Page 1

Haier

Model No. : HL22KN1

CHASSIS:

COLOR TV

MST721

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does

not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products

powered b electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product deal with in this service information by anyone else could result in serious injury or death.

WARNING

2009 (Qingdao Electronics

All rights reserved. Unauthorized copying and distribution is a violation of

law.

1

limited company

)

Page 2

Tableofconents

1.

General Information…………...............……………………………………………………..3

1.1. General Guidelines...………………………………………………………………….. ..3

1.2. Important Notice…………………………………………………………………………..3

1.3. How To Read This Service Manual………………………………………………… .4

2. Speciflcations……………………………………………………………………………..........5

3. Location Of Controls And Components…………………………………...................…......7

3.1Board Location……………………………….. ………………………………….……... .7

3.2 Main Board…………….……………………………….. ………………………………...8

3.3 Power Board……………………………….. …………………………………………...12

3.4 Lcd Panel……………………………….. …………………………………………….…13

4.Disassemble And Assemble………………………………………………………….........…14

5. Installation Instructions…………………………………………………………...................19

6. Operation Instructions…………………………………………………………….............….24

6.1 Front Panel Controls……………………………….. …………………………………....24

6.2 Back Panel Controls……………………………….. ………………………………..…...24

6.3 Universal Remote Controller……………………………….. …..……………………….26

7. Measurements And Adjustments…………………………………………………................27

8. Electrical Parts .………………………………………………………........... .............29

…………………………………………………………………………..………..2

CONTENT

8.1Connetive Wire Photo......................................................................................................29

9. Trouble Shooting……………………………………………………………………………...40

8.2Circuit Diagram................................................................................................................29

2

Page 3

1. General Information

1-1 General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit.

After servicing, see to it that all the protective devices such as insulation barriers, insulation papers

shields are properly installed.

After servicing, make the following leakage current checks to prevent the customer from being

exposed to shock hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3)Prevention of Electro Static Discharge(ESD)to Electrostatically Sensitive

1-2 Important notice

1-2-1. Follow the regulations and warnings

Most important thing is to list up the potential hazard or risk for the service personnel to open the

units and disassemble the units. For example, we need to describe properly how to avoid the

possibility to get electrical shock from the live power supply or charged electrical parts (even the

power is off).

This symbol indicates that high voltage is present inside. It is dangerous to

make any king of contact with any inside part of this product.

This symbol indicates that there are important operating and maintenance

instructions in the literture accompanying the appliance

1-2-2. Be careful to the electrical shock

To prevent damage which might result in electric shock or fire, do not expose this TV set to rain or

excessive moisture. This TV must not be exposed to dripping or splashing water, and objects

Filled with liquid, such as vases, must not be place on top of or above the TV

1-2-3. Electro static discharge (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

Components commonly are called Electrostatically Sensitive (ES) Devices. The following

tech-niquesshouldbeusedtohelpreducetheincidenceofcomponentdamagecausedbyelectro

Static discharge (ESD).

1-2-4. About lead free solder (PbF)

This product is manufactured using lead-free solder as a part of a movement within the consum-er

products industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

1-2-5. Use the genewing parts (specified parts)

Special parts which have purposes of fire retardant (resistors),high-quality sound (capacitors), low

noise(resistors), etc. are used.

When replacing any of components, be sure to use only manufacture's specified parts shown in

the parts list.

Safety Component

● Components identified by mark have special characteristics important for safety.

3

Page 4

1-2-6. Safety Check after Repairment

Confirm that the screws ,parts and wiring which were removed in order to service are put in the

original positions, or whether there are the portions which are deteriorated around the serviced

places serviced or not. Check the insulation between the antenna terminal or external metal and

the AC cord plug blades. And be sure the safety of that.

Insuration Test

1. Unplug the plug from the AC outlet.

2. Remove the antenna terminal on TV and turn on the TV.

3. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than M ohm by using the 500V insulation resistance meter

4. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester.

External exposure metal: Antenna terminal Headphone jack

1-2-7. Ordering Spare Parts

Please include the following informations when you order parts. (Particularly the Version

letter)

1. Model number and Version letter

The model number can be found on the back of each product and the Version letter can

be found at the end of the serial number.

2. Part No. and Description

You can find them in your service manual.

1-2-8. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of products, which

may differ from your products in some way.

1-3. How to read this Service Manual

1-4-1. Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable to the

reader, such as tips and tricks.

Caution:

A “caution” is used when there is danger that the reader, through incorrect manipulation,

may damage equipment, loose data, get an unexpected result or has to restart(part of)

a procedure.

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

4

icon is

Page 5

A “reference” guides the reader to other places in this binder or in this manual, where

he/she will find additional information on a specific topic.

2. Specification

Model

HL22KN1

Screen size

Aspect ratio

Brightness

Contrast Ratio

Angel of view

Color display

OSD language

3D decoder

2D comb filter

DNR

3A ENGINE

Same picture split demo(SPD)

double picture demo (DPD)

21.6inch

16:9

400cd/m2

800:1

H170/V160

16.7M

English,

NO

YES

YES

NO

NO

NO

AV stereo

Surrounding sound

NICAM

MUSIC/STANDARD/THEATRE/USE

Bass, Treble

Balance

BBE

LIP SYNC

Equalizer

Earphone

Mute

AV input

DVD terminal

YES

NO

YES

MUSIC/THEATRE/PERSONAL/VOICE

YES

YES

NO

NO

NO

YES

YES

NO

NO

S-video jack

YES

5

Page 6

Y P

B

PR

YES

Monitor out

D-SUB jack

DVI socket

HDMI

SCART jack

Windows Menu

pc automatic adjust

movie mode

Semitransparent menu

ZOOM

16:9 mode

ADVANCED 4:3

PIP

NO

YES

NO

YES

YES

NO

YES

NO

YES

NO

YES

YES

NO

POP

PBP

3A WINDOWS

ATS

Nation Select

Channel List

Input Frequency by Manual and Channel

Number Input

Lock

TELTEXT

NO. of built-in speakers

NO. of outer speakers

Color display

NO. of preset channels

NO

NO

NO

YES

YES

NO

NO

YES

10

2

No

240

100

OSD language

Color system

Audio system

Audio output power(Built-in)(W)

English

PAL/SECA M

DK,BG,I, LL'

1.5W×2

6

Page 7

Audio output power(outer)(W)

No

Total power input(W)

Voltage range(V)

Power frequency(Hz)

Time of sleep timer(MINS)

Net weight(KG) 5.38

Gross weight(KG) 6.73

Net dimension(MM) 537/189/454

Packaged dimension(MM) 595/225/460

60W

AC150V~AC240V

50~60Hz

240Min

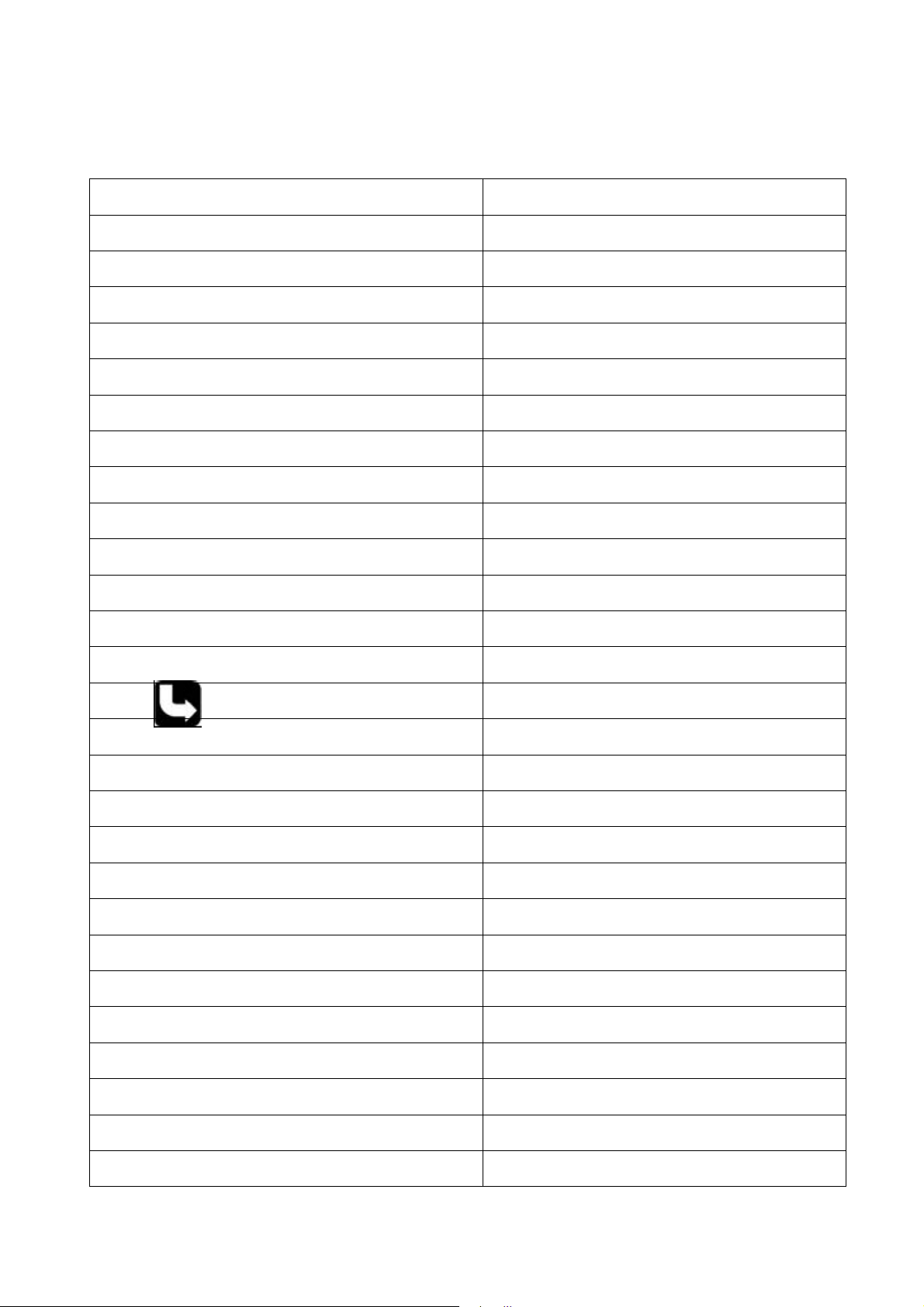

3. LOCATION OF CONTROLS AND COMPONENTS

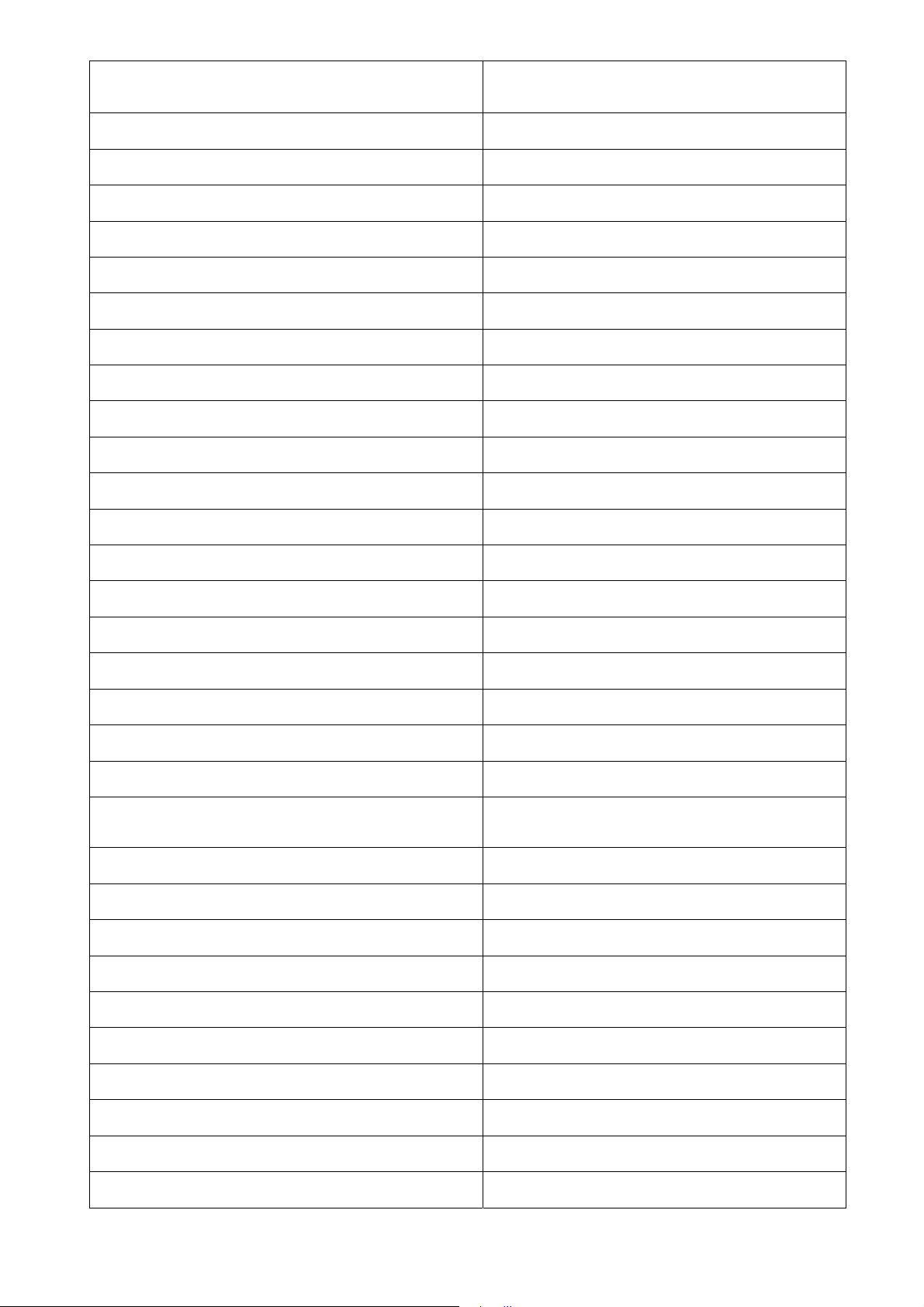

3.1. Board Location

7

Page 8

No. Parts number Description

A Board

B Board

C

MainBoard Assembly

Power adaptor

Speaker

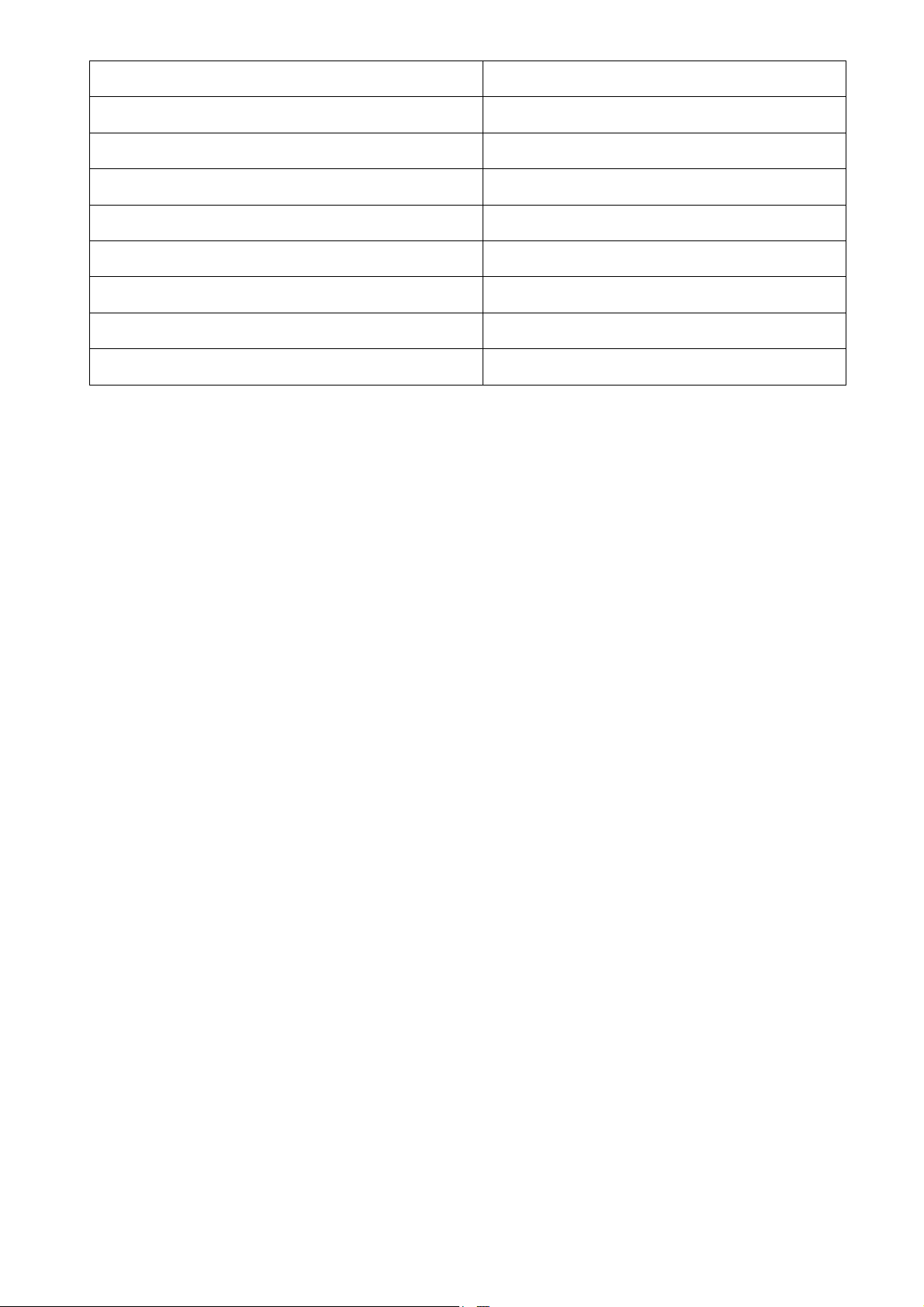

3.2.A.Board----MainBoard

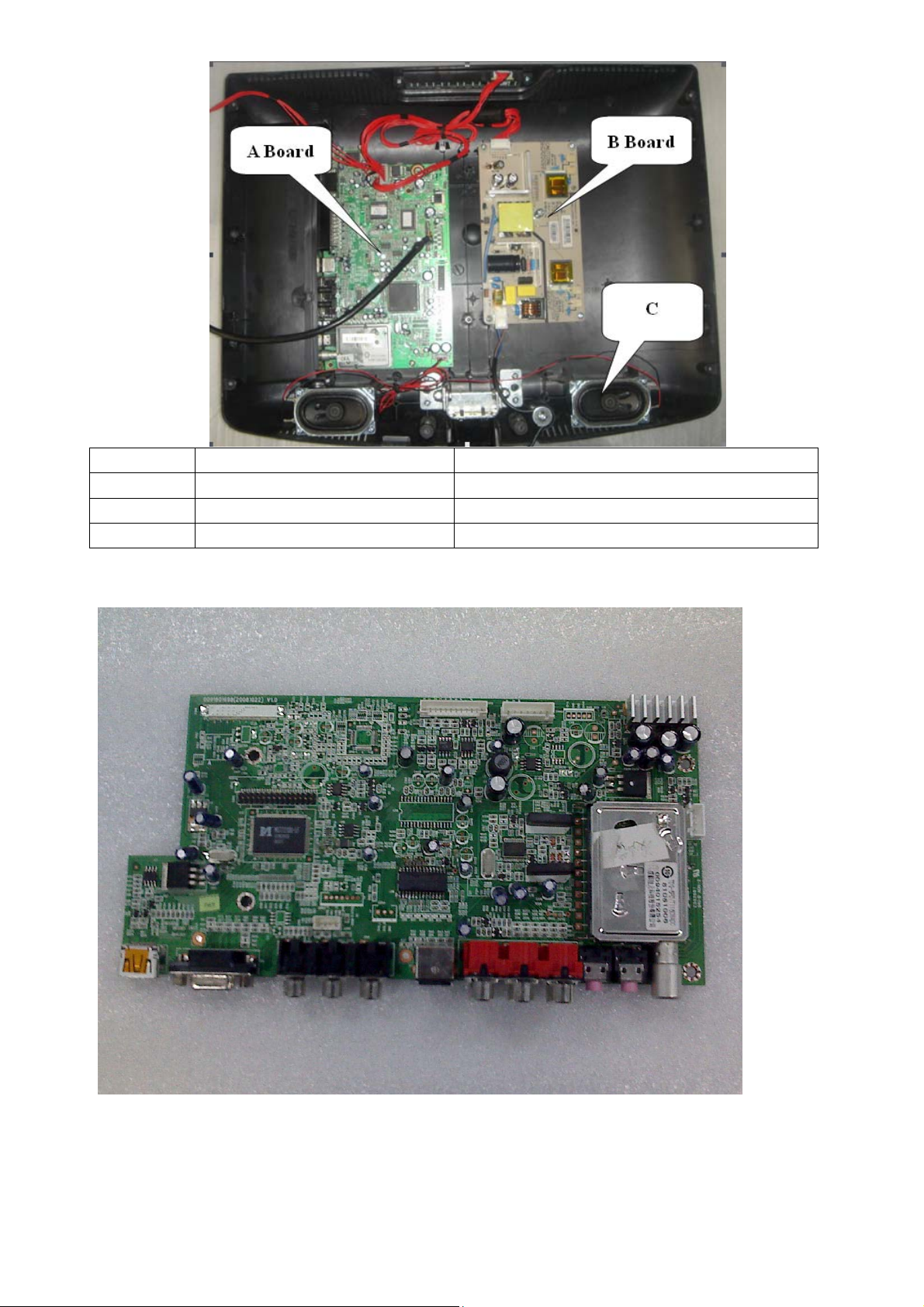

3.2. 1 Function Description:

Main Board:

8

Page 9

Process signal which incept from exterior equipment,then translate into signal that panel can display.

3.2.2 Connector definition

Main board connector

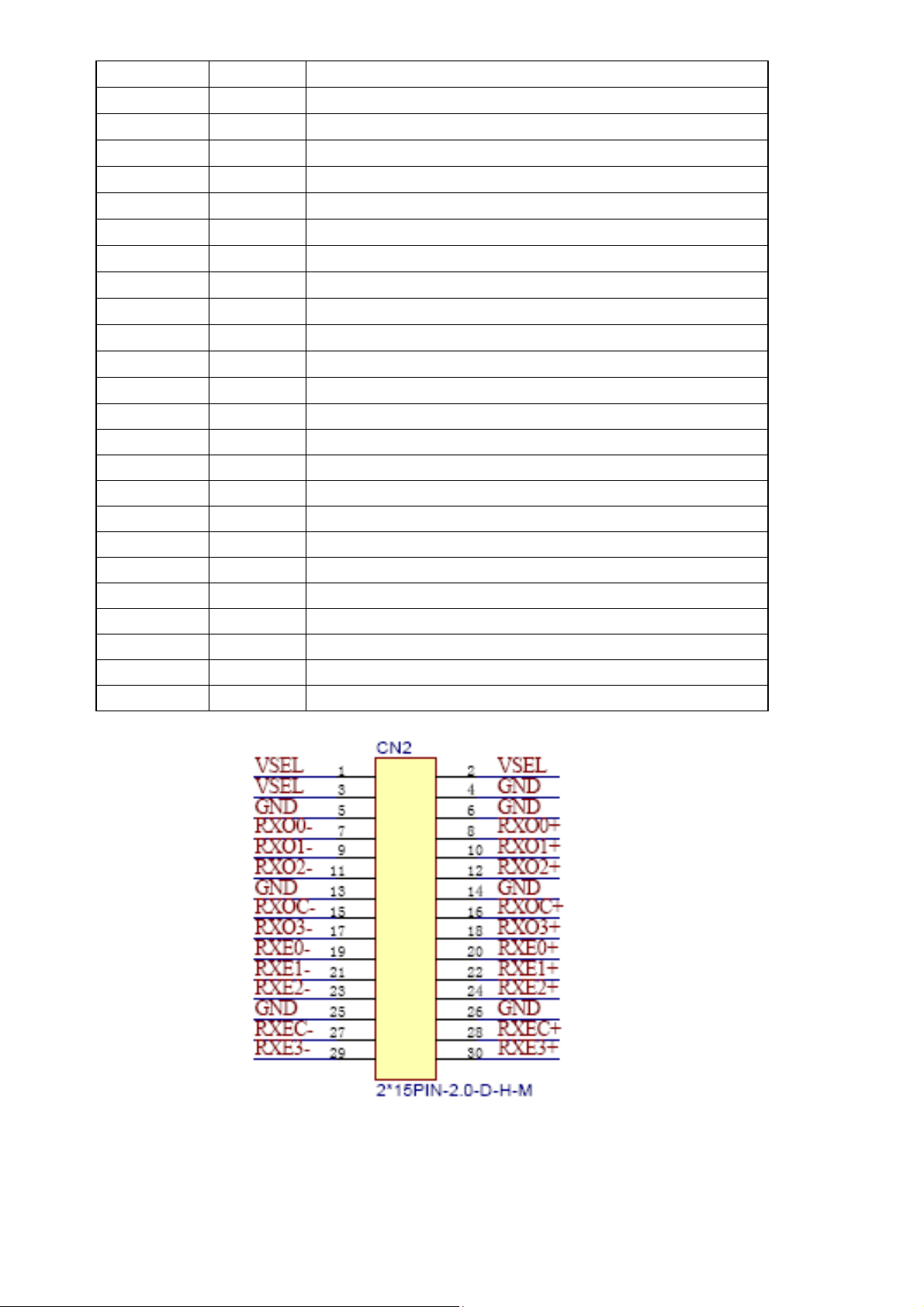

LCDS Connector (CN2)

Signal

Pin number

name Description

1 LCD-VDD

2 LCD-VDD

3 LCD-VDD

4 GND

5 GND

Supply voltage to Panel

Supply voltage to Panel

Supply voltage to Panel

Ground

Ground

9

Page 10

6 GND

Ground

7 RXO0- LVDS ODD 0–Signal

8 RXO0+ LVDS ODD 0 + Signal

9 RXO1- LVDS ODD 1 - Signal

10 RXO1+ LVDS ODD 1 + Signal

11 RXO2- LVDS ODD 2 - Signal

12 RXO2+ LVDS ODD 2 + Signal

13 GND

14 GND

Ground

Ground

15 RXOC- LVDS ODD Clock - Signal

16 RXOC+ LVDS ODD Clock + Signal

17 RXO3- LVDS ODD 3 - Signal

18 RXO3+ LVDS ODD 3 + Signal

19 RXE0- LVDS EVEN 0 - Signal

20 RXE0+ LVDS EVEN 0 + Signal

21 RXE1- LVDS EVEN 1 - Signal

22 RXE1+ LVDS EVEN 1 + Signal

23 RXE2- LVDS EVEN 2 - Signal

24 RXE2+ LVDS EVEN 2 + Signal

25 GND

26 GND

Ground

Ground

27 RXEC- LVDS EVEN Clock - Signal

28 RXEC+ LVDS EVEN Clock + Signal

29 RXE3- LVDS EVEN 3 - Signal

30 RXE3+ LVDS EVEN 3 + Signal

10

Page 11

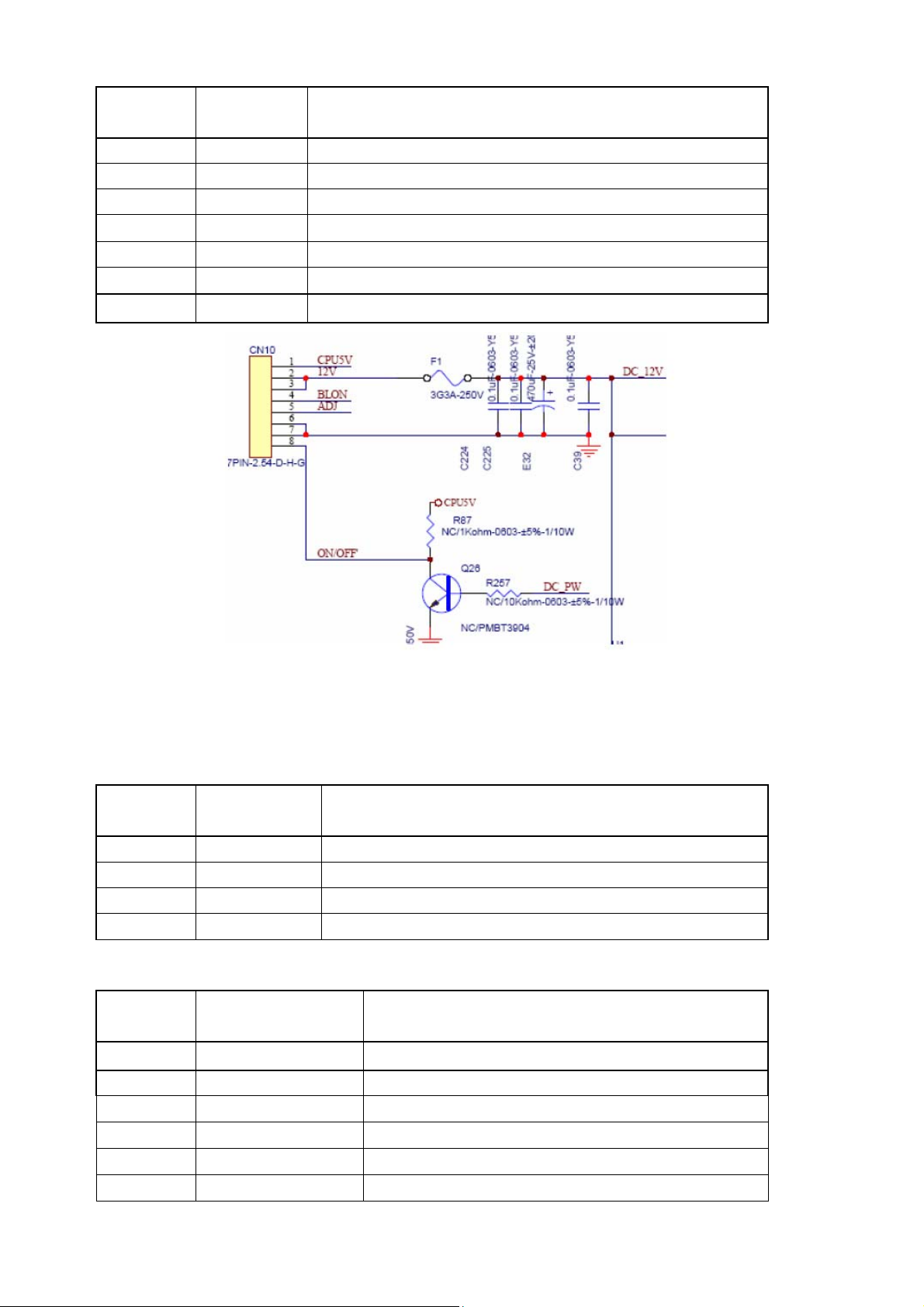

Power supply and Inverter Connector(CN10)

Pin

number Signal name Description

1 ON/OFF Preparative switch control

2 GND

3 GND

Ground

Ground

4 ADJ INVERTER Lightness Adjust

5 BLON INVERTER Switch Control

6 +12V 12V Power

7 +12V 12V Power

Audio Output Connector(CN11)

Pin

number Signal name Description

1 LSPK Left Audio Output

2 GND

3 GND

4 RSPK Right Audio Output

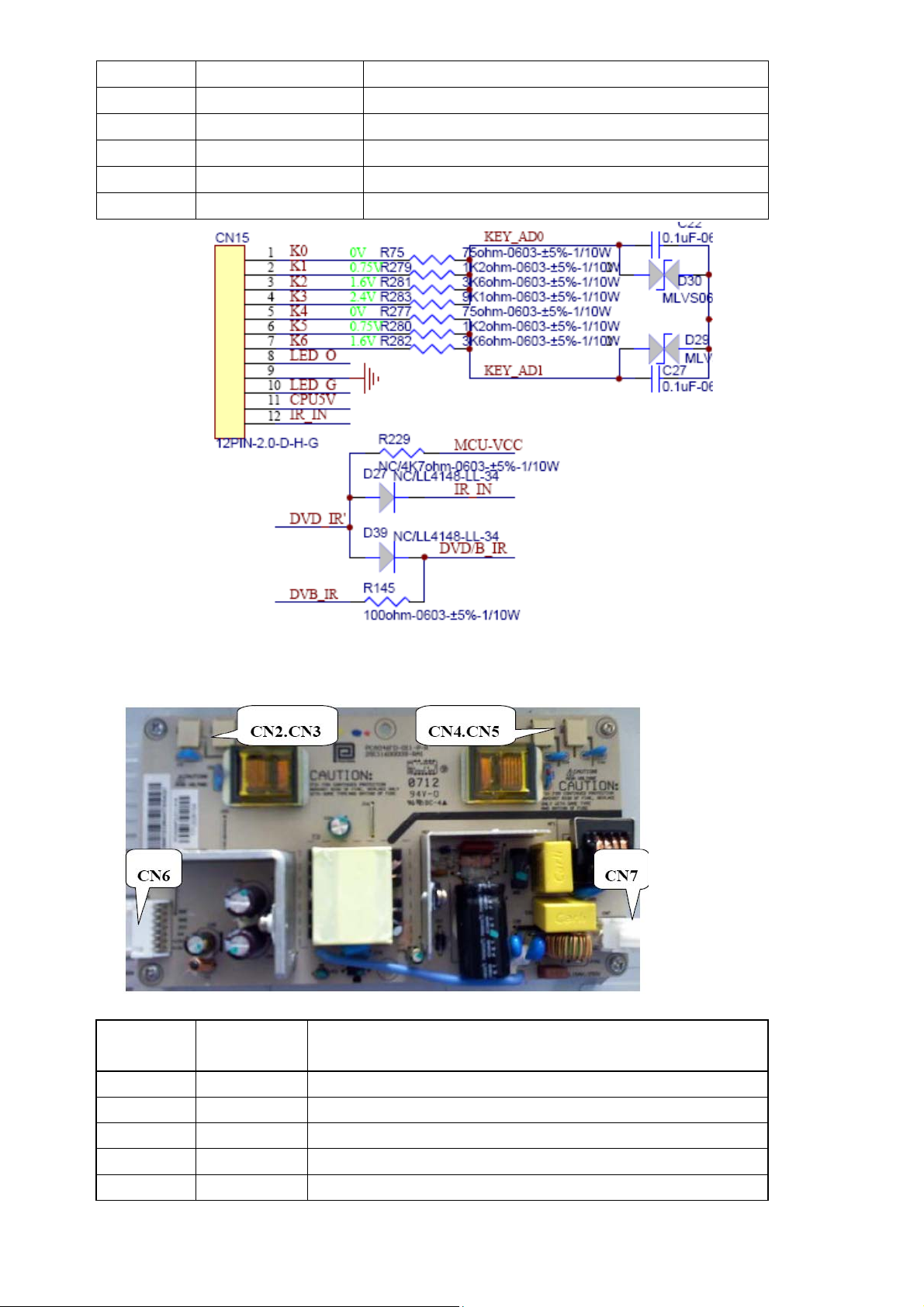

Remote Board and Key board Connector(CN15)

Pin

number Signal name Description

1 IR_IN IR

2 CPU5V 5V Power

3 LED_G Green Indicator light

4 GND

5 LED_R Red Indicator light

6 K6 Key Connector POWER

Ground

Ground

Ground

11

Page 12

7 K5 Key Connector MENU

8 K4 Key Connector P-

9 K3 Key Connector P+

10 K2 Key Connector V11 K1 Key Connector V+

12 K0 Key Connector SOURCE

3.3B Board-------(Power Board)

Supply power for Main board and Panel

Power supply and Inverter Connector(CN6)

Pin

number Signal name Description

1 ON/OFF Preparative switch control

2 GND

3 GND

Ground

Ground

4 ADJ INVERTER Lightness Adjust

5 BLON INVERTER Switch Control

12

Page 13

6 +12V 12V Power

7 +12V 12V

AC150V~AC240V Input (CN6)

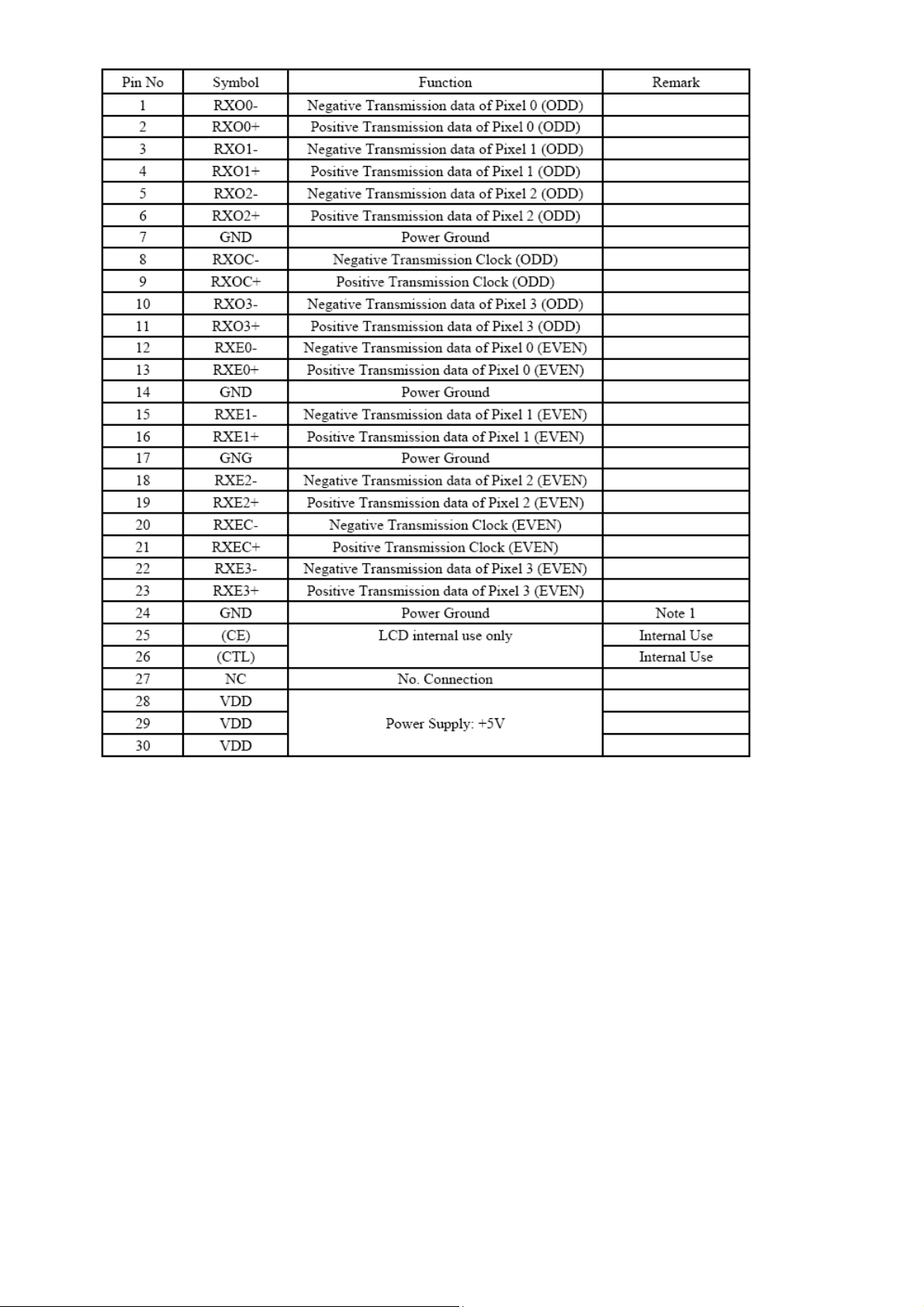

Power supply for panel (CN2. CN3. CN4. CN5.)

3.4. LCD PANEL.

Power

13

Page 14

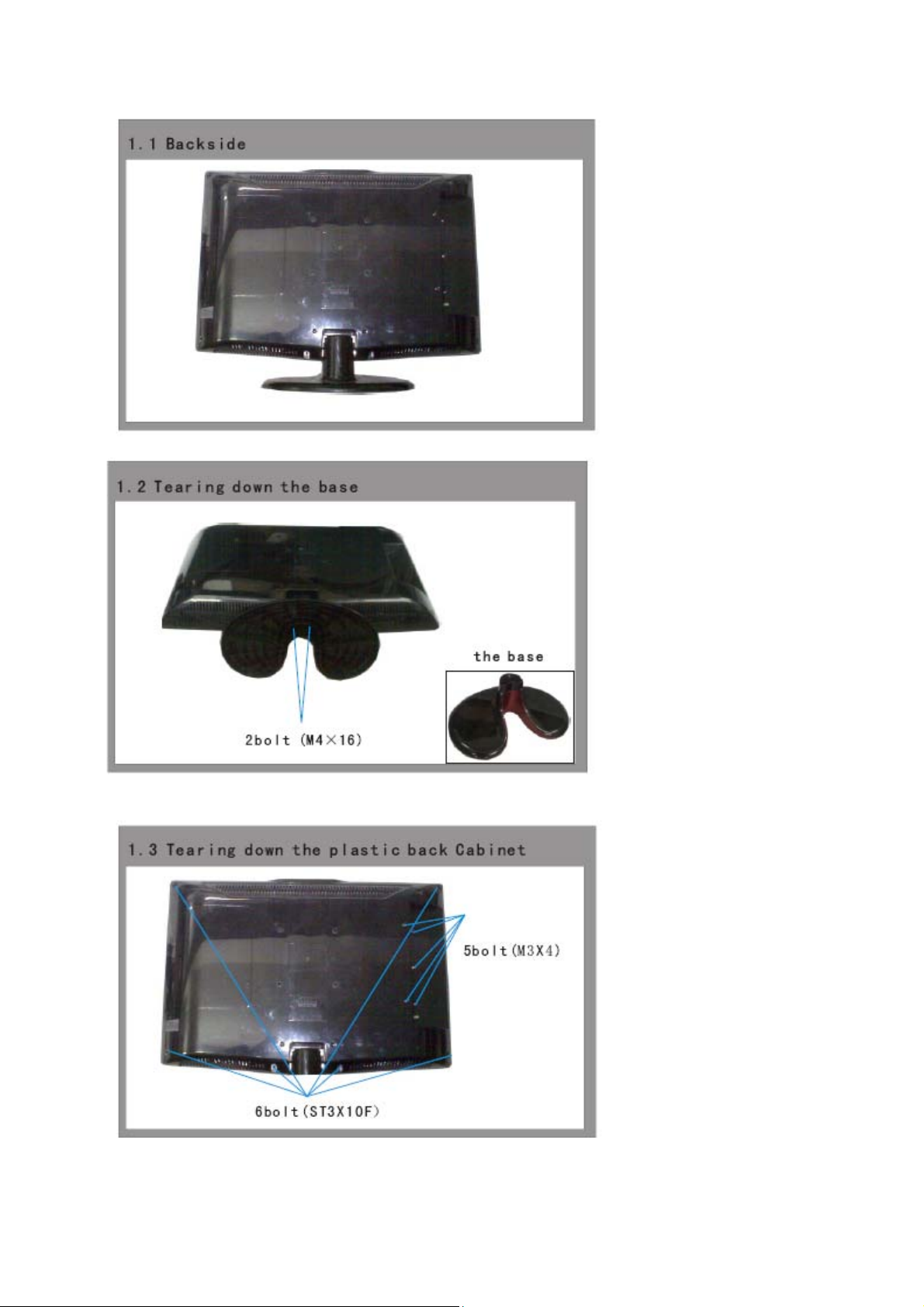

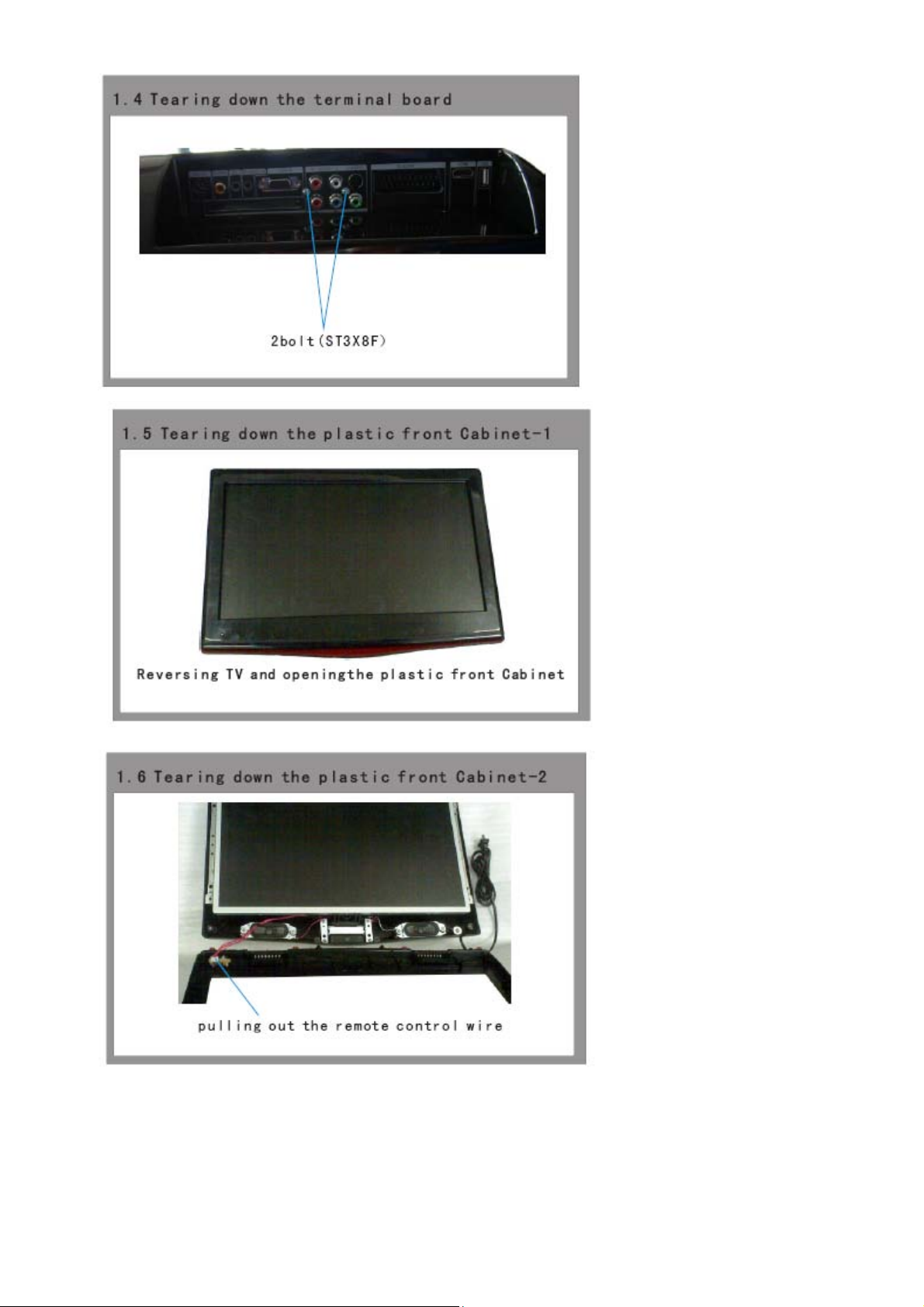

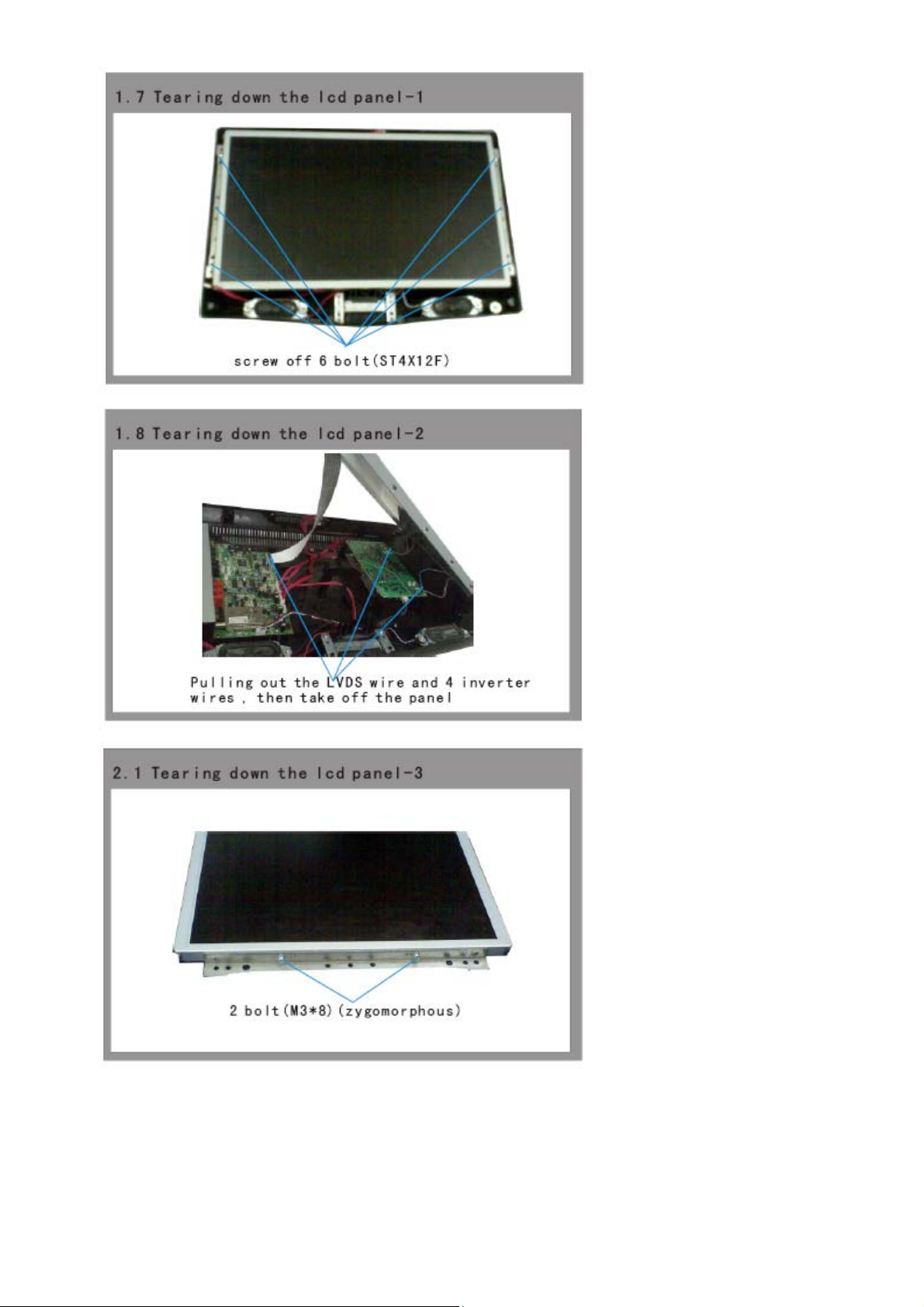

4.DISASSEMBLE AND ASSEMBLE

14

Page 15

HL22KN1 KNOCKED-DOWN SHOW

15

Page 16

16 17

Page 17

Page 18

18

Page 19

5. INSTALLATION INSTRUCTIONS

Accessories

Remote Control User Manual Battery Audio wire

19

Page 20

20 21 22 23

Page 21

Page 22

Page 23

Page 24

6. OPERATION INSTRUCTIONS

Basal information

6.1 Front panel controls

6.2 Back panel controls

24

Page 25

25

Page 26

6.3 Setting up Your Remote Control

26

Page 27

7. MEASUREMENTS AND ADJUSTMENTS

How to use

The way to the factory mode menu:

1st, press call,

2en, Bond followed by red, green, yellow button

3rd,press call again,

Finished these operations , system will be into the factory mode menu.

useable key:

1.menu: show the next menu page

2.p+/p-: select function

3.v+/v-; set function

27

Page 28

Press the button of OK to quit the factory menu.

28

Page 29

8 Electrical Parts

8.1 Connective Wire Photo

8.2 Circuit Diagram

Page 30

5

4

3

2

1

C1

10nC110n

C10

C10

10n

10n

10uH/4AL210uH/4A

D1

D1

NC/IN4148

NC/IN4148

10uH/4AL510uH/4A

D2

D2

NC/IN4148

NC/IN4148

L2

13

R2

12KR212K

+

+

CA2

CA2

R4

470uF/16V

470uF/16V

2.7KR42.7K

L5

13

R10

R10

12K

12K

+

+

CA7

CA7

R13

R13

470uF/16V

470uF/16V

2.7K

2.7K

5VSTB

CA3

CA3

10uF/16V

10uF/16V

+

+

+5V_DVD

CA8

CA8

10uF/16V

10uF/16V

+

+

C5

0.1uFC50.1uF

C15

C15

0.1uF

0.1uF

+12VU

+3.3V_MST

5VSTB

PANEL-ON/OFF

L1 NC/FBL1 NC/FB

L3 NC/FBL3 NC/FB

L4 FBL4 FB

POWER-ON/OFF

0N 1

OFF 0

PANEL-ON/OFF

0N 1

OFF 0

POWER-ON/OFF

R7

4.7KR74.7K

+12VU

R15

R15

4.7K

4.7K

1

C9

0.1uFC90.1uF

CA4

CA4

220uF/16V

220uF/16V

R5

10KR510K

Q1

2N3904Q12N3904

2 3

L6 FBL6 FB

L7 FBL7 FB

1

+

+

CA9

CA9

10uF/16V

10uF/16V

+

+

2 3

C6

0.1uFC60.1uF

Q2

2N3904Q22N3904

C13

C13

0.1uF

0.1uF

R11

R11

10K

10K

C4

0.1uFC40.1uF

R6

100KR6100K

C14

C14

0.1uF

0.1uF

R14

R14

100K

100K

1

2

3

4

U2

AO4803AU2AO4803A

S1

G1

S2

G2

VCC-Panel

8

D1

7

D1

6

D2

5

D2

+12VA

470uF/16V

470uF/16V

470uF/16V

470uF/16V

1482_ON/OFF

CA1

CA1

CA6

CA6

+12VU

+12VU

R16

R16

4.7K

4.7K

R1 100KR1 100K

+

+

C2

C3

0.1uFC20.1uF

3.9nC33.9n

C7

R3

0.1uFC70.1uF

6.8KR36.8K

R8 100KR8 100K

+

+

C11

C11

C12

C12

0.1uF

0.1uF

3.3n

3.3n

C16

C16

R12

R12

0.1uF

0.1uF

2.2K

2.2K

1

POWER

CON1

CON1

BL-ON/OFF

D D

C C

BRI_ADJ

GND

GND

CON7_2.5

CON7_2.5

DVD_POWER

+3.3V_MST

CON2

CON2

5

4

3

2

1

CON5_2.0

CON5_2.0

12V

12V

NC

R9

4.7KR94.7K

7

6

5

4

3

2

1

DVD_STB

+5V_DVD

+12VA

+12VU

BL-ON/OFF

BL-ADJUST

DVD_STB

+5V_DVD

+12VA

1482_ON/OFF

0N 0

2 3

Q3

2N3904Q32N3904

U1

MP1482U1MP1482

VCC2OUT

7

EN

6

COMP

8

SS

4

GND

U3

MP1482U3MP1482

VCC2OUT

7

EN

6

COMP

8

SS

4

GND

BST

BST

3

1

5

FB

3

1

5

FB

OFF 1

5VSTB

R17

R17

R181KR18

10K

10K

2 3

1K

R191KR19

BL-ADJUST

1K

Q4

2N3904Q42N3904

1

2 3

R21

R21

100R

100R

Q5

2N3904Q52N3904

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc>

A3

<Doc>

A3

<Doc>

A3

Date: Sheet of

Date: Sheet of

Date: Sheet of

C18

C18

0.1uF

0.1uF

BL-ON/OFF

C19

C19

2.2uF

2.2uF

1

<RevCode>

<RevCode>

211Thursday, November 27, 2008

211Thursday, November 27, 2008

211Thursday, November 27, 2008

<RevCode>

4

U4

C20

C20

0.1uF

0.1uF

OUT

OUT

2

U4

IN

IN

AMS1084-3.3

AMS1084-3.3

3

+

CA10

+

CA10

47uF/16V

47uF/16V

+3.3V_MST

C17

C17

0.1uF

0.1uF

MST721DU 250mA

+

CA11

+

CA11

47uF/16V

47uF/16V

U5

U5

AMS1117-1.2

AMS1117-1.2

5VSTB5VSTB

4

B B

ADJ

ADJ

1

A A

5

ADJ

ADJ

1

C21

C21

0.1uF

0.1uF

4

OUT

OUT

2

IN

IN

3

+

+

CA12

CA12

47uF/16V

47uF/16V

C22

C22

0.1uF

0.1uF

VCC1.2V

3

正常功耗为

建议先采用

1.25V

MST721DU 150mA

+

CA13

+

CA13

47uF/16V

47uF/16V

0.57W

TO-252

左右

封装

BRI_ADJ

BRI_ON/OFF

BRI_ADJ

BRI_ON/OFF

R22

R22

4.7K

4.7K

R20

R20

4.7K

4.7K

1

2

Page 31

5

4

3

2

1

R24

R24

4.7K

4.7K

ZD4

ZD4

ESD

ESD

R25

R25

4.7K

4.7K

VDDP

DVD_Status

Q6

2N3906Q62N3906

IR_in

ZD5

ZD5

ESD

ESD

AV_out

AV-Lout

AV-Rout

DVD_Status

IR_in

R32 NC/100R32 NC/100

R33 NC/100R33 NC/100

R42

R42

75R

75R

R43

R43

75R

75R

ZD8

ZD8

ESD

ESD

Y-in

C-in

R52

R52

75R

75R

DVD_AUDIO

CON4

CON4

1

2

3

CON3_2.0

CON3_2.0

R38 47RR38 47R

Q7

2N3906Q72N3906

3 2

ZD10

ZD10

ESD

ESD

DVD_L

DVD_R

R3547R R3547R

C25 47nFC25 47nF

C27 47nFC27 47nF

Close to MST IC

R47

R47

10R

10R

R51

R51

10R

10R

1

Q8

2N3904Q82N3904

R53

R53

75R

75R

ZD11

ZD11

ESD

ESD

R61

R60

R60

47K

47K

R61

47K

47K

32

R54

R54

75R

75R

R48

R48

220R

220R

S-Y2Y_DVD

DVD_Lin

DVD_Rin

S-Y2

S-C2

DVD_Lin

DVD_Rin

AV1_Vin+

AV1_Vin-

AV1_Lin

AV1_Rin

R36

R36

10K

10K

R44

R44

10K

10K

R45

R45

47R

47R

R57

R57

10K

10K

R59

R59

10K

10K

R50

R50

47R

47R

C23 47nFC23 47nF

C24 47nFC24 47nF

C26

C26

470pF

470pF

C28

C28

470pF

470pF

Close to MST IC

C29

C29

47nF

47nF

C31

C31

47nF

47nF

C32

C32

470pF

470pF

C33

C33

470pF

470pF

R26 47RR26 47R

ZD1

ZD1

ESD

ESD

C_DVD S-C2

ZD2

ZD2

ESD

ESD

I2C_SCL

I2C_SDA

S-Y1

S-C1

L9FBL9

+5V_Tuner

FB

C30

C30

R49

R49

2.2uF

2.2uF

10k

10k

CA14

CA14

1

47uF/16V

47uF/16V

R55

R55

4.7k

4.7k

CVBS_out

AV-Lout

AV-Rout

DVD_L

DVD_R

AV1

AV1-LinAV-Rout

AV1-Rin

ZD9

ZD9

ESD

ESD

R34 1KR34 1K

ZD3

ZD3

ESD

ESD

R41 1KR41 1K

ZD6

ZD6

ESD

ESD

ZD7

ZD7

ESD

ESD

ZD12

ZD12

ESD

ESD

R581KR58

1K

R29

R29

75R

75R

R31

R31

75R

75R

R46

R46

75R

75R

R561KR56

1K

R30 47RR30 47R

DVD_Y/C

CON3

CON3

D D

CON7_2.0

CON7_2.0

Y_DVD

1

2

C_DVD

3

4

IR_DVD

5

6

7

5VSTB

R23

R23

NC/4.7K

NC/4.7K

R270R R270R

R28100R R28100R

兼容克隆接口

S-video_input

C C

B B

5VSTB

R37

R37

NC/0

NC/0

R39

R39

0/NC

0/NC

P1

P1

3 4

5 7

S-VIDEO-Jack

S-VIDEO-Jack

2PJ-4018-001

2PJ-4018-001

21

6

R40

R40

0/NC

0/NC

AV_input & output

P2P2

9

9

8

7

6

5

4

3

2

1

A A

AV1-Rin

8

7

AV-Lout

6

AV1-Lin

5

4

AV_out

3

2

1

AV1

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

A3

<Doc> <RevCode>

A3

<Doc> <RevCode>

A3

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet of

311Tuesday, August 19, 2008

311Tuesday, August 19, 2008

311Tuesday, August 19, 2008

1

Page 32

5

4

3

2

1

Close to Mstar IC

VGA

CN1 VGACN1 VGA

5

15

10

4

14

9

3

13

8

2

12

D D

7

1

11

6

16

17

R62 100RR62 100R

R63 NC/100RR63 NC/100R

R64 100RR64 100R

R65 NC/100RR65 NC/100R

R7775R77

R7575R75

R7675R76

75

75

TXD

VGA_R

VGA_G

VGA_B

HSYNC

ZD15

ZD15

VSYNC

VGA_SDA

VGA_SCL

HSYNC

ZD19

ZD19

VSYNC

R66

R66

R69

R69

10K

10K

10K

10K

ESD

ESD

ZD16

ZD16

ZD18

ZD18

ESD

ESD

ESD

ESD

ESD

ESD

RXD

ZD14

ZD14

ZD13

ZD13

ZD17

VGA_B

VGA_G

VGA_R

75

R78 75RR78 75R

R79 75RR79 75R

R80 75RR80 75R

R68 47RR68 47R

R70 47RR70 47R

R72 47RR72 47R

R74 470RR74 470R

C34

47nF

C34

47nF

C35

47nF

C35

47nF

C36

47nF

C36

47nF

C37

1nF

C37

1nF

C38

47nF

C38

47nF

C39

47nF

C39

47nF

C40

47nF

C40

47nF

VGA-B+

VGA-G+

VGA-R+

VGA-SOG

VGA-R-

VGA-B-

VGA-G-

ZD17

ESD

ESD

ESD

ESD

ESD

ESD

HPD

HDMI_5V

Q9

2N3904Q92N3904

R671KR67

1K

5VSTB

R71

R71

4.7K

4.7K

R73

R73

4.7K

4.7K

HOTPLUG

+5V_VGA

VGA_HSYNC

VGA_VSYNC

VGA_HSYNC

VGA_VSYNC

CEC

R86

R86

100R

100R

M1

2N7002M12N7002

5VSTB

R87

R87

100R

100R

HDMI_CEC

HSYNC

R81 100RR81 100R

VSYNC

R82 100RR82 100R

VGA_SDA

D3

D3

2

3

1

+5V_Tuner

C C

NC/BAT54C

NC/BAT54C

+5V_VGA

VGA_SCL

U6

1

NC

2

NC

3

NC

GND4SDA

NC/24C02U6NC/24C02

VCC

VCLK

SCL

R85

R85

4.7K

4.7K

8

7

6

5

C41

C41

0.1uF

0.1uF

R83 10KR83 10K

R84 10KR84 10K

R89100RR89100R

R88100RR88100R

R90NCR90

NC

VGA_AUDIO

CN2

CN2

PC_PHONE_JACK

PC_PHONE_JACK

CN4

8

7

Y/Pb/Pr

Y/Pb/Pr

CN4

8

7

B B

4

2

1

3

5

6

6

5

5

4

4

3

3

2

2

1

1

ZD26

ZD26

ESD

ESD

PC_L

PC_R

ZD27

ZD27

ESD

ESD

ZD20

ZD20

ESD

ESD

ZD28

ZD28

R115

R115

75R

75R

ESD

ESD

ZD21

ZD21

ESD

ESD

R116

R116

75R

75R

R911KR91

1K

R921KR92

1K

C42

C42

R93

R93

470pF

470pF

10K

10K

Close to Mstar IC

R105 47RR105 47R

R109 47RR109 47R

R112 47RR112 47R

R114 470RR114 470R

R117

R117

75R

75R

ZD36

ZD36

HDMI_5V

ESD

ESD

+5V_Tuner

R96

R96

10K

10K

D16

D16

BAT54C

BAT54C

R97

R97

10K

10K

R98

R98

100R

100R

R101 100RR101 100R

R102 100RR102 100R

R103 10RR103 10R

R104 10RR104 10R

R106 10RR106 10R

R107 10RR107 10R

R108 10RR108 10R

R110 10RR110 10R

R111 10RR111 10R

R113 10RR113 10R

R100

R100

100R

100R

C44

C44

0.1uF

0.1uF

U7

R95

R95

4.7K

4.7K

24C02U724C02

VCC

WP

SCL

SDA

R99 NCR99 NC

GND

1

A0

2

A1

3

A2

4

HPD

HDMI_SDA

HDMI_SCL

CEC

RXCKN

RXCKP

RX0N

RX0P

RX1N

RX1P

RX2N

RX2P

8

7

6

5

VGA_Lin

VGA_Rin

C43

C43

R94

R94

470pF

470pF

10K

10K

ZD22

HPD

HDMI_5V

DDC_SDA

DDC_SCL

CEC

CLK-

CLK+

DAT0-

DAT0+

DAT1-

DAT1+

DAT2-

DAT2+

ZD29

ZD29

ZD22

ESD

ESD

ESD

ESD

HDMI_5V

ESD

ESD

ESD

ESD

ESD

ESD

ZD31

ZD31

ZD30

ZD30

ZD23

ZD23

ZD32

ZD32

ZD24

ZD24

ZD25

ZD33

ZD33

ZD25

ESD

ESD

ESD

ESD

ESD

ESD

ESD

ESD

ZD35

ZD35

ZD34

ZD34

ESD

ESD

ESD

ESD

C45

C45

47nF

47nF

C46

C46

47nF

47nF

C47

C47

47nF

47nF

C48

C48

1nF

1nF

HD_Pr

HD_Pb

HD_Y

HD_SOG

CN3

CN3

CONHDMI

CONHDMI

HPD

GND

DDC SDA

DDC SCL

CEC

CLKClk Shield

CLK+

DAT0-

Dat0 Shield

DAT0+

DAT1-

Dat1 Shield

DAT1+

DAT2-

Dat2 Shield

DAT2+

23

Fin

22

Fin

19

18

+5V

17

16

15

14

NC

13

12

11

10

9

8

7

6

5

4

3

2

1

20

Fin

21

Fin

A A

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet

VGA&YPbPr&HDMI

<Doc>

<Doc>

<Doc>

<RevCode>

<RevCode>

<RevCode>

of

411Thursday, September 11, 2008

411Thursday, September 11, 2008

411Thursday, September 11, 2008

1

Page 33

5

4

3

2

1

I2C ADDRESS(R263 NC):

24

VIF11VIF2

2

C62

C62

10nF

10nF

22

SIF123SIF2

OUT2

OUT1

3

C65

C65

390pF

390pF

R149

R149

47R

47R

R151

R151

47R

47R

READ is 0X87

WRITE is 0X86

AGND

AGND

C51

C51

R124

R124

1.5nF

1.5nF

330R

330R

21

AFC

FMPLL

4

R1570R157

0

Close to MST IC

AGND

C54NCC54

C53

C53

NC

220nF

220nF

17

18

19

20

VPP

VPLL

CVBS

AGND

DGND7TOP

DEEM

AUD_OUT8SDA

AFD

5

6

C64

C64

C66

C66

470nF

470nF

1nF

1nF

C74

C74

10nF

10nF

C71

C71

47nF

47nF

C72

C72

47nF

47nF

4MHzY14MHz

4

3

16

9

+5V_Tuner

R121

R121

R122

R122

22K

22K

22K

22K

Y1

C50

C50

R126

R126

R125

R125

0.1uF

0.1uF

22K

22K

1 2

C55

C55

22pF

22pF

14

13

15

NC

REF

TAGC

U10

10

R1550R155

0

TV-Vin+

TV-Vin-

U10

TDA9885

TDA9885

SCL

SIOMAD

11

12

R141NCR141

NC

C63

C63

1uF

1uF

AGND

NC(5)/VAGC(6)

R1291kR129

1k

1

100K

100K

AGND

R139 0R139 0

R154NCR154

NC

32

AGND

Q11

Q11

2N3904

2N3904

R135 100RR135 100R

R136 100RR136 100R

R138 100RR138 100R

R142

R142

220R

220R

C52

C52

0.1uF

0.1uF

C58

C58

0.1uF

0.1uF

CA15

CA15

+

+

47UF/16V

47UF/16V

+

CA17

+

CA17

47uF/16V

47uF/16V

R133

R133

75R

75R

IF-AGC

TV-V

SCL

SDA

TV_AUDIO

+5V_Tuner

I2C_SCL

I2C_SDA

TV_AUDIO

TV-SIFP

+5V_Tuner

D D

AGND

U8

TUNER_IFU8TUNER_IF

13

GND114GND215GND312GND4

38MHZ

C56

C56

0.1uF

0.1uF

R148

R148

10R/2W

10R/2W

R152

R152

NC/10K

NC/10K

R156 NC/4K7R156 NC/4K7

AGC1NC12AS3SCL4SDA55VA65VB7NC3833V9NC410IFout

4

U12

U12

IN

GND

IN

GND

OUT

OUT

C692.2uF C692.2uF

C68 0.1uFC68 0.1uF

+

CA18 100uF/16V+CA18 100uF/16V

R153

R153

NC/10K

NC/10K

Q14

Q14

1

NC/3904

NC/3904

2 3

C79

C79

NC/0.1uF

NC/0.1uF

11

R128 0RR128 0R

C59

C59

22pF

22pF

AGND

7805

7805

+5V_Tuner

321

+

C70 NC/0.1uFC70 NC/0.1uF

CA19 100uF/16V+CA19 100uF/16V

Q13

Q13

NC/AO3401

NC/AO3401

1

3 2

IF-AGC TV

R127 10RR127 10R

R130 10RR130 10R

C60

C60

22pF

22pF

L11

L11

NC/100uH

NC/100uH

13

L13 NC/FBL13 NC/FB

+5V_Tuner

C78

C78

0.1uF

0.1uF

SDA

SCL

5VSTB

IF_TV

C73

C73

NC/0.1uF

NC/0.1uF

AGND

R15875R158

75

10nF

10nF

10nF

10nF

C57

C57

R131

R131

4.7K

4.7K

AGND

C61

C61

R134NCR134

NC

AGND

TV-V

L12 FBL12 FB

+5V_Tuner

C C

B B

L10 NC/FBL10 NC/FB

CA16

CA16

47uF/16V

47uF/16V

+

+

+12VA

0N 1

OFF 0

3401_ON/OFF3

A A

3401_ON/OFF

R118

R118

R119

R119

4.7K

4.7K

4.7K

4.7K

D4 792D4 792

Q10

Q10

1

2N3904

2N3904

2 3

AGND

D5

792D5792

D6

792D6792

AGND

38MHZ

D7

792D7792

R137 NCR137 NC

R143

R143

4.7K

4.7K

31.5MHZ

1

2

R132

R132

NC/0

NC/0

IN

1

2

ING4OUT1

Q12

Q12

3904

3904

2 3

AGND

IN

ING4OUT1

SAW

SAW

3

AGND+5V_Tuner

R144

R144

4.7K

4.7K

R146 10KR146 10K

1

R147NCR147

NC

GND

AGND

OUT2

R123

R123

10K

10K

SAW

SAW

3

U11

U11

D6216N

D6216N

AGND

R120

R120

4.7K

4.7K

C49

C49

NC/10nF

NC/10nF

U9

U9

D9455N

D9455N

OUT2

5

GND

5

R145

R145

4.7K

4.7K

AGND AGND

C67

C67

10nF

10nF

R150

R150

75R

75R

R140

R140

5.6K

5.6K

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

Date: Sheet

Date: Sheet of

5

4

3

2

Date: Sheet of

TUNER&IF

<Title>

<Title>

<Title>

<Doc> <RevCode>

<Doc> <RevCode>

<Doc> <RevCode>

1

of

511Sunday, December 07, 2008

511Sunday, December 07, 2008

511Sunday, December 07, 2008

Page 34

5

IC POWER

+3.3V_MST

FB1FBFB1

FB

C84

C84

C83

C83

0.1uF

0.1uF

2.2uF

2.2uF

+3.3V_MST

+3.3V_MST

VCC1.2V

CON7

CON7

CON4_2.0

CON4_2.0

R202

R202

100K

100K

AVDD_LPLL

FB2FBFB2

FB

C91

C91

0.1uF

0.1uF

AVDD_MPLL

FB4FBFB4

FB

C96

C96

0.1uF

0.1uF

AVDD_12

FB6FBFB6

FB

C98

C98

0.1uF

0.1uF

R189

R189

4K7

4K7

R191

R191

4K7

4K7

5VSTB

R193

R193

4K7

4K7

5VSTB

1

2

RXD

R195 100RR195 100R

3

TXD

R196 100RR196 100R

4

5VSTB

3

2

D8

BAV99D8BAV99

1

R2061KR206

1K

CA21

CA21

2.2uF

2.2uF

D D

C C

LED_CTL

B B

A A

C85

C85

0.1uF

0.1uF

+3.3V_MST

VCC1.2V

R188 200RR188 200R

Q16

Q16

2N3904

2N3904

LED_RED

LED_GRE

Q17

Q17

2N3906

2N3906

R190 200RR190 200R

R194

R194

RX_SCL

TX_SDA

RXD

TXD

1

3 2

4K7

4K7

Q18

Q18

2N3906

2N3906

R209

R209

22K

22K

VDDP

C87

C87

C86

C86

0.1uF

0.1uF

0.1uF

0.1uF

AVDD_33

FB3FBFB3FB

C95

C95

C93

C93

C94

C94

C92

C92

0.1uF

0.1uF

FB5FBFB5

FB

C99

C99

0.1uF

0.1uF

+3.3V_MST

+3.3V_MST

+

CA20

+

CA20

10uF/16V

10uF/16V

R207

R207

100R

100R

5

VDDC

RESET

2.2uF

2.2uF

0.1uF

0.1uF

0.1uF

0.1uF

RXCKN

RXCKP

RX0N

HD_Pb

HD_SOG

HD_Y

HD_Pr

VGA-BVGA-B+

VGA-GVGA-G+

VGA-SOG

VGA-RVGA-R+

VGA_HSYNC

VGA_VSYNC

CVBS_out

RX0P

RX1N

RX1P

RX2N

RX2P

HOTPLUG

HDMI_SDA

HDMI_SCL

S-C1

S-Y1

S-C2

S-Y2

AV1_Vin+

AV1_VinTV-Vin+

TV-Vin-

C100

C100

C97

C97

0.1uF

0.1uF

0.1uF

0.1uF

C110

C110

1nF

1nF

AVDD_33

CLOSE TO MST721DU

CLOSE TO MST721DU

AVDD_33

AVDD_33

R187 390R1%R187 390R1%

C101 0.1u50VC101 0.1u50V

C102 0.1u50VC102 0.1u50V

C103 0.1u50VC103 0.1u50V

CVBS_OUT

4

CRYSTAL

C82

C82

22pF

22pF

50V

50V

12MHZY212MHZ

3

C88

C88

4

22pF

22pF

1 2

Y2

50V

50V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

SPI FLASH

CE#

SDO

SDI

SCK

4

U13

U13

RXCKN

RXCKP

GND

RX0N

RX0P

AVDD_33

RX1N

RX1P

RX2N

RX2P

HPLUG

REXT

DDC_DA

DDC_CK

HSYNC1

VSYNC1

VCLAMP

REFP

REFM

BIN1P

SOGIN1

GIN1P

RIN1P

BIN0M

BIN0P

GIN0M

GIN0P

SOGIN0

RIN0M

RIN0P

AVDD_33

GND

HSYNC0

VSYNC0

CVBS5P

CVBS4P

CVBS3P

CVBS2P

CVBS1P

VCOM1

CVBS0P

VCOM0

AVDD_33

CVBSOUT

GND

VIN

MST-721

MST-721

R1691MR169

1M

WP_CTL

1

3

5

7 8

PANEL-ON/OFF

POWER-ON/OFF

VDDC

AVDD_LPLL

VDDP

AVDD_MPLL

AVDD_12

153

155

154

156

XIN

XOUT

AVDD_12

AVDD_MPLL

FAULTZ47FB2_DPWM48FB1_DPWM49Q251Q1

AVDD_DPWMADC

50

2

RP10

RP10

4

33R

33R

6

152

R197

R197

33K

33K

143

148

145

149

151

144

147

150

146

141

142

DEO

GND

CLKO

VDDP

VDDC

GPIO[9]

GPIO[6]

GPIO[7]

GPIO[10]

VSYNCO

HSYNCO

MST-721

MST-721

1D/2A/6C Input

1D/2A/6C Input

with CCFL

with CCFL

VDDP

SAR055SAR156SAR2

QOR53GND54MCKO59AMUTE60AUWS61AUSCK62AUSD63SPDIFO64UART1_RX72UART1_TX

58

57

52

VDDP

KEY_1

KEY_0

AU_SCLK

AU_WS

AU_MCLK

R205

R205

NC/10K

NC/10K

C109

C109

0.1uF

0.1uF

1

2

CS

SO

SI

SCLK

SCLK

C113

C113

NC/22pF

NC/22pF

3

VDDP

139

138

140

RA0P

RA0N

VDDP

AVDD_LPLL

65

BRI_ADJ

AU_SD

BRI_ADJ

U16

U16

MX25LV040

MX25LV040

CS

SO

WP

GND4SI

135

137

136

GPIO[13]/RA2P

GPIO[11]/RA1P

GPIO[12]/RA1N

PWMD166PWMD0

VDDC67SCK68SDI69SDO70CSN

VDDC

SCK

VDDP

VCC

HOLD

SCK

133

131

132

134

GPIO[15]/RA3P

GPIO[16]/RA3N

GPIO[14]/RA2N

71

CE#

SDO

SDI

I2C_SCL

FB8FBFB8

FB

8

7

6

5

129

130

GA0P

GA0N

GPIO[17]/GA1P

GPIO[0]74GPIO[3]

73

WP_CTL

I2C_SDA

127

126

125

128

GND

GPIO[19]/GA2P

GPIO[20]/GA2N

GPIO[18]/GA1N

GPIO[1]75GPIO[2]76INT

77

78

DVD_Status

DVD_STB

IR_in

WP

C111

C111

0.1uF

0.1uF

3

GPIO[21]/GA3P

GPIO[22]/GA3N

GPIO[29]

GPIO[30]

BA0P

BA0N

BA1P

BA1N

BA2P

BA2N

BA3P

BA3N

VDDP

RB0P

RB0N

RB1P

RB1N

RB2P

RB2N

RB3P

RB3N

GB0P

GB0N

GPIO[23]/GB1P

GPIO[24]/GB1N

GPIO[25]/GB2P

GPIO[26]/GB2N

GB3P

GB3N

GPIO[27]

GPIO[28]

BB0P

BB0N

BB1P

BB1N

BB2P

BB2N

BB3P

BB3N

VDDC

RESET

CS_CEC

3

2

8

7

6

5

5VSTB

U15

U15

24C32

24C32

VCC

WP

SCL

PWR_ON

C1080.1uC1080.1u

GND4SDA

R204NCR204

NC

R210

R210

4.7K

4.7K

OE

CKV

STV

STH

POL

TP

GVON

GVOFF

B2P

B2N

B1P

B1N

B0P

B0N

G2P

G2N

G1P

G1N

G0P

G0N

CLKP

CLKN

RXO3RXO3+

RXE0RXE0+

BRI_ON/OFF

1482_ON/OFF

3401_ON/OFF

RXE1RXE1+

RXE2RXE2+

RXECRXEC+

RXE3RXE3+

HDMI_CEC

1

A0

2

A1

3

A2

C112

C112

0.1uF

0.1uF

EEP_SCL

EEP_SDA

RXO0-R2P

RXO0+R2N

RXO1-R1P

RXO1+R1N

RXO2-R0P

RXO2+R0N

RXOCRXOC+

VCC-Panel

GVON

GVOFF

+3.3V_MST

R1672KR167

R1682KR168

2K

2K

+3.3V_MST

R1814.7K R1814.7K

1482_ON/OFF

LED_CTL

BRI_ON/OFF

PANEL-ON/OFF

POWER-ON/OFF

WP

BRI_ADJ

AMP-MUTE

13.5V 190mA--250mA

3.3V 110mA

5

CD

4

R263 0R263 0

R264 0R264 0

1

2

3

4

5786

RP20RP2

0

FPC connector for 21.6CMO

FPC connector for 21.6CMO

KEY0_inKEY_0

KEY1_in

R1784.7K R1784.7K

R1794.7K R1794.7K

R1834.7K R1834.7K

R1844.7K R1844.7K

VGH

VGL

XAO

OE

CKV

STV

STH

POL

TP

VDA

VDD

GM1

GM2

GM3

GM4

GM5

GM6

GM7

GM8

GM9

GM10

GM11

GM12

GM13

GM14

CLKN

CLKP

G0N

G0P

G1N

G1P

G2N

G2P

B0N

B0P

B1N

B1P

B2N

B2P

KEY_1

VDD

XAO

5V

C104

C104

560pF

560pF

2

R175 1KR175 1K

R172 1KR172 1K

C89

C89

C90

C90

1nF

1nF

1nF

1nF

IRin

KEY0_in

KEY1_in

ESD

ESD

ESD

ESD

ESD

ESD

ZD39

ZD39

ZD38

ZD38

ZD40

ZD40

R192

R192

10K

10K

U14

U14

S-80937CNMC

S-80937CNMC

1

OUT

2

VDD

VSS3NC

C105 NCC105 NC

R0N

R0P

R1N

R1P

R2N

R2P

1

2

RP1

RP1

3

4

22R

22R

5

6

7 8

R162 22RR162 22R

R163 22RR163 22R

R164 22RR164 22R

R165 22RR165 22R

124

123

122

121

120

119

118

117

116

115

114

113

VDDP

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

GND

84

83

82

GND

81

80

SCL

79

SDA

WP

I2C_SCL

I2C_SDA

R208

R208

4.7K

4.7K

AMP-MUTE

R200

R200

R1994.7K R1994.7K

4.7K

4.7K

R198 100RR198 100R

R201 100RR201 100R

R203 100RR203 100R

U17

U17

24C08

24C08

1

A0

2

A1

3

A2

GND4SDA

VCC

SCL

R211NCR211

NC

EEP_SCL

EEP_SDA

WP

LED_CTL

1482_ON/OFF

3401_ON/OFF

PWR_ON

VDDC

RESET

RX_SCL

TX_SDA

5VSTB

8

7

6

5

IR_in

IR_in

C81

C81

100pF

100pF

R173 470R173 470

R174 1KR174 1K

R176 470R176 470

R177 1KR177 1K

LVDS

R1864.7K R1864.7K

R1824.7K R1824.7K

R1854.7K R1854.7K

CON6

CON6

1

GND

2

VGH

3

GND

4

VGL

5

XAO

6

OE

7

CKV

8

STV

9

NC

10

NC

11

STH

12

POL

13

TP1

14

VDA

15

VDA

16

VDA

17

VDD

18

VDD

19

GND

20

GM1

21

GM2

22

GM3

23

GM4

24

GM5

25

GM6

26

GM7

27

GM8

28

GM9

29

GM10

30

GM11

31

GM12

32

GM13

33

GM14

34

GND

35

R0N

36

R0P

37

R1N

38

R1P

39

R2N

40

R2P

41

CLKN

42

CLKP

43

G0N

44

G0P

45

G1N

46

G1P

47

G2N

48

G2P

49

B0N

50

B0P

51

B1N

52

B1P

53

B2N

54

B2P

55

GND

565657

57

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

Date: Sheet of

Date: Sheet of

Date: Sheet

1

R160

R160

IRin

R161 10KR161 10K

100R

100R

K6

K2

R171 2kR171 2k

K3

K1

K5

VCC-Panel

RXO0RXO1- RXO1+

RXO2- RXO2+

RXOCRXO3RXE0RXE1RXE2-

RXEC-

RXE3-

VCC-Panel

R249 4.7KR249 4.7K

5VSTB

LED_GRE

LED_RED

K6

K5

K4

K3

K2

K0K4

K1

K0

CON5

CON5

1

2

1

2

3

4

3

4

5

6

5

6

7

8

7

8

9

10

9

10

11

12

11

12

13

14

13

14

15

16

15

16

17

18

17

18

19

20

19

20

21

22

21

22

23

24

23

24

25

26

25

26

27

28

27

28

29

30

29

30

2*20P_2.0mm_HEADER

2*20P_2.0mm_HEADER

DIP15X2-79-V

DIP15X2-79-V

RXO3+

RXO3-

RXOC+

RXOC-

RXO2+

RXO2-

RXO1+

RXO1-

RXO0+

RXO0-

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

10

11

12

U840

U840

VCC

VCC

VCC

VCC

VCC

GND

GND

GND

NC

SELLCDS

NC

GND

RX3+

RX3GND

RXCLK+

RXCLKGND

RX2+

RX2GND

RX1+

RX1GND

RX0+

RX0GND

NC

GND

NC

GND

NC

C0N30-1.25

C0N30-1.25

CON10

CON10

1

2

3

4

5

6

7

8

9

PH-12A

PH-12A

C8

0.1uFC80.1uF

RXO0+

RXOC+

RXO3+

RXE0+

RXE1+

RXE2+

RXEC+

RXE3+

MST721 BLOCK

of

611Sunday, December 07, 2008

611Sunday, December 07, 2008

1

611Sunday, December 07, 2008

32

31

Page 35

5

4

3

2

1

+5V_Tuner

D D

RP110R RP110R

1

AU_SD

AU_SCLK

AU_WS

AU_MCLK

C C

B B

AV-Lout

AV-Rout

TV_AUDIO

TV_AUDIO

AV1_Rin

DVD_Rin

VGA_Rin

BTSC_L

BTSC_R

VGA_Lin

DVD_Lin

AV1_Lin

R224 1KR224 1K

R226 1KR226 1K

R216 NC/0R216 NC/0

R217 NC/0R217 NC/0

AV1_Rin

DVD_Rin

VGA_Rin

HDMI_Rout

BTSC_L

BTSC_R

HDMI_Lout

VGA_Lin

DVD_Lin

AV1_Lin

2

3

4

5

6

7 8

10nF

10nF

C145

C145

C140 2.2uFC140 2.2uF

C142 2.2uFC142 2.2uF

BTSC_L

BTSC_R

10nF

10nF

C159

C159

C124 1uFC124 1uF

C125 1uFC125 1uF

C126 1uFC126 1uF

C128 1uFC128 1uF

C130 1uFC130 1uF

C132 1uFC132 1uF

C134 1uFC134 1uF

C136 1uFC136 1uF

C138 1uFC138 1uF

C139 1uFC139 1uF

C141

C141

2.2uF

2.2uF

C143

C143

2.2uF

2.2uF

L14FBL14

FB

C1202.2uF C1202.2uF

C114

C114

10uF

10uF

C1210.1uF C1210.1uF

1

2

3

4

5

U18

U18

CS4344

CS4344

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SDATA

DEM/SCLK

LRCK

MCLK

VQ

I2S DAC (option)

C115

C115

0.1uF

0.1uF

9

AOUTLR

VADD

AGND

8

U19

U19

R2S15908

R2S15908

INR5

INR4

INR3

INR2

INR1

INL1

INL2

INL3

INL4

INL5

IGOUTL

VOLINL

IGOUTR

VOLINR

AOUTL

FILT

10

7

6

ROUT

LOUT

TRER

BASSR1

BASSR2

BASSL2

BASSL1

TREL

DGND

SDA

SCL

AGND

REF

VCC

C116 2.2uFC116 2.2uF

C117 2.2uFC117 2.2uF

C122

C122

10uF

10uF

28

27

C127 8200pC127 8200p

26

C129 0.068uC129 0.068u

25

C131 0.068uC131 0.068u

24

C133 0.068uC133 0.068u

23

C135 0.068uC135 0.068u

22

C137 8200pC137 8200p

21

20

19

18

17

+

CA24

16

15

CA24

10uF

10uF

R212 470RR212 470R

R213 470RR213 470R

SDA

R223

R223

100R

100R

SCL

R225

R225

100R

100R

R219

R219

AMP-R

AMP-L

8.2K

8.2K

R222

R222

8.2k

8.2k

C118

C118

470p

470p

I2C_SDA

I2C_SCL

+9VA

C144

C144

0.1uF

0.1uF

C119

C119

470p

470p

R21410K R21410K

R21510K R21510K

HDMI_Rout

HDMI_Lout

R218 10(1/2W)R218 10(1/2W)

R220 220R220 220

CA23

CA23

+

+

NC

NC

9V for Audio

Q19

Q19

2N3904

2N3904

+9VA+12VA

23

R221

R221

NC/0R

NC/0R

1

CA22

CA22

100uF/16v

100uF/16v

D99VD9

9V

A A

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

<Doc> <RevCode>

Custom

Date: Sheet

Date: Sheet of

5

4

3

Date: Sheet of

2

1

of

711Monday, November 24, 2008

711Monday, November 24, 2008

711Monday, November 24, 2008

Page 36

5

4

3

2

1

D D

C C

B B

TDA1517P

AMP-L

AMP-R

+12VU

D10

D10

3

BAV99

BAV99

1

2

R239

R239

CA31

CA31

+

+

2.2M

2.2M

220uF/16V

220uF/16V

0.1uF

0.1uF

C150

C150

R233

R233

2.2M

2.2M

R235

R235

10R

10R

Q20

Q20

2N3906

2N3906

R228

R228

470R

470R

R229

R229

470R

470R

R240

R240

22K

22K

C148

C148

3.3nF

3.3nF

AMP-MUTE7

R236

R236

470R

470R

1

C149

C149

3.3nF

3.3nF

R231 10KR231 10K

2 3

R241 1KR241 1K

+12VA

Q21

Q21

2N3904

2N3904

C146 2.2uFC146 2.2uF

C147 2.2uFC147 2.2uF

L15 FBL15 FB

L16 FBL16 FB

R234

R234

8.2K

8.2K

1

+

+

R232 2.2KR232 2.2K

Q22

Q22

2N3904

2N3904

2 3

470uF/16V

470uF/16V

CA28

CA28

+

+

CA29

CA29

47uF/16V

47uF/16V

U20

U20

TDA1517P

TDA1517P

+

+

CA30

CA30

100uF/16V

100uF/16V

R227

R227

3.3K

20

1

INV1

9

INV2

7

VP

8

M/SS

3

SVRR

GND

GND

2

5

OUT1

GND17GND18GND19GND

OUT2

GND12GND13GND14GND15GND

16

4

6

3.3K

+

+

CA26

CA26

470uF/16V

470uF/16V

+

+

CA27 470uF/16V

CA27 470uF/16V

R230

R230

3.3K

3.3K

CON9

CON9

PHONE_JACK_STEREO_SW

PHONE_JACK_STEREO_SW

4

2

1

3

5

SP_L1

SP_R1

AGND

SP_L1

SP_R2

SP_R1

SP_L2

R242

R242

100(1/2W)

100(1/2W)

SP_L2

SP_R2

CON4_2.5

CON4_2.5

1

2

3

4

CON8

CON8

1

1

M3

1

1

M4

1

HOLE-V8M4HOLE-V8

H6

H6

NC/HOLE-V8

NC/HOLE-V8

1

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc>

A3

<Doc>

A3

<Doc>

A3

Date: Sheet

Date: Sheet of

2

Date: Sheet of

811Sunday, December 07, 2008

811Sunday, December 07, 2008

811Sunday, December 07, 2008

1

<RevCode>

<RevCode>

<RevCode>

of

M2

1

HOLE-V8M2HOLE-V8

HOLE-V8M3HOLE-V8

H1

H1

1

5

4

3

2

NC/HOLE-V8

NC/HOLE-V8

A A

5

9

8

7

6

H2

H2

5

4

3

2

NC/HOLE-V8

NC/HOLE-V8

4

H3

1

9

8

7

6

H3

5

4

3

2

NC/HOLE-V8

NC/HOLE-V8

1

9

8

7

6

H4

H4

5

4

3

2

NC/HOLE-V8

NC/HOLE-V8

3

H5

1

9

8

H5

1

7

6

NC/HOLE-V8

NC/HOLE-V8

Page 37

5

4

3

2

1

D D

VCC-Panel

+5V

C154

C154

0.1uF

0.1uF

R245

R245

0805/3.3R/1%

0805/3.3R/1%

U24

U24

3

AT1380

AT1380

C203

C203

270pF

270pF

2

7

C202

C202

NC/0.1uF

NC/0.1uF

OUT

SCP

VCC

IN

FB

OSC

CTL

GND

4

6

R251

R251

200R

200R

1

2N3904

2N3904

2 3

C182 0.1uFC182 0.1uF

R255

R255

3K/1%

3K/1%

VDD

C C

PWR_ON

R1804.7K R1804.7K

R254

R254

10K

10K

走线要尽量短,尽量粗

5

1

8

Q36

Q36

10UH/1.7A

10UH/1.7A

R243

R243

2.2K/1%

2.2K/1%

C151

C151

0.1uF

0.1uF

L27

L27

13

1

R246

R246

10R

10R

C106

C106

100pF

100pF

32

U21

U21

AO3400L

AO3400L

R258

R258

1.8K

1.8K

D14

D14

SK24

SK24

R257

R257

47K

47K

VDA

VDA=0.5X(1+R2/R5)

R244

R244

0805/0R

0805/0R

2

3

2

C155

C155

NC/1uF

NC/1uF

3

U22

U22

NC/AO3401

NC/AO3401

1

1

R250

R250

NC/1K

NC/1K

5V

CA34

CA34

100uF/25V

100uF/25V

C206

C206

+

+

0.1uF

0.1uF

VDA

VDA=0.5X(1+R2/R5)

13.5V

CMO216 190MA-250MA

VCC-Panel

D17

D17

BAV99WPT

BAV99WPT

3

3

D18

D18

BAV99WPT

BAV99WPT

1

C205

C205

1uF

1uF

2

2

C152

C152

1

1uF

1uF

VDA

C156

C156

1uF

1uF

C157

C157

1uF

1uF

R252

R252

10K

10K

R248

R248

100K

100K

R247

R247

20K

20K

2N3906

2N3906

Q23

Q23

2N3906

2N3906

Q24

Q24

12

D13

D13

6.2/BZT52C6V2S-F

6.2/BZT52C6V2S-F

+

+

R2560RR256

0R

CA33

CA33

10uF/16V

10uF/16V

R260

R260

47K

47K

C204

C204

0.1uF

0.1uF

CA35

CA35

+

+

10uF/50V

10uF/50V

R259

R259

0603/0R

0603/0R

VGL

-5.5V 3mA

R253

R253

0603/0R

0603/0R

C153

C153

0.1uF

0.1uF

VGHP

25.6V 10mA

VDA

B B

R2610RR261

0R

Q25

Q25

NC/AO3401

NC/AO3401

2

3

2

VCC-Panel

3

R593

R593

1

CMO216 AMS1117-3.3

4

FOR CMO216 110mA

AMS1117-3.3

AMS1117-3.3

ADJ

OUT

ADJ

OUT

IN

IN

U23

U23

321

C158

C158

+

+

0.1uF

0.1uF

CA37

CA37

47uF/16V

47uF/16V

VDD

R585

R585

NC/10K

NC/10K

32

Q34

Q34

NC/AO3400

NC/AO3400

1

CA36

CA36

C107

C107

+

+

47uF/16V

47uF/16V

0.1uF

0.1uF

GVOFF

NC/560R

NC/560R

R594

R594

NC/2.7K

NC/2.7K

1

NC/AO3400

NC/AO3400

VGHVGHP

R591

R591

NC/1.2K/1%

NC/1.2K/1%

VDD

R590

R590

NC/10K

32

Q35

Q35

NC/10K

1

GVON

A A

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

A2

<Doc> <RevCode>

A2

<Doc> <RevCode>

A2

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet

1

of

911Thursday, November 27, 2008

911Thursday, November 27, 2008

911Thursday, November 27, 2008

Page 38

5

D D

4

3

R2671KR267

1K

2

1

C168 0.1uFC168 0.1uF

C169 0.1uFC169 0.1uF

C170 0.1uFC170 0.1uF

C171 0.1uFC171 0.1uF

GM1

GM2

GM3

GM4

GM5

GM6

GM11

GM13

GM10

GM12

GM14

GM7

GM8

GM9

C C

C172 0.1uFC172 0.1uF

C173 0.1uFC173 0.1uF

C174 0.1uFC174 0.1uF

C175 0.1uFC175 0.1uF

C176 0.1uFC176 0.1uF

C177 0.1uFC177 0.1uF

C178 0.1uFC178 0.1uF

C179 0.1uFC179 0.1uF

C180 0.1uFC180 0.1uF

C181 0.1uFC181 0.1uF

GM14

GM13

GM12

GM11

GM10

GM9

GM4

GM3

GM2

GM1

R271 10RR271 10R

R272 10RR272 10R

RP12

RP12

10R

10R

7531

8642

7531

8642

VDA_OP VS7

RP13

RP13

10R

GM8

GM7

GM6

GM5

10R

7531

8642

7531

8642

RP14

RP14

10R

10R

7531

8642

7531

8642

VDA

R287

R287

82.5R/1%

82.5R/1%

B B

R288

R288

10.5K/0.5%

10.5K/0.5%

2

R290

R290

2.55K/0.5%

2.55K/0.5%

R2910R291

0

VREF

1

D15

D15

CA50

CA50

+

+

10uF/16V

10uF/16V

3

LM431/GS431W(A)

LM431/GS431W(A)

VDA

C183

C183

1uF

1uF

VDA_OP

VS14

VS13

38

46

44

37

40

45

43

39

47

1

Mo

2

Lo

3

Ko

4

Jo

5

Io

6

Ho

7

VSS

8

VDD

9

Go

10

Fo

11

Eo

12

Do

48

No

VSS

VDD

Vcomo

Co13NC14VDD15NC16NC17Bo18VSS19Ao20VSS21VDD22Ai23Bi

VDA_OP

U40

U40

Ni

Mi

NC42NC41NC

VSS

VDD

Vcomi

VS12

36

Li

VS11

35

Ki

VS10

34

Ji

VS9

33

Ii

VS8

32

Hi

31

VSS

30

VDD

29

Gi

VS6

28

Fi

VS5

27

Ei

VS4

26

Di

VS3

25

Ci

24

VS2

VS1

VDA_OP

U40.8 U40.15 U40.22 U40.30 U40.43 U40.45

C185

C185

C186

0.1UF

0.1UF

C186

0.1UF

0.1UF

C187

C187

0.1UF

0.1UF

C188

C188

0.1UF

0.1UF

C184

C184

0.1UF

0.1UF

VDA_OP

EC5575/HX8915

EC5575/HX8915

VDA_OP

C189

C189

0.1UF

0.1UF

VREF VREF

R269

R269

1.33K/1%

1.33K/1%

VS1

R273

R273

750R/1%

750R/1%

VS2

R275

R275

1.18K/1%

1.18K/1%

VS3

R277

R277

620R

620R

VS4

R279

R279

360R/1%

360R/1%

VS5

R281

R281

732R/1%

732R/1%

VS6

R283

R283

1.1K/1%

1.1K/1%

VS7

R285

R285

6.2K/1%

6.2K/1%

R270

R270

6.81K/1%

6.81K/1%

R274

R274

715R/1%

715R/1%

R276

R276

R278

R278

R280

R280

665R/1%

665R/1%

R282

R282

1.4K/1%

1.4K/1%

R284

R284

787R/1%

787R/1%

R286

R286

665R/1%

665R/1%

VS8

VS9

825R/1%

825R/1%

VS10

422R/1%

422R/1%

VS11

VS12

VS13

VS14

A A

Title

Title

Title

<Title>

<Title>

<Title>

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

A2

<Doc> <RevCode>

A2

<Doc> <RevCode>

A2

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet

1

of

10 11Thursday, September 11, 2008

10 11Thursday, September 11, 2008

10 11Thursday, September 11, 2008

Page 39

5

D D

C C

I2C_SDA

I2C_SCL

+9VA

I2C_SDA

I2C_SCL

+9VA

C196

C196

100nF

100nF

B B

TV-SIFP

C200 220nFC200 220nF

CA47 4.7uF/16V

CA47 4.7uF/16V

TV-SIFP

+

+

4

R292

R292

8.2K

8.2K

R293

R293

150

150

C191 47nC191 47n

+

+

CA39 10uF/16V

CA39 10uF/16V

+

+

CA42 4.7uF/16V

CA42 4.7uF/16V

R295 100R295 100

C197 2.2uFC197 2.2uF C198 15nFC198 15nF

+

+

CA45 100uF/16V

CA45 100uF/16V

C201

C201

470n

470n

R296 2.2KR296 2.2K

+

+

CA49 10uF/16V

CA49 10uF/16V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

U26

U26

VEO

VEI

C-NR

C-M

C-DEC

AGND

DGND

SDA

SCL

VCC

COMP

V-CAP

C-P1

C-P2

C-PH

C-ADI

TDA9850T

TDA9850T

3

C-S

C-W

C-TS

C-TW

MAD

OUTL

C-ND

C-L

Vref

SAP

C-SDE

OUTR

C-R

C-SS

C-MO

CER

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

C190 1uFC190 1uF

C192 1uFC192 1uF

CA40 10uF/16V

CA40 10uF/16V

CA41 10uF/16V

CA41 10uF/16VC193 100nFC193 100nF

C194 100nFC194 100nF

C195 2.2uFC195 2.2uFR294 100R294 100

CA43 100uF/16V

CA43 100uF/16V

C199 2.2uFC199 2.2uF

C207 2.2uFC207 2.2uF

C208 2.2uFC208 2.2uF

C209 2.2uFC209 2.2uF

C210 2.2uFC210 2.2uF

2

+

+

+

+

BTSC_L

+

+

BTSC_R

BTSC_L

BTSC_R

1

1 2

X1 500KX1 500K

A A

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Date: Sheet of

Date: Sheet of

5

4

3

Date: Sheet

<Title>

<Title>

<Title>

<Doc> <RevCode>

A

<Doc> <RevCode>

A

<Doc> <RevCode>

A

of

11 11Thursday, September 11, 2008

11 11Thursday, September 11, 2008

2

11 11Thursday, September 11, 2008

1

Page 40

9.Trouble shooting

Power supply trouble

1、Power supply trouble

Check (F1/3A) for 12V?

N

Y

Check F1 and peripheral power supply Check E33/470μF/16V for 5V

N

F1 is damaged?

NY

Turn on the TV-set(By button or

remote control)

N

Y

LDO(U10,U13,U16,U18,U19,

Were those

etc.)worked normal?

Check power

OK

supply net

follow F1

Check U6/MCU

1:Power supply(U7、U9))

2:Reset signal

3:Crystal

Change U1/MP1410ES-LF or

D17/SK34A-SMA

Check U1 for 5V

output

YN

Check L9/47μH

LDO was damaged

or the loader is in

short circuit

Y

YN

OK

It’s normal but the

voltage is high

Check Pin No.4 of

U1/MP1410-ES or

change U1

It’s normal but the

voltage is Low

E33 was damaged

or the loader is in

short circuit

Page 41

Power supply trouble (DVB--T)T)

Power supply trouble (DVB

2

、

Check E43/470μF/16V for 5V

N

Check U15 Pin 3 for 12V pulse

Y

L16 open

or

damaged

NO 12V

Check The PCB board isn`t

open or in short circuit from

F1 to U15 Pin 2

N

Check U15 Pin

NO.2 for 12V

input,Pin

NO.7 for 3.3V

NO 3.3V

Check U6/MCU Pin NO.

5 for 3.3V output

Or change U6/MCU

U22 is

damaged

and

change it

N

Check U22

for 5V

input

Y

Check

U22

output

is in

short

circuit

N

Y

1 U22 is damaged and

change is。

2 Check the back

circuit

Check U22

(AIC1084-

33PM)for

3.3V output

N

Check the

circuit

before

U22

Check U34

for 1.2V

output

Check U34

for 3.3V

input

Y

Check

U34

isn`t in

short

circuit

N

Y

Y

Y

N

Y

U34 is damaged and

change it

Check

U32 and

change

it

1 U34 is damaged and

change is。

2 Check the back circuit

Check U32

(AZ1117H

-1.8)for

1.8V output

N

Check U32

for 5V

input

N

Check

U32

Front

Circuit for

power

supply

Page 42

Display trouble(exceptional

screen)

Y N

Check if the LCD

panel is ok

NY

Exceptional screen

Check if the cable is correct

and connected tightly

Change LCD

Check the circuit of output and

the CN2/Jack

Y

Check the power supply for

U5 and the clock circuit

N

Change or repair the

Damaged components

Change the cable for

Panel connector

Page 43

Display trouble(white screen)

NY

White screen

Check the power supply

for panel

Check the switch signal for

Q24/AO3401(changed

Check CN8 or change Q24

from 5~0V)

NY

Check the circuit from U6/NT68F631 to Q24

or U6 had been damaged

Check the output signal

Of U5

Y

Change the LCD panel or

The cable to panel

N

Check U5

Page 44

Display trouble(black screen)

Black screen

The voltage of BLON Signal

is 5v? (on CN10 )

Check if the inverter is

NY

Change the inverter

Y

working normal?

Check the power

supply for TV set

N

Check R25/22 ohm or change U6

Page 45

Audio trouble(No sound)

N

No sound

Check if have audio input signal

Y

Check the set of volume

and MUTE

Check the

audio

source

N

Reset it

Y

Check the

speaker

Check the circuit

from U6-pin2,30 to

U3-pin8 or U6 had

been damaged

Check U3-pin8 voltage≥9.2V

Y

Check if U3-pin4,6 have

audio signal output

N

Change U3

Check the output

circuit from U3

and CN23

Y

Check CN11 output

signal

Y

Check if U3-pin1,9 have

audio signal input

Y

Check audio input signal:

PC/SV/YPBPR:U21-pin53,54

SCAR:U21-pin56,57

YN

Check U21pin45 for 8V

or change

U21

N

Check U3/TPA1517NE-pin7

for power supply >11V

YN

N

Check if U21-pin60,61

have audio signal output

N

Check the

net between

audio input

jack and

U21

N

Y

Check the

Power supply

Circuit for

U3

Check the

net between

U21-pin60,61

And U3-pin1,9

Page 46

Function trouble

(TV video)

N

TV cann’t searched any channel/no picture

Confirm if the RF cable

does have signal

Check T1/VA1Y1ED2002

Check T1-pin4,5 for I2C

Y

Check T1-pin8 for signal

Pin7for 5V?

Y

Y

N

N

Check

external

RF

Signal

source

Y

Check the

circuit from

T1-pin8to

U21-pin24,25

and the power

supply for U21

TCheck T1pin1for

voltage 1.8~4.3V

changeT1

N

Check the circuit

NY

Check I2C circuit

(U6/NT68F631

PIN16,17)

Check the

power

supply

circuit

Page 47

Display trouble(exceptional

screen)

TV no audio but picture

The same as in PC and YPBPR mode?

Y

If there was signal on

Pin2 of SAW2/AF389A2D?

YN

N

Refer to ”6”

1. Change SAW2

2. Examine PIN No.29,30 of U21

3. Examine the power supply for

U21

4. Change U21

1.Check the circuit

between SAW2/pin2

and C133/0.01μF

2.change C133.

Page 48

Function Trouble (PC)

PC

Picture not

In center

Do “Auto adjust”

process

Missing

color

Check the R.G.B

input signal for U5

YN

Do “Reset“ process

on the menu

Check the circuit

of R.G.B

input

Picture

dithering

Check if the wave

of Vsync,Hsync is ok

Y

Do “Reset“ process

on the menu or

the input mode

cann’t be support

N

Check the

circuit of

Vsync,Hsync

No signal

Check the circuit

of Vsync,Hsync

or there was no

signal input

Page 49

Function Trouble (Scart,HDMI,YPBPR)

SCART RGB、HDMI 、YPBPR 、 SCART Video、S- Video

No signal

Check the circuit of

VSYNC and HSYNC

signal

Missing

color

Check the input signal of R.G.B

to U5

YN

Check R.G.B circuit

(If on scart channel,

Reset

should check the

input circuit of

SCART R.G.B)

PC/HDMI/YPBPR mode

No signal besides

Check the power