Page 1

SERVICE MANUAL

jury

Order No.: Ref1110S003V0

MODEL:

HBCW100ABB

HVFE040BBB

This service information is designed for experienced repair technicians only and is not designed for use by the general

public. It dose not contain warnings and cautions to advice non-technical individuals of potential dangers in attempting

to service a product. Product powered by electricity should by serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone

else could result in serious in

All right reserved. Unauthorized copying and distribution is a violation of law.

WARNING

or death.

Ƽ2011 (HAIER ELECTRICAL APPLIANCES COR. LTD)

Haier Group

Page 2

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Contents

Issue 2011-10-21

Rev.

Ref1110S003V0

Table of Contents ·········································································································· 2

1. General Information ···································································································3

1-1. General guideline ································································································ 3

1-2. Insurance test ······································································································ 3

1-3. How to read this Service Manual ········································································ 4

2. Product Feature ········································································································· 5

2-1. Specifications ······································································································ 5

2-2. External views ····································································································· 7

Installation, adjustments and maintenance

3.

3-1. Installation ········································································································· 8

3-2. Maintenance ····································································································· 9

4. Disassembly ··············································································································· 10

4-1. Door ···················································································································· 10

4-2. Light and Display Panel ······················································································ 11

4-3. Main Control Panel ····························································································· 12

5. Control principle of electronic component ····························································· 13

······················································ 8

2

5-1. Control and Display Panel ··············································································· 13

5-2. Function Schedule ··························································································· 13

5-3. Function Adjustment and Control Principles ···················································· 13

5-4. Failure Code Display ······················································································· 14

6. System flow principle ································································································ 16

6-1. Refrigeration flow chart ···················································································· 16

6-2. Compressor’s Starting and Stopping Control ··················································· 16

7. Circuit diagram ·········································································································· 17

7-1. Circuit Diagram ································································································· 17

7-2. Connection Sketch Map ··················································································· 18

8. Trouble shooting ······································································································· 19

8-1. Normal Problems ······························································································ 19

8-2.Compressor parameter ····················································································· 20

8-3.Abnormal Problems ··························································································· 21

Page 3

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Issue 2011-10-21

Rev.

Ref1110S003V0

Chapter 1 General Information

1-1. General Guidelines

When servicing, observe the original lead dress. If a short circuit is found, replace all parts which

have been overheated or damaged by the short circuit. After servicing, see to it that all the protective

devices such as insulation barriers, insulation papers shields are properly installed. After servicing,

make the following leakage current checks to prevent the customer from being exposed to shock

hazards.

1) Leakage Current Cold Check

2) Leakage Current Hot Check

3) Prevention of Electro Static Discharge (ESD) to Electrostatic Sensitive

1-2.Insurance Test

1. Check if there is any leak of current.

2. Cut out the power supply before the repair to avoid an electrical shock hazard.

3. In the case of a live-line test, insulating gloves should be worn to avoid potential electrical

shock.

4. Confirm the rated current, voltage and capacity before testing with any kinds of instruments.

5. Watch if the upper door is open when you check something at a lower position.

6. Take out every part in the cabinet before moving the machine, especially things like panels (e.g.

glass shelf).

7. Please wear intact cotton gloves when repair any parts of the evaporator, so that scratches by

the sharp fins can be avoided.

8. If there is a breakdown with the refrigeration system, please surrender the machine to the

service center, else the leaked refrigerant may pollute the atmosphere.

9. The refrigerator use AC of 115V with a frequency of 60Hz.

10. A big fluctuation of voltage may cause a start failure of the refrigerator, a burn-out of the control

panel and compressor, or an abnormal sound from the compressor in operation.

11. Take care not to damage the supply line. Don’t yank at the line; pull the plug out gently from the

receptacle. Don’t press the line under the cabinet or step on it. Take care not to roll on or

damage the supply line when moves the machine from the wall.

12. In the case of leakage of inflammable gases like carbon monoxide, open the door and windows.

Don’t pull out or insert the plugs of the appliance.

13. Don’t touch the refrigeration surface of the freezing compartment when the refrigerator is in

operation, especially when your hand is wet, else you may be glued to the surface.

14. Pull out the plug of power supply during clearance or power outage. Wait at least five minutes to

resume the power supply in order to prevent damage to the compressor caused by continuous

restart.

3

Page 4

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Issue 2011-10-21

Rev.

Ref1110S003V0

. Photo used in this manual

The illustration and photos used in this Manual may not base on the final design of products, which

may differ from the products in some way.

1-3. How to read this Service Manual

The meaning of each icon is described in the table below:

Note:

A “note” provides information that is not indispensable, but may nevertheless be valuable to the

reader, such as tips and tricks.

Caution:

A “caution” is used when there is danger t, through incorrect manipulation, may damage equipment,

loose data, get an unexpected result or has to restart (part of) a procedure.

4

Warning:

A “warning” is used when there is danger of personal injury.

Reference:

A “reference” guides the reader to other places in this binder or in this manual

Page 5

SERVICE MANUAL

+%&:$%% +9)(%%%

Model: HBCW100ABB/HVFE040BBB

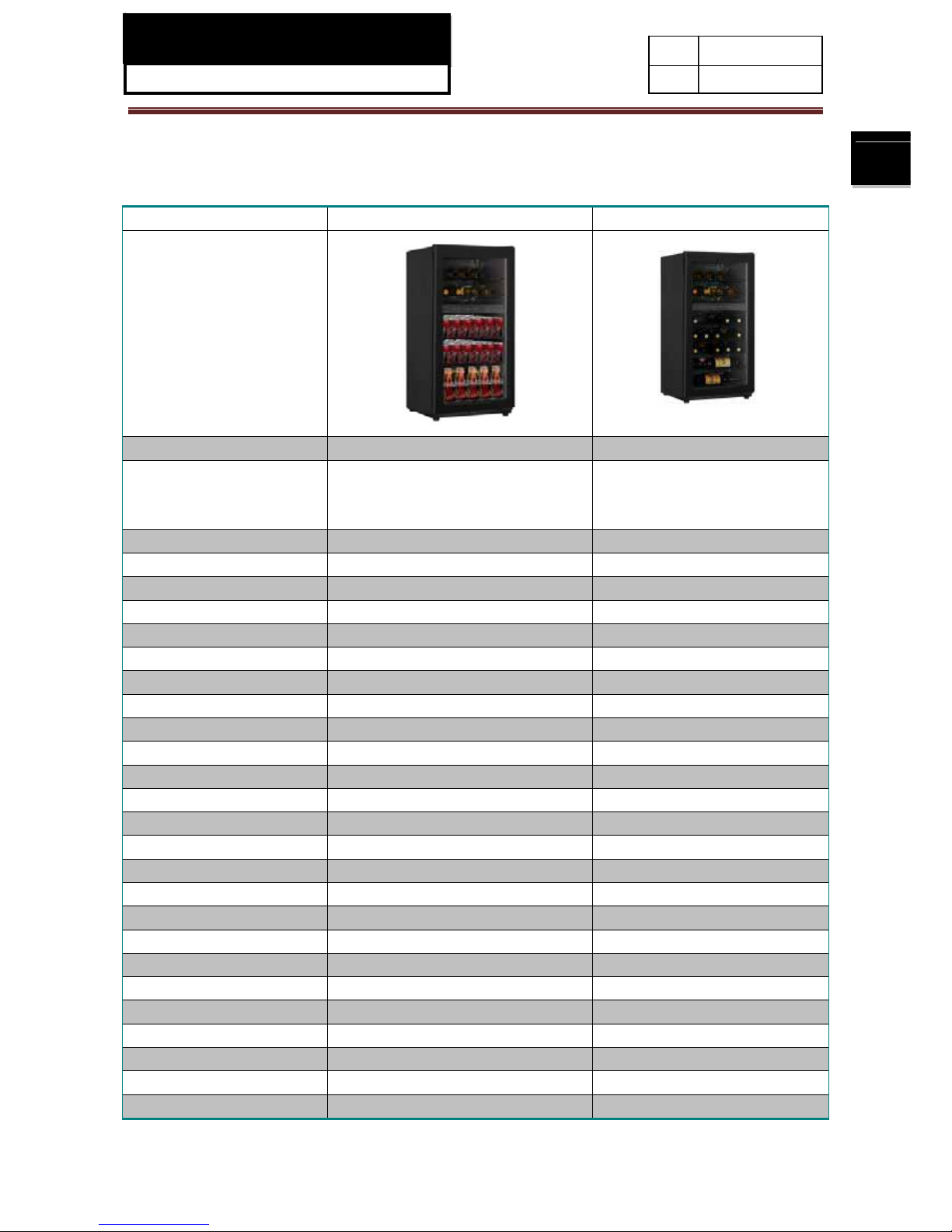

Chapter 2 Product Feature

2-1. SPECIFICATIONS

Issue 2011-10-21

Rev.

Ref1110S003V0

5

Model

PHOTO

Features

Capacity (Bottles)

Capacity (cubic feet) 4.1 4.1

Temperature Control Type Dual Zone Electronic Electronic

Led Display

Temp Level Display Yes Yes

Interior light Manual Manual

Door Type

Automatic Door Stop Yes Yes

Storage Racks QTY 4 7

Cabinet color Black Black

Interior Liner Color Black Black

Installation Type Free Standing Free Standing

Leveling Legs Yes Yes

Storage Compartments Two Two

Performance Data

Electrical Requirements ( v/Hz)

Amps

Start Up Amps

Temperature Setting Range

Min/Max Ambient Temperature

Technical Details

Door Insulation

Type Of Refrigerant Used

Ventilation ( Rear/Side/Front)

Number Of Lights

Type Of Light Bulb

Upper zone˖16 Bottles

Bottom zone˖ 60 Coke cans & 15

Coke Bottles

Flat

Full View Glass

115V~/60Hz 115V~/60Hz

1.75A 1.5A

10.0 (max) 10.0 (max)

Full View Glass

40

1-18°C 6-18°C

Double Pane Tempered Glass Double Pane Tempered Glass

R134a R134a

Rear Rear

1 1

LED LED

Flat

Page 6

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Issue 2011-10-21

Rev.

Ref1110S003V0

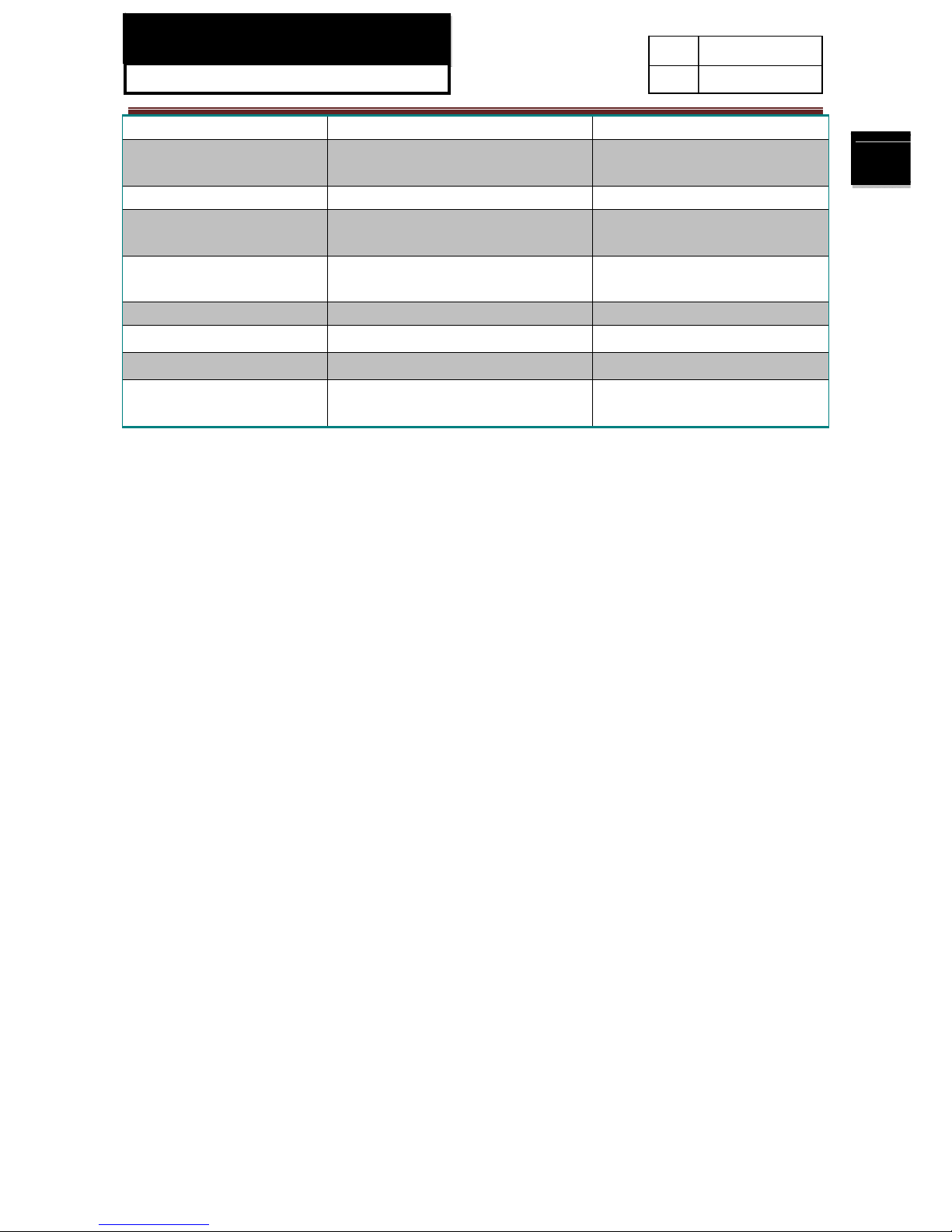

Dimensions

Unit dimensions

(H / W / D)mm

Net weight 45kg 45kg

Packing dimensions & load

ability

Packing dimensions (H /

W / D)mm

Gross weight 50kg 50kg

40 ' High cube container load 156pcs

Service

User instruction

(languages)

970/500/550 970/500/550

1040/568/640 1040/568/620

156pcs

English English

6

Page 7

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

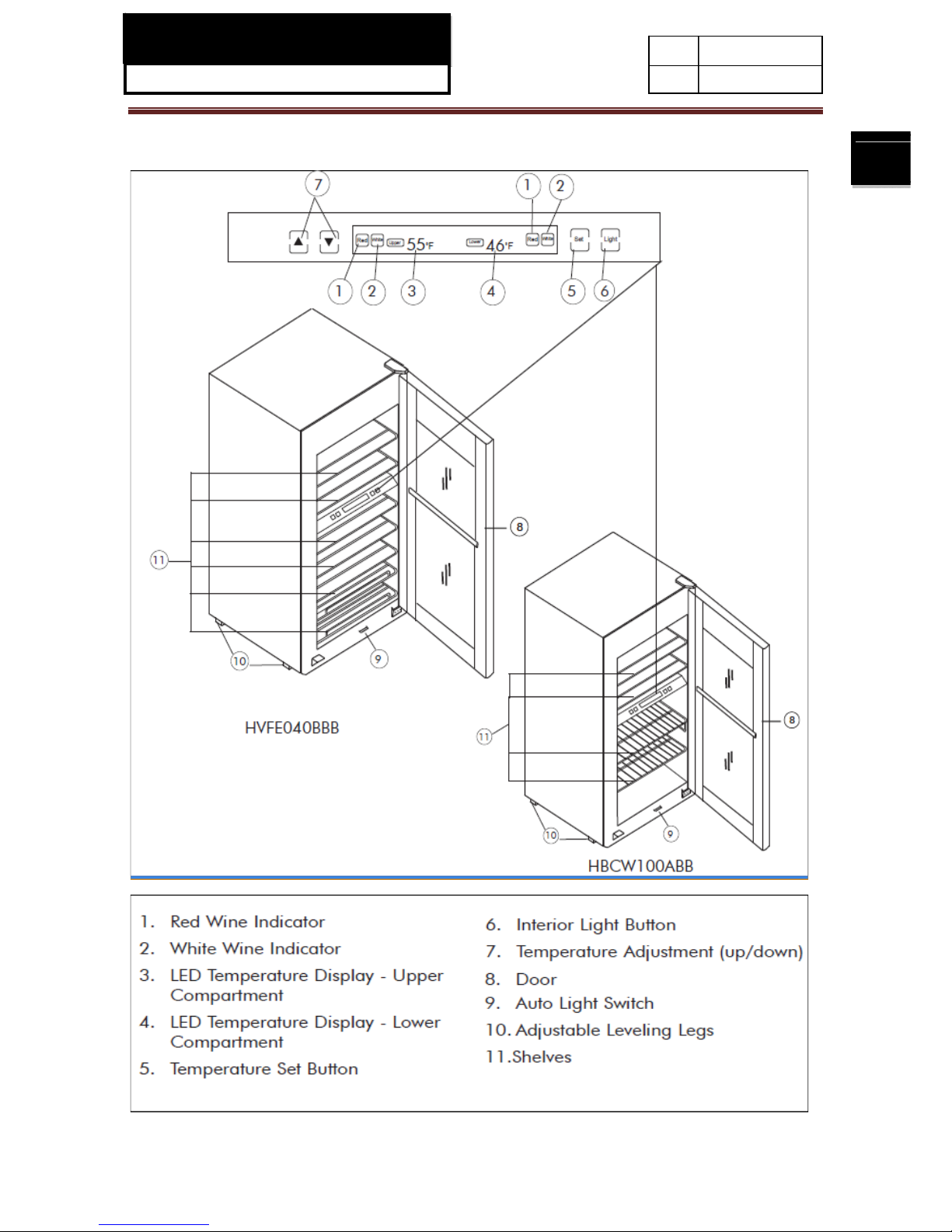

2-2. External views

Issue 2011-10-21

Rev.

Ref1110S003V0

7

Page 8

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Issue 2011-10-21

Rev.

Ref1110S003V0

Chapter 3 Installation, adjustments and maintenance

3-1. Installation

8

3-1-1.Unpacking the Unit:

Remove all packaging material. This includes the foam base and all adhesive tape holding the

Unit accessories inside and outside, compressor from shipping damage due to vibration and

shock.

Inspect and remove any remains of packing, tape or printed materials before powering on the

Unit.

3-1-2.Leveling the Unit:

The Unit has four leveling legs which are located in the front and rear corners of the Unit. After

properly placing the Unit in its final position, you can level the Unit.

Leveling cellar or by turning them clockwise to lower the unit, the unit door will close easier when

the leveling legs are extended.

Proper Air Circulation

1. To assure the unit works at the maximum efficiency it was designed for, you should install it in

a location where there is proper air circulation, plumbing and electrical connections.

2. The following are recommended clearances around the unit:

Sides…………..2” (50mm)

Top ……….……2” (50mm)

Back…………..2” (50mm)

3. Do not over fill the unit for proper internal air circulation.

3-1-3.Electrical Requirement

Make sure there is a suitable power outlet (115~V) with proper grounding to power the unit.

Avoid the use of three plug adapters or cutting off the third grounding in order to accommodate a

two plug outlet, this is a dangerous practice since it provides no effective grounding for the unit

and may result in shock hazard.

3-1-4.Install Limitations

Do not install the unit in any location not properly insulated or heated e.g. garage etc, the unit was

not designed to operate in temperature settings below 55 eFahrenheit.

Select a suitable location for the unit on a hard even surface away from direct sunlight or heat

source e.g. radiators, baseboard heaters, cooking appliances etc, any floor unevenness should

be corrected with the leveling legs located on the front and rear bottom corners of the unit.

The unit is designed for free-standing installation only; it is not designed for built-in application.

Page 9

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

3-1-5. Net Dimension

Issue 2011-10-21

Rev.

Ref1110S003V0

w

`

Model

Unit Dimension(W*D*H) 500*550*970

HBCW100ABB/ HVFE040BBB

D

9

H

3-2. Maintenance

To avoid electric shock always unplug the unit before cleaning, ignoring this warning

may result in death or injury.

General:

z Prepare a cleaning solution of 3-4 tablespoons of baking soda mixed with warm water, Use

sponge or soft cloth, dampened with the cleaning solution, to wipe down the unit.

z Rinse with clean warm water and dry with a soft cloth.

z Do not use harsh chemicals, abrasives, ammonia, chlorine bleach, concentrated detergent

solvents or metal scouting pads, some of these chemical may dissolve, damage and/or

discolor the unit.

Door Gaskets:

z Clean door gaskets every three months according to general instructions, Gaskets must be

kept clean and pliable to assure a proper seal,

Petroleum jelly applied lightly on the hinge side of gaskets will keep the gasket pliable and assure

a good seal

Page 10

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Chapter 4 Disassembly

4-1. Door

1. Remove the top hinge cover with flat screwdriver

Issue 2011-10-21

Rev.

Ref1110S003V0

10

2. Remove the screws fixed the top hinge with screwdriver and then lift the door, the door will be

removed.

4-2. light and the display panel

The light and the display panel both are in the electronic box which is on the middle of the

wine cellar.

Page 11

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

1. The middle partition is fixed on the cabinet with two screws, so you should loosen the screws

and take off the middle partition from the unit.

2. Then make the up lid , foam , low lid separate from the middle partition

3. Dissemble the lampshade from the low lid, and loosen the screws fixed the LED light.

4. Loosen the screws which fixed on the display panel.

Issue 2011-10-21

Rev.

Ref1110S003V0

The middle part

11

Page 12

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

4-3. Main control panel

Issue 2011-10-21

Rev.

Ref1110S003V0

1. Remove the cover of the cabinet which is on the back of the unit

2. Remove the screws which fix the main control panel box.

3. The main control panel is fixed in the panel box by a screw, dismantle it ,the control panel will

be removed

12

Page 13

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Chapter 5 Control and display system

5-1.Control and display panel

Issue 2011-10-21

Rev.

Ref1110S003V0

13

Once we plugged the unit, it needs to run for 30 minutes at least to acclimate itself before any

adjustments. During this time, depending on the internal temperature, the red or white wine

light will stay on for the upper compartment and red or white wine light will stay on for the

lower. The LED display will show the current internal temperature.

Page 14

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

5-2.Function Schedule

Button Function

Issue 2011-10-21

Rev.

Ref1110S003V0

14

Temperature adjustment up

Temperature adjustment down

Control the LED light

Temperature adjustment & enactment

5-3. Function adjustment and control principles

5-3-1 Temperature Adjustments:

1. Wine cellar (HVFE040BBB): It can be set to any temperature between 39and 65F in either of

the compartments to accommodate your wine storage requirements.

2. Wine/Beverage center(HBCW100ABB):The upper compartment can be set to any

temperature between 46and 65F;the lower compartment cab be set to any temperature

between 34and 62F

3. To set the temperature, hold the “ ” button for about 3 seconds. You will notice the

temperature display blink for the upper compartment. Press the” ” or “ “button to

increase or decrease the temperature setting, Once the desired temperature is attained,

press the “ ” button, Doing this, the electronic control panel will revert back to display

the inside temperature. It may take some time to reach the set temperature.

5-3-2 Light Adjustments

To complement the look of your wine collection, soft light has been built into the wine cooler.

Simply push the “ “button on the electronic controlled unit, and the light comes on,

push again for off. If you want to leave the light on always after closing the door, simply push

the “ “button, before closing the door leave light off when not viewing your collection.

Page 15

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

5-4. Failure code display

Issue 2011-10-21

Rev.

Ref1110S003V0

Some times the display works out of orders, reading the following contention may give you

some help.

Failure code display

Error

code

display

LL

HH

EE

Description and reason Solutions

“LL” blinks with buzzing; That means the

related compartment temperature is lower

than -5°C

“HH” blinks with buzzing; That means the

related compartment temperature is higher

than 50°C

“EE” is the abbreviation of “ERROR,

ERROR”; It is something wrong with the

sensors. Usually, the sensor circuit is

broken.

Stop the unit running until the

temperature rises up; Don’t use

the unit in lower temperature

environment if necessary.

Don’t use the unit in high

Check the sensor if connects

well with the main control panel

or find the location of the sensor

broken circuit and repair it.

environment

15

Buzzing sound we may hear when “LL” or “HH” or “EE” appears on the display panel, to

remove the buzzing sound ,we can press the ” ” button.

Page 16

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Chapter 6 System flow principle

6-1. Refrigeration Flow System Chat

HYDSRUDWRUXS

HYDSRUDWRU

GRZQ

Issue 2011-10-21

Rev.

Ref1110S003V0

16

FRQGHQVDWRU

Explanation: The electromagnetism valve includes two single valves. When the two

compartment temperature does not reach the set temperature, the two valves are keeping open;

when one compartment temperature reaches the set temperature, the related valve is closed and

the other one is keeping open. Both the two compartments temperature reaches each set

temperature; the valves don’t close but the compressor stop working.

6-2.Compressor’s starting and stopping control

Form: The temperature display & the compressor’s and valves’ working status

Set

ć

Actual ć

Working 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Not working 3 4 4 5 6 7 8 9 10 11 12 13 14 15 16

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

ILOWHU

HOHFWURPDJQHWLVP

YDOYH

Temperature

display

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Page 17

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Chapter 7 Circuit diagram

7-1.Circuit Diagram

Issue 2011-10-21

Rev.

Ref1110S003V0

17

Page 18

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

7-2.Connection Sketch Map

Issue 2011-10-21

Rev.

Ref1110S003V0

18

Page 19

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Issue 2011-10-21

Rev.

Ref1110S003V0

Chapter 8 Trouble shooting

8-1. Normal Problems

8-1-1 Sounds of Unit

1. Boiling water, gurgling sounds or slight vibrations that are the result of the refrigerant

circulating through the cooling coils.

2. The thermostat control will click when it cycles on and off.

8-1-2Temperature of Unit

Too warm

1. Frequent door openings.

2. Allow time for recently added wine to reach desired temperature.

3. Check gaskets for proper seal.

4. Clean condenser coils.

5. Adjust temperature control to colder setting.

19

Too cold

1. If temperature control setting is too cold, adjust to a warmer setting.

8-1-3 Unit runs too frequently

1. This may be normal to maintain constant temperature during high temperature and humid days.

2. Doors may have been opened frequently or for an extended period of time.

3. Clean condenser coils,

4. Check gasket for proper seal.

5. Check to see if doors are completely closed.

8-1-4

1. This is normal during high humidity periods.

2. Prolonged or frequent door openings.

3. Check door gaskets for proper seal.

Moisture builds up on interior or exterior of the unit:

Page 20

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

8-2.Compressor parameter

Issue 2011-10-21

Rev.

Ref1110S003V0

Part Name Ambient temperature 25°C

Compressor

Starter(PTC)

Overload

protector

model Main Wiring Auxiliary Wiring

AS35U6

Model

Resistance 4.7f20%

Max working

voltage

Max running

current

Model

Operate

temperature

Revert

temperature

Normal 4.6 9.4

20

QP2-4.7G

180 V

12 A

B77-120

120f5ć

61f8 ć

Page 21

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

8-3.Abnormal Problems

Issue 2011-10-21

Rev.

Ref1110S003V0

8-2-1. Compressor doesn’t start

21

Page 22

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

8-2-2.Poor cooling

Issue 2011-10-21

Rev.

Ref1110S003V0

Poor cooling

Check the diaplay temperature

nomber whether it is setted at 18°C

Y

Whether the rear side and the top is

too close to the wall

Y

Whether the cellar is under

sunlight directly

Y

Whether the cellar is near thermal

source

Y

22

N

N

N

Change to lower

Avoid these

matters which

will affect heat

radiation of

condenser and

reduce

refrigeration

ability

Whether the room temperature is

too hoot or not

Y

Whether the condenser is blocked

by cloth pieces or paper or dirt or

not

Y

Whether the glass door has been

closed well

Y

Whether the glass door door seal

bar is too dirty or sealed well

Frequent opening and extended

opening of glass door will reduce

refrigeration ability

N

N

Remove dirt and put on a little

talcum power

Page 23

SERVICE MANUAL

Model: HBCW100ABB/HVFE040BBB

Sincere forever

Issue 2011-10-21

Rev.

Ref1110S003V0

23

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...