Page 1

Pharmaceutical Refrigerator

Operation Manual

Model:

HYC-260

HYC-360

HYC-290

HYC-390

Certificate of Quality

Checker:

Haier Medical and Laboratory Products Co., Ltd.

Address: Haier Industrial Park, Economic Technology Development

Zone. Qingdao 266510.P.R.China

Web:www.haiermedical.com

Version:1st,2017

Dedicated code:0270501031

V13026

HYC-390F

HYC-610

HYC-890

HYC-940

HYC-940F

Read the Operation Manual carefully before using your appliance.

Keep the Operation Manual in a safe place.

Appearance , color and layout of the door may vary.

Translation of the original instruction.

This product is only applicable for storage of pharmaceutical products or drugs. Not

applicable for storage of blood or blood products including biological products, for

example biological vaccine, agents for in vitro diagnosis and etc.

Page 2

Packing List

EC Declaration of Conformity

according to the Machinery Directive 2006/42/EC

For the following equipment :

Product : Pharmaceutical Refrigerator

Type Designation/Trademark:

HYC-260

HYC-360

Model

Operation Manual

Plastic bag

Key

Shelves

Label strip

Drain hole cap

Fixed card

Brackets

(for rear wall distance)

Pad lock /

Handle Kits

Power cord Kits

HYC-260

1

1

2

4

4

1

16

2

/

/

HYC-360

1

1

2

5

5

1

20

2

/

/

HYC-290

1

1

2

5

5

1

/

2

1/0

1

HYC-390

1

1

2

7

7

1

/

2

1/0

1

HYC-390F

1

1

2

7

7

1

/

2

1/1

1

HYC-290

HYC-390

HYC-390F

Haier

HYC-610

HYC-890

HYC-940

HYC-940F

Manufactures Name : Haier Medical and Laboratory Products Co.,Ltd.

Manufactures Address : Haier Industrial Park, Economic Technology

Development Zone. Qingdao 266510.P.R.China

Refer to in this declaration confirms with the following directive(s)/standards:

2006/42/EC, EN60335-1, EN60335-2-89 EN62233

Model

Operation Manual

Plastic bag

Key

Shelves

Label strip

Drain hole cap

Fixed card

Brackets

(for rear wall distance)

Pad lock /

Handle Kits

Power cord Kits

HYC-610

1

1

2

6

/

1

24

/

0/1 /

/

HYC-890

1

1

4

12

12

/

48

/

/

HYC-940

1

1

4

12

12

/

48

/

/

/

HYC-940F

1

1

4

12

12

/

48

/

/

45

Page 3

Global Warming Potential

Rated voltage

Rated frequency

CO

Model

(

HYC-260 220~240 50/60 0.186

HYC-360 220~240 50/60 0.215

HYC-360 115 60 1.177

HYC-290 220~240 50/60 0.429

HYC-290 115 60 0.358

HYC-390 220~240 50/60 0.436

HYC-390 115 60 0.429

HYC-390F 220~240 50/60 0.436

HYC-610 220~240 50/60 0.601

HYC-610 115 60 0.501

HYC-890 220~240 50 0.358

HYC-940 220~240 50 0.472

HYC-940 220~240 60 0.615

HYC-940 115 60 0.458

HYC-940F 220~240 50 0.472

VAC

)

(Hz)

equivalent

2

(Tonnes)

The product is applicable to pharmacies, pharmaceutical factories, quarantine stations, health

centers and hospitals, used to store pharmaceuticals, medicine and other related products

which need a storage environment of 2~8℃.

Temperature

Control

Safety

System

The unit is equipped with a computer control, digital display of

temperature of 0.1℃ accuracy and a temperature range of 2℃ to 8℃.

Multi-fault alarm (high and low temperature alarm, low battery alarm,

power failure alarm, sensor error alarm and door ajar alarm)

Two alarm methods(Audible buzzer alarm and flashing indicator alarm)

All independent components are safely grounded

into the atmosphere.

GWP=global warming potential

Refrigerant type GWP

R134a 1430

Refrigeration

System

User-friendly

Design

Refrigeration system is optimized with high quality hermetically sealed

compressors and other components for a high efficiency performance.

User-friendly design, computer control, smart and carefree, adjustment

not required.

High performance thermal insulation.

Electric heated glass door with multiple anti-condensation

technologies(except HYC-260/360).

Automatic removal of condensate water.

Note: Technical information might be somewhat different on your refrigerator than

published due to continuous improvement.

44

1

Page 4

Specification

Content:

Product Feature........................................................

Content.....................................................................

Safety Precautions...................................................

Application guidelines..............................................

Product Installation ...................................................

Component Names Control Panel...........................

Application method ...................................................

1

2

3

6

7

13

21

Name

Model

Exterior Dimensions

(W×D×H)

(mm)

Interior Dimensions

(W×D×H)

(mm)

Effective Volume

Door

Insulation

Compressor

Shelves

Load

Refrigerating Method

Exterior / Interior

Condenser/Evaporater

Pharmaceutical Refrigerator

HYC-940 HYC-940F

1130×755×1980

1030×590×1425

890L

Glass door with electric heat

CFC-Free foamed-in-place urethane

High Quality Hermetically sealed compressor

12 Polyester coated wire shelves

≤20kg per shelf

Force-air cooling circulation

Cold-rolled steel with power coated/Cold-rolled steel with power coated

Fin tube type / Fin tube type

Solid door

Alarm........................................................................

Cleaning and Maintenance.......................................

FAQ..........................................................................

Circuit Diagram.........................................................

Specification&Packing List.......................................

29

31

33

34

39

Temperature Control

Interior light

Net Weight

Temperature Range of

sensor in glycerin bottle

Voltage

Rated Power/Current

Refrigerant

Noise Level(Lp)

Foaming Agent

Climate Type

Anti-shock Safety Classification

Power connection type

Alarm system

Battery duration for alarm system

Rechargeable Battery

Microprocessor controlled

LED 9W

227kg 207kg

2℃~8℃

220-240V~/50Hz 220-240V~/60Hz

850W/4.5A

R134a 330g

High & low temperature alarm, sensor error alarm, power failure alarm,

770W/4.5A

R134a 430g R134a 320g

45dB(A)

CP/IP

low battery power alarm, door ajar alarm

48 h (when the battery is fully charged)

DC 12V rechargeable battery

115V~/60Hz

4

I

Y

850W/11A

220-240V~/50Hz

600W/3A

R134a 330g

2

Note: Climate Type 4 means the temperature is +30℃,the relative humidity is 55%.Technical information may vary from

the appliance that you have just purchased due to technical improvements.

43

Page 5

Safety Precautions

Specification

Name

Model

Exterior Dimensions

(W×D×H)

(mm)

Interior Dimensions

(W×D×H)

(mm)

Effective Volume

Door

Insulation

Compressor

Shelves

Load

Refrigerating Method

Exterior / Interior

Condenser/Evaporater

Temperature Control

Pharmaceutical Refrigerator

HYC-890

1130×755×1980

1030×590×1425

890L

Glass door with electric heat

CFC-Free foamed-in-place urethane

High Quality Hermetically sealed compressor

12 Polyester coated wire shelves

≤20kg per shelf

Force-air cooling circulation

Cold-rolled steel with power coated/Cold-rolled steel with power coated

Fin tube type / Fin tube type

Microprocessor controlled

Dear users:

Thanks for your choice of Haier pharmaceutical refrigerator, please make sure you have carefully

read and observed the contents with following signs in the manual, for better understanding of this

manual and better use of this product, so as to prevent personal injuries and refrigerator damage.

Ignoring this warning may result in

death or serious injury

Ignoring this warning may result in

death or serious injury,and/or damage

Actions or operations

which are prohibited

Actions or operations

which must be followed

to the refrigerator and property

When there is a leak of flammable gas, shutoff the feed valve of the gas. Open windows

for ventilation and exhaust. Do not plug in your refrigerator or unplug your refrigerator as

spark in these processes can cause an explosion or fire.

We recommend the unit be installed by a professional to avoid any electrical hazard.

Place the refrigerator on solid and flat ground to avoid tipping the unit over to cause

personal injury.

Only connect the refrigerator unit with a dedicated power outlet specified by the nameplate

of the unit. This is to avoid fire or electric shock.

Interior light

Net Weight

Temperature Range of

sensor in glycerin bottle

Voltage

Rated Power/Current

Refrigerant

Noise Level(Lp)

Foaming Agent

Climate Type

Anti-shock Safety Classification

Power connection type

Alarm system

Battery duration for alarm system

Rechargeable Battery

Note: Climate Type 4 means the temperature is +30℃,the relative humidity is 55%.Technical information may vary from

the appliance that you have just purchased due to technical improvements.

High & low temperature alarm, sensor error alarm, power failure alarm,

low battery power alarm, door ajar alarm

48 h (when the battery is fully charged)

DC 12V rechargeable battery

LED 6W

227kg

2℃~8℃

220-240V~/50Hz

800W/4A

R134a 250g

45dB(A)

CP/IP

4

I

Y

If the supply voltage is lower than 198 V or higher than 242 V, an automatic voltage

regulator of at least 4,000 W should be installed with the refrigerator.

If the power cord needs to be lengthen, the cross section area of the extension line’s

conductor should be at least 2 mm² and the length of the extension cord should be limited

to 3 m. This is to prevent electric fire or shock.

The power cord of the unit is equipped with a 16 A three-prone power plug. Do not remove

the ground pin of the power plug under any circumstances. Make sure the plug is securely

plugged into the power outlet to prevent fire.

The power socket must be equipped with a ground wire to prevent electric shock. If the

socket fails to be grounded, the ground wire must be installed before the refrigerator is

plugged in.

The refrigerator shall not conduct outdoor service. Electrical leakage or shock may be

caused if wet by rainwater.

Do not place the refrigerator in humid places or places where the unit may get splashed

on by water. This is to avoid electric shock due to deterioration of insulation.

In case the fire, do not pour water onto the refrigerator unit as a means to prevent electric

shock or short circuit.

42

3

Page 6

Do not place containers of water or heavy objects on the refrigerator. Falling objects may

cause personal injury and overflown water may damage the insulation to cause electric

shock and fire.

Do not ground the refrigerator through gas pipes, water supply pipes, telephone lines or

lighting conductors. These types of connections can cause electric shock.

Do not touch electric parts such as power plugs or switches with wet hands to prevent

electric shock.

When pulling the plug out of the power socket, hold the power plug instead of power cable.

Pulling the cable can cause a damage and personal injury.

Unplug the refrigerator unit if it malfunctions to avoid fire or personal injury.

Specification

Name

Model

Exterior Dimensions

(W×D×H)

(mm)

Interior Dimensions

(W×D×H)

(mm)

Pharmaceutical Refrigerator

HYC-610

780×840×1945

680×640×1400

Dismantling, repairing and retrofitting a unit should only be performed by a professional to

avoid personal injury.

Disconnect the refrigerator when repairs or maintenance are performed on the

refrigerator to prevent electric shock or personal injuries.

Do not inhale airborne particles inside and near the refrigerator during routine

maintenance. This is to avoid health hazard.

To avoid any potential danger to human health or environment, the refrigerator should be

used in safe regions to store toxic, harmful or radioactive particles.

If the refrigerator is to be decommissioned, unplug the power cord to avoid electric shock,

current leakage, or fire caused by aged power lines.

If the refrigerator is left unused in area where supervision is unavailable for a long time,

make sure children are not near the unit and the door cannot be completely closed and

locked.

End of life disposal of a unit should only be performed by a professional. Remove the

door to avoid accidents such as suffocation.

Do not store flammable, explosive or volatile articles inside the refrigerator and do not use

flammable sprays nearby. This is to avoid an explosion or a fire.

Do not store corrosive articles such acid or alkali in the refrigerator. These chemicals can

damage internal components or electrical parts.

Do not place packaging plastic bags within the reach of children to prevent suffocation

accidents.

Do not climb to the top of the refrigerator or place plastic bags on top of the refrigerator.

This is to prevent tip over of the refrigerator, which can cause personal injury.

Do not use any metal objects such as iron nails or wires into holes, gaps or vents for

internal air circulation. This is to prevent personal injury due to contact of articles behind

the holes.

Effective Volume

Door

Insulation

Compressor

Shelves

Load

Refrigerating Method

Exterior / Interior

Condenser/Evaporater

Temperature Control

Noise Level(Lp)

Interior light

Net Weight

Temperature Range of

sensor in glycerin bottle

Voltage

Rated Power/Current

Refrigerant

Foaming Agent

Climate Type

Anti-shock Safety Classification

Power connection type

Alarm system

Battery duration for alarm system

610L

Glass door with electric heat

CFC-Free foamed-in-place urethane

High Quality Hermetically sealed compressor

6 Polyester coated wire shelves

≤30kg per shelf

Force-air cooling circulation

Powder coated cold rolled steel/Stainless steel

Fin tube type / Fin tube type

Microprocessor controlled

43dB(A)

LED 3W

204kg

2℃~8℃

220-240V~/50Hz/60Hz

550W/3.5A

R134a 420g R134a 350g

CP/IP

4

I

Y

High & low temperature alarm, sensor erroe alarm, power failure alarm,

low battery power alarm, door ajar alarm

48 h (when the battery is fully charged)

560W/7.5A

4

Rechargeable Battery

Note: Climate Type 4 means the temperature is +30℃,the relative humidity is 55%.Technical information may vary from

the appliance that you have just purchased due to technical improvements.

DC 12V rechargeable battery

41

Page 7

Specification

Name

Model

Exterior Dimensions

(W×D×H) (mm)

Interior Dimensions

(W×D×H) (mm)

Effective Volume

Door

Insulation

Compressor

Shelves

Load

Refrigerating Method

Exterior / Interior

Condenser/Evaporater

Temperature Control

HYC-290

665×710×1665

530×555×1080

290L

Glass door with electric heat

High Quality Hermetically sealed compressor

5

≤26kg per shelf

Cold-rolled steel sheet with powder coated /HIPS plate

Pharmaceutical Refrigerator

HYC-390

665×710×1965

530×555×1380

390L

CFC-Free foamed-in-place urethane

7

≤26kg per shelf

Force-air cooling circulation

Fin tube type / Plate type

Microprocessor controlled

HYC-390F

665×710×1965

530×555×1380

390L

Solid Door

7

≤26kg per shelf

Always check the settings in the controller after restarting a unit from a power outage or

shut off. Change of settings may cause damage to the products stored.

If the power is shut off, let the unit sit for 5 minutes before it is powered up again to avoid

damaging the compressor or the system.

Wear gloves when performing maintenance to prevent personal injury as a result of sharp

edges or corners.

Hold the knob when closing the door to prevent finger pinching.

The angle of inclination shall not be greater than 45°when handling the refrigerator.

Be aware of the danger of tripping when working with the refrigerator to avoid managing

the unit or personal injury.

Do not use the door knob to prevent refrigerator damage or personal injury.

Do not damage the refrigeration line.

Do not use electrical appliances inside the food storage compartments of the appliance,

unless they are of the type recommended by the manufacturer.

Position the refrigerator to make sure the power plug is accessible.

Interior light

Net Weight

Temperature Range of

sensor in glycerin bottle

Voltage

Rated Power/Current

Refrigerant

Noise Level(Lp)

Foaming Agent

Climate Type

Anti-shock Safety

Classification

Power connection type

Alarm system

Battery duration

for alarm system

Rechargeable Battery

LED 3W

105kg

2℃~8℃

220-240V~/50/60Hz

340W/2.2A

R134a 300g

43dB(A)

CP/IP

4

I

Y

High & low temperature alarm, sensor error alarm, power failure alarm,

LED 3W

116kg

2℃~8℃

115V~/60Hz 115V~/60Hz

460W/5.0A

R404a 250g

47dB(A)

low battery power alarm, door ajar alarm

220-240V~/50/60Hz

380W/2.4A

R134a 305g

43dB(A)

CP/IP

48 h (when the battery is fully charged)

DC 12V rechargeable battery

500W/5.5A

R404a 300g

47dB(A)

4

I

Y

LED 3W

106kg

2℃~8℃

220-240V~/50/60Hz

300W/2.4A

R134a 305g

43dB(A)

CP/IP

4

I

Y

The appliance must be placed on a solid and flat surface, or excessive vibration and

noise may be produced when the appliance in operation.

The appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capacibilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance in a

safe way and understand the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

If the power supply cord is damaged, it should be replaced by a qualified technician to

avoid a hazard condition.

Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of

obstruction.

If your cabinet is to be discard, you must remove the door and leave the shelves in

place. This will reduce the posibility of danger to children. And the flammable foaming

needs to be disposed by professional persons.

CP/IP foaming materials are flammable, need professional processing.

Note: Climate Type 4 means the temperature is +30℃,the relative humidity is 55%.Technical information may vary from

the appliance that you have just purchased due to technical improvements.

40

5

Page 8

Application guidelines

The battery in the refrigerator may be low after the refrigerator has been in storage for a long time.

Turn on the battery charge switch when the unit is powered up to allow the battery to be recharged.

Specification&Packing List

Specification

The battery will be in full capacity after about a week’s charging.

Before loading the refrigerators, make sure the unit is at set temperature. Do not load in more than

1/3 of the storage volume to avoid thermally overloading the unit.

The display on the panel shows the sensor temperature located in the refrigerator. It is not

necessary the same as the temperature in the center of the refrigerator. The cabinet temperature

will gradually reach an equilibrium state.

Only clean the unit with light soapy water. Never use brushes, acids, gasoline, soap powders,

polishing powders or hot water to clean refrigerators as these materials may damage the interior

painting and surface, parts and components. Never wide plastic parts with volatile solvents such

as gasoline.

If the unit is to be stored for a long period of time, turn off the power switch and the battery

charging switch.

To reduce the possibility of temperature fluctuation in the refrigerator, please attempt to cut down

the time to open to the door to remove and load products.

If the door is opened, the temperature of the refrigerator will warm up somewhat. That is normal.

Name

Model

Exterior Dimensions

(W×D×H) (mm)

Interior Dimensions

(W×D×H) (mm)

Effective Volume

Door

Insulation

Compressor

Shelves

Load

Refrigerating Method

Exterior / Interior

Condenser/Evaporater

Pharmaceutical Refrigerator

HYC-260

620×655×1720

550×460×1065

260L

Glass door

CFC-Free foamed-in-place urethane

High Quality Hermetically sealed compressor

4 Polyester coated wire shelves

≤20kg per shelf

Force-air cooling circulation

Scratch resistant painted steel / HIPS

Wire tube type / Fin tube type

HYC-360

620×655×1995

550×460×1340

360L

Glass door

5 Polyester coated wire shelves

≤20kg per shelf

Force-air cooling circulation

Scratch resistant painted steel / HIPS

Wire tube type / Fin tube type

The temperature will recover to a stable condition in a short time.

The refrigerator is designed to operate at a condition of 16 ℃ to 32 ℃ and humidity less than

85%RH (for HYC-260/360,the humidity should be less than 70%RH). Small amount of condensation

can occur on the surface of the unit if the actual condition is outside of this range. The storage

temperature of the unit, however, is not impacted. To reduce the condensation, please improve the

ventilation and drop the ambient temperature if possible.

Only professional people should perform maintenance work.

Meaning of crossed –out wheeled dustbin:

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection

facilities.Contact you local government for information regarding the collection systems available.

If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into

the groundwater and get into the food chain, damaging your health and well-being.When replacing

old appliances with new ones, the retailer is legally obligated to take back your old appliance for

disposals at least free of charge.

Temperature Control

Interior light

Net Weight

Temperature Range of

sensor in glycerin bottle

Voltage

Rated Power/Current

Refrigerant

Noise Level(Lp) 43dB(A) 43dB(A)

Foaming Agent

Climate Type

Anti-shock Safety Classification

Power connection type

Alarm system

Battery duration for alarm system

Rechargeable Battery

Microprocessor controlled

Fluorescent lamp 15W

88kg

2

℃~8℃

220-240V~/50Hz/60Hz

300W/2.1A

R134a 130g

CP/IP

4

I

Y

High & low temperature alarm, sensor error alarm, power failure alarm,

low battery power alarm, door ajar alarm

48 h (when the battery is fully charged)

DC 12V rechargeable battery

220-240V~/50Hz/60Hz

Microprocessor controlled

Fluorescent lamp 15W

99kg

℃~8℃

2

315W/2.2A

R134a 150g

CP/IP

4

I

Y

115V~/60Hz

340W/4.5A

R404a 300g

47dB(A)

6

Note: Climate Type 4 means the temperature is +30℃,the relative humidity is 55%.Technical information may vary from

the appliance that you have just purchased due to technical improvements.

39

Page 9

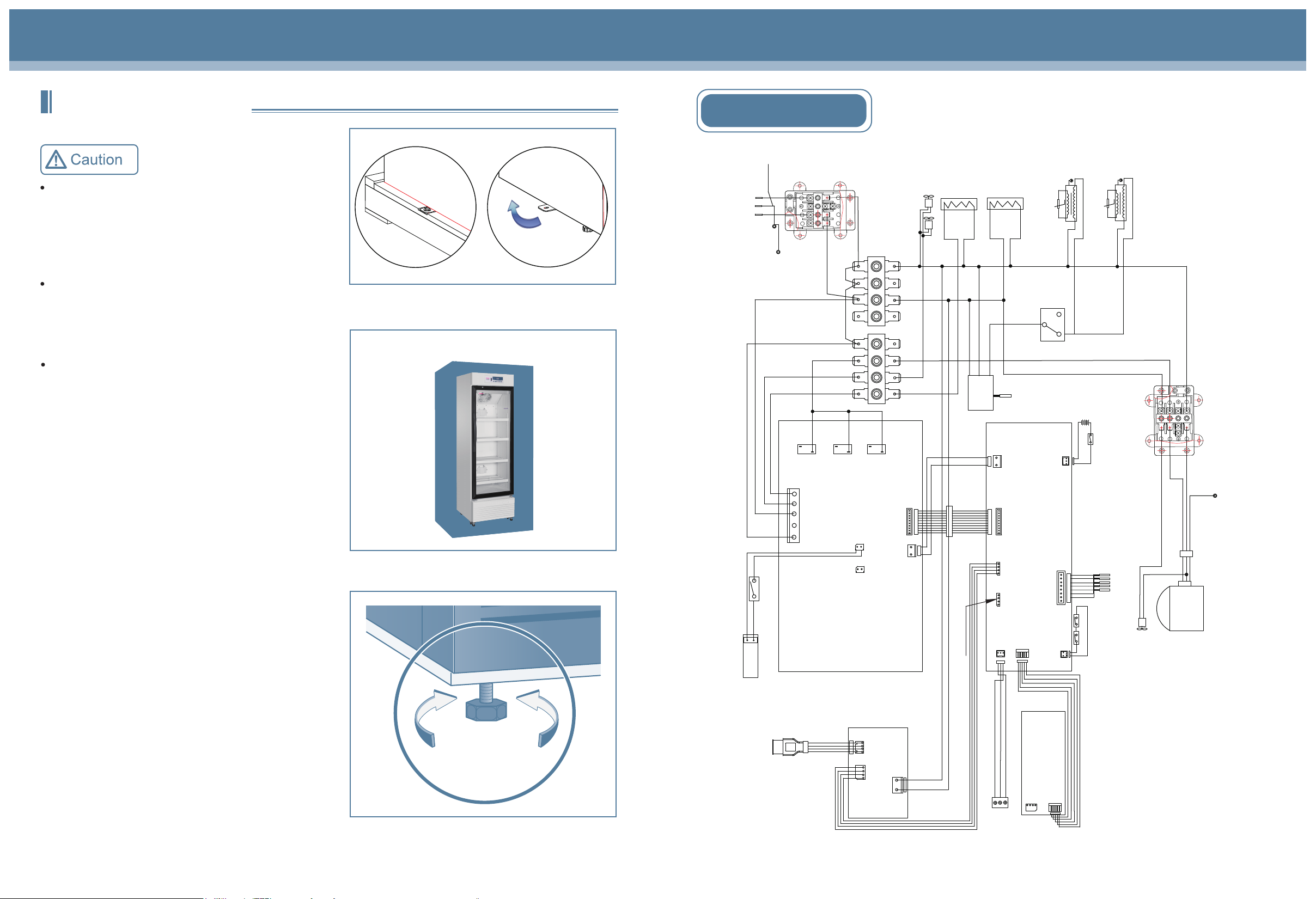

Product Installation

Circuit diagram(HYC-940/940F)

Junction

Power wire

N

E

L

to the roof of cabinet

Terminal connected

Terminal connected

box

N

L

1

to the compressor

bottom board

NC

K3

NO

CN2

HTR

FAN

L

N

N

L

2

NC

NC

K7

NO

Power panel

GND

+12V

CN4

CN5

Lamp switch

LED lamp set

LED lamp set

Installation environment

Ambient temperature: 16 ℃ to 32 ℃, the range of 18 ℃ to 25 ℃ is optimal. Air conditioning

system is required as necessary.

Ambient humidity: below 85%RH(for HYC-260/360,the humidity should be less than 70%RH).

Internal fan

t

Door heating strip

t

Door heating strip

Door heating transformer

Door heating transformer

Avoid excessive dust.

Avoid mechanical vibration.

outlet

at the cabinet

Heating strip

strip

heating

Defrosting

The refrigerator shall operate at an altitude lower than 2000m.

Input voltage: no greater than ±10% of rated voltage.

Performance of the refrigerator is degraded if the operational conditions are

beyond the specifications mentioned above.

thermostat

prevention

High temperature

L

C

H

applicable for products with the foaming door.

Note: The content in the frame with dotted lines are not

The unit should be installed indoors. Electric leakage or shock is possible if the

unit gets wet by rainwater.

Installation site

N

L

1

The installation site shall meet following requirements for normal operation and best performance of

N

2

L

K4

NO

CN1

GND

16V

CN3

CN11

GND

16V

CN2

CN1

USB

Main control panel

CN4

PRINT

NC

NO

COM

Printer communication interface

CN5

CN6

BAT-

BAT+

Sensor

door

BT1

Battery switch

Terminal connected to the

compressor bottom board

CN3

Alarm

Defrosting

Control

Lower temperature

Upper temperature

VCC

GND

Door switch

CN7

Cooling fan

Compressor

Cooling fan

Display panel

CN2

Remote alarm port

NO

COM

CN1

NC

refrigerator:

Do not install the refrigerator in a narrow and confined space as heat may be trapped to increase

ambient temperature. Additionally, the unit should not be installed in a space where the entry door

way is low to prevent an easy maneuver of the unit for maintenance and operation.

The floor for the installation site should be solid and flat. It should also be well ventilated and free

from direct sunshine.

The power outlet for the refrigerator must be a dedicated power outlet. The power plug must be

plugged in to the outlet securely.

Do not twist or jam the power cord.

If the power cord needs to be extended, the cross section area of the conductor in the extended

line should be no less than 2 squared millimeters and no longer than 3 meter.

Inspect the operating voltage range before operation. If the voltage supply is unstable, install a

voltage stabilizer of 4000 W or greater to ensure the supply voltage is within 10% of the rated

voltage supply.

The refrigerator must be grounded reliably.

Check the integrity of the socket ground before power up. If it is not grounded appropriately,

repair the wiring before installing the unit.

Do not ground the refrigerator through gas lines, water lines, telephone lines, or lighting rods as

these devices may cause electric shock and danger.

The power plug and outlet should be located in a place where they can be

accessed easily and immediately in case of an emergency. Air vents must be

free of obstruction.

The power plug can be accessed after installation to ensure the power line can

be pulled out in a timely manner in emergency cases. The air vent shall free from

barriers.

38

7

Page 10

Preparation before usage

1. Remove all packaging materials.

For safety reason, the equipment of

HYC-890/940/940F is situated on a wooden

pallet and secured by metal brackets. Please

remove the screws and place the metal

brackets under the unit.(Pic.1).

Forklift or specialty lifting equipment should be

used to remove the unit off the pallet. Forklift

should reach the bottom of the wood pallet for

lifting.

The unit should not be tilted at an angle of

more than 45 degree.

2. Inspect standard accessories shipped with the unit

Inspect the accessories against packing list. Should

there be any discrepancy, contact the after-sale

department.

3. Installation

Leave a minimum space of 10 cm around the

refrigerator for ventilation and heat dissipation.

(Pic.2).

4. Adjust the leveling leg

Rotate the leveling legs with a wrench in clockwise

to extend them out and secure them onto the ground.

This is to make sure the refrigerator does not move

during operation.(Pic.3).

> 10cm from

the back

> 10cm from

the left

Pic.1

> 30cm from the top

Pic.2

> 10cm from

the right

Circuit diagram(HYC-890)

Junction

Power wire

N

E

L

to the roof of cabinet

Terminal connected

Lamp switch

LED lamp set

Terminal connected

box

N

L

1

to the compressor

bottom board

NC

K3

NO

CN2

HTR

FAN

L

N

N

L

2

NC

NO

Power panel

K7

GND

+12V

CN4

CN5

Internal fan

NC

K4

NO

CN1

GND

16V

CN3

strip

heating

Defrosting

L

Printer communication interface

C

N

controller

Electronic

CN6

Heating strip

at the front vertical beam

CN11

GND

16V

CN2

CN1

USB

CN4

PRINT

NC

NO

COM

t

Door heating strip

prevention

High temperature

C

Sensor

Main control panel

Sensor

CN5

thermostat

L

H

BT1

BAT-

BAT+

CN3

CN7

door

Door heating transformer

Battery switch

Alarm

Defrosting

Control

Lower temperature

Upper temperature

VCC

GND

Door switch

t

Door heating strip

Door heating transformer

L

1

2

L

Compressor

Cooling fan

N

N

Terminal connected to the

compressor bottom board

8

Downward

Leveling legs

Pic.3

upward

USB port

CN2

J5

N

L

USB panel

CN1

Remote alarm port

NC

NO

COM

Display panel

CN2

CN1

37

Page 11

Circuit diagram(HYC-610)

prevention

thermostat

Low temperature

L

C

LED lamp bank

Lamp switch

H

High

prevention

temperature

L

C

H

thermostat

Defrosting heating strip

thermostat are exchangeable.

L of the low temperature prevention

Note: Cables at terminal C and terminal

Switch

Heating strip at the cabinet outlet

t

Door heating strip

Door heating transformer

Null wire

Earth wire

Live wire

Filter

Grounding

Double-throw switch

Grounding

Wiring terminal

Power line

5. Standing

Do not immediately power up the refrigerator after it is installed. Let the unit stand still for 24 hours

and then power it up to ensure the unit works properly.

6. Installation of Shelves and Label strip

HYC-260/360/610/890/940/940F

Take out the shelf, label strip and rack fastener from the

refrigerator. Fix the shelf fasteners on the liner plate at the

appropriate distance and height. After mounting the shelf

and label strip, place them on the shelf fastener and ensure

the shelf is placed firmly.See Pic. 1 (see Pic. 2 for HYC-610、

Pic.1

HYC-890);

HYC-290/390/390F

After mounting the shelf and label strip, place them on the

liner plate slot at the appropriate distance.

Pic.2

NC

NC

K3

NO

CN2

HTR

FAN

L

N

CN2

NC

K7

NO

CN4

CN5

K4

NO

GND

16V

GND

+12V

CN4 and CN5 are both LED power supply interfaces.

Power panel

CN1

CN3

CN11

GND

16V

CN2

CN1

USB

CN4

NO

CN6

Printer communication interface

Main control panel

PRINT

NC

COM

CN5

BAT-

BAT+

CN3

Sensor

door

BT1

CN7

Battery switch

Alarm

Defrosting

Control

Lower temperature

Upper temperature

VCC

GND

Door switch

7. Install handle (HYC-390F/HYC-610/HYC-940F)

1

a.Place the end

of handle with a

hole facedown.

3

c.Raise the handle

after securing the

handle and holder.

2

b.Align the handle with

the holder on the door.

4

d.Use screws to fasten

the handle at the bottom.

36

N

L

J5

USB drive board

CN1

Internal fan

NC

NO

Remote alarm port

COM

Display panel

CN2

CN1

Temperature recorder (optional)

Cooling fan

Compressor

9

Page 12

8.Back Bracket(HYC-260/360/290/390/390F)

HYC-260/360

Install the support bolts into the mounting holes on the back of the

refrigerator. (See Pic.3)

Circuit diagram(HYC-290/390/390F)

t

HYC-290/390/390F

Remove four M5 bolts from the back of cabinet,then fix the back

bracket for rear wall distance with the removed bolts.(See Pic.4)

9. Power line bracket installation (HYC-290/390/390F)

Use two M3.5 screws to fix the power line brackets to the refrigerator.

(See Pic.5)

For the power supply cable with loose prevention hook it is not

configured clamp stand.

Pic.3

Pic.4

Pic.5

LED lamp bank

LED lamp bank

Lamp switch

NC

CN2

C

K3

NO

HTR

FAN

L

N

Condensate fan

Compressor

terminal C and

terminal H of the

thermostat can be

exchanged.

mechanical

Note: Cables at

L

H

NC

NO

NC

K7

CN4

CN5

GND

K4

NO

+12V

CN4 and CN5 are both LED

power supply interfaces.

Power panel

GND

16V

CN1

CN3

Internal fan

Printer

Door heating strip

Door heating transformer

NO

CN6

CN11

CN2

CN1

CN4

COM

GND

16V

USB

PRINT

NC

CN5

BATBAT+

Main control panel

Sensor

door

Note: HYC-390F has no Door heating strip,

Door heating transformer and mechanical

thermostat.

BT1

CN3

CN7

Battery switch

Alarm

Defrosting

Control

Lower temperature

Upper temperature

VCC

GND

Door switch

L

N

2

applicable for products with the printer.

Note: The content in the frame with dotted lines are

Grounding

10

CN2

L N

J5

USB drive plate

CN1

CN2

CN1

USB transfer plate

Display panel

CN2

Remote alarm port

NC

NO

COM

CN1

1

L

N

Terminal box of power line

LNE

Power line

35

Page 13

Circuit Diagram

Circuit diagram(HYC-260/360)

NC

NO

K3

NC

NO

K7

NC

K4

NO

Compressor

Internal fan

Condensate fan

CN11

GND

16V

Initial Power-on

Follow the flow chart below to start the refrigerator.

While the refrigerator is empty, connect the power line to the appropriate dedicated socket and

make sure the power supply in the socket matches the required voltage and frequency.

After the power is switched on, turn on the battery charging switch. The audible alarm is usually

triggered. Press the buzzer to stop the alarm. The audible alarm continues to operate until the

temperature of the sensor reaches 5℃±3℃.

Lamp

BT1

BATBAT+

Battery switch

Starter

Ballast

The refrigerator has been preset to operate at 2~8℃ in the factory and it is not required to set

temperature

CN2

HTR

FAN

Power panel

L

N

CN1

GND

16V

CN3

CN4 and CN5 are both LED power supply interfaces.

CN4

CN5

GND

+12V

CN6

CN2

Lamp switch

CN1

Main control panel

CN3

Sensor

CN7

door

Alarm

Defrosting

Control

Lower temperature

Upper temperature

VCC

GND

Door switch

Grounding

L

N

N

2

1

L

USB

CN4

NC

NO

COM

CN5

Terminal box of power line

It usually takes several hours for the refrigerator temperature to reach a stable condition. When

the temperature becomes stable, inspect the actual temperature to make sure it matches the set

point.

Turn on the light switch and ensure the light inside the freezer operates properly.

When the refrigerator passes all the functional inspections, load in products in batches.

Display panel

CN2

CN1

N

E

L

34

Power line

11

Page 14

FAQ

This unit should be managed a dedicated professional person. Operating conditions

should be checked and recorded using appropriate methods. When the refrigerator

temperature is out of specification, take proper actions to protect the stored samples.

No products should be stored in the unit unless the unit operates without issues.

The refrigerator is a pharmaceutical refrigerator designed to operate within 2℃ to 8 ℃.

Make sur to store only products that fit this temperature range.

Due to the refrigeration effect, the displayed temperature may be somewhat different

from actual temperature and humidity. This is a normal process.

Do not place any article in the space between liner bottom and underbed shelf of the

refrigerator to avoid blocking of air duct which may affect homogeneity of temperature

inside.

Warm products should only be loaded into the units in batches to reduce the load to

the cooling system. Overloading the system can cause the refrigerator temperature

to rise and the compressor to work under undesirable stress, which can shorten the

life of the system.

Do not damage the refrigeration lines.

Do not use an electrical apparatus in the refrigerator without proper approval.

If you have any questions about the operation of the refrigerator, please refer

to the table frequent asked questions as follows. Call Haier technical support

if you still have questions. Do not attempt to maintain or dismantle the unit by

yourselves.

Fault

The refrigerator does not work

The refrigeration effect is

weak and temperature

exceeds upper limit.

Troubleshooting

Inspect the power supply to make sure it meets the requirement.

Inspect the connection between the power plug and the socket.

Check the power cord for any obvious damage.

Whether the voltage is too low

The unit is loaded with too much warm sample and product.

There is a lack of space between stored samples.

There might be a direct sunlight or other heat radiation energy on the refrigerator.

The door is opened too frequently.

Operation after Power Outage

The control parameters are stored in the control system in the refrigerator even there is a power

outage. When the power recovers after the outage, the refrigerator continues to operate in

accordance to the set parameters before the power outage.

If the unit is shut off, allow a 5 minutes hiatus before powering it up again.

If the unit is to be shut down for a long time, be sure to turn off the power

switch, and the battery switch. Unplug the unit from the power outlet. This is

to a hazardous condition due to aging power lines.

If the refrigerator is decommissioned and left unattended, make sure children

cannot get close to the refrigerator and the door cannot be closed completely.

Unit seems to emit

too much noise.

Alarm light flashes

and alarm buzzer sounds

Ambient temperature is too high.

Air duct is blocked.

Check the installation of the unit to make sure the unit does sit on a solid floor

without vibration.

Part of the refrigerator leans against a wall.

As a reference, the published sound data is obtained at specific laboratory condition.

It is normal that the actual sound level in the field differs due to subtle installation and

operation conditions.

Warm products have been placed into the unit recently and the refrigerator has not

stabilized yet at 2℃to 6 ℃. The alarm condition will be automatically corrected once

the temperature reaches the set value.

The door is not closed properly.

The unit lost power recently and it is in the process of cooling down.

Ambient temperature might exceed the designed range.

12

33

Page 15

Component Names Control Panel

Purchasing backup battery for temperature recorder

You can purchase a high quality battery from a store for the same size and voltage(9V). You may

also call Haier to purchase a high quality replacement battery. The lead time to deliver the battery is

15 days after receiving the payment. Please call Haier for details.

Battery maintenance

When the refrigerator works continuously, please test battery charge level every 15 days (please

refer to “Alarm Test” on Page 27 for test method). In case of low battery charge level, make sure

that battery switch is on and battery is charged. When the battery has been charged for consecutive

7 days, please retest battery charge level. In normal conditions, battery charge should be full. If low

battery charge level remains, it is recommended to replace the rechargeable battery.The battery of

power failure alarm is a consumable item with 3-year service life. If it has been used for more than 3

years, power failure alarm may not act when alarm conditions occur. It is recommended to replace

the battery earlier. Please contact a Haier after-sales service technician for battery replacement.

Rechargeable battery recycling

Component Names

HYC-260/360

Light switch

Control panel

Door ajar alarm switch

Door lock

Handle

The refrigerator has a built-in rechargeable battery. The battery is recyclable; when its service life

expires, please ask a local relevant battery recycling organization for check or discard it properly.

a.Battery location

The built-in battery of the refrigerator-freezer is used for power failure alarm and located in the

electrical compartment.et.

There are high-voltage electrical components in the electrical compartment.

To avoid electric shock, the cover of the electrical cabinet must be opened by a

qualified technician.

b.Battery removal

1) Unplug the unit from the power outlet.

2) Remove the screws on the cover with a screw driver.

3) Unplug the battery’s connecting plugs.

4) Remove the battery’s holding clip and remove the battery.

5) Recycle or dispose of the used battery as required.

Prohibition

Shelf

Glass door

Glycerin bottle for

temperature sensor

When replacing the battery, make sure that brown wire is connected to the battery's positive pole

and blue wire to the battery's negative pole. Do not misconnect; otherwise the charging circuit of

computer board would be burned out easily and thus the battery cannot be charged.

32

Leveling leg

13

Page 16

Cleaning and Maintenance

HYC-290/390

Door lock

Interior light

Battery

switch

Handle

Door ajar

alarm switch

Light switch

Control panel

USB port(Optional)

Component Cleaning

To avoid electric shock or personnel injuries, make sure to power off the

refrigerator before any repair work or maintenance is performed.

Make sure no drug or aerosol around the refrigerator is inhaled during

maintenance, otherwise your health will be threatened.

Refrigerator cleaning

The refrigerator should be cleaned once a month to keep the appearance new and reduce the

chance for gem formation.

Use a damp cloth to clean off dust on the refrigerator. If necessary, use light detergent water to

wipe off the unit if necessary. Then use a dry cloth to wipe it again.

Do not dump water directly onto the interior of the unit to avoid damage to electrical systems.

Compressor and other mechanical parts are hermetically sealed. They don’t need lubrication.

Lamp replacement

Glass door

Shelf

(1) HYC-260/360 is equipped with a fluorescent lamp on the upper front part of the refrigerator.

When you change the tube, please pay attention:

Unplug the power cord.

Remove the lamp cover.

Remove the tube.

Replace the original florescent lamp with a new lamp.

Switch on the power.

Replacement lamp must have the same specification as the original one.

If the starter is defective, remove the old starter and install a new starter.

(2)HYC-290/390/390F/610/890/940/940F is equipped with a LED lamp. To replace the lamp,

please contact the service department.

Purchasing chart paper for temperature chart recorder

The chart recorder papers are imported chart papers designed for the recorder. The papers that are

supplied with the unit usually last about half of a year. When you are running short of the chart paper,

please contact Haier to purchase more. The lead time to deliver the charts is 15 days after receiving

the payment . Please call Haier for details.

Caster Leveling leg

14 31

Page 17

Automatic Alarm Recovery

HYC-390F

This series of refrigerator is has an automatic alarm recovery feature.

When the system is in the alarm mode, you can press the “Silence” on the display panel to

cancel the alarm. (The remote alarm will not be stopped.)

If the alarm condition still exists, the buzzer will return to the alarm mode again

automatically 20 minutes later.

HYC-260/360 series does not have the remote alarm function.

Remote Alarm Terminals

HYC-290/390/390F/610/890/940/940F has remote alarm terminals:

Remote alarm terminals are installed on the

refrigerator and the alarm signal behind the

compartment is output by the terminals. The

bearing capacity of the terminals is DC 30V, 2A.

Terminal output:

Remote alarm terminals include NO, NC and COM.

COM

NO

NC

Handle

Pad lock

Door

lock

Door ajar

alarm switch

Light switch

Battery

switch

Control panel

USB port

The user can choose “NO” or “NC” if needed.

Solid door

Caster Leveling leg

30

15

Page 18

Alarm

HYC-610

Glycerin bottle for

temperature sensor

Light switch

Control panel

Interior light

Alarm or Safety

High

temperature

Low

temperature

Outage

Door ajar

Phenomenon

If upper temperature sensor or lower

temperature sensor perceives

temperature of the refrigerator ≥8℃

If upper temperature sensor or lower

temperature sensor perceives

temperature of the refrigerator < 2℃

Outage of the refrigerator

Outer door ajar or open

Open circuit or short circuit of

the upper temperature sensor

Alarm Indication

Alarm light flashes

Alarm light flashes

Temperature Display area

displays inside temperature

for 60s and stop displaying

for 60s, then repeat

Alarm light flashes

after 10 min delay

Alarm light flashes,

temperature display

area displays E1

Buzzing Alarm

Impulsive sound alarm

Impulsive sound alarm

Impulsive sound alarm

within 48h outage

Give impulsive sound

alarm after 10 min delay

Impulsive sound alarm

Handle

Door lock

Caster

Shelf

Door ajar alarm switch

USB port(Optional)

Temperature

recorder

Sensor

abnormities

Open circuit or short circuit of

the lower temperature sensor

Open circuit or short circuit of

the control sensor

Open circuit or short circuit of

the defrosting sensor

Alarm light flashes,

temperature display

area displays E2

Alarm light flashes,

temperature display

area displays E3

Alarm light flashes,

temperature display

area displays E4

Impulsive sound alarm

Impulsive sound alarm

Impulsive sound alarm

If alarm condition is not corrected within 20 minutes, buzzer and remote control

contact will restart.

IF there is a power outage, a fully charged emergency battery can keep the

alarm function in working condition for 48 hours.

Once the unit starts up and restarts after a long time in storage, charge the

battery for to keep the alarm function for 48 hours.. Even if the battery

discharges, remote alarm contact shall keep in working condition.

Press "Alarm Test " key. For each press, the buzzer goes off thrice with frequency

as 1Hz continuously. Meanwhile, the alarm indicator light flashes thrice and the

remote alarm relay is disconnected after pull-in thrice, which means the alarm

system functions normally.

16

Leveling leg

29

Page 19

1. If control buttons are not touched in 60 seconds, all changes of parameters will not

HYC-890

become effective. The previous settings are restored.

2. If the unit is powered off before the parameters are saved, the control parameters in

the RAM will be lost. The unit will retain the previous set up once the power recovers.

3. Humidity measuring range: 20 ~ 90% RH; humidity measurement accuracy: ± 5% RH

(40% RH ~ 80% RH); ± 8% RH (Others)

Door lock

Light switch

USB port

Control panel

Handle

Glass door

Caster

Shelf

Leveling leg

28

17

Page 20

HYC-940

Door lock

Light switch

Control panel

shows“1P” once again. Users can set 1P-5P again. After the setting, press the “Cal ” for 5s, and all s

ettings will be automatically saved. And then the display area of inner temperature shows the inner

temperature normally.

Note: during the said 1P-5P setting process, parameters can be specifically regulated via the

“Sensor ” (increase) or “Cal Cancel” (decrease) keys. For example,in the case that current display

area of inner temperature shows 1P (year), and the year (1P)and month (2P) need not regulation,

Handle

press the “Cal Cancel” to choose the date (3P) so as to reset the date directly. Then press the “Cal ”

and the display area of inner temperature blinks the date. Press the “Sensor ”(decrease) or

“Cal Cancel” (increase) to regulate the current date. And then press the “Cal ” to save it. After that,

the display area of inner temperature shows the hour (4P). If hour setting is necessary, press the

“Cal ” to regulate. Otherwise press “Cal Cancel” (increase) to enter the minute (5P) setting.Upon the

finish of setting, press the “Cal ” for 5s to save it and exit. Then the display area of inner temperature

shows the inner temperature normally. During the said 1P-5P setting process, after setting any

parameter, if other parameters do not need to set, press the“Cal ” for 5s to save it and exit.

Please checking the time before use, if the time is not right, follow the upper

method to adjust the time 。

Anti-condensation controller(HYC-890)

Anti-condensation controller intelligently operates the heating on the door and cabinet parameter to

prevent condensate from forming, using the environment temperature and the humidity as input

parameters. Therefore, in environment with high humidity, the heater in the door glass and

18

Glass door

Caster

Leveling leg

Shelf

parameter of the frame will be powered up.

Display description

The left panel window displays the temperature and humidity, and keypad is on the right side.

Display description is as follows:

It is 2-1/2 digital display, as shown in the right picture:

① Alarm symbol: displayed when alarming;

② Heating symbol: displayed during heating operation;

③ Defrost symbol: (not used);

①

②

③

④ Humidity symbol: displayed when checking humidity;

Humidity display range: 20 ~ 90% RH;

④

Modify control humidity

Three buttons “SET” ,“▲”,“▼” on the instrument are used for controller operation.

Press button “SET” for 1 second, display shows the current set operating point;

Use “▲” or “▼” to increase or decrease the set humidity value, until it reaches the desired value;

Press button “SET” for 5 seconds to confirm and exit setup.

27

Page 21

USB Function

Functions of USB interface

The computer has a USB function. Test data can be exported via the USB port. The computer can

automatically collect and store the test data within the recent 10 years. It collects data every other 6

minutes and stores them automatically. The latest data will automatically replace the earliest data

when the data storage is full.With a USB port plugged in, the computer will automatically identify it

and start to export data to the USB port.In the data exporting process, if you press “ Cal ” , the

screen will blink “ USb” , which indicates the data are now exporting and not finished yet. After

blinking 5s, it exits and displays the actual temperature in the case.If the displays “ ALL” stably, the

HYC-940F

Control panelLight switch

Door lock

data export is finished. It exits 5s later can displays the actual temperature in the case.The USB port

can be removed at this point. The exported data are in the following formats:

序号/No.

0

1

2

...

Time setting of USB interface data recording (time system current setting):

Press the “Cal” for 10s and the display area of inner temperature shows “1P” stably. Press the “Cal ”,

and the display area of inner temperature blinks the year. Press the “Sensor ” (decrease) or

“Cal Cancel” (increase) to choose the year. It displays 10 to 99 recurrently. For example, to set 2013,

choose 13 and press the “Cal ” to save it. And then the display area of inner temperature shows "2P"

stably. Press the “Cal”, and the display area of inner temperature blinks the month . Press the

“Sensor ” (decrease) or “Cal Cancel” (increase) to choose the month. It displays 01 to 12 recurrently.

When the current month comes out, press the “Cal ” to save it. And then the display area of inner

时间/Time

20130425

20130425

20130425

...

设定温度/Setting Temp.

5

5

5

...

箱内温度/Inner Temp.

5.6

5

4.9

...

Door ajar alarm switch

Handle

temperature shows “3P” stably. Press the “Cal ”, and the display area of inner temperature blinks

the date . Press the“Sensor ” (decrease) or “Cal Cancel” (increase) to choose the date. It displays

01 to 31 recurrently. When the current local date comes out, press the “Cal ” to save it. After that,

the display area of inner temperature shows “4P” stably. Press the “Cal ”, and the display area of

inner temperature blinks the hour.Press the “Sensor ” (decrease) or “Cal Cancel” (increase) to

choose the hour. It displays 00 to 23 recurrently. When the current local hour comes out, press the

“ Cal ” to save it. After that, the display area of inner temperature shows “5P” stably. Press the

“ Cal ”, and the display area of inner temperature blinks the minute. Press the “Sensor ”(decrease)

or “Cal Cancel” (increase) to choose the minute. It displays 00 to 59 recurrently. When the current

local minute comes out, press the “Cal ” to save it. After that, the display area of inner temperature

26

Caster

Leveling leg

19

Page 22

Control Panel

Calibration of Recorder

The temperature recorder has been accurately adjusted before leaving the factory even if the power

supply is interrupted. If there is a need to be adjusted, perform the following procedures.

HYC-260/360/290/390/390F/890/940/940F

HYC-610

1. Let the unit run for at least 2 additional hours after it reaches stable condition,

2. Place a standard thermocouple in the temperature solution bottle filled with 100 ml 10%

glycerol solution. Place the sensor of the temperature recorder into the sensor bottle as well.

3. Place the sensor bottle in the refrigerator for at least 4 hours. Compare the thermocouple

reading and the recorder reading. If there is a discrepancy, press the adjustment button on the

left (1#) or on the right (2#) of the panel to adjust the temperature value of the recorder so that

recorder reading matches the reading of the thermocouple.

Note: The recorder pen will start moving 5 seconds after the button is left out.

The recorder has been calibrated before leaving the factory. Do not make adjustment except in

special circumstances.

The recorder is optional for HYC-610 only, not available for others.

20

25

Page 23

Maintenance and replacement of the recorder's standby battery

When the recorder’s LED light blinks green, check the recorder performance as follows.

1) Remove the standby battery. If the LED light is off and the recorder stops working, the

main power supply of the recorder fails. Check the main power supply for connection and

any other issues. When the main power is available and the recorder starts working

Application method

Temperature display

This refrigerator has been set capable of reaching appropriate temperature (2~8℃) automatically

before delivery.

properly, Install the standby power supply. If the LED light stops blinking, it means the

standby battery is in good condition. If the LED light continues to blink, it indicates the

standby battery is low in power and it should be replaced. The green LED light will stay on

and the does not blink any more.

2) Remove standby power. If the LED light continues blinking and the recorder works

properly, it means the main power supply is in good condition and the standby battery is low

and should be replaced.

Replace recorder paper

Please follow the steps below for the replacement of recording paper:

1. Find the pressing button (3#) at the top left corner in the front of the recorder panel;

2. Press and hold the button (3#) for about 1 second till the recording pen begins to move toward the

left of the paper;

3. After the recording pen completely moves outside the recording paper, loosen the central bolt and

remove the old recording paper. When replacing a new recording paper, carefully align the timeline

on the paper to the time slot on the panel (there is a small indentation at the left of the panel);

4. Retighten the central bolt, press and hold the button 3# for about 1 second to make the recording

Display Temperature

Operation

1

2

3

4

Plug in, switch on power

Press Display

Temperature key

Press Display

Temperature key

Press Display

Temperature key

Key

Operation

Display

Average temperature

of monitoring bottle

up

Temperature of

upper monitoring bottle

up

Temperature of

lower monitoring bottle

up

Average temperature

of monitoring bottle

up

low

low

low

low

Light on

Display Mode

Average temperature

Temperature of upper

monitoring bottle

Temperature of lower

monitoring bottle

Average temperature

Light off

pen reset and start to record temperature;

5. Examine whether the recording pen is easy to use on the paper; if it is not easy to use, adjust the

crossbeam of the recording pen to make the nib contact with the recording paper. (Note: Do not

damage the nib and crossbeam. If it is difficult to be adjusted, use a screwdriver to dismount the

crossbeam. After bending the crossbeam with a little strength, install back the crossbeam and repeat

the above operations);

6. Ensure the accuracy of the recorder. Calibrate the preciseness of the recording pen after each

replacement of paper. Methods are set as follows: Press and hold the button (3#) till the recording

pen leaves the recording paper; then repress and hold the button (3#) till the pen get back to the

recording paper. At the moment, the pen will pause at the outermost temperature scale of the

recording paper (such a scale may not be marked with temperature value, but it is the outermost

scale). If the pen does not pause at the above location, you may utilize arrow key of 1# or 2# to

adjust the location of the pen within 5 seconds to make the nib aligning to the outermost scale.

Repeat step 6 if you do not complete the adjustment of the location of pen within 5 seconds.

5

The displayed temperatures indicate upper and lower temperatures of the refrigerator perceived by

the sensor in glycerin bottle. It is not always of 5℃. Temperature sensor indicates average temperature

inside the refrigerator.

Repeat operation from 2

24

21

Page 24

TEMP. SET

Temperature Recorder (optional)

If you want to reset the temperature, for example, 5℃ is set originally and you want to change the

temperature to 5.5℃, please operate according to the following steps:

TEMP. SET

Key Operation

1

The temperature in the refrigerator displays.

Display

The original temperature set value 5℃

Press both “Sensor” and

2

“Cal Cancel” for 5s at

the same time.

appears and flickers.(Please follow the

following steps in 5s since the value

flickers. Otherwise, the display panel will

return to the temperature in the refrigerator)

Click “Cal Cancel”

3

(0.1℃ higher/time) or “Sensor”

(0.1℃ lower /time)

The original temperature set value 5℃

changes accordingly, until the temperature

displayed on the display panel is 5.5℃.

The temperature value 5.5℃ stops

Chamber temperature recorder with 6 inch standard panel is optional for HYC-610 to record

chamber temperature change.

Installation and operation

To operate and use the recorder correctly, please follow the steps below:

1. Open the recorder door to see the recorder;

2. Switch on the 9V DC battery on top right corner of the recorder, the battery is standby power;

3. Check the recording paper. If it is necessary to replace the paper, please follow the operation

steps in P24;

4. Take down plastic cap of recording pen and close the recorder door.

The recorder will not work until the chamber temperature reaches record range of

the recorder.

9 volt battery

Chart Adjustment Buttons

Imprinting Stylus

flickering after being displayed and

After the demanded temperature 5.5℃

4

is set, stop the operation.

flickering for 5s and then is saved in the

system. After successful setting, the

display panel will display the temperature

in the refrigerator again.

Defrost Cycle

The refrigerator has two automatic defrost cycles.

1) Cycle defrost

To maintain a constant temperature inside the refrigerator, the refrigeration system cycles on and off

according to the temperature demand. When the refrigeration compressor cycles off, a small electric

heater is energized to thaw the frost off the evaporator surface. The function does not have an

obvious impact to the chamber temperature.

2) Forced defrost cycle(HYC-260/360/290/390/390F only have this funtion)

When the environmental humidity is too high or the products loaded into the refrigerator emit much

moisure, cycle defrost will not be sufficient to remove all frost and ice accumulated on the evaporator

Date Reference Mark

Chart Adjustment Buttons

Center Nut and Chain

Chart Paper

Power supply

When the storage box operates, the recorder normally use AC supply. If the AC power supply fails,

LED indicator light on the recorder will blink and give alarm to indicate abnormal power supply. The

recorder continues to record chamber temperature through standby battery supply. Each standby

battery supply can sustain power for nearly 30h (Note: The battery shall be replaced timely when the

battery is low to avoid corrosion of battery button caused by delayed replacement. To save battery,

please disconnect battery button when the storage box is not used. During normal use, please install

standby battery to ensure normal recording in case of power failure). LED indicator light of the

recorder blinks continuously until main power supply (AC) is switched on and its stand-by power

battery is replaced. When the standby battery is low, LED indicator light of the recorder blinks to

indicate that the battery shall be replaced.

surface. The equipment will start the forced defrost cycle. Once the frost is thawed, the refrigerator

will resume normal operation.

22

23

Loading...

Loading...