method for pitched roof 10

1、tile roof 10

2、color steel roof 16

B、installation method for flat roof 18

C、installation method for vertical wall 22

Ⅴ、pipeline for solar panels 28

3

Instruction manual for collector installation

I. Introduction of the plate collector

1. Technical parameters of the plate collector

Model

Light receiving

area (m2)

Exterior size (mm)

Net weight

(kg)

Gross weight

(kg)

PGT2.0-2

1.9

2000*1020*84

40

43

Maximum loadability of the plate collector: without being damaged by the test pressure of 1.2MPa

and the working pressure is 0.15~0.2MPa.

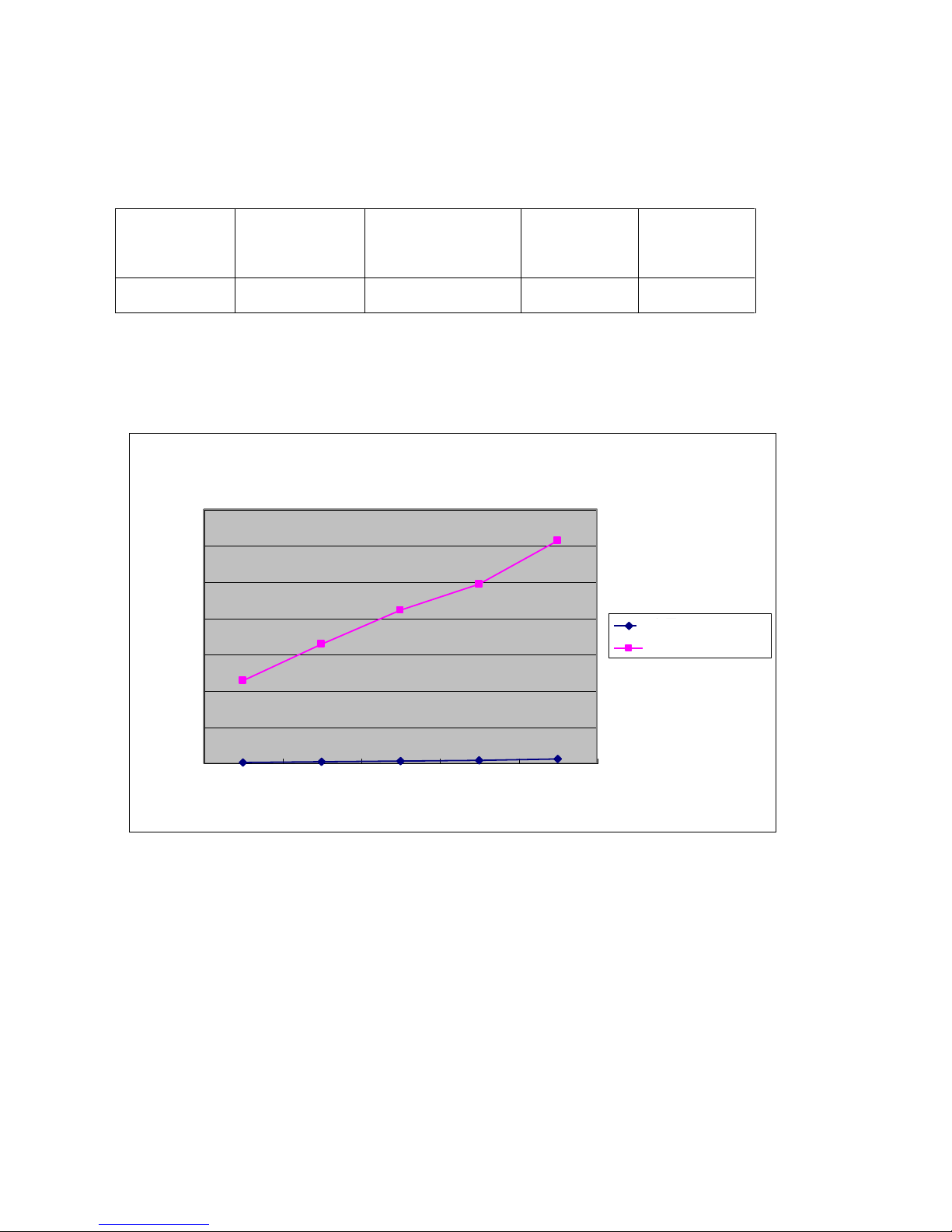

2. Pressure drop graph of one collector

Flow/pressure graph of one plate heat collector

0.01

0.019

0.029

0.038

0.058

1.14

1.64

2.11

2.47

3.07

0

0.5

1

1.5

2

2.5

3

3.5

1 2 3 4 5

流量(L/S)

压降(KPa)

流量(L/s·台)

压降(KPa)

The four major factors that impact the pressure drop of the collector are as following:

The quantity of the liquid flowing through the collector:When the diameter and the coarseness of the

draining pipe and collecting pipe for the collector is fixed, the pressure drop increases along with the

quantity increase of the liquid flowing through the collector.

The diameter of the draining pipe and collecting pipe for the collector:When the coarseness of the inner

wall of the pipe and the liquid quantity is fixed, the pressure drop increases along with the decrease of

the diameter.

The coarseness of the inner wall of the draining pipe and collecting pipe for the collector: When the

liquid quantity and pipe diameter is fixed, the pressure drop increases along with the increase of the

coarseness of the pipe’s inner wall.

The liquid viscosity: when other conditions are the same, the pressure drop increases along with the

viscosity increase of the liquid flowing in through the collector.

Flow

Pressure drop ()KPa)

Flow

Pressure drop ()KPa)

set

4

3. The angle for mounting the collector

How to select the tilt angle α for mounting the collector:

When the solar system is applicable in four seasons: α=β

When the solar system is used mainly in summer: α=β-10

o

When the solar system is used mainly in winter: α=β+10o

Note: α——Title angle for mounting the collector;

β——Geographical latitude of the area for mounting the collector;

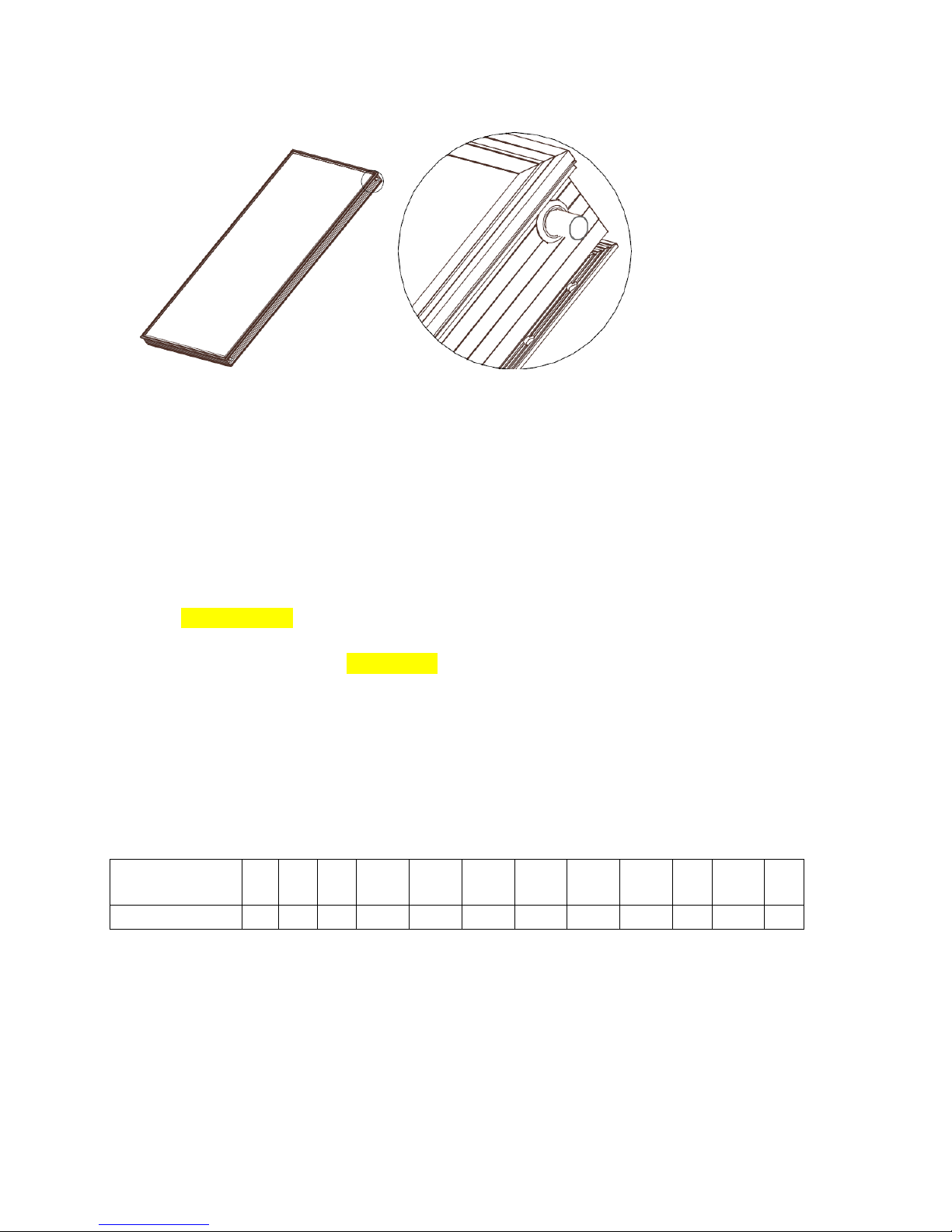

4. For the detailed sizes for mounting the plate collector, see the figure below(in: mm):

5

The 16 holes (φ9) above are prepared for fixing the collector.

II. The introduction of the relevant heat conducting media of the plate heat collecting

system

It is the twice (secondary) circulation system that must be selected for the area where icing is possible. The

antifreeze shall be used in the heat conducting medium and propylene glycol is recommended to be used as the

antifreeze (It is forbidden to use the once (primary) circulation system in the area where icing is possible);

The secondary circulation system is recommended for the area where icing is impossible in any season and the

antifreeze could be used as the heat conducting medium. Pure water is recommended to conduct thermal energy.

The primary circulation system is not recommended;

The primary circulation system is not recommended to be used by the plate collector in any case; if it is inevitable

to use the primary circulation system, the problem with the scaling in of the copper pipe must be solved;

The table below contains the valves of the freeze points of the propylene glycol antifreezes which concentrations

are different. The concentration of the propylene glycol antifreeze to be filled in depends on the lowest

temperature of the application area. (It is for your reference only).

Concentration

(volume percent)

5

10

15

20

25

30

35

40

45

50

55

59

Freezing point ℃

-1.7

-3.3

-5.3

-7.2

-9.7

-12.8

-16.4

-20.9

-26.1

-32

-39.7

-50

The processes for filling liquid:

1. Inspect the pipes which have been connected to make sure that the check valve, gate valve, filter and circulation

pump are connected correctly, and that the pipes and connectors have been tightened while the pipes have been

fixed firmly (for the pipe connection, see the figure below);

6

2. Pressurization test(Pressurizing with water):

接室内用水

平板集热器

储水箱

自来水

压力安全阀

膨胀罐

阀1

阀2

阀3

自动排气阀

过滤器

单向阀

过滤器

单向阀

循环泵

阀4

(Principle schematic drawing of the heat collecting system)

阀1

阀3

储液罐

注液泵

压力表

阀2

过滤器

膨胀罐

压力安全阀

单向阀

循环泵

(Schematic drawing for the liquid filling components)

Plate heat collector

automatic exhaust valve

valve 4

Valve3

Valve1

Valve2

Valve2

Valve2

Valve3

Valve1

Circulation pump

Check valve

expansion tank

water reservoir

Pressure relief valve

filter

Check valve

filter

Tap water

connecting to the water used indoor

Liquid tank

circulation pump

Check valve

Pressure relief valve

expansion tank

filter

Manometer

Liquid filling pump

7

Open the automatic exhaust valve first and close the valve at the inlet of the expansion tank. Connect the outlet of

the liquid filling pump to valve 1 and ensure that the water flows in the same directions for mounting check valve.

Connect the suction nozzle of the pump and water-return pipe to the liquid filling tank. Close valve 2 and open the

valve below the highest automatic exhaust valve on the array of the collector. Allow the liquid filling pump to fill

water into the system. Observe the water flowing back and close the water return valve 3 (marking it) when you

find that the returned water is clean and flows evenly, and there are no more bubbles. Pressurize it at the pressure

which is 1.5 times the pressure for opening the relief valve. Observe the connection points carefully to find out if

there is any leakage or oozing. It passes the test when there is no leakage or oozing, and the pressure drop is less

than 0.02MPa in 10 minutes.

Attention:

a. The test pressure is 1.5 times of the pressure for opening the relief valve;

b. Notice the relative positions of the relief valve and manometer.

3. Pipe cleaning:

Pipes shall be cleaned before and after testing the pressure of the system by flushing them and cleaning the filter.

Then drain the liquid from the pipe so as to fill antifreeze; if the liquid is not drained up from the system, you can

blow the liquid out with a blower; blow it until it is dried up.

4. Antifreeze filling:

The process for filling antifreeze is same as the above. The different work is that the valve connecting to the

expansion tank must be opened before filling the antifreeze; it should also be noticed that the pressure for filling

the liquid must be consistent to pre-filling pressure of the expansion tank, 0.15MPa to 0.2MPa in general;

5. Close valve 4 below the automatic exhaust valve when antifreeze is fully filled to prevent the medium

vaporizing when the system operates;

Requirements on maintenance and notices:

1. If it will stay idle for long time, cover the plate collector with a nontransparent object and disconnect it from the

power supply to prevent overheating of the collector.

2. Check the system regularly to find out if it operates properly; check the manometer to look at if the pressure

valve on it is normal; if the pressure value is under standard, check if there is any leakage on the pipes; if not,

antifreeze shall be refilled into the system.

3. If the system needs the antifreeze to be replaced, it shall be emptied first. The liquids in the pipes shall be

drained up so as to fill antifreeze into it. If liquid cannot be drained up from the system, dry it by blowing the

system with a blower; don’t stop blowing until the system is completely dry(Attention, the replacement should be

assisted by the local after-service providers).

4. Check the low temperature resistibility of the antifreeze regularly(For the detailed interval, consult the local

antifreeze supplier).

5. Pull the lever of the relief valve monthly to flush the valve seat and valve clack; keep dirt and scaling off its

sealing surface since they would cause leakage or Open/Close failing. Check if the valve can be opened or closed

normally.

8

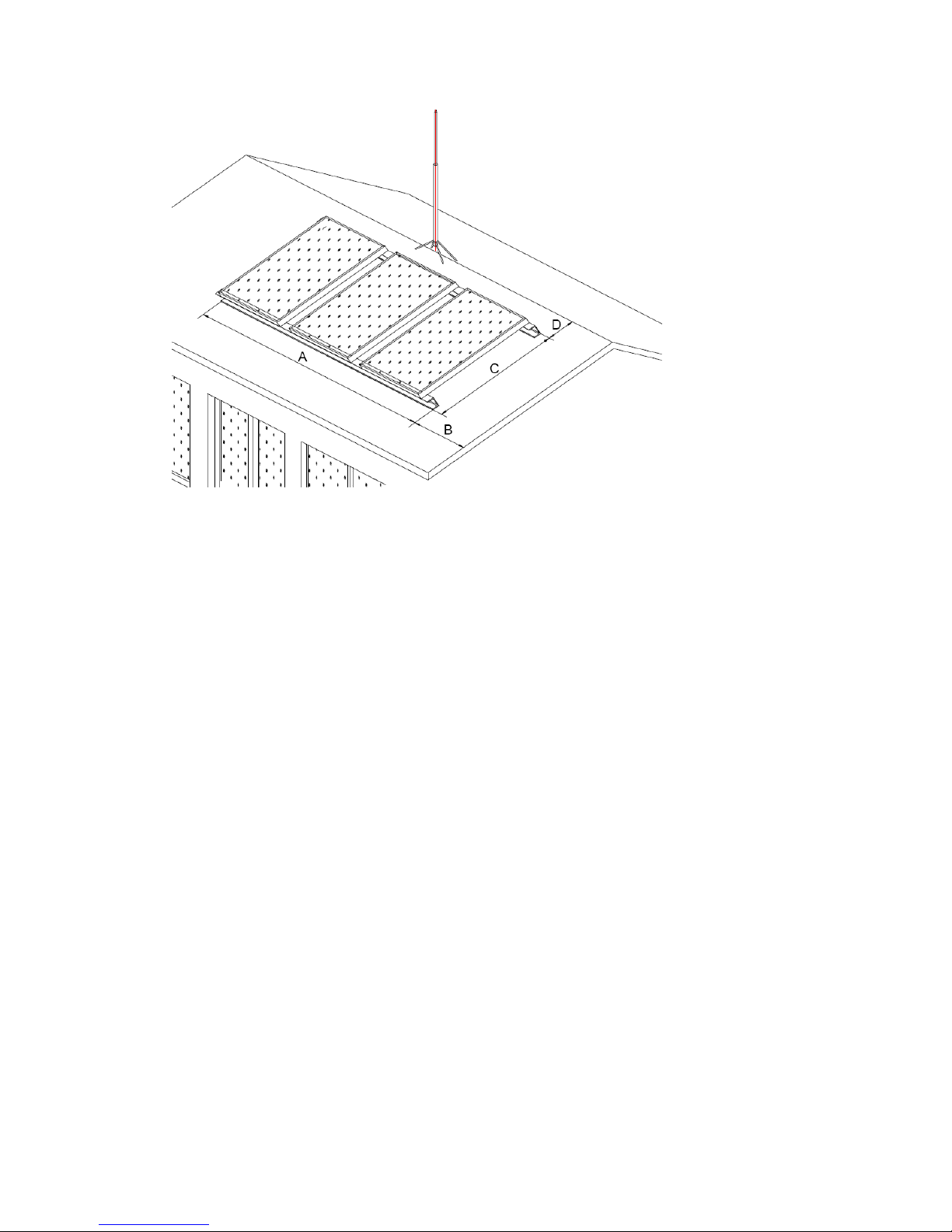

III. Introduction of the lightning arrestor

Since collectors are mounted on roofs, they are vulnerable to lightning strikes. Therefore, they shall be mounted in

the area which is well protected against lightning. If there isn’t any lightning arrestor, to protect the plate collector,

a lightning rod or grounding line is required. The following is a simple drawing for mounting the lightning rod on

a flat or sloped roof:

● The drawing for mounting the lightning rod on a flat roof:

The lightning rod can be welded onto a frame, or an independent lightning rod can be manufactured and it can be

fixed with a wire rope.

● The drawing for mounting the lightning rod on sloped roof:

Making an independent lightning rod is recommended; it can be fixed with a wire rope and the equipotential

bonding shall be applied between it, the frame and the lightning belt.

Lightning rod

Grounding line

9

Notes:

1. If the building has a lightning arrestor, it shall be made sure by the local professional if the collector is well

protected by the lightning arrestor.

2. If the collector can be protected, the frame mounted on-site shall be connected to the existing lightning belt

with equipotential bonding. For the connection material, connection and anti-corrosion method, the local

specifications about the lightning system designing shall be followed.

3. If the collector cannot be protected, making a lightning rod is required; it shall be the relevant professionals that

decide how to select the materials, decides its height and how to fix it; the lightning rod and its frame mounted

on-site shall be connected to the existing lightning belt with equipotential bonding. For the connection material,

connection and anti-corrosion method, the local specifications about the lightning system designing shall be

followed.

IV. How to mount and fix the plate collector

Different ways to mount and fix the plate collector:

How to mount it on a sloped roof;

How to mount it on a flat roof;

How to mount it on a wall;

10

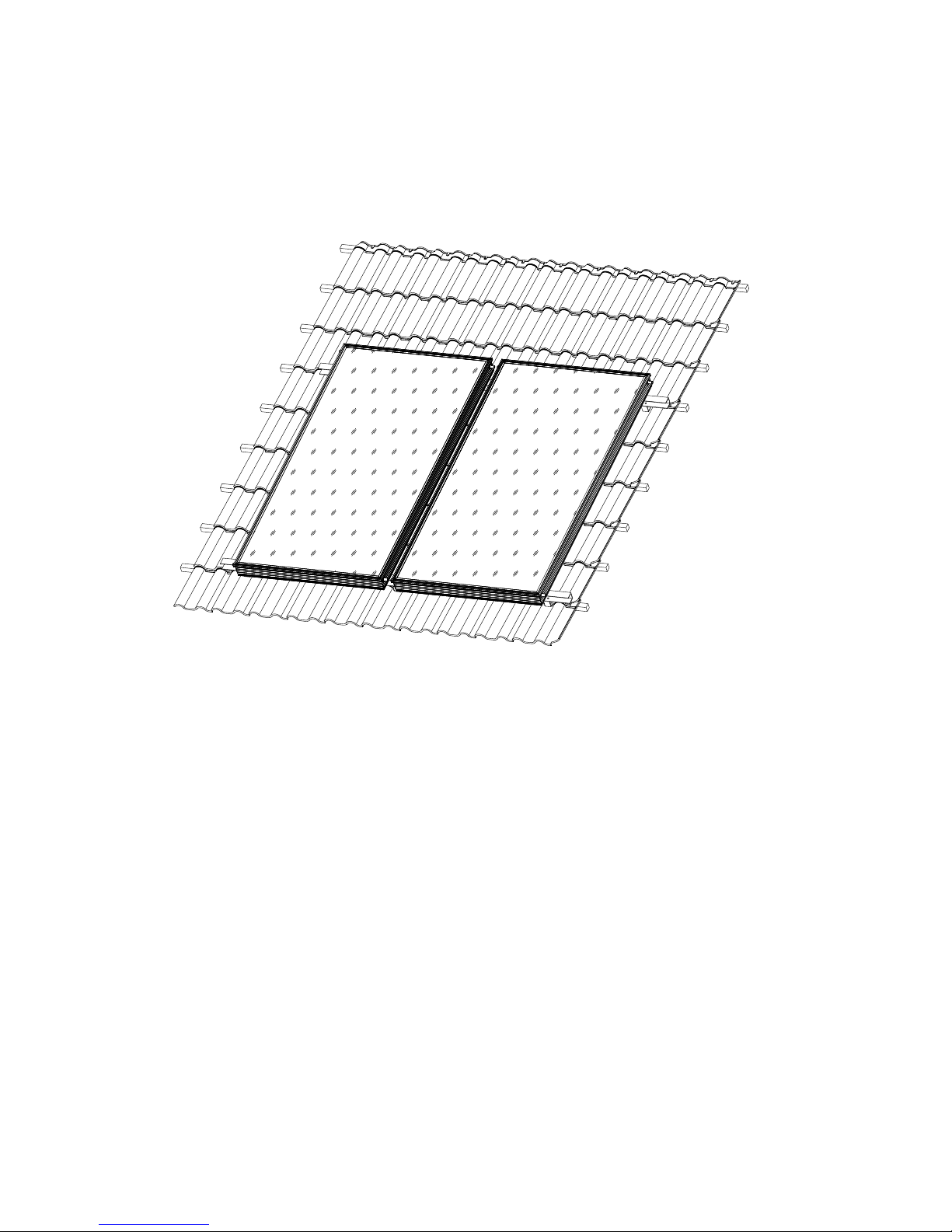

(I) There are two ways to mount the collector on a sloped roof, depending on the roof style:

How to mount it on a tile roof:

How to mount it on a color steel roof:

1. How to mount it on a tile roof:

(1) How to assemble the fittings of the plate collector

① How to connect and fix it with batten

11

平板集热器

角钢件

L40*70*120*4

集数器连接件

固定螺栓M8 16

焊接

挂瓦条

Plate heat collector

Set bolt

Batten

Plate heat collector

connector

Welding

Angle iron piece

Loading...

Loading...