Page 1

User's Manual

HWM70-10A

Computerized Full-auto

Washing Machine

Multiple program for washing

Weeny adjustment of time and degree

Please read this manual carefully before using.

Retain it for future reference

Please check if the power receptacle has good earthing

condition before using to guarantee your safety.

The manufacturer will not bear the responsibility for

those risks occurred from not obeying this manual.

Contents

Before using

Names of the parts The 2nd cover

Safety precautions

Installation and adjustment

Install the water inlet hose 5

Using process

Preparation before washing

Put in the laundries

Put in 9

Use the operation buttons

Close the top lid

Finish washing

Disposal after washing 17

Trouble shooting *

Answers to questions 18

Specifications the back cover

detergent and softener

1

3

10

17

17

19

7

8

Page 2

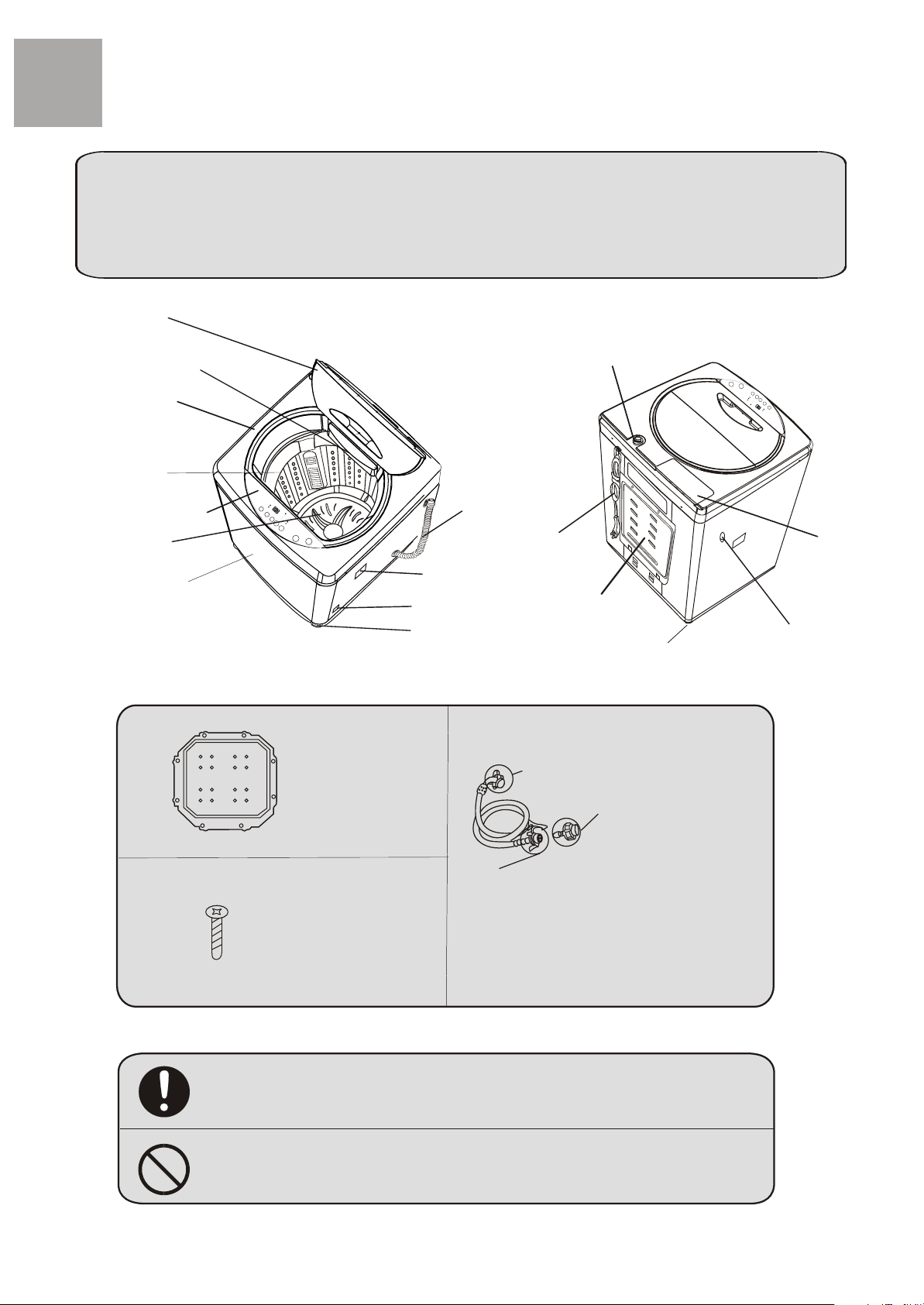

Names of the parts

Before Using

Honourable users:

Thank you for choosing our products.

Our products intergrade high-tech,precision,frontier science.

To facilitate using it,please read this manual carefully and operate this machine according to it.

Top lid

Scour container

Control panel

Inner tub

Control panel film

Pulsator

Cabinet

Accessories

Bottom plate

(one piece)

Water absorption cushion

Drain hose

Handle

Adjustable foot film

Adjustable foot

Power cord

Rear cover

Fixing foot(three)

the end connecting to the washing machine

jointer connecting the water

inlet hose and the water faucet

Decorative faceplate

Drain hose hanging hole

the end connecting to the water inlet hose jointer

Tapping screws

ST4X16

(eight pieces)

Meaning and description of the symbols

Contents marked with that symbol are related to the safety of the product and the personal

safety of the users. Please operate in strict conformity to the contents, otherwise it may

result in damage of the machine or influence the personal safety of the users.

Contents marked with that symbol are actions forbidden to perform. Performing of those

actions may result in damage of the machine or influence the personal safety of the users.

Water inlet hose

(one piece)

Water inlet hose joint

(one piece)

Page 3

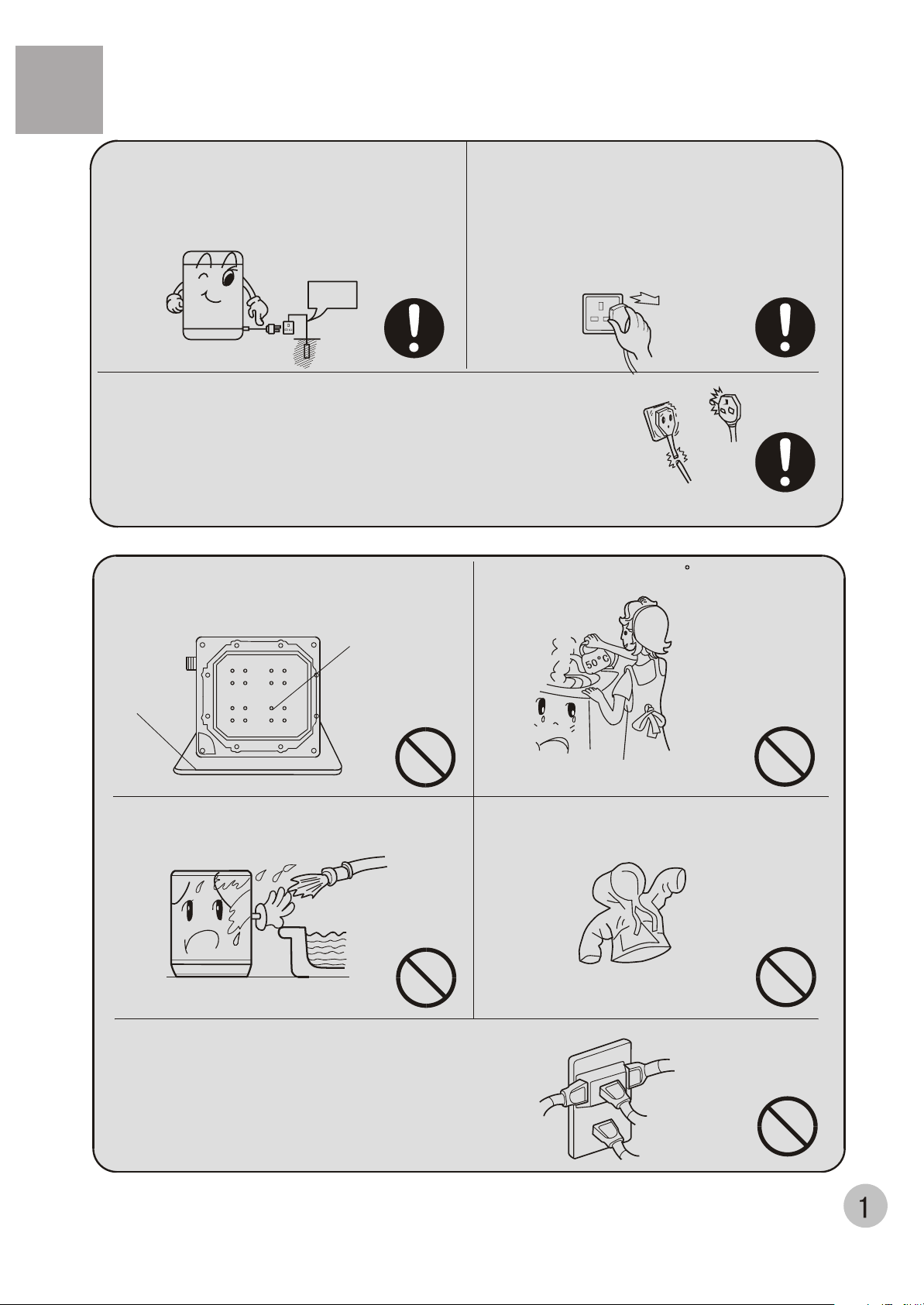

Safety precautions

Before Using

Before Using

Please plug the power plug on special

receptacle. Be sure to use three-pins

power receptacle. Ensure that the earthing

prong of the power receptacle is earthed

reliably. Use leakage protector if possible.

Earth

Do not bend, stretch, twist, bind the power cord by force,

or reform it. Do not press or clamp it with heavy items. If the

power cord and power plug are bad, or the receptacle is loose,

be sure to have it replaced by the technicians of our special shop

or our agent, or the after-sales service department for the sake

of avoiding any risk. Keep the prong of the power plug clean.

If dust is found on the power plug, please wipe it off with dry cloth.

In case the washing machine is installed on ground with

carpet, do not block the ventilation hole with carpet.

In normal usage of the washing machine,

the power plug shall be ready to be pulled

or plugged with hand. Be sure to pull the

plug off and close the water faucet in

following cases: power failure, delivering

the machine, setting the machine idle or

cleaning the machine. Do not plug

or pull the power plug with wet hand.

Do not use water hotter than 50 C .

The ventilation

holes at the bottom

Soft object

Do not put the machine at damp place like

the bathroom. Never wash it with water.

Do not let the machine share one receptacle with other electric

appliances. If the power plug plugging into the receptacle is

loose, do not use the plug any more.

Do not wash water-proof laundries like the raincoat,

bike covers etc. to avoid abnormal vibrations in spinning.

Page 4

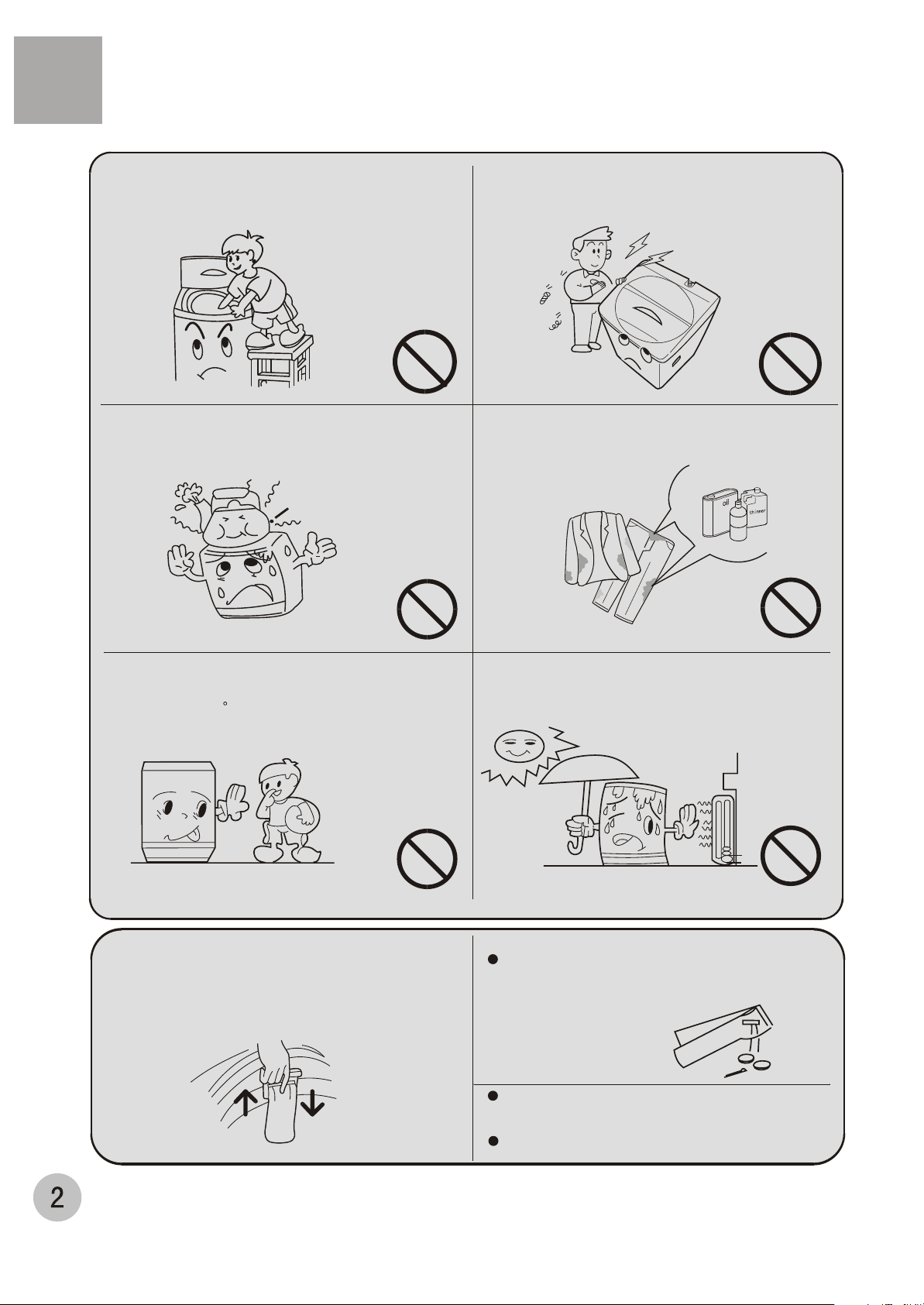

Safety precautions

Before Using

Do not stretch hands into the working machine.

It is dangerous even if the rotation is slow.

Take special care of the children.

Do not put any hot or heavy items (such as the kettle

with hot water) on the washing machine

Do not decompose, repair or alter the machine

by yourself.

Do not wash laundries with volatile materials

(such as thinner, petrol etc.).

Benzene

The handicapped or children without care shall not

use the machine.

The lint filter shall be kept in good condition, and

installed to proper position. If the lint filter is lost

or damaged, please contact the local after-sales

service department of our company.

Dismantle

Install

Keep the machine away from direct sunlight and

heat source like the heater.

To protect your laundries and machine, please

clear the pocket, take out the coins, sand,

hairpins etc before washing.

Please set down the drain hose, connect the

water inlet pipe and unbolt the water faucet.

Advice to use lower foamy powder.

Page 5

Before Using

Installation and adjustment

Before Using

Please install and adjust the machine according to the requirement of the manual.

It is very important to your security and correct operating the machine.

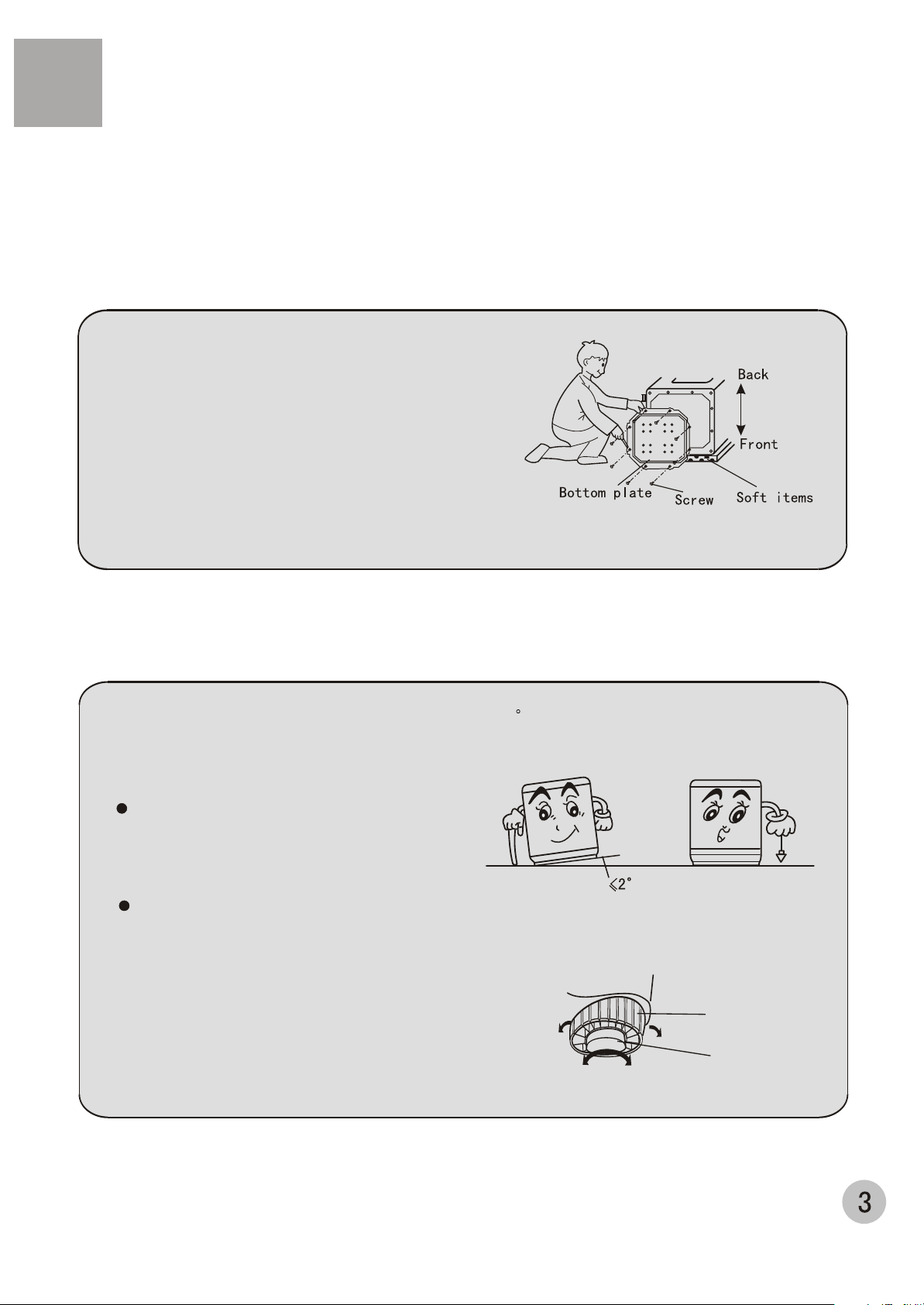

Install the bottom plate

After you open the package, please lean the washing

machine gently down on soft items (like the towel cloth,

blanket, etc.).

Install the bottom plate to the bottom of the machine

with the eight screws by a cross screwdriver, then

lift the machine up gently. See to the right Figure:

Adjust the Installation position

The largest allowed slope of the shank base of the machine is 2 . The slanting or rough ground will result in

unstable running or stoppage of the machine. Please adjust it with following methods:

Confirm it's horizontal

Hang the plumb to confirm it's horizontal

Adjust the adjustable foot

(1) To twist the adjustable foot at the right front of

the cabinet (front the sight of front), please first

lift up the side of the foot slightly, loosen the

adjustable nut, and twist the foot.

(2) Fasten the nut after adjustment.

Loosen

High

Low

adjustable nut

Fasten

adjustable foot

Page 6

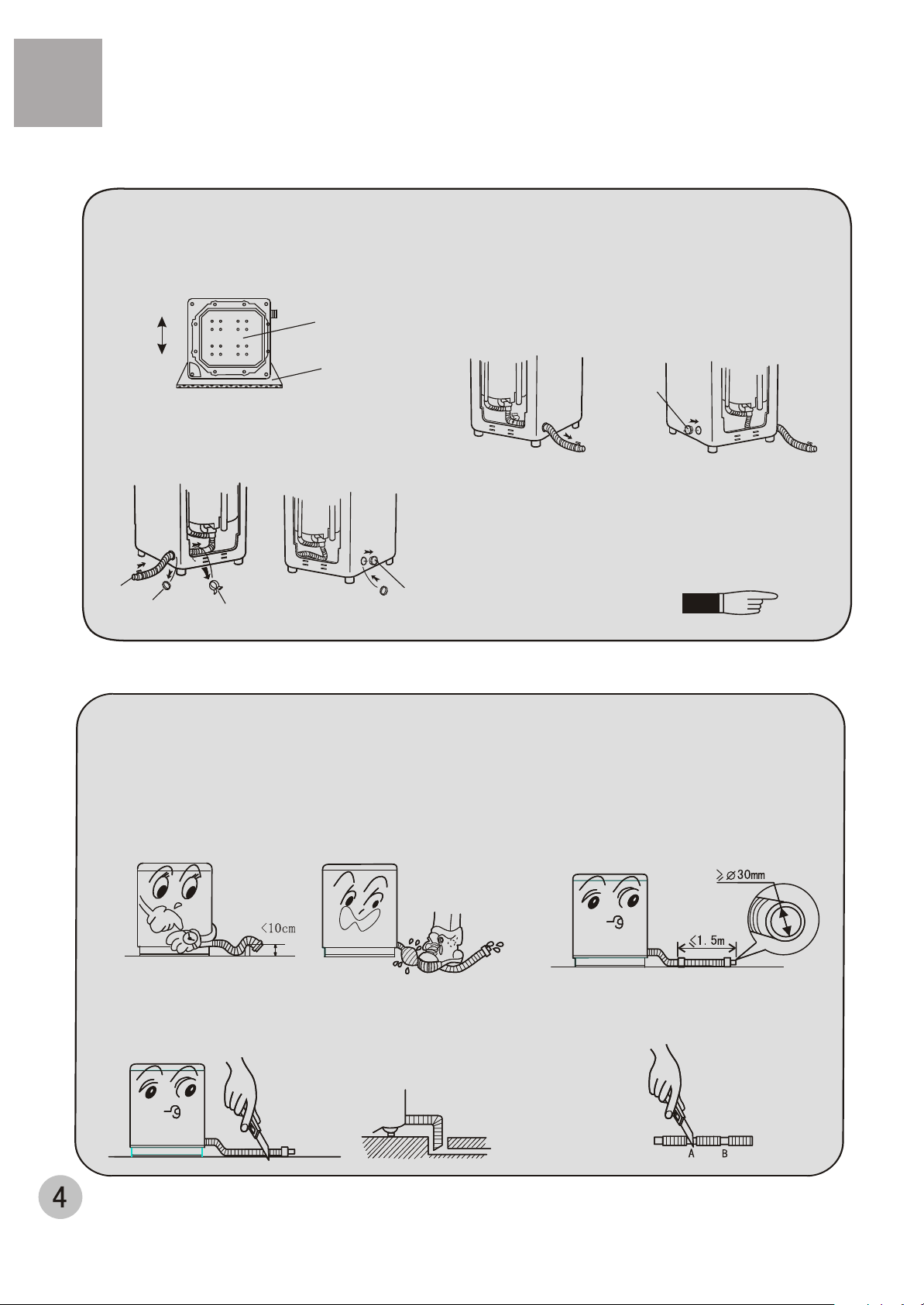

How to change the direction of the drain hose

Before Using

Before Using

1.Dismantle the rear cover of the washing machine.

2.Lean the machine down gently with the front

surface facing the ground. Loosen the eight

screws by a cross screwdriver.

Back

Front

Bottom

Soft item

3.Put down the drain hose. Take off the drain

hose nut and the drain hose frame as indicated

in Figure 1.Take the drain hose into the cabinet

as indicated in Figure 2.

Drain hose

Drain hose nut

Figure 1 Figure 2

Drain hose frame

Drain outlet protecting cover

4.Dismantle the drain outlet protecting cover at the

other side, and replace it with drain hose nut as

indicated in Figure 2.

5.Extend the drain hose from the other side. Fix the

drain hose with drain hose frame onto the cabinet

as indicated in Figure 3.

Figure 3

Figure 4

6.Install the drain outlet protecting cover to the other

side as indicated in Figure 4.

Install the bottom plate(method as described in page 3).

Lift up the machine gently. Then install the rear cover

of the machine.

Page 3

Usage of the drain hose

The drain hose shall drain smoothly

1.The height of the drain hose shall be

less than 10cm, or the drainage will not

be smooth, and cost such long time that

the machine may stop at mid way.

2.Do not ramp or press the drain hose.

3.If the drain hose is too long, cut it at mid

point. To make smooth drainage, cut the

front end of the hose slantingly.

4.If extra drain hose is needed, please

make separate purchase. The inner

diameter of the extra hose shall not

less than 30mm, and the length shall

not exceed 1.5m.

If the extra hose is too long, cut it

either at A or at B point.

Page 7

Before Using

Before Using

Before Using

Install the water inlet hose

Install the water inlet hose

Before Using

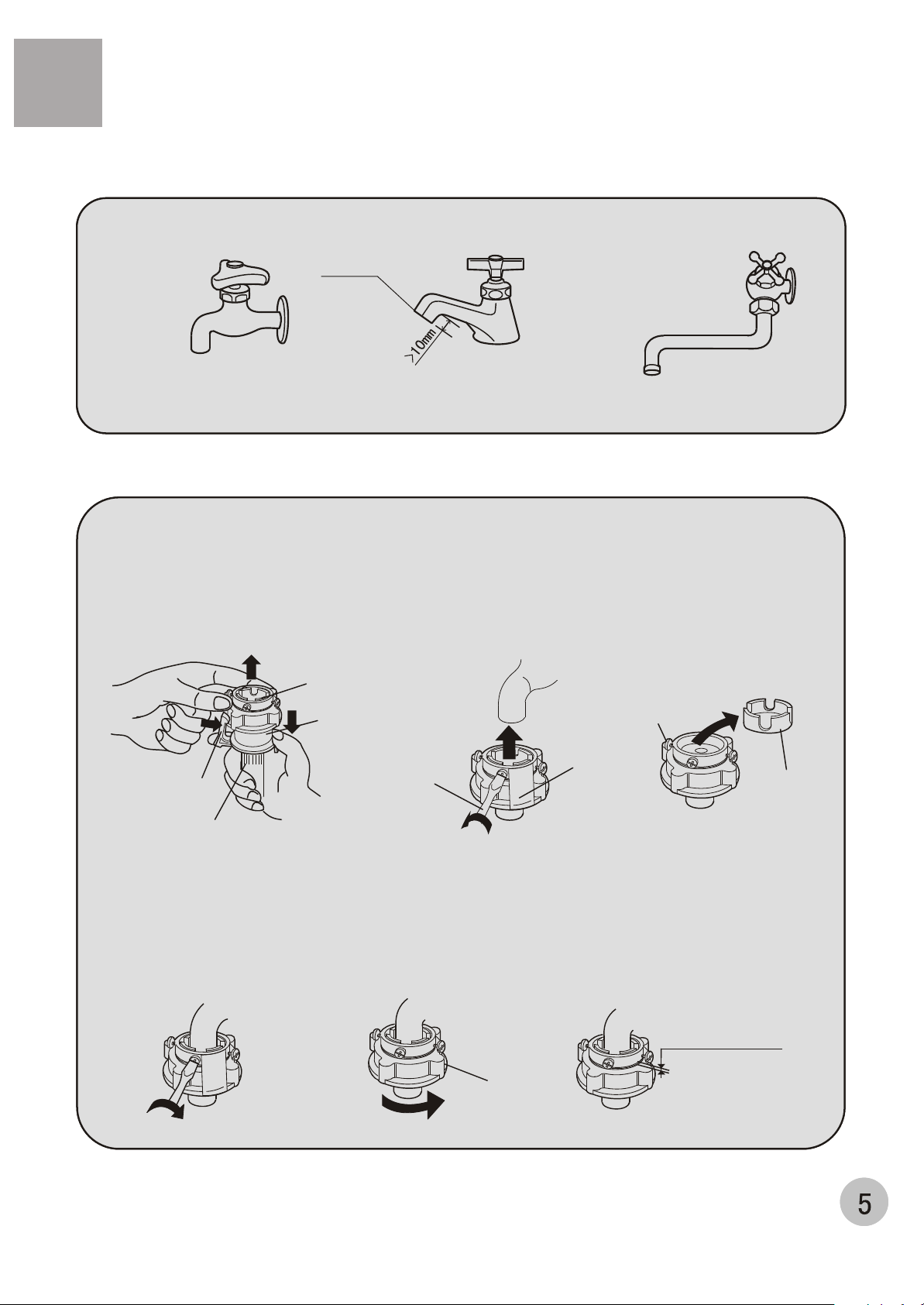

Confirm the water faucet

water faucet, suitable water faucet, not suitable

water faucet, suitable water faucet, not suitable

The exit end face of the faucet

The exit end face of the faucet

It is required that the front end shall be longer than 10cm.

It is required that the front end shall be longer than 10mm.

The exit end face of the faucet shall be flat and smooth. If not please file it to avoid leakage.

The exit end face of the faucet shall be flat and smooth. If not please file it to avoid leakage.

Connection between the water inlet hose jointer and the water faucet

1.Press the lower end of the lock lever and push down the slider. Take off the water inlet hose jointer from the

1.Press the lower end of the lock lever and push down the slider. Take off the water inlet hose jointer from the

water inlet hose component. See to Figure 1.

water inlet hose component. See to Figure 1.

2 Loosen the screw till the water faucet can be accessed. Put the jointer of the water inlet hose on the faucet.

2 Loosen the screw till the water faucet can be accessed. Put the jointer of the water inlet hose on the faucet.

See to Figure 2. (If the faucet is too large and the jointer can not be set on the water faucet, please loosen

See to Figure 2. (If the faucet is too large and the jointer can not be set on the water faucet, please loosen

the four screws and take out the bushing in the jointer. The front end of the faucet must be smooth,

the four screws and take out the bushing in the jointer. The front end of the faucet must be smooth, otherwise

it may leak water. See to Figure 3.)

otherwise it may leak water. See to Figure 3.)

water inlet hose jointerwater inlet hose jointer

water inlet hose jointerwater inlet hose jointer

Screw

Slider

Slider

Nameplate

Lock level

Lock level

water inlet hose

water inlet hose

3.Fasten the four screws evenly. See to Figure 4.

3.Fasten the four screws evenly. See to Figure 4.

4 Take off the nameplate. Twist the fastening nut as per the indication of the figure

4 Take off the nameplate. Twist the fastening nut as per the indication of the figure

to seal up the exit end face of the faucet. See to Figure 5.

to seal up the exit end face of the faucet. See to Figure 5.

Remark: .Before twisting the fastening nut, the threading is 4mm above the upper

Remark: .Before twisting the fastening nut, the threading is 4mm above the upper

surface of the nut. After twisting, the threading is less than 2mm above the upper

surface of the nut. After twisting, the threading is less than 2mm above the upper

surface of the nut. See to Figure 6

surface of the nut. See to Figure 6

Figure 4

Figure 4

Figure 1

Figure 1

Screw knife

Screw knife

Screw nut

Screw nut

Figure 5

Figure 5

Figure 2

Figure 2

Nameplate

Screw

Bushing

Bushing

about 4mm after twisting

about 4mm after twisting

About above 2mm after twisting

About above 2mm after twisting

Figure 6

Figure 6

Figure 3

Figure 3

Page 8

Connection between the water inlet hose and the washer

Before Using

Before Using

1.Do not take off the water absorption cushion. Please check if the

cushion is dropped or damaged before each usage. If it happens

please contact our after-sale department immediately.

2 Put the nut of the water inlet hose on the valve jointer.

3 Fasten the nut. Swing it gently to confirm if it's suitable.

jointer of the water inlet valve

nut of the water inlet hose

water absorption cushion.

Connection between the jointer of the water inlet hose

and the water inlet hose

1.Push down the slider. Insert the water inlet hose into the jointer.

2 Hang the lock lever to the jointer. Release the slider

till a click sound is heard.

Locking level

the jointer of the water inlet hose

Slider

Check the connection between the jointer of the water inlet hose

and the water faucet

1.Swing the hose gently to confirm if it is fastened stable.

2.After installation, open the faucet to check if it leaks.

3.Do not bend the hose with overstrain.

4.Before each usage please check if the connection

between the jointer of the water inlet hose and the

water faucet, and the installation of the water inlet

hose are firm, so as to prevent dropping from

improper installation position.

Dismantle the water inlet hose

1. Close the water faucet.

2. Press the locking lever. Push down the slider. Then pull of the water

inlet hose. If the machine is used frequently, the jointer of the water inlet

hose can be kept on the faucet to prevent damaging the fixing screw.

Locking level

Slider

Page 9

1 Preparation before washing

Preparation before washing

1.Connect the water inlet hose. Open the water faucet.

2.Confirm that the washing machine is earthed reliably.

Then insert the power plug into the receptacle. The

earth terminal shall not link to gas pipeline and

faucet water pipeline.

3.Put down the drain hose.

Pay attention to followings before washing the laundries

Using process

Using process

Check if

the laundries

has special

requirement

on washing

a. Check if the laundries are applicable for washing with machine.

b. Divide the laundries that are not colorfast from other laundries.

c. Put those laundries difficult to absorb water into water with hand.

d. For those laundries with heavy soil, please first remove the dirt like mud or dust.

For the parts with heavy soil, please apply detergent on them in advance, which

can make it easier to remove the soil.

e. For those laundries that may get lint ball and those with long fur, turn it over before

putting in.

f. Do not put those laundries polluted by chemicals into the washing machine directly.

g. For those small laundries and those may get twisting or worn, and those woolen/fur

laundries, please put them into mesh bag before washing.

Clear the

pocket. Take

out the coins,

sand, hairpins

etc.

Tie the long

strips; fasten

the buttons;

close zippers.

The quantity of

the laundries

shall not be too

large. Stretch

and loosen the

laundries before

putting them in

the tub.

When the pulsator

is running , the

buttons of the

laundries may

cause noise. For

the sake of

discretion, please

put the laundries

with buttons into

other laundries.

Page 10

2 Put in the laundries

The capacity of washing and spinning of the machine

refer to the largest weight of the standard laundries

under dry condition that can be washed or spinning

in one time. One time washing quantity shall be

lower than the rated capacity. The largest capacity

of this machine is 7.0kg.

The thickness, size, type of the cloth will influence the

actual washing capacity. It is suitable for one time

washing to put in reasonable amount of laundries

and the laundries can be turned round in washing.

Do not select high water level for laundries small

than 2.5kg, so as to avoid splashing of water.

When washing fleecy laundries such as carpet, please

control the quantity of laundries below than 3.0kg.

Using process

Using process

Reference weight of the laundries:

working suit up,down

cotton,about 1120g

blanket

cotton,about 900g

pajamas

about 200g

Shirt

cotton,about 300g

jeans about 800g

blending coat

about 800g

jacket

cotton,about 800g

single bed sheet

cotton,about 600g

undershirt

cotton,about 180g

underpants

cotton,about 70g

socking

blending,about 50g

Page 11

3 Put in the detergent and softener

Using process

Powder detergent entrance

close

Detergent container

How to use the whitener

Fill water to decided level .Dilute the whitener with

container. Pour it slowly into the washing tub.

Avoid using whitener on laundries with colour or

pattern as they are prone to lose colour.

The whitener shall not touch the laundries directly.

Refer to the user's manual for the usage and

quantity of the whitener.

For powder whitener, please dissolve it before use.

Usage of softner and its quantity is according to

the instruction of softener

open

Softener entrance

Put the detergent and softener into the

detergent container, see to the left figure.

Then close the detergent container surly.

Quantity of detergent is according to the

following table.

How to use the washing powder

Direct dissolved in the machine(not applicable for fuzzy

and reserve programs)

1.Fill small quantity of water.

2.Add the power. Run for 30 seconds to dissolve

it completely.

3.Put in the laundries. Select suitable water level.

The instant dissolving of the washing powder:

1. Prepare warm water of 30 and a container.

2. Add the powder while stirring to fully dissolve it.

Please add powder according to the quantity of laundries

and the water level, water quantity you selected.

It is suggested not to use high sudsing detergent.

Washing power with poor quality or not used for a long

period may get blocked. Please clean the detergent box

in time.

The consumption of washing powder is different with

different kind of powder, which is according to the

using explication of washing powder.

Selection of water level, water quantity and powder quantity

Laundries

quantity

(kg)

Water

level

High

Medium

Low

Water

quantity

About56

About52

About49

About46

About43

About

About36

About

About28

About

About20

About

Common powder, Concentrated powder,

Add 40g in each 30L water

About

About69.3

About65.3

About

About57.3

About

About48

About

About37.3

About33.3

About26.7

About

Add 25g in each 30L water

About

About

About

About38.3

About35.8

About

About

About26.7

About

About20.8

About16.7

About

Page 12

4.Push the operating button

RESERVE

WATER LEVEL

SOAK

WASH

RINSE

SPIN

RESERVE

a

Function of operating buttons

Digital tube

State and signification of indicator light

The frame of indicator is not lighted.

the frame of the indicator is flashing : indicate the running program.

the frame of the indicator is on : indicate the program about to run,

or indicate the selected mode

the frame of the indicator is flashing rapidly: indicate abnormal condition.

Funny adjustment of time and degree, when

selecting water level, it displays parameter

During working , it displays the remained reserve time (min).

During reserve, it displays the remained reserve time (h)

In case of trouble, it displays the abnormal symbol

(see to page 16)

Using process

Page 16

RESERVE button

During operation, the digital tube will display

the remained time before finishing in minute.

Push the reserve button. The digital tube will

display the reserve time for finishing of washing

in hour. The indicator will flash to indicate that

the reserve function is working.

WATER LEVEL button

You need to select the water level by yourself. During the working state,

if you want to select water level, you must push START/PAUSE button

firstly and then select water level.

If you put in wet laundries, you need to select

suitable water level manually. Refer to

Selection of water level, water quantity

and powder quantity in page 9.

In selecting the quick wash program, VFD displays 10 (min) ,the

water level is set to 2 automatically. When the 2 is reached, it

will do washing while filling water. When 4 is reached, it will

perform normal washing.

Due to the variable cloth and humidity, the set water level may be

different from the actual water level. Sometimes it may perform

water adding.

During washing, push the water level knob to add water.

Page 9

PARAMETER SETUP button

Set up the parameter of different procedure, that is

setting up soak time(min), wash time(min), rinse

times(time), spin time(min).

Remarks: pushing PARAMETER SETUP button, the

machine comes into self-programme function, push

PROGRAM button to select SOAK, WASH, RINSE

OR SPIN procedure , when referring soak time,

wash time, rinse degree or spin time is displayed

on VFD, then you can push PARAMETER SETUP

button to adjust soak time, wash time, rinse degree

or spin time by yourself. After pushing

START/PAUSE button to start the machine, you

can not set up the parameter of different procedure.

Page 13

Using process

Using process

START/PAUSE button

After the power is switched on, push it to start the machine

During working, push it to pause working.

During pause, push it to resume working.

POWER ON/OFF button

Push the "On/Off" button to switch on the power.

When the power is on, push it again to switch off

the power.

After the power is switched on , if the washing machine is idle

for 10 minutes, it will switch off the power automatically.

PROCESS button

one or more programs among soak wash

rinse spin can be selected.

Pushing PARAMETER SETUP button, times

of soak, wash, rinse or spin can be selected.

PROGRAM button

The following four programs are available.

Program Available status

Common washing

Jeans

Gentle

Quick

Washing large , thicker ,

or heavily soiled laundries

Washing woolen textile

or underwear

10-minute quick wash for the

laundries with under 3 kg

Page 14

Using process

Using process

Steps of using the operation buttons and description of the steps

b

Push the POWER ON/OFF button to switch on the power.

Push the PROGRAM button to select the suitable automatic program.

After switching on the power, the machine will set to standard program automatically. To select other program, push the

Program button till the corresponding indicator is on. Refer to the Program button in Page 11.

Page 11

For an example: select quick wash for the quick washing of the laundries with light dirt.

Push PROCESS button to select suitable procedure

After switching on the power, the machine will set to WASH-RINSE-SPIN program automatically. That is the most

common program. To select other program, push the PROCESS button to select one or more procedures

among SOAK WASH RINSE SPIN .

Refer to the in Page 13 for the selection.selection method of procedure programs

Page 13

Page 15

NOTES

The machine will begin to spin for a period of

time even though there is no water in inner tub.

Do not select Soak program when washing haircloth.

Take apart the clothings depigmenting easily from others.

If the affusion can not reach the scheduled water level, the pulsator does not work.

Selection method of the procedure programs

Using process

Times of pushing

the PROCESS

button

If you push the process button for 6 times, it will resume the initial mode, and it will circulate in that way.

The soak program can be used as fitting of the standard/jeans automatic programs.

It will do soaking with intermittent stirring of pulsator.

If you select the Gentle program, you can select Wash, Rinseand Spin discretionarily

If you select the Quick program, the machine perform Wash, Rinse and Spin process automatically, you can not

select process discretionarily.

Selected procedure

program

Wash, rinse, spin

(standard program)

Wash (the washing liquid

remains in the tub)

Wash (the rinsing liquid

remains in the tub)

Rinse, spin

Spin

(spin after drain)

soak wash, rinse, spin

Applicable procedure

When the common laundries need

washing , rinsing and spinning

Repeat using the washing liquid

Repeat using the rinsing liquid

When the laundries need rinsing and

spinning after hand washing

When the laundries only need spinning

after hand washing(first spin then drain)

If the laundries are very dirty, or the sleeve

and collar are dirty, first soak then wash

Contents (the lighted indicators

indicate the programs about to run)

Soak

Soak

Soak

Soak

Soak

Soak

Wash

Wash

Wash

Wash

Wash

Wash

Rinse Spin

Rinse Spin

Rinse Spin

Rinse Spin

Rinse Spin

Rinse Spin

4 Push the WATER LEVEL button to select suitable water level

After switching on the power , If you want to select water level yourself, please push

WATER LEVEL button before your pushing START/PAUSE button. If you want to

select other water level during the working state, please push START/PAUSE button

firstly and then push WATER LEVEL button to select proper water level. Referring

to standard dosage of the detergent and water quantity in page 9 and WATER LEVEL

button in page 10 to select.

Page 9

Page 10

Page 16

Time list of each program

Using process

PROGRAM

NORMAL

JEANS

GENTLE

QUICK

WATER

LEVEL

~

~

~

SOAK

(MIN)

about15~25

about20~30

WASH

(MIN)

about10~15

about10~15

about

about

RINSE(MIN)

Rinse twice , each about 2

Rinse twice , each about 2

Rinse twice , each about 2

Rinse once , about 2

SPIN

(MIN)

about6

about6

about3

about2

Total time of common process(MIN)

Excluding SOAK

about36 41

about36 41

Including SOAK

about51 66

about56 71

about25

about10

* Total time: including the normal water filling time, drain time.The water level and pressure of water filling will affect

the finishing time.

* Spin time: the time from intermittent running to finishing.

*If the SOAK program is selected, the machine will set the washing program of SOAK, WASH, RINSE and SPIN.

* If QUICK procedure is selected, the machine will set the complete washing program of WATER LEVEL,

WASH, RINSE and SPIN automatically.

Push the PARAMETER SETUP button to set up the parameter of processes

Pushing PARAMETER SETUP button, parameter of the first process your selecting is displayed

(relevant indicator light blinks) Push PROCESS button to select your preconcerted process

(relevant indicator light blinks), then we can push PARAMETER SETUP button to set up the

parameter according to us(Refer to PARAMETER SETUP button in page 10) and

TIME REMAINED will be displayed after three minutes .

Page 10

Step 5 is necessary for setting up parameter ourselves, if you will not use this function ,

please jump to step 6.

P

ush RESERVE button to select proper preconcerted washing time

After switching on the power, preconcerted washing program is defaulted closed state, when you want the

wash finishing in your preconcerted time, please push RESERVE button to set up proper

finishing time. Refer to RESERVE button in page 10.

Confirmation of operating RESERVE program

Page 10

TIME REMAINED(MIN)

After starting up RESERVE, relevant indicator light blinks and TIME

RESERVE(HOURS LATER)

REMAINED that indicate the time to finishing wash

After starting up RESERVE, if you want to change the program or

Washing will be finished for about 18 hours later

WATER LEVEL DISPLAY

cancel RESERVE, please remember to switch off the power and set up again.

Push the START/PAUSE button

SETTING DISPLAY

Page 17

c

Example of self-programme function

Using process

Push the POWER ON/OFF button to switch on the power.

Push the PROGRAM button to select the suitable automatic program.

After switching on the power, the machine will set to standard program automatically. This example

will be according to the standard program

Push PROCESS button to select suitable procedure

After switching on the power, the machine will set to WASH-RINSE-SPIN program automatically.

This example will be according to the procedure of WASH,RINSE,SPIN.

4 Push the WATER LEVEL button to select suitable water level

After switching on the power ,You can push WATER LEVEL button to select water level yourself.

.Please select water level before starting your machine. During the working state, if you want to

select water level, you should push START/PAUSE button firstly and then select water level.

We will select 6 water level in this example.

Page 18

Using process

Push the PARAMETER SETUP to set up the parameter of each program

Pushing PARAMETER SETUP button, the machine turn into programme function, where we

assume that you set up the spinning time 6 min. When the WASH light blinks, push PROCESS

button until the SPIN light blinks, and then push the PARAMETER SETUP button until 6 is

displayed on the digital tube.

Push the RESERVE button to set the proper finishing time of wash.

After switching on the power ,RESERVE program is defaulted in locking state ,where we assume

that you would not setup the RESERVE function, that is the relevant indicator light does not blink.

Push the START/PAUSE button

The above programme function is based on the tolerant STANDARD program ,with which the setup

of this function based on other program is the same.

When you set the soaking time,please push the PARAMETER SETUP button before selecting the

SOAK process, when the relevant indicator light blinks.

After pushing the PARAMETER SETUP button to turn into programme function, the indicator light of

relevant process which is selected blinks. If we do not push the PARAMETER SETUP or PROCESS

button in 3 min , the relevant indicator light will not blink and the programme function abate automatically.

Parameter range of each program and process(min)

JEANS

about0~35

about0~20

about0~4

about0~8

GENTLE

about0~20

about0~4

about0~8

Soaking time

Washing time

Rinsing time

Spinning time

STANDARD

about0~35

about0~20

about0~4

about0~8

Soaking time adds from 0 to the max 35 and then returns to 0.

Washing time,rinsing time and spinning time add from 0 to the max and then return to 0.

When the digital tube displays - - ,which indicates the number is 0.

Page 19

5 Close the top lid

If we open the top lid during the working state, the machine will stop working

Using process

6 Finish washing

When the wash finishing, the power will be switched off automatically.

When the wash finishing,

the machine will give

an alarm automatically

7 Disposal after washing

After using, please clean the lint and foreign materials of the lint filter etc. in time. Otherwise it may influence your using the machine.

Please first pull off the power plug from the receptacle before cleaning.

Clean the detergent container clearly, then

insert it into the control panel seat.

disassemble Install

The filter screen of the water inlet valve is likely to be

blocked by foreign materials and influence the water inlet.

Please clean it with brush every two months.

The lint filter must be used during washing.

It must be cleaned in time after each using

disassemble Install

If the cabinet is dirty, wipe it with wet cloth

Do not flush it directly with water.

Wipe it with neutral detergent.

Do not wipe it with thinner, petrol, alcohol etc.

Petrol

hinner

T

Alcohol

disassemble

1.After washing, close the water faucet. ( If needed, you can dismantle the water inlet hose).

2.Do not store water in the washing machine for a long period. Drain the water completely after each using.

3.Be sure to pull off the power plug before maintenance.

4.Hang up the power cord and drain hose.

5.Wipe off the water drops on the surface of the machine and inside the tub. Open the top lid for some time (about 1 hour),

then close the top lid.

Page 20

Trouble-shootingAnswers to questions

Trouble-shootingAnswers to questions

Trouble-shootingAnswers to questions

Trouble-shootingAnswers to questions

(If there's breakdown, please pull off the power plug before checking) The following phenomena are not breakdowns sometimes.

Please confirm again before sending it to repair. If there are real breakdowns, please come to the special maintenance department

or after-sale service department of our company. Do not repair it by yourself.

Phenomenon Reason How to solve

It rings after starting the reserve

function. The digitron displays E0.

The drainage cannot work, or is too slow.

The digitron displays E1 and it rings.

After washing and rinsing, it stops

running during spinning. The

digitron displays E2 and it rings.

The safety switch acts, and the

spinning cannot work (after twice

automatic imbalance revising). The

digitron displays E3 and it rings.

The water inlet does not work, or is

too slow (cannot reach the water

level after about 15 minutes). The

digital displays E4 and it rings.

The cascade current is poor or

there's no cascade current.

The machine

does not act.

There's abnormal sound inside

the machine

Not wash

Not spin

The top lid is opened.

Is the drain hose blocked?

The top lid is not closed.

Are the laundries put slantingly?

Is the machine slanting?

Is the water faucet opened, or is

there water supply failure?

Is the water inlet valve blocked?

Is there foreign material blocking

the spray outlet?

Is there power failure?

Is the power plug inserted tightly?

Is the water level reached preset

position?

Is the power plug inserted tightly?

Is the top lid closed reliably?

Are the laundries set flat?

Is the machine slanting?

Are there any foreign materials?

Are the laundries put slantingly in

spinning?

Close the top lid.

Clean the foreign material. Push

the start button again.

Close the top lid.

Reorder the laundries. Close the top lid.

Set the washing machine horizontally and

then open and close the top lid once.

Open the water faucet. Push the

Start/Pause button again.

Clean the water inlet valve then push the

Start/Pause button again.

Clear the foreign material.

Please use it when there's power supply.

Insert the power plug tightly.

Fill water to the preset position.

Insert the power plug tightly.

Close the top lid.

Set the laundries flat.

Adjust the machine to be even

Remove the foreign materials.

Reorder the laundries and close the top lid.

The water faucet leaks water

No water inlet.

Is the screw of the water inlet hose

jointer loose?

Is the screw of the water inlet hose

jointer twisted awry?

Is the power plug plugged tightly?

Is the water faucet opened?

Are the POWER ON/OFF and

START/PAUSE buttons pushed down?

Common phenomena

Phenomena Explanation

The spinning is intermittent when it starts.

Push the PROCESS button to select SPIN, but it doesn't work.

The pulsator pauses during water inlet in wash and rinse.

There may be some water flowing out of the drain hose in the first

use of the machine.

Fasten the screw of the jointer properly.

Plug the power plug tightly.

Open the water faucet.

Push the power ON/OFF button and

START/PAUSE button.

Balance the laundries to avoid slanting.

The program is setting the drain time. Some time is needed

before it starts spinning.

It is to avoid splashing during water inlet.

It is the water remained in the factory inspection of performance.

Page 21

Packing list

Name

User s manual

Lint filter

Water inlet hose

Bottom plate

Tapping screw ST4X16

Computerized Full-auto washing machine

Quantity

One

One

One

One

eight

One

Page 22

Specification

Type

Rated voltage and frequency

WATER LEVEL/QUANTITY (about)

Large consumption of water

Rated washing capacity

Rated spinning capacity

Rated washing input power

Rated spinning input power

Affusion hydraulic pressure

Weight

Dimension (mm)

XQB70-10 A

220V-240V 50Hz

1/15L 2/20L 3/25L 4/28L 5/32L 6/36L

7/41L 8/43L 9/46L 10/49L 11/52L 12/56L

About 168L( standard program with high water level)

7.0kg

7.0kg

360W

260W

0.03Mpa 0.78Mpa

About 39kg

L610mm W560mm H980mm

Loading...

Loading...