Page 1

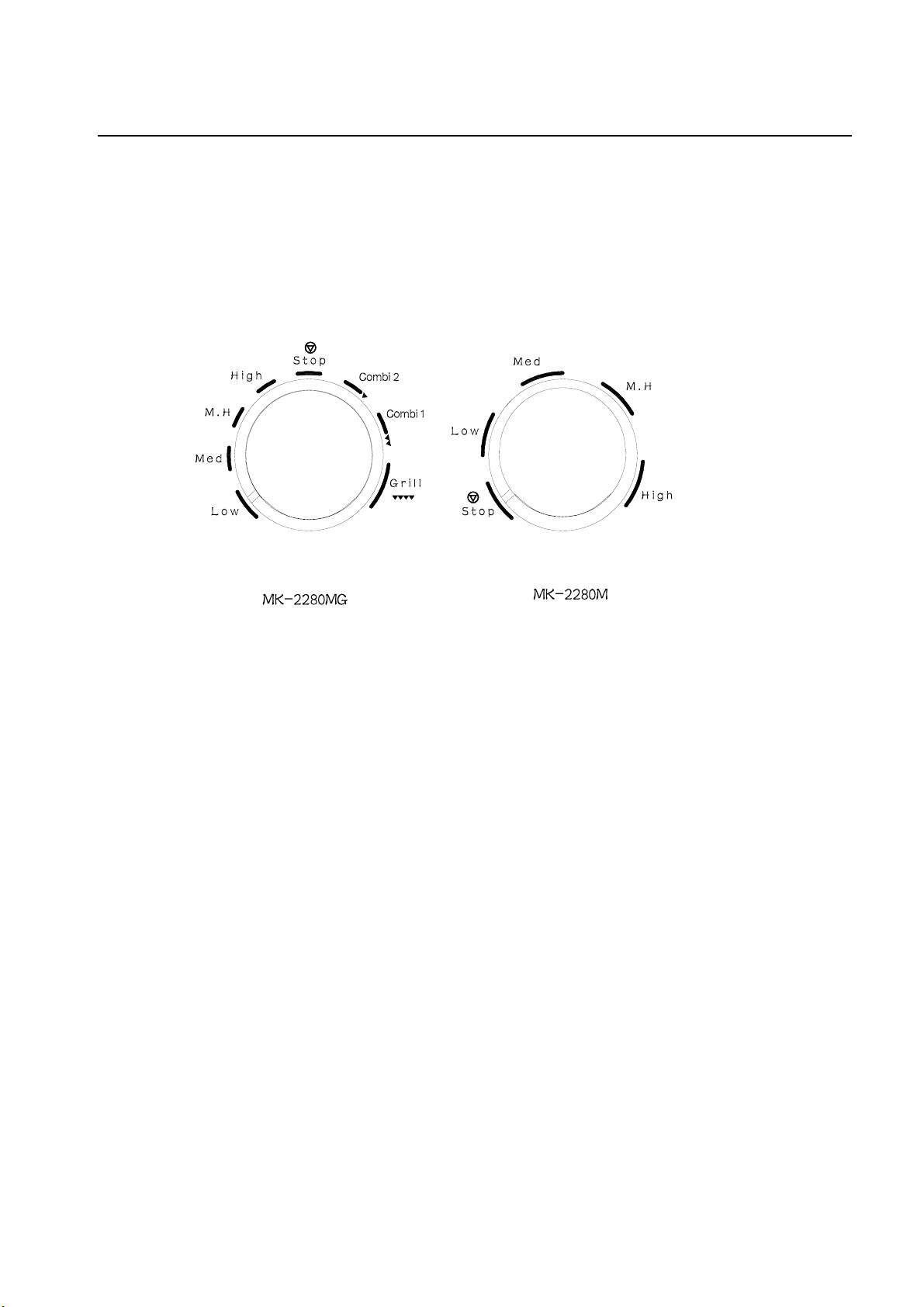

Semi-electronic

Microwave Oven

Service Manual

MK-2280M

MK-2280MG

Features

●

Safe to use

●

Shining appearance

●

● Healthy and germicidal

High-temperature grill (Only MK-2280MG)

●

Haier Group

Edition:2005-11

- 1 -

- 11

Page 2

Contents

Contents

1. Contents……………..…………………………………………………………………1

2. Product Code illumination and Series Introduction ……………………...…...2

3. Features….……………………………………………………..…………………….3

4. Specifications……..…………………………………………...………………….4

5. Safety Precaution…………………………………………..………………………5

6. Warning and Cautions……………………………………………………………..6

7. Installation and Accessory Parts…………………………………………………9

8. Parts and Functions………………………………………………………………..11

9. Maintenance Service and Trouble Shooting…………………………………...12

10. Circuit Diagram and Circuit Explanation………………………………………..23

11. Exploded View and Part of Lists

………………………………………………...29

- 2 -

Page 3

Product Code illumination and Series Introduction

2.Product Code illumination and Series Introduction

Model Identification

M K -□ □ □ □ □ □

A B C D E F

A: Abbreviation of Microwave Oven.

B:Appearance

c: Code name of Nominal cavity capacity.

D: One tenth of the microwave output power consumption.

E:Type of operation

M:Mechanical E:Electronic

F---Function With G:Grill function

Examples:

MK-2280MG:

It represents mechanical microwave oven with grill function, the cavity

volume is 21L, the microwave output power is 800w, K appearance.

MK-2280M:

It represents mechanical microwave oven without grill function, the cavity

volume is 22L, the microwave output power is 800w, K appearance.

- 3 -

Page 4

Features

3.Features

3.1 Safe to use

The door adopts unique anti-choke structure and integrated punch forming, and thus

effectively prevents the microwave from leaking.

It is controlled by two-step interlock switch. The power will be switched off

automatically when the door is open, therefore it is much safer to use.

3.2 Shining appearance

The door shell and operation panel frame shell adopt in ported high-quality stainless

steel material, and will never get rust and change color. It has modern appearance and

superior quality, and thus becomes the best choice for the household microwave oven.

3.3 Healthy and germicidal

It is produced with antiseptic materials, and can suppress the reproduction of the

bacteria effectively. The special function of the microwave oven can eliminate the germ in

the food quickly and completely.

3.4 Simple operation and accurate time counting

With two knobs, one for adjusting time and another for power levels, plus LED display,

on which cooking time is displayed, it has feature of simple operation of mechanical

microwave oven as well as accurate time counting of electronic microwave oven.

- 4 -

Page 5

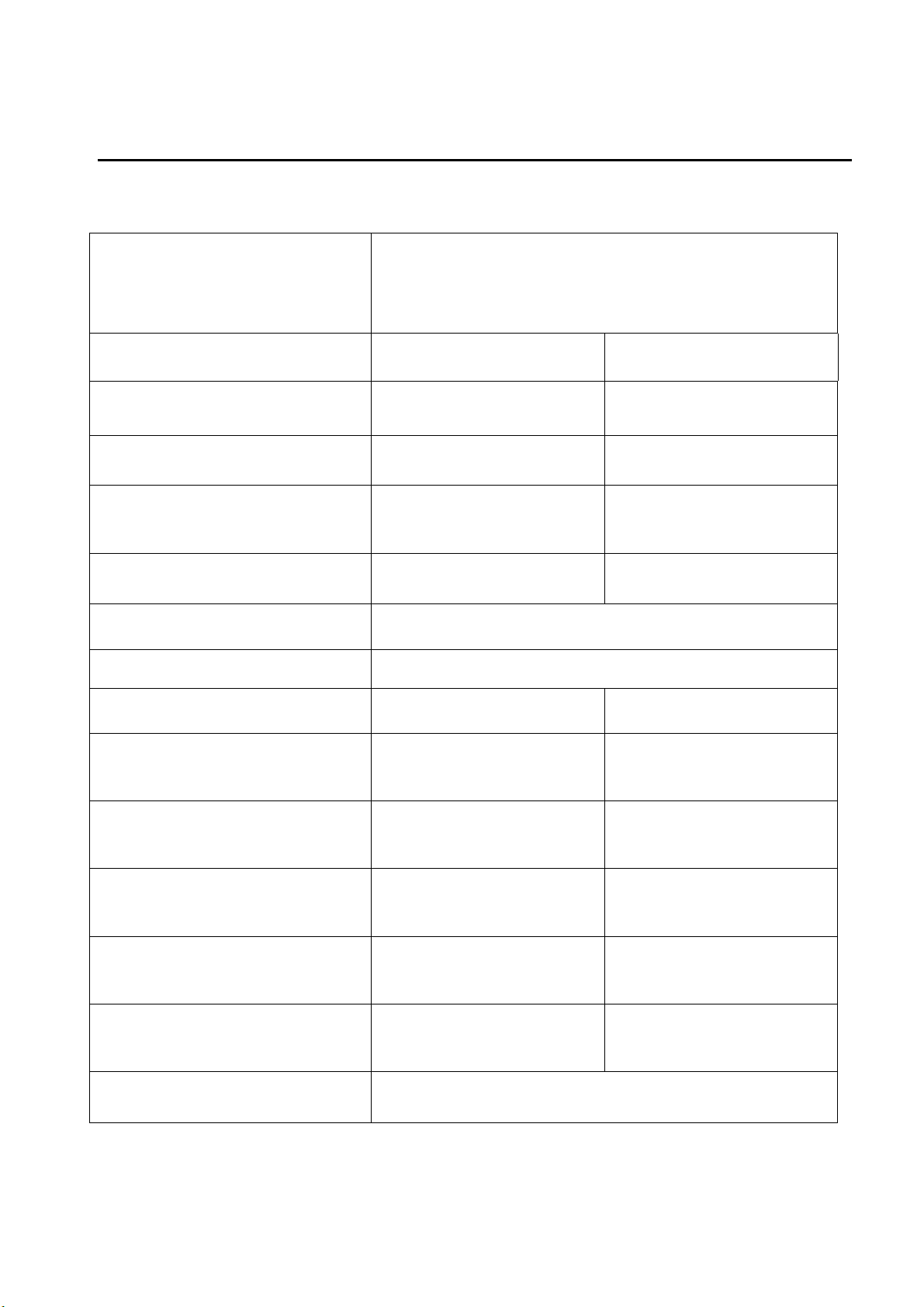

4.Specifications

Item Description

Model MK-2280M MK-2280MG

Specifications

Power source

~230V/50Hz ~230V/50Hz

Input Power consumption 1300W 1300W

output Power consumption 800W 800W

Power consumption

-------- 1000W

For grill

Oscillating frequency 2450MHz

Timing range 30’

Power level 4 4

Unit Dimension

(W×D×H)mm

486×370×288 486×370×288

Cavity Dimension

(W×D×H)mm

302×318×221 302×318×221

Carton Dimension

(W×D×H)mm

538×394×350 538×394×350

Volume/

22L 21L

effective volume

Weight(unit/carton) 14Kg 14.5Kg

Instruction manual, glass tray, turn

Accessories

plate-bracket groupwaregl, turn axis

- 5 -

Page 6

Safety Precaution

5.Safety Precaution

Only professional technicians can do the maintenance. Please refer to the proper

maintenance procedures in the service manual for safe operations, so as to avoid

unexpected injury.

Points of attention during maintenance:

1. Do not operate the microwave oven while the door of the oven is open.

2. Please check following before operation: (1) the door lock is flexible; (2) the door

works well in opening and closing; (3) the door is sealed well (without deforming and

bending); (4) identify any damage and loosening of the components and accessories;

(5) identify damages owing to abnormal usage or dropping.

3. Please confirm that the magnetron, microwave conductor pipe and wire are installed

and connected well before switch on the power to do maintenance or check the

functional components.

4. In case that the door lock, seal gasket, microwave radiating and transmission system

are damaged, or something wrong in debugging, please make repair, replacement or

adjustment according to the requirement of this manual before usage.

Components detachable that may

touch voltage higher than 250V

1. Magnetron

2. High-voltage transformer

3. High-voltage capacitor

4. High-voltage diode

5.

H.V. FUSE

During maintenance, the technicians shall pay attention that:

Microwave radiation

Do not expose to the radiation emitted by the microwave generator or other parts

transmitting the microwave.

Components that may cause excessive

microwave leakage

1. The magnetron is not properly installed on the

wave guide;

2. The door hook, door body and the up/down

hinge are not properly adjusted;

3. The door body or the shell is damaged;

The above reasons may cause excessive

microwave leakage.

Attention

- 6 -

Page 7

Safety Precaution

Attention: The mark must be exactly lined up with a power level. Otherwise there is a continuous

beep tone indicating microwave can’t work properly.

- 7 -

Page 8

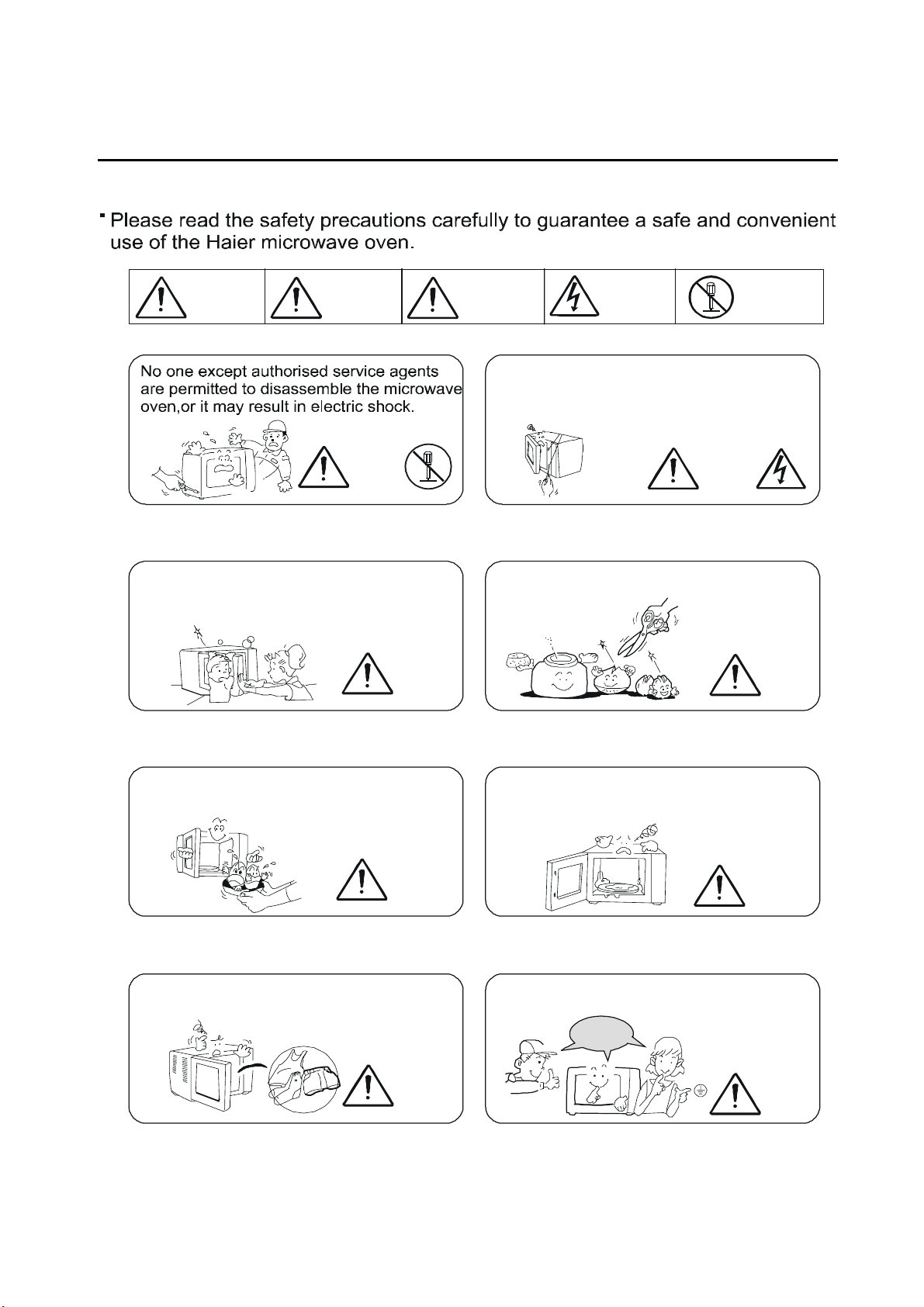

6.Warning and Cautions

Warning and Cautions

Danger

Do not apply excessive force to the door.

It may cause distortion of the door and

result in microwave leakage.

Warning

Danger

warning

Electric

Attention

shock

hazard

Do not use a metal rod to enter the interlock

switch hole on the front side of the cavity.

interlock switch hole

Danger

Do not use sealed containers. For those

foods with skin, please prick holes on the

skin.

No

dismantle

warning

Do not cook eggs in their shell as they may

burst.

warning

Do not use the microwave oven for purposes

other than for cooking food.

warning

- 8 -

Remember to clear away excess grease

form the inside the cavity. Otherwise it may

cause smoke or fire during heating.

warning

This appliance must be earthed.

safe and

reliable

warning

Page 9

A

Warning and Cautions

When roasting, the face of the door and

the top of the cabinet may become hot to

touch.

warning

Do not use metallic dishware to cook as it

will cause internal arcing.

warning

Waring

Do not use the microwave with the cavity

empty. It will damage the microwave oven.

warning

llow the cavity to cool after long cooking

processes (i.e. Roasting) before starting

another cook cycle.

warning

If the door seal or the door body is damaged, please do not use the

1.

appliance until it is repaired by an authorised service agent.

2. Before use, please check if the cooking containers are suitable for

the microwave oven.

3. If you find smoke in the oven, leave the door in the closed position, and

switch off the power supply of the microwave (remove the plugtop from

the supply socket).

4. We do not recommend the use of plastic, paper or other combustible

containers for cooking, Please be sure to observe the operating

instruction for the microwave oven, in order to avoid accidents.

5. When you heat liquid in the oven, please take care of delayed bubbling

because of boiling liquid.

Do not use the microwave oven if there is no food inside.

6.

7.

Do not use product for any industrial and commercial purpose.

- 9 -

Page 10

Warning and Caution

1 Baby food or drink should be shaken or stired evenly so that the heat is distributed and

may only be handed to your child after having checked the temperature of the food or

drink.

2 .Never put combustible materials near the microwave oven. Watch the cooking

condition while the microwave oven is working. Set cooking time correctly, for over time

setting may cause fire.

POINTS OF ATTENTION

Not like the other household appliances, the microwave oven is a kind of

high-voltage appliance. Although common operations will not risk the user in

hazard, please operate it carefully.

1. Do not use duplex receptacle in usage and maintenance.

2. Do not touch any components and circuit when the microwave is running.

3. Be sure to switch off the power before you touch the inside structure of the oven.

4. The high-voltage capacitor may still maintain electricity even 30 seconds after the

microwave oven stops working. To make replacement or checking at this time, be sure

to use insulated screwdriver to short out the two ends of the capacitor and discharge

the stored electricity.

5. Prevent the wristwatch from touching the microwave oven.

6. Do not operate the microwave oven when there is no food or water inside.

7. Protect the seal gasket and front board of the oven door from damage.

8. Do not put metal tools on the magnetron.

9. Do not put any items into the hole of the door lock or the door lock switch.

10. Confirm that the magnetron is installed properly and firmly.

Only professional technicians can do the maintenance of this

microwave oven.

- 10 -

Page 11

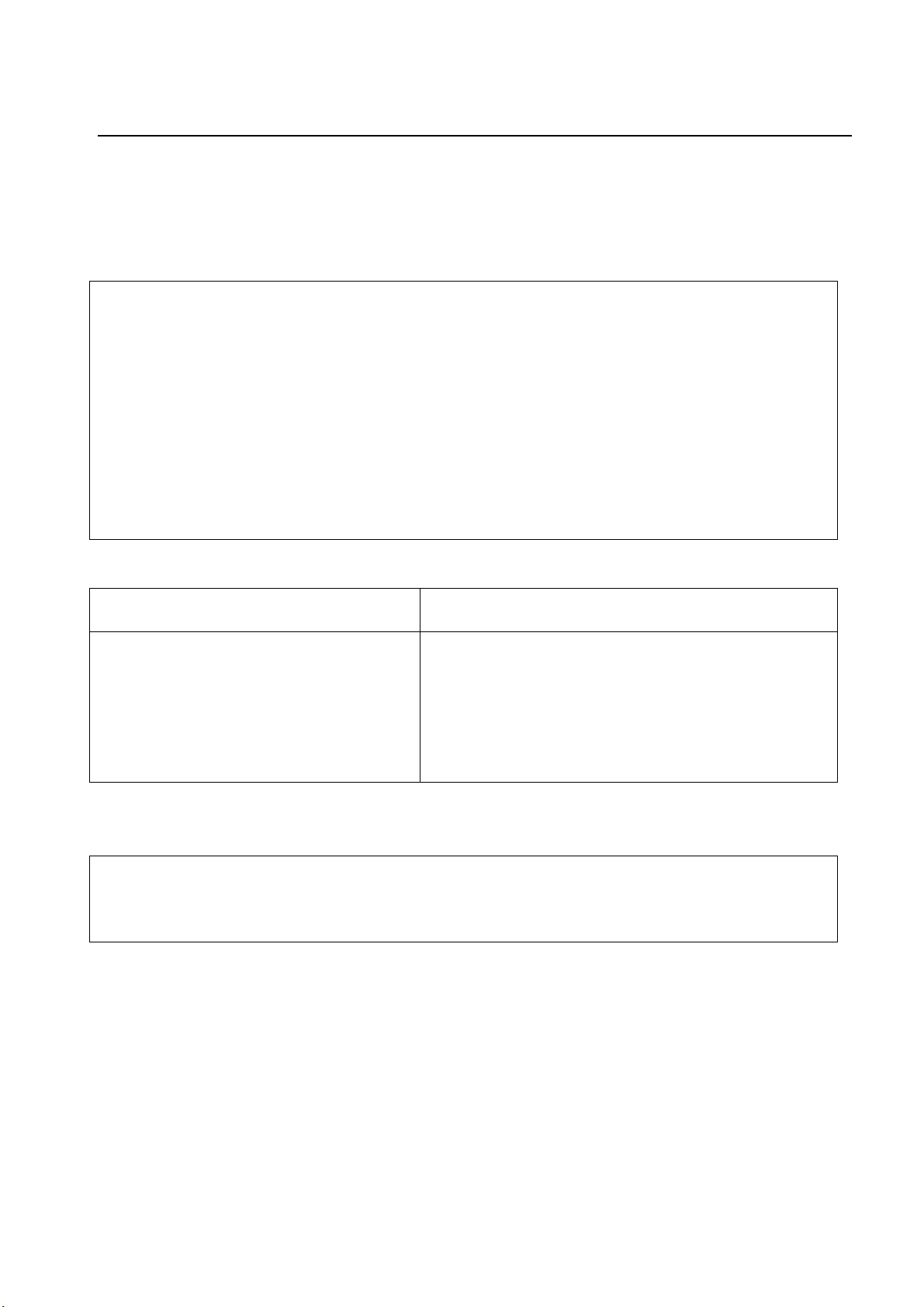

7.Installation and Accessory Parts

7.1 Installation

Installation and Accessory Parts

Do notinstall the microwave oven in

an environment that is humid or with

high temperature.

attention

7.2 key Point In Installation Adjustment

Attention

Please read following before installation.

7.2.1 Install the microwave oven

1. Clear all of the items inside the oven, then wipe the cavity with wet soft cloth. Check if

the door is even, and if there’s damage on the inner/outer side of the door.

2. The microwave oven, the food and the cooking tools shall be placed on firm and stable

table, desk or shelf. During delivery please note that the side with control panel is much

heavier.

3. Do not block the ventilation hole and air inlet. Otherwise it may damage the oven or

cause poor cooking. Confirm that the oven shelf is placed properly to guarantee the

ventilation.

4. Avoid high temperature and vapor. Protect the appliance and the mechanical part from

damages.

5. The ambient temperature shall be lower than 40℃.

6. The plane bearing the oven shall be even and firm.

7. Keep the microwave oven away from the TV, radio, computer, etc. to avoid

interference.

7.2.2 Installation of the earth wire

The microwave oven must be earthed before use. Please pay special attention on that.

Warning: This microwave oven must be earthed.

- 11-

Page 12

Installation and Accessory Parts

Hint:

Connect the wires as indicated below:

The yellow/green wire is earth wire; the blue wire is null wire; the brown wire is live wire.

If the colors of the wires are not in accordance with the power source terminals, please

operate as per below:

Connect the yellow/green wire to the wire marked with “E” or the green wire; connect the

blue wire to the wire marked with “N” or the black wire; connect the brown wire to the

wire marked with “L” or the red wire.

7.3 Accessory parts

Open the

carton

Install

AUTO COOKING MENU

1. Beverage

2. Fish

3. Auto

Reheat

4. Instant Noodle

5. Barbecue

AUTO MENU

6. Vegetable 7. Chicken

8. Auto

Defrost

MICRO POWER

GRILL/COMBI

PAUSE/CANCEL

+ TIME/W EIGHT ADJUST -

START

+ 30 SEC

accessory box

Put the microwave oven at the position

you choose. Keep good ventilation.

Glass rotary tray

Warranty

Certificate

rotary tray support

Select an independent socket, with

a current of at least 10A. Be sure to

ground it.

The gaps should all be above 15cm.

- 12 -

Page 13

8.Parts and Functions

Parts and Functions

shell

door seal

door hook

door

cavity

operation

board

11L

baking

mesh

glass rotary

tray

hb d

diagrammtic sketch for

- 13 -

Page 14

Maintenance Service and Trouble Shooting

9.Maintenance Service and Trouble Shooting

9.1SERVICE GUIDE AND REPLACING PARTS

9.1.1 Tools and gauges

9.1.2 Necessary tools 9.1.3 Necessary gauges

Generally, the tools used in maintenance of (1) Universal meter

the TVs are suitable for the maintenance of (2) Microwave leakage detector:

the microwave oven. The standard set of (3) Ruler

tools is: (4) Glass thermometer 100℃

(1) Angle pliers

(2) Nipper pliers

(3) Cross Screwdriver

(4) Monkey-spanner

(5) Iron, solder

(6) 6mm box spanner

Leakage test of the microwave oven Measurement

Points of attention: (1) Set the gauge according to the

(1) Please first check the leakage of the user’s manual.

Microwave oven after maintenance and (2) Add 15-275ml, 5℃-20℃ water

before usage. into a container, and put the

(2) If the microwave oven can operate container at the center of the tray.

while the door is open, STOP ANY (3) Set the oven at the highest

OPERATION OF THE OVEN. power level to start working.

(3) The leakage standard of the microwave (4) Measure the leakage with the

2

oven is <5mW / cm

gasket is 5mm thick, and the probe

shall be perpendicular against

. leakage detector. The detecting

- 14 -

Page 15

Maintenance Service and Trouble Shooting

measured part.

9.2. Checking under decomposed condition 9.3 Installation and adjustment

A. Dismantle the shell

In replacing the magnetron, after all the ①Switch off the power.

Parts are replaced and measured, and before ②First loosen the rear screw. Take

the shell is installed, check the energy leakage off the shell towards upper rear

of the microwave oven. Please pay special side.

attention to the following parts:

- Around the magnetron Attention: Be sure to pull off the

- Wave guide pipe power plug

Warning: Do not touch any high-voltage parts. B. Power cord

①After dismantle the shell, loosen

the two earth screws.

2. Checking under fully installed condition ②Pull off the two jointers on the

(1) After all of the parts are installed to proper filter seat.

Position including the shell, the parts needed ③Lift it up slightly to take off the

Checking are: the view window, air outlet power cord.

and air inlet.

(2) During working, pull the door slightly to Attention: The power cord must

do checking. be replaced with the special

(3) The leakage of the microwave shall not power cord offered by the

exceed the standard in any cases. manufacturer.

3. Record and notice of the checking result ①Dismantle the plug wire of the

(1) After checking of the leakage, the result control panel.

data shall be recorded as reference and ②Loosen the fixing screw with the

input into the service record. cross screwdriver. Take out the

(2) If the checking result is: all of the parts control panel from the microwave

are normal and work well. At the same time

the replaced parts are chosen as per this

manual, the leakage shall not exceed the ①Loosen the two hexagonal screws

standard. of the up hinge with monkey-

(3) Please check the leakage of the microwave spanner orФ5 box spanner.

oven with microwave leakage detector in a ②Loosen the two screws of the

year. down hinge with cross screwdriver.

C. Control panel

D. Dismantle of the oven door

- 15 -

Page 16

Maintenance Service and Trouble Shooting

②Pull up the door towards you to

take off it.

Attention:

After installation of the oven door, please check if the first/second lockout switch and

monitoring switch work well.

After oven door is installed, check the leakage with leakage detector.

Attention: In installation, please install gasket on the up/down hinge. In installing the door,

the position of the door can be calibrated by adjusting the up/down hinge. At the same

time please note that 0.4mm gap is required between the inside surface of the door and

the front board of the cavity. (You can add 3-4 pieces of paper between the door and the

front board. Too big gap may cause excessive leakage of microwave; too small gap may

cause overheating of the door and the front board.)

10

E. Dismantling of the high-voltage transformer

①Discharge the electricity of the high-voltage capacitor. ②Dismantle the connecting

high-voltage wires of the magnetron, the high-voltage transformer and the high-voltage

capacitor.

③Loosen the four screws connecting the high-voltage transformer to the bottom plate

with cross screwdriver.

F. Dismantling of the fan motor

①Discharge the electricity of the high-voltage capacitor.

②② Dismantle the connecting wires between the fan motor, filter and high-voltage

capacitor.

③Loosen the screw connecting the high-voltage diode to the bottom plate with cross

screwdriver.

④Loosen the four screws connecting the flare, fan motor and rear board.

⑤Lift the flare up to take out the flare group. Pull off the fin and take out the fan motor

backward.

G. Dismantling of the high-voltage capacitor, diode and AK rectifier

①Take off the flare group ②Loosen the screw connecting the flare to the high-voltage

capacitor.

③Take off the high-voltage group ④Pull off the plug of the high-voltage diode and the

AK rectifier with nipper pliers.

- 16 -

Page 17

Maintenance Service and Trouble Shooting

Attention: Be sure to discharge the high-voltage capacitor to do dismantling

immediately after working.

H: Dismantling of the duct and lamp

(1) Cut off the connecting wire of the lamp (2) Loosen the screw fixing the duct and the

magnetron

(3) Open the hook at the middle of the duct connecting to the magnetron installation

board with a screwdriver

(4) Move outward slowly to take out the duct

(5) Nip the barb fixing the lamp with nipper pliers to take out the lamp upward

I: Dismantling the magnetron

(1) Cut off the connecting wire between the high-voltage transformer and the capacitor

(2) Loosen the four screws fixing the magnetron

(3) Move outward slowly to take out the magnetron

Attention: Never damage the ends of the magnetron

J: Dismantling of the rotary tray motor

(1) Take out all of the accessories in the cavity

(2) Put the oven upside down

(3) Cut off the die part of the bottom plate with angle pliers and take it off

(4) Cut off the connecting wire of the tray motor

(5) Loosen the two screws fixing the tray motor with a cross screwdriver. Take off the tray

motor

(6) In installing, first fix the motor. Connect the wire. Then invert the die block of the

bottom plate. Put one end into the interface on the bottom plate, and fix the other end

with M4 screw.

Attention: When dismantling the leading wire, remember to nip the connecting

terminal to pull out. Do not nip the wire.

K. Dismantling of the timer Dismantling of the control panel

(1) Pull off the two knobs on the control (1) Loosen the two screws fixing

panel with nipper pliers. The computer board with cross

- 17 -

Page 18

(2) Loosen the four screws fixing the timer screwdriver.

with a cross screwdriver. (2) Pull off the interface of the film

Maintenance Service and Trouble Shooting

(3) Take off the timer from the rear of the switch on the computer board.

control panel. (3) Take off the computer board

from the rear of the control panel.

L: Dismantling of the lockout device

1. Function of the lockout mechanical structure: The door lockout is a special design to

stop the microwave emission completely when the door is open, so that it can prevent

the hazard of microwave leakage.

2. Installation position of the first/second/monitoring switch is indicated in the figure

3. Connection between the lockout board and the oven body:

①Install the lockout group on the door body. Twist the two screws on the installation holes

with cross screwdriver without fastening.

②Close the oven door. Adjust the lockout to guarantee that there’s no gap between the

door and the front board after the door is closed.

③Fasten the screws.

④Open the door to check. The loosen range shall not exceed 0.5mm. the micro-switch

shall be closed normally. The door shall be opened and closed smoothly. The

micro-switch shall act as following: Open the door Æ the first lockout switch

(micro-motion switch1)Æ the second lockout switch(micro-motion switch2) Æ

monitoring switch (micro-motion switch3)act in turn. The turn is in counter sequence

when closing the door. Please observe carefully.

M: Dismantling of the heater pipe

(1) Cut off the connecting wire of the heater pipe.

(2) Loosen the three hexagonal screws fixing the heater pipe with M6 hexagonal box

spanner.

(3) Take off the heater pipe from the cavity slowly.

Attention: In installing the heater pipe, be sure to fix the screw tightly.

Otherwise it may cause microwave leakage.

8.4. Components Test

Attention:

1. Be sure to switch off the power any time before dismantling the shell;

discharge the high-voltage capacitor before test; cut off the primary circuit

connecting to the high-voltage transformer.

2. All of the test on the emission of the microwave shall be performed in the

container with one liter water.

A. Conduction test of the lockout switch

- 18-

Page 19

Test of the lockout switches

If trouble appears in use of the oven, please first check the mode of the lockout

Maintenance Service and Trouble Shooting

switches:

When the door is open, the first/second lockout switch is off. The monitoring switch

is on. When the door is close, the switches are in counter mode. You can observe by sight.

If you are not sure, please measure with gauges.

In maintenance, pull the door with hands as slowly as possible to see if the micro

switches act in following turn: in opening: the first lockout switch – the second lockout

switch – monitoring switch; in closing: monitoring switch – the second lockout switch – the

first lockout switch.

If there’s abnormal phenomenon, please adjust the lockout holder.

B. Test of the high-voltage transformer

lamp coil

second coil

primary coil

Item Position Normal value

Resistance

value

Primary coil

Secondary coil

lamp winding

Primary coil – shell of the

transformer

lamp winding – shell of the

transformer

About 1-2Ω

About 100-200Ω

About 0Ω

Infinite

Infinite

C. Test of the magnetron

- 19 -

Page 20

antenna

Maintenance Service and Trouble Shooting

Item Position Normal value

Two ends of the heater

shileding

lamp terminal

About less than 1Ω

End and shell of the

heater

Attention: In test of the magnetron, confirm that the gasket is in good condition

and installed well.

D.

Test of the high-voltage capacitor

Under normal condition: 1. The resistance value of the two terminals shall be several

ohm at the beginning of the test, then return to infinite.

2. The resistance value between the terminal and the shell is

infinite.

Infinite

E. Test of the high-voltage diode

Measure with RX1000 range. The conduction resistance value shall be several ohm.

No matter which step is used in the measurement, the result shall be infinite.

F. Measurement of the fan motor

The resistance value of the two terminals shall be 200~300ohm

G. Measurement of the rotary tray

- 20 -

Page 21

motor

Maintenance Service and Trouble Shooting

The resistance value of the two terminals shall be 14k~15kohm

Measurement of the H.V. fuse

Under nomal condition, it is short circuit to measure in two condition.

Attention: If the MWO can not make the food warmer, it is probably

breakdown by the HV fuse. If there is open-circuit between the two

condition, Please check the HVT and HVD according to this manual. And

replace the HV fuse.

Attention: All of the tests shall be performed after the H:

stubs are pulled off.

I:PC BOARD:

Door monitoring

switc

fan montor

relay switch

grill relay

switch

power switch

Test of the filter

microwave relay

MK-2280MG

- 21 -

Page 22

power switch

Maintenance Service and Trouble Shooting

Door monitoring

switc

fan montor

relay switch

microwave relay

MK-2280M

I:TEST OF THE FILTER:

- 22 -

Page 23

GND

C2

C3

L(OUT)

L1

N(OUT)

L(OUT)

L1

C2

C3

N(OUT)

TAPI

DELAY CIRCUIT

OEG OMIF-S-124LM

RELAY

K1

K2

R1 100Ω

FUSE

15A/250VAC

C1

FUSE

15A 230V

R1

NL

FILTER

R1

C1

K1

K2

L(IN)

PTC

R2 7W 9.1KΩ

N(IN)

Maintenance Service and Trouble Shooting

9.5. Trouble-Shooting

In case that there are complaints from the customers, please study the reported

troubles carefully. For the problems listed below, please introduce the proper usage to the

customers to avoid necessary troubles.

Attention:

(1) Please first check the installation of the earth wire before trouble-shooting.

(2) Be extremely careful to touch the high-voltage circuit.

(3) Discharge the high-voltage capacitor.

(4) In checking the continuity of the controller or the high-voltage transformer,

you shall do the checking under the condition that the AC power source is

switched off, and one wire is cut off from the part. Otherwise the result is

not accurate, or even damages the measure device.

(5) Do not touch the IC die on the PCB board to protect it from the damage of

the static electricity.

1. The oven doesn’t work

reason:

A. The power terminal box has too many plugs and over load, Avoid sharing one line with

other electric appliances.

B. The power plug is not tightly inserted, Confirm the plug is inserted tightly.

2. The microwave output power consumption is too low

reason:

A. The input Ac voltage is too low, connect the microwave oven to power source with

sufficient voltage.

B. The temperature to cook the food is too low ,Prolong the cooking time .

- 23

Page 24

3. Lighting and sparking

reason:

A. Metal container is used in cooking and touches the cavity, please use containers

stipulated in the operation instructions.

B. Containers embedded with metal or silver head are used in cooking

4. Uneven cooking

reason:

The microwave intensity is uneven

A .pack the thinner part with aluminum foil.

B. Use preservative file or cover.

C. When cooking soup, drink or milk, please stir once or twice during cooking.

. Maintenance Service and Trouble Shooting

Trouble 1The oven works normally, but the heating is too slow.

(1).the output power consumption is too small

Check the power voltage:

If 90% lower than the normal voltage, the voltage is too low, adjust the power

supply.

If normal, check the output power of the microwave ,find the magnetron has

trouble ,replaced it.

(2).The fan motor and the lamp do not work.

Check the fan motor、lamp:

If abnormal ,the motor、lamp is bad, replaced it.

If normal, the timer is bad , replaced it.

Attention: a simple method to check the output power of the microwave is :Put

one liter water into the oven and heat one minter with the highest power

level ,If the output is normal, the water temperature shall raise at least 8.5℃

Trouble 2The lamp and the fan motor work normally, But there’s no

microwave emission(no other abnormal phenomenon)

1.Check the conduction of the power switch of the timer ,if abnormal, the timer has

trouble ,replaced it.

2.Cut off the connecting wire of the microwave relay, and check the conduction of it.

If not conduct ,the control panel has trouble, replaced it.

If normal, check the conductor wire of the high-voltage transformer I

- 24-

Page 25

Maintenance Service and Trouble Shooting

abnormal ,replaced it. If normal, Replace the fuse ,cut off the connection wire between

the transformer and the high-voltage capacitor ,then start the oven .If normal, the AK

rectifier ,is bad, replace it.

1. The fuse is not broken

Check the conduction of the thermostat1and thermostat2,if wrong, replace it.

Trouble 4After start, The oven keeps running and, can’t stop.

1. Cut off the connecting wire of the microwave relay and check the conduction .If always

in conduction ,The control panel has trouble ,replace it.

2. Check the conduction of the timer motor ,If abnormal ,the timer motor has

trouble ,replace it .If normal, Check the timer knob, find interfere with the control panel

frame ,that is because the knob is blocked and can’t rotate, adjust it.

Trouble5After a period in baking ,the power is switch off.

Check the thermostat 3,If always in conduction during baking ,because the thermostat

is bad, replace it .If normal, check the themostat 2,it is off, that is because the protective

thermostat has misoperation .Remind the user to pay attention to the environment of the

oven.

Trouble 6:After starting, the noise of the oven is too large.

Dismantle the shell to see

1. if the fan bumps other parts ,The fan rotates with high speed, and cause the loose

parts vibrate and make noises.

2. The electromagnetic field attracts the shell to vibrate and bump other parts to make

noises. Increase the thickness of the sponge strip or shock-resistance rubber to avoid

the vibration of the shell.

Attention: The working sound of the microwave oven contains two parts:

1. The fan rotates with high speed (near 3000 r.p.m.). The fin rubs the air and

makes rubbing noises.

2. The high-voltage transformer will output 2000V high-voltage during work,

and produce a strong magnetic field. It will attract the shell to vibrate slightly

and make some noises.

- 25 -

Page 26

Circuit Diagram and Circuit Explanation

10.Circuit Diagram and Circuit Explanation

Cx

L

(OUT)

T

Cy

Cy

Fan motor

Lamp

Curbing motor

Monitoring switch

DELAY

CIRCUIT

H.V

FUSE

H

V

T

HVC

Magnetron

E

S

F

U

L

R

N

Cx

L

(OUT)

T

Cy

Cy

Fan motor

Curbing motor

Lamp

Grill heater

Monitoring switch

DELAY

CIRCUIT

H.V

FUSE

H

V

T

HVC

Magnetron

L

N

U

F

S

E

R

- 26 -

Page 27

Circuit Diagram and Circuit Explanation

Circuit description:

1. This is the mode that the door is open and the timer is not set yet.

2. Now set the time. The Timer Switch 1 is closed. The lamp is on. But the other parts do

not start because the door lock 1 and 2 are open.

3. Now close the door. The timer switch 1 and 2 are closed. There is voltage between the

two ends then starts working. The rotary tray , the fan start rotating. The lamp is on.

The timer motor also starts.

4. The function of the timer switch 2 is to control the power consumption by regular

on/off.

5. The monitoring surface is used to offer protection in case that the lockout switch 1 and

2.

6. The thermostat offers protection against overheating in abnormal cases.

- 27 -

Page 28

Circuit Diagram and Circuit Explanation

HVC

V

H.

E

S

FU

H

V

T

Magnetron

(A)

HVC

M

a

g

n

e

t

r

H

V

T

o

n

(B)

1.

The figure A. is applicable for the MWO that were produced before June 2003,the

figure B is applicable for the MWO that were produced after June 2003.

age is added between the two ends of the

ter the oven st

Af

2.

high-volt

o

art w

age transformer

rking, a 230V AC

.

volt

3. The 230V voltage will make 2000V induction voltage between the two ends of the

high-volt

age coil, and 3.5V low-volt

age betw

een the two ends of the heater winding.

4. The 2000V voltage will be doubled by the high-voltage capacitor, then be rectified by

the high-volt

age diode, finally become a 4000V

negative high-volt

age to ground at the

FA end of the magnetron.

5. One end of the heater coil is connected to the negative high-voltage, the other end to

the F end of the magnetron.

Therefore the working conditi

on of the magnetron is made

up: low-voltage and high electric potential.

28

Page 29

Exploded View

MK-2280M

7

3

9

4

51

2

46

45

44

43

6

42

40

5

50

47

48

49

41

39

52

9

32

31

30

38

27

28

37

29

33

34

35

36

8

1

10

20

21

54

53

12

55

11

22

23

24

25

26

14

13

15

16

17

18

19

29

Page 30

Part of list (MK-2280M)

No.

1 0050400385

2 0050400465 WIRING HARNESS 1 MK-2280M

3

4 0050200532

5 0050200531 TURN AXIS

6 0050800344

7 0050100473 OUTER CASING 1 MK-2280M

8

9 0050600033 ST4*10 BOLT 2 MK-2280M

10 0050201517

11 0050201397 FLARE 1 MK-2280M

12 0050400480

13 0050400373 FAN MOTOR 1 MK-2280M

14 004HR2501G

15 0057109128

16

17

18

19 0050600033

20 0056200109

21 0050200468

22 0050800554

23 0050400323 MOCROMOTION SWITCH 1 MK-2280M

24 0057109128

25 0050400605

26 0050400604

27 0050400597 TURNPLATE MOTOR 1 MK-2280M

28 0050600033

29 0054500063 HV-TRANSFORMER 1 MK-2280M

30 0057100104

31 0050600033 ST4*8 BOLT 1 MK-2280M

SPARE PARTS

NUMBER

0050900056 GLASS TRAY 1 MK-2280M

0057109128

0057109123

0050400489

0050400622

SPARE PARTS DESCRIPTION IN ENGLISH Q.TY MODEL

POWER SUPPLY CORD 1 MK-2280M

TURNPLATE-BRACKET GROUPWAREGL

TIME KNOB ASYY

ST4*12 BOLT

FAN

H.V. RECTIFIER

ST4*19 BOLT

ST 4*12BOLT

M3*8BOLT

THERMOSTAT 1

MAGNETRON

ST4*10 BOLT

LAMP

WIND DUCT

CHAIN-SWITCH HOLDER GROUP

ST4*12 BOLT

MOCROMOTION SWITCH (NORMAL OFF)

MOCROMOTION SWITCH (NORMAL OPEN)

ST4*8 BOLT

HV-CAPACITOR 1.03uF

1 MK-2280M

1 MK-2280M

1 MK-2280M

MK-2280M

4

1 MK-2280M

1

MK-2280M

MK-2280M

2

2 MK-2280M

2 MK-2280M

MK-2280M

1 MK-2280M

1 MK-2280M

MK-2280M

1

1 MK-2280M

1 MK-2280M

1 MK-2280M

1 MK-2280M

1 MK-2280M

2 MK-2280M

1 MK-2280M

30

Page 31

32 0050100273

33

0050400479

34 0057109128

HV-CAPACITOR HOLDER

H.V. DIODE

ST4*12 BOLT

1 MK-2280M

MK-2280M

1

4 MK-2280M

35 0057109128 ST4*12 BOLT 3 MK-2280M

36 0056201102

FOOT

4 MK-2280M

37 0050100268 BASE-PLANE 1 MK-2280M

38 0057109128

39

40

0050400459

0050200876

ST4*12 BOLT

PC BOARD

CONTROL EST

1 MK-2280M

MK-2280M

1

1

MK-2280M

41 0050600008 ST 3*8 BOLT 2 MK-2280M

42 0050800343 POWER KNOB ASYY 1 MK-2280M

MK-2280M

43 0050201076

DOOR CASE

44 0050900064 OUTER SCREEN (GLASS)

45

46

47

0050801303

0050200525

0050200471 DOOR SEAL

DOOR JOINING GROUP

INSIDE SCREEN

1

1 MK-2280M

1

MK-2280M

1

MK-2280M

MK-2280M

1

48 0050600027 DOOR-HOOK SPRING 1 MK-2280M

49 0050200470

DOOR-HOOK 1 MK-2280M

50 0050600033 ST4*8 BOLT 2 MK-2280M

51 0050300121 WAVE GUIDE COVER 1 MK-2280M

52

0050800331

CAVITY ASSY

1

MK-2280M

53 0050400395 DELAY CIRCUIT 1 MK-2280M

54 0050201001 DELAY CIRCUIT FIXED BOARD 1 MK-2280M

55 0050400394 FILTER 1 MK-2280M

31

Page 32

Exploded View

60

2

44

43

MK-2280MG

61

45

7

8

3

9

4

51

5

50

47

46

53

38

54

55

52

37

56

32

31

30

27

28

29

33

1

9

10

20

21

22

58

57

12

59

11

23

24

25

26

14

13

15

16

17

18

19

48

49

6

39

42

40

41

34

35

36

32

Page 33

Part of list (MK-2280MG)

SPARE

No.

PARTS

SPARE PARTS DESCRIPTION IN ENGLISH

NUMBER

1 0050400385 POWER SUPPLY CORD

2 0050400466 WIRING HARNESS 1 MK-2280MG

3 0050900056 GLASS TRAY 1

4

5 0050200531 TURN AXIS 1 MK-2280MG

6 0050800344

7 0050100335 OUTER CASING

8

9

10

11 0050201397 FLARE 1 MK-2280MG

12

13

14 004HR2501G

15

16

17

18

19 0050600033 ST4*10 BOLT 1 MK-2280MG

20 0056200109

21 0050200468 WIND DUCT 1 MK-2280MG

22 0050800554

23 00504003604 MOCROMOTION SWITCH 1 MK-2280MG

24 0057109128

25 0050400605

26 0050400604

27 0050400597 TURNPLATE MOTOR 1 MK-2280MG

28 0050600033

29 0054500063 HV-TRANSFORMER 1 MK-2280MG

30 0057100104

0050200532

0057109128

0050600033 ST4*10 BOLT

0050200683

0050400480

0050400373

0057109128

0057109123

0050400489 THERMOSTAT

0050400622

TURNPLATE-BRACKET GROUPWAREGL

TIME KNOB ASYY

ST4*12 BOLT

FAN

H.V. RECTIFIER

FAN MOTOR

ST4*19 BOLT

ST 4*12BOLT

M3*8BOLT

MAGNETRON

LAMP

CHAIN-SWITCH HOLDER GROUP

ST4*12 BOLT

MOCROMOTION SWITCH (NORMAL OFF)

MOCROMOTION SWITCH (NORMAL OPEN)

ST4*8 BOLT

HV-CAPACITOR 1.03uF

Q.T

Y

1 MK-2280MG

1

1 MK-2280MG

1 MK-2280MG

4

2

1

1

1

2 MK-2280MG

2

2

1

1

1 MK-2280MG

1 MK-2280MG

1 MK-2280MG

1 MK-2280MG

1 MK-2280MG

2 MK-2280MG

1 MK-2280MG

MODEL

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

MK-2280MG

Page 34

31 0050600033 ST4*8 BOLT 1 MK-2280MG

32 0050100273

HV-CAPACITOR HOLDER

1 MK-2280MG

33 0050400479 H.V. DIODE 1 MK-2280MG

34

0057109128

35 0057109128 ST4*12 BOLT 3

36 0056201102

37

0050100268 BASE-PLANE 1 MK-2280MG

38 0057109128

ST4*12 BOLT

FOOT

ST4*12 BOLT

4

MK-2280MG

MK-2280MG

4 MK-2280MG

1

MK-2280MG

39 0050400460 PC BOARD 1 MK-2280MG

40 0050200877

CONTROL EST

1 MK-2280MG

41 0050600008 ST 3*8 BOLT 2 MK-2280MG

42 0050800343 POWER KNOB ASYY 1 MK-2280MG

43 0050201076 DOOR CASE 1 MK-2280MG

44 0050900064 OUTER SCREEN (GLASS)

45 0050801303

46

47

48

49

0050200525 INSIDE SCREEN 1 MK-2280MG

0050200471 DOOR SEAL 1

0050600027 DOOR-HOOK SPRING

0050200470

DOOR JOINING GROUP

DOOR-HOOK

1 MK-2280MG

1 MK-2280MG

MK-2280MG

1

MK-2280MG

MK-2280MG

1

50 0050600033 ST4*8 BOLT 2 MK-2280MG

51 0050300121

52 0050800245 CAVITY ASSY

53

54

55

56

0050400493

0050600033

0050100288

0050400476

WAVE GUIDE COVER 1 MK-2280MG

1 MK-2280MG

THERMOSTAT

ST4*8 BOLT

HEATER HOLDER

HEATER (LIGHT WAVE)

1

MK-2280MG

2

MK-2280MG

2

MK-2280MG

2

MK-2280MG

57 0050400395 DELAY CIRCUIT 1 MK-2280MG

58 0050201001 DELAY CIRCUIT FIXED BOARD 1 MK-2280MG

59 0050400394 FILTER 1 MK-2280MG

60 0050100555

61

0050501358

GRIDIRON

BAKING MESH FIXED BOARD

34

1

MK-2280MG

1

MK-2280MG

Page 35

Sincere Forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...