Order No. Ref1404S005V0

2014(HAIER ELECTRICAL APPLIANCES COR. LTD)

©All right reserved. Unauthorized copying and distribution is a violation of law.

Chest Freezer

MODEL: HF50CM23NW

HF71CM33NW

Haier Group

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It

dose not contain warnings and cautions to advice non-technical individuals of potential dangers in attempting to service a product.

Product powered by electricity should by serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

WARNING

S

ERVI

C

E MAN

U

AL

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

2

Issue 2014-04-12

Rev.

Ref1404S005V0

Contents

Chapter 1 General Information ............................................................................................................. 3

1-1. General Guidelines ........................................................................................................................ 3

1-2. Insulation Test ................................................................................................................................ 3

1-3. How to read this Service Manual ................................................................................................... 4

Chapter 2 Product Feature ................................................................................................................... 5

2-1. Specification .................................................................................................................................. 5

2-2. External views ............................................................................................................................... 6

Chapter 3 Installation, adjustments and maintenance .......................................................................... 7

3-1. Installation ..................................................................................................................................... 7

3-2 Defrosting and Draining .................................................................................................................. 7

3-3 Cleaning the Freezer ...................................................................................................................... 8

Chapter 4 Disassembly ......................................................................................................................... 9

4-1. Door assembly (Door, hinge, hinge cover) .................................................................................... 9

4-2. Compartment grill assembly .......................................................................................................... 9

4-3. Control panel assembly (Panel, cover board, knob, indicator light) ............................................. 10

4-4. Thermostat assembly .................................................................................................................. 1 1

Chapter 5 Control and display system ................................................................................................ 12

5-1. Control panel ............................................................................................................................... 12

5-2. Starting the Freezer ..................................................................................................... ................ 12

Chapter 6 System flow principle ......................................................................................................... 13

6-1. Refrigeration flow chart ................................................................................................................ 13

6-2. Refrigeration flow scenograph ..................................................................................................... 14

Chapter 7 Circuit diagram ................................................................................................................... 15

7-1. Brief principle diagram ................................................................................................................. 15

Chapter 8 Trouble shooting ................................................................................................................ 16

8-1. Normal phenomena .........................................................................................................

............ 16

8-2. Abnormal phenomena.................................................................................................................. 18

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

3

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 1 General Information

1-1. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit. After servicing, see to it that all the protective

devices such as insulation barriers, insulation papers shields are properly installed. After servicing,

make the following leakage current checks to prevent the customer from being exposed to shock

hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatic Sensitive

1-2. Insulation Test

1. Check if there is any leak of current.

2. Cut out the power supply before the repair to avoid an electrical shock hazard.

3. In the case of a live-line test, insulating gloves should be worn to avoid potential electrical shock.

4. Confirm the rated current, voltage and capacity before testing with any kinds of instruments.

5. Watch if the upper door is open when we check something at a lower position.

6. Take out every part in the cabinet before moving the machine, especially things like panels (e.g. glass

shelf).

7. Please wear intact cotton gloves when repair any parts of the evaporator, so that scratches by the

sharp fins can be avoided.

8. If there is a breakdown with the refrigeration system, please surrender the machine to the service

center, else the leaked refrigerant may pollute the atmosphere.

9. The refrigerator use AC of 115V with a frequency of 60Hz.

10. A big fluctuation of voltage (exceed the range 98~126V) may cause a start failure of the refrigerator , a

burn-out of the control panel and compressor, or an abnormal sound from the compressor in

operation.

11. Take care not to damage the supply line. Don’t yank at the line; pull the plug out gently from the

receptacle. Don’t press the line under the cabinet or step on it. Take care not to roll on or damage the

supply line when moves the machine from the wall.

12. In the case of leakage of inflammable gases like carbon monoxide, open the door and windows. Don’t

pull out or insert the plugs of the appliance.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

4

Issue 2014-04-12

Rev.

Ref1404S005V0

13. Don’t touch the refrigeration surface of the freezing compartment when the refrigerator is in operation,

especially when our hand is wet, else we may be glued to the surface.

14. Pull out the plug of power supply during clearance or power outage. Wait at least five minutes to

resume the power supply in order to prevent damage to the compressor caused by continuous restart.

Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of products, which may

differ from the products in some way.

1-3. How to read this Service Manual

Icons are used to attract the attention of the reader to specific information. The meaning of each icon is

described in the table below:

Note:

A “note” provides information that is not indispensable.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation, may damage

equipment, loose data, get an unexpected result or has to restart (part of) a procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides to find additional information on a specific topic.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

5

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 2 Product Feature

2-1. Specification

/

Superfast freezing.

Adjustable thermostat to realize freezing and

cooling

High pressure and microbiological foam filled door

for energy conservation.

convenient water drain.

External controls.

0%CFC.

Comply with RoHS.

/

/

1. Type Model / HF50CM23NW

HF71CM33NW

Commercial brand / Haier Haier

Product description / Chest Freezer Chest Freezer

Type of appliance (FS=free standing /BI= built-in) / FS FS

Climate class (N=16-32℃ ST=18-38℃ T=18-43℃)

/ N N

2. Key index / / /

Gross capacity l 142 198

Total net capacity l 142 198

Defrosting (Manual-Automatic) / Manual Manual

Kind of coolant (R134a/R600a) / R600a R600a

Foaming components (R141b/C-P) / C-P C-P

3. Technical data / / /

Voltage / frequency/Compressor brand V/Hz 115V/60Hz 115V/60Hz

Input power / currency W/A 1.69A 1.70A

Lowest Temperature °C

≤-18°C ≤-18°C

Energy consumption (EN153) per year kWh/year

216kW·h/year 248kW·h/year

Cooling system:(K=Compressor / A=Absorbtion) / K K

4. Product net dimensions / / /

Unit dimensions (H / W / D) cm 84.5/72/55 84.5/94/55

Net weight kg 33 38

5. Packing dimensions & loadability / / /

Packing dimensions (H / W / D) cm 89.0/77.5/58.0 89.0/99.5/58.0

Gross weight kg 36 36

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

6

Issue 2014-04-12

Rev.

Ref1404S005V0

2-2. External views

Door

Cabinet

Control panel

Drain pipe

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

7

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 3 Installation, adjustments and maintenance

3-1. Installation

The freezer should be conveniently located for day-to-day use in a dry well-ventilated room.

Do not install the freezer where the temperature will go below 0°F or above 110°F, because it will not

maintain proper temperatures.

Be sure to install the freezer on a floor strong enough to support it when it is fully loaded.

The freezer must be solidly positioned on the floor if it is to function at its best. Shims may be used to

accomplish this wherever the floor is too uneven. If the place selected for the freezer is damp or moist,

place 2 X 4 s (51 mm X 102 mm) under its entire length to assure adequate support.

If the freezer has been inclined more then 45° position, we need wait 24 hours before

restarting the freezer.

3-2 Defrosting and Draining

In most climates, defrosting will be necessary only about twice a year.

To have the freezer operate most efficiently, do not permit more than 1/2” (13 mm) of frost to

accumulate on the shelves.

To remove frost, scrape with a plastic or wood spatula or scraper.

Do not use an ice pick or sharp-edged instrument as it may damage or scratch the freezer.

Do not use any electrical device in defrosting the freezer.

For Complete Defrosting

1. Turn the temperature control to the OFF position and unplug the freezer.

2. Remove all food and place it in corrugated boxes, insulated bags, picnic coolers, etc. Use towels

and newspapers for insulation as needed.

3. With the doo r/lid open, use pans of hot water to speed loosening of frost. Remove large pieces

before they melt.

Chest models have a defrost water drain at the front.

4. Sponge excess water from the bottom of the freezer as it collects to prevent over flowing.

5. After defrosting, clean the inside of the freezer.

6. Replace the drain plug inside the cabinet and the cap on the defrost drain. Fold over and dry the

gasket on the hinge side of the lid.

7. Plug in the freezer. Return the temperature control to its previous position and return food to the

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

8

Issue 2014-04-12

Rev.

Ref1404S005V0

freezer.

Water may drip from the back flange of the lid cover during defrosting. This is normal. Ice

builds up in the lid insulation when the lid is open for adding or removing food, and melts during the

defrosting operation.

3-3 Cleaning the Freezer

Outside. Protect the paint finish. The finish on the outside of the freezer is a high quality baked-on

paint finish. With proper care, it will stay new-looking and rust-free for years. Apply a coat of appliance

polish wax when the freezer is new and then at least twice a year. Appliance polish wax also works

well to remove tape residue from freezer surfaces.

Keep the finish clean. Wipe with a clean cloth lightly dampened with appliance polish wax or mild

liquid dishwashing detergent. Dry and polish with a clean, soft cloth. Do not wipe the freezer with a

soiled dishwashing cloth or wet towel. Do not use scouring pads, powdered cleaners, bleach, or

cleaners containing bleach.

Inside. Clean the inside of the freezer at least once a year. We recommend that the freezer be

unplugged before cleaning. If this is not practical, wring excess moisture out of sponge or cloth when

cleaning in the vicinity of switches, lights or controls.

Use warm water and baking soda solution-about a tablespoon of baking soda to a quart of water.

Rinse thoroughly with water and wipe dry. Do not use cleaning powders or other abrasive cleaners.

An open box of baking soda in the freezer will absorb stale freezer odors. Change the box ever y three

months.

Care should be taken in moving the freezer away from the wall. All types of floor coverings can

be damaged particularly cushioned coverings and those with embossed surfaces.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

9

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 4 Disassembly

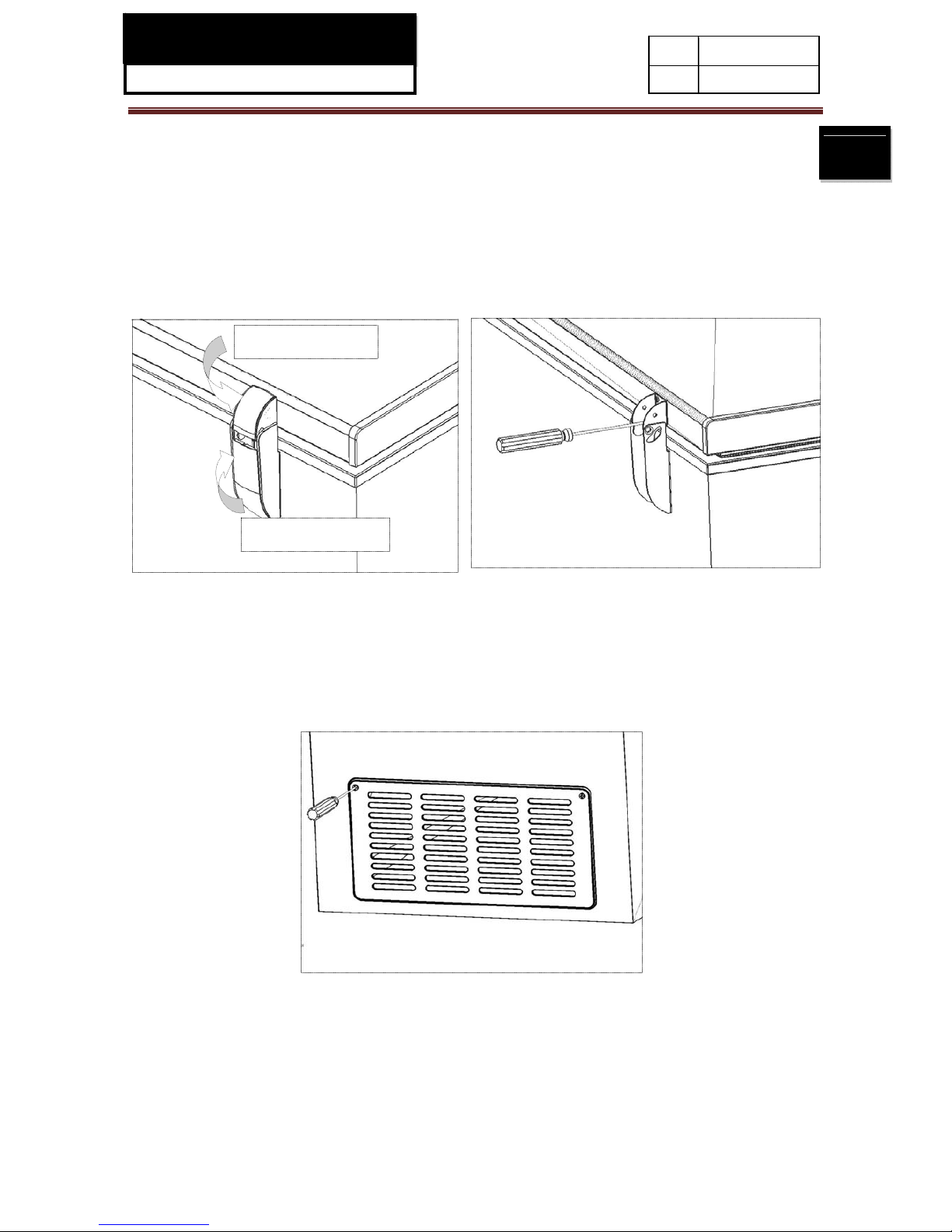

4-1. Door assembly (Door, hinge, hinge cover)

Unscrew the hinge cover screw with screwdriver, take away the top and bottom cover by pull it, and

then unscrew the screws on the hinge, so the whole hinge could be moved.

4-2. Compartment grill assembly

Unscrew the two screw of grill; we can take away the grill.

Top hinge cover

Bottom hinge cover

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

10

Issue 2014-04-12

Rev.

Ref1404S005V0

4-3. Control panel assembly (Panel, cover board, knob, indicator light)

Unscrew the compartment grill (refer 4-2), push the panel claw gently with our finger or tools, at the

same time pull panel outside then take away it.

Take away the knob with a sharp-edged tool.

Press the cover board and take it away.

Press two claws on indicator light side and push it from back to front.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

11

Issue 2014-04-12

Rev.

Ref1404S005V0

4-4. Thermostat assembly

First take off the knob (refer 4-3), Use turnbuckle spanner or acutilingual plier unscrew the turnbuckle,

and then thermostat can be moved from back of panel.

Note: When assembly thermostat we should placed thermostat in originally direction.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

12

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 5 Control and display system

5-1. Control panel

Freezing temperature selection is made by setting the control from 1to 7(coldest).

If we want colder or warmer temperatures, adjust the control one step at a time.

Allow several hours after each one-step adjustment for the freezer temperature to stabilize.

5-2. Starting the Freezer

1. Clean the inside of the freezer with a mild solution of baking soda and water

2. Connect cord to power outlet.

3. On models with a Temperature Monitor or High-Temp Alarm Switch, set the switch to the Min

position.

4. Make sure the temperature control is set at 4.

5. Allow freezer to operate for at least four hours before placing food inside.

6. On models with a Temperature Monitor or High-Temp Alarm Switch, set the switch to the ON

position.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

13

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 6 System flow principle

6-1. Refrigeration flow chart

The refrigeration system of direct cooling single-system cooler belongs to the category of a

single-temperature and single-control refrigerating system with one evaporators and is controlled by a

single temperature control.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

14

Issue 2014-04-12

Rev.

Ref1404S005V0

6-2. Refrigeration flow scenograph

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

15

Issue 2014-04-12

Rev.

Ref1404S005V0

Chapter 7 Circuit diagram

7-1. Brief principle diagram

HF50CM23NW

HF71CM33NW

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

16

Issue 2014-04-12

Rev.

Ref1404S005V0

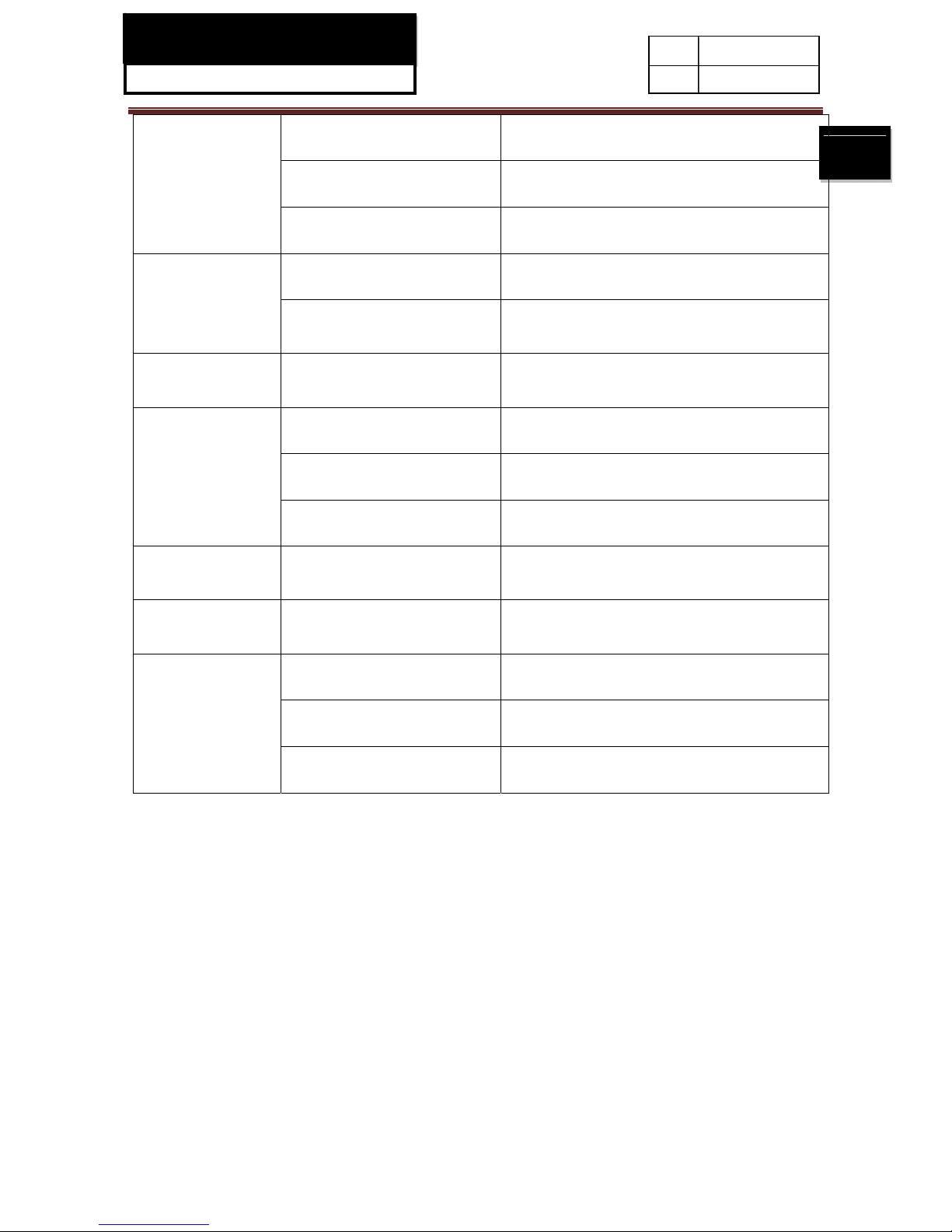

Chapter 8 Trouble shooting

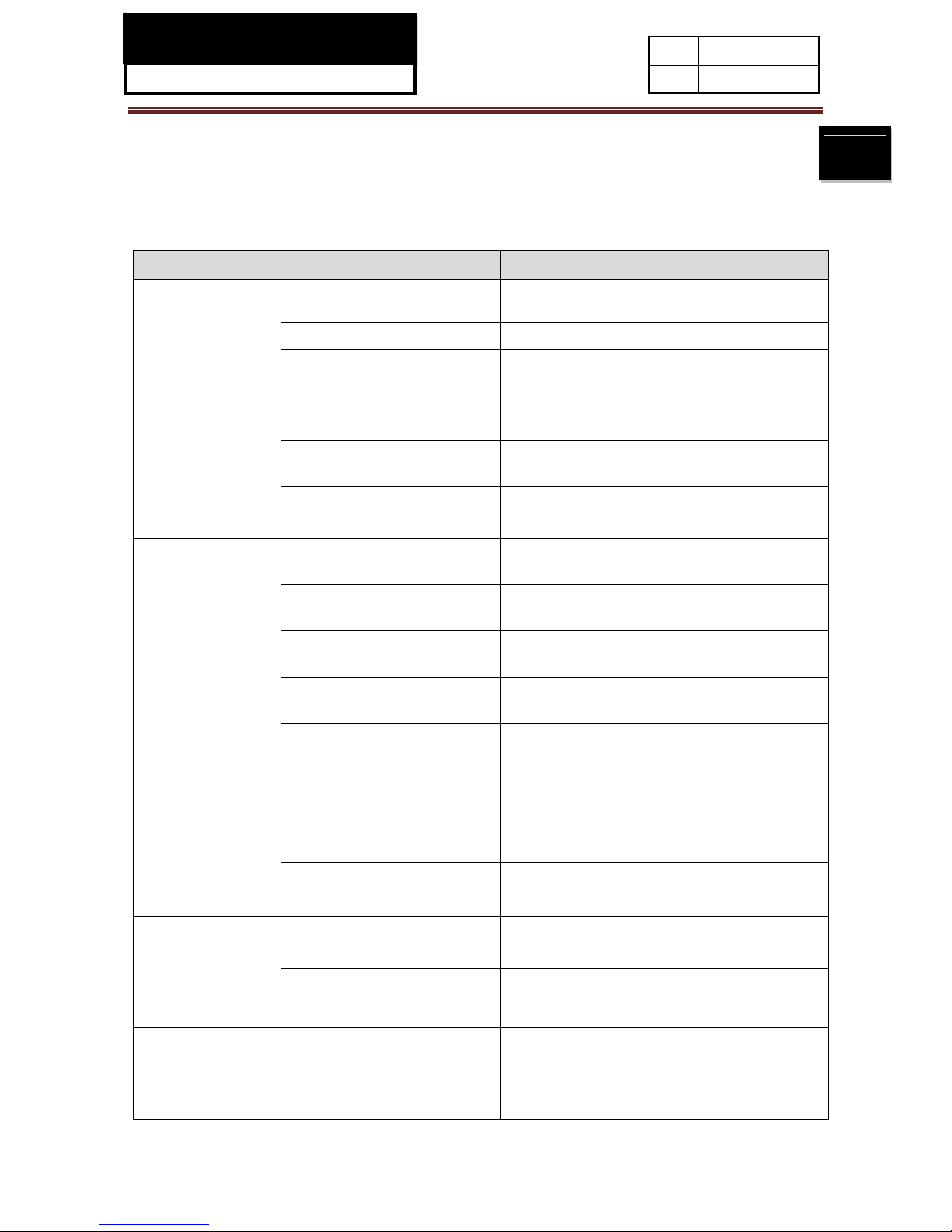

8-1. Normal phenomena

Problem Possible Causes What To Do

Freezer does not

operate or

Power-On Light is

not on

Temperature control in OFF or

Min or 0 position.

Move the control to a temperature setting.

Freezer is unplugged. Push the plug completely into the outlet.

The fuse is blown/circuit

breaker is tripped.

Replace fuse or reset the breaker

Freezer

starts/stops too

frequently

Door/lid left open.

Check to see if package is holding door/lid

open.

Too frequent or too long to

door/lid openings.

Temperature control set too

cold.

See About the operation of the freezer

Freezer operates

too long

Door/lid left open.

Check to see if package is holding door/lid

open.

Too frequent or too long

door/lid openings.

Temperature control set too

cold.

See About the operation of the freezer

Inadequate air circulation

space around cabinet.

See Preparing to install the freezer

Fast Freeze switch is in the

ON position (on some

models)

See About the operation of the freezer

Noisy operation

or cabinet

vibrates

Floor may be weak, causing

freezer to vibrate when

compressor is on.

Placing 2 X 4s (51 mm X 102 mm) under the

length of the freezer will help support it and

may reduce vibration.

Cabinet is not positioned

solidly on floor

See Preparing to install the freezer Or use

shims for uneven floor

Freezer

temperature too

warm

Door/lid left open.

Check to see if package is holding door/lid

open.

Too frequent or too long

door/lid openings.

Foods defrosting

Temperature control OFF or

Min or 0 positions.

Move the control to a temperature setting.

Freezer is unplugged. Push the plug completely into the outlet.

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

17

Issue 2014-04-12

Rev.

Ref1404S005V0

The fuse is blown/circuit

breaker is tripped.

Replace fuse or reset the breaker

Door/lid left open.

Check to see if package is holding door/lid

open.

Too frequent or too long

door/lid openings.

Freezer

temperature too

cold

Temperature control set too

cold.

See About the operation of the freezer

Fast Freeze switch is in the

ON position or has run for too

long (on some models)

About the operation of the freezer

Moisture forms

on outside of

cabinet

Not unusual during periods of

high humidity

Wipe surface dr

Interior light does

not work (on

some models)

No power at outlet. Replace fuse or reset the breaker

Freezer is unplugged. Push the plug completely into the outlet.

Light bulb burned out. Replace bulb.

Door/lid wont

fully close by

itself

Package holding door/lid

open.

Slow starting

time after being

off

Built-in overload product.

Excessive frost

build-up

Door/lid left open.

Check to see if package is holding door/lid

open.

Too frequent or too long

door/lid openings.

Not unusual during periods of

high humidity

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

18

Issue 2014-04-12

Rev.

Ref1404S005V0

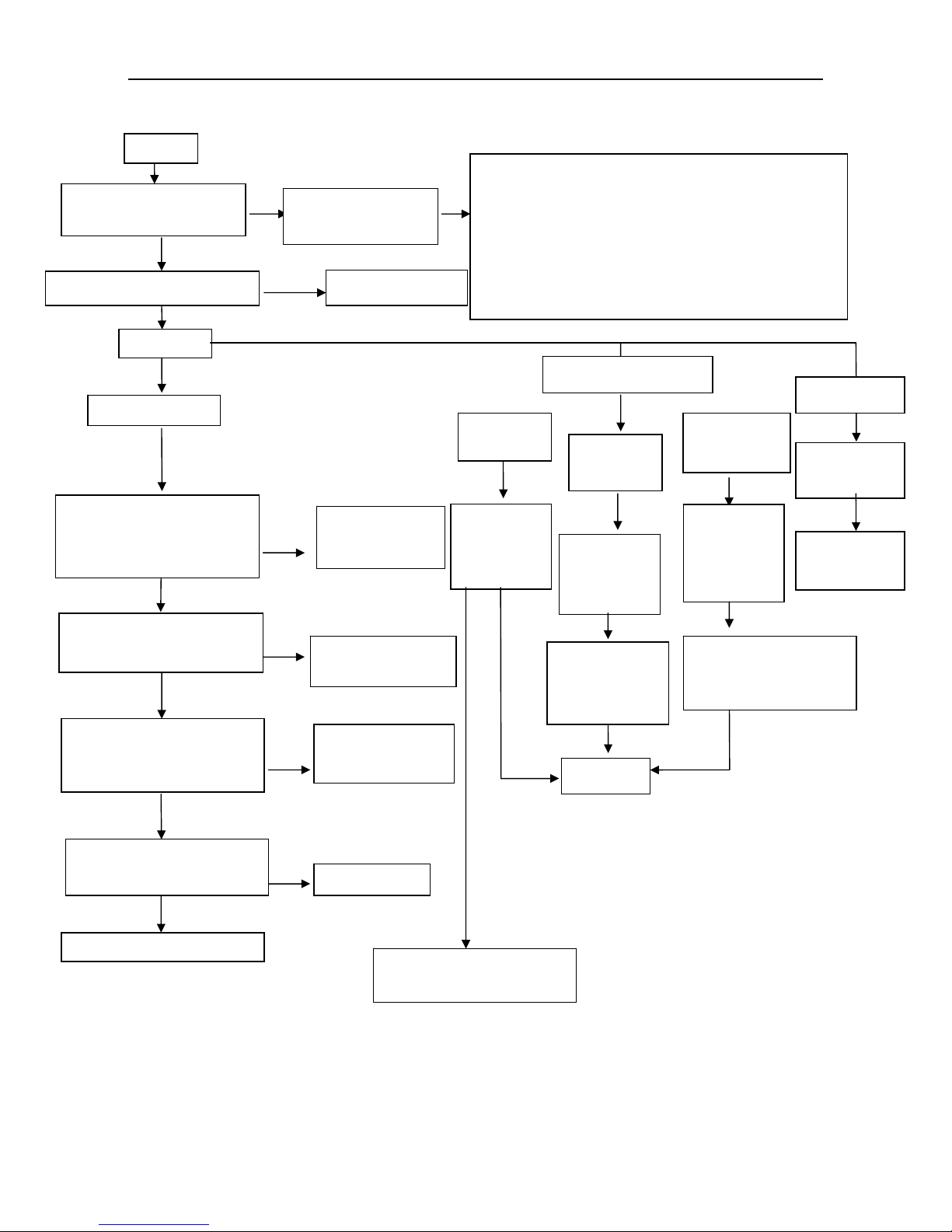

8-2. Abnormal phenomena

8-2-1. No cooling

No cooling

Whether the freezer can start

Test according to the process of the

freezer can not start

Cooling system or drier filter is blocked.

To evacuate and pour the cooling system and

recharge refrigerant again

Whether the temperature knob on “off”

position

Exchange the thermostat

Check whether the working current of

compressor is higher than 120% of

normal operating current

If the noise of compressor is loud

Check whether the working current of

compressor is lower than 80% of normal

o

p

erating current

The working sound of compressor is small

If compressor can run naturally and temperature

raising of condenser is very low

If the temperature raising of condenser

and drier filter is very low

Both high-pressure pipe and low-pressure

pipe temperature are same as the ambient

temperature

Refrigerant leak, check and

repair charge refrigerant again.

Compressor defect and change it

YES

YES

NO

YES

YES

YES

YES

NO

YES

NO

NO

YES

SERVICE MANUAL

Model: HF50CM23N

W

/

HF71CM33N

W

19

Issue 2014-04-12

Rev.

Ref1404S005V0

8-2-2.Compressor no start

Compressor no start

Check if the home power is

connecte

r

Connect the powe

r

NO

Check if thermostat is set at “0”

YES

Adjust thermostat setting position

Ambient temperature >25℃ 1~3 Grade

Ambient temperature <25℃ 4~7 Grade

Check if the thermostat is normal

Test if the thermostat is normal under power on status:

Setting thermostat to coldest position (7 grade); observe if the machine can be started.

If compressor still not start, it means that the thermostat maybe failure.

Check if the starter is normal?

Test if resistance of PTC starter if it is ZERO or INFINITE, means the

starter is out of work. For PTC starter, when shake it, it should not have

noise, if it has, means the starter Magnetic Disk burned.

YES

Check if the overload protector is

normal?

1. Measure whether two ends of overload protector is through

using multimeter Ohm grade. Not thorough means protector is

defective.

2. Measure starting current and running current of compressor

using clamp-type tester. If overload protector act when current is

normal, means protector failure and should be replaced.

Check if the run capacitor is

normal?

Before measurement, remove the capacitor from circuit firstly,

and then connect two terminals for discharge.

1. IF the finger of multimeter swings to 0 quickly and then

swings

back slowly when measuring two poles of capacitor, it means the

run capacitor is normal.

2. If the finger of multimeter does not swing, it means the run

capacitor is open circuit. If the finger of mlimeter swings to 0 and

stops means it is short circuit, if it stops on any other position, it

means the capacitor leaka

ge.

Check if each connector of starter

overload protector, run capacitor

are in good condition?

Check each connectors of the starter overload protector and

run capacitor, ensure each contact is in good condition, then

power on and retest the machine.

Check if the compressor is normal?

YES

Check if the starting current of

compressor excess too much?

Test the resistance parameter of the compressor; if it is

ZERO, inner winding is short circuit. if it is infinite, inner

windin

g

is break circuit

If all technical parameter of compressor and compressor accessories (starter,

overload protector, run capacitor) are normal after above test, but compressor

still can not be started, and overload protector action, the actual starting

current excess too much. This phenomenon usually caused by compressor

inner mechanical failure (cylinder-block or axis-hung problem).

NOT

NORMAL

Compressor

accessories

failure

Compressor

accessories

failure

NOT

NORMAL

YES

Compressor

accessories

failure

YES

NO

YES

NOT

NORMAL

YES

YES

8-2-3 .Noisy

Noisy

Whether has exterior

influence factor?

Whether the sound is normal?

Noise type

Compressor noise

Is there collision between

compressor/pipe/compressor

support bracket/drain pipes?

Whether the compressor

fixing clips or bolts are loose

Whether the damper block of

compressor is disabled or no

flexibility?

Whether terminal box is

fixed tightly?

Compressor-self noise

Relay sound

Compressor

starter noise

Replace

starter

Cooling system noise

Wind blow

sound

Rumble

sound

Refrigerant

eruption

Is the

rumble

sound big?

Whether the

pipeline

does

resonate?

Thecapillary

tube is not

smooth or

has burr.

Is the freezing

evaporator is

fixed tightly?

Refilling

Add shock damper glue

or fix the evaporator

tightly.

Adjust distance

to more than

5mm

Adjust and fix bolts

or fixing clip

Replace rubber

damper cushion

Adjust and fix

Adjust pipeline, or add shock

damper glue

Adjust appliance and

explain to user

Explain to user

Exterior factor and solution measure :

1. The adjustable foot is not level.--Explained the ground

is uneven, user can use spanner adjust refrigerator food,

locates the freezer in the horizontal position

2. The freezer and other goods bump or near to the

wall--The user may move the goods which bumps or

adjust the distance between freezer and wall (10-20cm)

YES

YES

NO

NO

NO

NO

NO

YES

YES

YES

YES

NO

YES

YES

YES

NO

NO

YES

YES

YES

Sincere forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...