Page 1

Dual Tap Beer Dispenser BrewMaster

Conjuguent Fontaine à Bière

BrewMaster

Dobla Dispenser De Cerveza

BrewMaster

User Manual

HBF205E

Guide de l’Utilisateur

HBF205E

Manual del Usuario Modelo

HBF205E

Quality n Innovation n Style

Page 2

English

SAFETY PRECAUTIONS

Read all of the instructions before using this appliance.

When using this appliance, always exercise basic safety

precautions, including the following:

1. Use this appliance only for its intended purpose as described in this

operation manual.

2. This appliance must be properly installed in accordance with the installation

instructions before it is used. See the installation section for more details.

3. This appliance must be connected to a proper electrical outlet with the

correct electrical supply.

4. Proper grounding must be ensured to reduce the risk of shock and fire. Do

not cut or remove the grounding plug! If you do not have a three-prong

electric receptacle outlet in the wall, have a certified electrician install the

proper outlet. The wall receptacle must be properly grounded.

5. Never unplug your appliance by pulling on the power cord. Always grasp

the plug firmly and pull straight out from the outlet.

6. Immediately replace worn power cords, loose plugs and power outlets.

7. To reduce the risk of electric shock or fire, do not use extension cords or

adapters to connect the unit to an electrical power source.

8. Unplug your appliance before cleaning or making any repairs.

9. We suggest that a certified technician perform the service if for any reason

this product requires service.

10. If your old appliance is being discarded, we recommend that you remove the

door and leave the shelves in place. This will reduce the possibility of danger

to children.

11. This appliance should not be recessed or built into an enclosed cabinet.

It is designed for freestanding installation only.

12. Do not operate your appliance in the presence of explosive fumes.

13. Do not tamper with the controls.

14. Do not operate this appliance unless all enclosure panels are properly

in place.

15. Do not operate this appliance when parts are missing or broken.

16. Do not use this appliance for commercial use.

17. This appliance is designed for indoor use only and should not be

used outdoors.

18. To reduce the risk of injury, do not allow children to play in or on the

appliance. Close supervision is necessary when the appliance is used

near children.

1

Page 3

English

19. The appliance door must be closed during operation. Do not leave the door

open when children are near the dispenser.

Important Safety Precautions of CO2 (Carbon Dioxide) Gas

1. CO2 gas can be dangerous! CO2 cylinders contain high-pressure

compressed gas, which can be hazardous if not handled properly.

Make sure you read and understand all the procedures for the CO2

cylinders before installation.

2. Always connect the CO2 cylinder to a regulator! Failure to do so may

cause an explosion resulting in possible death or injury when the cylinder

valve is opened.

3. Never connect the CO2 cylinder directly to the product container.

4. Always follow the correct procedures when changing cylinders.

5. Never drop or throw a CO2 cylinder.

6. Always keep CO2 cylinders away from heat. Store extra cylinders in

a cool place (preferably 70˚ F). Securely fasten with a chain in an

upright position when storing.

7. Always ventilate and leave the area immediately if CO2 leakage

has occurred!

8. Always check the D.O.T. (Department of Transport) test date on the cylinder

neck before installation. If it has been over 5 years, do not use. Return the

cylinder to your gas supplier.

9. Never connect a product container unless there are at least two safety

devices in the pressure system: one on the CO2 regulator and the other

on the product container or in the pressure gas line.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

DANGER!

Risk of child entrapment! Before throwing away your

old appliance, remove the door so that children may

not easily become trapped inside.

Thank you for purchasing our Haier

product. This easy-to-use manual

will guide you in getting the best

use of your beer dispenser.

Remember to record the model and

serial number. They are on a label

in back of the unit.

Model number

Serial number

Date of purchase

2

Page 4

English

TAblE OF CONTENTS

SAFETY PRECAUTIONS ................................................................1-2

General Safety ................................................................................1

CO2 (Carbon Dioxide) Gas Safety .....................................................2

UNPACKING AND ACCESSORIES INVENTORY ..........................4

PARTS AND FEATURES .................................................................5

PROPER LOCATION ......................................................................6

ELECTRICAL CONNECTIONS......................................................... 6

ASSEMBLY INSTRUCTIONS ..........................................................7-11

Installing the Casters ........................................................................ 7

Installing the Beer Tap ......................................................................7

Installing the Guardrail ..................................................................... 8

Installing the CO2 Regulator and CO2 Cylinder ...................................8

Tapping the Beer Keg (Single-Valve Type Barrel) ..................................9

Important Safety Message for Draft Beer Dispensing ............................11

OPERATING YOUR BEER DISPENSER ..........................................12

Dispensing the Beer ......................................................................... 12

Understanding Beer Temperature .......................................................13

Understanding the Temperature Control Setting ...................................13

Normal Operating Sounds ................................................................13

BEER SERVING GUIDE.................................................................. 14

Beer Serving Tips ............................................................................. 14

What a 1/2 Barrel Keg (Full Keg) of Beer Gives You ........................... 14

Tips for Cleaning Beer Glasses .......................................................... 14

2 Simple Tests for Cleaning Beer Glasses ...........................................14

ENERGY SAVING TIPS .................................................................16

PROPER CARE AND CLEANING OF THE BEER DISPENSER ........ 17

Installing the Cleaning Kit ................................................................. 17

Cleaning and General Maintenance ..................................................18

TROUBLESHOOTING GUIDE ........................................................20-23

WARRANTY ..................................................................................24

3

Page 5

English

UNPACkINg ANd ACCESSORIES INVENTORY

1. Remove all packing materials. This includes the foam base and all adhesive

tape holding the accessories both inside and outside.

2. Inspect and remove any remaining packaging, tape or printed materials

before turning on the beer dispenser.

Note: Allow the beer dispenser to stand in an upright position for 2 hours before

turning on the power.

Check all supplied accessories in the carton to be sure that all pieces are present

and in good condition. A checklist of accessories is listed below for your

reference. If you find any accessories that are not in good condition or are

missing, please contact our customer service department for assistance.

Our Toll-Free number is 1-877-337-3639.

2 Keg Couplers (Beer Taps), Low Profile Type

1 CO2 Regulator, Single Gauge, Dual Outlet

1 CO2 Cylinder, 5 lbs.

1 Cleaning Kit, Including: 32 Ounce Bottle With Cap

4 Ounce Powder Cleaner

Faucet / Line Cleaning Brush

Spanner Wrench (For Installing Beer Faucets to

Draft Arm)

1 Draft Arm, 2 Faucet

Type Including: 2 Faucets

2 Red CO2 Lines

4 Hose Clamps

2 Black Knobs

1 3” Lower Gasket

1 CO2 Cylinder Ratainer (Bracket, nut and screw)

1 Guardrail

1 Drip Tray

4 Casters

1 Wrench

4 Large Phillips Head Screws

8 Small Phillips Head Screws

2 Retainer Fixing Screws

1 Keg Joining Bracket Kit

4

Page 6

English

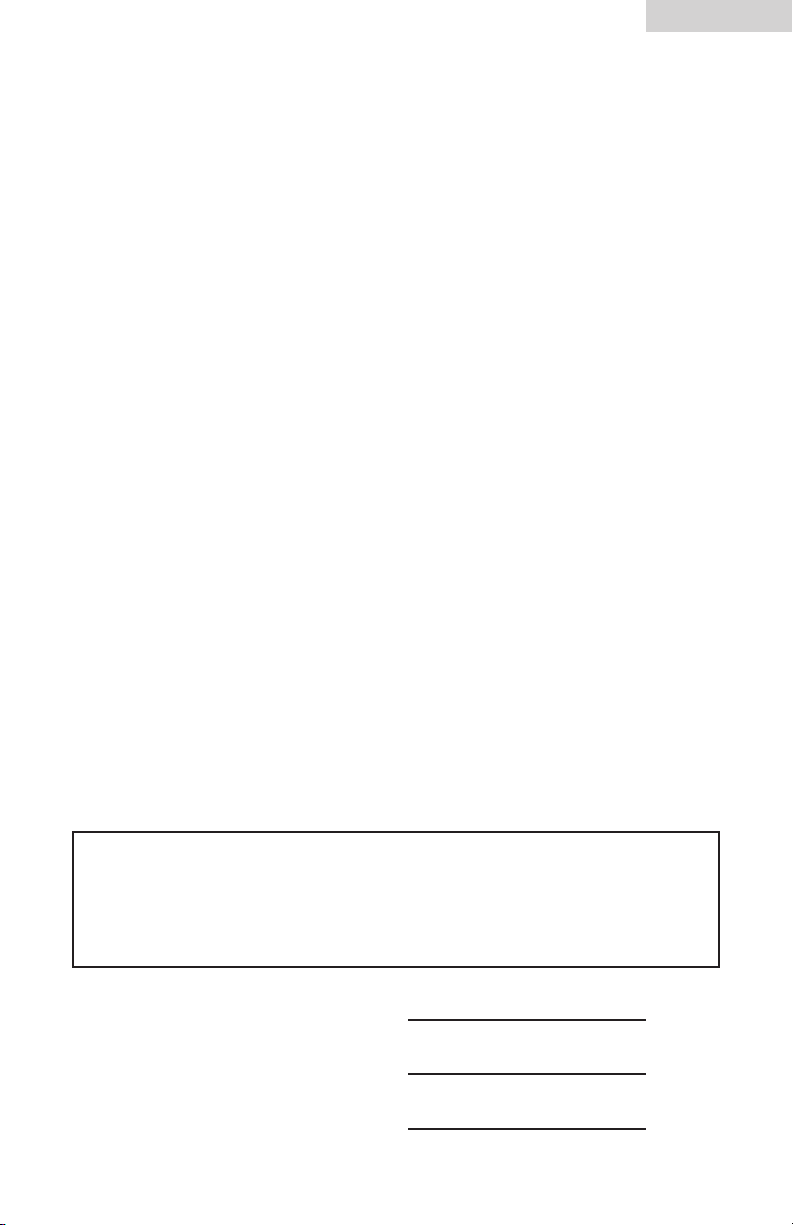

PARTS ANd FEATURES

7

86

5

4

3

2

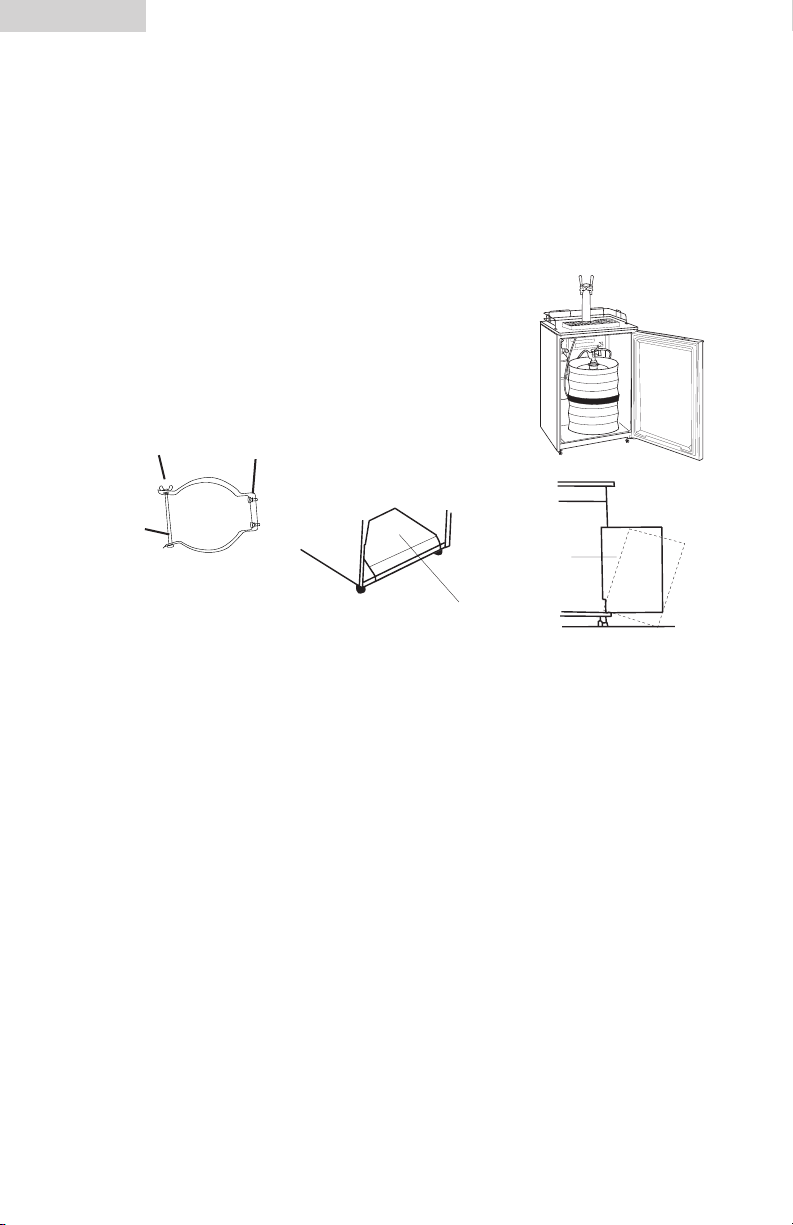

1. Casters (Total 4)

9

10

11

1

7. Dual Chrome Beer Tap

2. Interior Keg Support

3. Cabinet

4. C02 Tank

5. Work Top

6. Chrome Guardrail

5

8. Adjustable Thermostat (Located in

the rear)

9. Drip Tray

10. 1/4 Barrel Kegs (Not included

shown for illustration purpose only)

11. Keg joining Bracket

Page 7

PROPER lOCATION

• To ensure that your beer dispenser works at the maximum efficiency it was

designed for, install it in a location where there is proper air circulation,

plumbing and electrical connections.

• Choose a location where the beer dispenser will be away from heat and will

not be exposed to direct sunlight.

• This beer dispenser is designed for indoor use only and should not be

used outdoors.

• This beer dispenser is a freestanding design and should not be placed in a

built-in or recessed area.

• The following dimensions are the recommended clearances around the

beer dispenser.

Sides .....................3/4" (19mm)

Back ..........................1" (25mm)

ElECTRICAl CONNECTIONS

Grounding Instructions

This appliance must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire for the

electric current. This appliance is equipped with a cord containing a grounding

wire and a grounded plug. The plug must be inserted into an outlet that is

properly installed and grounded.

English

• Improper use of the plug may result in the risk of electric shock.

• Consult a qualified electrician or service technician if the grounding

instructions are not completely understood or if in doubt as to whether

the appliance has been properly grounded.

Wiring Requirements

This appliance must be plugged into a 15Amp, 115 Volt, 60Hz

GROUNDED OUTLET.

Note: Where a standard two-prong outlet is encountered, it is the personal

responsibility and obligation of the consumer to have it replaced with a

properly grounded three-prong outlet.

Extension Cords

We do not recommend the use of an extension cord with this unit.

Power Interruptions

Occasionally, there may be power interruptions due to thunderstorms or

other causes. Remove the power cor d from wall outlet when a power

outage occurs. When power has been restored, re-plug the power

cord into wall outlet.

6

Page 8

Caster

Wrench

Nut

Large Philip Head

Small Phillips Head

Draft Arm Assembly

Gasket

Beer Hose

Guard Rail

Handle

pilot holes

English

ASSEmblY INSTRUCTIONS

Read carefully and understand all installation instructions before installing the

beer dispenser. If after completing the process you are still unsure whether the

beer dispenser has been properly installed, we recommend that you contact a

qualified installer.

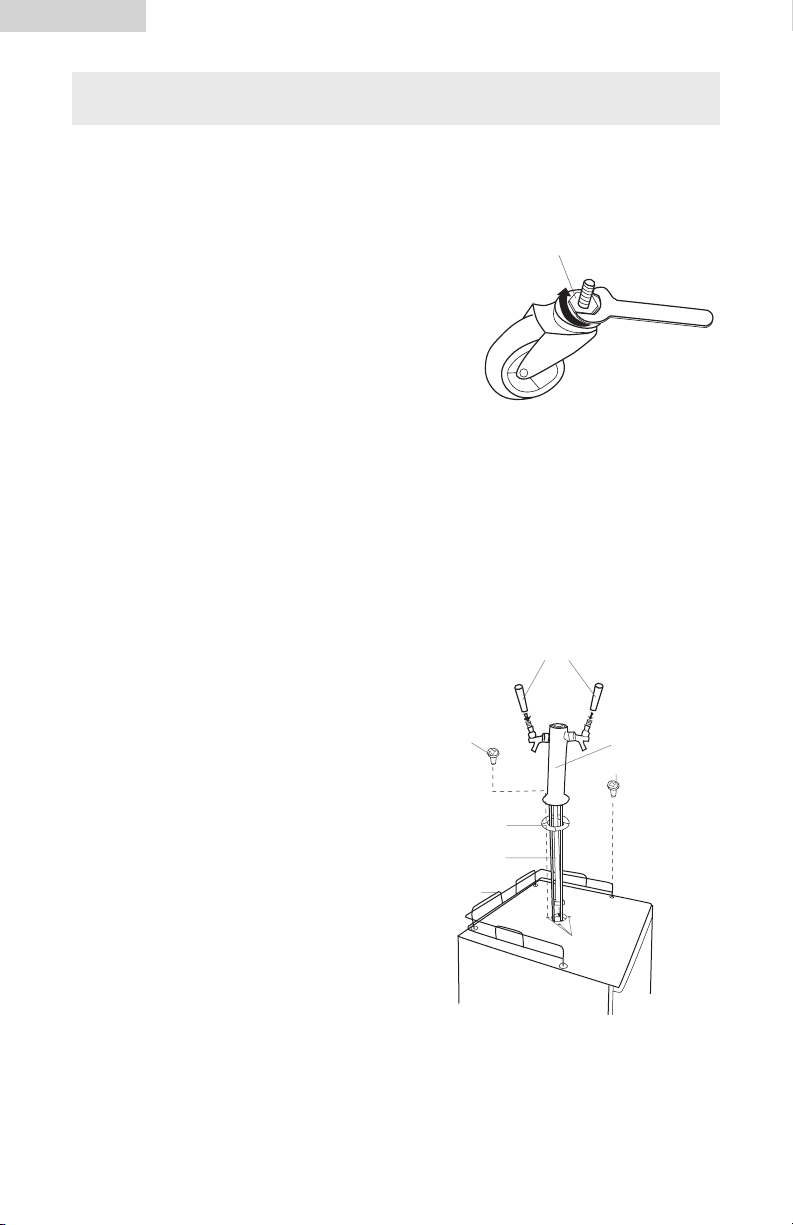

Installing the Casters

Follow the steps below to install the casters.

1. Empty the inside of the cabinet completely

and lay the beer dispenser down sideways.

We recommend that you place a piece of

cardboard or cloth underneath the cabinet to

prevent dents or scratches to the cabinet.

2. Insert the casters into the holes on the bottom

corners of the cabinet. Tighten each caster by turning the nut clockwise with

the wrench provided.

3. Once all four casters have been tightened evenly, stand the cabinet in an

upright position.

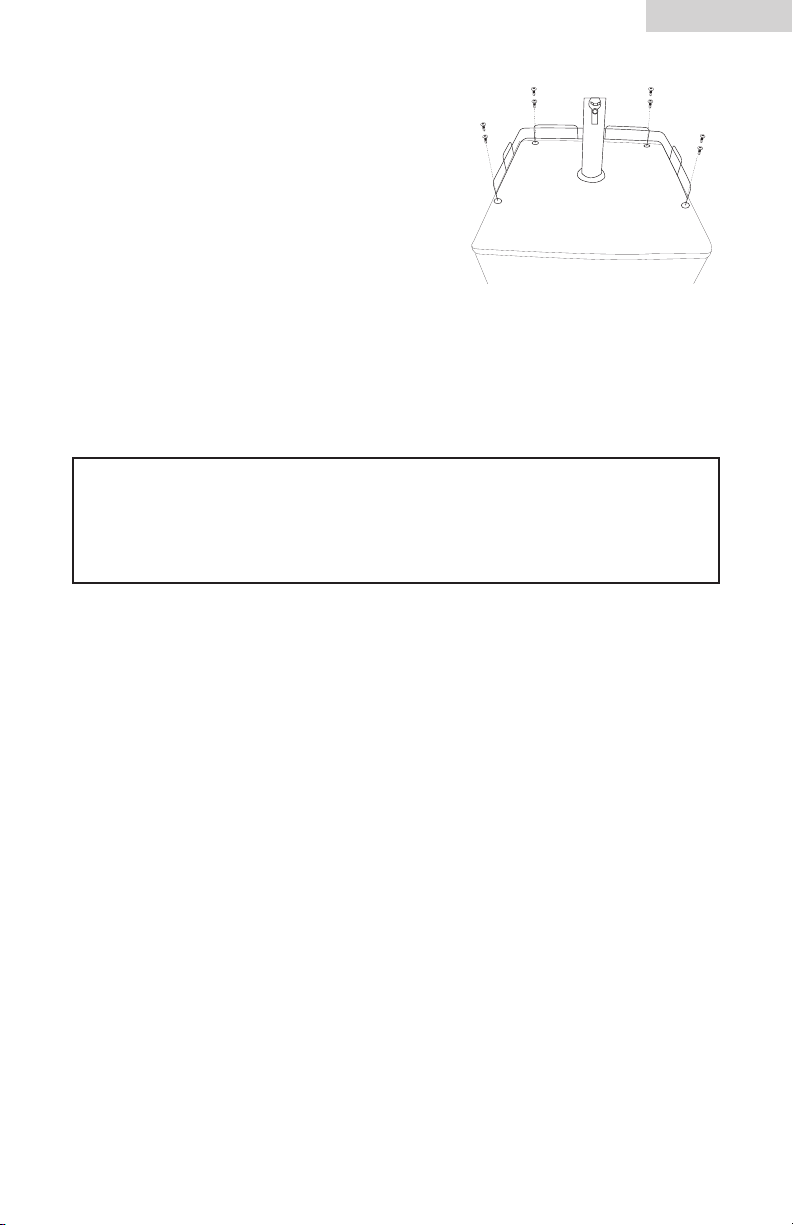

Installing the Beer Tap

Follow the steps below to install the beer tap.

1. First, remove the cabinet tap hole cover

Note: Store this plug in a safe place

2. Place the gasket over the hoses on the

3. Pass the beer tubes through the gasket

4. Push both the hoses and the beer

5. Align the holes of the draft arm with the gasket and pilot holes on the worktop

6. Secure the draft arm to the cabinet by inserting four large Phillips Head screws

7

located on the worktop. Firmly grasp

cover, twist and pull upward.

as it will be required when

converting the beer dispenser

into a beverage center.

bottom of the draft arm.

to the base of the draft arm.

hose through the hole in the worktop

until the draft arm is resting on top

of the cabinet.

of cabinet. Make sure that the faucets are facing the front.

into the holes and tightening.

Page 9

Installing the Guardrail

Follow the steps below to install the guardrail on

the worktop.

1. Place the guardrail on top of the cabinet.

2. Align all holes of the guardrail with the holes

of the cabinet.

3. Secure the guardrail to the cabinet with eight

small Phillips-Head screws.

Installation Instructions

Note: Your CO2 cylinder is shipped empty to avoid any possible accidents

during transportation. When you purchase the first keg of beer, have your

CO2 cylinder filled by your local compressed gas supplier. (See Welding

Supply in Yellow Pages)

WARNING!

CO2 can be dangerous! CO2 cylinders contain high-pressured gas, which

can be hazardous if handled improperly.

They must be handled with care.

English

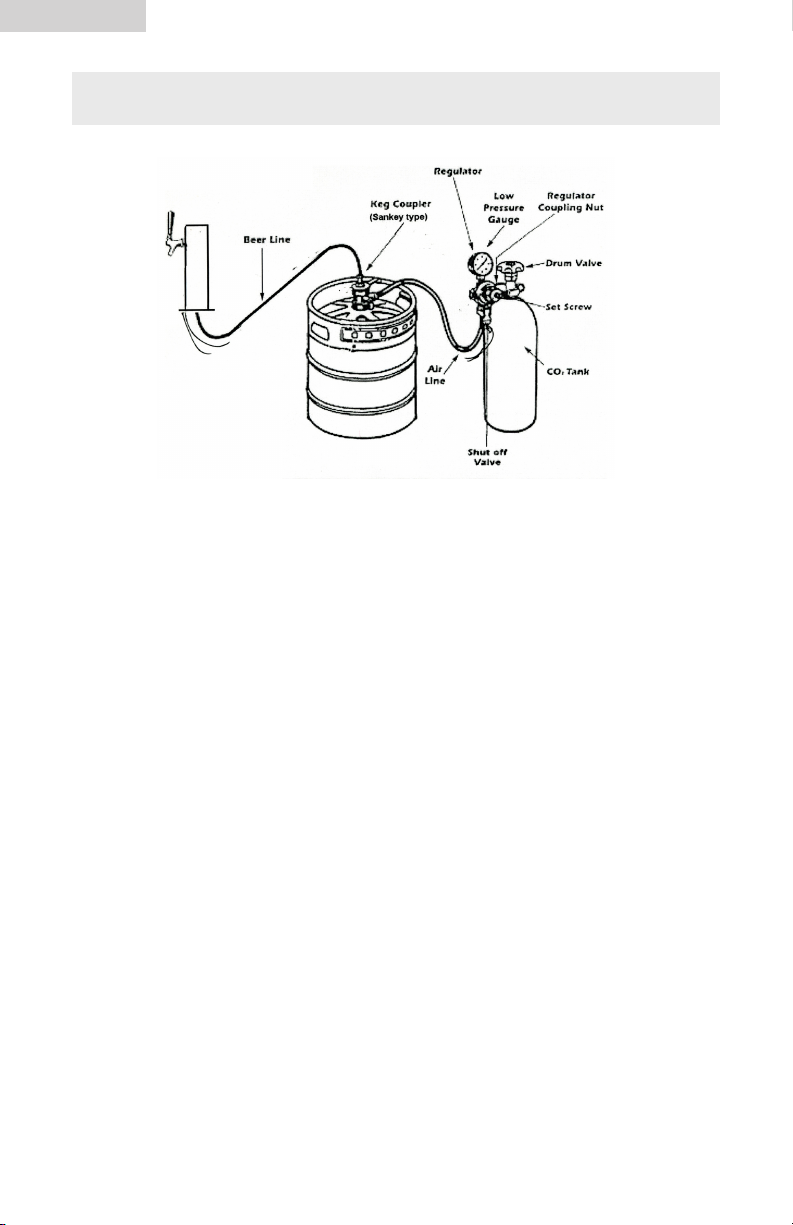

Tapping the Beer Keg (American Sankey Type Barrel)

Your beer dispenser comes with “Lo-Boy Sankey Coupler American Type.”

This brand name is the most widely used in the United States. Before purchasing

a keg, check with your beer distributor to make sure that an American Sankey

Tap can be used. (Replacement and other taps are available at

www.draughttech.com)

Remove and identify the following components from

the parts box:

1. (1) CO2 Regulator – single gauge – dual outlet

2. (1) CO2 Tank – 5 pound - EMPTY

3. (2) Keg couplers – low profile type (Lo-Boy Sankey Coupler

American Type)

4. (4) White plastic squeeze clamps

5. (2) 4 foot long red hose

6. (1) Cleaning kit

BE SURE THAT BEFORE INSTALLATION YOU HAVE FILLED YOUR

TANK WITH GAS

8

Page 10

English

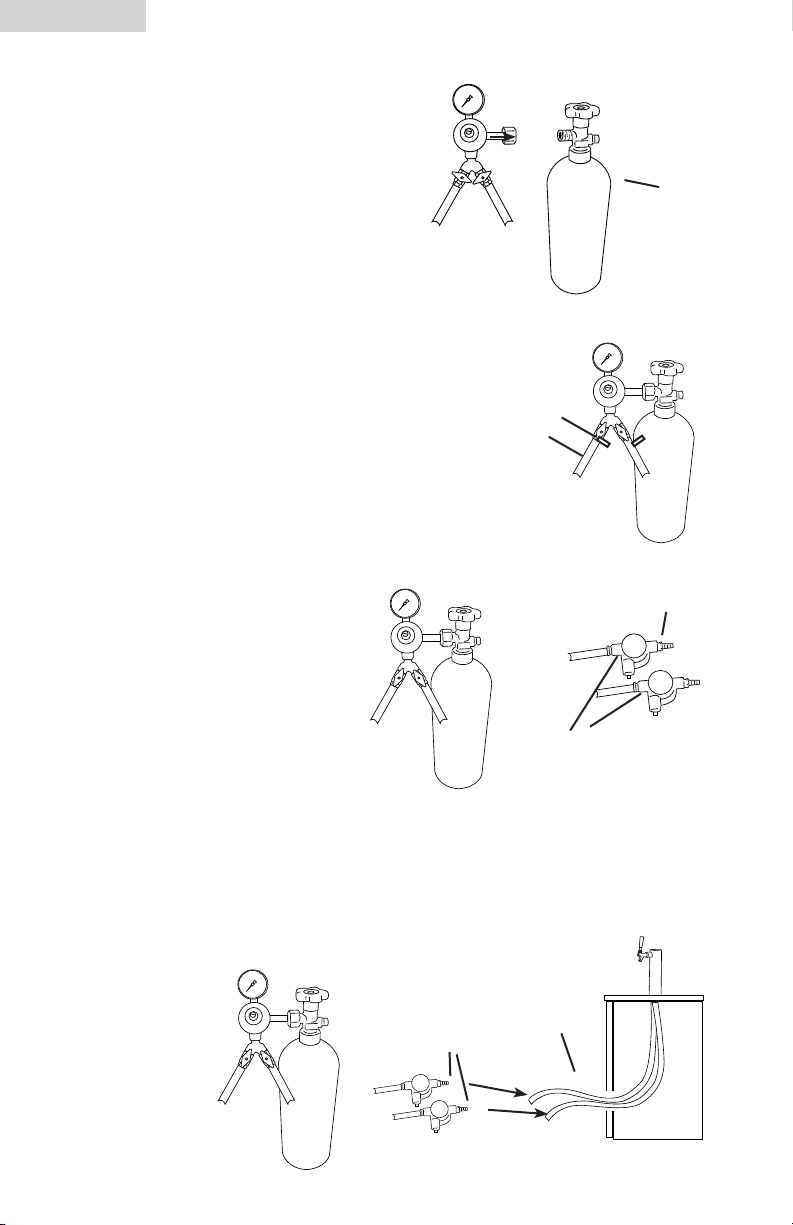

STEP 1

DO NOT TURN ON GAS YET

Connect the CO2 regulator to tank by

screwing regulator nut onto threaded tank

valve. HAND TIGHTEN ONLY – it is not

necessary to use a wrench to tighten this

nut. At this point make sure that both the

shut off (black) valves are in the off (sideways) position.

STEP 2

Attach one red gas hose to each of the shut off valve

outlets on the bottom of the regulator and clamp tight

using two of the white squeeze clamps provided.

Clamp

Red

Hose

STEP 3

Attach the other end of each red gas hose to

the LARGER of the two hose barbs

on the keg coupler and secure with

the remaining two white squeeze

clamps.

C02 Cylinder

Keg Coupler

Large Barb

STEP 4

Locate the two clear hoses from the draft arm

installed previously.

(These should be inside the refrigerator at this point). Attach one clear

beer hose to the SMALLER hose barb on each keg coupler being

certain to push the hose completely onto the barb. This connection

does not require a white squeeze clamp.

Small Barb

9

Clear Hose

Page 11

T

U

R

N

C

L

O

C

K

W

I

S

E

PUSH DOWN

THEN

English

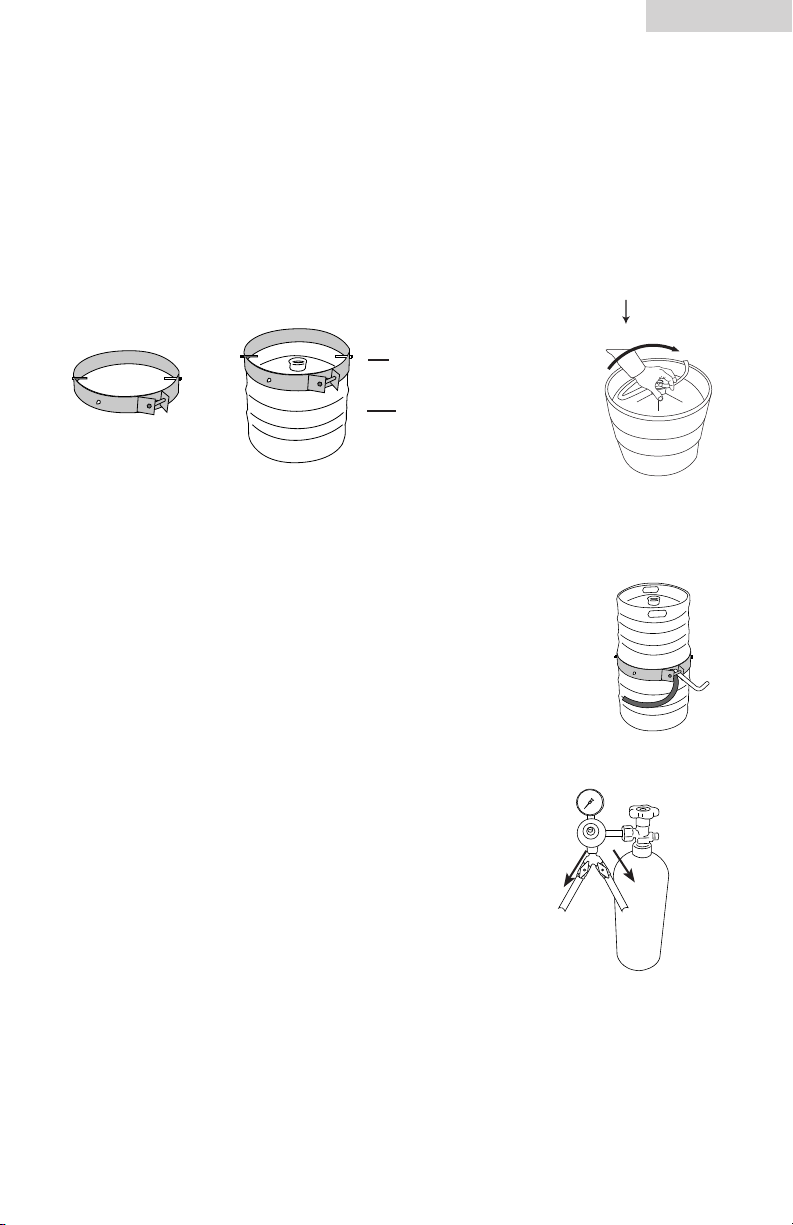

STEP 5

Note: Make sure the body of the keg coupler is in the closed (up) position

before installing it on the beer keg.

Install keg joining bracket to the first 1⁄4 barrel keg. Place one of the two keg

couplers onto the first (bottom) keg and turn clockwise to engage. To activate

push down the coupler and turn clockwise. BE SURE THAT THE HOSES ARE

OVER THE KEG JOINING BRACKET. It is normal to have some beer spray from

the keg during this process.

Keg Joining Bracket

1/4 Barrel Keg

STEP 6

Place the second (top) keg into the top of the keg joining bracket

and tighten side screws. Place the remaining keg coupler onto the top keg and

turn clockwise to engage. To activate push down the coupler and turn clockwise.

It is normal to have some beer spray from the keg during this process.

IMPORTANT: The red and white hose of the bottom keg

should be routed over the split of the

joining bracket as shown in the picture.

Note: Be sure keg couplers are engaged completely

prior to inserting kegs in to the beer dispenser.

STEP 7

YOU MAY NOW TURN ON THE GAS AT THE TANK

AND OPEN BOTH BLACK HANDLES TO THE UP/DOWN

POSITION. With a flat head screw driver, turn screw on

top of regulator clockwise until the top gauge reads 8 PSI

STEP 8

At this time check the flow of beer by pulling each of the

taps forward. Make sure you use a container so as not to

spill the beer on the unit.

STEP 9

Remove the nut from the retainer bolt. Use two retainer fixing screws to secure

the retainer to the holes on the back of the cycliner. Then slide the cylinder

through the retainer and place it in the cabinet. Then tighten the retainer nut.

Carefully tilt the two beer kegs combination and rest the edge on the stainless

steel keg floor support on the bottom of the interior cabinet. Slide the kegs in

slowly, ensuring that it is properly located. THIS MAY REQUIRE 2 PEOPLE

TO COMPLETE.

10

Page 12

El Apoyo del barril

El Barril de la cerveza

Levante Vertical

English

Note: If only one keg is to be dispensed you must still complete all the above

steps. Simply leave one keg coupler disconnected in the upright / locked

position. Please make sure that the black shut off valves are on the C02

regulator are in the off position.

When stacking 2 kegs be certain to securely install the included

keg joining bracket with the supplied hardware.

Make sure the hoses are not damaged by the kegs.

Wing Nut

Fixing Screws

Retainer

Screw

CO2 Retainer

Important Safety Message for Draft Beer Dispensing

When CO2 is used for draft beer dispensing, the system must be adequately

protected against excessive pressure build-up. This is accomplished by the

already installed two safety devices with adequate relief capacity in the system.

Safety devices are installed in the following places:

A. On or immediately downstream from the CO2 regulator.

B. On the keg coupler.

11

Page 13

OPERATINg YOUR bEER dISPENSER

Dispensing Beer

Follow the steps below to dispense beer.

1. Make sure that the beer dispenser is plugged in properly to a 120V, 60Hz,

15 Amp grounded AC outlet.

2. Place the drip tray under the beer faucet.

3. Open the beer faucet by pulling the tap towards you quickly and completely

to dispense the beer.

Note: If for any reason the beer does not come out of the tap, refer to the

trouble-shooting guide on page 17.

4. Increase the pressure if the beer runs too slowly. At the correct pressure and

temperature, a 10oz. glass should be filled in 5 seconds.

5. Hold the glass steady at a 45˚ angle. When it is 2/3 full, start straightening

the glass. Proper foam should be a tight creamy head and the collar on an

average glass should be 3/4" to 1" high.

Note: It is normal to see condensation forming on the outer surface of the

faucet. It is caused by the difference in temperature between the cold beer

and the inner surfaces of the faucet when beer is flowing through the line.

English

12

Page 14

English

Understanding Beer Temperature

• The recommended temperature for serving chilled beer is between 34˚ and

38˚F. To maintain this temperature in average room conditions of 70˚F, set the

thermostat to "Normal."

Note: During the summertime when temperatures are warmer, we recommend

that you adjust the control to a cooler setting accordingly.

• Select and maintain the proper temperature inside the refrigerator cabinet.

This is necessary for maintaining the flavor freshness of beer.

• The best temperature for storing a keg is between 38˚ and 40˚F.

• Excessively cold or warm temperatures inside the refrigerator cabinet may

cause a loss of flavor.

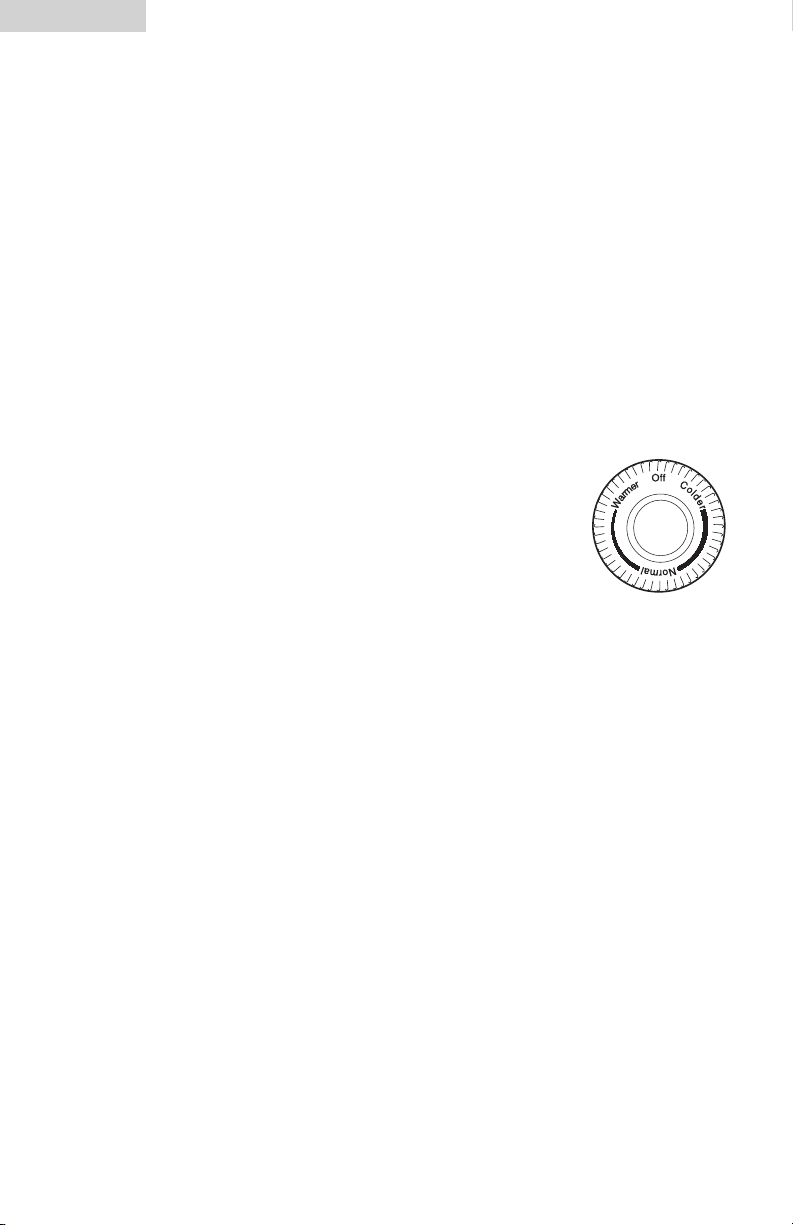

Understanding the Temperature Control Setting

The temperature control is located at the rear of the unit on the

bottom left-hand corner. After turning the unit on, you must wait

24 hours for the unit to cool properly. You may then adjust the

temperature setting based on your needs and preferences.

Automatic Defrosting

It is not neccessary to defrost the beer dispenser/refrigerator. Ice that has

deposited on the evaporator is automatically defrosted when the compressor

cycles off. The defrosted water collects in the water collection tray at the rear

of the unit and evaporates.

Understanding Normal Operating Sounds

• Bubbling or gurgling sounds and slight vibrations are the result of the

refrigerant circulating through the cooling coils.

• Sizzling or popping sounds occur during the automatic defrost cycle.

• Dripping sounds occur as ice melts from the evaporator and flows into the

water collection tray during the automatic defrost cycle.

• Cracking or popping sounds are caused by the expanding and/or contracting

of the cooling coils during the automatic defrost cycle.

13

Page 15

bEER SERVINg gUIdE

Beer Serving Tips

The following tips will help you serve the perfect beer.

Before serving beer from the tap, check for the following:

• Cleanliness • Temperature • CO2 pressure

Usable Keg Size Combinations:

1) Two 1/4 barrel kegs

2) Two 1/6 barrels kegs (narrow)

3) One 1/4 barrel (slim) keg One 1/6 barrel (narrow) keg

4) One 1/2 barrel keg

English

14

Page 16

English

Tips for Cleaning Beer Glasses

For the freshest flavor, it is important to serve beer in clean glasses. For your

convenience, the following tips explain how to properly clean beer glasses before

serving beer.

• Do not wash beer glasses together with glasses that have contained milk or

any other fatty substance.

• An excessive amount of germicide build-up will also leave a fatty film on the

glasses, which may cause flat beer.

• Wash glasses thoroughly with a good detergent to remove all fatty substances

(i.e. lipstick).

• Do not use soap.

• Do not wipe glasses dry. Allow glasses to air-dry by placing them on a wire

rack or on corrugated metal.

• Rinse in fresh cold water just before serving beer. It is best to serve beer in a

wet glass.

Two Simple Tests for Clean Beer Glasses

1. Wash the glasses using your usual method. Immerse the glass heel first in

clean water. Empty the glass. If water droplets cling to the glass or if spots

appear on the glass while pouring, the glass has not been cleaned properly.

A clean glass should air-dry crystal clear.

2. Again, wash the glass using your usual method. Pour out the water and then

shake salt into the wet glass. If salt does not cling to the entire inside wall of

the glass and clear unsalted spots remain, the glass is not clean.

15

Page 17

English

ENERgY SAVINg TIPS

Follow the energy-saving tips below for optimum efficiency.

• Limit the opening and closing of the door on hot and humid days. When you

open the door, close it quickly to prevent hot air from entering.

• Check regularly for proper air circulation around the unit to make sure that the

unit receives sufficient airflow.

• Keep the door gasket clean and straight to ensure a proper seal. If the

door gasket is not sealed properly, hot air may easily enter into the unit,

making the interior temperature warmer. The compressor must then run

continuously to keep the unit cool, thus making the energy consumption

very high and inefficient.

Note: Replace a damaged door gasket to restore energy efficiency.

16

Page 18

English

PROPER CARE ANd ClEANINg OF THE bEER

dISPENSER

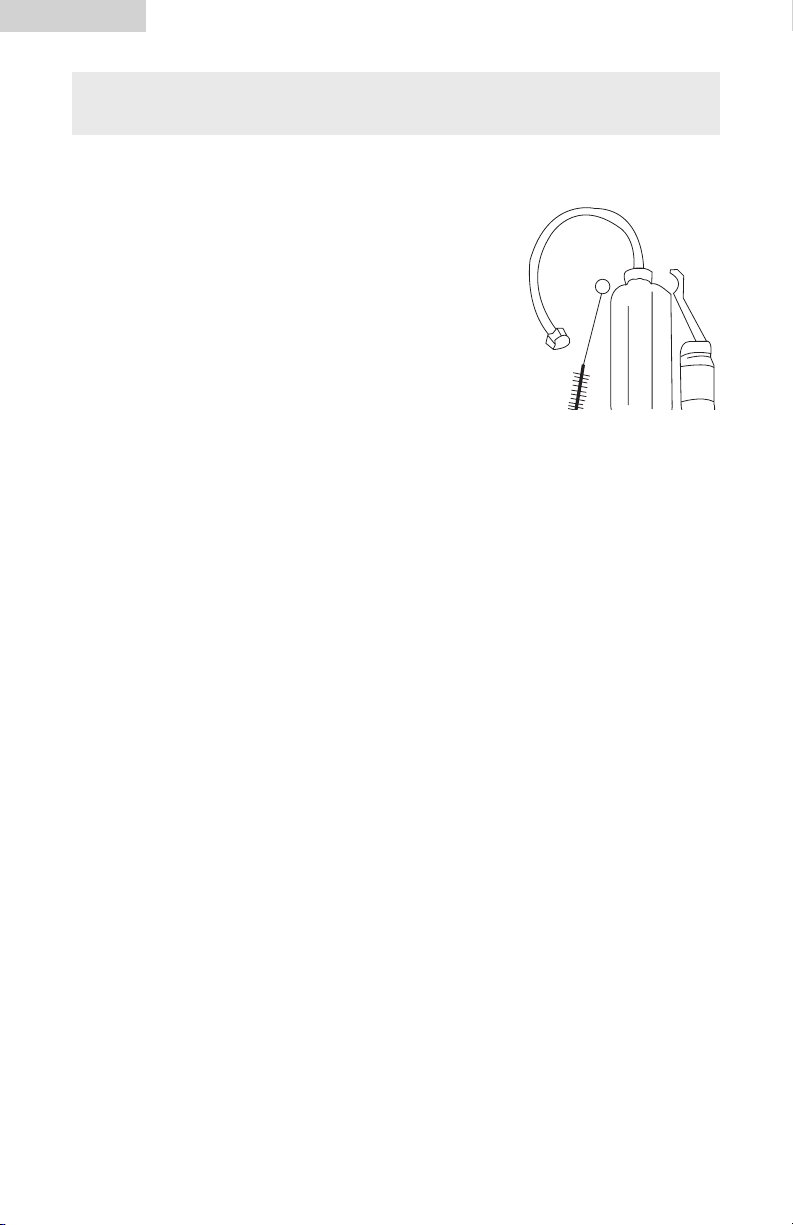

Instructions for Using Cleaning Kit

1. Mix one gallon of warm water and one ounce of

cleaner in a bucket. DO NOT USE SOAP.

2. Remove the cleaner cap assembly, fill the jar and

reassemble. Leave the remaining solution in the

bucket.

3. Turn off the air cock on the regulator and turn off

the valve on the CO2 tank.

4. Disconnect the keg coupler from the keg and then

disconnect the beer line from the tap.

5. Remove the faucet from the draft tower with the wench provided and attach

the fitting from the end of the cleaning bottle in its place. Make sure there is

a washer in the back of the fitting.

6. Hold the cleaning jar upside down until the solution runs through to the

bucket. DO NOT SQUEEZE THE JAR. THIS WILL CAUSE THE SOLUTION

TO LEAK.

7. Fill the jar with clean cool water and repeat the process until clear water

flows into the bucket.

8. Rinse the keg couple in the bucket with the remaining solution and then in

the bucket with the clean water.

9. Remove the cleaning fitting from the tower and replace the faucet. Make

sure the washer is in the back of the faucet.

10. Reattach the beer hose to the keg coupler and attach the keg coupler to

the keg.

Repeat the process for the additional tap system.

17

Page 19

English

Cleaning and General Maintenance

General Interior and Exterior Cabinet Cleaning

1. Prepare a cleaning solution of 3-4 tablespoons of baking soda mixed with

warm water. Use a sponge or soft cloth dampened with the cleaning solution

to wipe down the interior and exterior surfaces of the cabinet.

2. Rinse with clean, warm water and dry with a soft cloth.

Note: Do not use harsh chemicals, abrasives, ammonia, chlorine bleach,

concentrated detergents, solvents or metal scouring pads. Some of these

products may dissolve, damage and/or discolor the cabinet finish.

Door Gasket Cleaning

1. Clean the door gasket with a damp cloth every three months. The gasket must

be kept clean and pliable to ensure a proper seal.

2. Petroleum jelly applied lightly to the hinge side of the gaskets will keep the

gasket pliable and ensure a good seal.

Cleaning Behind the Beer Dispenser

1. We recommend that you clean the rear of the refrigerator at least

twice a year.

Note: Some operating environments may require more frequent cleaning.

2. Use a vacuum or a brush to clean the coils.

WARNING!

To avoid electric shock, always unplug your beer dispenser before

cleaning. Failure to do so may result in possible death or injury.

CAUTION!

Before using cleaning products, always read and follow the

manufacturer’s instructions and warnings to avoid personal injury

and product damage.

18

Page 20

English

kEg CONNECTIONS

How do I replace an empty CO2 tank?

1. Close tank drum valve by turning clockwise.

2. Unscrew adjustment Set Screw (counter-clockwise) as far as it will go and

close shut off valve.

3. Remove regulator from empty tank.

4. Remove dust cap from the new full tank. Open and close drum valve quickly

to blow of the dust from the outlet.

5. With drum valve in closed position, reattach regulator to the tank. Be sure to

check the washer, which is pre-installed on the CO2 regulator.

6. Open drum valve all the way. (This is important because this drum valve seals

in two places.)

7. Readjust regulator pressure by turning set screw and open shut off valve.

Tank Information: Tank must always be fastened in the upright position.

It takes about 1/2 lb. of CO2 to dispense 1/2 barrel keg of

beer. A 5 lb. CO2 tank should dispense between 8-10 1/2

barrel kegs or 18-20 1/4 barrel kegs. Full weight of 5 lb. tank

is appx. 17-1/2 lbs.

19

Page 21

English

TROUblESHOOTINg gUIdE

When dispensing beer into the glass, if you find that the beer is Cloudy, Flat,

Bubbly, Off-Taste, Sour, Wild or Tail-End Beer, refer to some of the following hints.

Beer Condition: Cloudy Beer

The beer in the glass appears hazy, and not clear.

Cause 1

Excessively low temperatures may cause hazy or cloudy beer, particularly when

the beer lies in the cold coil for long periods of time.

Correction

• Make certain that the lines are thoroughly cleaned and then raise the

temperature slightly.

Cause 2

The beer faucet was only opened partially.

Correction

• Open the faucet quickly and completely.

• Replace any worn washers and parts in the faucet when necessary to allow the

faucet to be fully opened.

Beer Condition: Flat Beer

Beer lacks its usual brewery-fresh flavor. The foamy head disappears quickly.

Cause 1

The glass is greasy.

Correction

• Do not wash beer glasses together with glasses that have contained milk or

any other fatty substance. An excessive amount of germicide build-up may

also leave a fatty film, which will cause beer to go flat.

• It is preferable to steam and sterilize glasses where health laws permit.

• Wash glasses thoroughly with a good detergent to remove all fatty substances

(i.e. lipstick).

• Do not use soap.

• Do not wipe the glasses dry. Permit glasses to air-dry by placing them on a

wire rack or on corrugated metal.

• Rinse the glasses in fresh cold water just before serving beer. It is best to serve

beer in a wet glass.

Cause 2

Improper drawing of beer into the glass.

Correction

• Open the faucet quickly and completely.

• Proper foam should be a tight creamy head. The collar on the average glass

should be 3/4" to 1" high. Beer drawn without head has the appearance of

being flat.

20

Page 22

English

Cause 3

Not enough pressure.

Correction

• Increase the pressure if beer runs too slowly. The correct flow should fill a

10oz. glass in 5 seconds.

• Check the pressure source to determine whether there are obstructions in the

air line.

• Replace a sluggish air source or the CO2 regulator and gauge.

• The tank pressure must always be higher than the pressure used on the keg.

• Always apply pressure to the keg before drawing beer.

Beer Condition: Loose Foam

Large soap-like bubbles that settle quickly.

Cause 1

This is generally the same as the Flat Beer condition. See the Flat Beer

causes above.

Beer Condition: Off-Taste Beer

Often bitter and bitey; sometimes completely lacking in flavor and zest. May

also have an oily or foul odor, which carries an unpleasant taste.

Cause 1

Improper cleaning of the tap.

Correction

• Brush and clean the tap properly. It should be scoured using a detergent, then

rinsed clean.

Cause 2

Contaminated gas line.

Correction

• Gas line should be examined. If contaminated, it should be replaced.

Cause 3

Improper type of gas line

Correction

• A rubber hose will absorb and retain odors. Be sure you are using the hoses

supplied with your unit.

General Recommendations for Off-Taste Beer:

Beer lines should be flushed after each keg is emptied. Maintain fresh, clean,

sanitary conditions around the dispenser. Smoke, cooking odors and disinfectants

will harm the taste and flavor of beer. These conditions, as described, may come

from an air source or from actual contact with the glass when drawing beer.

21

Page 23

English

Beer Condition: Sour Beer

Beer tastes and smells extremely yeasty or moldy.

Cause 1

Improper transporting of beer kegs. Beer that is delivered on an open truck

during high summer temperatures may start a secondary fermentation process.

Correction

• If possible, have beer kegs delivered in a closed, refrigerated truck. If an open

truck is used, cover beer kegs with tarpaulin for protection against summer heat

and warm air.

Beer Condition: Wild Beer

Beer that is either all foam, or too much foam and not enough liquid.

Cause 1

Improper drawing of beer into the glass.

Correction

• Open the faucet quickly and completely.

• Proper foam should be a tight, creamy head, and the collar on the average

glass should be 3/4" to 1" high.

Cause 2

Yeast growth or other obstructions in the faucet, which is usually caused by

a non-refrigerated faucet. Worn faucet parts and worn faucet washers.

Correction

• Check for, and replace any kinked, dented, or twisted lines from the barrel to

the faucet.

• Examine for frayed coupling washers behind the faucet that may cause an

obstruction.

Cause 3

The beer was stored in an area that is not cold enough and has thus

become warm.

Correction

• Keep kegs of beer refrigerated at all times at 40°F or below all year round!

Cause 4

Too much pressure.

Correction

• First, check the source of pressure to make sure it is working. Then adjust the

pressure to suit a properly balanced system. The correct beer flow should fill a

10oz. glass in 5 seconds at the proper temperature.

22

Page 24

English

Cause 5

Excessive amounts of CO2.

Correction

• Adjust the CO2 pressure to as low as possible. However, the applied pressure

must remain slightly higher than the internal pressure of the beer. No more

than 18 lbs. should be applied. The proper amount should be between

6 - 9 psi/lbs.

• The colder the beer and the higher the applied CO2 pressure, the more

rapid the absorption of CO2 by the beer. This over-carbonates the beer,

causing Wild Beer.

• Check the pressure regulators periodically to ensure that the operating

pressures remain constant.

Cause 6

Not enough pressure or no pressure at all.

Correction

• Check for defective air vents.

• Always turn the pressure on before drawing beer.

Cause 7

An old keg of beer which has not been stored in cool temperatures has

been used.

Correction

• If beer has been allowed to stand in warm temperatures beyond 45°F for an

excessive length of time, it may begin a secondary fermentation. Store beer at

40°F or below all year round.

Beer Condition: Tail-End Beer

Beer draws well at the beginning of the keg. Towards the bottom, it becomes

flat. This is more likely to occur when beer turnover is slow.

Cause 1

Where air is used as a pressure source, air replaces the CO2 in beer, causing

flat beer. This problem is not evident when beer is being drawn rapidly.

Correction

• Whenever possible, use CO2 Gas as a pressure source.

23

Page 25

lImITEd WARRANTY

English

In-Home Service

What is covered and for

how long?

This warranty covers all defects in

workmanship or materials for a

period of:

12 months labor

12 months parts

5 years sealed system(parts only)

The warranty commences on the date

the item was purchased and the original purchase receipt must be presented

to the authorized service center before

warranty repairs are rendered.

EXCEPTIONS: Commercial or

Rental Use warranty

90 days labor (carry-in only)

90 days parts

No other warranty applies

What is covered?

1. The mechanical and electrical parts,

which serve as a functional purpose

of this appliance for a period of

12 months. This includes all parts

except finish and trim.

2. The components of the sealed system

e.g. hermetic compressor, condenser

and evaporator from manufacturing

defects for a period of 5 years from

the date of purchase. Any

damages to such components

caused by mechanical abuse or

improper handling or shipping will

not be covered.

What will be done?

1. We will repair or replace, at our

discretion any mechanical or

electrical part which proves to be

defective in normal usage during the

warranty period so specified.

2. There will be no charge to the

purchaser for parts and labor

on any covered items during the

initial 12 month period. Beyond

this period only parts are covered

in the remaining warranty. Labor

is not provided and must be paid

by the customer.

3. Contact your nearest authorized

service center. For the name of the

nearest service center please visit

our website at www.HaierAmerica.

com or call 1-877-337-3639 for

more information.

THIS WARRANTY COVERS

APPLIANCES WITHIN THE

CONTINENTAL UNITED STATES,

PUERTO RICO AND CANADA.

IT DOES NOT COVER

THE FOLLOWING:

Damages from improper installation.

Damages in shipping.

Defects other than manufacturing.

Damage from misuse, abuse, accident,

alteration, lack of proper care and

maintenance or incorrect current

or voltage.

Damage from other than householduse.

Damage from service by other than an

authorized dealer or service center.

D ecorative trims.

Transportation and shipping.

Labor (after the initial 12 months).

THIS LIMITED WARRANTY IS GIVEN

IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR INCLUDING THE

WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR

PURPOSE.

The remedy provided in this warranty

is exclusive and is granted in lieu of all

other remedies.

This warranty does not cover

incidental or consequential damages,

so the above limitations may not

apply to you. Some States do not

allow limitations on how long an

implied warranty lasts, so the above

limitations may not apply to you.

This warranty gives you specific legal

rights, and you may have other rights,

which vary, from state to state.

Haier America

New York, NY 10018

24

Page 26

Français

CONSIgNES dE SÉCURITÉ

ImPORTANTES

Lisez toutes les instructions avant d’utiliser cet équipement.

Lorsque vous utilisez cet équipement, veuillez respecter les

consignes de sécurité de base suivantes:

1. Utilisez cet équipement uniquement pour l’usage auquel il est destiné comme

indiqué dans ce manuel.

2. Cet équipement installé correctement et conformément instructions

d’installation utilisation. Consultez la section l’installation pour de plus

amples détails.

3. Cet équipement doit être branché sur une électrique d’une tension adéquate.

4. Cet équipement doit être mis à la masse (terre) afin d’éviter tout risque

d’électrocution et d’incendie. Ne pas couper ni retirer la broche de masse!

Si votre prise de courant murale ne peut accueillir une fiche à trois broches,

veuillez faire électricien qualifié en installe une. La doit être reliée à la terre.

5. Ne débranchez jamais cet équipement en tirant sur le cordon d’alimentation.

Saisissez fermement la fiche et tirez tout droit sur cette dernière.

6. Remplacez immédiatement tout cordon, toute fiche ou prise usé(e),

desserré(e).

7. Afin de réduire tout risque d’électrocution et d’incendie, n’utilisez pas de

rallonges ni d’adaptateurs afin de raccorder l’équipement à une source de

courant.

8. Débranchez l’équipement avant de le nettoyer ou de le réparer.

9. Nous vous recommandons de contacter un technicien réparateur breveté si

cet équipement tombe en panne.

10. Si vous comptez jeter votre ancien équipement, nous vous recommandons de

retirer la porte et de laisser les étagères en place. Vous réduirez ainsi tout

risque de danger pour les enfants.

11. Cet équipement ne doit pas être placé dans un renfoncement ni encastré

en aucune façon. Il a été conçu afin d’être placé seul sans l’intégrer à un

espace clos.

12. Ne faites pas fonctionner cet équipement en présence de vapeurs explosives.

13. Ne jouez pas avec les commandes.

14. N’utilisez pas cet équipement à moins que toutes les cloisons soient bien

en place.

15. N’utilisez pas l’équipement lorsque des pièces s’avèrent défectueuses.

16. N’utilisez pas votre équipement à des fins commerciales ou industrielles.

17. Cet équipement a été conçu afin d’être utilisé à l’intérieur et ne doit en aucun

cas être utilisé à l’extérieur.

1

Page 27

Français

18. Afin de réduire tout risque de blessures, ne laissez pas les enfants jouer sur

ou à l’intérieur de cet équipement. Il est nécessaire de surveiller attentivement

les enfants lorsque vous utilisez cet équipement à proximité des enfants.

19. La porte de l’équipement doit être fermée lorsqu’il fonctionne. Ne laissez

pas la porte ouverte lorsque des enfants se trouvent à proximité de la

fontaine à bière.

Consignes de sécurité importantes pour le CO2

(gaz carbonique)

1. Le gaz carbonique ou dioxyde de carbone peut être dangereux! Les bouteilles

de CO2 contiennent du gaz sous pression qui peut être dangereux si vous ne

le manipulez pas correctement. Veuillez lire et comprendre toutes les

consignes

concernant les bouteilles de CO2 avant de procéder à l’installation.

2. Veuillez toujours raccorder la bouteille de CO2 à un régulateur!

Le non-respect de cette consigne risque de provoquer une explosion et

d’entraîner des blessures graves voire mortelles lorsque vous ouvrez la valve

de la bouteille.

3. Ne raccordez jamais la bouteille de CO2 directement sur le contenant,

tonnelet, baril ou fût de bière.

4. Respectez toujours la marche à suivre lorsque vous changez de bouteille.

5. Ne jamais lancer ou laisser tomber une bouteille de CO2.

6. Conservez toujours les bouteilles de CO2 loin des sources de chaleur. Stockez

les bouteilles de rechange dans un endroit frais (de préférence 70°F ou 21°C).

Fixez solidement la bouteille en place avec une chaîne, en la plaçant droite.

7. Assurez-vous que l’endroit possède une bonne ventilation et quittez

immédiatement cet endroit en cas de fuite de CO2!

8. Vérifiez toujours la date à laquelle la bouteille a été testée par le D.O.T.

(Ministère des transports américain) figurant sur le col de la bouteille avant

l’installation. Si cette date est antérieure à 5 ans, n’utilisez pas la bouteille.

Ramenez la bouteille à votre fournisseur.

2

Page 28

Français

DANGER!

Les enfants risquent de se faire pièger et de demeurer bloqués

l'intérieur de l'équipement. Avant de jeter votre ancien

équipement, retirez la porte afin que les enfants ne puissent se

faire pièger à l'intérieur.

Merci pour acheter notre produit

de Haier. Ce manuel facile d'utilise

vous dirigera dans obtenant le

meilleur usage de votre

distributeur de bière.

N'oubliez pas de noter le modèle

et le numéro de série. Ces derniers

se trouvent sur une étiquette au dos

de l'appareil.

Numéro du modèle

Numéro de série

Date d'achat

3

Page 29

TAblE dES mATIÉRES

CONSIGNES DE SÉCURITÉ ..............................................................1-3

La sécurité en général .........................................................................1-2

La sécurité avec le CO2 (gaz carbonique) ..............................................2-3

DÉBALLAGE ET INVENTAIRE DES ACCESSOIRES ............................... 5

PIÈCES ET CARACTÉRISTIQUES .......................................................... 6

CHOISIR UN BON EMPLACEMENT .................................................... 7

INSTRUCTIONS DE MONTAGE .................................................... 8-12

Montage des roulettes ............................................................................8

Montage du robinet de bière ..................................................................8

Montage de la barre de sécurité ............................................................. 9

Montage du régulateur et de la bouteille de CO2 ......................................9

Mise en perce du fût de bière (baril à valve unique) ................................10

Consigne de sécurité importante pour le tirage de la bière .......................10

UTILISATION DE LA FONTAINE À BIÈRE ................................... 13-14

Servir la bière .....................................................................................13

Comprendre la température de la bière ..................................................13

Comprendre la commande de réglage de température.............................13

Dégivrage automatique ........................................................................14

Bruits de fonctionnement normaux ..........................................................14

Français

GUIDE POUR SERVIR LA BIÈRE........................................................15

Conseils pour tirer la bière .................................................................... 15

Équilence pour 1/2 fût de bière ............................................................15

Conseils pour nettoyer les verres de bière ............................................... 15

2 tests faciles pour nettoyer les verres à bière .........................................15

ENTRETIEN ET NETTOYAGE DE LA FONTAINE DE BIÈRE ........... 17-18

Montage du kit de nettoyage ................................................................17

Nettoyage et entretien général ..............................................................18

KEG CONNECTIONS .......................................................................19

GUIDE DE DÉPANNAGE ............................................................. 20-23

GARANTIE ........................................................................................24

4

Page 30

Français

dÉbAllAgE ET INVENTAIRE dES ACCESSOIRES

1. Retirez tous les matériaux d'emballage y compris le socle en mousse et le

ruban adhésif retenant les accessoires à l'intérieur et à l'extérieur. Sortez

l'équipement en le glissant et retirez le plastique ou la mousse de protection

protégeant le compresseur lors du transport.

2. Inspectez l'équipement et retirez tout matériau d'emballage restant, ruban

adhésif ou documentation avant de mettre sous tension la fontaine à bière.

Remarque: Placez la fontaine à bière debout afin qu'elle soit droite pendant 2

heures avant de la mettre en marche.

Vérifiez tous les accessoires fournis avec le carton et assurez-vous que toutes les

pièces sont en bon état. Reportez-vous à la liste ci-dessous. Si un des accessoires

est en mauvais état ou s'avère manquant, veuillez contacter notre service à la clientèle. Notre numéro d'assistance sans frais est le 1-877-337-3639.

2 Coupleurs de tonnelet

1 Détendeur de CO2, double jauge

1 Cartouche de CO2 de 2,270 kg

1 Kit de nettoyage comprenant : 1 Bouteille de 945 ml avec un bouchon

115 g de poudre nettoyante

1 Robinet/Une brosse à nettoyer

1 Clé (pour installer les robinets de bière au

manchon à pression)

1 Manchon à pression

2 Robinets: 2 Robinets

2 lignes de CO2 rouges

4 Serre-joints

2 Boutons noirs

1 Joint d’étanchéité de 76 mm

1 étrier de fixation pour bouteille de CO2 (Le crochet, la noix, et visser)

1 barre de protection

1 bac ramasse-gouttes

4 roulettes

1 clé

4 vis cruciforme Phillips

8 petites vis cruciforme Phillips

2 étagères métalliques

1 parenthèse se joignante de barillet

5

Page 31

PIèCES ET CARACTÉRISTIqUES

7

86

Français

5

4

3

2

1. Roulettes (4)

2. Support baril interne

3. Coffret

4. Cartouche de CO2

5. Plan de travail

6. Protection en chrome

9

10

11

1

8. Thermostat réglable

(Situé à l’arrière)

9. Bac récolte-gouttes

10. Baril Tonnelets (Non inclus, montré

à des fins d’illustration)

11. Dispositif de raccordement du

tonnelet

7. Double robinets en chrome

6

Page 32

Français

CHOISIR UN bON EmPlACEmENT

• Afin d'être certain que votre fontaine à bière fonctionne à son rendement

maximum, montez-la dans un emplacement présentant une bonne circulation

d'air, des points de raccordement adéquats pour la plomberie et l'électricité.

• Choisissez l'emplacement où vous comptez monter la fontaine à bière en

veillant qu'il soit loin de toute source de chaleur et qu'il ne soit pas en

plein soleil.

• Cette fontaine à bière a été conçue afin d'être utilisée à l'intérieur

uniquement et ne doit en aucun cas être utilisée à l'extérieur en plein air.

• Cette fontaine à bière ne doit pas être placée dans un renfoncement ni

encastrée en aucune façon. Elle a été conçue afin d'être placée seule sans

l'intégrer à un quelconque système.

• Les dimensions suivantes sont les distances de dégagement et de sécurité

autour de la fontaine à bière:

Côtés ............... 3/4 po. (19 mm)

Dessus ................. 1 po. (25 mm)

CONNEXIONS ElECTRIqUES

Fonder Instructions

Cet appareil doit être fondé. En cas d'un court-circuit électrique, fonder réduit le

risque de décharge électrique en fournant un fil d'évasion pour le courant

électrique. Cet appareil est équipé avec une corde contenant un fil fondant et un

bouchon fondé. Le bouchon doit être inséré dans une sortie qui est

convenablement installé et est fondé.

• L'usage déplacé du bouchon peut avoir pour résultat le risque de

décharge électrique.

• Consulter un électricien ou un technicien d'entretien qualifié si les

instructions fondant ne sont pas complètement comprises ou si en doute

si l'appareil a été convenablement fondé.

Conditions d'installation éléctrique

Cet appareil doit être connecté à un 15 Ampli, 115 Volt, 60Hz A FONDE

LA SORTIE.

Note: Où une sortie de deux-broche de norme est rencontrée, c'est la

responsabilité et le devoir personnelle du consommateur pour avoir l'a

remplacé avec un a fondé convenablement la sortie de trois-broche.

Extension Cordes

Nous ne recommandons pas l'usage d'une rallonge avec cette unité.

Alimenter des Interruptions

De temps en temps, il peut y avoir les interruptions de pouvoir en raison

des orages ou les autres causes. Enlever le cordon d'alimentation de la

prise murale quand une coupure de courant arrive. Quand le pouvoir a

7

été restauré, re-bouche le cordon d'alimentation dans la prise murale.

Page 33

Clé plate

Noix

La grande Vis

de Tête de Philip

Petite Vis à

tête phillips

Esquisser

l'Assemblée de Bras

Joint

Canal de bière

Garder la Barre

voler la noix

Poignée

piloter des

Français

INSTRUCTIONS dE mONTAgE

Veuillez lire attentivement et comprendre toutes les instructions d'installation de la

fontaine à bière. Si après avoir terminé le montage, vous n'êtes pas certain que

la fontaine à bière a été correctement installée, nous vous recommandons de

contacter un installateur qualifié.

Montage des Roulettes

Suivez les étapes suivantes pour monter les roues.

1. Videz complètement l'intérieur de la caisse et

placez la fontaine à bière à plat, sur le côté.

Nous vous conseillons de placer un morceau

de carton ou de chiffon sous le caisson afin

d'éviter de rayer ce dernier.

2. Introduisez les roulettes dans les trous des coins inférieurs du caisson. Serrez

chaque roue en tournant l'écrou dans le sens des aiguilles d'une montre avec

la clé fournie.

3. Après avoir serré les quatre roues, placez le caisson debout.

Montage du Robinet de Bière

Suivez les étapes ci-dessous pour monter le robinet de bière.

1. Premièrement, retirez le cache-trou du coffret situé sur le plan de travail.

Saisissez fermement le cache, tournez-le et tirez-le vers le haut.

Remarque: Rangez ce capuchon en lieu sûr car il sera nécessaire pour

convertir le distributeur de bière en distributeur de boissons.

2. Placez le joint d’étanchéité sur les tuyaux au

bas du manchon à pression.

3. Passez les tubes à bière à travers le joint à la

base du manchon à pression.

4. Appuyez sur les deux tuyaux et le tuyau de

sortie de la bière à travers le trou dans le

plan de travail jusqu’à ce que le manchon à

pression soit sur le coffret.

5. Alignez les trous du manchon à pression avec

le joint d’étanchéité et les trous des pilotes sur

le plan de travail.

6. Sécurisez le manchon à pression sur le coffret

en insérant quatre large vis Philips dans les trous et en les serrant fermement.

8

Page 34

Français

Montage de la Barre de Sécurité

Suivez les étapes ci-dessous afin d’installer la

barre de sécurité sur la surface de travail.

1. Positionnez la barre sur le dessus du caisson.

2. Alignez tous les trous de la barre sur ceux du

dessus du caisson.

3. Fixez la barre sur le caisson en utilisant huit

petites vis cruciforme Phillips.

Instructions d'installation

Note: Votre CO2 cylindre est expédié vide pour éviter des accidents possibles

pendant le transport. Quand vous achetez le premier fût de bière, avez

votre CO2 cylindre rempli par votre fournisseur de gaz serré local. (Voir

Soudant la Provision dans lesPages Jaunes)

AVERTISSEMENT!

Le CO2 peut être dangereux ! Les bouteilles de CO2 contiennent un

gaz à haute pression qui peut peut être dangereux si ce dernier

n’est pas manipulé correctement. Ces bouteilles doivent être

manipulées précaution.

Taper le Fût de Bière (le Baril de Type de SanKey américain)

Votre distributeur de bière est fourni avec "l'Attelage de Sankey de

Voilà-Garçon Type américain". Ce nom de marque est le le plus largement

utilisé aux Etats-Unis. Avant d'acheter un fût, un contrôle avec votre distributeur

de bière pour s'assurer qu'un Robinet de Sankey américain peut être utilisé.

(Le remplacement et autre robinet sont disponibles à www.draughttech.com)

Retirez les différentes pièces du carton :

1. (1) Détendeur de CO2, double jauge, double prise

2. (1) Cartouche de CO2 de 2,270 kg

3. (2) Coupleurs de tonnelet

4. (4) Attaches blanches

5. (2) Tuyaux rouges de 122 cm

6. (1) Kit de nettoyage

VÉRIFIEZ QUE VOUS AVEZ BIEN REMPLI LE RESERVOIR DE GAZ.

9

Page 35

ETAPE 1

N’ALLUMEZ PAS ENCORE LE GAZ

Connectez le détendeur de CO2 au

réservoir en utilisant les écrous sur

la valve du réservoir. SERREZ A LA

MAIN. Il n’est pas nécessaire d’utiliser

une clé pour serrer cet écrou.

ÉTAPE 2

Attachez un tuyau rouge à chaque sortie de la valve

au bas du détendeur et fixez bien en utilisant les

attaches blanches fournies.

ÉTAPE 3

Attachez l’autre extrémité des

tuyaux rouges à la pointe la plus

large sur les coupleurs et fixez bien

en utilisant les deux autres

attaches blanches.

Français

C02 Cylinder

Clamp

Red

Hose

Keg Coupler

Large Barb

ÉTAPE 4

Trouvez les deux tuyaux transparents du manchon à pression installé

précédemment. (Ils devraient être à l’intérieur du réfrigérateur.) Attachez un tuyau

à bière transparent à la PETITE pointe de chaque coupleur, en faisant bien

attention de pousser le tuyau bien profondément dans la pointe. Cette connexion

ne nécessite pas d’attache blanche.

Small Barb

Clear Hose

10

Page 36

T

U

R

N

C

L

O

C

K

W

I

S

E

PUSH DOWN

THEN

Français

ÉTAPE 5

Note: Assurer que le corps de l'attelage de fût est dans le fermé

(augmente) la position avant de l'installer sur le fût de bière.

Installez le dispositif de raccordement au premier quart du tonnelet. Placez un

des deux coupleurs sur le bas du premier tonnelet et tournez dans le sens des

aiguilles d’une montre. Pour activer, poussez vers le bas et tournez dans le sens

des aiguilles d’une montre. ASSUREZ-VOUS QUE LES TUYAUX SOIENT AU

DESSUS DU DISPOSITIF DE RACCORDEMENT. Il est normal d’avoir de fines

gouttelettes de bière durant la procédure.

Keg Joining Bracket

1/4 Barrel Keg

ÉTAPE 6

Placez le deuxième tonnelet du haut dans le haut du dispositif de raccordement

du tonnelet et serrez les vis. Placez le coupleur restant sur le tonnelet du haut et

tournez dans le sens des aiguilles d’une montre. Il est normal d’avoir de fines

gouttelettes de bière durant la procédure.

IMPORTANT: Le tuyau rouge et blanc du fût inférieur

devrait être mis en déroute la division de

rthe de ove du crochet joignant selon

l'image.

Note: Etre attelages de fût sûr que les sont

complètement engagés avant insérer de fûts

dans au distributeur de bière

ÉTAPE 7

VOUS POUVEZ A PRESENT OUVRIR LE GAZ ET OUVRIR

LES DEUX POIGNEES NOIRES. Avec un tournevis plat

tournez le détendeur dans le sens des aiguilles d’une

montre jusqu’à ce qu’il soit inscrit sur la jauge

55 kPa (8 PSI).

ÉTAPE 8

Vérifiez maintenant le débit de la bière en appuyant sur les languettes. Utilisez un

récipient pour ne pas que de la bière coule sur l’appareil.

11

Page 37

Support du füt

Füt de Biére

Sou;evez le Füt

Français

ÉTAPE 9

Enlever le mais du boulon de retenue. Utiliser deux vis réparant de retenue pour

obtenir le de retenue aux trous sur le dos du cycliner. Alors glisser le cylindre

bien que le reatiner et l'arpente dans le cabinet. Alors resserrer la noix de

reatiner. Soigneusement pencher la deux combinaison de fûts de bière et reposer

le bord sur le soutien de plancher de fût d'acier inoxydable sur le fond du

cabinet intérieur. Glisser les fûts dans, s'assurant lentement qu'il est

convenablement localisé. CE MAI EXIGE que 2 GENS POUR aient COMPLETE

Note: Si seulement un fût va être dispensé vous doit toujours complète toutes les

étapes ci-dessus mentionnées. Simplement partir un attelage de fût

débranché dans le montant/la position fermée à clef. S'il vous plaît

s'assurer que le noir a éteint des soupapes sont sur le CO2 régulateur est

dans le de la position.

En empilant 2 fûts sont certains installer assurément le fût inclus

joignant le crochet avec le matériel fourni. Assurer que les tuyaux

ne sont pas écrasées par les fûts.

Wing Nut

Retainer

Screw

C02 Retainer

Fixing Screws

Le Message important de Sûreté pour la Bière Pression

Dispense

Quand CO2 est utilisé pour la bière pression dispense, le système doit être

suffisamment protégé contre l'accumulation de pression excessive. Ceci est

accompli par l'a installé déjà deux appareils de sûreté avec la capacité de

soulagement suffisante dans le système.

Les appareils de sûreté sont installés dans les endroits suivants:

A. Sur ou tout de suite en aval du CO2 régulateur.

B. Sur l'attelage de fût.

12

Page 38

Français

l'OPÉRATION dE VOTRE dISTRIbUTEUR dE bIèRE

Bière dispensant

Suivre les étapes au dessous de dispenser la bière.

1. S'assurer que le distributeur de bière est branché sur convenablement à un

120V, 60Hz, 15 Ampli a fondé la sortie de courant alternatif.

2. Placer le plateau de goutte sous le robinet de bière.

3. Ouvrir le robinet de bière en tirant le robinet vers vous rapidement

et complètement dispenser la bière.

Note: Si pour n'importe quelle raison que la bière ne sort pas du robinet, se

référer au dépanner le guide à la page 17.

4. Augmenter la pression si la bière court aussi lentement. A la pression et à la

température correctes, un 10 once. le verre devrait être rempli de 5 seconde.

5. Tenir le verre assure à un 45° l'angle. Quand c'est 2/3 plein, commencer

àredresser le verre. La mousse correcte doit être une tête crémeuse tendue et le

col sur un verre moyen doivent être 3/4" à 1" haut.

Note: C'est normal pour voir former de condensation sur la surface extérieure

du robinet. Il est causé par la différence dans la température entre la

bière froide et les surfaces intérieures du robinet quand la bière coule par

la ligne.

13

Page 39

La Température de Bière de compréhension

• La température recommandée pour servir a refroidi la bière est entre 34° et

38°F. Pour maintenir cette température dans les conditions de pièce de

moyenne de 70°F, régler le thermostat à “Normal.”

Note: Pendant l'été quand les températures sont plus chaudes, nous

recommandons que vous ajustiez le contrôle à un cadre plus frais en

conséquence.

• Choisir et maintenir la température correcte dans le cabinet de réfrigérateur.

Ceci est nécessaire pour maintenir la fraîcheur de parfum de bière.

• La meilleure température pour emmagasiner un fût est entre 38° et 40°F.

• Excessivement froid ou chauffer des températures dans le cabinet

de réfrigérateur peuvent causer une perte de parfum.

Note: La bière aigre est produite à la suite de la fermentation secondaire

au-dessus de 45°F.

La compréhension du Cadre de Régulation de la

Température

La régulation de la température est localisée à l'arrière de

l'unité sur le coin à gauche inférieur. Après avoir allumé

l'unité, vous devez attendre 24 heures pour l'unité pour

refroidir convenablement. Vous pouvez ajuster alors lat

empérature réglant a basé vos besoins et vos préférences.

Français

Dégivrer automatique

Ce n'est pas neccessary pour dégivrer le distributeur/réfrigérateur de bière.

Glacer cela a déposé sur l'évaporateur est automatiquement dégivré quand le

compresseur va à vélo de. L'eau dégivrée recueille dans le plateau de collection

d'eau à l'arrière de l'unité et évapore.

La compréhension Opération Normale Semble

• Le glouglou ou gargouiller semblent de le et les vibrations insignifiantes sont le

résultat du réfrigérant circulant par les bobines de refroidissement.

• Grésillant de ou le son sautant arrivent pendant l'automatique dégivre le cycle.

• Dégouttant des sons arrivent comme la glace fond de l'évaporateur et des fluxs

dans le plateau de collection d'eau pendant l'automatique dégivre le cycle.

• Craquant de ou le son sautant sont causés par l'augmenter et/ou contractant

des bobines de refroidissement pendant l'automatique dégivre le cycle.

14

Page 40

Français

gUIdE POUR SERVIR lA bIèRE

Conseils pour tirer la bière

Les conseils suivants vous aideront à servir une bière parfaite.

Pour servir une bière à partir du robinet de la même qualité que celle tire

directement des cuves de l’usine, verifies les points suivants:

• Propreté • Température

• Pression • Utilisez le CO2 à chaque fois que c’est possible.

Les Combinaisons utilisables de Taille de Fût:

1) Deux 1/4 fûts de baril

2) Deux 1/6 fûts de barils (réduit)

3) Un 1/4 baril (mince) le fût Un 1/6 baril (réduit) le fût

4) Un 1/2 fût de baril

15

Page 41

Français

Conseils pour Nettoyer les Verres de Bière

Pour une fraîcheur optimale, il est important de servir la bière dans des verres

propres. Pour faciliter les choses, les conseils suivants vous expliquent comment

nettoyer correctement les verres avant de servir la bière.

• Ne lavez pas les verres de bière en même temps que les verres ayant contenu

du lait ou toute autre substance grasse.

• Toute accumulation excessive d'agent antiseptique et de germicide dans

laissera une pellicule grasse sur les verres et risque d'éventer la bière et de

rendre plate.

• Lavez les verres attentivement en utilisant un bon liquide-vaisselle afin

de retirer toute trace de corps gras (par ex: rouge à lèvres, etc.)

• N’utilisez pas de savon.

• N’essuyez pas les verres. Laissez les verres sécher à l’air libre en les plaçant

sur un égouttoir ou une tôle ondulée.

• Rincez les verres avec de l’eau propre juste avant de servir la bière. Il est

recommandé de servir la bière dans un verre mouillé.

Deux tests faciles pour nettoyer les verres de bière

1. Lavez les verres en utilisant votre méthode habituelle. Trempez toujours le pied

du verre en premier dans l’eau propre. Videz le verre. Si des gouttes d’eau

collent au verre ou si des traces apparaissent sur le verre lorsque vous videz

soncontenu, le verre n’a pas été lave correctement. Un verre propre devrait

sécher sans laisser de traces.

2. Lavez à nouveau le verre en utilisant votre méthode habituelle. Versez l’eau

contenu dans le verre et saupoudrez du sel dans le verre mouillé. Si le sel ne

colle pas à toute la paroi intérieure du verre et des endroits clairs non-salés

demeurent, le verre n’est pas propre.

16

Page 42

Français

ENTRETIEN ET NETTOYAgE dE lA FONTAINE à bIèRE

Instructions pour l’utilisation du kit de nettoyage

1. Mélangez 3,80 litres d’eau chaude et 30 g de nettoyant dans un seau.

N’UTILISEZ PAS DE SAVON.

2. Retirez le bouchon, remplissez le bocal et réassemblez.

3. Fermez l’air du détendeur et fermez la valve de la cap-

sule de CO2.

4. Déconnectez le coupleur du baril et déconnectez ensuite

la ligne de bière du robinet en tournant l’écrou dans le

sens contraire des aiguilles d’une montre.

5. Retirez le robinet de la tour avec la clé fournie et attachez

à la place

l’accessoire à l’arrière de la bouteille de nettoyage.

6. Tenez la bouteille de nettoyant à l’envers jusqu’à ce que la solution coule dans

le godet. NE PRESSEZ PAS LA BOUTEILLE. CELA PROVOQUERAIT DES FUITES

DE LA SOLUTION.

7. Remplissez la bouteille avec de l’eau tiède et recommencez le processus

jusqu’à ce que l’eau qui coule dans le seau soit de l’eau propre.

8. Rincez le coupleur dans le seau avec le reste de la solution et ensuite dans le

seau avec de l’eau propre.

9. Retirez l’accessoire de nettoyage de la tour et remettez le robinet en place.

Assurez-vous que le nettoyant est à l’arrière du robinet.

10. Rattachez le tuyau de la bière au coupleur et attachez le coupleur au

tonneau.

17

Page 43

Français

Nettoyage et Entretien Général

Nettoyage de l'habillage intérieur et extérieur

1. Préparez une solution de 3 à 4 cuillères de bicarbonate de soude avec de

l'eau tiède. Utilisez une éponge ou un chiffon humidifié de solution afin

d'essuyer les surfaces intérieures et extérieures du caisson.

2. Rincez avec de l'eau propre tiède et séchez avec un chiffon doux.

Remarque: N'utilisez pas de produits chimiques puissants, de produits de

nettoyage abrasifs, de l'eau de Javel, de la lessive au chlore,

des détergents concentrés, de solvants ou des tampons récureurs.

Certains de ces produits risquent de dissoudre, d'endommager et

de décolorer le fini de l'habillage.

Nettoyage du joint de porte

1. Nettoyez le joint de porte avec un chiffon humide tous les trois mois. Le joint

doit demeurer propre et souple afin d'assurer l'étanchéité de la porte.

2. Appliquez une fine couche de vaseline (pétrolatum) sur le côté du joint où se

trouve les charnières afin que ce dernier demeure souple et assure une bonne

étanchéité.

Nettoyage du dos de la fontaine

1. Nous vous conseillons de nettoyer l'arrière du réfrigérateur au moins deux fois

par an.

Remarque: Certains environnements d'exploitation risquent de devoir être

nettoyés plus fréquemment.

2. Utilisez un aspirateur ou une brosse afin de nettoyer les serpentins.

AVERTISSEMENT!

Pour éviter tout risque d'électrocution, débranchez toujours votre

fontaine à bière avant de la nettoyer. Le non-respect de cette

consigne risque d'entraîner des blessures graves voire mortelles.

ATTENTION!

Avant d'utiliser des produits de nettoyage, veillez à toujours lire et

respecter les instructions et les mises en garde du fabricant afin

d'éviter tout risque de blessure et de dommages matériels.

18

Page 44

Français

CONNEXIONS dE FUT

Comment remplace-t-j'un vide C02 réservoir?

1. La soupape proche de tambour de réservoir en tournant dans le sens des

aiguilles d'une montre.

2. Dévisser la Vis de Série d'ajustement (opposé dans le sens des aiguilles d'une

montre) aussi loin qu'il ira et fermera a éteint la soupape.

3. Enlever le régulateur du réservoir vide.

4. Enlever la casquette de poussière du nouveau réservoir plein. Ouvrir et la

soupape proche de tambour rapidement pour souffler de la poussière de la

sortie.

5. Avec la soupape de tambour dans la position fermée, rattacher le régulateur

au réservoir. Etre sûr de vérifier la rondelle, qui est pré-a installé sur le C02

régulateur.

6. La soupape ouverte de tambour complètement. (Ceci est important parce que

cette soupape de tambour scelle dans deux endroits.)

7. Rajuster de la pression régulatrice en tournant la vis de série et ouvre a éteint

la soupape.

Information de réservoir: Le réservoir toujours doit être attaché dans la position

debout. Il prend environ 1/2 livre de C02 pour

dispenser 1/2 fût de baril de bière. Un 5 livre. C02

réservoir doit dispenser entre 8-10 1/2 fûts de baril ou

18-20 1/4 fûts de baril. Le poids plein de 5 livre le

réservoir est appx. Le 17-1/2 livres.

19

Page 45

Français

gUIdE dE dÉPANNAgE

Lorsque vous tirez la bière dans un verre, si vous trouvez que la bière est trouble,

plate, aigre, incontrôlable, pétille ou a un faux-goût, reportez-vous aux conseils

suivants.

État de la bière: la bière est trouble

La bière dans le verre parait trouble, elle n'est pas claire.

Cause no.1

Toute température excessivement basse risque de rendre la bière trouble, surtout

lorsque cette dernière demeure dans un serpentin froid pendant longue période.

Mesure Corrective

• Nettoyez complètement les conduites et augmentez légèrement la température.

Cause no.2

Le robinet de bière n'était pas complètement ouvert.

Mesure Corrective

• Ouvrez rapidement et complètement le robinet.

• Remplacez toute rondelle usée ainsi que les pièces à l'intérieur du robinet

lorsque cela s'avère nécessaire afin que le robinet puisse s'ouvrir

complètement.

État de la bière: la bière est plate

La bière n'a pas son bon goût habituel, son goût n'est pas celui d'une bière

qui provient directement de la brasserie.

Cause no.1

Le verre est sale et graisseux.

Mesure Corrective

• Ne lavez pas les verres de bières avec d'autres verres car ils peuvent avoir

contenu du lait ou toute autre substance grasse.

• Toute accumulation excessive d'agent antiseptique et de germicide dans l'eau

laissera une pellicule grasse sur les verres et risque d'éventer la bière et de la

rendre plate.

• Il est préférable de nettoyer les verres au jet de vapeur (ou dans une autoclave

à vapeur) ou de stériliser les verres lorsque la réglementation le permet.

• Lavez les verres attentivement en utilisant un bon liquide-vaisselle afin

de retirer toute trace de matière grasse (par ex: rouge à lèvres, etc.)

• N’utilisez pas de savon.

• N’essuyez pas les verres. Laissez les verres sécher à l’air libre en les plaçant

sur un égouttoir ou une tôle ondulée.

• Rincez les verres avec de l’eau propre juste avant de servir la bière. Il est

recommandé de servir la bière dans un verre mouillé.

20

Page 46

Français

Cause no.2

La bière n'a pas été tirée correctement dans le verre.

Mesure Corrective

• Ouvrez rapidement et complètement le robinet.

• La mousse devrait être fine et compacte et le col de mousse devrait mesurer

1,9 cm à 2,5 cm d’épaisseur. Une bière tirée sans chapeau de mousse donne

l'impression que cette dernière est plate.

Cause no.3

Il n'y a pas suffisamment de pression.

Mesure Corrective

• Augmentez la pression si la bière coule trop lentement. Le flux de bière devrait

pouvoir remplir un verre de 29 ml en 5 secondes.

• Vérifiez la source de pression afin de déterminer si la conduite d'air est

bouchée ou obstruée.

• Remplacez toute source de pression trop lente ou le régulateur de CO2 et le

manomètre.

• La pression de la bouteille doit toujours être supérieure à celle utilisée avec le

fût de bière.

• Mettez toujours le fût sous pression avant de tirer la bière.

État de la bière: la mousse se détache

La mousse est caractérisée par des grosses bulles semblables à des bulles de

savon et elle tombe rapidement.

Cause no.1

Ce cas est généralement semblable à celui de la bière plate. Voir les raisons et

causes de la bière plate.

État de la bière: la bière a un faux-goût

La bière peut avoir un goût amer ou fade. Elle peut également avoir un goût

huileux ou un mauvaise odeur et un goût déplaisant.

Cause no.1

Le robinet n'a pas été nettoyé correctement.

Mesure Corrective

• Brossez et nettoyez correctement le robinet. Récurez-le en utilisant

un détergent, puis rincez-le à l'eau claire.

Cause no.2

Ligne de gaz contaminée

Mesure Corrective

• La conduite gazer la ligne doit être examinée. Si elle est contaminée, elle doit

être impérativement remplacée.

21

Page 47

Français

Cause no.3

La conduite gaz est d'un type erroné.

Mesure Corrective

• Un tuyau en caoutchouc absorbera et conservera les odeurs. Etre sûr que vous

utilisez les tuyaux fournis avec votre unité.

Recommandations Générales en cas de Faux-goût:

Les conduites de bière doivent être rincées après chaque fin de fût. Veillez à ce

que le périmètre autour de la fontaine à bière demeure propre. La fumée, les

odeurs de cuisine et les désinfectants nuiront au goût et à la saveur de la bière.

Ces conditions peuvent être causées par la source d'air ou par le contact direct

avec le verre lorsque vous servez la bière.

État de la bière: la bière est aigre

La bière a un fort goût de levure et une forte odeur de levure ou de moisi.

Cause no.1

Les fûts n'ont pas été transportés correctement. La bière qui est livrée sur un

camion ouvert pendant les chauds mois d’été risque de provoquer seconde

fermentation.

Mesure Corrective

• Si possible, faites-vous livrer des fûts de bière par camion frigorifique fermé.

Si la livraison est effectuée par un camion ouvert, couvrez les fûts de bière

avec une bâche afin de les protéger contre la chaleur de l'été.

État de la bière: bière incontrôlable.