Haier HRF-488FR/A Parts Manual

Parts & Service Manual

Top Mounted Refrigerator

Model:

HRF-488FR/A

MARCH 2013

2

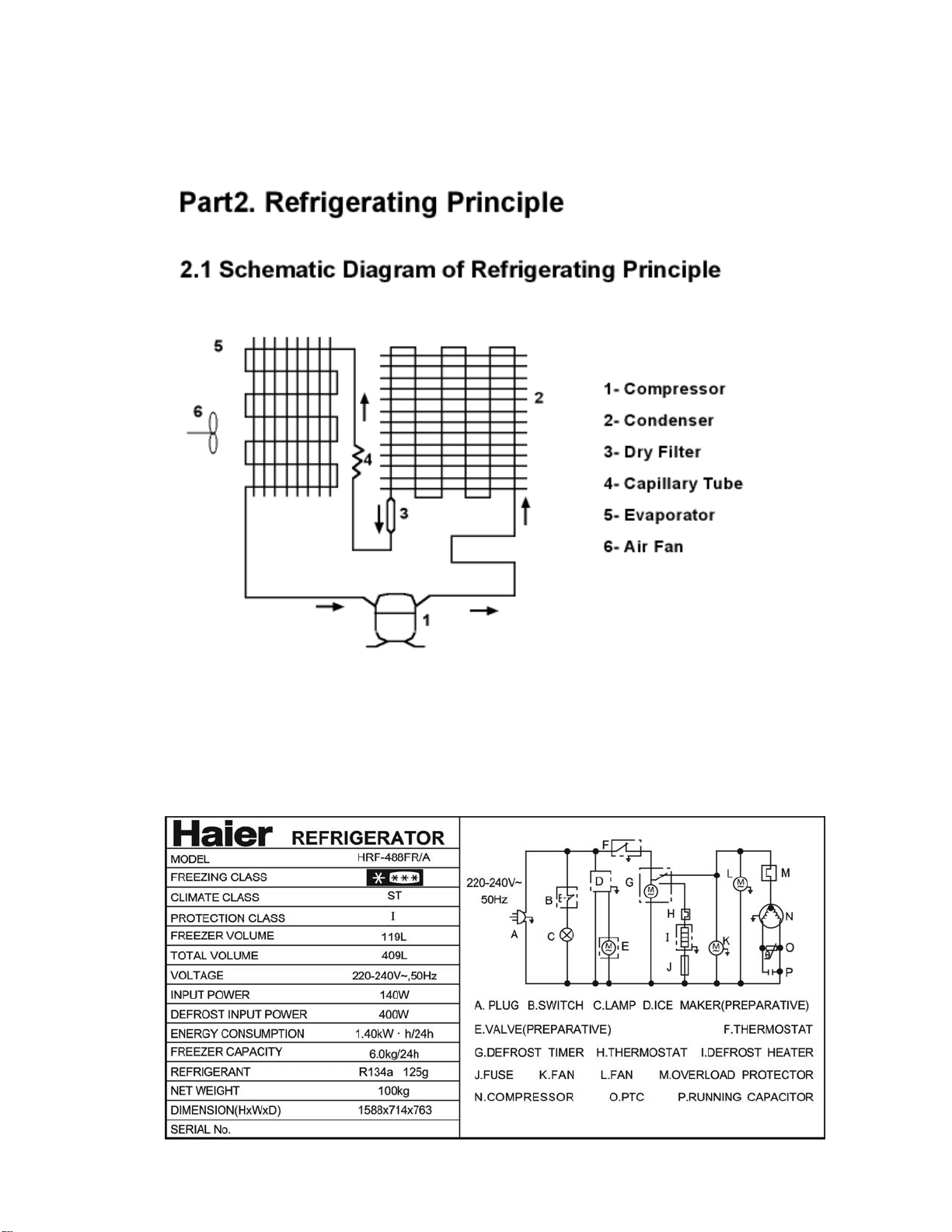

MODEL HRF-488FR/A(BCD-409WD)

Part1.Specifications

Model HRF-488FR/A

BCD-409WD

Cavity Supply(V/Hz) 220-240~/50

Power Consumption(kW•h/year)

Unit Dimensions (WDH)(cm) 76.3 X 158.8X71.4

Unit Weight(Kg) 100

Box Dimensions(WDH)(cm) 84.5 X 162X79

Box Weight(Kg) 107

Box Cubic(Cubic Feet) 45.1

Container Quantity(40’Hc) 41

Specifications are subject to change without prior notice.

550

2

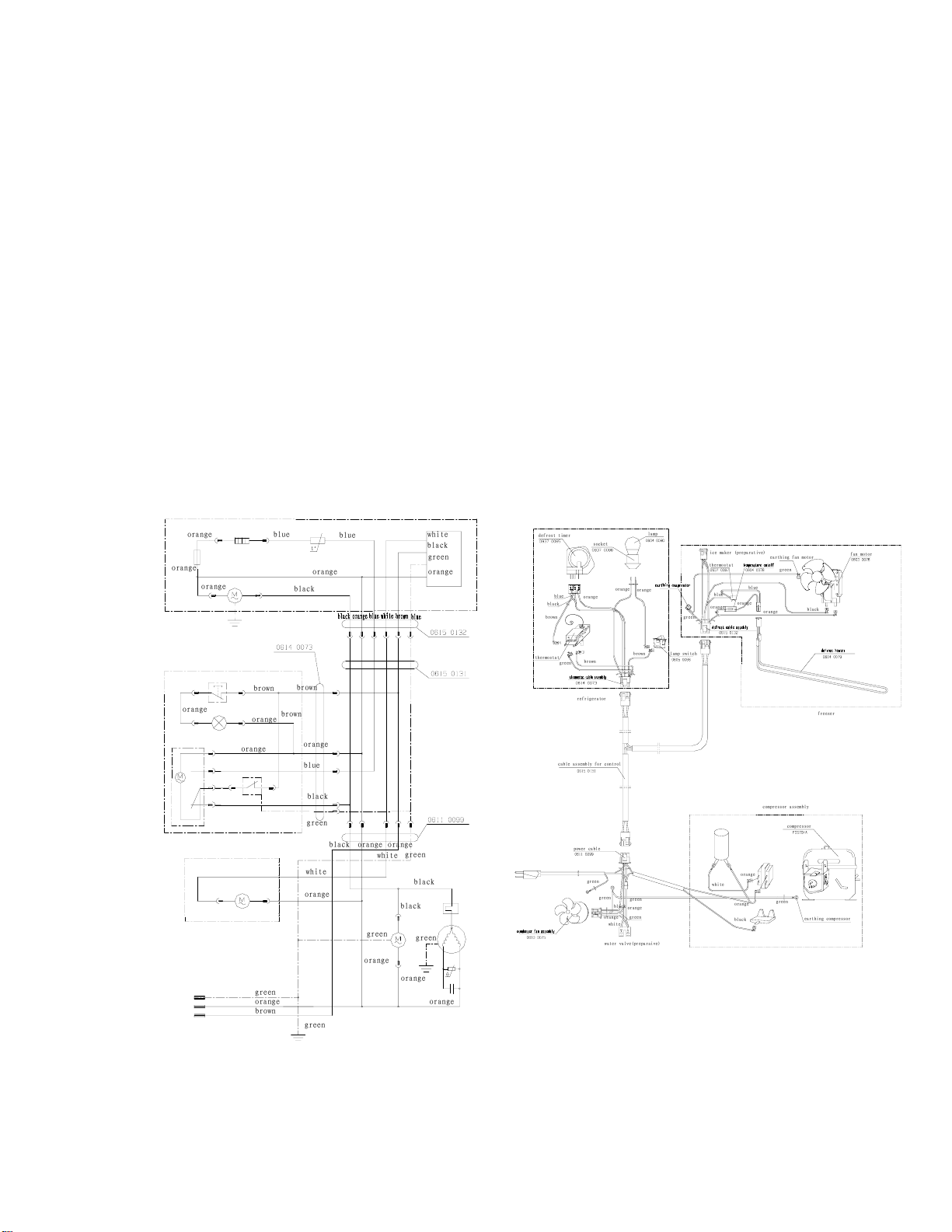

Part3. Principle of Electric Control

Schematic Circuit Diagram

3

Brief Description of Control Principle

HRF-488ER/A is the forced air cooling refrigerator with two doors.

A mechanical type of all the control is generally adopted. The

thermostat directly controls the start and stop of compressor, and

hence the refrigerator temperature.

Low Temperature Compensation in the above schematic diagram,

When the ambient is below the set temperature, the switch will be

closed and the heating will work, thus ensuring the normal start, and

operation of refrigerator at lower ambient temperature, in such case,

the freezer compartment temperature can reach a good point.

orang

orang

e

e

orang

e

blu

e

orang

blu

e

e

black

white

black

green

orang

lam

defrost timer

socke

t

e

blu

e

orang

black

brown

e

p

ice maker (preparative)

thermosta

orang

e

orang

e

blu

e

orang

e

green

earthing fan moto

t

green

blu

e

orang

e

orang

e

fan motor

r

black

orang

brown

thermosta

t

brown

green

brown

brown

e

orang

orang

brown

e

orang

e

e

blu

e

refrigerato

r

cable assembly for contro

l

lamp switch

freezer

black

orang

black

orang

e

compressor assembly

e

green

compresso

r

earthing compressor

green

orang

brown

green

orang

green

orang

e

white

black

e

green

black

green

power cable

green

green

orang

white

water valve(preparaive)

green

black

orang

e

green

e

white

e

orang

e

orang

e

black

orang

white

orang

e

e

green

4

Part6. Troubleshooting and Repair

6.1 Normal Phenomena—Not Troubles for Refrigerators

In a domestic refrigerator, there is not only a complicated electric control

system, but also a refrigerating system that is difficult to discern whether it is in

a good working condition. Both the systems are related and affect each other. If

a certain part of a refrigerator works abnormally .Its refrigerating efficiency will

decrease, operation properties will become unstable, or even it cannot be used

normally for those serious cases.

Refrigerators are generally of larger volume, once troubles appear, to send them

to a service department is really a tough thing, if such is the case, the user will

always be in suspense, sometimes, normal phenomena will be erroneously

regarded as troubles. Therefore, before we deal with the topics of frequently

occurring troubles of refrigerators and their remedies, we should firstly give a

brief account of some normal phenomena which are not troubles .In case any

one of such phenomena occurs, there is no need to worry about it, and the user

can use it at total ease.

1). When the compressor of a refrigerator has just stopped running, a rumbling

sound can be heard from inside its evaporator. This is a sound caused by the

flowing of refrigerant in the evaporator tubing. Because the pressure difference

is still greater after the compressor has just stopped running, the refrigerant will

flow for a certain time; therefore, this sound is a normal phenomenon.

2). A click sound can often be heard from the refrigerator. This is a normal

sound produced by the pull-in or release of the armature of a current deadweight

start relay when starting the compressor .The compressor motor will produce a

slight and uniform sound while it is running. This sound is not easy to be heard

in the daytime, but of course it can be heard distinctly at night.

3).The compressor consists of an electric motor and a compressing

apparatus .During its normal operation ,the motor’s stator core and windings

will rise to a temperature in the range of 100

the piston and cylinder of the compressing mechanism can also reach as above

100

radiates to the air through the compressor casing ,therefore ,its casing is

due to the heat produced when compressing refrigerant .Most of the heat

~110 ,and the temperature of

generally at a temperature between 85

summer when the ambient temperature is higher .All these are normal

phenomena .

~90 ,it is very hot ,particularly in

9

4). For the forced air cooling refrigerator, a kind of irregular crack sound can be

often heard when the compressor is running for a certain period of time or has

just stopped its running. The stress relief due to expansion and contraction

causes this sound when temperature changes, and will not affect the normal

application of refrigerator.

6.2 Common Troubles in Refrigerators and Their Remedies

Causes for troubles occurring in refrigerators are closely related to the quality of

components and workmanship in assembling by manufacturers as whether

refrigerators are properly used and maintained .The parameters generally used to

express the working conditions of a refrigerator include the temperature inside

the refrigerator, operation rate, electric power consumption, noise level, and

other functional indexes .If any one of these parameters is beyond its

permissible range, this indicates that there is a fault or trouble in the refrigerator.

During the whole service life of a refrigerator, the probability of troubles

occurring within a union time is called its failure rate. Making a comparison

between the control circuit system of a refrigerator and its refrigerating system,

we can find that the failure rate of the former is higher, and that of the

thermostat is the highest. In troubleshooting, the first thing you must do is to

determine where the trouble comes from --- the control system or the

refrigerating system. There is general no trouble indicating instrument mounted

on the domestic refrigerator, locations and natures of troubles should be

determined according to their respective features, therefore, experience in

servicing is very important to troubleshooting. Service technicians with rich

experience can correctly locate them and take reasonable remedy measures

based on their comprehensive analysis of trouble characteristics as well as

operating conditions for various kinds of refrigerators.

Three Essentials for Checkup

1) Look

a) Check the tubing of refrigerating system for cracks and various welding

points for leaks; if leakage occurs, an oil stain can be seen definitely .

b) Check the suction and exhaust pressure values (high pressure and low

pressure) of compressor to see whether they are normal.

c) Check the conditions of frost attached to its evaporator and gas return

tube .It is abnormal if frost has formed on part of the evaporator or there is no

10

frost attached to it. (This criterion is not applicable to the evaporator of

refrigerator compartment.)

d) Pay attention to the speed of temperature drop inside both the

refrigerator compartment and freezer compartment .It is abnormal if the speed

of temperature drop is obviously slower than the corresponding normal speed.

e) Check the environment to see whether it is suitable for placing a

refrigerator.

f) Check refrigerator door seal, case, and table surface and heat insulation

layer.

2) Listen

a) Listen to the noises produced when the compressor is running

Hums from a fully enclosed aggregate unit is the sound caused by overload

indicating that the motor cannot be started normally, meanwhile, a clattering

sound can be heard from inside the start relay, which is produced because the

start contacts cannot be released normally whistling sound is caused by the high

pressure gas flowing out of the crack of the pressure tube inside the compressor,

and clucks are the sound of striking after the suspended spring inside the

compressor has broken.

During the normal operation of compressor, a slight and uniform hum sound

due to undulation of electric current can be heard generally, this is a normal

phenomenon. However, if it sounds like “tong, tong…”, i.e., an impact sound

inside the compressor, this means that a large quantity of wet vapor of

refrigerant or refrigerating oil has come into the compressor cylinder; if it

sounds like “dang, dang…”, a striking sound of metal parts inside the

compressor ,this means that some moving parts have loosened (note to

differentiate this sound from those formed during starting or stopping the

compressor).

b) Listen to the sound caused by the flowing of gas in the evaporator

Open the refrigerator door while the compressor is in operation , incline your

ear and listen attentively the gas flow sound inside the evaporator .If it sounds

like gentle whistling accompanied by a sound similar to water flowing ,this is

the sound produced by the normal circulation of refrigerant within the

evaporator .In case only the gas flowing sound can be heard and there is no

water flowing sound ,this indicates that the refrigerant has already percolated .If

neither the flowing sound nor the gas sounds from the evaporator can be

heard ,this means that the filter or capillary has been clogged .

3) Touch and Feel

11

a) Feel the compressor when running ,its temperature should be generally

less than 90

in the normal state (it may exceed 90 in case of running for a

longer period of time ).

b) After the compressor has operated normally for 5~10 minutes, touch

and feel the condenser, the temperature of its upper part should be higher than

that of its lower part (or its right part is hotter than its left part, depending on the

type of condenser coil), this indicates that the refrigerant is circulating. If the

condenser is not hot, this means the leakage of refrigerant, In case the condenser

radiates heat for only several minutes and then cools down, this means that the

filter and capillary have been clogged. As for the forced air cooling condenser,

hot air will be blown out of it; this means that the system is out of order.

c) Feel the filter’s temperature. During the normal operation of

refrigerating system, the temperature on the filter’s surface should be a little

higher than the ambient temperature; if you touch it with your hand, you will

have a sense of slight heat. In case dew condensation appears due to the fact that

its temperature is obviously lower than the ambient temperature, this means that

most meshes of its screen has been clogged, resulting in an obstructed flowing

of refrigerant, thus causing a drop in temperature due to throttling.

d) Feel the temperature of exhaust gas from the refrigerating system .the

exhaust gas should be very hot and this is the normal working state. For those

refrigerator with enclosed type of compressor refrigerating system, no frost or

dew drop will from on the gas suction tube, otherwise, there is something wrong

in the system (Frosting and dew condensation may appear for a very short time

period when just starting the machine, this is a normal phenomenon).

Because a refrigerator is a combination of several components, they are related

and have influence on each other .In case an abnormal phenomenon has been

found through the above-mentioned checkups, you need not to make a hasty

conclusion based on only one abnormal phenomenon .It is advisable to find out

two or more abnormal phenomenon, or conduct troubleshooting

comprehensively with the aid of instruments or other ways, because several

kinds of troubles may share a common abnormal phenomenon, and two or more

abnormal phenomena may occur simultaneously due to a certain trouble .With

this method , you can reject some suspicious troubles and finally make a correct

judgment .

6.3 Analysis of Troubles and Troubleshooting

A. Poor Refrigerating Effect

12

The so-called “poor refrigerating effect “ refers to the fact that the refrigerator

can operate and refrigerator normally, but the temperature in the refrigerator

cannot drop to the prescribed value under the stipulated working conditions. In

view of there are many causes for this phenomenon, we are going to discuss and

analyze it in the following 7 aspects:

1) Leakage of refrigerant

Analysis of Trouble

The leakage of refrigerant in the system will result in an insufficient

refrigerating capacity, the resulting phenomena are its lower gas suction

pressure and exhaust pressure as well as higher exhaust gas temperature. The

exhaust tube feels rather hot, and a continuous gas flowing sound louder than

usual can be heard at the outlet of the capillary, and no frost or a smaller

quantity of loose frost appears on the evaporator. After shut down, the balance

pressure in the system is usually lower than the saturation pressure

corresponding to the same ambient temperature.

Remedy

In case there is leakage of refrigerant from the system, do not hurry to recharge

it with refrigerant, manage to find out leak points immediately, and make a note

of from where it leaks ---welding points and parts. After having them repaired,

recharge refrigerant.

There are so many joints and sealed surfaces in a refrigerator, accordingly, quite

a lot potential leak points do exist in the system. In troubleshooting, pay

attention to those parts that are liable to leak, check main connection points for

oil seepage and tubing for cracks. If there is no severer leak point, charge the

system with nitrogen and detect leak points with the commonly adopted method,

repair them, evacuate, charge the system with refrigerant, and then turn on the

refrigerator to make a test run.

2) Too much refrigerant charged into the system

Analysis of Trouble

a) In case the amount of refrigerant charged into the system exceeds its

nominal capacity, the superfluous refrigerant will of course take some space of

the evaporator, thus reducing its heat-dissipation area and hence the

refrigerating efficiency of the system. The abnormal phenomena caused by this

reason are as follows: the gas suction and exhaust pressures are generally higher

than their respective normal values, the temperature of its condenser is higher

and the electric current of the compressor rises, loose frost forms on the

13

Loading...

Loading...