OPERATION & INSTRUCTION

MANUAL

No. 0010575124

B

DUCT TYPE AIR CONDITIONER

AD88NAHAAA

AU88NATAAA

HDU-88H03/(H)

Please read this manual carefully before installing and using the air conditioning unit.

Please keep this manual safe for future use.

1

TABLE OF CONTENTS

OPERATION

9-14

MALFUNCTION

15-16

CARE AND MAINTENANCE

17

FOR PREPARATION OF HEATING("HOT KEEP")

18

IS THE UNIT INSTALLED CORRECTLY

19

INSTALLATION MANUAL FOR WIRE CONTROLLER

20-21

INSTALLATION MANUAL FOR INDOOR UNIT

22-27

INSTALLATION MANUAL FOR ELECTRIC WIRING

28-31

SAFETY PRECAUTIONS

3-5

PARTS AND FUNCTIONS

6-8

CAUTIONS

2

INSTALLATION MANUAL FOR OUTDOOR UNIT

32-38

CAUTIONS

2

All electrical ropairs must be carried out

by qualified electricians. Inadequate repairs

may result in a major source of danger for

the user of the air conditoiner.

Do not damage any parts of the air

conditioner that carry refrigerant by piercing

or perforating the air conditioner's tubes with

sharp or pointed items, crushing or twisting

any tubes, or scraping the coatings off the

surfaces. If the refrigerant spurts out and gets

into eyes, it may result in serious eye injuries.

Do not obstruct or cover the ventilation

grille of the air conditioner. Do not put fingers

or any other things into the inlet/outlet and

swing louver.

Do not allow children to play with the air

conditioner. In no case should children be

allowed to sit on the outdoor unit.

Disposal of the old air conditioner

Before disposing an old air conditioner that

goes out of use, please make sure it's

inoperative and safe. Unplug the air

conditioner in order to avoid the risk of

child entrapment.

It must be noticed that air conditioner

system contains refrigerants, which require

specialized waste disposal. The valuable

materials contained in a air conditioner can

be recycled. Contact your local waste

disposal center for proper disposal of an

old air conditioner and contact your local

authority or your dealer if you have any

question. Please ensure that the pipework

of your air conditioner does not get

damaged prior to being picked up by the

relevant waste disposal center, and

contribute to environmental awareness by

insisting on an appropriate, anti-pollution

method of disposal.

Disposal of the packaging of your new

air conditioner

All the packaging materials employed in

the package of your new air conditioner

may be disposed without any danger to the

environment.

The cardboard box may be broken or cut

into smaller pieces and given to a waste

paper disposal service. The wrapping bag

made of polyethylene and the polyethylene

foam pads contain no fluorochloric

hydrocarbon.

Consult your local authorities for the name

and address of the waste materials collecting

centers and waste paper disposal services

nearest to your house.

Safety Instructions and Warnings

important observations relating to the

assembly, operation and maintenance of the

air conditioner.

Installation shall be done by professional

people, don't install unit by yourself.

All these valuable materials may be taken to

a waste collecting center and used again

after adequate recycling.

Damaged air conditioners are not to be put

into operation. In case of doubt, consult your

supplier.

Use of the air conditioner is to be carried

out in strict compliance with the relative

instructions set forth in the User's Guide.

For the purpose of safety , the air conditioner

must be properly grounded in accordance

with specifications.

Always remember to unplug the air

conditioner before opening inlet grill. Never

unplug your air conditioner by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet.

The manufacturer does not accept

responsibility for any damages that may arise

due to non-observation of the following

instruction.

Before starting the air conditioner, read the

information given in the User's Guide

carefully. The User's Guide contains very

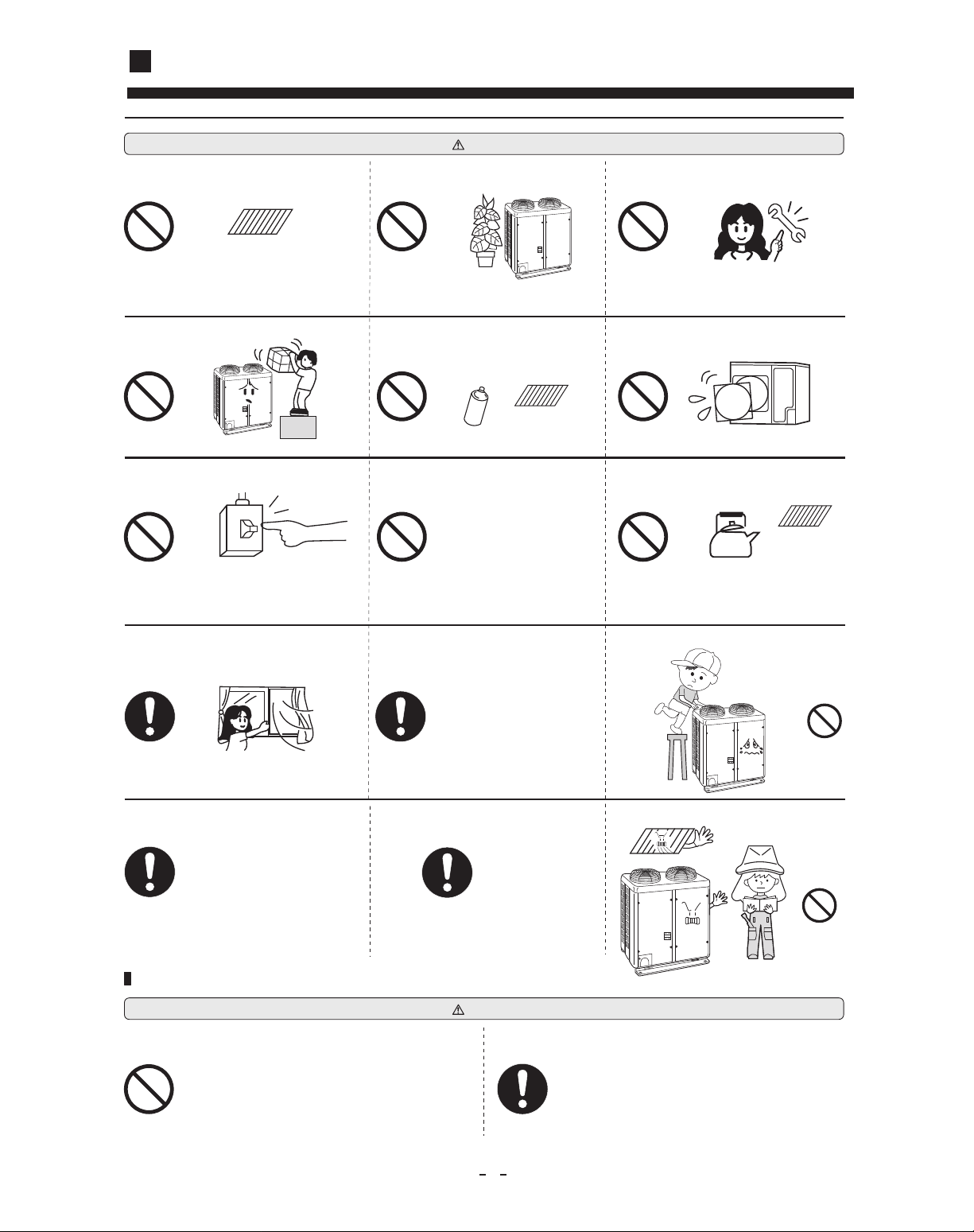

SAFETY PRECATIONS

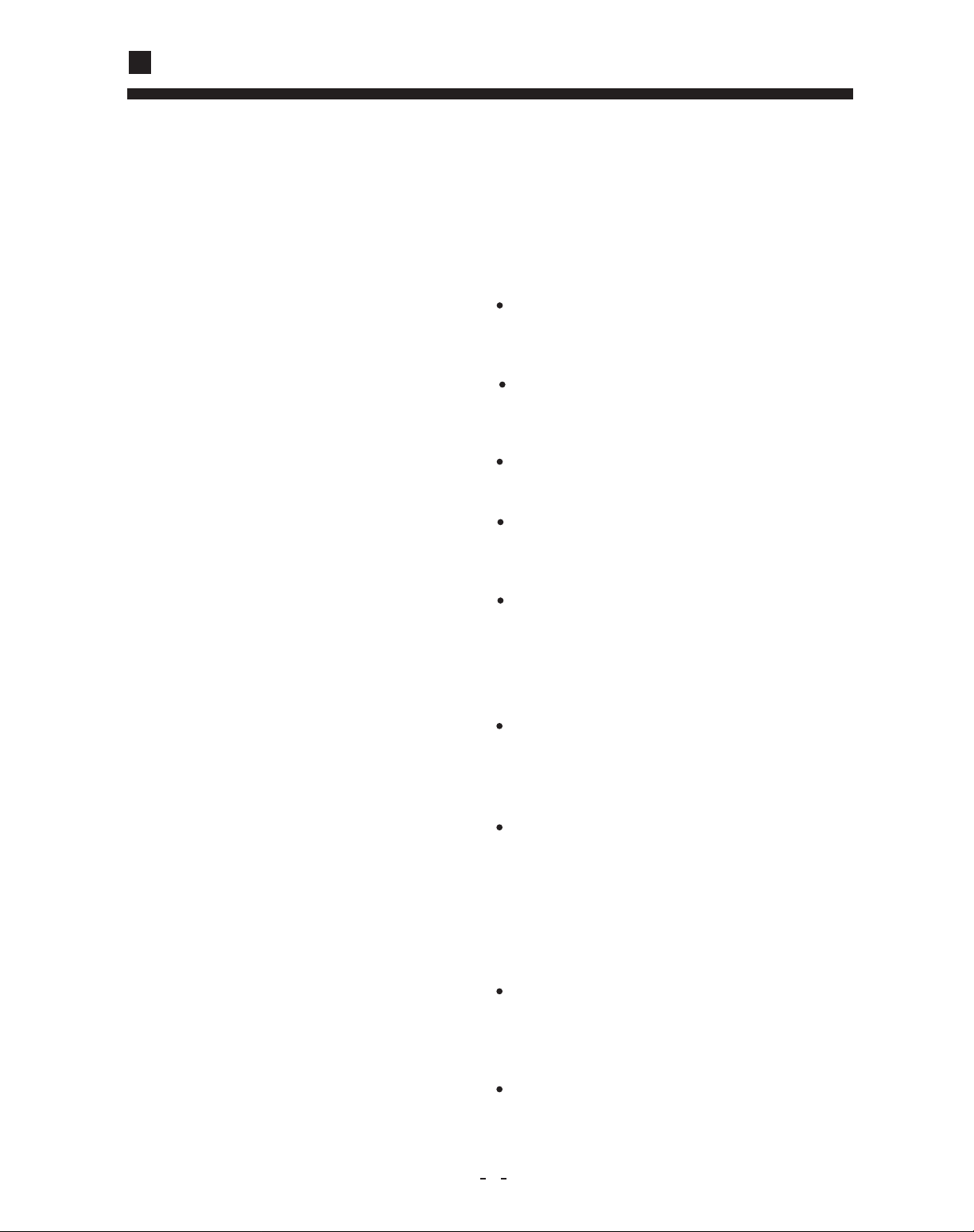

Before starting to use the system, read carefully this"SAFETY PRECAUTIONS" to ensure a proper operation of the system.

Safety precautions described here are classified to " WARNING" and " CAUTION". Precautions which are shown in the column of

"

WANING" means that an improper handing could lead to a grave result like a death, serious injury, etc. However, even if precautions

are shown in the column of " CAUTION", a very serious problem could occur depending on situation. Make sure to observe these safety

precautions faithfully because they are very important information to ensure the safety.

Symbols which appear frequently in the text have following meanings.

Strictly prohibited.

Observe instructions faithfully.

Provide a positive grounding.

When you have read through the manual, keep it always at hand for read consultation. If the operator is replaced, make sure to hand over

this manual to the new operator

.

ON

OFF

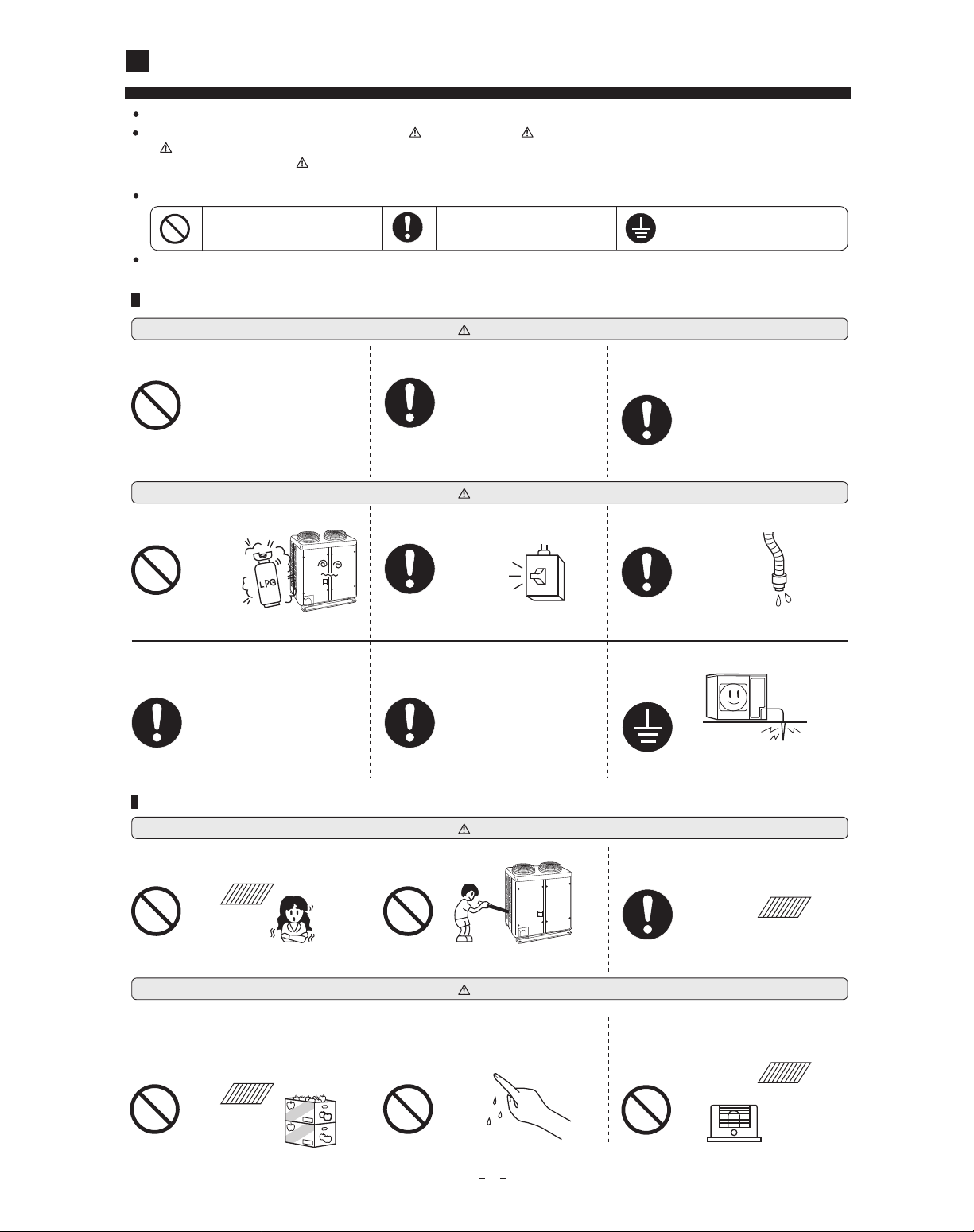

WARNING

CAUTION

WARNING

CAUTION

CAUTIONS FOR INSTALLATION

The system should be applied to places as

of

fice, restaurant, residence and the like.

The system should be installed by your

dealer or a professional installer

.

When you need some optional devices such as a humidifier

, electric heater, etc., be sure to use the products

which are recommended by us. These devices should

be attached by a professional installer.

Application to inferior environment such as an engineering shop, could cause equipment malfunction and

serious injury or death

Installation by yourself is not encouraged because

it could cause such problems as water leakage,

electrical shock or fire accident by some improper

handing

Installation by yourself is not encouraged because it

could cause such problems as water leakage, electrical

shock or fire accident by some improper handing

Do not install nearby the place where may

have leakage of flammable gas.

Depending on the place of installation, a

circuit breaker may be necessary

.

Drain pipe should be arranged to provide a

positive draining

If the gas leakes and gathers around, it may cause the

fire

Unless the circuit breaker is installed, it could

cause elecrical shocks

Where strong winds may prevail, the

system should be fixed securely to prevent

a collapse.

Install on the place where can endure

the weight of air conditioner

.

Make sure the system is grounded.

If the pipe is arranged improperly, furniture or the

likes may be damaged by leaked water

Bodily injury could result by a collapse

Bodily injury could result by a careless installation

Grounding cable should never be connected to a gas

pipe, city water pipe, lightning conductor rod or

grounding cable of telephone If the grounding cable

is not set properly

, it could cause electric shocks

CAUTIONS FOR OPERATION

You should refrain from exposing your body

directly to cool wind for a long time.

Do not poke the air inlet or outlet with a

bar, etc.

When any abnormal condition (scorching smell or others) is found, stop the operation immediately and turn

of

f the power switch. Then consult your dealer.

It could affect your physical condition or cause some

health problems

Since the internal fan is operating with a high

speed, it could cause an injury

If you continue the operation without removing the

cause, it could result in a trouble, electric shock or fire

The system should never be used for any

other purposes than intended such as for

preservation of food, flora and fauna, precision deices or work of art.

Do not handle switches with a wet hand.

Combustion apparatus should not be placed

allowing a direct exposure to wind of air conditioner

Incomplete combustion could occur on the apparatus

It could cause electric shocks

It could cause deterioration of food or other problems

3

SAFETY PRECAUTIONS

4

CAUTION

Do not wash the air conditioner with water.

Do not install the system where the air outlet

reaches directly the flora and fauna

Make sure to use a fuse of proper electric

rating.

Do not operate the system while the

air outlet grill is removed.

It is strictly prohibited to place a container of

combustible gas or liquid near the air conditioner or to spray it directly with the gas or liquid.

Neither stand on the air conditioner nor

place something on it.

Do not use the power switch to turn on or

of

f the system.

Do not touch the air outlet section while

the swing louver is operating.

Do not use such equipment as a water

heater, etc. around the indoor unit or the

wire controller.

ON

OFF

It could cause electric shocks

It will not be good for their health

Use of steel or copper wire in place of a fuse is strictly

prohibited because it could result in a trouble or fire

accident

There is a risk of injury

It could cause a fire accident

There are risks of falling or injury by collapsed object

It could cause a fire or water leakage There is a risk of injury

If the system is operated at the vicinity of such equipment which generates steam, condensed water may

drip during cooling operation or it could cause a fault

current or short-circuit

When operating the system simultaneously

with a combustion

apparatus, indoor air must

be ventilated frequently.

Check occasionally the support structure of

the unit for any damage

after a use of long

period of time.

Insufficient ventilation could cause an

oxygen deficiency accident

If the structure is not repaired immediately, the

unit could topple down to causea personal injury

When cleaning the system, stop the operation

and turn of

f the power switch.

Do not put water containers on the unit

such as a flower vase, etc.

Cleaning should never be done while the internal

fans are running with high speed

If the structure is not repaired immediately, the

unit could topple down to cause apersonal injury

WARNING

CAUTIONS FOR TRANSFER OR REPAIR

Modification of the system is strictly prohibited. When the system

needs a repair

, consult your dealer.

When the air conditioner is relocated, contact your dealer or a professional installer

.

Improper practice of repair could cause water leakage, electric shock or fire Improper practice of installation could cause water leakage, electric shock or fire

Do not place any objects on or climb on

the unit

Do not try to repair or reconstruct by yourself.

SAFETY PRECAUTIONS

5

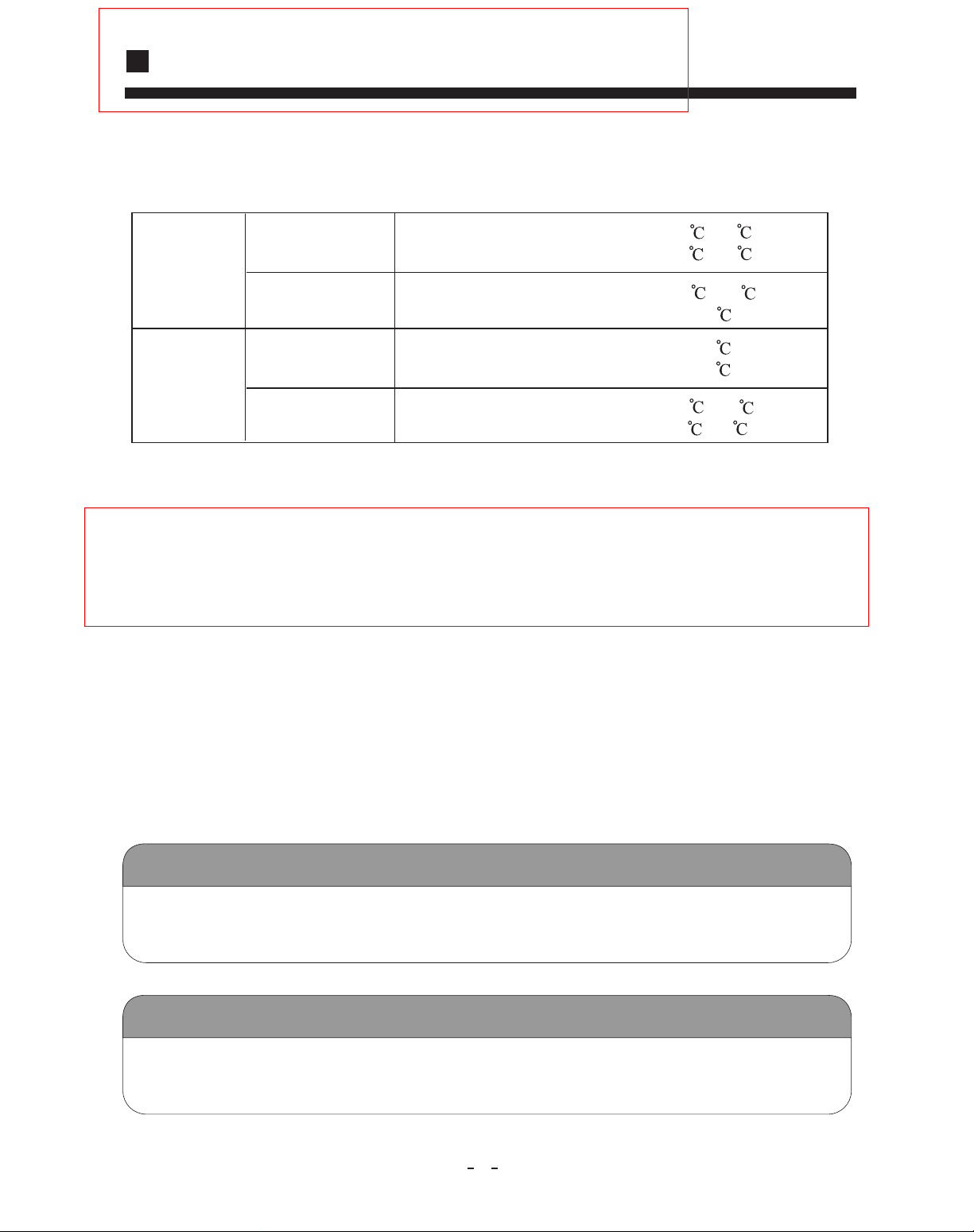

1. Applicable ambient temperature range:

The machine is adaptive in following situation

Cooling

Heating

Indoor

Indoor

Outdoor

Outdoor

Maximum:

Minimum:

Maximum:

Minimum:

Maximum:

Minimum:

Maximum:

Minimum:

D.B / W.B

D.B / W.B

D.B / W.B

D.B / W.B

D.B / W.B

D.B / W.B

D.B

D.B

D.B

32 / 23

18 / 14

-7 / -8

24 / 18

43

15

15

27

/ 26

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent

or a similar qualified person.

3. If the fuse on PC board is broken please change it with the type of T. 3.15A /2500.

4. The wiring method should be in line with the local wiring standard.

5. The power cable and connecting cable are self-provided. The power cable should be

5x5.0mm2 .The connecting cable should be 4x2.0mm2.

All the cables shall have got the European authentication certificate. During installa tion, when the connecting cables break off, it must be assured that the grouding wire is

the last one to be broken off.

6. The breaker of the air conditioner should be all-pole switch; and the distance between its

two contacts should be no less 3mm.

7. The indoor unit installation height is at least 2.5m.

Installation and maintenance must be meet the local installation and miantenance instructions and

should operate by the experienced special installation and maintenance technicians .itherwise we

donít take any duty of the units damage or injure to the person caused by improper operation.

NOTE!

1.The sharp edges and corners and coil surface have the danger to injury ,should avoid of them;

2.Itís very danger to remove the units and power supply wire.because it can cause injury and death .

Cut off all the power supply before mintenance.

WARNING!

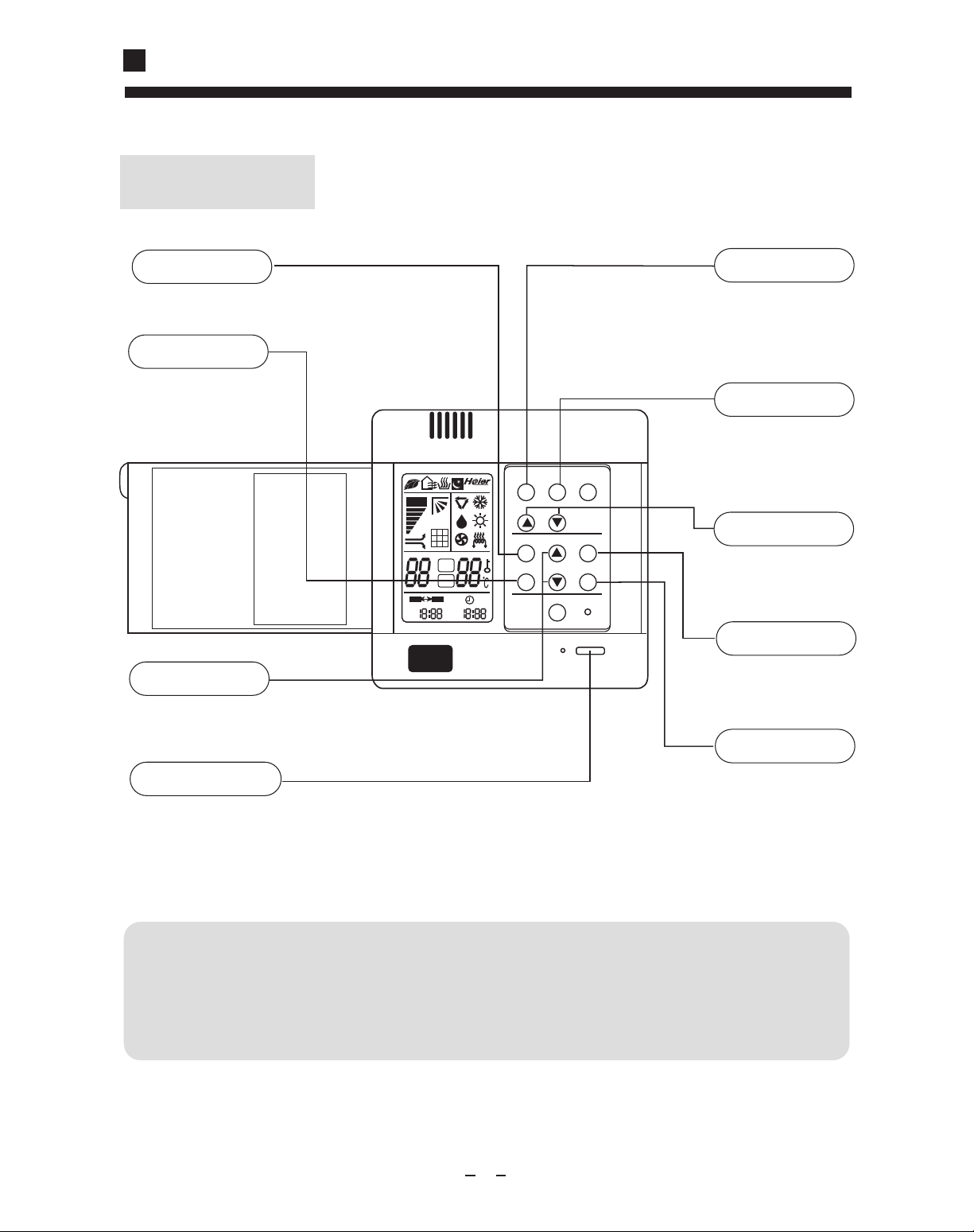

PARTS AND FUNCTIONS

6

Indoor Unit

Air outlet

Air inlet

Air inlet

Duct

Duct

Drainpipe

Air outlet

Air inlet

Buttons and display of the wire controller.

Cautions:

On cooling only unit, heating

mode is not available.

Note:

The above information is the explanation of

the displayed information therefore varies

with those displayed in actual operation.

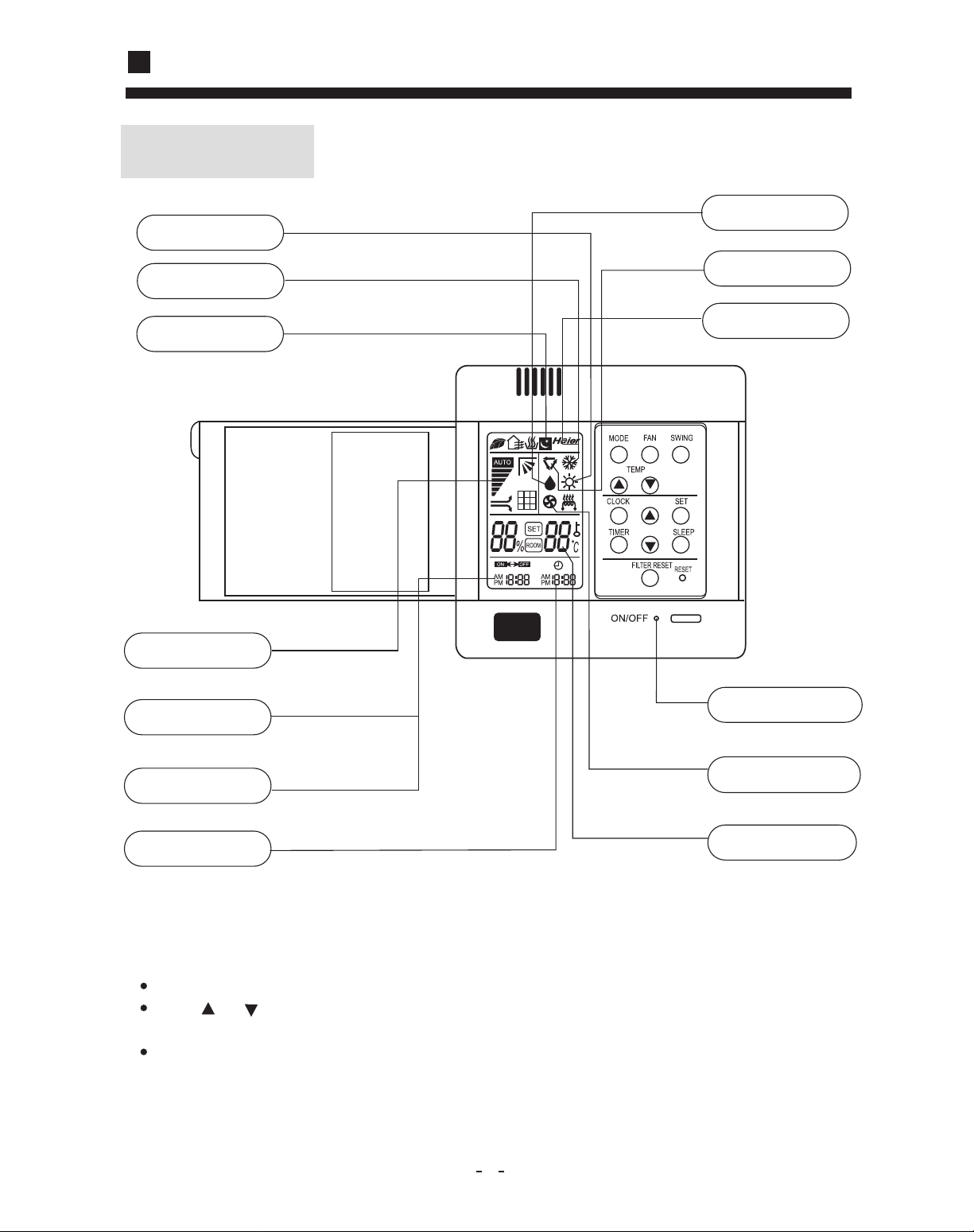

7

CLOCK

Used to set correct time.

TIMER

Used to select

TIMER ON,

TIMER OFF

,

TIMER ON/OFF.

TIME

Used to set clock and

timer setting.

Used for unit start and

stop.

Power ON/OFF

MODE

Used to select AUTO

RUN, COOL, DR

Y,

HEAT and FAN

operation.

FAN SPEED

Used to select fan

speed: LO, MID, HI,

AUT

O

TEMP

Used to select your

desired temp.

SET

Used to confirm Timer

and Clock settings.

SLEEP

Used to select sleep

mode.

AM

PM

AM

PM

PARTS AND FUNCTIONS

Operation

AUTO

%

SET

ROOM

ON OFF

MODE

FAN SWING

TEMP

CLOCK SET

TIMER SLEEP

RESET

F LTER RESET

ON/OFF

PARTS AND FUNCTIONS

8

Buttons and display of the wire controller.

Clock set

When unit is started for the first time, clock should be adjusted as follows:

Press CLOCK button, "AM"or "PM" flashes.

Press or to set correct time. Each press will increase or decrease 1min. If the

button is kept depressed, time will change quickly.

After time setting is confirmed, press SET, "AM "and "PM" stop flashing, while clock

starts working.

Operation

OPERATING LAMP

FAN SPEED

TIMER ON

FAN OPERATION

SLEEP

DRY

HEAT

COOL

AUTO

TIMER OFF

CLOCK

TEMP.

Remote control

MODE

FAN SWING

TEMP

CLOCK SET

TIMER SLEEP

RESET

FILTER RESET

ON/OFF

1

4

3

2

AM

ROOM

OPERATION

9

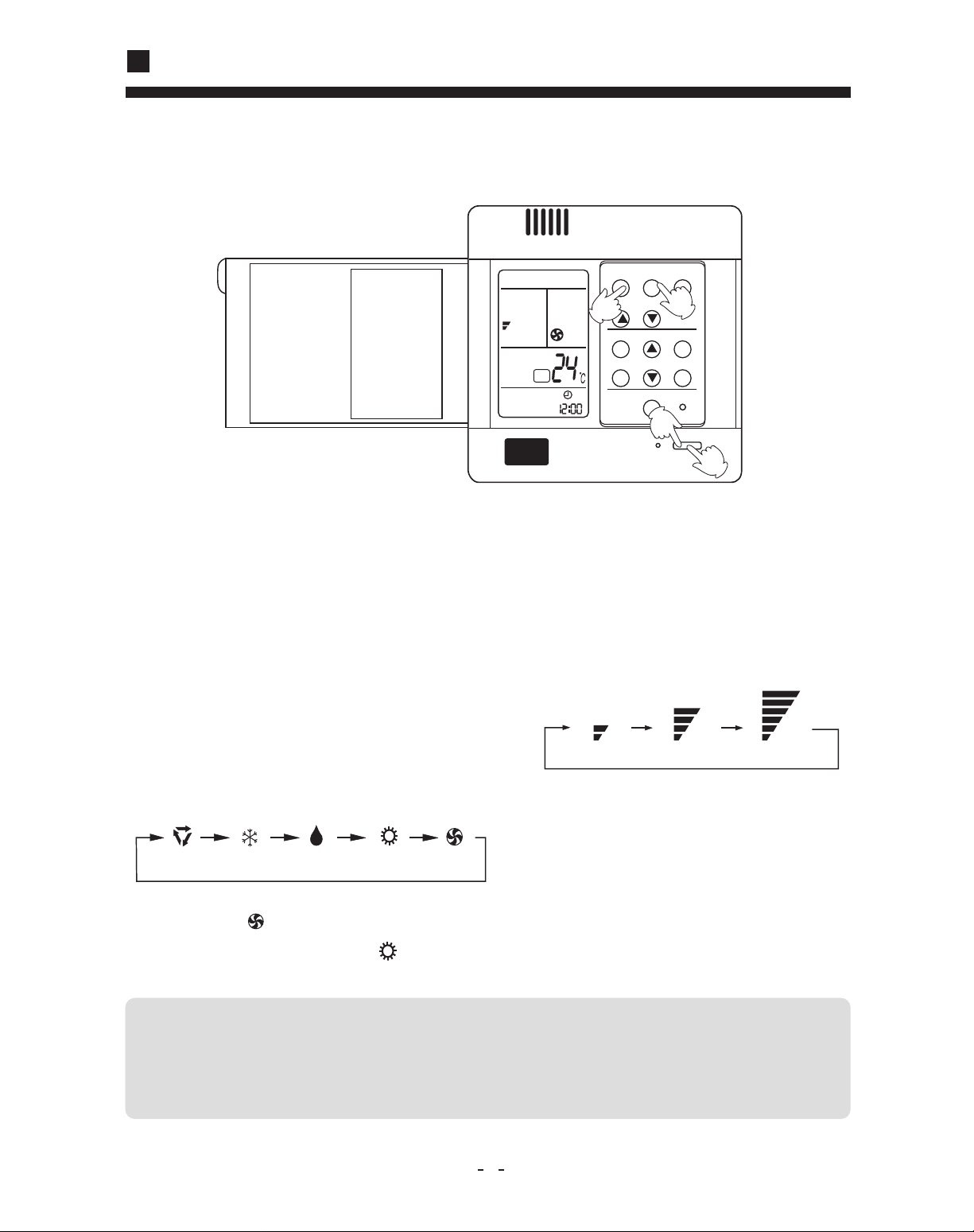

Fan operation

Enjoy yourself by just a gentle press.

(1) Unit start

(2) Select operation mode

(3) Fan

Press ON/OFF button, unit starts.

Previous operation status appears on display.

(Not Timer setting)

Power indicator lights up.

Press MODE button. For each press, operation

mode changes as follows:

Unit will run in selected mode.

stop display at " " FAN.

Press FAN button. For each press, fan speed

changes as follows:

Unit will run at selected fan speed.

Wire controller can memorize settings in each operation mode. To run it next time just select

the operation mode and it will start with the previous setting.

No reselecting is needed.(TIMER ON/OFF needs reselecting)

In FAN mode, temp. can't be set.

Hints

For cooling only type no " HEAT " function.

AUTO COOL DRY F AN

The air conditioner has the function of POWER

FAILURE RESUME.

(4) Unit stop

Press ON/OFF button.

Only time and room temp remains on LCD.

All indicators go out.

Vertical flap closed automatically.

HEAT

LOW

MID HIGH

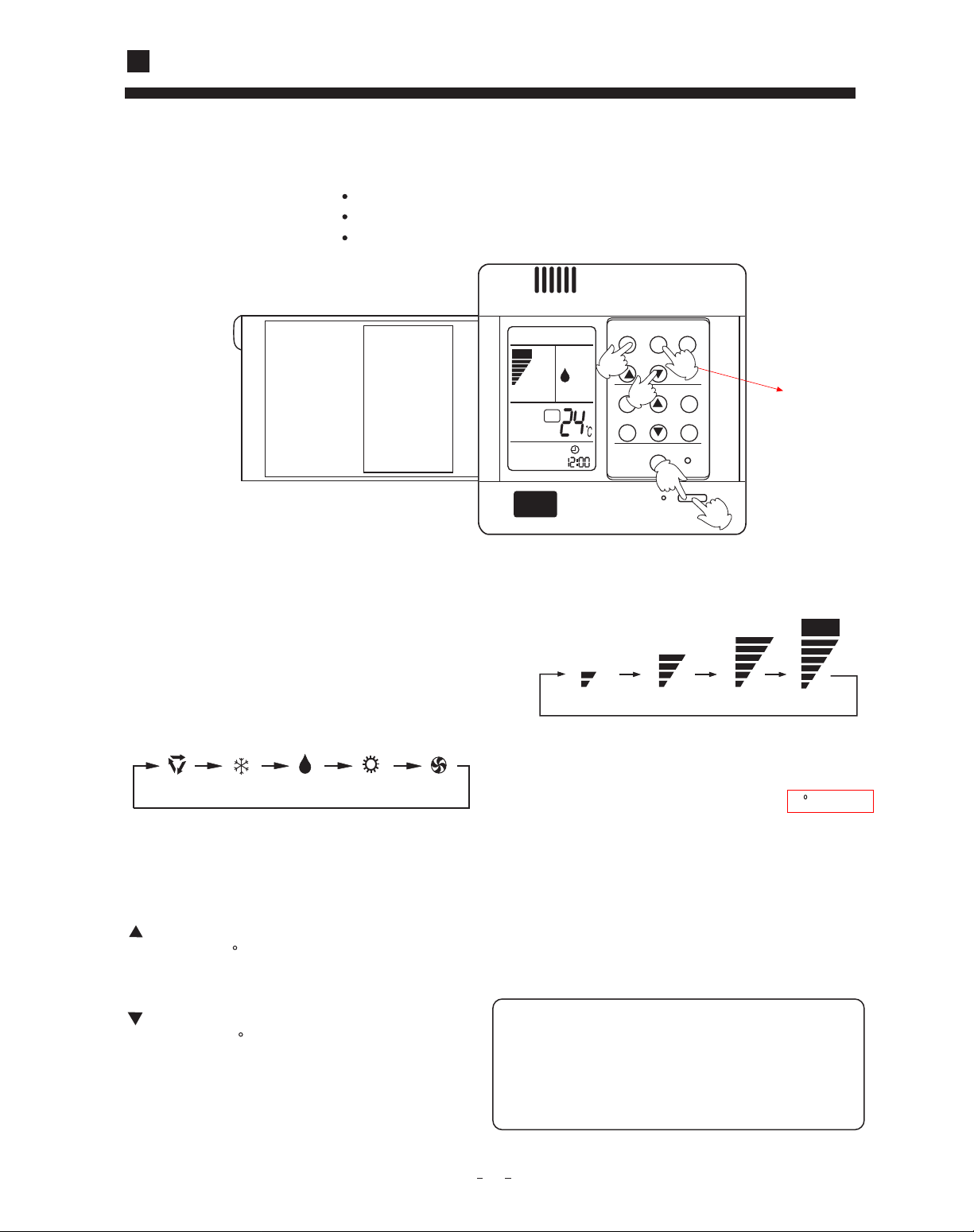

AUTO RUN, COOL,HEAT and DRY operation

Use COOL in summer.

Use HEA

T in winter.

Use DRY in spring,autumn and in damp climate.

(1) Unit start

(2) Select operation mode

(3) Select temp. setting

Press ON/OFF button, unit starts.

Previous operation status appears on display

(Not

Timer setting). Power indicator lights up.

Press MODE button. For each press, operation mode

changes as follows:

Unit will run in operation mode displayed on LCD.

Stop display at your desired mode.

Every time the button is pressed, temp. setting

increases 1 C.

If button is kept depressed, temp.setting will

increase quickly

.

Every time the button is pressed, temp. setting

decreases 1 C.

If button is kept depressed, temp. setting will

decrease quickly.

Recommendations

Hints

Wire controller can memorize each operation

status.

When starting it next time, just press

ON/OFF button and unit will run in previous

status.

Press FAN button. For each press, fan speed changes

as follows:

(4) Fan speed selection

Unit runs at the speed displayed on LCD.

In HEA

T mode, warm air will blow out after a short

period of time due to cold-draft prevention function.

In DRY mode, when room temp. becomes 2 C

higher than temp. setting, unit will run intermittently

at LOW speed regardless of FAN setting.

Unit will start running to reach the temp. setting

on LCD.

Press ON/OFF button.

Only time and room temp remains on LCD.

All indicators go out.

V

ertical flap closes automatically.

(5) Unit stop

Press TEMP button

10

AUTO

LOW

MID HIGH

AUTO

AUTO COOL DRY F ANHEAT

AM

******

******

*****

P9*11*12*

13***

OPERATION

AUTO

MODE

FAN SWING

TEMP

CLO SET

TIMER SLEEP

RESET

FILTER RESET

ON/OFF

1

5

2

3

4

SET

ON

MODE

FAN SWING

TEMP

CLOCK SET

MER SLE

ET

FILTER R

ON/OFF

AM AM

1

2

4

3

SET

OPERATION

11

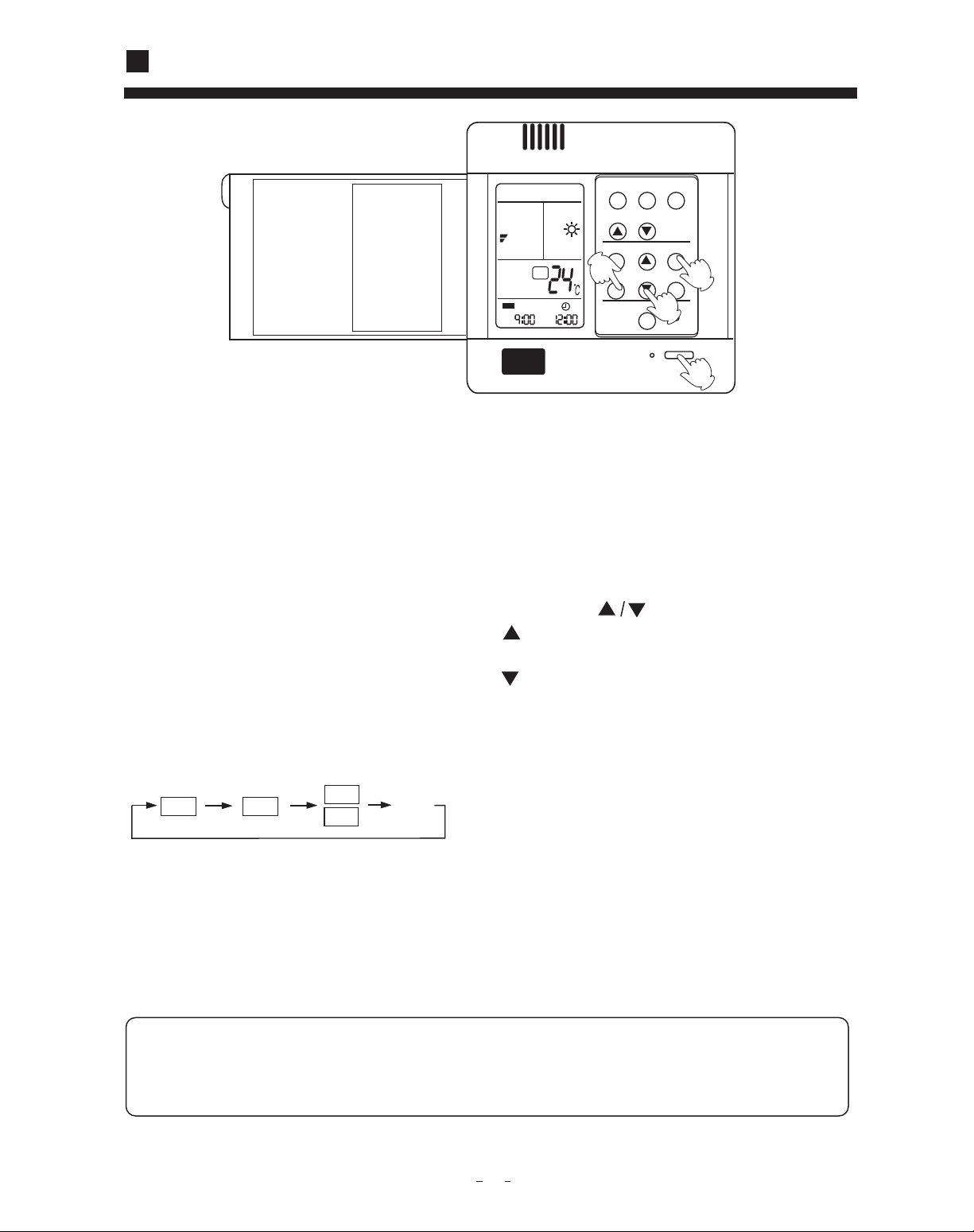

TIMER operation

Hints

Set Clock correctly before starting Timer operation.

Y ou can let unit start or stop automatically at following time: Before you wake up in the

morning, or get back from outside or after you fall asleep at night.

Operation mode will be displayed on LCD.

Power indicator lights up.

(2)TIMER mode selection

Press TIMER button to change TIMER mode.

Every time the button is pressed, display changes

as follows:

Select your desired TIMER mode (ON or OFF)

(3)Timer setting

Press TIME button.

Every time the button is pressed, time increases 10min.

If button is kept depressed, time will change quickly

.

Every time the button is pressed, time decreases 10min.

If button is kept depressed, time will change quickly.

Time will be shown on LCD. It can be adjusted within

24hours.

(4)Confirming your setting

After setting correct time, press SET button to confirm

"ON" or "OFF" stops flashing.

T

ime displayed: Unit starts or stops at x hour x min (ON

or OFF).

Timer mode indicator lights up.

TIMER ON/OFF

To cancel TIMER mode

Just press TIMER button several times until TIMER mode disappears.

Wire controller possesses memory function, when use TIMER mode next time, just

press SET

button after mode selecting if timer setting is the same as previous one.

(1)After unit start, select your desired

operation mode.

blank

ON

OFF

ON

OFF

ON OFF

MODE

FAN SWING

TEMP

CLOCK SET

MER SLEEP

T

FILTER RE

ON/OFF

PM

AM

1

5

6

4

2

3

SET

blank

ON

OFF

ON

OFF

OPERATION

12

TIMER ON-OFF

Operation mode will be displayed on LCD.

Power indicator lights up.

Every time the button is pressed, display changes as follows:

Select .

(3)Time setting for TIMER ON

Press TIME button.

(5)Time setting for TIMER OFF

To cancel TIMER mode

Every time the button is pressed, time increases 10min.

If button is kept depressed, time will change quickly .

Every time the button is pressed, time decreases 10min.

If button is kept depressed, time will change quickly.

Time will be shown on LCD.

It can be adjusted within 24hours.

AM refers to morning and PM to afternoon.

Time displayed: Unit starts at Xhour X min.

After time setting, press TIMER button to confirm.

"ON" stops blinking,

While "OFF" starts blinking.

(4) Time confirming for TIMER ON

Follow the same procedures in "Time setting for

TIMER ON".

(6)Time confirming for TIMER OFF

After time setting, press SET button to confirm

"OFF" stops flashing.

Time displayed: Unit stops at X hour X min.

Just press TIMER button several times until TIMER mode disappears.

According to the Time setting sequence of TIMER ON or TIMER OFF, either Start-Stop or Stop-Start can

be achieved.

(1)After unit start, select your desired

operation mode

(2) Press TIMER button to change TIMER

mode

ON

OFF

AM

OFF

OPERATION

about 6 hrs

1 hr

1 hr

increase 1 C

increase 1 C

13

At night, before going to bed you

can press down the SLEEP

button

on the controller and the airconditioner will run by the

comfortable sleeping mode to

make you sleep more comfortable.

One hour after sleeping operation start, the temp. is 1 C higher than the setting one. After another

hour the temp. rises 1 C and then run continuously for another 6

hrs' and then close. The actual

temp. is higher than the setting one which is to prevent from being too cool to your sleep.

In cooling, dehumidifying mode

One hour after start up, the temp. decrease 2 C lower than the setting one. After another hour

decrease by more 2 C.

The temperature will automatically rise by 1 C after another 3hrs' operation, and then automatically

close after 3hrs' continuous operation.

The actral temperature is lower than the setting one which

is to prevent from being too hot to your sleep.

In heating mode

SETTING T

SLEEP RUN BEGINS SLEEP RUN STOPS

1 hr

1 hr

3 hrs

about 3 hrs

decrease 2 C

decreases 2 C

increase1 C

SHUT DOWN

SLEEP RUN STOPS

Heat mode

SLEEP RUN BEGINS

SETTING T

SHUT DOWN

Cooling mode

Comfortable Sleep

Note:

In AUTO mode, unit will run in SLEEP function according to the operation mode.

After setting SLEEP function, it is forbidden to calibrate clock.

If the set sleep-time does not reach 8 hours, the unit will stop operation automatically after set

time is complete.

Set "TIMER-OFF" function first, then set SLEEP, and the sleep-set is performance; set TIMERON function first, the sleep function can only be set before TIMER-ON; if set theSLEEP function

first, the TIMER function can not be set.

Press SLEEP button once to make the air conditioner have the previous-set sleep time (first poweron is "1h"), the sleep symbol will appear

. Press time button / , you can choose the time in

1~8 hours. Each press of / , the time increases/reduces 1 hour and "xh" appears in the humidity

setting part, "OFF" appears in "TIMER OFF" display part and timer-off time; press SLEEP button

again to cancel sleep function, the sleep symbol diappears.

MODE

FAN SWING

TEMP

CLOCK SET

TIMER SLEEP

R

FILTER RESET

ON/OFF

AM

SET

14

OPERATION

Power Failure Compensation (to be applied for a necessary situation)

After the power failure compensation is set, if power failure suddenly occurs while the air conditioner

is working, it will resume the previous working state when the power is supplied again.

Setting Method: When the wire controller is on (excluding timer mode and fan mode), press

the "Sleeping" button on the remote controller 10 times within 5 seconds, and

after the buzzer rings 4 times, the air conditioner will enter the state of power

failure compensation.

Cancel Method: Press the "Sleeping" button on the wire controller 10 times within 5 seconds,

and after the buzzer rings 2 timer, the power failure compensation mode will be

cancelled.

Notes: When a power failure suddenly occurs during the air conditioner is working after the power

failure compensation is set, if the air conditioner will not be used for a long time, please cut off the

power supply to prevent its operation from being resumed after the power is supplied again, or press

the "Switch On/Off" button after the power comes again.

In this series changeover switch is set:

1. ON 2.OFF 3.OFF 4.OFF

15

please check the following things about your air conditioner before making a servie call.

Unit fails to start

MALFUNCTION

ON

OFF

Is the power source

switch adjust cut in?

Is city supply power in

normal?

Power

stoppage?

Isn't the signal receiving

section exposed to the

dir

ect sunlight or strong

illumination?

Isn't the earth leakage

br

eaker in action?

It is dangerous. Turn off

the power supply switch

immediately and contact

the sales dealer

.

Power supply switch is

not ON.

Cooling or heating is not sufficient

Is the thermostat adjust

as r

equired?

Isn't the air filter dirty?

Isn't any doors or windows

left open?

Doesn't any obstacle

exist at the air

inlet or

outlet?

Cooling is not sufficient

Isn't sun-shine invading

dir

ect?

Isn't any unexpected

heating load generated?

Isn't the room much

cr

owded?

Isn't the swing louver

horizontal?

(At HEA

TING mode)

If swing louver is horizontal,

the blow wind does not reach

floor

.

The wind does not blow

during heating operation

Isn't it warming up?

page 9

When the air conditioner does not operate properly after you have checked the above mentioned

items or when the following phenomenon is observed, stop the operation of the air conditioner

and contact your sales dealer

.

The fuse or breaker often shuts down.

W

ater drops off during cooling operation.

There is a irregularity in operation or abnormal sound is audible.

When the CHECK lamp (red) flickers, an irregularity has occurred in the air conditioner.

Note:

This unit has a function of automatic restart system after recovering power stoppage. Please contact the sales

dealer if it is not required.

Flickering

E0

The trouble

of the

drainage

system

Content

of defect

E1

The trouble

of the room

temp sensor

E2

The trouble

of the pipe

temp sensor

E3

The trouble

of the outdoor

temp sensor

E4

The trouble of

the outdoor

pipe temp

sensor

E5

The trouble of

the overload

current

E6

The trouble of

the low pressure

pressure of pipe

E8

The trouble of the

main control board

communication

E9

The trouble of the

main control board

outdoor board

communication

16

MALFUNCTION

The followings are not malfunction

Shuru

Shuru

When the air conditioner is started, when the compressor starts or

stops during operation or when the air conditioner is stopped, it

sometimes sounds "shuru shuru" or "gobo gobo". It is the flowing

sound of the refrigerant, and it is not a trouble.

Water flowing

sound is heard.

This is caused by heat expansion or contraction of plastics.

Cracking sound is heard.

It smells.

Air which blows out from the indoor unit sometimes smells.

The smell results from residents of tobacco smoke or cosmetics

stuck inside of unit.

When the air conditioner is used at restaurant etc. where dense

edible oil fume is always exists, white fog sometimes blows out

of air outlet during operation.

In this case consult sales dealer for cleaning the heat exchanger.

During operation,

white fog comes

out of indoor unit.

Unit does

not start

Wait for

three

minutes

It is switched into the FAN mode

during cooling.

To prevent frost from being accumulated on the indoor unit heat

exchanger, it is sometimes automatically switched to the FAN mode

but it will soon return to the cooling mode.

Even if the operation switch is turned on, cooling, dehumidifying

or heating is not operable for three minutes after the conditioner is

stopped. Because the protecting circuit is activated.

(During this time air conditioner operates in fan

mode.)

The air conditioner can not be

restarted soon after it stops.

Air does not blow or the fan

speed can not be changed during

dehumidifying

During operation, operation mode

has changed over automatically.

Water or steam generates from

the outdoor unit during heating.

When it is excessively cooled during dehumidifying, the blower

automatically repeats reducing and lowering the fan speed.

Isn't the AUTO mode selected?

In the case of AUTO mode, operation mode is changed automatically from cooling to heating or vise-versa according to the room

temperature.

This results when frost accumulated on the outdoor unit is removed

(during defrosting operation).

17

CARE AND MAINTENANCE

Points to observe

Turn off the power supply switch. Do not touch with wet hand.

Do not use hot water or volatileliquid.

ON

OFF

Thinner

Do not

use!

Benzine

Tooth powder

Cleaning

1. Clean the air filter by lightly tapping it or with the cleaner. It is more

effective to clean the air filter with water.

If the air filter is very dirty, dissolve neutral detergent in the lukewarm

water (approx. 30 C), rinse the air filter in the water, and thoroughly

wash the air filter off the detergent in the plain water.

2. After drying the air filter, set it up on the air conditioner.

CAUTION

Do not dry the air filter with fire.

Do not run the air conditioner without the air filter

.

Do not open the inlet grill until fan stops completely.

Fan will continue rotating for a while by the law of inertia after operation is being stopped.

CAUTION

Pre-Season Care

See that there are no obstacles blocking the air inlet and air outlet of both indoor and outdoor units.

Make sure that the air filter is not dirty

.

Cut in the power supply switch 12 hours before starting run.

Post-Season Care

Operate the unit with FAN mode on a fair day for about half a day to dry the inside of the unit well.

Stop operation and turn of

f the power supply switch. Electric power is consumed even the air conditioner is in stop.

Clean the air filter and set it in the place.

Care and Cleaning of the unit

Clean with soft and dry cloth.

If it is very dirty

, dissolve neutral detergent in the lukewarm water and make the cloth wet with the water.

After wiping, clean off the detergent using clean water.

18

FOR PREPARATION OF HEATING("HOT KEEP")

"HOT KEEP"is operated in the following cases.

When heating is started:

In order to prevent blowing out of cool wind, the indoor unit fan stopped

according to the room temperature which heating operation is started. Wait

for approx. 2 to 3 minute, and the operation will be automatically changed

to the ordinary heating mode.

Defrosting operation (in the heating mode):

When it is liable to frost. the heating operation is stopped automatically

for 5 to 12 minutes once per approx. one hour, and defrosting is operated.

After defrosting is completed, operation mode is automatically changed

to ordinary heating operation.

When the room thermostat is actuated:

When room temperature increases and room temperature controller actuates, the fan speed is automatically changed to stop under low temperature

condition of indoor heat exchanger. When room temperature decreases,

air conditioner automatically changes over to ordinary heating operation.

WARMING OPERATION

Heat pump type warming

Defrosting operation

Atmospheric temperature and warming capacity

Period of warm-up

With the heat pump type warming, the mechanism of heat pump that concentrate heat of outdoor

air with the help of refrigerant to warm the indoor space, is utilized.

When a room is warmed with a heat pump type air conditioner, frost accumulates on the heat exchanger of outdoor unit along with the drop of indoor temperature. Since the accumulated frost reduces the effect of warming, it is necessery to automatically switch the operation to the defrosting

mode. During the defrosting operation, heating operation is interrupted.

Warming capacity of heat pump type air conditioner decreases along with the

drop of outdoor temperature.

When the warming capacity is not sufficient, it is recommended to use another

heating implement.

Since the heat pump type air conditioner employs a method to circulate warm

winds to warm the entire space of a room, it takes time before the room temperature rises.

It is recommendable to start the operation a little earlier in a very cold morning.

19

IS THE UNIT INSTALLED CORRECTLY

For inspection and maintenance

When you change your address or the installation place

Electric work

Confirm the following items for safe and comfortable use of air conditioner.

The installation work is to be burden on the sales dealer, and do not conduct it by yourself.

Installation place

Avoid installing the air conditioner

near the place where possibility of

inflammable gas leakage exists.

Install the unit at well ventilated

place.

Install the air conditioner firmly on

the foundation that can fully support

the weight of the unit.

If not, it may cause vibration or noise.

If some obstacle exist, it may cause

capacity reduction or noise increase.

Explosion (Ignition) may occur.

Select the place so as not to annoy

neighbor with the hot air or noise.

Snow protection work is necessary

where outdoor unit is blocked up

by snow.

It is advisable not to install the air conditioner at the following special place.

It may cause malfunction, consult the

sales dealer when you have to install

the unit on such a place.

The place where corrosive gas generates

(Hot spring area etc.)

The place where salt breeze blows

(Seaside etc.)

The place where dense soot smoke exists

The place where humidity is extraordinarily high

The place where near the machine which

radiates the electromagnetic wave

The place where voltage variation is considerably large

For details consult your sales dealer.

The electric work must be burden on the authorized engineer with qualification for electric work and

grounding work, and the work must be conducted in accordance with electric equipment technical standard.

The power source for the unit is to be of exclusive use.

An earth leakage breaker should be installed.(This is necessary to prevent electric shock.)

The unit must be grounded.

Special technology is required for removal or reinstallation of air conditioner, consult the sales dealer.

Besides, construction expense is charged for removal or reinstallation.

The capacity of air conditioner will decrease by contamination of inside of unit when it is used for about

three years although depending upon the circumstances under which it is used, and so in addition to the

usual maintenance service, special inspection/maintenance service is necessary. It is recommended to

make a maintenance contract (charged) by consulting your sales dealer.

Air outlet

Air inlet

Air inlet

INSTALLATION MANUAL FOR WIRE CONTROLLER

20

1. Remove upper part of wire controller

Remove upper part of wire controller

by press.

2. Install wire controller

(1) For exposed installation,

use 2 wood screws (accessory).

(2) For recessed installation,

use 2 wood screws (accessory).

Note

Try as far as possible a flat surface for installation. Don't use excessive

force when tightening screws, or lower part might got deformed.

PCB is mounted on lower part of wire

controller, be careful not to damage it.

Lower part of wire

controller

Upper part of wire

controller

INSTALLATION MANUAL FOR WIRE CONTROLLER

21

3. Indoor unit wiring

Connect terminals (A,B,C,D) on lower

part of wire controller to terminals (A,

B,C,D) on PCB of indoor unit.

Hint

When make wiring, please keep

a distance between wires and

power supply cord.

Hint

Tread surface of the terminal well so that

shielding may not contact other part.

Cord kind

Size

Shield wire (4 core) (refer to Hint 3,4)

0.33mm

2

Wire size

Hint

1. Switch box and cord for wiring are not supplied.

2. Don't touch PCB with hand.

Use shielede wires for telecommunication

between wire controller and indoor unit;

indoor unit and outdoor unit. Ground the

shield on one side.

Otherwise misoperation because of

noise may occur.

Lower part of

wire controller

A B C D

Upper part of

wire controller

wiring from here

4. Replace the upper part of wire controller

Be careful not to press the wiring.

Shielded wire

ground

Signal wire is self-provided.

22

INSTALLATION MANUAL FOR INDOOR UNIT

1. Safety precautions

Please read these "Safety Precautions" first then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings,

and , those points which are related to the strong possibility of an installation done in error

resulting in death or serious injury are listed in the section. However, there is also a

possibility of serious consequences in relationship to the points listed in the section as well.

In either case, important safety related information is indicated, so by all means, properly observe all that is

mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation

tests, please explain operating methods as well as maintenance methods to the user (customer) of this equipment,

based on the owner's manual.

Moreover, ask the customer to keep this sheet together with the owner's manual.

CAUTION

WARNING

WARNING

CAUTION

WARNING

This system should be applied to places as office, restaurant, residence and the like. Application to inferior

environment such as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations

can result in water leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned

countermeasure for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration.

In regards to preparing this countermeasure, consult with the company from which you perchased the equipment,

and make the installation accordingly. In the rare event that a refrigerant leakage and exceeding of threshold

concentration does occur, there is the danger of a resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is

insufficient, injury can result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons

and hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only

exclusive use circuits are used.

Insufficient power source circuit capacity and defective installation execution can be the cause of electric

shocks and fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted

to the terminal connection part, through properly securing it. Improper connection or securing can result in

heat generation or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation

can also result in heat generation or fire.

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the

designated refrigerant (R22) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by

this company can result in water leakage, electric shock, fire and refrigerant leakage.

CAUTION

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a

telephone ground wire. Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit.

Not installing an earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas.

The rare event of leaked gas collecting around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate

it to prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior

items.

23

INSTALLATION MANUAL FOR INDOOR UNIT

1. Before installation [Before finishing installation, do not throw the attached parts installation

needs]

NOTICE

All Wiring of this installation must comply with NATIONAL, STATE AND LOCAL REGULATIONS. These

instructions do not cover all variations for every kind of installation circumstance. Should further information be

desired or should particular problems occur, the matter should be referred to your local distributor.

WARNING

BE SURE TO READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD CAUSE SERIOUS INJURY OR DEATH, EQUIPMENT

MALFUNCTION AND/OR PROPERTY DAMAGE.

Confirm the way to move the unit to the installation place.

Before moving the unit to the installation place, do not remove their packages.

When have to remove the package, use a soft material or protection board with rope to lift the unit

assembly to avoid unit damage or bumping a scrape.

2. Choose installation place

(1) The chosen installation place should meet the following requirements and get the userís consent.

Place ensures ideal airflow distribution.

The passage of airflow has no obstacles.

When importing outside air, it should be imported directly from outdoors. (if the pipe can not be

extended, it also can not be imported from top)

Place ensures enough space for maintenance.

The pipe length between indoor and outdoor unit is in the permitted limit (referring to outdoor unit

installation part).

The indoor unit, outdoor unit, electric wire and connection wire is at least 1m away from television

and radio. This is to avoid the image disturbance and noise caused by the above-mentioned home

appliance. (Even if 1m away, if the electromagnetic wave is too strong, it can also cause noise.)

(2) The height of ceiling

The indoor unit can install on the ceiling, which height is no more than 3m.

(3) Install and use the hoisting screw. Check if the installation place can bear the weight of unit

assembly.

If not certain, strengthen it before install the unit.

(600x600)

Over 100

Over 900

Air out

Air in

Checking meatus

Ceiling

Over 300

Over 200

24

INSTALLATION MANUAL FOR INDOOR UNIT

(1) The position relation among hoisting screw (unit: mm)

3. Preparation before installation

360

1640

250

794

Down side

Up side

(2) If necessary, cut the opening installation and checking needed on the ceiling. (If has ceiling)

Before installation, finish the preparation work of all the pipes (refrigerant, drainage) and wire

(wire controller connection wire, indoor and outdoor unit connection wire) of indoor unit, so that

after installation, they can be immediately connected with outdoor unit.

Cut the opening on the ceiling. Maybe it needs to strengthen the ceiling to keep the ceiling even

and flat and prevent the ceiling from vibration. For details, please consult to the builder.

(3) Hanger bolts installation

Use care of the piping direction when the unit is installed.

Hanging bolt M10

Hole-in anchor

Hole-in plug

Insert

Concrete

(Use M10 screw bolt)

In order to bear the weight of the unit, for existed

ceiling, using foundation screw bolt, for new ceiling,

using burying embedded screw bolt, burying screw

bolt or spot supplied other parts.

Before going on installation, adjust the gaps with ceiling.

4. Installation of indoor unit

Fix the indoor unit to the hanger bolts.

If required, it is possible to suspend the unit to the beam, etc.

Directly by use of the bolts without using the hanger bolts.

When the dimensions of main unit and ceiling holes does not match, it can be adjusted with the slot

holes of hanging bracket.

Note

Hanging bolt

M10 nut

Main unit

M10 washer

M10 spring washer

25

INSTALLATION MANUAL FOR INDOOR UNIT

Adjusting to the levelness

(a) Adjust the out-of levelness using a level or by the following method.

Make adjustment so that the relation between the lower surface of the unit proper and water level in the

hose becomes as given below.

(b) Unless the adjustment to the levelness is made properly, malfunctioning or failure of the float

switch may occur.

PVC hose

Piping side

Supply water

Water level

0~5 mm

(0~0.2")

Bring the piping side slightly lower.

Drain hose

Stage

difference

part

Drain socket

Drain socket

Main unit

VP 25 joint

(field purchased)

Pipe cover(large)

[for insulation]

(accessory)

VP 25

(field purchased)

Pipe cover

[for insulation]

(field purchased)

Drain hose

(accessory)

Pipe cover(small)

[for insulation]

(accessory)

Clamp

(accessory)

Adhesion

For drain pipe, use hard PVC general purpose pipe VP-25(I.D.1") which can be purchased locally. When

connecting, insert a PVC pipe end securely into the drain socket before tightening securely using the

attached drain hose and clamp. Adhesive must not be used connection of the drain socket and drain hose

(accessory).

(c)

5. Drain Piping

(a) Drain piping should always be in a downhill grade (1/50~1/100) and avoid riding across an elevation or

making traps.

When connecting the drain pipe to unit, pay suffcient attention not to apply excess force to the piping

on the unit side. Also, fix the piping at a point as close as possible to the unit.

(b)

Good piping

1.5m ~ 2m

Suspension

bolts

Heat

insulation

A downhill grade

of 1/100 or more

Do not pipe under water

Keep free from traps

Avoid riding across an elevation

Air vent

Inproper piping

26

INSTALLATION MANUAL FOR INDOOR UNIT

Drainage Test

Conduct a drainage test after completion of the electrical work.

During the trial, make sure that drain flows properly through the piping and that no water leaks from

connections.

In case of a new building, conduct the test before it is furnished with the ceiling.

Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

Supply about 1000 cc of water to the unit through the air outlet using a feed water pump.

Check the drain while cooling operation.

(g)

1

2

3

4

1

2

VP 30

Secure the elevation as high as possible

(approx. 100 mm)

A downhill grade of

1/100 or more

When constructing drain piping for several units,

position the common pipe about 100 mm below

the drain outlet of each unit as shown in the sketch.

Use VP-30(11/4") or thicker pipe for this purpose.

(d)

(e)

The stiff PVC pipe put indoor side should be

heat insulated.

(f)

Avoid putting the outlet of drain hose in the places with irritant gas generated. Do not insert the drain

hose directly into drainage, where the gas with sulfur may be generated.

Backwater bend

Because the drain spout is at the position, which negative pressure may occur. So with the rise of water

level in the drain pan, water leakage may occur. In order to prevent water leakage, we designed a

backwater bend.

The structure of backwater bend should be able to be cleaned. As the below figure shown, use T type joint.

The backwater bend is set near the air conditioner.

As figure shown, set a backwater bend in the middle of drain hose.

H1H2

H1=100mm or the static pressure of air sending motor

H2=1/2H1 (or between 50~100mm)

6. Installation of air suction and discharging duct

A

Insulation

muffler cavity (air sending)

Sacking joint

Air volume adjuster

Air outlet

Enlarging chart of

profile chart A

Vibration resistance hook

Checking meatus

Air conditioner

main unit

Ceiling

Air suction grille with air filter

Please consult the after-sales service worker of Haier Air Conditioner for the choosing and installation

of suction inlet, suction duct, discharging outlet and discharging duct. Calculating the design drawing

and outer static pressure, and choose the discharging duct with proper length and shape.

27

INSTALLATION MANUAL FOR INDOOR UNIT

Straight part

Bend part

Air out part

Static pressure box

Air inlet grille (with air filter)

Calculate as per 1m length 1Pa, 1Pa/m

Each bend takes as a3~4m long straight duct

Calculate as 25Pa

Calculate as 50Pa/each

Calculate as 40Pa/each

Good exampleBad exampleBad example

The length difference among every duct is limited below 2:1.

Reduce the length of duct as possible as can.

Reduce the amount of bend as possible as can.

Use heat insulation material to bind and seal the part connecting main unit and the flare part of air

discharging duct. Perform duct installation work, before the fitment of ceiling.

7. Calculation method of the dimension of the simple quadrate air duct

Presuming the unit length friction impedance of the duct is 1Pa/m, when the dimension of one side of

the air duct is fixed as 250mm, as shown below:

Note:1Pa/m=0.1mmAg/m

The chosen chart of simple duct

m3/h(m3/n)

100

200

300

400

500

600(10)

800

1,000

1,200(20)

250 x 60

(mmxmm)

250 x 90

250 x 120

250 x 140

250 x 170

250 x 190

250 x 230

250 x 270

250 x 310

Shape

Item

Air volume

Square duct

Dimension

m3/h(m3/n)

1,400

1,600

1,800(30)

2000

2400

3,000(50)

3,500

4,000

4,500

5,000

5,500

6,000(100)

(mmxmm)

250 x 350

250 x 390

250 x 430

250 x 470

250 x 560

250 x 650

250 x 740

250 x 830

250 x 920

250 x 1000

250 x 1090

250 x 1180

Shape

Item

Air volume

Square duct

Dimension

Static pressure box

Air conditioner

Equipped with

air filter (bought)

B

A

A

A

600m3/h

(10m3/min)

Duct

(mmxmm)

2400m3/h

(40m3/min)

250x560

250x190

Air volume

B

A

300m3/h

(5m3/min)

Duct

(mmxmm)

1200m3/h

(20m3/min)

250x310

250x120

Air volume

AD242AHAAA

AU242AOAAA

(HDU-24H03/H)

AD42NAHAAA

AU42NAQAAA

(HDU-42H03/H)

The calculation of duct resistance (the simple calculation is as follow table)

28

INSTALLA TION MANUAL FOR ELECTRIC WIRING

8. The attentive matters in installation of air suction and discharging duct

Recommend to use anti-frost and sound-absorbing duct. (locally bought)

The duct installation work should be finished before the fitment of ceiling.

The duct must be heat insulated.

The specific air-discharging outlet should be installed at the place where the airflow can be reasonably

distributed.

The surface should leave a checking meatus for checking and maintenance.

Air

Air

Duct

Special air discharging outlet

Use screw bolt to fix

9. The examples of improper installation

Do not use air in duct and take the ceiling inner side instead. The result is because of the irregular

outer air mass, strong wind and sunshine, the humidity is increased.

There may be water drop on the outside of duct. For cement and other new constructions, even if

not taking ceiling inner side as duct, the humidity will also be so high. At this time, use glass fiber

to perform heat preservation to the whole. (use iron net to bind the glass fiber)

Maybe exceeding the unit operation limit (for example: when indoor dry bulb temperature is 35 C,

wet bulb temperature 24 C), it may lead to overload of compressor.

Affected by the capacity of air discharging fan, the strong wind in the outer duct and wind direction,

when unit air sending volume exceeds the limit, the discharged water of heat exchanger will overflow,

leading to water leakage.

Air discharging fan

Improper example

29

10. The operation method of fan controller

Through the fan controller switch in the electric box, the air volume of this unit can be continuously

adjusted.

It is unnecessary to adjust air volume through the duct side wind level (unit outside static adjustment).

The air volume set should be in the operation air volume range.

Figure I shows the position of fan controller in the electric box and operation method.

After finishing the electric work, perform test run. According to the main points in Figure II making the

chosen switch No. accordant.

And confirm if it reaches the needed air volume.

Note:

1) When operating the fan controller, it is possible to touch the electric charging part, so do cut off the

power supply

.

2) Do not set the dial at the position less than 1.

3) The figure circled in Figure II indicate the capacity number of fan controller. The non-listed capacity

number may exceed the permitted operation capacity range, so it is impossible to operate.

4) When delivering from factory, the capacity number of fan controller is set at ìNo.5î.

Rotate this switch

(capacity number

setting:

No. 1 ~ No. 8)

Once the fan controller

has trouble, this linker

can perform emer

gency

assistant control When

this linker is connected

to the linker from the

PCB, it can operate with

total load

When this linker is

connected to the linker

from the PCB, through

the fan speed adjustment

panel to adjust speed

High

Condition of standard air volume

Low

(air volume 100Pa)

Outer static pressure Pa

Example of

duct

Lower limit

Upper limit

Standard air volume

(m3/min)

The example of the method of choosing capacity number:

1) If the unit is in high-speed operation, needing take outer static pressure is 180Pa in capacity air volume 34m3/min

as working condition point, according to Figure II ìThe characteristic chart of air volumeî, the capacity number

of fan controller is No. 2.

2) If the unit is in low speed operation, needing take outer static pressure is 60Pa in capacity air volume 32m3/min as

working condition point, according to Figure II ìThe characteristic chart of air volumeî, the capacity number

of fan controller is No. 4.

INSTALLA TION MANUAL FOR ELECTRIC WIRING

200

150

100

50

0

26 30 34 35 40 43

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Figure 1

Figure 2

30

11. Refrigerant pipe

[The air side pipe, liquid side pipe must be faithfully heat insulated, if no heat insulation, it may cause

water leakage.]

The outdoor unit has been charged with refrigerant.

When connect the pipe to the unit or dismantling the pipe from the unit, please follow the figure shown,

use spanner and torque spanner together.

When connect cone nut, the inner side and outside of cone nut should paste with refrigerant oil. Use

hand to twist 3-4 rings, then fasten with spanner.

Referring to Table I to confirm the fasten torque. (too tight may damage nut leading to leakage)

Check if the connection pipe leaks, then do heat insulation treatment, as below figure shown.

Only use seal cushion to bind the joint part of air pipe and heat insulation parts.

Paste the refrigerant oil here

Torque spanner

Spanner

Pipe joint

Cone nut

Middle size seal cushion (accessory)

(Use seal cushion to

bind the pipe joint)

Clamp

Heat insulation (accessory)

(for liquid pipe)

(for gas pipe)

Heat insulation (accessory)

Gas pipe

Liquid pipe

1.2~2.050N.m

(mm)

Specification of pipe

Tighten torque

Cone

Cone dimension

A (mm)

R0.4~0.8

A

90 0.5

45 2

INSTALLA TION MANUAL FOR ELECTRIC WIRING

Liquid pipe

Gas pipe

Electric box

Upper

Air inlet

Air outlet

Down side

Drain hose connection mouth

VP25 PVC pipe

310

30

530

80 510

12.70

INSTALLA TION MANUAL FOR ELECTRIC WIRING

Electric wiring

WARNING

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER SOURCE BEFORE

MAKING ANY ELECTRIC CONNECTIONS. GROUND CONNECTIONS MUST BE

COMPLETED BEFORE MAKING LINE VOLTAGE CONNECTIONS.

(1) Selection of size of power supply and interconnecting wires.

Precautions for Electric wiring

Electric wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round type crimped

terminal lugs with insulated grip on the ends of the wires.

Use copper conductor only.

Select wire sizes and circuit protection from table below. (This table shows 20 m length wires with

less than 2% voltage drop.)

(2) Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor unit is supplied by

terminals.

Item

Model

Phase

Switch breaker

(A)

Circuit breaker

Overcurrent protector

rated capacity (A)

Power source

wire size

(minimum)

Switch

breaker

Earth leakage breaker

Leak

current

OUTDOOR UNIT

TERMINIAL BLOCK

INDOOR UNIT

TERMINIAL BLOCK

1

2

3

1

2

3

R

S

T

N

3

30

20 4.0mm

2

30 30mA

Connecting cable

is self-provided.

Power cable

is self-provided.

380-400V~,50Hz

Power

31

INSTALLA TION MANUAL FOR OUTDOOR UNIT

Air out

Air in

Air in

Air in

Mounting and maintenance

surface

32

Warning

Selection of installation site

It should be installed at places where it is firm enough to withstand the weight of the air conditioner to

prevent falling.

Typhoon and earthquake prevention. It should be installed according to specific requirements.

Inasppropriate installation may lead to accidents.

Note: Obstacles should be 2000mm off the top of the out door unit. Obstacles nearby should be 400mm lower

than the top of the unit.

1. Handing

As there is no protective package for the outdoor unit,so

the following points merit attention:

(1) When forklift is used, insert the fork into the holes in

the base plate.

(2) When crane is used, lift the unit with 4 pieces of steel

rope with diameter above 6 mm.

(3) Put protective materials between the cable and the

unit to prevent deformation and damage of the surface.

2.Mounting

(1) The distance between two connections

must not beless than 20mm.

(1)During installation, connect the outdoor unit and align

the mounting surface(See the figure on the right).Mount

the electric distribution device on the external side of

the unit in accordance to the installation instructions for

electric distribution device.

(2)To ensure good performance of the machine and facili tate installation and maintenance, adequate space must

be reserved (See figure on the right).

Installtion space

20mm 20mm

M12 foundation bolt

(4 pieces each)

Steel rope

Protective cushion

Base plate

20

Steel rope

A vertical view of the outdoor unit

Above 300mm

20mm 20mm 20mm Above 20mm

1000mm

Above

Above

(front side)

Above

INSTALLA TION MANUAL FOR OUTDOOR UNIT

Through hole(15x20)

1100

790

33

Refer to the following figure for the distance between the

foundation bolts.

(2)When the refrigerant pipe is connected from the bottom of

the unit,the unit should be raised at least 500mm(see the

figure below)

(3)In snowy regions,snow-proof facilities should be used(see

the figure below).

(Poor snow-proof facilities may lead to damge.To avoid

inconveniences,the unit should be raised and snow-proof

covers should be installed at the air inlet and outlet.)

(4)During installation,anti-vibration rubber pads should be

used between the machine and the bracket.

3.Connection of refrigerant pipe

During installation,if refrigerant leakage occurs,ventilation measures must be taken.When refrigerant

meets with fire,hazadous gas will be produced.

After installation,make sure that there is no refrigerant leakage.

Refrigerant,if meeting with heaters and stoves,ect in the room,may produce hazardous gas.

Connection of refrigerant pipe

(1) The joints of the refrigerant pipe are inside the unit.Take off the access hole cover in front of the unit.

(2) The pipe can be connected from the front or bottom of the outdoor unit.

(3) Remove the L-shaped pipe from the valve by welding and connect the accessory pipe to the valve.

(4) In the case of front connection,cut the accessory pipe at the height of the fixing panel.Then join the

pipe with an elbow and let it go through the fixing panel.For the convenience of maintenance,bend

the pipe down (once) and then connect pipe to the right or left.

(5) In the case of bottom connection,join the pipe with accessory pipe through the holes in the base plate

of the outdoor unit,and connect pipe the left or right or the back.

Warning

Air inlet snow-proof cover

Air outlet snowproof cover

Air inlet snowproof cover

Refrigerant tube

Above 500mm

INSTALLA TION MANUAL FOR OUTDOOR UNIT

12.70

Base plate

Tube to the tight

Tube to the back

Access hole cover

M4

M6

Tube fixing

panel

Tube to the left

Tube to the left

Tube to the tight

outdoor unit

indoor unit

indoor unit

outdoor unit

34

(7)The maximum connnection pipe is 50 meters ,the maximum drop difference between indoor

unit and outdoor unit is 30 meters.

(8)It should installation the liquid check-ring and accumulator according to the outdoor unit and

indoor unit position.(see the attached diagram)

Diag1.outdoor unit below the indoor unit.

Diag2. Outdoor unit is above the indoor unit

Liuid check-ring

Accumulator (set 1

per 6 meters)

(6) During welding,the gas pipe valve must be cooled down with a wet cotton cloth.

During welding of the distribution pipe

1.In case of brazing weld of joint,nitrogen must be filled in the pipe to prevent oxidization.

2.The refrigerant pipe should be newly-made and clean.During installation,do not let water and other

substance into the pipe.

3.Use two spanners to tighten the connecting nut.One spanner will make loose connection.

The torque moment should conform to the specified value.(Refer to the below)

Tube diameter

(mm)

Torque moment for

pre-installation (N.m)

Torque moment for tightening the nut

Torque moment for

tightening up (N.m)

INSTALLA TION MANUAL FOR OUTDOOR UNIT

35

Outdoor unit pipelines connection

According to the pipeline connection method connection the distribute pipes and inlet & outlet liquid pipes.

Matters needing attention

Never use oxygen,flamable and poisonous gases for the leak test.

Field tube

installation

Field tube

installation

To the unit

To the unit

(Gas side)three-way valve

(Gas side )access hole

Detailed diagram of the

three-way valve

To the gauge

distributor

(Liquid side)access hole

Three-way valve fully closed

liquid side

6.4

6.4

Copper pipe

Relief valve

Nitrogen bottle

VL VH

Gauge distributor

High-pressure

gauge

Low-pressure

gauge

Three-way valve fully

closed(gas side)

Solder joint

Solder joint

Tightly

closed

Indoor unit

Indoor Outdoor

Access hole

Copper

pipe

Solder joint

Tightly

closed

Tightly

closed

Access hole

Outdoor unit

(Liquid side)three-way valve

Leak Test

Leak test must be made after connection of the refrigerant pipe according to the following diagram.

Close all the gas and liquid valves.To prevent nitrogen gas from invading the outdoor circulating

system,close the valve tightly before pressure increase,(Both the gas and liquid valves must be tightly

closed.)

Every cooling system must be charged slowly from the gas and liquid valves.

It must be charged from the gas and liquid valves.

To the unit

To the unit

(Gas side)three-way valve

(Gas side )access hole

Detailed diagram of the

three-way valve

To the gauge

distributor

(Liquid side)access hole

Three-way valve fully closed

liquid side

6.4 Copper pipe

Vacuum pump

Gauge distributor

High-pressure

gauge

Low-pressure

gauge

Three-way valve fully

closed(gas side)

Solder joint

Solder joint

Tightly

closed

Indoor unit

Indoor Outdoor

Access hole

Solder joint

Tightly

closed

Tightly

closed

Access hole

Outdoor unit

(Liquid side)three-way valve

Field tube

installation

Field tube

installation

P

INSTALLA TION MANUAL FOR OUTDOOR UNIT

36

Step 1:Charge for more than 3 minutes under 0.3MPa(3.0kg/cm2g)

Step 2:Charge for more than 3 minutes under 1.5MPa(15kg/cm2g)

-----------Serious leakage may be found.

Step 3:Charge for more than 24 hours under 3.0MPa(3.0kg/cm2g)

----------Small leakage may be found.

Check for pressure decrease

Without pressure decrease-Pass

With pressure decrease-Check for leaage.

There will be a 0.01MPa(0.1kg/cm2g) pressure change for every 1 C ambient temperature change

during the 24-hour pressure charge.It should be corrected during the test.

In the case of pressure decrease during steps 1 to 3 ,check the joints with the ear,hand or soapsuds

for leakage.Repair it by welding or tighten the connecting nut up.

Use vacuum pump to evacuate the air.Never use the refrigerant for the evacuation.

Drain off the nitrogen gas after the leak test and then connect the vacuum pump as shown in the figure

below.

The vacuum pumping must be done from both the liquid and gas inlets.

Check for leakage

Vacuum Pumping

INSTALLA TION MANUAL FOR OUTDOOR UNIT

Use a vacuum pump with high degree of vacuum(below-755mmHg) and large volume

displacement (above 40L/min)

The pumping time depends on the length of the connecting pipe.Generally,it takes about 2-3

hours.Make sure that the Y-shaped valves on both the gas and liquid sides are closed before

pumping.

If the vacuum can no reach-755mmHg within 2 hours,continue pumping for another 1 hour.

If the vacuum can no reach-755mmHg after more than 2 hour's pumping,close the valves V

L

and VH on the gauge distributor and stop pumping.One hour later,check the vacuum again.If

the vacuum has changed,it means there is a leakage.Repair it.

After the above steps,replace the vacuum pump with the refrigerant pump and refill refrigerant.

37

After finished vacuum the system ,change the vacuum to the refrigerant pump.,charging the

refrigerant .

Calculation of the the refrigerant charge

Note:when the unit shipping out of the factory ,charge the refrigerant not including the

construction procedure charged parts.

The calculation of the refrigerant charging:

When the connection pipe (L) <=5 meters ,not need to add refrigerant ;If the connection pipe

(L)>5 meters,we need recharge the 115g refrigerant per add 1 meter.

That is :the quantity of refrigerant charging=(L-5)*115(g)

Refrigerant charge

Refill refrigerant

When the outdoor valve is shut,fill the refrigerant from the access hole at the gas and liquid

sides.

If the required filling is impossible,open all the gas and liquid valves,then slightly shut the gas

valve, run the compressor and fill the refrigerant from the access hole at the gas side.

Now adjust the gas valve to control the refrigerant flow,which will be gasified during absorption

by the system.

If there is insufficient refrigerant in the system caused by leaks,refill it after the remaining

refrigerant is recollected.

Open all valves

Open all the valves of the outdoor unit.

Heat isolation of the pipes

Separate isolation should be made for the liquid and gas pipes.

Materials used for the pipe isolation at the gas side must withstand above 120 C temperature.

Loading...

Loading...