Page 1

User Manual and Installation Instructions

Gas & Electric Dryer

Sécheuses à chargement frontal à gaz et

électrique

Manual para el usuario e instrucciones

de instalación. Secadora a gas y eléctrica

Model, Modéle, Modelo

HDE5000AW, HDG5000AW ; HDE5300AW, HDG5300AW

CHDE5000AW; CHDE5300AW

Quality n Innovation n Style

(Picture for illustration purposes only. Actual model may vary per model purchased.)

Front Load Dryers

Page 2

1

English

PAGE

IMPORTANT SAFETY INSTRUCTIONS .......................................2-4

INSTALLATION INSTRUCTIONS ..............................................5-19

Tools and Materials Required ............................................................ 5

Electrical Requirements ..................................................................5-6

Unpacking Your Dryer ..................................................................... 6

Exhaust System Requirements ........................................................7-8

Gas Supply Requirements ................................................................ 9

Location of Your Dryer ................................................................... 10

Location of Your Dryer in a Closet.................................................... 11

Manufactured (Mobile) Home Instruction .........................................12

Changing the Drum Light ................................................................ 13

Electrical Installation ......................................................................14

3-Wire Cord Connections ..............................................................15

4-Wire Cord Connections ..............................................................16

Gas Connections ..........................................................................17

Replacement Parts .........................................................................19

OPERATING INSTRUCTIONS ............................................... 20-33

Understanding the Control Panel

(HDE/HDG5300AW, CHDE5300AW) . 20-22

Understanding the Control Panel

(HDE/HDG5000AW, CHDE5000AW) . 22-24

Preparations before Drying ............................................................. 25

Load clothes into Dryer ...................................................................26

Auto Dry Cycle

(HDE/HDG5300AW, CHDE5300AW) ......................... 27-28

Auto Dry Cycle

(HDE/HDG5000AW, CHDE5000AW) ...............................29

Manual Dry Cycle

(HDE/HDG5300AW, CHDE5300AW) ...........................30

Manual Dry Cycle

(HDE/HDG5000AW, CHDE5000AW) ...........................31

Rack Dry Cycle

(HDE/HDG5300AW, CHDE5300AW) ............................... 31

Rack Dry Cycle

(HDE/HDG5000AW, CHDE5000AW) ............................... 32

Other Features ............................................................................... 32

Normal Operating Sounds ..............................................................33

CARE AND CLEANING GUIDE

.......................................................33

TROUBLESHOOTING .................................................................. 34

LIMITED WARRANTY .................................................................35

TABLE OF CONTENTS

Page 3

2

English

IMPORTANT SAFETY INSTRUCTIONS

Before beginning installation, carefully read these instructions. This will simplify

the installation and ensure the dryer is installed correctly and safely.

NOTE: The electrical service to the dryer must conform with local codes and

ordinances and the latest edition of the National Electrical Code, ANSI/

NFPA 70 or in Canada, CSA C22.1 Canadien Electrical Code Part 1.

NOTE: The gas service to the dryer must conform with local codes and

ordinances and the latest edition of the National Fuel Gas Code, ANSI

Z223.1 or in Canada, CAN/CGA B149.1.

NOTE: The dryer is designed under ANSI Z21.5.1 or ANSI/UL 2158 - CAN/

CSA C22.2 No. 112-97 (latest editions) for HOME USE ONLY. This

dryer is not recommended for commercial application such as restaurants,

beauty salons, etc.

ADVERTENCIA

ADVERTISSMENT

For your safety the information in this manual must be

followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss

of life.

Combustible materials, gasoline, and other flammable vapors and

liquids must not be stored near the dryer.

WHAT TO DO IF YOU SMELL GAS

1. Do not try to light any appliance

2. Do not touch any electrical switch. Do not use any phone in

your building.

3. Clear the room, building, or area of all occupants.

4. Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

5. If you cannot reach your gas supplier, call the Fire Department.

Installations must be performed by a qualified or licensed

contractor, plumber, or gasfitter qualified or licensed by the state,

province, or region where this appliance is being installed.

Page 4

English

IMPORTANT SAFETY

INSTRUCTIONS

WARNING - To reduce the risk of fire, electric shock, or

injury to persons when using your appliance, follow the

basic precautions, including the following:

1. Read all of the instructions before using this appliance.

2. Don’t dry articles that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry clean solvents or other

flammable explosive sub stains as they give off vapors which could

ignite or explode.

3. Do not allow children to play on or in the appliance. Close

supervision of children is necessary when the appliance is used near

children.

4. Before the appliance is removed from service or discarded, remove the

door to the drying compartment.

5. Do not reach into the appliance if the drum is moving.

6. Do not install or store this appliance where it will be exposed to water

and/or to the weather.

7. Do not tamper with controls.

8. Do not repair or replace any part of the appliance or attempt any

servicing unless specifically recommended in the user-repair

instructions that you understand and have skills to carry out.

9. Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturers of the fabric softener or

product.

10. Do not use heat to dry articles or products to eliminate static unless

recommended by the manufacturers of the fabric softener or

product.

11. Clean lint screen before or after each load.

12. Keep area around the exhaust opening and adjacent surrounding

areas free from the accumulation of lint, dust and dirt.

13. Keep the dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air through the louvered panel

located on the rear of the dryer.

14. The interior of the appliance and the exhaust duct should be cleaned

periodically by qualified service personnel.

3

Page 5

English

4

Thank you for using our Haier

product. This easy-to-use manual

will guide you in getting the best

use of your dryer.

Remember to record the model and

serial number. They are on a label

in back of the dryer.

Model number

Serial number

Date of purchase

Staple your receipt to your manual.

You will need it to obtain warranty service.

15. Do not place items exposed to cooking oils in your dryer. Items

contaminated with cooking oil may contribute to a chemical reaction

than could cause a load to catch fire.

16. If material has been used with any flammable liquids or solids, it

should not used in the dryer until all traces of flammable liquids and its

fumes have been removed.

17. This dryer must be properly installed in accordance with the

installation instructions before it is used. See grounding instructions in

the installations sections.

18. Proper grounding must be ensured to reduce the risk of electric shock

and force. Check with a qualified electrician or service personnel if

you are in doubt as to whether the dryer is properly grounded.

19. Use the dryer only for its intended purpose: drying clothes.

20. Always disconnect dryer from electrical supply before attempting any

service. Disconnect power cord by grasping the plug, not the cord.

21. Replace worn power cord and/or loose plugs.

22. To reduce the risk of electric shock or fire, do not use extension cords

or adapters to connect dryer electrical power source.

SAVE THESE

INSTRUCTIONS

DANGER

Risk of child entrapment. Before you throw away your old dryer,

take off the door so that children may not get trapped inside.

Page 6

5

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

Risk of Fire:

1. Clothes dryer installation must be performed by a qualified installer.

2. Install the clothes dryer according to the manufacturer’s instructions and local

codes.

3. Do not install a clothes dryer with flexible plastic venting materials. If flexible

metal (foil type) duct is installed, it must be of a specific type identified by the

appliance manufacturer as suitable for use with clothes dryers. Flexible

venting materials are known to collapse, be easily crushed and trap lint. These

conditions will ostruct clothes dryer airflow and increase the risk of fire.

4. To reduce the risk of severe injury or death, follow all installation instructions.

Tools and materials required

• Phillips-Head and flathead screwdrivers

• Channel-lock adjustable pilers

• 1/2-inch open-end wrench

• Carpenter’s level

• Measuring tape (12ft. min.)

• Duct tape

• Pipe thread sealer (Gas)

• Rigid or flexible metal 4 inch (102cm) duct

• Vent hood

Safety Warning:

1. Before starting installation, make sure that the gas shut off valve is in the

off position.

2. All old gas connectors and gas piping should be discarded.

ELECTRICAL REQUIREMENTS (Electric Dryers)

Model Numbers:

(CHDE/HDE5000AW and CHDE/HDE5300AW)

C ircuit

Individual 30 Amp branch circuit fused with 30 Amp time-delay fuses or circuit

breakers.

INSTALLATION INSTRUCTIONS

English

WARNING

Page 7

English

6

P ower Supply

3 or 4 wire, 120/240 Volt, 1 Phase, 60Hz, AC

P ower Supply Cord Kit

(Not supplied when sold in US. Must be purchased to meet local electrical

codes.) The dryer MUST employ a 3-conductor power supply cord NEMA 10-30

Type SRDT rated at 240 Volt AC minimum, 30 Amp, with 3 open end spade lug

connectors with upturned ends or closed loop connectors and marked for use

with clothes dryers.

(When sold in Canada - 4-wire power supply cord provided and

attached on dryer)

Dryers being installed in a manufactured (mobile) home MUST employ a

4-wire power supply cord NEMA 14-30 type SRDT or ST (as required) rated

to 240 Volt AC minimum, 30 Amp, with 4 open-end spade lug connectors

with upturned ends or closed loop connectors and marked for use with clothes

dryers. See Electrical Connections for more information on a 4-wire system.

O utlet Receptacle

NEMA 10-30R receptacle should be located so the power supply cord is

accessible when the dryer is in the installed position. (Canada - NEMA 14-30R

receptacle)

ELECTRICAL REQUIREMENTS (Gas Dryers)

Model Numbers:

(HDG5000AW and HDG5300AW)

C ircuit

Individual 15 Amp branch circuit fused with 15-Amp maximum time delay fuse

or circuit breakers.

P ower Supply

3 wire, 120 Volt, 1 Phase, 60Hz, AC

P ower Supply Cord

The dryer is equipped with a 120 Volt 3-wire power supply cord.

NOTE: This dryer is equipped with a three-prong grounding plug for your

protection against shock hazard and should be plugged into a properly

grounded three-prong receptacle. Do not under any circumstance cut or

remove grounding prong from plug.

Unpacking Your Dryer

1. Remove all packaging material. This includes the foam base and all adhesive

tape holding the dryer accessories inside and outside.

2. Inspect and remove any remains of packaging, tape or printed materials

before using the dryer.

Page 8

The following are specific requirements for

proper and safe operation of your dryer. Failure

to follow these instructions can create excessive

drying times and fire hazards.

1. Do not use plastic flexible duct to exhaust the dryer. Excessive lint can build up

inside exhaust system and create a fire hazard and restrict air flow. Restricted

air flow will increase drying time. If your present system is made up of plastic

duct or metal foil duct, replace it with a rigid or flexible metal duct. Ensure

present duct is free of any lint prior to installing dryer duct.

2. The dryer must not be exhausted into any gas vent, chimney, wall, ceiling or

any concealed space of a building. The dryer exhaust system MUST be

exhausted to the outdoors. If the dryer is not exhausted outdoors, some

fine lint will be expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

3. Exceeding the length of duct pipe or number of elbows allowed in the

“Maximum Length” chart can cause an accumulation of lint in the exhaust

system. Plugging the system could create a fire hazard, as well as increase

drying times.

4. Do not screen the exhaust ends of the vent system. Lint can become caught in

the screen, increasing drying time. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with duct tape.

5. All male duct pipe fittings must be installed downstream with the flow of air.

6. Exhaust duct must not be connected or secured with screws or other fastening

devices which extend into the interior of the duct.

7. Do not allow combustible material (clothing, draperies/curtains, paper, etc.) to

come in contact with exhaust system.

Explosion hazard:

Do not install the dryer where gasoline or other flammables are kept or

stored. Failure to do so can result in death, explosion, fire or burns.

Exhaust Requirements:

Use only rigid of flexible metal duct and approved vent hood which has a swingout damper hat open when the dryer is in operation. When the dryer stops, the

dampers automatically close to prevent drafts and the entrance of insects and

rodents. To avoid restricting the outlet, maintain a minimum of 12 inches (30.5cm)

clearance between the vent hood and the ground or any other obstruction.

The vent flap should be able to move freely, although vertical orientation of the

exhaust system is acceptable. Certain extenuating circumstances could affect the

performance of the dryer:

WARNING

EXHAUST SYSTEM REQUIREMENTS

English

7

Page 9

1. Only rigid metal duct work should be used.

2. Venting vertically through a roof may expose the exhaust system to down

drafts causing an increase in vent restriction.

3. Running the exhaust system through an uninsulated area may cause

condensation and faster accumulation of lint.

4. Compression of crimping of the exhaust system will cause an increase in

vent restriction.

5. In Canada, that only those foil-type flexible ducts, if any, specifically identified

for use with the appliance by the manufacturer shall be used. In the United

States, that only those foil-type flexible ducts, if any, specifically identified

for use with the appliance by the manufacturer and that comply with the UL

Outline for clothes Dryer Transition Duct, Subject 2158A (2006), shall be

used.

6. In Canada, that the exhaust duct shall be 102 mm in diameter. In the United

States, the required exhaust duct diameter.

The exhaust system should be inspected and cleaned a minimum of every 12

months with normal usage. The more the dryer is used the more often you should

check the exhaust system and vent hood for proper operation.

Side and Bottom Exhaust

For your convenience, your dryer can be exhausted through the side or the

bottom. If you need to change the exhaust on the dryer to the side or the

bottom of the cabinet, you will need to order the exhaust kit from your Haier

dealer or call 1- 800-313-8495

English

8

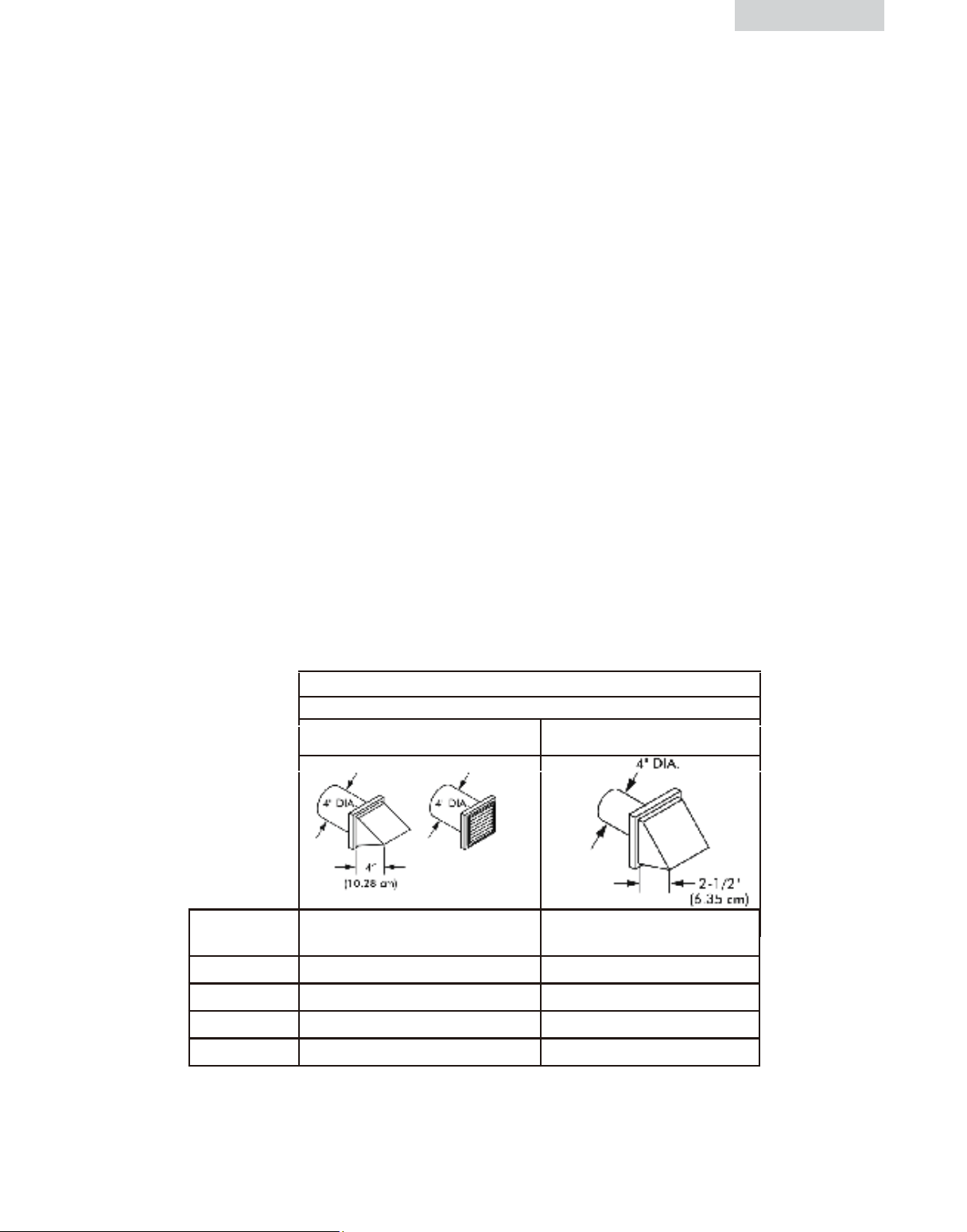

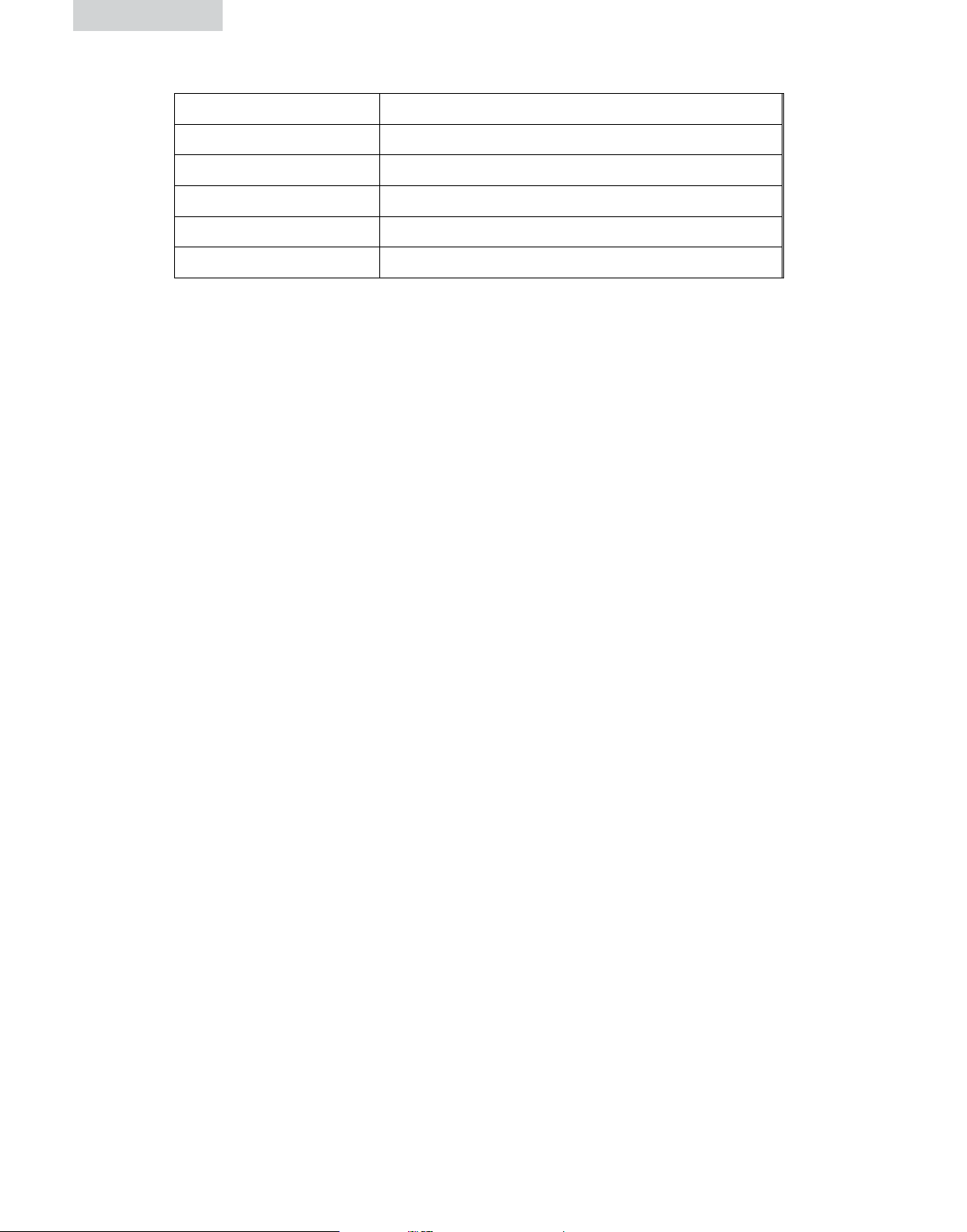

RECOMMENDED MAXIMUM

Exhaust Hood Types

Recommended

Use only for short

run installations

No. of 90º

elbows

Rigid Metal Rigid Metal

0 90 ft. 60 ft.

1 60 ft. 45 ft.

2 45 ft. 35 ft.

3 35 ft. 25 ft.

The total length of flexible metal duct shall not exceed

94 inches.

Page 10

GAS SUPPLY REQUIREMENTS

English

9

ADVERTENCIA

ADVERTISSMENT

Replace copper connecting pipe that is not plastic

coated. Stainless steel or plastic-coated brass

MUST be used.

1. Installation MUST conform with local codes. In the absence of local codes,

installation must conform with the National Fuel Gas Code, ANSI Z223.1

(latest edition) or in Canada, the current CAN/CGA B149.1

2. The gas supply line should be 1/2 inch (1.27cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your dryer to the

gas supply line. The tubing MUST be constructed of stainless steel or plasticcoated brass.

4. The gas supply line MUST have an individual manual shutoff valve installed

within 6 feet (183cm) of the dryer in accordance with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

In Canada, an individual manual shut-off valve MUST be installed in

accordance with the B149.1, Natural Gas and Propane Installation Code.

5. A 1/8 inch (0.32cm) N.P.T. plugged tapping, accessible for test gauge

connection, MUST be installed immediately upstream of the gas supply

connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping system during

any pressure testing of the gas supply piping system at test pressures in excess

of 1/2 psig (3.45kPa).

7. The dryer MUST be isolated from the gas supply piping system during any

pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

Page 11

English

10

Do Not Install Your Dryer:

1. In an area exposed to dripping water or outside weather conditions.

2. In an area where it will come in contact with curtains, thick carpet, or

anything that will obstruct the flow of combustion and ventilation air.

3. On carpet, floor must be solid with a maximum slope of 1inch (2.54 cm). Any

floor unevenness should be corrected with leveling legs located on the bottom

of the dryer.

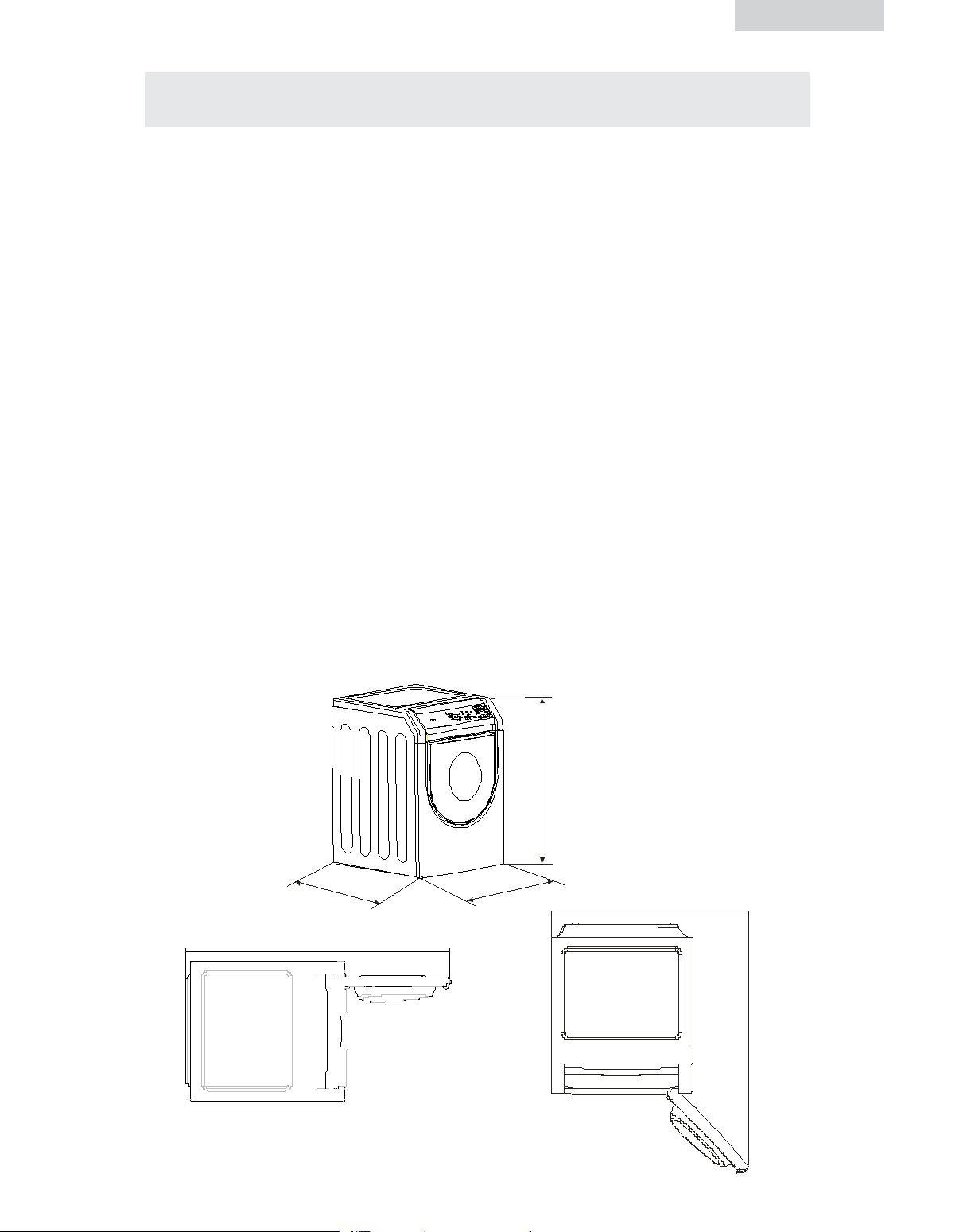

Installation in Alcove or Closet:

1. DO NOT install your dryer in a closet with a solid door.

2. A dryer installed in a bedroom, bathroom, alcove or closet MUST be

exhausted outdoors.

3. No other fuel burning appliance shall be installed in the same closet as the

gas dryer.

4. Refer to the images on this page to ensure the installation provides the

minimum amount of clearance required for ventilation.

5. When installing the dryer in a closet with a door, a minimum of 120 square

inches (774.2 square cm) of ventilation in the door is required. Openings must

be equally divided at the top and bottom of the door and airflow must be

unobstructed. A louvered door with equivalent air openings for the length of

the door is acceptable.

LOCATION OF YOUR DRYER

8

2

5

m

m

6

8

6

m

m

1010mm

1295mm(51”)

960mm( 37-13/16“)

39-3/4”

2

7

”

3

2

-

1

/

2

”

Page 12

English

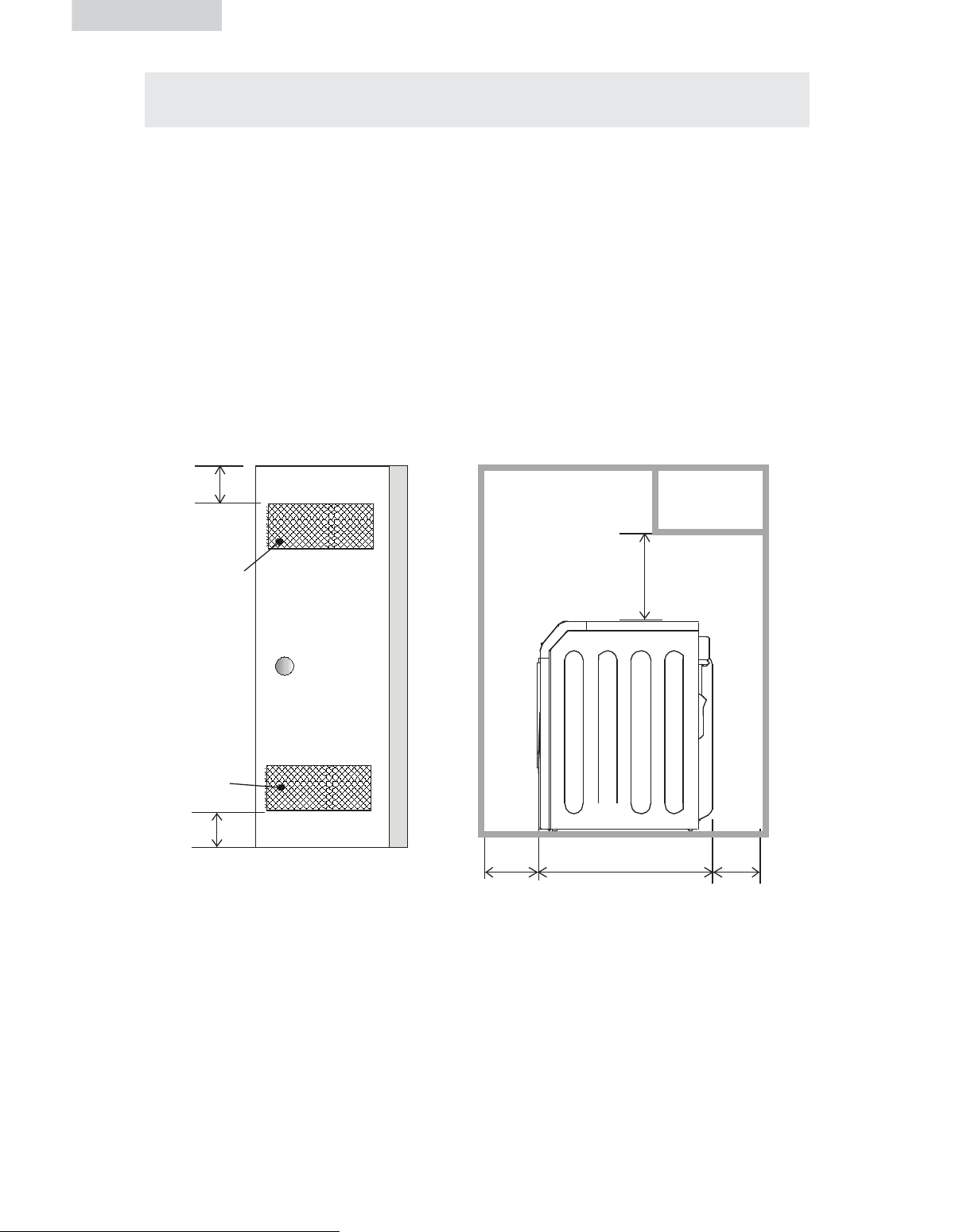

Following are instructions concerning and the minimum clearances required for

any closet, recessed area, or customized under-counter installation:

• Additional distances facilitate installation and servicing.

• Addtional clearances might be required for wall, door and floor moldings.

• Additional distances of 1 in. (25.4mm) on all sides of the dryer is

recommended to reduce noise transfer.

• For closet installation with a door, minimum ventilation openings in the top

and bottom of the door are required. Louvered doors with equivalent ventilation

openings are acceptable. Companion appliance spacing should be

considered.

LOCATION OF YOUR DRYER IN A CLOSET OR RECESSED AREA

11

32. 5"

1 5 "

1

"

3

"

( 5. 4mm)

2

( mm)(8 25mm)

( 38.1 mm)

3"

(76 mm)

3"

(76 mm)

60"

2

( )

387 .1cm

2

60"

2

( )

387 .1cm

2

7

6

Page 13

English

12

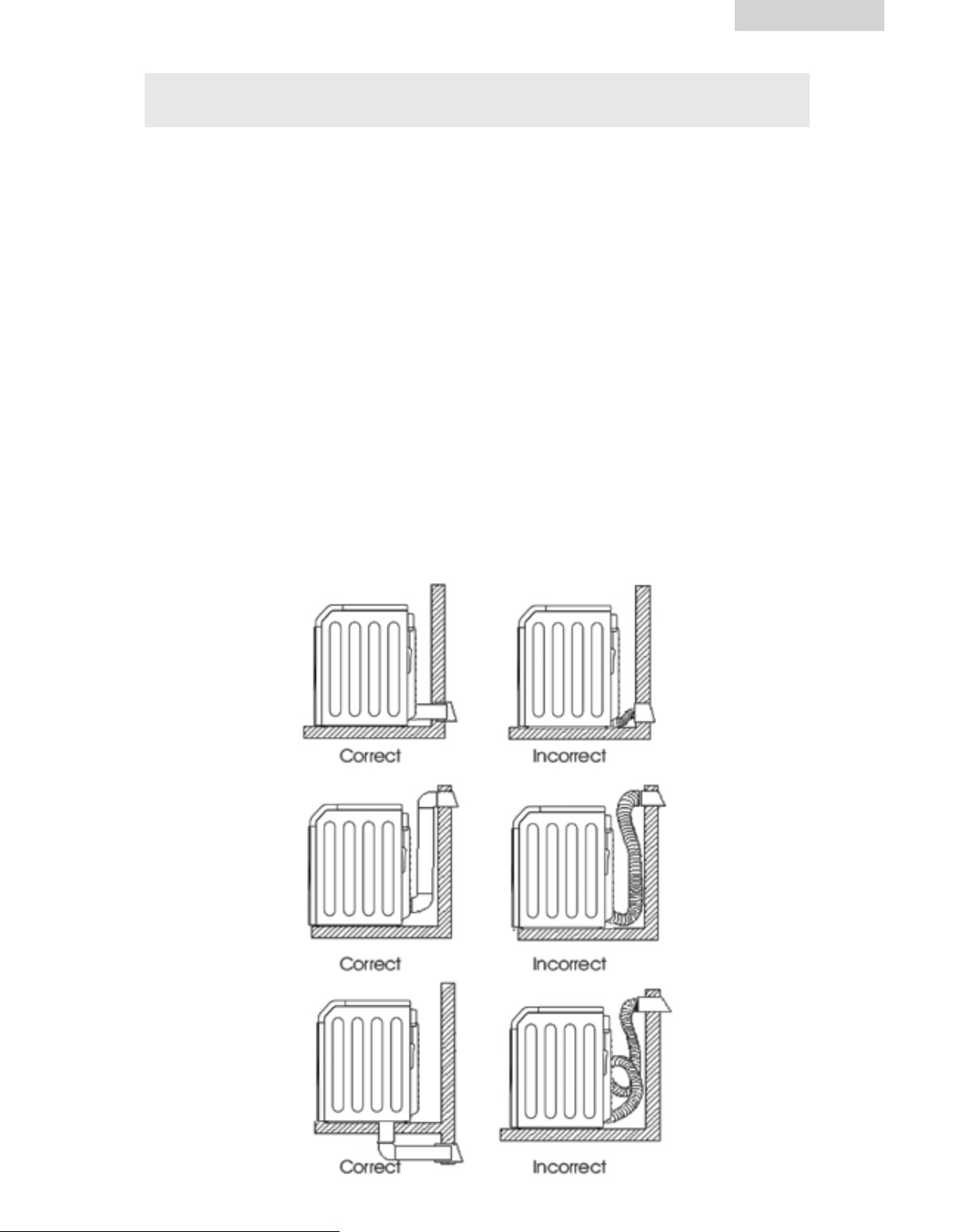

1. Dryer MUST be exhausted outside (outdoors, not beneath the manufactured

home) using metal ducting that will not support combustion. Metal ducting must

be 4 inch (10.16 cm) in diameter with no obstructions. Rigid metal duct

is preferred.

2. If dryer is exhausted through the floor and area beneath the manufactured

home is enclosed, the exhaust system MUST terminate outside the enclosure

with the termination securely fastened to the mobile home structure.

3. When installing a gas dryer into a manufactured home, a provision must be

made for outside make up air. This provision is to be not less than twice the

area of the dryer exhaust outlet.

4. This dryer MUST be fastened to the floor using P/N 0030807988

Manufactured Home Installation Kit. Follow the instructions supplied with

the kit.

5. Refer to previous sections for other important venting requirements.

6. Installation must conform to current Manufactured Home Construction & Safety

Standard (which is a Federal Regulation Title 24 CFR-Part 32-80) or when

such standard is not applicable, with American National Standard for Mobile

Homes. In Canada, the CSA Z240 is applicable.

MANUFACTURED (MOBILE) HOME INSTALLATION

DO DON’T

DON’T

DON’T

DO

DO

Page 14

English

1. For your safety, please unplug the power cord before changing the drum light.

2. Open the dryer door, find the location of the drum light. Using a phillip head

screw driver remove the light cover (as shown below).

3. Remove the bulb by turning it counterclockwise. Replace the bulb with a

15-watt lamp only, then install the cover and tighten the screw.

4. Use your dryer after plugging it in the electrical socket.

CHANGING THE DRUM LIGHT

Screw

13

Page 15

English

The following are specific requirements for

proper and safe electrical installation of your

dryer. Failure to follow these instructions can

create electrical shock and/or fire hazard.

WARNING

1. This appliance must be properly grounded. Electrical shock can result if the

dryer is not properly grounded. Follow the instructions in this manual for

proper grounding.

2. Do not use an extension cord with this dryer. Some extension cords are not

designed to withstand the amounts of electrical current this dryer utilizes and

can melt, creating electric shock and/or fire hazard. Locate the dryer within

reach of the receptacle for the length power cord to be purchased, allowing

some slack in the cord. Refer to the electrical requirements in this manual for

the proper power cord to be purchased.

3. A UL approved strain relief must be installed onto power cord. If the strain

relief is not attached, the cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical shock.

4. Do not use an aluminum wire receptacle with copper-wired power cord and

plug (or vice versa ). A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The proper wiring and receptacle

is a copper-wired power cord with a copper-wired receptacle.

NOTE: Dryers operating on 208 Volt power supply sill have longer drying times

than operation on 240 Volt power supply.

ADVERTENCIA

ADVERTISSMENT

Improper connection of the equipment grounding conductor can

result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is

properly grounded.

1. Gas dryers are equipped with a factory installed three-prong 15 Amps ~120

Volts (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

ELECTRICAL INSTALLATION

ELECTRIC Dryer (CHDE/HDE5000AW and CHDE/HDE5300AW)

GAS Dryer (HDG5000AW and HDG5300AW)

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown,

grounding will reduce th risk of electric shock by providing a path of least

resistance for electric current. This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances. This appliance must be connected to a

grounded metal, permanent wiring system, or an equipment-grounding conductor

must be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance.

14

Page 16

English

3-Wire System (US models only)

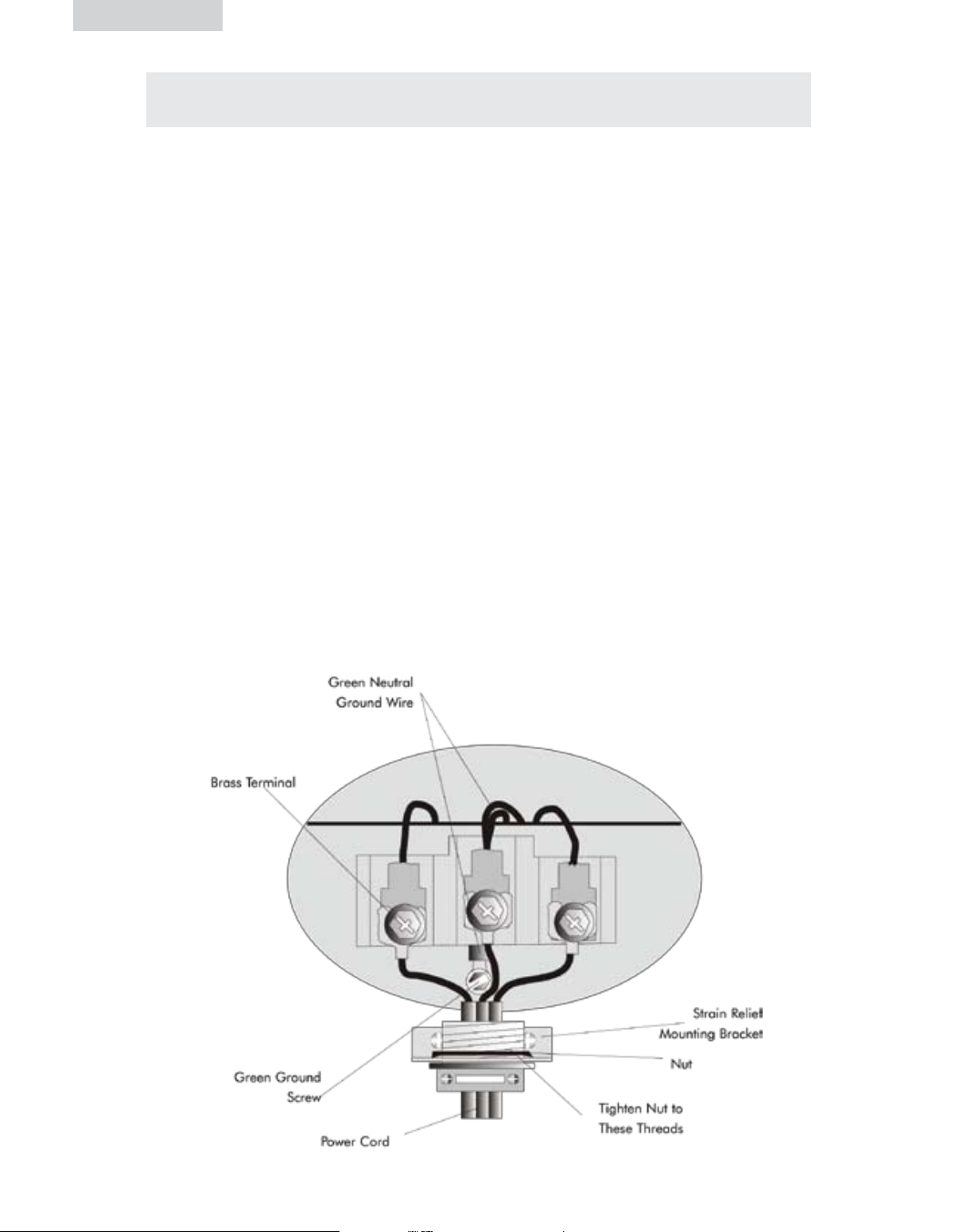

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer’s upper corner.

2.

Install a U.L. approved strain relief into the power cord entry hole of the

mounting bracket. Finger tighten the nut only at this time.

3. Thread a U.L. Approved 30 Amp. Power cord, NEMA 10-30 Type SRDT,

through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the brass colored

center terminal on the terminal block. Tighten the screw securely.

5. Attach the remaining two power cord outer conductors to the outer brass

colored terminals on the terminal block. Tighten both screws securely.

WARNING: Do not make a sharp bend or crimp wiring/conductor at

connections.

6. Reattach the strain relief mounting bracket to the back of the dryer with two

screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against the power cord.

8. Tighten the strain relief nut securely so that the strain relief does not turn.

9. Reinstall the terminal block cover.

ELECTRICAL CONNECTIONS

ELECTRIC Dryer (HDE5000AW and HDE5300AW)

15

Page 17

English

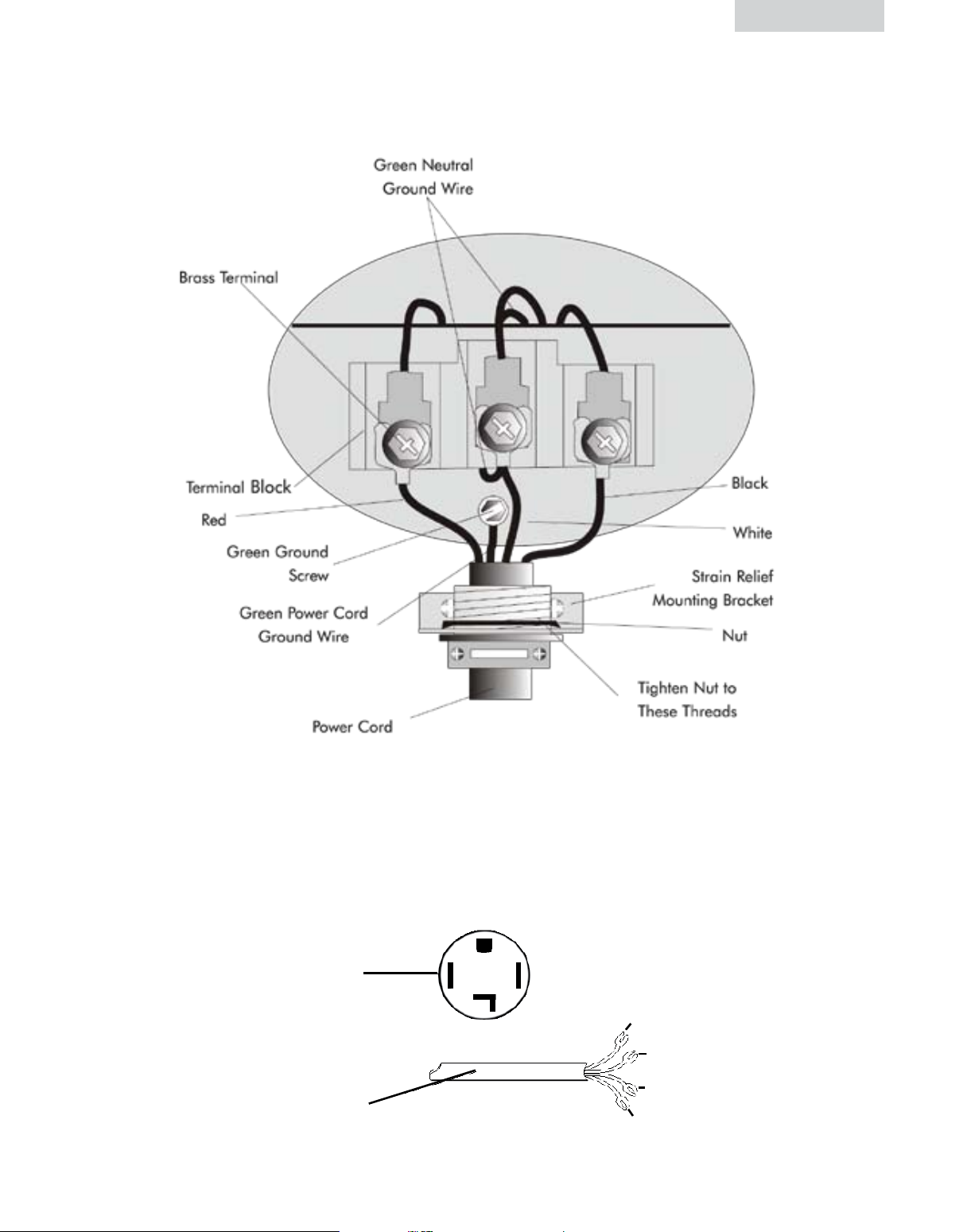

4-Wire Cord Connections (US Models Only)

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer upper corner.

2. Install a UL approved strain relief into the power cord entry hole of the

mounting bracket . Finger tighten the nut only at this time.

3. Remove the green neutral ground wire from the green ground screw located

above the terminal block.

Black 240V

White Neutral

Red 240V

Green Ground

Typical Conductor

Receptacle

Typical 4

Conductor Cord

ELECTRIC Dryer (HDE5000AW and HDE5300AW)

16

Page 18

4. Thread a U.L. approved 30 Amp power cord. NEMA 14-30 type ST or SRDT

through the strain relief.

5. Attach the green power cord ground wire to the cabinet with green ground screw.

6. Attach the green wire conductors from the dryer and white (neutral) power cord

conductors to the brass-colored center terminal on the terminal block. Tighten the screw

securely.

7. Attach the red and black power cord conductors to the outer brass-colored terminals on

the terminal block.

Warning: Do not make a sharp bend or crimp the wiring /conductor at connections.

8. Tighten the screws securing the cord restraint firmly against the power cord.

9. Tighten the strain relief nut securely so that the strain relief does not turn.

10. Reinstall the terminal block cover.

NOTE: DO NOT connect the dryer to L.P. gas service without converting the

gas valve. An L.P. Conversion Kit must be installed by a qualified gas

technician.

1. Remove the shipping cap from gas pipe at the rear of the dryer.

2. Connect a 1/2 inch (1.27cm) I.D. semi-rigid or approved pipe from gas supply line to

the 3/8 inch (0.96cm) pipe located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27cm to 0.96cm) reducer for a connection. Apply an approved thread sealer

that is resistant to the corrosive action of liquified gases on all pipe connections.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on a soapy water solution. NEVER TEST FOR GAS

LEAKS WITH AN OPEN FLAME.

5. Connect the exhaust duct to the outside exhaust system. Use duct tape to seal all joints.

6. With the dryer in its final position, adjust one or more of the legs until the dryer is

resting solid on all four legs. Place a level on top of the dryer. THE DRYER MUST BE

LEVEL AND RESTING SOLID ON ALL FOUR LEGS.

7. Plug the power cord into a grounded outlet. NOTE: check to ensure power is OFF at

circuit breaker/fuse box before plugging the power cord into the outlet.

8. Turn on the power at the circuit breaker/fuse box.

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

Before operating the dryer, make sure the dryer area is clean and

free from combustible materials, gasoline, and other flammable

vapors. Also see that nothing (such as boxes, clothing, etc.) obstructs

the flow of combustion and ventilation air through the louvered

panel located on the rear of the dryer.

9. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary for the gas line to be

bled of air. If the burner does not light within 45 seconds the first time the dryer is

turned on, the safety switch will shut the burner off. If this happens, turn the dryer to

“OFF” and wait 5 minutes before making another attempt to light.

NOTE: Follow instructons supplied with kit.

GAS CONNECTIONS

GAS Dryer (HDG5000AW and HDG5300AW)

English

17

Page 19

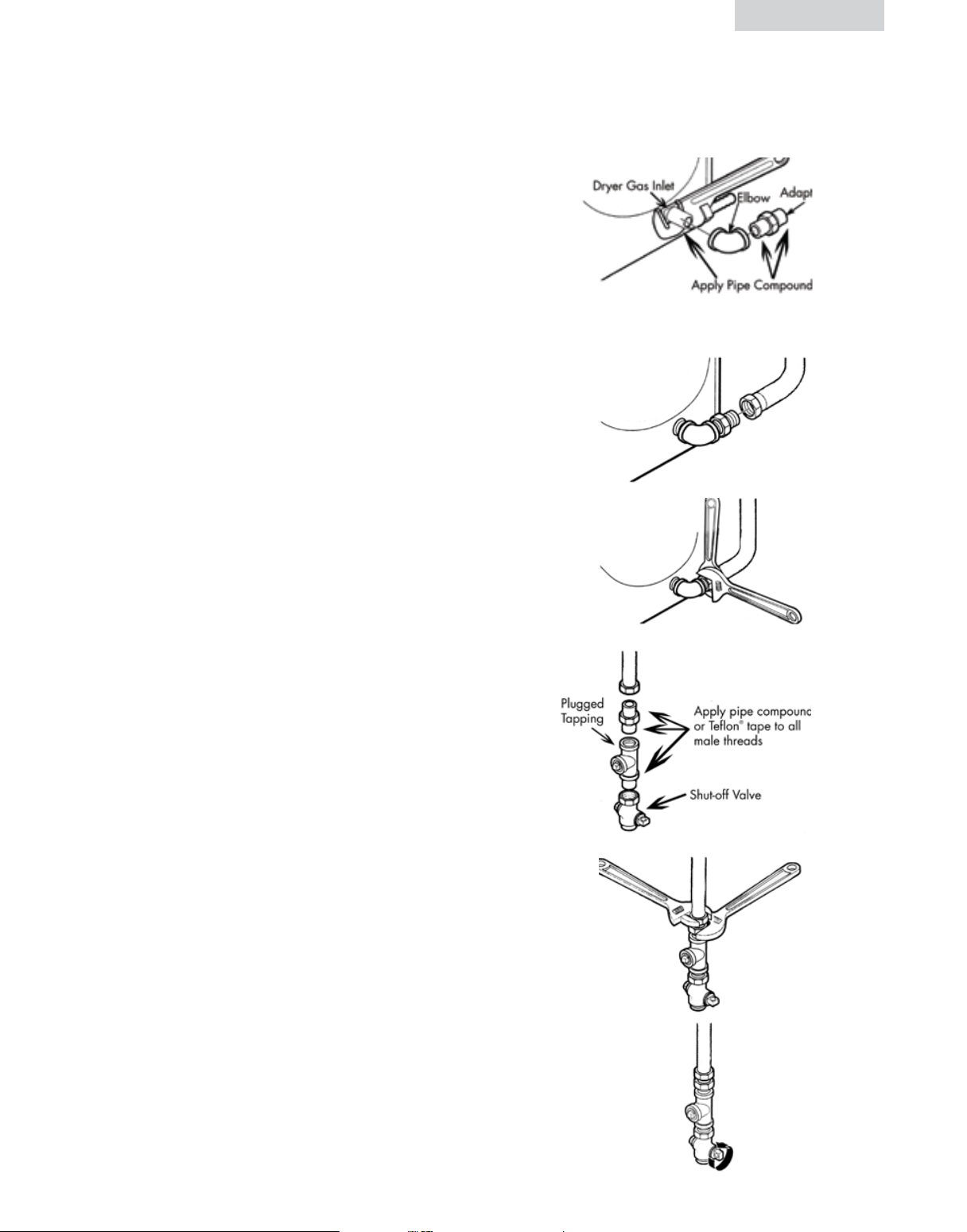

A) Connect female 3/8” NPT elbow to gas

inlet on dryer. Then connect 3/8” flare

union adapter to female elbow.

IMPORTANT: To prevent the inlet from

twisting, please use a pipe

wrench to secure the dryer

gas inlet. Affix Teflon®

tape or pipe compound to

adapter and gas inlet.

B) Attach the flexible metal gas line connector

to the adapter.

C) Make sure flexible gas line seal is secure.

Use two wrenches for the best possible

connection.

D) To check gas inlet pressure, attach 1/8”

NPT plugged tapping to dryer gas line shutoff valve. Then connect flare union adapter

to plugged tapping. Affix Teflon® tape to

the threads of the adapter and plugged

tapping to ensure seal.

E) Use two adjustable wrenches to tighten

every connection.

IMPORTANT: Do not overtighten!

F) Open gas shut-off valve.

CONNECTING THE DRYER TO THE GAS SUPPLY

English

18

Page 20

REPLACEMENT PARTS

Replacement parts and accessories for US and Canada can be purchased

through Haier America at 1-800-313-8495

WARNING

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Check unit for proper operation after servicing.

ADVERTENCIA

ADVERTISSMENT

Discard or destroy the carton and plastic bags after the

dryer is unpacked. Children should not be allowed to use

them to play with. Cartons covered in rugs, bedspreads or

plastic sheets can become an airtight chamber and cause

suffocation leading to death. Make all packing materials

inaccessible to children.

ADVERTENCIA

ADVERTISSMENT

The instructions in this manual and all other literature

included with this dryer can not cover every possible

condition and situation that may occur. Good safe practice

and caution must be applied when installing, operating,

and maintaining any appliance. If you are in doubt after

installing, call a certified electrician to install and wire the

dryer.

19

English

Page 21

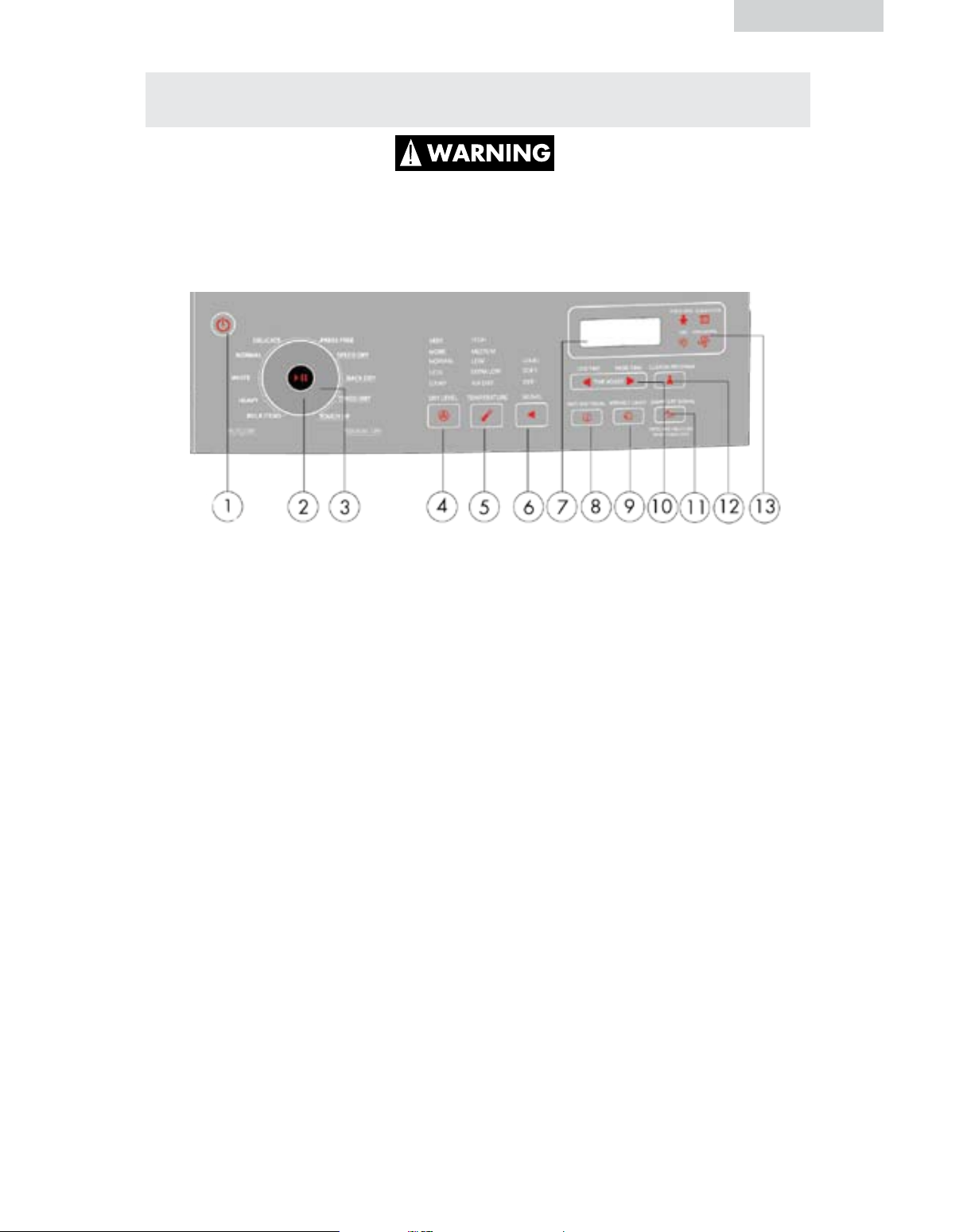

Understanding the Control Panel

HDE/HDG5300AW, CHDE5300AW

TOUCH SENSITIVE CONTROL PANEL

Power On/Off Pad: (1)

• Touch the pad to power dryer on. To power off, touch the pad for 2

seconds.

Start/Pause Pad: (2)

• Touch the pad to turn the dryer ON. Touch this pad for 2 second to start the

dry process. Touch this pad for 2 seocnd again to pause the activity during the

dry cycle.

Dry Cycles: (3)

Manual Dry Cycles:

• The “Manual Dry Cycles” pad will let you select an amount of drying time and

a drying temperature as required by you. In this selection the remaining time

on display shows the actual time remaining in the cycle. The actual time can be

changed in the Manual Drying cycles by touching “More Time” or “Less Time”

pads. Time for Auto Dry cycles can not change.

- Speed Dry: Use for small loads that need a short drying time.

- Rack Dry: Used for items that should not tumble E.g. Sweaters, silk, lingerie

or sneakers.

- Timed Dry: Use this cycle to dry heavy weight items like comforters, etc.

- Touch Up: This cycle removes wrinkles from items such as clothes packed in

a suitcase or wrinkles in items from being left in the dryer too long.

Auto-Dry (Sensor Dry) Cycles:

• “Auto-Dry (Sensor Dry) cycles” pad will let you select your desired dry cycles.

For your convenience, there are 6 fabric care dry cycles programmed in this

mode: Bulk Items, Heavy, White, Normal, Delicate, Press Free. A sensor detects

the moisture in the load and automatically adjust the drying time for optimum

drying.

OPERATING INSTRUCTIONS

20

ADVERTENCIA

ADVERTISSMENT

To reduce the risk of fire, electric shock, or injury to persons, read

all of the IMPORTANT SAFETY INSTRUCTIONS before using this

appliance.

English

Page 22

English

Dry Level Pad: (4)

• Used to set drying level of auto-programs. If manual dry is selected, touching

the pad will cause two beeps to sound. There are 5 selections: Very, More,

Normal, Less, Damp. First select sensor dry cycle then adjust the dry level to

how much you want to dry the load.

Note: Dry level selection can only be made while using the Auto (Sensor) Dry

Cycles.

Temperature Pad: (5)

• Used to set drying temperature. There are 5 available drying temperatures:

High, Medium, Low, Extra Low and Air Dry (No heat).

NOTE: In rack dry cycle the temperature selection is limited to Extra Low and

Air Dry. For Auto Dry Cycles the temperature can be selected only for settings

below the default setting, Air Dry cannot be selected.

Signal Pad: (6)

• Selects beeping volume or turns off the buzzer. You can choose loud, soft, or

off. This controls the volume of beep when you touch any pads on the control

panel or when the dry cycle is completed.

Digital Display (7)

• Indicates the remaining time during cycle operation.

Note: If the dryer has any problems, it will display an error message.

Anti Bacterial (8)

• This function can be selected only in certain cycles. Here the heat temp is

raised to the highest dry level. This option can only be used with heavy, bulky

items, White and Normal cycle.

Note: Cannot use on Delicates, Press Free or Manual Dry Cycles.

Wrinkle Saver Pad: (9)

• This convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop and then rotate for

a brief period every few minutes. Press the wrinkle saver pad to activate. This

feature will work for 1 hour after the drying program is completed. Stop the

setting at any time by pressing the wrinkle pad or by opening the dryer door.

More Time & Less Time Pad: (10)

• Used to set time from 0 to 2 hours when Timed Dry, Rack Dry, Speed Dry or

Touch Up cycles selected.

Damp Dry Signal (11)

• If activated the dryer will beep when the load is approximately 80% dry. This

will allow you to remove lightweight items that are dry or other items that you

Bulk Items Drying bulky clothing, such as bed sheets.

Heavy Heavy weight material such as jeans or bath towels.

White For clothes such as linens and sheets.

Normal Use to select normal clothes worn in daily use.

Delicate Drying small quantity clothes and delicate fabric.

Press Free For wrinkle-free, permanent press, and knits.

21

Page 23

English

Custom Program: (12)

• This allows you to save a favorite cycle,set the desired settings and touch

“Custom Program”pad for 3 seconds. A beep will sound to indicate the

cycle has been saved. To recall your custom cycle ,touch the “Custom

Program”pad before drying a load. To change the saved cycle,set the desired

settings and “Custom Program”pad must be again programmed for 3 seconds.

You can also program Anti-Bacterial, Wrinkle Saver and Damp Dry Signal.

Touch custom program and touch start/pause pad to activate.

Function Light Indicator: (13)

- Child Lock: You can lock the controls to prevent any selections from being

changed or You can lock the controls after you have started a

cycle. Children can not accidentally start the dryer by touching

pads when this option is selected.

To lock the dryer,touch and hold “Damp Dry Signal”for 3

seconds. A single beep tone is heard and Child Lock will glow.

To unlock the dryer, touch and hold the “Damp Dry Signal” for

3 seconds.

- Check Filter: After the power pad is touched, the Check Filter indicator

will flash until Start/Pause is selected.

This is just a reminder to clean the lint filter before the dry

program starts.

- Dry: When lit this indicates the process the cycle is currently in drying mode.

- Cool Down: When lit this indicates the process the cycle is currently in cool

down mode.

Understanding the Control Panel

HDE/HDG5000AW CHDE5000AW

NOTE: Features may vary per model.

Power On/Off Button: (1)

• Press the button to power on the dryer. To power off, press button again.

Cycle Select Dial: (2)

• Select from the Auto-Dry cycles (Bulky Items, Heavy, White, Normal, Delicate

and Press Free) or Manual Cycles (Touch Up, Time Dry, Rack Dry Cycle or

Speed Dry).

22

Panel

1

2

3

4

5

6

7

10

11

12

13

8

9

13

POWER

START/PAUSE

Page 24

English

Start/Pause Button: (3)

• Press the button to turn the dryer ON. Press this button once to start the dry

process. Press this button once again to pause the activity during the dry

cycle.

Dry Levels: (4)

• Used to set drying levels of auto programs. There are 3 selections: More,

Normal, and Less.

Note: Dry level selection can only be made while using the Auto (sensor) Dry

Cycles.

Temperature Button: (5)

• Used to set drying temperatures. There are four available drying temperatures

to choose from: High, Medium, Low, and Air Dry.

Note: In rack dry cycle the temperature selection is limited to Extra Low and

Air Dry. For Auto Dry Cycles the temperature can be selected only for settings

below the default setting, Air Dry cannot be selected.

Signal: (6)

• This feature selects the beeping volume or turns off the buzzer entirely. There

are three choices: Louder, Softer or Off.

Anti Bacterial (7)

• This function can be selected only in certain cycles. Here the heat temp is

raised to the highest dry level. This option can only be used with heavy, bulky

items, white and normal cycle.

Note: Cannot use on delicate fabrics

Wrinkle Saver Button: (8)

• This convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop and then tumble for

a brief period every few minutes. Press the wrinkle saver button to activate. This

feature will work for 1 hour after the drying program is completed. Stop the

setting at any time by pressing the wrinkle saver button or opening the dryer

door.

More Time & Less Time Button: (9)

• Used to set time from 0 to 2 hours when Timed Dry, Rack Dry, Speed Dry or

Touch Up cycle is selected.

Damp Dry Signal (10)

• If activated the dryer will beep when the load is approximately 80% dry. This

will allow you to remove lightweight items that are dry or other items that you

may wish to iron. This feature is available for “Auto Dry” cycles only.

Bulk Items Drying bulky clothing, such as bed sheets.

Heavy Heavy weight material such as jeans or bath towels.

White For clothes such as linens and sheets.

Normal Use to select normal clothes worn in daily use.

Delicate Drying small quantity clothes and delicate fabric.

Press Free For wrinkle-free, permanent press, and knits.

23

Page 25

English

Custom Program: (11)

• This allows you to save a favorite cycle,set the desired settings and press

“Custom Program”button for 3 seconds. A beep will sound to indicate the cycle

has been saved. To recall your custom cycle ,press the “Custom Program”button

before drying a load. To change the saved cycle,set the desired settings and

“Custom Program”button must be pressed again for 3 seconds. You can also

program Anti-Bacterial, Wrinkle Saver and Damp Dry Signal. Press custom

program and press start/pause button to activate.

Digital Display: (12)

• Indicates the remaining time during cycle operation.

Note: If the dryer has any problems, it will display an error message.

Fuction Light Indicator: (13)

- Child Lock: You can lock the controls to prevent any selections from being

changed.Or you can lock the controls after you have started a

cycle. Children cannot accidentally start the dryer by touching

pads when this option is selected.

To lock the dryer,press and hold “Damp Dry Signal”for 3

seconds. A single beep tone is heard and Child Lock will glow.

To unlock the dryer,press and hold the “Damp Dry Signal”for 3

seconds.

- Check Filter: After the power button is pressed, the Check Filter indicator will

flash until Start/Pause is selected.

This is just a reminder to clean the lint filter before the dry

program starts.

- Dry: When lit this indicates the process the cycle is currently in drying mode.

- Cool Down: When lit this indicates the process the cycle is currently in cool

down mode.

24

Page 26

• Sort clothes of the same kind (cotton, synthetics, woolen) to dry.

• Dark and light colored clothes should be separately dried. Fabrics prone to

losing lint and those prone to adhering lint should be separately dried. Clothes

prone to falling lint should be turned inside out before putting into the dryer.

• Make sure buttons and ornaments on the clothes are high temperature

resistant and won’t damage drum surface. Before loading, the clothes should

have their zippers zipped up, buttons and hooks done up and belts tied so as

to avoid entanglement or other obstacles.

• If possible, turn out the clothes pockets for uniform drying.

• Check if clothes remain soiled. If so, wash them again, otherwise soils may be

permanently set.

• Small articles should be collected in a mesh bag before loading and drying, so

as to avoid entanglement and ensure easy removal.

• Make sure the power socket is reliably grounded. The grounding terminal

should not be connected to gas or tap water pipelines.

• Make sure exhaust duct has been properly connected.

• Make sure lint filter is clean and properly installed. If lint filter is not in place,

tumbling items could enter the exhaust system and cause damage to the dryer.

NOTE: Applies to Auto Dry cycle and Timed Dry cycle.

• For Rack Dry cycle, remove the lint filter and assemble the drying rack with its

rear end slightly downward inclined. The configuration is as shown on page

26.

PREPARATIONS BEFORE DRYING

English

25

Page 27

English

26

• The appropriate load should be 1/3 ~ 1/2 of the drum volume. The drum

capaicity is 7.5 Cubic Foot. Avoid too much load, as space is needed to allow

clothes free rotation for uniform and wrinkle-proof drying.

• When drying big articles, only 2-3 pieces should be loaded at a time and

supplemented with small and medium-sized articles.

• For delicate clothes or less load, two towels may be added to get better

drying and wrinkle-proof effects.

• Do not excessively dry clothes to avoid wrinkles, shrinkage, roughness,

electro-static charge accumulation, and/or more lint.

Rack Dry cycle

• This program is designed specially for articles like sport shoes. During drying,

please make sure the articles are placed on the rack with no risk of

entangling the baffles while the drum is rotating.

NOTE: If drying rack is not in place, rolling inner tub could collide with drying

rack and causes damage to the dryer and drying rack.

Using the Dryer Rack

1. Open the dryer door.

2. Check that the drum is empty.

3. Remove the lint filter. (Fig 1)

LOAD CLOTHES INTO DRYER

4. Lift the dryer rack horizontally into the drum.(Fig.2)

5. Place the dryer rack so that the catches are inserted at the front and locked in

place.(Fig.3)

6. Insert the lint filter, must be inserted flush with the drum edge.(Fig.4)

Fig.1

Fig.2

Fig.3

Fig.4

Page 28

English

HDE/HDG5300AW, CHDE5300AW

1. Touch the Power On/Off pad

• The computer board will beep once and the dryer will change from off status

to the initial operating status (NORMAL program).

• If the “Start/Pause” pad is not touched in 5 min after powering on, it

automatically cuts off power and returns to off status.

• The dryer returns to off status immediately upon end of each cycle. Regardless,

the status of the control panel, touching OFF will stop all operations.

• The default status is “NORMAL” program.

AUTO DRY CYCLE

2. Touch “Auto-Dry Cycles” pad to select a suitable full automatic cycle.

• The NORMAL program will be automatically selected after powering on. If

another full automatic program is desired, touch “Auto-Dry Cycles” pad until

corresponding indicator turns on.

• To select your desired settings, the “Custom Program” function should be

chosen.

• The dryer can memorize programs defined by user and display the previous

program upon next application of this function.

3. Touch “Dry Level” pad to select a suitable drying level.

4. Touch “Temperature” pad to select a suitable temperature.

5. Touch “Signal” pad, and the buzzer will sound upon end of a cycle.

• The user may define three prompt sound conditions: “Louder”, “Softer” and

“Off”.

6. Touch the “Wrinkle Saver” pad to select a suitable reserved drying program.

• This convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop and then tumble

for a brief period every few minutes. Press the wrinkle saver pad to activate.

Stop the setting at any time by pressing the wrinkle saver pad or opening

the dryer door. This feature will work for 1 hour after the drying program is

complete.

27

Page 29

English

7. Touch “Anti Bacterial” pad.

• This function can be selected only in certain cycles. Here the heat temp is

raised to the highest dry level. This option can only be used with heavy,

bulky items, white and normal cycle.

NOTE: Can not use on delicate fabrics

8. Touch “Damp Dry Signal”

• If activated the dryer will beep when the load is approximately 80% dry.

This will allow you to remove lightweight or other items that you may wish

to iron.

9. Touch “Start/Pause” pad

• When starting the machine, first close the door and then touch this pad.

• If pause is needed during machine operating, touch this pad. Touching

again will resume operation.

28

• sihT convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop and then tumble

for a brief period every few minutes. Press the wrinkle saver button to

activate. Stop the setting at any time by pressing the wrinkle saver button or

opening the dryer door. This feature will work for 1 hour after the drying

Wrinkle

saver

Anti

bacterial

Signal

Damp

signal

Air Dry

*

*

*

*

*

*

Page 30

HDE/HDG 5000AW, CHDE5000AW

1. Press the power On/Off button to power on the dryer.

2. Set the cycle select dial to required auto dry cycle. The signal, temperature,

and dry levels are preprogrammed. To change this setting:

• Press the “Dry Level” button to select suitable drying level after powering on

the dryer. There are 3 options to choose from: More, Normal, or Less.

• Press the “Signal” button, and the buzzer will sound upon end of cycle.

• The user can choose from Louder, Softer, or OFF.

• Press the “Wrinkle Saver” button to select a suitable reserved drying

program.

• This convenient feature helps keep wrinkles from setting when you cannot

unload the dryer at the end of a cycle. The dryer will stop and then tumble

for a brief period every few minutes. Press the wrinkle saver button to

activate. Stop the setting at any time by pressing the wrinkle saver button

or opening the dryer door. This feature will work for 1 hour after the drying

program is complete.

• Press the “Anti Bacterial” button.

• This function can be selected only in certain cycles. Here the heat temp is

raised to the highest dry level. This option can only be used with heavy,

bulky items, white and normal cycle.

NOTE: Cannot use on delicate fabrics

• Press the “Damp Dry Signal” button.

• If activated the dryer will beep when the load is approximately 80% dry.

This will allow you to remove light weight or other items that you may wish

to iron.

• Press Start/Pause button.

• When starting the machine, close the door first, then press this button.

• If a pause is needed during drying, press this button. Pressing again will

resume operation.

AUTO DRY CYCLE

English

29

Wrinkle

saver

Anti

bacterial

Signal

Damp

signal

Air Dry

*

*

*

*

*

*

Page 31

HDE/HDG 5300AW, CHDE5300AW

1. Touch power On pad to power on.

2. Touch “Manual Dry Cycles” pad and select Timed Dry cycle, Speed Dry

or Touch Up cycles.

3. Touch “More Time” and “Less Time” pads to set a suitable time.

• After setting you can press either of these two pads to increase or

decrease drying time as you desire.

4-6. Touch pads “Temperature,” “Signal,” “Wrinkle Saver,” to define your desired

program.

NOTE: For “Manual” program, use of pads “Temperature,” “Signal,” “Wrinkle

Saver,” is the same as for auto-programs. “Anti-Bacterial”, “Damp Dry”

and “Dry Level” are inactive, and 2 beeps will sound if touched.

7. Touch “Start/Pause” pad to activate cycle.

MANUAL DRY CYCLE

English

30

Page 32

HDE/HDG 5000AW, CHDE5000AW

1. Press power ON button to power on. The control panel will beep once and

the dryer will change from “OFF” to the operating status. If Start/Pause button

is not pressed in five minutes after powering on, the dryer will automatically

return to OFF status.

2. Set the cycle select dial to Manual Dry Cycle.

3. Press “More or Less Time” button to set the required drying time.

4-6. Press “Temperature,” “Signal,” “Wrinkle Saver,” to define the required

programs.

NOTE: For “Manual Dry” program use of “Temperature,” “Signal,”

“Wrinkle Saver,” is the same as for auto-programs. “Anti-Bacterial,”

“Damp Dry Signal” and “Dry Level” are inactive, and 2 beeps will

sound if pressed.

7. Touch “Start/Pause” button to activate cycle.

MANUAL DRY CYCLE

RACK DRY CYCLE

31

English

HDE/HDG 5300AW, CHDE5300AW

1. Touch power On pad to power on.

2. Touch “Manual Dry Cycles” pad and select Rack Dry.

3. Touch “Temperature” pad to a suitable temperature.

4. Touch “More Time” and “Less Time” pads to set a suitable time.

5. Touch “Start/Pause” pad to activate.

Page 33

HDE/HDG 5000AW, CHDE5000AW

1. Press power On button to power on.

2. Turn the cycle dial to Manual Dry cycle and select Rack Dry.

3. Press “Temperature” button to select suitable temperature.

4. Press “More Time” and “Less Time” buttons to set a suitable time.

5. Press “Start/Pause” button to activate.

Other Features

Your dryer also has the following features for your convenience:

Lint Filter:

• All dryers come with a lint filter that needs to be cleaned before or after every

use (read “Care and Cleaning Guide” Section).

Leveling Legs:

• Your dryer has four leveling legs which are located in the front and rear

corners of your dryer. After installing your dryer in its final position, you can

level your dryer.

• Leveling legs can be adjusted by turning them clockwise to raise your dryer or

by turning them counterclockwise to lower your dryer.

Pausing or Restarting:

• To pause the dryer at any time open the door or touch or press the start/pause

button once. To restart, close door and touch or press start/pause button once.

NOTE: Dryer will continue from where the cycle was interrupted, when door

is closed within 5 minutes. If the cycle is interrupted for more than 5 minutes

the dryer will shut off. New cycle settings must be selected before restarting the

dryer.

RACK DRY CYCLE

32

English

Page 34

The following sounds are normal during the operation of the dryer.

• Tumbling sound: this is normal as the heavy wet clothes in the dryer are

continuously being tossed around.

• Air rushing noise: this happens as the dryer drum spins at very high RPM and

the air is rushing through the dryer drum.

Tips

• For best drying results, clean the lint filter before or after every use.

• Do not overload the dryer. The appropriate load should be 1/3” to 1/2” of the

drum volume.

• Balance the dryer load evenly throughout the dryer for the best result.

• Drying time depends on many variables: load size, type of fabric and

moisture in it, heat and moisture in the room, electric voltage, length of the

exhaust duct, etc.

• To eliminate guessing and to conserve energy,it is recommend for certain clothes

to dry on an auto-drying setting.

• Always follow the fabric care instructions supplied by the garment manufacturer.

NORMAL OPERATING SOUNDS

CARE AND CLEANING GUIDE

WARNING!

Over time,the lint from the drying

process collects around the lint filter

shield,and the lint can be easily

removed using your vacuum cleaner,

at least once a month.

!

• Lint filter needs to be cleaned before or after each use

for your unit to operate at optimum efficiency.

The filter can be removed by pulling on the tabs located

on the inside of the dryer door. The filter may be washed

or vacuumed. Remove the excess water from the filter by

gently shaking the filter. This will remove dust and

particles trapped in the filter. Lint built up in screen

will restrict airflows, which causes longer drying

times. After cleaning, slide the filter back in place.

Do not use your dryer without the lint filter.

• Do not use any type of spray cleaner when cleaning the interior.

• Hazardous fumes or electric shock could occur. If dryer drum becomes

stained, clean the drum with damp cloth. Remove any residue before

drying next load.

• Clean the cabinet with mild soap and water. Do not use harsh or

abrasive cleaners, as this could damage the dryer.

• Clean the duct and the vent on a regular basis to avoid clogging

which could affect the efficiency of the dryer.

Lint Filter

33

English

Page 35

Dryer does not operate:

• Check if unit is plugged in. The plug may have come loose.

• Check if the electrical wall receptacle is of proper voltage.

• Check if the circuit breaker needs to be reset, or if the fuse needs to

be replaced.

• Check if the unit is in the “off” mode. Press start button again.

• Check if the door is open.

Dryer is working but not drying the clothes:

• Unit may be overloaded. The dryer drum should be at most half full.

• Check exhaust ducts and vents. Vents should be free of obstruction.

• Duct should be dust - and lint - free, and cleaned regularly.

• Dryer load need to be resorted. Heavy clothes may need to be separated

from regular clothes.

• Bulk clothes may require repositioning.

• If the clothes dries unevenly a higher dry setting may be required, or clothes

in the dryer need to be resorted.

Dryer makes noise when drying:

• Check for coins, loose change, buttons and other heavy objects that could be

causing the noise.

• Dryer may need to be leveled.

• Read operating guide for normal operating sounds.

Static:

• Caused by over drying. Adjust for shorter drying time.

• Mixed with synthetics fabric. Sort and separate different fabric.

• Use a fabric softener.

TROUBLESHOOTING

34

English

Page 36

Full ONE Year Warranty

For 12 months from the date of original retail

purchase, Haier will repair or replace any part

free of charge including labor that fails due to

a defect in materials or workmanship.

Second Year to Fifth Year.

After only year from the original retail purchase

date Haier shall provide a part at no cost, as

indicated above, to replace said part as a

result or a defect in materials or workman ship,

Haier is solely responsible for the cost of the

part. All other costs such as labor trip charge,

etc are the responsibility of the owner.

NOTE: This warranty commences on the

date the item was purchased and the original

purchase receipt must be presented to the

authorized service representative before

warranty repairs are rendered.

Exceptions: Commercial or Rental Use

warranty.

90 days labor from date of original purchase.

90 days parts from date of original purchase

NO OTHER WARRANTY APPLIES.

For Warranty Service

Contact your nearest authorized service center.

All service must be performed by a Haier

authorized service center. For the name and

telephone number of the nearest authorized

service center please call

1-877-337-3639.

Before calling please have available the

following information:

Model number and serial number of your

appliance( found on the rear of the unit on the

upper left hand side).

The name and address of the dealer you

purchased the unit from and the date of

purchase.

A clear description of the problem.

A proof of purchase (sales receipt).

This warranty covers appliances within the

continental united States. Puerto Rico and

Canada .

What is not covered by this warranty:

Replacement or repair of household fuses,

circuit breakers, wiring or plumbing.

A product whose original serial number has

been removed or altered.

Any service charges not specifically identified

as normal such as normal service area or

hours.

Damage to clothing.

Damage incurred in shipping

Damage caused by improper installation

or maintenance.

Damage from misuse, abuse accident, fire,

flood, or acts of nature.

Damage from service other than on authorized

Haier dealer or service center.

Damage from incorrect electrical current,

voltage or supply.

Damage resulting from any product

modification, alteration or adjustment not

authorized by Haier.

Adjustment of consumer operated controls as

identified in the owners manual.

Hoses, knobs, lint trays and all attachments,

accessories and disposable parts.

Labor, service transportation, and shipping

charges for the removal and replacement of

detective parts beyond the initial

12-month period.

Damage from other than normal household

use.

Any transportation and shipping charges.

THIS LIMITED WARRANTY IS GIVEN IN LIEU

OF ALL OTHER WARRANTIES EXPRESSED

OR INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE

The remedy provided in this warranty is

exclusive and is granted in lieu of all

other remedies.

This warranty does not cover incidental

or consequential damages so the above

limitations may not apply to you .Some states

do not allow limitations on how long on

implied warranty lasts, so the above limitations

may not

apply to you.

This warranty gives you specific legal rights,

and you may have other rights, which vary,

from state to state.

Haier America

New York, NY 10018

LIMITED WARRANTY

English

35

Page 37

1

Español

PÁGINA

INSTRUCCIONES IMPORTANTES DE SEGURIDAD .................... 2-4

INSTRUCCIONES DE INSTALACIÓN .....................................5-19

Herramientas y materiales requeridos .................................................... 5

Requisitos eléctricos...........................................................................5-6

Cómo desempacar la secadora ........................................................... 6

Requisitos del sistema de escape ........................................................7-8

Requisitos del sistema de suministro de gas ..........................................9

Ubicación de la secadora ................................................................. 10

Colocación de la secadora en un armario ........................................... 11

Instrucción de instalación en una casa prefabricada (móvil) ................. 12

Cómo cambiar la luz del tambor ....................................................... 13

Instalación eléctrica .......................................................................... 14

Conexiones de cables de 3 hilos ....................................................... 15

Conexiones de cables de 4 hilos ....................................................... 16

Conexiones del sistema de gas ......................................................... 17

Refacciones ..................................................................................... 19

INSTRUCCIONES DE FUNCIONAMIENTO ........................... 20-33

Descripción del panel de control (HDE/HDG5300AW, CHDE5300AW) 20-22

Descripción del panel de control (HDE/HDG5000AW, CHDE5000AW) 22-24

Antes de encender la secadora .......................................................... 25

Colocación de ropa en la secadora .................................................... 26

Ciclo de secado automático (HDE/HDG5300AW, CHDE5300AW) ...27-28

Ciclo de secado automático (HDE/HDG5000AW, CHDE5000AW) ....... 29

Ciclo de secado manual (HDE/HDG5300AW, CHDE5300AW) ............ 30

Ciclo de secado manual (HDE/HDG5000AW, CHDE5000AW) ............ 31

Ciclo de secado con rejilla (HDE/HDG5300AW, CHDE5300AW) ......... 31

Ciclo de secado con rejilla (HDE/HDG5000AW, CHDE5000AW) ......... 32

Otras características .......................................................................... 32

Sonidos normales de funcionamiento .................................................. 33

GUÍA DE CUIDADO Y LIMPIEZA ............................................. 33

SOLUCIÓN DE PROBLEMAS ................................................... 34

GARANTÍA LIMITADA ............................................................ 35

Page 38

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Antes de comenzar la instalación, lea detenidamente estas instrucciones a fin

de simplificar la instalación y garantizar que la secadora se instale de manera

correcta y segura.

NOTA: El servicio eléctrico de la secadora debe cumplir con los códigos y las

normativas locales, así como con la edición más reciente del Código

Nacional de Electricidad (National Electrical Code), ANSI/ NFPA 70;

o en Canadá, con la Parte 1 del Código Canadiense de Electricidad

(Canadian Electrical Code), CSA C22.1.

NOTA: El servicio de suministro de gas de la secadora debe cumplir con los

códigos y las normativas locales, así como con la edición más reciente

del Código Nacional de Gas Combustible (National Fuel Gas Code),

ANSI Z223.1; o en Canadá, con el documento CAN/CGA B149.1.

NOTA: De conformidad con los documentos ANSI Z21.5.1 o ANSI/UL

2158 - CAN/CSA C22.2 N.° 112-97 (ediciones más recientes), la

secadora fue diseñada para USO DOMÉSTICO ÚNICAMENTE. No

se recomienda utilizar la secadora en comercios como restaurantes,

salones de belleza, etc.

Por su seguridad, se deben seguir las indicaciones del presente

manual a fin de reducir al mínimo el riesgo de incendio o

explosión; o para evitar daños materiales, lesiones físicas o la

muerte.

No se debe almacenar materiales combustibles, gasolina ni otros vapores o

líquidos inflamables cerca de la secadora.

QUÉ HACER SI HUELE A GAS

1. No intente encender el electrodoméstico.

2. No toque ningún interruptor eléctrico. No utilice ningún teléfono dentro del

edificio.

3. Evacue a los ocupantes del cuarto, el edificio o la zona.

4. Llame inmediatamente a su proveedor de gas desde un teléfono externo. Siga

las instrucciones del proveedor de gas.

5. Si no puede comunicarse con su proveedor de gas, llame al departamento de

control de incendios.

Toda instalación debe ser realizada por un contratista, plomero o técnico en gas

calificado o autorizado por el estado, la provincia o la región donde vaya a

instalarse este aparato electrodoméstico.

2

Español

ADVERTENCIA

ADVERTISSMENT

Page 39

3

Español

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA – A fin de disminuir el riesgo de incendio, descarga

eléctrica o lesión física al usar el electrodoméstico, siga las

precauciones básicas, como las que se mencionan a continuación:

1. Lea todas las instrucciones antes de usar este aparato.

2. No introduzca en la secadora artículos que hayan sido limpiados, lavados,

sumergidos o rociados con gasolina, solventes de limpieza en seco u otros

tintes explosivos inflamables, ya que emiten vapores que podrían provocar

ignición o explotar.

3. No permita que los niños jueguen sobre la secadora o en su interior. Es

necesario supervisar a los niños atentamente cuando estén cerca del aparato y

este se encuentre funcionando.

4. Antes de desechar o dejar de usar el aparato electrodoméstico, retire la puerta

del compartimiento de secado.

5. No introduzca objetos en el aparato si el tambor está en movimiento.

6. No instale ni almacene este aparato en lugares donde esté expuesto a la

humedad y/o a la intemperie.

7. No manipule los controles.

8. No repare ni cambie ninguna de las partes del aparato ni intente realizar

actividades de mantenimiento a menos que las instrucciones de reparación para

el usuario lo recomienden específicamente, y usted las comprenda y pueda

seguirlas adecuadamente.

9. No utilice suavizantes de tela ni productos diseñados para eliminar la estática a

menos que los fabricantes de dichos productos lo recomienden.

10. No seque artículos con calor ni utilice productos diseñados para eliminar la

estática a menos que los fabricantes de dichos productos lo recomienden.

11. Limpie el filtro atrapapelusa antes o después de cada carga.

12. No permita que se acumule pelusa, polvo o suciedad en la zona que rodea el

orificio del escape y las zonas circundantes adyacentes.

13. Mantenga la superficie de la secadora libre de objetos que pudieran obstruir

el flujo de aire de combustión y ventilación a través del panel con rejillas

ubicado en la parte trasera de la secadora.

14. Personal de servicio calificado debe limpiar periódicamente el interior del

electrodoméstico y el ducto de escape.

15. No coloque sobre el electrodoméstico objetos que hayan sido expuestos

a aceites de cocina, ya que pueden provocar una reacción química que

ocasionaría que una carga se incendiara.

16. Si se utiliza algún material que contenga líquidos o sólidos inflamables, no

debe colocarse en la secadora sino hasta que se hayan eliminado todos los

rastros de dichos líquidos, así como sus vapores.

Page 40

4

Español

17. Antes de utilizar la secadora, debe instalarse adecuadamente de conformidad

con las instrucciones de instalación. Consulte las instrucciones de conexión a

tierra en las secciones de instalación.

18. Asegúrese de realizar las conexiones a tierra adecuadas para disminuir el

riesgo de descarga eléctrica e impulso. Consulte a un electricista o personal

de servicio calificado si no sabe si la secadora está conectada a tierra

adecuadamente.

19. Sólo utilice la secadora para lo que fue diseñada: secar ropa.

20. Siempre desconecte la secadora del suministro eléctrico antes de realizar

cualquier actividad de mantenimiento. Desconecte el cable de suministro

eléctrico sujetándolo por el enchufe, no por el cable.

21. Cambie el cable de suministro eléctrico si está desgastado o si el enchufe

está flojo.

22. A fin de disminuir el riesgo de descarga eléctrica o incendio, no utilice

cables de extensión ni adaptadores para conectar la secadora a la fuente de

suministro eléctrico.

GUARDE ESTAS INSTRUCCIONES

PELIGRO

Existe el riesgo de que los niños queden atrapados. Antes de

desechar su secadora vieja, quítele la puerta para que los niños no

puedan quedar atrapados adentro.

Gracias por usar nuestro producto

Haier. Este manual de fácil uso

lo guiará para que aproveche al

máximo su secadora.

Recuerde registrar el modelo y

número de serie, que se encuentran

en una etiqueta en la parte

posterior

Número de modelo

Número de serie

Fecha de compra

Page 41

5

Español

INSTRUCCIONES DE INSTALACIÓN

Riesgo de incendio:

1. Un instalador calificado debe instalar la secadora de ropa.

2. Instale la secadora de ropa según las instrucciones del fabricante y los

códigos locales.

3. No instale la secadora de ropa con materiales de ventilación de plástico

flexible. Si se instala un ducto de metal flexible (como de papel aluminio),

debe ser del tipo específico que el fabricante del electrodoméstico considere

adecuado para secadoras de ropa. Se sabe que los materiales de ventilación

flexibles se rompen, se aplastan con facilidad y atrapan pelusa. Estas

condiciones bloquean el flujo de aire de la secadora de ropa y aumentan el

riesgo de incendio.

4. A fin de reducir el riesgo de sufrir una lesión grave o la muerte, siga todas las

instrucciones de instalación.

Herramientas y materiales requeridos

• Destornillador de cruz (Phillips) y destornillador plano.

• Pinzas ajustables Channel Lock.

• Llave española de ½ pulgada.

• Nivel de carpintero.

• Cinta métrica (mínimo 12 pies [3.65 m]).

• Cinta sellaductos.

• Sellador para roscas de tubo (de gas).

• Ducto de metal rígido o flexible de 4 pulgadas (10.2 cm).

• Campana de ventilación.

1. Antes de comenzar la instalación, asegúrese de que la válvula de paso de gas

se encuentre cerrada.

2. Todos los conectores y tubos viejos del suministro de gas deben desecharse.

REQUISITOS ELÉCTRICOS (para secadoras eléctricas)

Números de modelo: (CHDE/HDE5000AW y CHDE/HDE5300AW)

Circuito

Circuito derivado individual de 30 amperios con fusibles o interruptor de carga

de demora de tiempo de 30 amperios.

ADVERTENCIA

ADVERTENCIA

ADVERTISSMENT

PRECAUCIÓN

ATTENTION

Page 42

6

Español

Suministro eléctrico

Cable de 3 ó 4 hilos de CA, 120/240 voltios, monofásico, de 60 Hz.

Equipo del cable de suministro eléctrico

(No se incluye cuando se vende en los EE. UU. Debe comprarse uno que cumpla

con los códigos locales de electricidad). La secadora DEBE usar un cable de

suministro eléctrico de 3 hilos, tipo NEMA 10-30 SRDT, mínimo de 240 voltios

CA, 30 amperios, con 3 cables de horquilla con terminales abiertas y dobladas

hacia arriba o conectores de bucle cerrado y marcados para uso en secadoras

de ropa.

(Si el producto se vende en Canadá, la secadora incluye un cable

de suministro eléctrico de 4 hilos).

Las secadoras que se instalan en casas prefabricadas (móviles) DEBEN usar un

cable de suministro eléctrico de 4 hilos tipo NEMA 14-30 SRDT o ST (según

se requiera), mínimo de 240 voltios CA, 30 amperios y 4 cables de horquilla

con terminales abiertas y dobladas hacia arriba o conectores de bucle cerrado

y marcados para uso en secadoras de ropa. Consulte la sección Conexiones

eléctricas para obtener más información sobre un sistema de 4 hilos.

Tomacorriente

El tomacorriente tipo NEMA 10-30R debe estar colocado en un lugar tal que

se pueda acceder al cable de suministro eléctrico cuando la secadora esté

instalada. (En Canadá, el tipo de tomacorriente debe ser NEMA 14-30R).

REQUISITOS ELÉCTRICOS (para secadoras a gas)

Números de modelo: (HDG5000AW y HDG5300AW)

Circuito

Circuito derivado individual de 15 amperios con fusibles o interruptor de carga

de demora de tiempo de 15 amperios como máximo.

Suministro eléctrico

Cable de 3 hilos de CA, 120 voltios, monofásico, de 60 Hz.

Cable de suministro eléctrico

La secadora incluye un cable de suministro eléctrico de 3 hilos y 120 voltios.

NOTA: Esta secadora está equipada con un enchufe de conexión a tierra de

tres clavijas para protegerla contra el riesgo de descarga eléctrica, por

lo que debe conectarse a un tomacorriente para tres clavijas conectado

a tierra adecuadamente. Por ningún motivo corte o quite la clavija de

conexión a tierra del enchufe.

Cómo desempacar la secadora

1. Quite todos los materiales de empaque, como la base de espuma y toda la

cinta adhesiva que sujeta los accesorios de la secadora por dentro y por

fuera.