Haier HRF347F Parts Manual

HRF-347F

REFRIGERATOR

Service Manual

CONTENT

1.SPCIFICATION LIST…………….…….…2

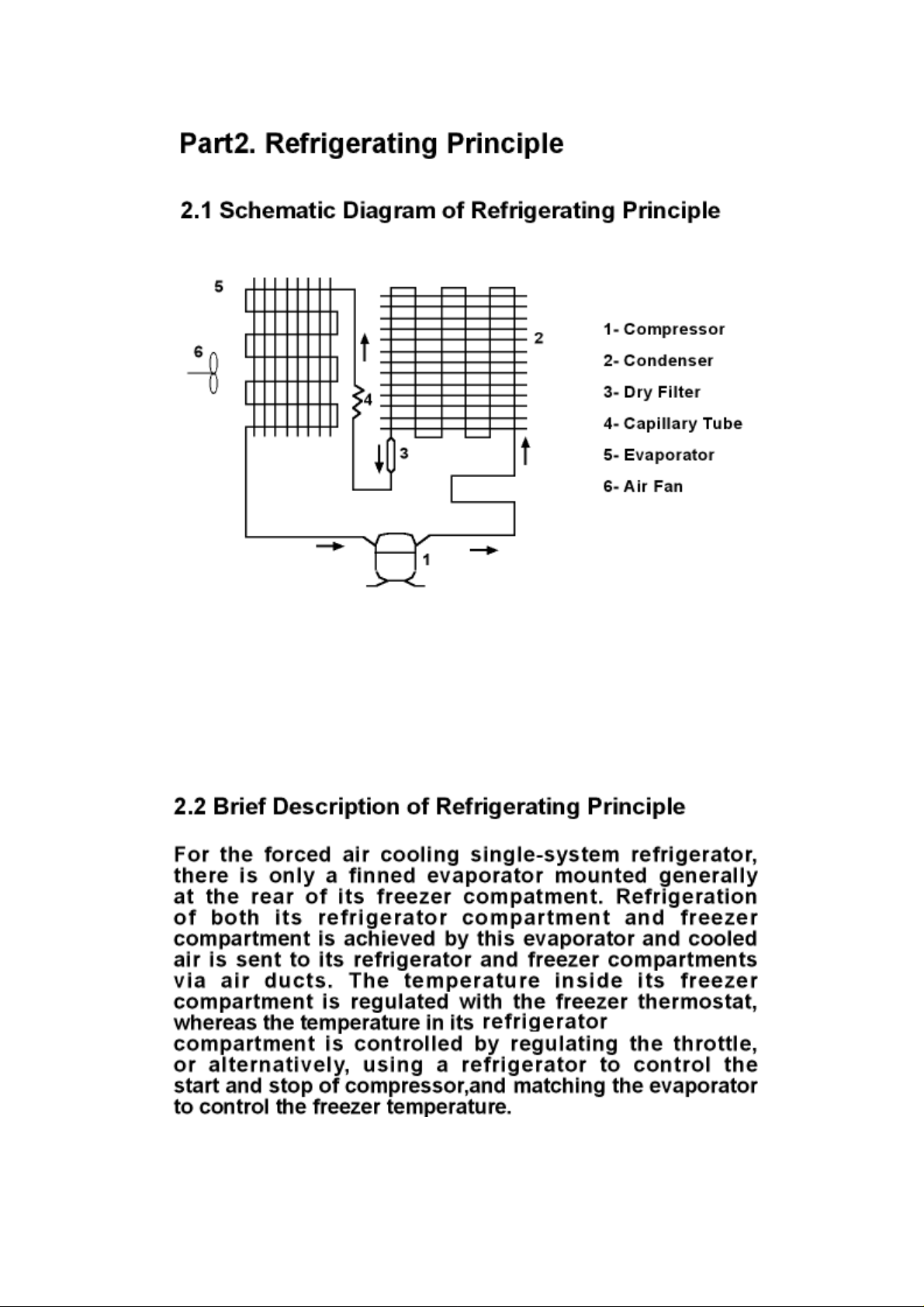

2.REFRIGERATING PRINCIPLE...…...….3

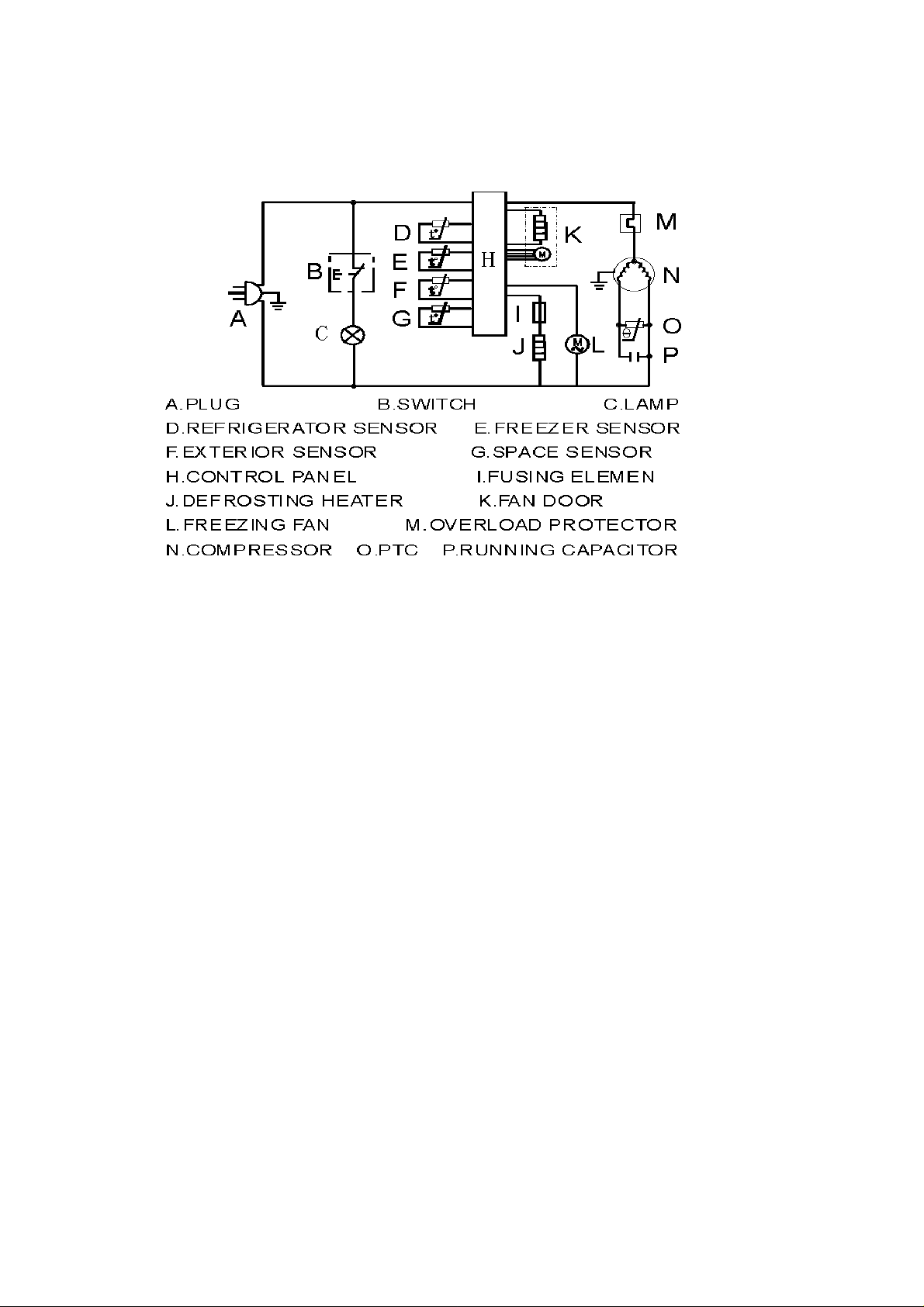

3.PRINCIPLE OF ELECTROIC CONTRO...4

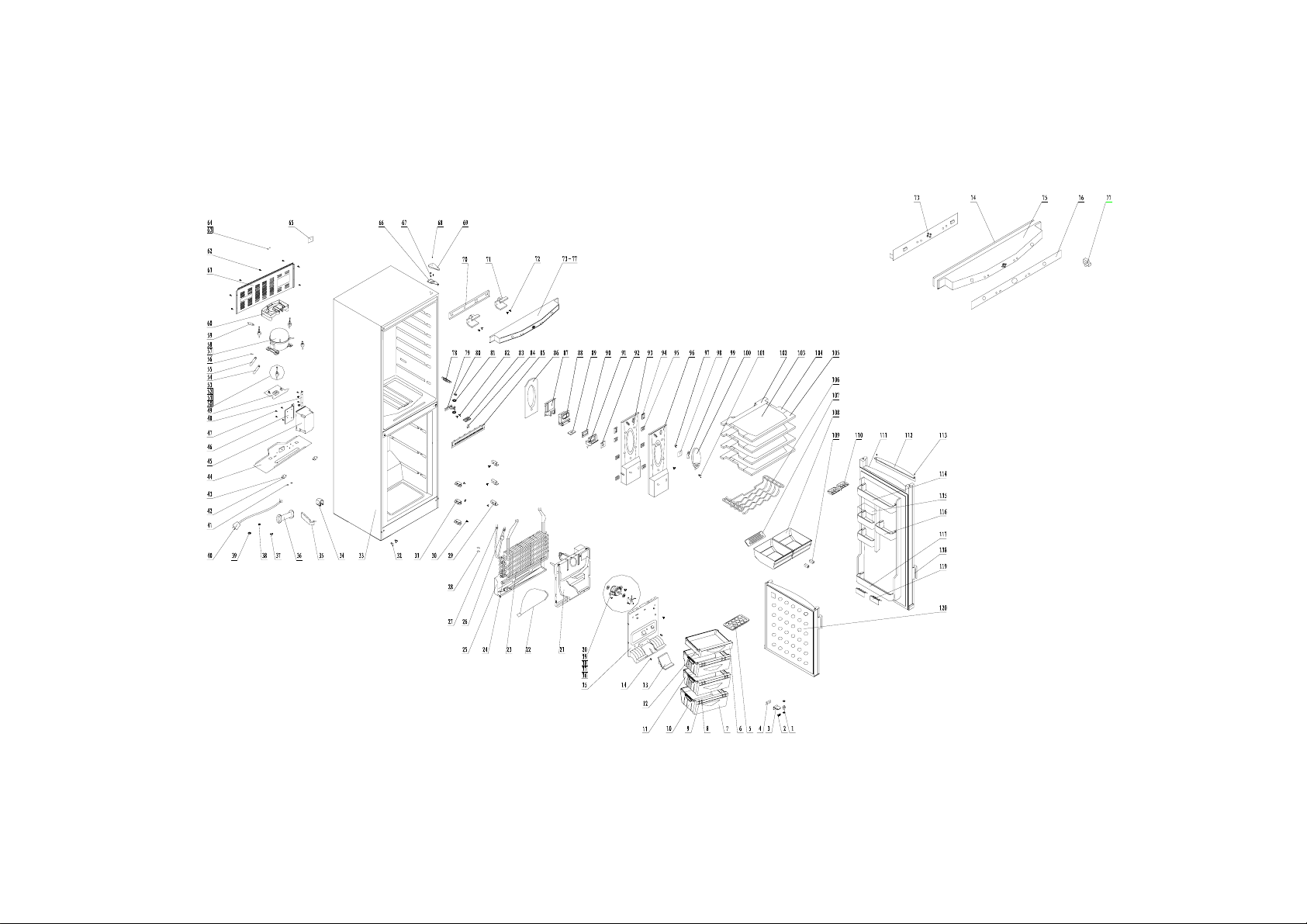

4.ASSEMBLY FIGURE……..………………5

5.PARTS LIST…..……………………….…6~8

6. TROUBLESHOOTING AND REPAIR..…8~38

7 REPLACEMENT PARTS LIST.…… 38~39

Features

.Large fridge, humidity and freshness retained

.Small freezer, super freeze

.Curve appearance

.Europe style

Haier Group

1

Model HRF-347F

Part 1 Specification

Model HRF-347F

Capacity L 248

Power Supply V/Hz 220-240~/50

Rated Input Power W 160

D

efrost Power W 250

Net Weight kg 74

Gross Weight kg 90

Unit Dimension (DXWXH)mm 660x600x1665

Packing Dimension (DXWXH)mm 790X685X1755

Container Quantity 40’

Container Quantity 40’HC

Specifications are subject to change without prior notic.

2

Schematic Circuit Diagram

3

Part 3 Principle of Electric Control

Brief Description of Control Principle

HRF-347F is the forced air cooling refrigerator with two

doors. A electrical type of all the control is generally

adopted. The thermostat directly controls the start and stop of

compressor, and hence the refrigerator temperature.

Low Temperature Compensation in the above schematic

diagram, When the ambient is below the set temperature, the

switch will be closed and the heating will work, thus

ensuring the normal start, and operation of refrigerator at

lower ambient temperature, in such case, the freezer

compartment temperature can reach a good point.

4

Par t 4 Assembly figure

5

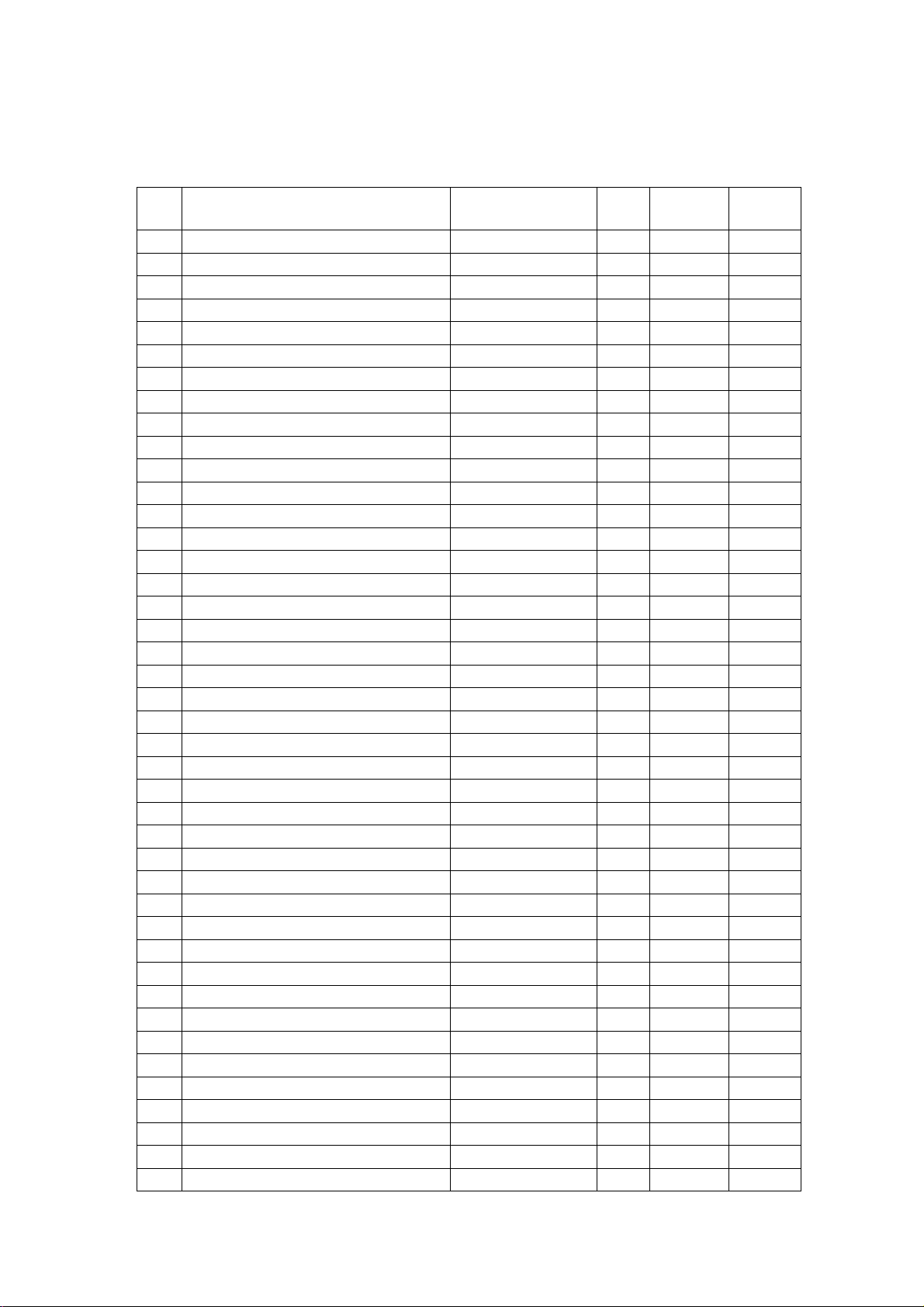

Part 5. Specification list:

Part secialized

NO. Name of part

code QTY

1 Hinge bolt 0060102333 1

2 Oval head screw 0060802007 2

3 Lower hinge pedestal 0060102186 1

Lower hinge washer

4

0067744096 1

5 Ice mould 0067402438 1

Small drawer cover

6

drawer cover

7

0060202878 1

0060202875 1

8 Without tinctorial cursor 0060203267 6

9 Blue cursor 0060203268 6

Short drawer

10

Lang drawer

11

12

Small drawer 0060202877 1

13

Freezer cover 0060203265 1

14 screw

15

Freeze wind road cover

16

Lamina

17

Electric fan buffer cusnion

18

Electric fan

0069790334 1

0069790333 2

00608010088 3

0060202873 1

0060205561

0060205406 2

0060803759 1

19 screw 0064098059 2

20 Bracket of electric fan 0060103647 1

21

Freezer wind road

0060202872 1

22 Fusing elemen 0060803758 1

23 Alar evaporator 0060701827 1

24 Defrosting heater complete

25 Drip tray complete

Louk annulus 0060508018

26

Louk annulus 0060508019

27

0060807146

0060807213

28 Capillary clip 0060214104 2

29 Right drawer stay 0060203566 3

30 Oval head screw 0064098068 6

31 Left drawer stay 0060203565 3

Nut

32

33 Foam housing

Clip of fixup cable

34

Put clip

35

Saddle clip

36

0060205630 2

0060806236

0067412148 1

0060145089 1

0060405012 1

37 Oval head screw 0060802008 1

38 Rubbery washer 0060405099 4

39 Dentiform washer 0060806003 1

40 Power supply cable 0060400012 1

Washer

41

42

Truckle

0060809001 2

0060215020 2

Price of

material REMARK

1

1

1

1

1

1

6

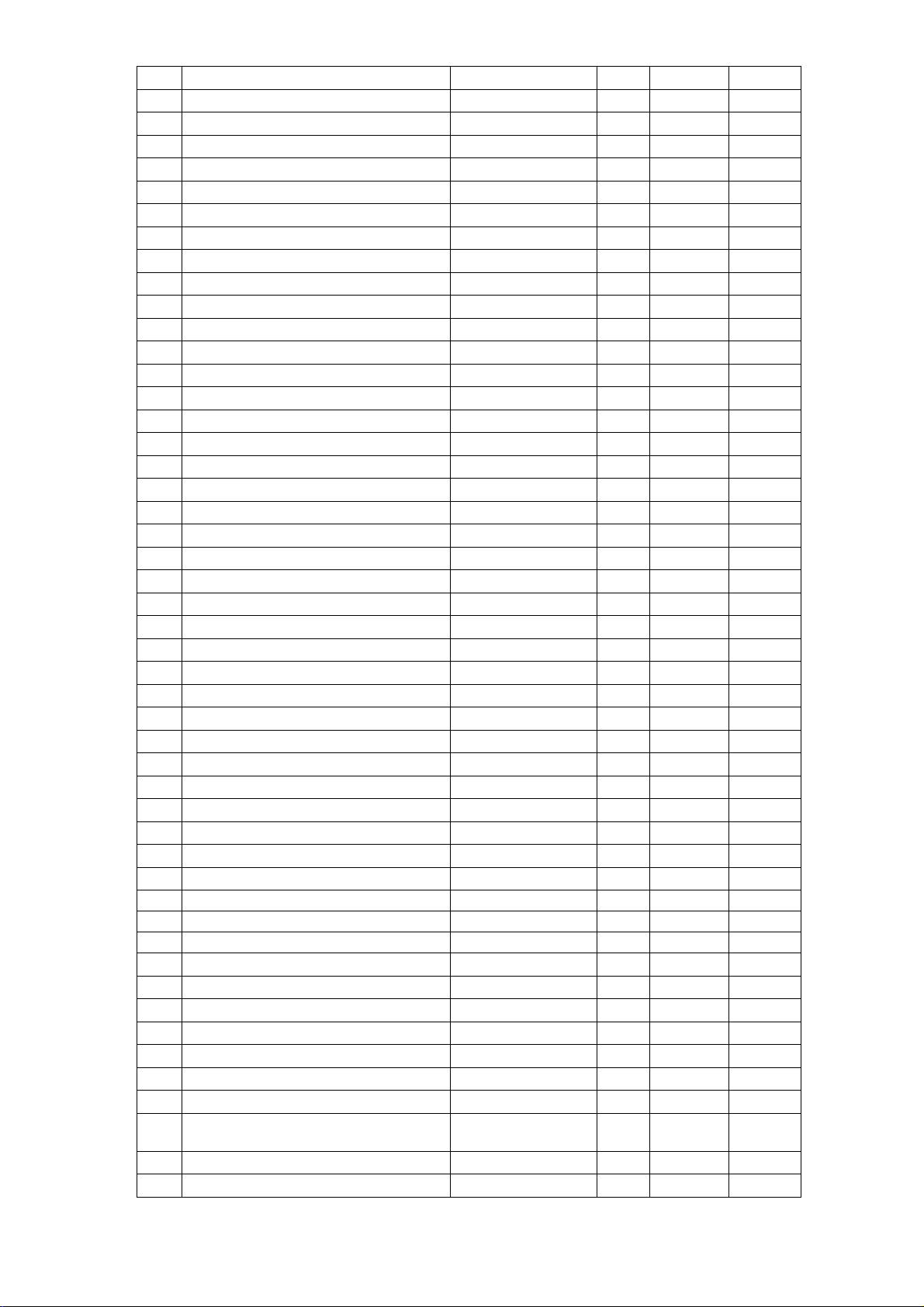

Truckle axis

43

Compresser underprop

44

Transformer box 0060211564

45

Transformer box cover 0060211603

46

47 Oval head screw

Transformer box fixity 00601470275

48

49 Power supply board

0060151010 2

0060100803 1

1

1

006082811

8

1

0064000213

1

50 Spring washer 0064240002 4

51 Bolt 00608040017 4

52 Washer

53 Sleeve

Connective tube

54

0060147208

0060145577

4

4

0060700603 1

55 Filling pipe 0060143039 2

56 Screws 0064098028 1

57 Compressor 0060700185 1

58 Compressor parts 0060700186 1

59 Dry filter 0060503012 1

60 Evaporator 0067402711 1

61 Compressor cover 00602160308 1

62 Oval head screw 0061098005 7

63 screw

64 screw cover

Name plate

65

66 Upper hinge

67 screw

68 screw

69 Upper hinge box

70 Front border strip underprop

71 Front border strip fixity

72 Oval head screw

Single windtight scrip

73

74 Control panel

75 Top border strip

76 Border strip

Lamp tuch

77

0064082811

00602140306

1

1

0060509409 1

0060102945

0064084005

0064084006

0060204220

0060102947

0060102946

0060801019

1

3

1

1

1

2

1

0067270130 0.6M

0064000217

0060203388

0060204434

1

1

1

00606050066 1

78 Sensor box cover 0060204126 1

79 Middle hinge

0060102943

1

80 Below baffle 0060203103 2

81 Dentiform washer 0060806011 2

82 screw

83 Sensor box cover

84 screw

85

Top wind road grid 0060205631

86

Wind road pressurize tray 0060204307 1

87

Wind road foam 0060204221 2

88

Exceed wind mouth 0060203266 1

0064082716

0060213085

0064082811

2

1

1

1

89

Exceed wind mouth pressurize tray 0060204527 1

90

Fan door pressurize tray 0060204526 1

91

Fan door complete 0060203761 1

7

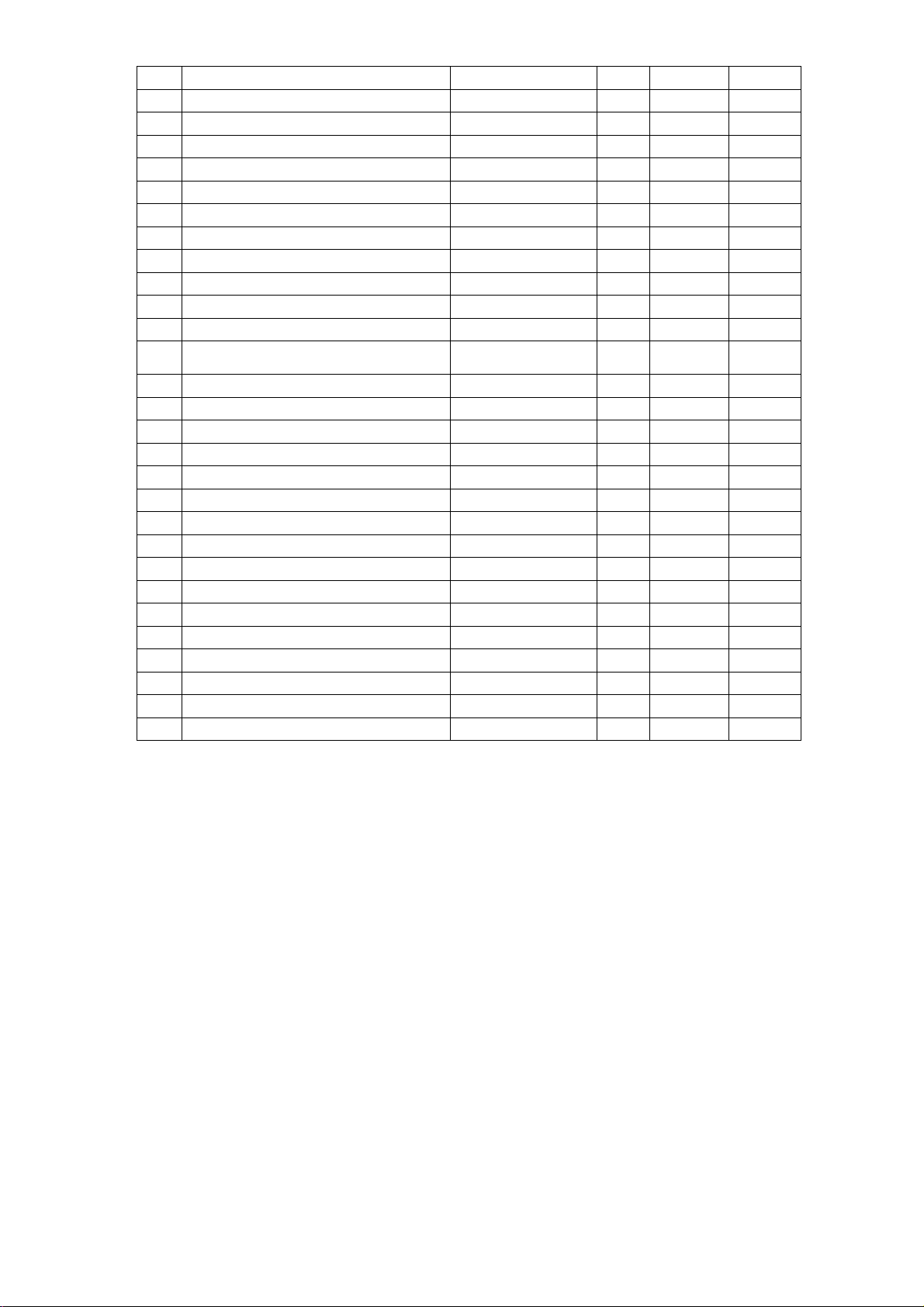

92

Pressurize tray 0060204529 1

93

Refrigerator wind road 0060203385 1

94

Pressurize tray 1 0060206163 2

95

Pressurize tray 2 0060206164 8

96

Wind road cover 0060202879 1

97

screw 0064082915 3

98

Viewfinder

99 Lamp

Light shade

100

101

Screw tuck 0060205342 1

102

Behind glass strip 0060203387 4

103

Glass 0060300201 4

104

Left/Right glass strip

105

Front glass strip 0060203386 4

106

Beer shelf 0060103584 1

107

Return wing cover board 0060205267 1

108 Vegetable bin

109 Stator piece

110 Egg holder

111 Refrigerator foam door complete

112 Top border strip cover

113 Screw

114 Bottle holder I(Egg holder)

115 Bottle holder cover

116 Short bottle holder

117 Bottle holder II

118 Door handgrip

119

Ward bottle ware

120 Freezer foam door complete

0060300327 1

0060604048 1

0060203382 1

0060205268/0060205269

0060806285 2

0060702033 2

0060211296 2

0060806244

0060203392 1

0060600046 2

00602111573

00602111447

00602111446

00602111571

0060204222 1

0060206133

0060806246

4

1

1

1

3

1

2

1

Part6. Troubleshooting and Repair

6.1 Normal Phenomena—Not Troubles for Refrigerators

In a domestic refrigerator, there is not only a complicated electric control

system, but also a refrigerating system that is difficult to discern whether

it is in a good working condition. Both the systems are related and affect

each other. If a certain part of a refrigerator works abnormally .Its

refrigerating efficiency will decrease, operation properties will become

unstable, or even it cannot be used normally for those serious cases.

Refrigerators are generally of larger volume, once troubles appear, to

8

send them to a service department is really a tough thing, if such is the

case, the user will always be in suspense, sometimes, normal phenomena

will be erroneously regarded as troubles. Therefore, before we deal with

the topics of frequently occurring troubles of refrigerators and their

remedies, we should firstly give a brief account of some normal

phenomena which are not troubles .In case any one of such phenomena

occurs, there is no need to worry about it, and the user can use it at total

ease.

1). When the compressor of a refrigerator has just stopped running, a

rumbling sound can be heard from inside its evaporator. This is a sound

caused by the flowing of refrigerant in the evaporator tubing. Because the

pressure difference is still greater after the compressor has just stopped

running, the refrigerant will flow for a certain time; therefore, this sound

is a normal phenomenon.

2). A click sound can often be heard from the refrigerator. This is a

normal sound produced by the pull-in or release of the armature of a

current deadweight start relay when starting the compressor .The

compressor motor will produce a slight and uniform sound while it is

running. This sound is not easy to be heard in the daytime, but of course it

can be heard distinctly at night.

3).The compressor consists of an electric motor and a compressing

apparatus .During its normal operation ,the motor’s stator core and

windings will rise to a temperature in the range of 100℃~110℃ ,and the

9

temperature of the piston and cylinder of the compressing mechanism can

also reach as above 100℃ due to the heat produced when compressing

refrigerant .Most of the heat radiates to the air through the compressor

casing ,therefore ,its casing is generally at a temperature between 85℃

~90℃ ,it is very hot ,particularly in summer when the ambient

temperature is higher .All these are normal phenomena .

4). For the forced air cooling refrigerator, a kind of irregular crack sound

can be often heard when the compressor is running for a certain period of

time or has just stopped its running. The stress relief due to expansion and

contraction causes this sound when temperature changes, and will not

affect the normal application of refrigerator.

6.2 Common Troubles in Refrigerators and Their Remedies

Causes for troubles occurring in refrigerators are closely related to the

quality of components and workmanship in assembling by manufacturers

as whether refrigerators are properly used and maintained .The

parameters generally used to express the working conditions of a

refrigerator include the temperature inside the refrigerator, operation rate,

electric power consumption, noise level, and other functional indexes .If

any one of these parameters is beyond its permissible range, this indicates

that there is a fault or trouble in the refrigerator.

During the whole service life of a refrigerator, the probability of troubles

occurring within a union time is called its failure rate. Making a

comparison between the control circuit system of a refrigerator and its

10

refrigerating system, we can find that the failure rate of the former is

higher, and that of the thermostat is the highest. In troubleshooting, the

first thing you must do is to determine where the trouble comes from ---

the control system or the refrigerating system. There is general no trouble

indicating instrument mounted on the domestic refrigerator, locations and

natures of troubles should be determined according to their respective

features, therefore, experience in servicing is very important to

troubleshooting. Service technicians with rich experience can correctly

locate them and take reasonable remedy measures based on their

comprehensive analysis of trouble characteristics as well as operating

conditions for various kinds of refrigerators.

Three Essentials for Checkup

1) Look

a) Check the tubing of refrigerating system for cracks and various

welding points for leaks; if leakage occurs, an oil stain can be seen

definitely .

b) Check the suction and exhaust pressure values (high pressure and

low pressure) of compressor to see whether they are normal.

c) Check the conditions of frost attached to its evaporator and gas

return tube .It is abnormal if frost has formed on part of the evaporator or

there is no frost attached to it. (This criterion is not applicable to the

evaporator of refrigerator compartment.)

11

d) Pay attention to the speed of temperature drop inside both the

refrigerator compartment and freezer compartment .It is abnormal if the

speed of temperature drop is obviously slower than the corresponding

normal speed.

e) Check the environment to see whether it is suitable for placing a

refrigerator.

f) Check refrigerator door seal, case, and table surface and heat

insulation layer.

2) Listen

a) Listen to the noises produced when the compressor is running

Hums from a fully enclosed aggregate unit is the sound caused by

overload indicating that the motor cannot be started normally, meanwhile,

a clattering sound can be heard from inside the start relay, which is

produced because the start contacts cannot be released normally whistling

sound is caused by the high pressure gas flowing out of the crack of the

pressure tube inside the compressor, and clucks are the sound of striking

after the suspended spring inside the compressor has broken.

During the normal operation of compressor, a slight and uniform hum

sound due to undulation of electric current can be heard generally, this is

a normal phenomenon. However, if it sounds like “tong, tong…”, i.e., an

impact sound inside the compressor, this means that a large quantity of

wet vapor of refrigerant or refrigerating oil has come into the compressor

cylinder; if it sounds like “dang, dang…”, a striking sound of metal parts

12

Loading...

Loading...