Haier HDU-60CA03T3, HDU-50HT03/H, HDU-42CA03T3/H, HDU-50CA03T3/H, HDU-60CA03T3/H Service Manual

Page 1

Commercial Air Conditioning

SERVICE MANUAL

Models

HDU-50HT03/H

HDU-42CA03T3/H

HDU-50CA03T3/H

HDU-60CA03T3/H

Features

T3 climate

High energy efficiency

Fixed frequency

Long distribution pipe and high drop

Flexible and easy installation

Auxiliary electric heating function (optional)

Optional safety devices and much more precision control device

Weekly timer (standard)

Group control function(Optional)

Auto restart function

Manual code: SYJS-012-08REV.0 Edition: 2008-07-23

Page 2

Commercial Air Conditioner

CONTENTS

Contents………………………………………………………...2

1. Description of products & features………………………..3

2. Specification…………………………………………………5

3. Safety precaution……………………………………………7

4. Net dimension………………………………………………..9

5. Installation instructions………..……………………………10

6. Parts and functions…………………………………………15

7. Controller functions…………………………………………16

8. Electrical control functions…………………………………16

9. Electrical data……………………………………………….31

10. Troubleshooting…………………………………………...34

11. Noise curves..................................................................36

12. Performance curves.......................................................37

2

Page 3

Commercial Air Conditioner

1.DESCRIPTION OF PRODUCTS & FEATURES

1.1. Products code explanation

1.2 Brief Introduction for T1 、T2、T3 working condition

Type of Air

Conditioner

Climate type

T1 T2 T3

Cooling Only

18 ℃~43℃ 10℃~35℃ 21℃~52℃

Heat pump

-7℃~43℃ -7℃~35℃ -7℃~52℃

Electricity Heating

~43℃ ~35℃ ~52℃

1.3 Operating Range of Air Conditioners(for T3 climate)

Temp. Mode Rated Maximum Minimum

Cooling

Indoor

DB ℃

29 32 18

WB ℃

19 23 14

Outdoor

DB ℃

46 52 10

WB ℃

24 31

6

Heating

Indoor

DB ℃

20 27 15

WB ℃

14.5 --- --

Outdoor

DB ℃

7 24 -7

WB ℃

6 18 ---

H D U - 42 C A 03 T3 / H

H:high ESP duct unit;M:middle ESP duct unit

T3:climate type

Power supply type: 03 stands for 200-220V, 50Hz

Design sequence

C: cooling; H: heating

Cooling capacity: 42=42000BTU/h

U: single split unit

Product type : “B” stands for cassette type, “CF” stands for

convertible type, ”D” stands for duct, ”P” stands for cabinet

system,

Haier Brand Air Conditioner

3

Page 4

Commercial Air Conditioner

1.4 Product features

Flexible and easy installation

The outdoor can meet the higher request of installation. From the specifications, you will find for

each unit, how long and how high the piping will be, which will be convenient for design and installation.

High efficiency filter

The unit adopts G3 grade filter, can efficiently filter the dirt etc, and improve the room air quality, at

the same time, the filter can pull out from downside, convenient for maintenance and cleaning.

Multi-mode for installation

The indoor unit can be installed with or without an air return duct according to the installation need.

Free setting of air discharging duct

The number of the airflow outlet and its installation position can be freely selected according to the

environment of the room, sufficiently considering the load of the room and the uniform temperature of the

room to realize more perfect comfort.

High esp design

Max. external static pressure of 196 Pa brings the quick temperature adjustment to the room.

Adopts high pressure fan to provide quich speed of air blowing while keeping a low sound level and

ensuring a good air circulation of the whole indoor space.

Optional safety devices and much more precision control device

a. Ambient temperature sensor, coil temperature sensor and compressor temperature sensor

make the temperature control and defrosting control more precise.

b. High/low pressure switch can feel the discharging pipe pressure and suction pipe pressure on

time and precisely. If the pressure is too low or too high, it will stop the compressor to prevent it

being damaged for the sake of pressure.

c. 3 minutes delay protection for the compressor, the device can protect the compressor from

some damages and make the compressor have a long life.

Group control and Central control if connected with with a group

controller or a central controller

Weekly timing function, if connected with a weekly timer YCS-A001

4

Page 5

Commercial Air Conditioner

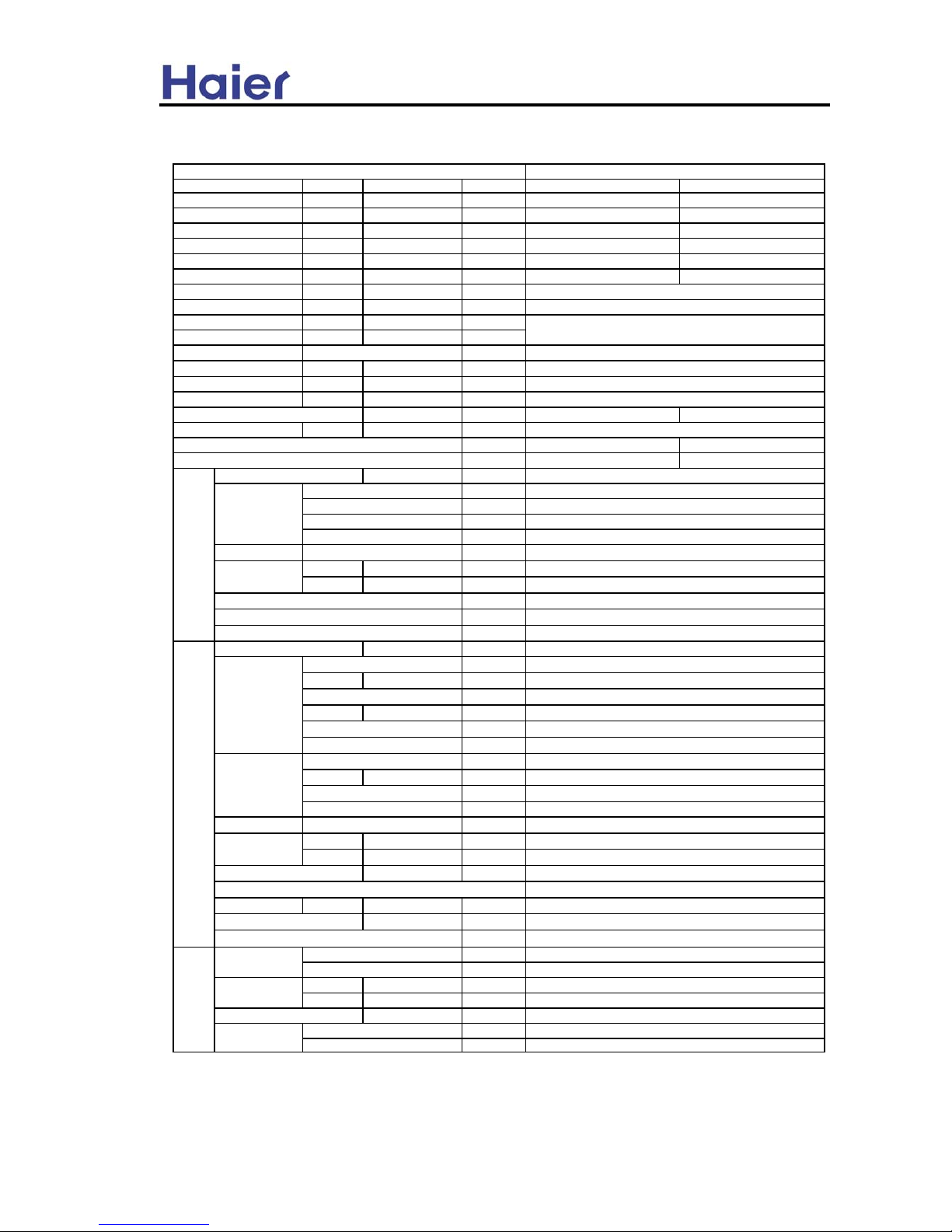

2. SPECIFICATION

Function

coolin

g

heatin

g

Capacity BTU/h

49800 56300

Capacity kW

14.6 16.5

Sensible heat ratio

0.7

W

6540 5830

W

7767 6160

EER or COP

W/W

2.2 2.8

Dehumidifying capacity

10‐³×m³/h

Power cable section

Signal cable section

Connecting cable section

Wired control cable for wired control unit section

Power source N, V, Hz

A / A

Start Current A

Class of anti electric shock

CLASS I CLASS I

Circuit breaker A

Max. operating pressure of heat side Mpa

2.8 2.8

Max. operating pressure of cold side Mpa

2.8 2.8

Unit model (color)

Type × Number

Speed(H-M-L) r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

External

(L×W×H)

mm×mm×mm

Package

(L×W×H)

mm×mm×mm

Control type (Remote /wired /model)

dB(A)

kg / kg

Unit model (color)

Model / Manufacture

Oil model

Oil charging

Type

Protection type

Starting method

Type × Number

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Heat exchanger Type / Diameter mm

External

(L×W×H)

mm×mm×mm

Package

(L×W×H)

mm×mm×mm

Refrigerant control method mm/mm

Noise level dB(A)

crankcase heater power W

kg / kg

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

Connecting Method

m

m

4 x 0.33 mm2

55/52/47

40

64

840

6000

Fan

inner grooved/φ9.52

Fan

Compressor

Inner thermal protection

SCROLL

Defrosting

Automatic

Axial*2

hard startup

Capillary tube

0.06

MAX.Drop

50MAX.Pi

ping

length

Weight (Net / Shipping)

91/111

30

Refrigerant

wired

PIPING

R22/4300

65

Pipe

φ9.52

φ19.05

Flared

Between I.D &O.

Outdoor unit

HDU-50HT03/H(WHITE)

Weight (Net / Shipping)

65/80

Dimension

948*340*1250

1090*410*1350

ZR61KH-TFD-522/COPELAND

SONTEX 200 LT

1656

item Model

HDU-50HT03/H

5.0

5G×2.5mm2

Total power input

Max. power input

Running /Max.Running

centrifugal

Dimension

50

1560~2650

1385×965×418

1197×828×355

inner grooved/φ7

4G×1.5mm2

30

0.27

1110/880/720

3N,380-400V,50HZ

Indoor unit

HDU-50HT03/H(GREY)

Noise level (H-M-L)

Cooling 9.5A/11.3A Heating 9.1/10.35

5

Page 6

Commercial Air Conditioner

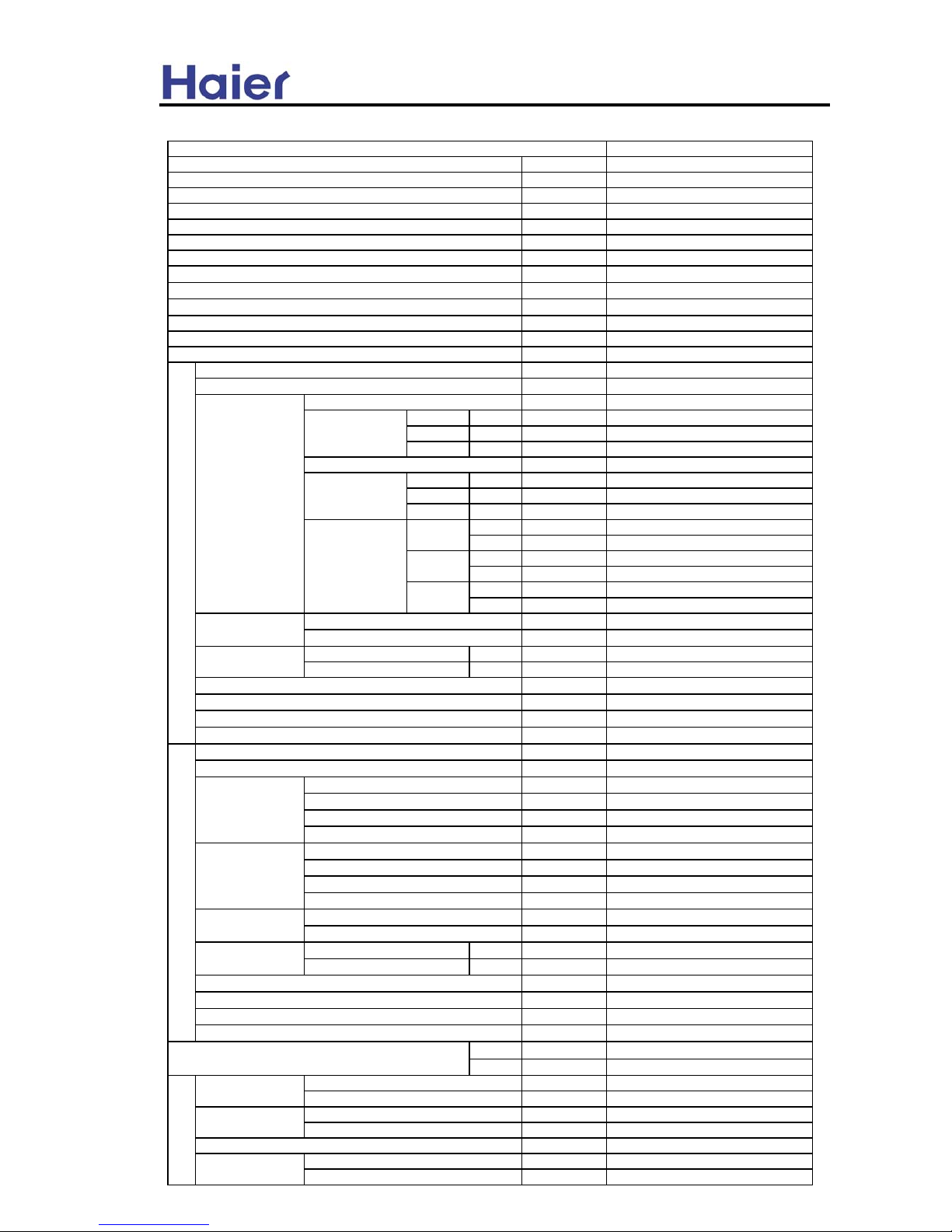

HDU-42CA03T3/H

cooling only

Btu/h

42000(12309W/10584kca/h)

%

80

W

4150

W

5700

W/W

3.0

L/h

3.5

N, V, Hz

3N~,380-415V,50Hz

V

342

V

462

A / A

7.5A /10.0A

A

56

A

30

HDU-42CA03T3/H (GREY)

N, V, Hz

1PH,220-240V,50Hz

centrifugal×2

blue plug

(H-L)

r/min

1215-1050

red plug

(H-L)

r/min

1140-880

white plug

(H-L)

r/min

1050-880

kW

0.45

blue plug H Pa

100

red plug H Pa

80

white plug H Pa

50

0Pa m³/h

H:2950 L: 2400

100Pa m³/h

H:2250 L: 1920

0Pa m³/h

H:2460 L: 1980

80Pa m³/h

H:2250 L: 1720

0Pa m³/h

H:2400 L: 1980

50Pa m³/h

H:2250 L: 1820

mm

9.52

m²

0.452

L×W×H mm×mm×mm 1197×830×350

L×W×H mm×mm×mm 1430×940×420

mm

PVC 26/32

hard wired / YR-E12

dB(A)

54-52

kg / kg

62/70

HDU-42CA03T3/H (WHITE)

N, V, Hz

3N~,380-415V,50Hz

ZR54KS-TFD-522/COPELAND

BLENDED WHITE MINERAL OIL

1242cm³

SCROLL

axial×2

r/min

1000±40

kW

0.23×2

m³/h

6000

mm

9.52

2/1.60

L×W×H mm×mm×mm

948×340×1250

L×W×H mm×mm×mm

1095×415×1400

capillary tubes

L

3.2

dB(A)

60

kg / kg

95/100

Hi MPa

2.85

Lo MPa

1.2

g

R22/3000

g/m

65

mm

Φ9.52

mm

Φ19.05

Flare type

m30

m50

red plug

white plug

Design Pressure

Total air-flow

External

Control type (type/model)

Oil type

Oil charging

Type

Noise level (H-L with blue plug)

Weight (Net / Shipping)

Unit model

Model / Manufacture

Starting Current

item Model

Outdoor unit

Compressor

Fan + motor

Heat exchanger

Dimension

Tube diameter

Face area

Heat exchanger

Power source

Min. Spec. Voltage

Max. Spec. Voltage

Running /Max.Running current

Fan motor input power

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER

Dehumidifying capacity

Fan motor input power

Fan + motor

Circuit breaker

Model

Type × Number

Indoor unit

Package

Drainage pipe (material , I.D./O.D.)

Fan speed

Air-flows

Fan motor plugs &

static pressure

blue plug

Gas

PIPING

Refrigerant

Pipe

Between I.D &O.D

Connecting Method

MAX.Drop

Recharge quantity

Liquid

MAX.Piping length

Volume of Accumulator

Noise level

Weight(Net / Shipping)

Type / Charge

Power source

Power source

Package

Refrigerant control method

Diameter

Row / Fin pitch (mm)

Speed

External

Type × Number

Dimension

6

Page 7

Commercial Air Conditioner

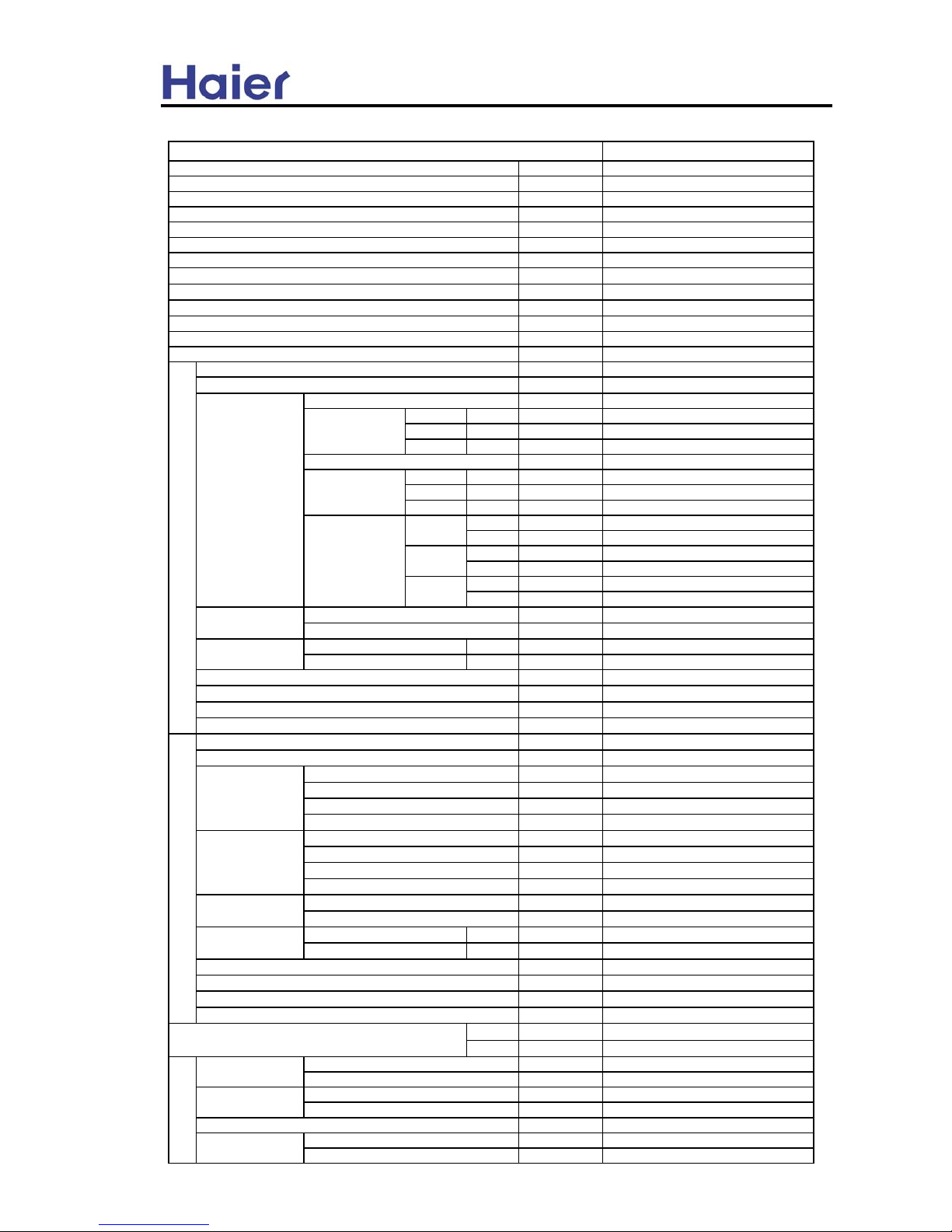

HDU-50CA03T3/H

cooling only

Btu/h

50000(14654W/12600kca/h)

%

77

W

4590

W

6300

W/W

3.2

L/h

4.5

N, V, Hz

3N~,380-415V,50Hz

V

342

V

462

A / A

7.85A /10.5A

A

59

A

30

HDU-50CA03T3/H (GREY)

N, V, Hz

1PH,220-240V,50Hz

centrifugal×2

blue plug

(H-L)

r/min

1215-1050

red plug

(H-L)

r/min

1140-880

white plug

(H-L)

r/min

1050-880

kW

0.45

blue plug H Pa

100

red plug H Pa

80

white plug H Pa

50

0Pa m³/h

H:2950 L: 2400

100Pa m³/h

H:2250 L: 1920

0Pa m³/h

H:2460 L: 1980

80Pa m³/h

H:2250 L: 1720

0Pa m³/h

H:2400 L: 1980

50Pa m³/h

H:2250 L: 1820

mm

9.52

m²

0.452

L×W×H mm×mm×mm 1197×830×350

L×W×H mm×mm×mm 1430×940×420

mm

PVC 26/32

hard wired / YR-E12

dB(A)

54-52

kg / kg

62/70

HDU-50CA03T3/H (WHITE)

N, V, Hz

3N~,380-415V,50Hz

ZR61KS-TFD-522/COPELAND

BLENDED WHITE MINERAL OIL

1242cm³

SCROLL

axial×2

r/min

1000±40

kW

0.23×2

m³/h

6000

mm

9.52

2/1.60

L×W×H mm×mm×mm

948×340×1250

L×W×H mm×mm×mm

1095×415×1400

capillary tubes

L

3.2

dB(A)

60

kg / kg

99/104

Hi MPa

2.85

Lo MPa

1.2

g

R22/3400

g/m

65

mm

Φ9.52

mm

Φ19.05

Flare type

m30

m50

Design Pressure

item Model

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER

Dehumidifying capacity

Power source

Fan motor plugs &

static pressure

Air-flows

Min. Spec. Voltage

Max. Spec. Voltage

Running /Max.Running current

Starting Current

blue plug

red plug

white plug

Heat exchanger

Tube diameter

Face area

Circuit breaker

Indoor unit

Model

Fan + motor

Type × Number

Fan speed

Fan motor input power

Dimension

External

Package

Drainage pipe (material , I.D./O.D.)

Control type (type/model)

Noise level (H-L with blue plug)

Weight (Net / Shipping)

Outdoor unit

Unit model

Compressor

Model / Manufacture

Oil type

Oil charging

Type

Package

Fan + motor

Type × Number

Speed

Fan motor input power

Total air-flow

Row / Fin pitch (mm)

Dimension

External

Between I.D &O.D

Refrigerant control method

Volume of Accumulator

Noise level

Weight (Net / Shipping)

MAX.Drop

MAX.Piping length

PIPING

Pipe

Liquid

Gas

Connecting Method

Power source

Power source

Refrigerant

Type / Charge

Recharge quantity

Heat exchanger

Diameter

7

Page 8

Commercial Air Conditioner

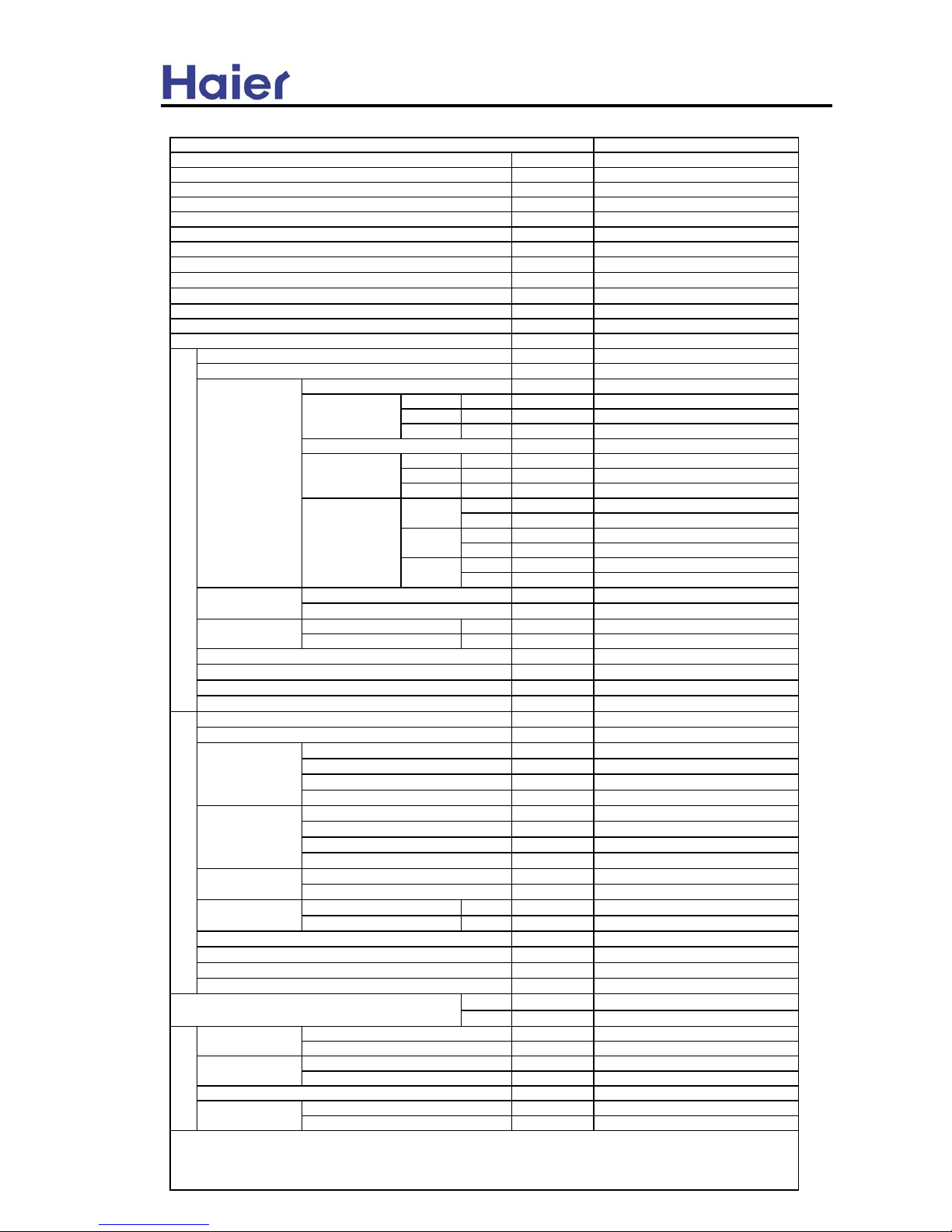

HDU-60CA03T3/H

cooling only

Btu/h

57000(16705W/14364kca/h)

%

73

W

5200

W

7000

W/W

3.2

L/h

5.5

N, V, Hz

3N~,380-415V,50Hz

V

342

V

462

A / A

9.0.A /13.3A

A

74

A

30

HDU-60CA03T3/H (GREY)

N, V, Hz

1PH,220-240V,50Hz

centrifugal×2

blue plug

(H-L)

r/min

1210-1050

red plug

(H-L)

r/min

1150-880

white plug

(H-L)

r/min

1050-880

kW

0.45

blue plug H Pa

100

red plug H Pa

80

white plug H Pa

50

0Pa m³/h

H:2950 L: 2400

100Pa m³/h

H:2250 L: 1920

0Pa m³/h

H:2460 L: 1980

80Pa m³/h

H:2250 L: 1720

0Pa m³/h

H:2400 L: 1980

50Pa m³/h

H:2250 L: 1820

mm

9.52

m²

0.452

L×W×H mm×mm×mm 1197×830×350

L×W×H mm×mm×mm 1430×940×420

mm

PVC 26/32

hard wired / YR-E12

dB(A)

54-52

kg / kg

62/70

HDU-60CA03T3/H (WHITE)

N, V, Hz

3N~,380-415V,50Hz

ZR68KC-TFD-522/COPELAND

BLENDED WHITE MINERAL OIL

1774cm³

SCROLL

axial×2

r/min

1000±40

kW

0.23×2

m³/h

6000

mm

9.52

2/1.60

L×W×H mm×mm×mm

948×340×1250

L×W×H mm×mm×mm

1095×415×1400

capillary tube+piston throttle (102#)

L

3.2

dB(A)

60

kg / kg

106/111

Hi MPa

2.85

Lo MPa

1.2

g

R22/4000

g/m

65

mm

Φ12.7

mm

Φ19.05

Flare type

m30

m50

Norminal condition: indoor temperature (cooling): 29 ℃DB/19℃WB, Outdoor temperature(cooling): 46℃DB/24℃WB,

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter. It

is a sound pressure noise level. The detailed method please refer to the following information:

Design Pressure

item Model

Function

Capacity

Sensible heat ratio

Total power input

Max. power input

EER

Dehumidifying capacity

Fan motor input power

Fan motor plugs &

static pressure

Air-flows

Power source

Min. Spec. Voltage

Max. Spec. Voltage

Running /Max.Running current

blue plug

red plug

white plug

Heat exchanger

Tube diameter

Face area

Starting Current

Circuit breaker

Indoor unit

Model

Fan + motor

Type × Number

Fan speed

Dimension

External

Package

Drainage pipe (material , I.D./O.D.)

Control type (type/model)

Noise level (H-L with blue plug)

Weight (Net / Shipping)

Outdoor unit

Unit model

Compressor

Model / Manufacture

Oil type

Oil charging

Type

Package

Fan + motor

Type × Number

Speed

Fan motor input power

Total air-flow

Row / Fin pitch (mm)

Dimension

External

Between I.D &O.D

Refrigerant control method

Volume of Accumulator

Noise level

Weight (Net / Shipping)

MAX.Drop

MAX.Piping length

PIPING

Pipe

Liquid

Gas

Connecting Method

Power source

Power source

Refrigerant

Type / Charge

Recharge quantity

Heat exchanger

Diameter

8

Page 9

Commercial Air Conditioner

Installation state: the unit should be placed on the flat floor or be mounted in horizontal

direction.

Testing method:

duct unit without auxiliary duct: duct unit with auxiliary duct:

1.4m

2m

duct

auxiliary duct

2m

1.4m

1m

auxiliary duct

outdoor unit:

1.air outlet from side: the noise level is the average sound pressure level measured from front, left, right directions.

2.air outlet from top: the noise level is the average sound pressure level measured from front, back, left, right directions.

measured point:

H ( height to the ground) = (h (unit height) + 1m) /2

and, it is 1m to each side.

h

1m

1m

1m

1m

Note: ⊙ is the real time

analyser position

9

Page 10

Commercial Air Conditioner

3. Safety precaution

Carefully read the following information in order to operate the airconditioner correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING!

Incorrect operations may result in severe consequences of death or serious injuries.

CAUTION!

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

WARNING!

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately, and contact

the dealer to find out the handling

method.

Don't dismantle the outlet of the

outdoor unit.

The exposure of fan is very dangerous

whichmay harm human beings.

switch

off

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

When need maintenance and repairment,

call dealer to handle it.

After a long time use of air-conditioner

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

10

Page 11

Commercial Air Conditioner

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

Connect earthing wire.

Use discharge pipe correctly to ensure

efficient discharge.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, in-correct

earthing may cause shock.

Incorrect pipe use may cause water

leaking.

Earthing

WARNING!

Installed electrical-leaking circuit

breaker.

It easily cause electrical shock without

circuit breaker.

Please let the dealer be responsible for

installing the conditioner.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Call the dealer to take measures to

prevent the refrigerant from leaking.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

even in case of refrigerant leakage.

When conditioner is deinstalled or

reinstalleddealer should be responsible

for them.

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

No goods or nobody is permitted to

placed on or stand on outdoor unit.

The falling of goods and people may

cause accidents.

Don't operate the air-conditioner with

damp hands.

Otherwise will be shocked.

Only use correctly-typed fuse.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

11

Page 12

Commercial Air Conditioner

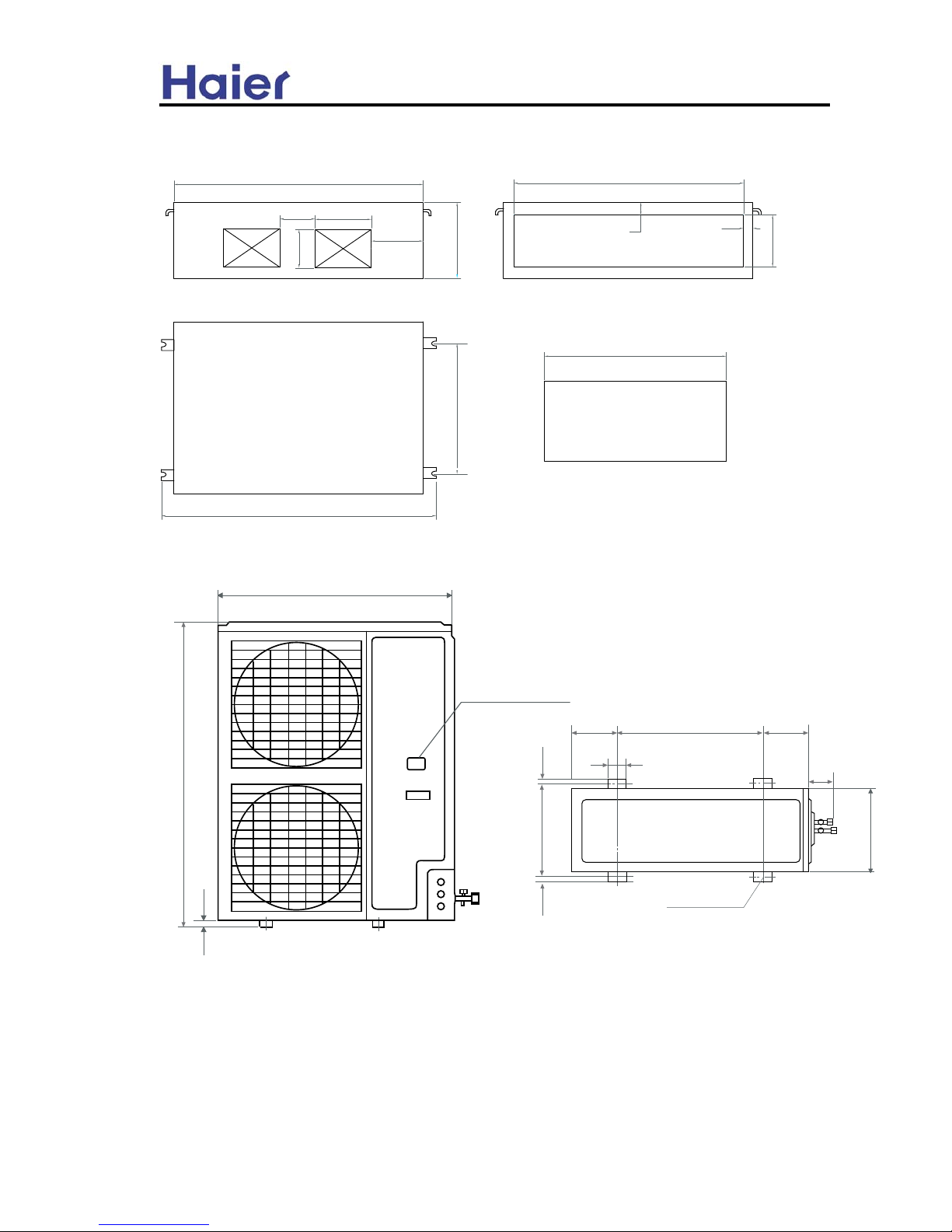

4. Net dimension

1105

1200

170 270

250

365

185

250

60

45

800

1320

830

(mm)

948

1250

25

Power wiring Terminal

184 184

55

Screw Hole

580

70

380

18

340

18

(4xM10)

12

Page 13

NO

L1

500

Commercial Air Conditioner

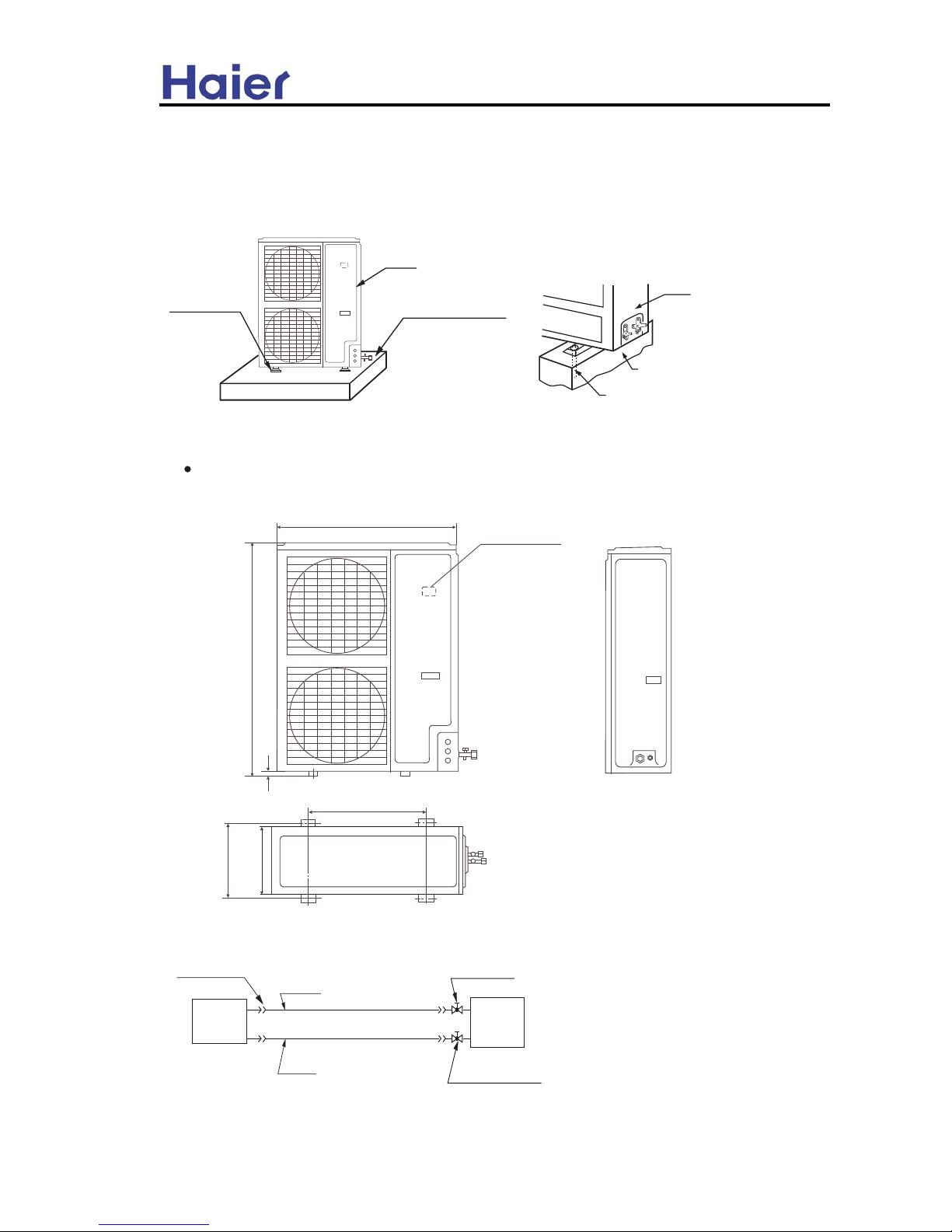

5. Installation Instructions

5.1 Outdoor unit installation

1. Accessories

"Edging" for protection of electric wires from an

opening edge.

2. Selection of the place of installation

Edging

Select the place of installation satisfying the following conditions and, at the

same time, obtain a consent from the client or user.

Place where air circulates.

Place free from heat radiation from other heat sources.

Place where drain water may be discharged.

Place where noise and hot air may not disturb the neighborhood.

Place where there is not heavy snowfall in the winter time.

Place where obstacles do not exist near the air inlet and air outlet .

Place where the air outlet may not be exposed to a strong wind.

Place surrounded at four sides are not suitable for installation. A 1m or more

of overhead space is needed for the unit.

Mount guide-louvers to place where short-circuit is a possibility.

When installing several units, secure sufficient suction space to avoid short

circuiting.

(1) Open space requirement around the unit

Air inlet

L3

(Servicing

inlet

space)

Air outlet

L2

Air

Note :

(1). Fix the parts with screws

(2).Don't intake the strong wind directly to the

outlet air-flow hole.

(3).A one meter distance should be kept from the

unit top

(4).Don't block the surroundings of the unit with

sundries

Unit: mm

Case

Distance

open

open

open

500

150

150

300

300

0

L1

L2

L3

I

II

III

Wind direction

(2) Installation where the area with strong winds.

Install the unit so that the air outlet section of the unit must NOT be faced

toward wind direction.

13

Page 14

Commercial Air Conditioner

3. Installation of outdoor unit

(1) Installation

Fix the unit in a proper way according to the condition of a place where it is

installed by referring to the following .

(a) Concrete foundation (b) Foundation anchor

Unit

To fix by bolts

Anchor bolt

Concrete foundation

Unit

Concrete foundation

Anchor bolt

Note: (1) Give enough room for the concrete

foundation to fix by anchor bolts.

Note: (1) Place the concrete foundation deep enough.

Install the unit so that the angle of inclination must be less than 3 degrees.

(2) Installation sketch of outdoor unit

340

580

380

948

Power wiring Terminal

25

1250

4. Refrigerant piping

Flare connection

3-way stop valve

Outdoor

unit

Gas pipe

Liquid

pipe

Indoor

unit

2-way stop valve

14

Page 15

Y/G

Commercial Air Conditioner

Piping size

Install the removed flare nuts to

90+0.5

Gas pipe

9.52x0.8mm

19.05x1.0mm

Liquid pipe

HDU-50HT03/H

the pipes to be connected, then

flare the pipes.

Limitations for one way piping length and vertical height difference.

Model

One way piping length

Vertical height difference

(between indoor and outdoor)

less than 50 m

less than 30 m

HDU-50HT03/H

The detail information please refer to the installation manual.

Selection of size of power supply and interconnecting wires.

Select wire sizes and circuit protection from table below. (This table shows 20 m length

wires with less than 2% voltage drop.)

Item

Circuit breaker

Power

Earth leakage breaker

Model

Phase

Switch breaker

(A)

Overcurrent

protector

source wire

size

Switch

break

Leak

curren

HDU-50HT03/H

3

30 20

2.5mm

2

30

30mA

Wiring connection

N 1 2 3

Y/G

R S T

POWER SUPPLY:

To Indoor Unit

3N~,380-400V,50Hz

Gas pipe

Liquid pipe

Gas pipe

9.52x0.8mm

12.7x0.8mm

19.05x1.0mm

Liquid pipe

19.05x1.0mm

HDU-42CA03T3/H

HDU-50CA03T3/H

HDU-60CA03T3/H

HDU-42CA03T3/H

HDU-50CA03T3/H

HDU-60CA03T3/H

Model

One way piping length

Vertical height difference

(between indoor and outdoor)

less than 50 m

less than 30 m

it is also apply to HDU-42CA03T3/H,HDU-50CA03T3/H,

HDU-60CA03T3/H

15

Page 16

Hint

Siz

wire

wire

Commercial Air Conditioner

5.2 Indoor unit installation

1. Remove upper part of wire controller

Remove upper part of wire controller

PCB is mounted on lower part of wire controller, be careful not to damage it.

Upper part of wirecontroller

2. Install wire controller

(1) For exposed installation, use 2 wood screws .

(2) For recessed installation, use 2 wood screws .

Lower part of wire

controller

Note:

Try as far as possible a flat surface for installation. Don't use excessive force when

tightening screws, or lower part might got deformed.

3. Indoor unit wiring

Connect terminals (A,B,C,D) on lower part of wire

When make wiring, please

controller to terminals (A, B,C,D) on PCB of indoor

keep a distance between

unit.

wires and power supply cord.

wiring from here

Wire

AB CD

Lower part of

Cord kind

Shield wire (4 core) (refer to Hint

0.33mm

2

Use shielede wires for telecommunication between

wire controller and indoor unit; indoor unit and

outdoor unit. Ground the shield on one side.

Otherwise misoperation because of noise may occur.

Signal wire is self-provided.

Upper part of

ground

Shielded wire

16

Page 17

Hint

Hint

Commercial Air Conditioner

Tread surface of the terminal well so that shielding may not contact other part.

4. Replace the upper part of wire controller

Be careful not to press the wiring.

1. Switch box and cord for wiring are not supplied.

2. Don't touch PCB with hand.

Change-over switch

Mark

ON

OFF

1

Fixed Frequency Inverter

2

Have rise and drop No rise and drop

3

Swing Not Swing

4

The collection

temperature of

indoor unit

The collection

temperature of wire

controller.

For

HDU-50HT03/H

, change-over switch is set:

1. ON 2.OFF 3.OFF 4.OFF

The detail information please refer to the installation manual.

5. Electric wiring

WARNING

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER SOURCE BEFORE

MAKING ANY ELECTRIC CONNECTIONS. GROUND CONNECTIONS MUST BE

COMPLETED BEFORE MAKING LINE VOLTAGE CONNECTIONS.

(1) Selection of size of power supply and interconnecting wires.

Precautions for Electric wiring

Electric wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round type crimped

terminal lugs with insulated grip on the ends of the wires.

Use copper conductor only.

Select wire sizes and circuit protection from table below. (This table shows 20 m length

wires with less than 2% voltage drop.)

Item

Circuit breaker

Power

Earth leakage breaker

Model

Phase

Switch breaker

(A)

Overcurrent

protector

source wire

size

Switch

break

Leak

curren

HDU-50HT03/H

3

30 20 2.5mm

2

30 30mA

(2) Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor unit is supplied by

terminals.

N 1 2 3R S T

Y/G

1 2 3

POWER SUPPLY:

Y/G

3N~,380-400V , 50Hz

INDOOR UNIT TERMINAL BLOCK

it is also apply to HDU-42CA03T3/H,HDU-50CA03T3/H,

HDU-60CA03T3/H

17

Page 18

Commercial Air Conditioner

6. Parts and Functions

XZXUJSINSL UTQJ

LZFWINSL UQFYJ

J[FUTWFYTWnNSXNIJo

IZHY

IWFNS UNUJ

JQJHYWNH GT]

XYTU [FQ[J

XZXUJSINSL GTQY

DLU LQOHW

DLU RXWOHW

FRPSUHVVRUnLQVLGH RI XQLWo

VWRS YDOYH

18

Page 19

Commercial Air Conditioner

7.Refrigerant circuit

19

Page 20

Commercial Air Conditioner

8. Controller functions

For HDU-50HT03/H,HDU-42,50,60CA03T3/H, the indoor unit can be controlled by wired controller

YR-E06.

9. Electrical Control Functions

9.1 For indoor unit

1. General notes for the function

1.1 The electric system can control the following functions of the commercial air conditioner.

Operation mode includes auto run, cooling, dehumidifying, venting, and heating. It can set the

compulsory cooling, and indoor fan motor has auto, high, med, low three selection. And it can set

TIMER ON, TIMER OFF, TIMER ON/OFF and SLEEP; auto check water level in the container and

control the drainage; swing controlled by synchro-motor; equipped with compressor 3-minutes

protection; overload protection; freezing protection; sensor broken down protection, etc. Also it can

check communication failure and measure indoors room temperature, indoor coil temperature.

Operation panel adopts LCD display, receiving the indication by pressing buttons, and it can realize

remote control function, also is responsible to measure indoor room temperature and it adopts

serial communication type with main board.

1.2 LED indication: when the unit is switched on by the controller, the POWER LED will be ON,

when being switched off, the POWER LED will be OFF. If the controller is in TIMER and SLEEP

mode, the TIMER LED will be on; if it is not in TIMER and SLEEP mode, the TIMER LED will be off.

When the compressor is running, the compressor LED will be on; when it stops, this LED will be off.

1.3 Temperature compensation control: select the 4 degree compensation when use ambient

temperature sensor on the indoor PCB( include: remote control type and wired control type use

indoor ambient temperature sensor).

1.4 There is set temperature in AUTO mode as default.

1.5 Do not receive the remote OFF signal when enter defrost mode.

2. Control modes selection

2.1 Auto fan speed selection

The following Tr stands for room temperature, Ts stands for set temperature.

2.1.1 In cooling mode

If it is the first time to enter auto fan mode(fan motor is stop), when Tr>Ts+2, it is in High speed; Tr

≤Ts, it is in Low speed; Otherwise, it is in Med speed. If the current mode is auto high speed, when

Tr<Ts+2, fan speed will turn to med speed automatically. If the current mode is auto med speed,

when Tr>Ts+3, it will turn to high speed, Tr<Ts,

it will turnto

low speed.

If current

mode is low

Temp. reducing

Med

Ts +2℃

High

Ts +3℃

High

speed, when

Ts +1℃

Med

Tr>Ts+1, it

will turn to med

Ts

Low

speed. When fan

Low

speed changes from low to

Temp. arising

20

Page 21

Commercial Air Conditioner

high, current mode will continue running 3 minutes and then turn to high speed. But nor while the

mode change from high to low.

2.1.2 In heating mode(Cooling only unit without this function)

Wired type units: If it is the first time to enter auto fan mode(fan motor is stop), when Tr>Ts-1, it is

in Low speed; Tr≤Ts-3, it is in High speed; Otherwise, it is in Med speed. If the current mode is

auto low speed, when Tr<Ts-1, fan speed will turn to med speed. If the current mode is auto med

speed, when Tr>Ts, it will turn to low speed, Tr>, it will turn to high speed, If the current mode is

high speed, when Tr>Ts-2, it will turn to med speed. (Ts is the set temperature in the wired

controller)

When fan speed changes from low to high, current mode will continue running 3 minutes and then

turn to high speed. But nor while the mode change from high to low.

Temp. reducing

Low

High

Ts

Med

Ts -1℃

Med

T

s-2℃

High

arising

Te mp .

Low

Remote type units: If it is the first time to enter auto fan mode, when Tr>(Ts+4)-1, it is in Low

speed; Tr≤(Ts+4)-3, it is in High speed; Otherwise, it is in Med speed. If the current mode is auto

low speed, when Tr<(Ts+4)-1, fan speed will turn to med speed automatically. If the current mode

is auto med speed, when Tr>Ts+4, it will turn to low speed, when Tr<(Ts+4)-3, it will turn to high

speed. If current speed is high, when Tr>(Ts+4)-2, it will turn to med speed. (Ts is the set

temperature in the remote controller)

When fan speed changes from low to high, current mode will continue running 3 minutes and then

turn to high speed. But nor will the mode change from high to low.

Please refer to the sketch map:

Temp. reducing

Low

High

(Ts+4)

Med

(Ts+4)-1

(Ts+4)-2

Med

(Ts+4)-3

High

Low

arising

Te mp .

2.2 Auto run

a. Heat pump unit

After starting up, operation mode turns to auto run; system will decide the operation mode

according to the difference in current setting temperature and room temperature. Tr stands for room

21

Page 22

-3

Commercial Air Conditioner

temperature, Ts stands for setting temperature.

When it is the first time to auto run, operation mode will be selected according to the following

conditions:

Tr>Ts select cooling mode

Tr=Ts select blowing mode(compressor stopped when in cooling mode)

Tr<Ts select heating mode

After the system enters auto run mode, the running mode can convert automatically according to

variation of room temperature between cooling and heating in the way shown as the chart below: If

the current mode is cooling, when it arrive at the compressor stop temperature, the compressor will

stop; after 3 minutes, the unit measure the temperature again, at this time, if Tr<Ts- 3℃, it will enter

heating mode, or it will still be in cooling mode; if the current mode is heating, when it arrive at the

compressor stop temperature, the compressor will stop, after 3 minutes, the unit will measure the

room temperature, if Tr>Ts+ 3℃, it will enter cooling mode, or it will still be in heating mode.

When system is in heating, if temperature of indoor heat exchanger is more than 63℃, the unit will

convert to cooling mode automatically, within 1 hour the temperature of indoor heat exchanger will

not be limited; heating operation stop, after 1 hour, the unit will select the right mode according to

the above conditions.

When it is the first time to select heating, compressor and outdoor fan motor start up, within 8

minute it will not measure indoor room temperature. The conversion chart is below:

Temp. reducing

cooling

Ts +3 ℃

cooling

blowing

Temp. arising

Ts -3 ℃

Ts

Ts -3℃℃

heating

heating

b. Cooling only unit

When it is the first time to auto run, operation mode will be selected according to the following

conditions:

Tr≥Ts + 3 ℃ select cooling mode

Tr<Ts + 3 ℃ select blowing mode

After the system enters auto run mode, the running mode can convert automatically according to

variation of room temperature between cooling and blowing in the way shown as the chart below: If

the current mode is cooling, when Tr<Ts - 3 ℃, it will turn to blowing; if the current mode is blowing,

when Tr≥Ts + 3 ℃, it turns to cooling mode. The conversion is the below chart:

Temp. reducing

heating

Ts+3 ℃

blowing

cooling

Ts-3 ℃

blowing

Temp. arising

22

Page 23

压机开

压机关

Commercial Air Conditioner

Room temperature is controlled by the set temperature ( control precise is +1℃).

Fan blade can select swing or stay in one position; fan speed can be low, med, high or auto speed.

Also timer or sleep can be set.

2.3 Cooling operation

2.3.1 The solenoid valve is powered off, the controller determines compressor run/stop according

to the difference between current room temperature and set temperature.

Tr≥Ts+1 compressor run

Tr≤Ts-1 compressor stop

Ts-1<Tr<Ts+1 compressor in original state Refer to the below chart:

Temp. reducing

compressor run

Ts +1

Ts -1

compressor stop

Temp. arising

2.3.2 Anti-current rush: 1.6 seconds later after compressor is running, outdoor and indoor motor

can work.

2.3.3 Freeze protection

After the compressor has run for 6 minutes, If the temperature of indoor coil pipe Ticp < 1℃ and it

keep 1 minute, the compressor and outdoor fan motor will stop and change to blowing mode. They

will run again after the compressor stops if both the following conditions are meeted:

1) 9 minutes have passed since compressor stops.

2) Ticp exceeds 10℃

2.3.4 Temperature cutoff protection

For 2HP units: If indoor coil temperature Ticp > 68℃ and it keep 10 seconds, compressor and

outdoor motor will stop. After compressor stops, if Ticp < 48℃ and compressor stop more than 9

minutes, the compressor and outdoor motor will resume to run normally.

For 3HP and 5HP units: After compressor running for 9 minutes, indoor unit will check the indoor

coil temperature (Ticp) and send to outdoor. If Ticp > 68℃ and it keep 10 seconds, indoor will send

the signal of stop compressor to outdoor. After compressor stops, if Ticp < 48℃ and compressor

stop more than 9 minutes, indoor will send the signal to start up compressor, and the compressor

will resume to run normally. Outdoor fan motor is controlled by outdoor.

2.3.5 Current peak value protection

For controller of 3HP and 5HP single chip units, controlled by outdoor unit.

For 2HP units, when CT current is more than I3(21A) and lasts for 3 seconds after compressor has

run for 60 seconds, compressor and outdoor motor will stop. After compressor stops 3 minutes, the

compressor and outdoor motor will resume to run normally.

2.4 Dehumidification operation

a. When it is the first time to dehumidify, compressor, outdoor fan motor, indoor fan motor will

operate according to below rules:

23

Page 24

Commercial Air Conditioner

(1). Tr>Ts+2℃, compressor, outdoor fan motor continue running, while indoor fan motor runs at

set fan speed. This working area is defined as area A.

(2). Ts≤Tr≤Ts+2℃, the compressor and outdoor fan motor run for 10 minutes then pause for 6

minutes, while indoor blowing fan runs at low speed. This working area is defined as area B.

(3). Tr < Ts, the compressor and outdoor fan motor stop working while outdoor blowing fan runs at

low speed. This working area is defined as area C.

b. After dehumidifying program starting, the system converts between A, B and C areas according

to variations of room temperature with running mode. If working in area A, when Tr<Ts+1, it

converts to area B; If working in area C, when Tr > Ts, it converts to area B; If working in area B,

when Tr>Ts+3, it converts to area A, and Tr<Ts-1, it converts to area C. The conversion is shown

as the chart below:

Temp. reducing

Area A

Area A

Ts +3

Ts +1

Area B

Area B

Ts

Ts -1

Area C

Area C

Temp. arising

c. Freeze protection

After the compressor has run for 6 minutes, If the temperature of indoor coil pipe Ticp< 1℃, the

compressor and outdoor fan motor will stop and change to blowing mode. They will run again after

the compressor stops if both the following conditions are meeted:

1) 9 minutes have passed since compressor stops.

2) Ticp exceeds 10℃

d. Overheat protection

2.5 Blowing operation

Outdoor fan motor and compressor stop, and indoor fan speed can be set as high, med or low. Fan

blade can be set swing or stay in one position. Also it can set timer or sleep and high voltage

removing dirt or fresh air function.

2.6 Heating operation(Cooling only unit without this function)

2.6.1 Wired type unit

a. 4-way valve control: enter heating mode and compressor starts up; 4-way valve is on. If in

heating mode, compressor stop, 4-way valve will stop after 2 minutes. If it is from heating mode to

other mode, compressor will stop firstly,

after 2 minutes 4-way valve stop, too.

b. The first time to heating mode,

compressor and outdoor fan motor start

Temp. reducing

compressor stop

Ts +1

up, the controller determines compressor

run/stop according to the difference

between current room temperature and

Ts -1

Temp. arising

set temperature.

compressor run

24

Page 25

Commercial Air Conditioner

Tr≥Ts+1 compressor stop

Tr≤Ts-1 compressor run

Ts-1<Tr<Ts+1 compressor in original state

2.6.2 Remote type units:

a. 4-way valve control: enter heating mode and compressor starts up; 4-way valve is on. If in

heating mode, compressor stop, 4-way valve will stop after 2 minutes. If it is from heating mode to

other mode, compressor will stop firstly, after 2 minutes 4-way valve stop, too.

b. The first time to heating mode, compressor and outdoor fan motor start up, after 8 minutes,

system will check the indoor room temperature, the controller determines compressor run/stop

according to the difference between current room temperature and set temperature. Every starting

up, it will not be affected by indoor room temperature within 8 minutes. The remote controller can

release 8-minute limit.

Ts stands for set temperature in remote controller, Tr stands for current room temperature, △

Tstands for compensation temperature. So:

Tr≥(Ts + 4)+△T + 1 compressor stop

Tr≤(Ts + 4)-1 compressor run

(Ts +4 )- 1 <Tr<(Ts+ 4 )+△T + 1 compressor in original state

Temp. reducing

compressor stop

(Ts +4 +△T)+1

compressor run

(

Ts +4)-1

Temp. arising

In heating mode, there is auto temperature compensation, whose condition is compressor achieve

the temperature condition and the time < 5 minutes from the compressor shut off to the compressor

start up again. The rule is below:

A. △T=Ts-Tr (compressor start up)

B. If Ts-Tr≥2℃, △T=2℃; If Ts-Tr=1℃, △T=1℃; If Ts-Tr≤0℃, △T=0℃。

C. With compensation, if pressing the temperature reducing button of remote controller, △T=0℃; if

pressing the temperature increasing button, △T will remain the original value.

Anti-current rush: 1.6 seconds later after compressor is running, outdoor and indoor motor can

work.

Outdoor fan motor and compressor will open and close simultaneously (except for overheating),

indoor fan speed can be set high, med, low, auto. And the air blade can swing or stay in one

position. Also it can be set timer or sleep.

2.6.3 Overheat protection (for the unit with outdoor communication, the outdoor motor is

controlled by outdoor unit, but the compressor is still controlled by indoor unit, and their temperature

points will not be accordant completely)

In heating mode, compressor has started up and indoor motor has run for over 30 seconds, if indoor

coil temperature Tg>60℃, outdoor motor will stop; if Tg<56℃, and outdoor motor has stop for 45s,

outdoor motor will run again; if Tg>68℃, the compressor will stop and indoor motor will run

25

Page 26

Commercial Air Conditioner

according to the thermostat state. After the compressor stops for 3 minutes and Tg reduces to 48℃,

the unit will resume to heating mode, and the compressor and the outdoor motor will run again.

2.6.4 Anti cool air function in heating mode:

When it is the first time to heat or after last defrosting is over, if Ticp<28℃, indoor fan motor will stop

running. If Ticp≥28℃ and Ticp<38℃, indoor fan motor will run in low speed. If Ticp>38℃ and

compressor has run for more than 4 minutes, indoor fan motor will run at set fan speed.

2.6.5 Blowing surplus heat in heating mode:

a. For 3HP and 5HP units: In heating mode when set temperature has arrived, the compressor will

stop. For wired type unit, indoor fan motor will continue running 50 seconds at low speed and then

stop. For remote type unit fan motor will continue running 4 minutes at low speed and then stop.

b. For 2HP units:If the unit shut off in heating, indoor fan motor will continue running 50 seconds at

low speed and then stop.

2.6.6 Crankcase heater

No matter at any mode, if compressor is on, the heater is off; if compressor is off, the heater is on.

2.6.7 Auxiliary electric heating

Auxiliary electric heating will work when the following conditions be met:

A. Tr≤Ts-2℃

B. Compressor work and running for 1 minute

C. Tr≤23℃

D. Indoor fan motor must run well

E. There is starting signal for electric heating function

Only when the above 5 conditions must be met simultaneously, electric heating can work.

When either of the following conditions be met, auxiliary electric heating will stop working.

A. Compressor or indoor fan motor stop working

B. Tr≥25℃

C. Tr≥Ts-1℃

D. There is no starting signal for electric heating function

2.6.8 Current peak value protection

For controller of 3HP and 5HP single chip units, controlled by outdoor unit.

For 2HP single chip units, when CT current is more than I1(13.5A) and lasts for 5 seconds after

compressor has run for 60 seconds, outdoor motor will stop. After motor stops 45 seconds and

compressor current is less than I2(11A), outdoor motor will run. when CT current is more than

I3(21A) and lasts for 3 seconds, the compressor and outdoor motor will stop. After compressor

stops 3 minutes and CT current is less than 18A, the compressor and outdoor motor resume to run

normally.

2.6.9 Auto defrosting function

Project 1: With outdoor PCB:

(1) Staring condition of defrosting

A. The unit enter heating mode and compressor runs for 30 minutes continuously.

B. Compressor run more than 45 minutes totally and compressor run more than 5 minutes

continuously.

When one of the above conditions be met, and when indoor unit has received the signal of

defrosting temperature arrival from outdoor unit, the unit will begin to defrost and send defrosting

beginning signal to outdoor.

26

Page 27

Commercial Air Conditioner

(2) Finishing defrosting conditions

When the defrosting temperature arrival signal has been removed or the defrosting time has been more

than 12 minutes (including each 1-minute conversion time for before and after defrosting), defrosting will

finish and send the defrosting removal signal to outdoor.

Project 2: For the unit without outdoor PCB

(1) Enter condition

● Indoor occurs overload protection and outdoor motor stops, if outdoor motor can not enter overheat

state in 10 minutes after it runs again, also the compressor runs for 45 minutes in all and has run for

over 20 minutes continuously, Ticp is below 43℃;

● The compressor runs for 20 minutes continuously, Ticp will reduce 1℃ for every 6 minutes and

happen 3 times continuous, and Ticp is below 40℃, 5 minutes later after the compressor restarts up.

● The compressor runs for 3 hours in all and has run for over 20 minutes continuously, Ticp is below 40

℃;

● The temperature difference between Ticp and Tr is below 16℃ and the compressor runs for 45

minutes in all and has run for over 20 minutes continuously, Ticp is below 40℃

If one of the above conditions can be met, the unit will enter the defrost.

(2) Quit condition

The defrosting time is over 10 minutes .

Project 3: For the unit without outdoor PCB but with defrosting sensor

a. Enter condition

In heating mode, timing when outdoor coil temperature Tp<0℃ and stop timing when Tp>=0℃, count

continuously.

When being electrified for the first time or defrosting is over, compressor starts up, after running for 3

minutes, the system will check Tp0 (when Tp0<-2℃, count as the actual value; the other conditions,

count as -2℃), detect the Real-time temperature of coil sensor Tp, so △T= Tp-Tp0.

①Accumulative time[15m~30m], △T<-12℃, enter defrost(time is over 3 minutes);

②Accumulative time [30m~60m], △T<-8℃, enter defrost(time is over 3 minutes);

③Accumulative time [1Hr~2Hr], △T<-5℃, enter defrost(time is over 3 minutes);

④Accumulative time [2Hr~3Hr], △T<-3℃, enter defrost(time is over 3 minutes);

Accumulative time[3Hr~], enter defrost.

b. Quit condition

The defrosting time is over 10 minutes (excluding conversion time for before and after defrosting). Or

Tp>10℃, quit defrosting.

(3) After beginning defrosting, each load will take the following performance:

In the course of defrosting, compressor, 4-way valve will be controlled by indoor unit, and outdoor fan

motor will be controlled by outdoor unit. Detailed is below:

Compressor, outdoor fan motor will stop and meanwhile, indoor fan motor will stop, too. After 55

seconds, the 4-way valve will close. After another 5 seconds, compressor will start up.

After defrosting finishing, compressor will not stop, outdoor motor run and 30 seconds later, 4-way valve

. will open, indoor unit will run at anti-cool air mode

27

Page 28

T

Commercial Air Conditioner

(4) For units with auxiliary electric heating:

a. If when defrosting condition is met, electric heating is working, the unit will stop electric heating firstly,

after 20 seconds, it will enter defrosting mode.

b. If before defrosting, auxiliary electric heating is on, then after defrosting, when auxiliary electric

heating condition is met, it will start up electric heating.

compressor

Indoor fan motor

Run at anti-cool air mode

Outdoor fan motor

4-way valve

Max:10min

55s

1min

55s

1min

2.6.10 Manual defrosting

When operation panel sends the manual defrosting signal, indoor and outdoor unit do not adjust the

defrosting condition and directly perform the defrosting function, its defrosting course is as the same as

the auto defrosting course. The quit condition is that the defrosting time is 5 minutes.

2.7 Sleep function

When the unit is in cooling, dehumidifying, or heating mode, sleep function can be set. In cooling or

dehumidifying mode, after in sleep mode for 1 hour, set temperature will arise 1℃, after a second 1 hour,

set temperature will arise a second 1℃, and continue working for 6 hours, the unit shut off.

s

Ts +1

Ts +2

Sleep sketch map in non-heating mode

T

28

Page 29

Commercial Air Conditioner

In heating mode, after in sleep mode for 1 hour, set temperature will reduce 2℃, after a second 1

hour, set temperature will reduce a second 2℃, and after continue working for 3 hours, set

temperature will arise 1 ℃, and continue working 3 hours, the unit shut off.

Sleep sketch map in heating mode

1 2 5 8

Ts

Ts -2

Ts -3

Ts -4

℃

2.8 Compulsory cooling operation

When received the compulsory cooling signal from operation panel, the main unit will run for 5

minutes at indoor and outdoor fan motor in high speed, in cooling mode (that is compressor running

5 minutes) and send this signal to outdoor. Within 5 minutes, the system will not adjust any

protection, and not affected by ambient temperature. But the compressor will be protected by 3

minutes protection function, and after 5 minutes, it will turn to normal cooling mode. In compulsory

cooling mode, the crank heater, negative ion, fresh air function will stop completely.

2.9 Water level and drainage control

a. In cooling (including automatic cooling mode and cooling by emergency switch) and

dehumidifying modes, the water pump works if the compressor runs otherwise it will stop 5 minutes

later after the compressor stops.

b. In heating and blowing mode, when water tank is fully filled, the float switch will be off. The water

pump will start to work after a controller has detected this signal and has last for 2 seconds. it will

continue working for 5 minutes after the float restores to normal state.

c. If the full water signal is detected continuously over 5 minutes, the water pump indicator will flash

to alarm and compressor stops running. The water pump will run 5 minutes, then pause for 5

seconds before next 5 minutes’ running, ... until the float restores to normal state, after which the

pump will run for 5 minutes then stop.

2.10 Negative ion and high voltage collecting dirt function

When there is health setting signal, and indoor fan motor running, gate switch close, negative

ion/high voltage collecting dirt function will work.

2.11 Fresh air function

When there is fresh air signal, there will be fresh air output signal. In any mode of ON/OFF state,

there always is fresh air output (controlled by the fresh air signal from the operation panel, not

limited by the ON/OFF signal from operation panel). Fresh air function includes continuous and

auto types:

a. Continuous: as soon as there is fresh air signal, it will be in fresh air mode all along unless

receive the stop signal to stop fresh air function.

b. Auto: Fresh air be on for 20 minutes, and off for 20 minutes. Repeat in this way unless receive

the stop signal to stop fresh air function.

2.12 pressure protection

After compressor is running for 3 minutes, the unit will check the pipe pressure, when the pipe

pressure is too low and low pressure switch is running for 30 senconds, compressor and outdoor

fan motor will stop and will send failure, then compressor will not start up again; when being

29

Page 30

Commercial Air Conditioner

electrified after being powered off, the protection will be cancelled.

3 System protection

3.1 3-minute protection for compressor startup

After the compressor stops, at least 3 minutes later, the compressor can restart up; if the unit is

powered off in running, after being electrified, 3 minutes later, the compressor can restart up. Being

electrifed for the first time, there is 3-minute delay protection.

3.2 Failure code

The remote receiver, wired controller and indoor PCB indicator all can indicate the failure code.

Failure code list

Failure

code on

panel

Power lamp flash

times/LED on

PCB flash times

failure description reasons treatment

E1

1

Indoor ambient temp.

sensor failure

sensor broken down or short circuit

for more than 2m continuously

due to the signal,

resumable

E2

2

Indoor pipe temp.

sensor failure

sensor broken down or short circuit

for more than 2m continuously

due to the signal,

resumable

E3

3

Outdoor ambient

temp. sensor failure

sensor broken down or short circuit

for more than 2m continuously

due to the signal,

resumable

E4

4

Outdoor pipe temp.

sensor failure

sensor broken down or short circuit

for more than 2m continuously

due to the signal,

resumable

E5

5

overcurrent Detected current is above the limit

when run

Need to be

checked, reset

E6

6

High pressure

malfunction

High pressure switch acts 3 times in

30m

Need to be

checked, reset

E8

8

Communication

failure between panel

and indoor unit

communication abnormal for more

than 4m continuously

due to the signal,

resumable

E9

9

Communication

failure between indoor

and outdoor unit

communication abnormal for more

than 4m continuously

due to the signal,

resumable

E0

10

Fault in drain system Float switch is open for more than

5m continuously

due to the signal,

resumable

E6

16

Low pressure

malfunction

low pressure switch acts for 30m Need to be

checked, reset

3.3 Sensor malfunction

If indoor ambient temp. sensor and indoor pipe temp. sensor are valid, there is no outdoor

sensor, in the following conditions, the unit will confirm the sensor is failure:

Mainboard checks that the sensor is in open circuit, short circuit or close to short circuit

continuously for 2 minutes, the mainboard will confirm that sensor is failure, the system will stop

running, alarm occurs; If the signal is resumed, the system will resume automatically.

If indoor ambient temp. sensor and indoor pipe temp. sensor is valid, also there is outdoor

sensor, in the following conditions, the unit will confirm the sensor is failure:

Mainboard checks that the outdoor pipe temp. sensor is in open circuit, short circuit or close to

30

Page 31

Commercial Air Conditioner

short circuit continuously for 2 minutes, the mainboard will confirm that sensor is failure, the system

will stop running, alarm occurs; If the signal is resumed, the system will resume automatically.

8.2 For outdoor unit

1. Outdoor motor control

When the system does not occur overcooling, overheating, and over current protections, the

outdoor motor will occur the below changes according to the outdoor ambient temperature and

indoor coil temperature.

1.1 General information

Outdoor motor is 2-speed type: high, low and stop.

The fan speed will change unless every step has been run for 45 seconds.

1.2 Cooling mode

1.2.1 Indoor coil temp.≥15℃, outdoor motor runs at high speed.

1.2.2 Indoor coil temp.<5℃, outdoor motor runs at low speed.

1.2.3 5℃≤Indoor coil temp.<15℃, outdoor motor will change due to the outdoor ambient temp.

Outdoor ambient temp. >28℃, enter high speed; outdoor ambient temp.<26℃, enter high speed;

26≤outdoor ambient temp.≤28℃, keep the current speed.

In running, the system will be controlled as 2℃ temperature tolerance; if outdoor ambient temp. <

26℃, enter low speed; if outdoor ambient temp.>28℃, enter high speed.

1.3 Heating mode (heat pump model)

1.3.1 Indoor coil temp.≥50℃, outdoor motor will run at low speed.

1.3.2 Indoor coil temp. <40℃, outdoor motor will run at high speed.

1.3.3 40℃≤indoor coil temp.<50℃, outdoor motor will change with outdoor ambient temp.

Outdoor ambient temp.<13℃, enter high speed; Outdoor ambient temp.>15℃, enter low speed;

13≤Outdoor ambient temp.≤15℃, keep the current speed;

In running, the system will be controlled as 2℃ temperature tolerance; if outdoor ambient temp. <

13℃, enter high speed; if outdoor ambient temp.>15℃, enter low speed.

Every step will run at least 45 seconds, and the motor will start up 2 seconds earlier than

compressor.

2. Defrost control

2.1 Defrosting condition

In heating mode, the compressor will run for 30 minutes continuously or run for 45 minutes in all

and for over 5 minutes contineously, outdoor motor at least runs for 2 minutes; If the outdoor

ambient temperature and outdoor coil temperature can comply with the shadow area in the figure

and keep for 1 minute, the defrost will work and send defrost signal to indoor unit, then indoor unit

will control indoor motor accordingly.

2.2 Quit condition

Outdoor coil temp. arrives the defrost-end temp. 14℃ or the defrost time is over 12 minutes, the

defrost will finish and send signal to indoor unit.

2.3 Defrost operation

Compressor and outdoor motor stop, indoor motor stops meanwhile; 55 seconds later, the

reversing valve will close. Another 5 seconds later, compressor starts up.

After defrost is over, compressor stops, outdoor motor runs at high speed; 55 seconds later, the

reversing valve will open. Another 5 seconds later, compressor starts up and indoor motor runs at

anti-code mode.

31

Page 32

Commercial Air Conditioner

Type 1: Standard defrost

1) If Tr≥-2℃, when Tp≤-6℃, enter defrost.

2) If -12℃≤Tr<-2℃, when Tp≤-6℃, please refer to the following chart.

3) No matter the ambient temperature, when Tp≤-16℃, enter defrost.

Type 2: Non-standard defrost (rectify defrost data by the device)

1) If Tr≥6℃, when Tp≤-6℃, enter defrost.

2) If -18℃≤Tr<-6℃, when Tp≤-6℃, please refer to the following chart.

3) No matter the ambient temperature, when Tp≤-18℃, enter defrost.

-6℃

A

mbient

Coil tem

p.(

℃

)

6℃-18℃

-6℃

-

A

mbient

Coil temp.(℃

)

-

-

-16℃

2.4 Manual defrost

Indoor sends defrost signal to outdoor, and the outdoor will receive the defrost signal when

compressor is running in heating mode, then enter the defrost process. When outdoor coil

temperature arrives the defrost-end point and the defrost time is over 5 minutes, outdoor will send

the defrost-end signal to finish the defrost.

3. Compressor crankcase heater working condition

By the N.C. (normal close) auxiliary point of AC contactor to control, when compressor stops, the

heater will work; when compressor works, the heater will stop.

4. System protection function

4.1 Anti-freezed protection

32

Page 33

Commercial Air Conditioner

When compressor has run for over 6 minutes, to prevent indoor evaporator freezing (in cooling/dry

mode), if indoor coil temp. is below -1 degree for over 1 minutes, compressor and outdoor motor will

stop and enter Fan mode. After compressor stops for 9 minutes, and indoor coil temp. rises up to 10

℃, the unit resumes to cooling mode, compressor and outdoor motor will work again.

4.2 Overheat protection

In heating mode, if indoor motor is running and the compressor has run for over 30 seconds, the

sensor will check the indoor coil temperature, and send the temp. to outdoor; if indoor coil temp.

>T1(53℃), the outdoor motor will enter low speed; if indoor coil temp.<T2(50℃), outdoor motor

will enter high speed; if indoor coil temp. >T3(56℃), outdoor motor will stop; if indoor coil temp.

<T4(53℃), outdoor motor will resume low speed; when indoor PCB receive the signal of outdoor

motor stop from outdoor PCB over 2 minutes, if indoor coil temp. >T6(70℃)or 10 minutes later

indoor coil temp. >T5(56℃), send compressor stop signal to outdoor unit; if indoor coil temp.<46

℃ and the compressor has stopped over 3 minutes, send compressor run signal to outdoor unit,

and compressor resume to normal.

The outdoor motor is control by oudoor unit.

4.3 Over current protection

4.3.1 In heating mode

After compressor running for 40 seconds, if the current thermostat has measured that system

working current is more than 21A and keep it for 5 seconds, outdoor motor will convert into low

speed; if working current is less than 18A, it will resume to high speed; if working current is more

than 25A and keep it for 5 seconds, outdoor motor will stop; if working current is less than 22A,

outdoor will resume to low speed (fan speed conversion frequency must be more than 45 seconds);

after compressor running for 5 minutes, if working current is more than 34A and keep it for 5

seconds, compressor will stop and will resume 3 minutes later.

If within 30 minutes there are 3 times compressor over current protection, compressor will not start

up, meanwhile, LCD will display E5. Only shut off and powered on again, the protection can be

cancelled.

4.3.2 Not in heating mode

After compressor running for 5 minutes, if working current is more than 34A and keep it for 5

seconds, compressor will stop and will resume 3 minutes later.

If within 30 minutes there are 3 times compressor over current protection, compressor will not start

up, meanwhile, LCD will display E5. Only shut off and powered on again, the protection can be

cancelled.

4.4 Power protection

4.5 High/Low Pressure protection (cooling only unit without this function)

After compressor running for 8 minutes, the system will check the pipe pressure. If pipe

pressure is over high, high pressure switch has acteivated more than 15 seconds, compressor,

outdoor motor will stop and 3 minutes later it will resume. If within 30 minutes there are stop

phenomenon 3 times because of pressure over high, the compressor will stop and LCD will display

E6. only shut off and powered on again, the protection can be cancelled.

Low pressure protection

(1) After compressor running for 3 minutes, if low pressure switch has acteivated for 15 seconds

continuously, compressor will stop and alarm.

(2) Check the low pressure switch when compressor is stop, the compressor will not run if low

33

Page 34

Commercial Air Conditioner

pressure switch act, low pressure switch has acteivated more than 30 seconds, LCD will display

Low pressure abnormal

(3) In defrosting and in 6 minute after defrost is over , low pressure switch will not be checked.

(4) In heating, compressor run and outdoor motor stop, low pressure switch will be shielded.

(5) Low pressure protection can be resumable when power-off.

4.6 3-minutes protection for compressor

After compressor stops, it cannot be started until 3 minutes later. During the machine’s running,

if the time not more than 3 minutes after power is off, the compressor cannot be restarted until 3

minutes later after it is powered on again

4.7 Sensor broken down protection

a. Check if sensor breaks down

After compressor has run for 2 minutes, the unit will check the sensor, Outdoor board checks

the sensor in short circuit or in open circuit or near to short/open circuit for 2 minutes continuously,

then it will adjust the sensor broken down.

b. How to deal with it?

If the outdoor ambient temperature sensor and the outdoor coil temperature sensor have

broken down, the unit will stop running, and alarm E3, E4, E4 simultaneously.

4.8 Starting current control

Outdoor unit load control: after the outdoor motor running for 2 seconds, main compressor start

up, the secondary compressor will run 2 seconds later.

4.9 4-way valve control

5. Outdoor PCB test

(1) There are three pins marked with TEST, please make the two ones near to COOL in short circuit.

Outdoor begin to run in cooling mode, that is, compressor run and outdoor motor works at high

speed.

(2) There are three pins marked with TEST, please make the two ones near to HEAT in short circuit.

Outdoor begin to run in heating mode, that is, compressor and 4-way valve run, outdoor motor

works at low speed.

6. Failure code list

Failure description

Code on wired

controller

Flash times of indoor

receiver board

Room temp. sensor abnormal 01 Power LED flashes 1 time

Indoor coil temp. sensor abnormal 02 Power LED flashes 2 times

Outdoor temp. sensor abnormal 4A Power LED flashes 3 times

Outdoor coil temp. sensor abnormal 49 Power LED flashes 4 times

Over-current malfunction 48 Power LED flashes 5 times

High / Low pressure abnormal 53 Power LED flashes 6 times

Communication malfunction between indoor and wired controller 07 Power LED flashes 8 times

Communication malfunction between indoor and outdoor abnormal 06 Power LED flashes 9 times

Drainage system malfunction 08 Power LED flashes 10 times

Alarm of exterior annunciator 0B Power LED flashes 11 times

Coil gas pipe temp. Sensor abnormal 03 Power LED flashes 12 times

Temperature protection malfunction 0D Power LED flashes 13 times

34

Page 35

&$3$&,725

75$16)250(5

CIRCUIT DIAGRAM OF INDOOR UNIT

0010573510

,

Commercial Air Conditioner

9. Electric data

9.1 Electric Wiring diagram and PCB photo

For HDU-50HT03/H

::+,7(%%/$&.

55('%/%/8(

<*<(//2:*5((1

027253$576,17+('$6+('3$577+('(7(&725,6237,21$/3$57:,7+

127(+,*+ǃ0('ǃ/2:(63,6$9$,/$%/(%<&211(&7(':,7+7+(',))(5(17)$1

:+,&+7+(&(175$/&21752/,6$9$/$%/('$6+('3$576$1'&211(&7('

3,3,1*7(036(1625

%/

:

)$102725

0

5(/$<

)$102725

5

<*

:

7(50,1$/%/2&.

5(680$%/(

3527(&725

21(2))

3527(&725

+($7(5

&21752//(5

:,5('

)/2$7

72287'22581,7

'(7(&725

)86(

:,5(6$5(127$9$/$%/()2512(/(&75,&+($7,1*)81&7,2181,7

%

:

%

5

<*

&1

7$9$&

&1

&1

&1

-.

&1

&1

&1

&1

CIRCUIT DIAGRAM OF OUTDOOR UNIT

0010573510

B:BLACKBL:BLUE

GR:GRAY

TO INDOOR UNIT

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

OUTDOOR PIPING SENSOR

COMPRESSOR VENT SENSOR

OUTDOOR AMBIENT SENSOR

Y/G:YELLOW/GREEN

R:RED

CN2

CN10

CN1

CN3

CN12

CN11

POWER SUPPLY

W

W:WHITE

R

BL

B

B

RST

R

N

S

10P

5P

SW1

L2

L1

L3

N

1

2

Y/G

3

T3.15A/250VAC

FUSE

TRANS.

NOTE:

FAN MOTOR

FAN

MOTOR

CRANKCASE

HEATER

2

4

6

8

B

CN4

CN9

CN7

CN5

W

R

B

BL

BL

BL

B

Y/G

COMPRESSOR

4-WAY

VALV E

SOLENOID

R

R

S

T

W

GR

M

NO

7

COM

5

3

NC

1

FAN

MOTOR

CAP

FAN

MOTOR

CAP

2

5

CT

1

3

6

4

Y/G

Y/G

1. DASHED PART 1 IS NOT AVAILABLE IN COOLING CAPACITY BELOW 36000Btu

2. DASHED PARTS 2 3 ARE NOT AVAILABLE IN ONLY COOLING TYPE

6.

FOR COOLING CAPACITY IS 52000BTU TYPE

,THE LINE THROUGH CT IS ONE CIRCUIT,

FOR COOLING CAPACITY IS 42000BTU 36000BTU AND 28000BTU TYPES

,THE LINE THROUGH CT IS TWO CIRCUITS.

3. DASHED PART 4 IS OPTIONAL FOR LOW AMBIENT TEMP. COOLING,

AND THERE IS NO FAN MOTOR SPEED CONTRLLER IN NORMAL TYPE

4. DASHED PARTS 5 6 ARE NOT AVAILABLE IN SOME TYPE

5. FOR COOLING CAPACITY IS 52000BTU AND 28000BTU TYPES,THE DIP SWITCH SW1 IS ON 5P SIDE,FOR COOLING CAPACITY IS 42000BTU AND 36000BTU TYPES,THE DIP SWITCH SW1 IS ON 10P SIDE.

FAN MOTOR

SPEED

CONTROLLER

MAGNETIC CONTACTOR

35

Page 36

Commercial Air Conditioner

0010452441 for the outdoor unit

CN8

CN10

CN9

CT1

CN7

CN1

CN5

L1

N

CN4

L2

L3

SW1

CN3

CN12

CN11

S

LED

As for indoor unit, the PCB code is 0010400132.

36

Page 37

Commercial Air Conditioner

For HDU-42CA03T3/H,HDU-50CA03T3/H,HDU-60CA03T3/H

0150500674

CN19 CN11

FUSE

T6.3A/250VAC

CN1

CN2

WWB

BRR

1

BL W

W

R

B

B

B

B

M

BL

BL

BL

W

RELAY

2 3

Y/G

Y/G

CN9

Y/G

CN3

CN8

BM

1234

HEATER

ONE CUT-OFF PROTECTOR

CN20 CN21

L

N

CN14 CN15 CN24

FLOAT

WIRED

CONTROLLER

PIPING TEMP.

SENSOR

SWITCH

DIP-SWITCH

DETECTOR

TO OUTDOOR UNIT

FAN MOTOR

CAP.

W:

WHITE B:BLACK

R:

RED

BL:BLUE

Y/G:YELLOW/GREEN

TRANS.:TRANSFORMER

TRANS.

RESUMBLE PROTECTOR

CIRCUIT DIAGRAM OF INDOOR UNIT

NOTE:

1、THE DETECTOR IS OPTIONAL,WHICH IS USED TO REALIZE REMOTE CONTROL FUNCTION.

2、

DASHED PARTS ARE SELECTED ACCORDING TO THE DIFFERENT MODELS.

3、THE DIP-SWITCH HAS BEEN SETTED WHEN OUT OF FACTORY,PLEASE DO NOT CHANGE.

4、 CN11 IS SHORT CONNECTED IF THE UNIT IS WITHOUT FLOAT SWITCH.

NOTE:

THIS UNIT CAN REALIZE THE

SELECTION OF HIGH/MIDDLE/LOW

ESP BY CONNECT THE BLUE/RED/WHITE INDOOR MOTOR

PORT IN THE DASHED FRAME.

CIRCUIT DIAGRAM OF OUTDOOR UNIT

0150503553

TO INDOOR UNIT

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

COMPRESSOR VENT SENSOR

OUTDOOR AMBIENT SENSOR

CN2

CN10

CN1

CN3

CN11

POWER SUPPLY

W

R

BL

B

R

S

T

R

N

S

L2

L1

L3

N

1

2

Y/G

Y/G

3

T3.15A/250VAC

FUSE

TRANSFORMER

FAN

MOTOR

FAN MOTOR

COMPRESSOR

MAGNETIC CONTACTOR

CAP.

CAP.

NOTES:

THE MARK R-S-T IS EQUAL TO U-V-W,T1-T2-T3 。

CN4

CN7

BLBL

Y/G

RR

R

S

T

WW

M

CT

B:BLACKBL:BLUE

Y/G:YELLOW/GREEN

R:RED W:WHITE

CN14

CN13

Y/G

Y/G

37

Page 38

Commercial Air Conditioner

0010451429 for the outdoor unit

As for indoor unit, the PCB code is 0010452032.

N L1 L2 L3 S

CN11

CN3

CN10 CN2 CN1

CN8

LED

CN9

CN7

CN4

38

Page 39

Commercial Air Conditioner

9.2 Sensor characteristic

10. Troubleshooting

As for the failure code, please refer to the page 26 and page 30

1) Sensor failure

no

no

no

yes

yes