Page 1

Installation & Operation Manual

Air Handler

13 SEER 2 3 4 5 Ton

WARNING

WHEN THIS APPLIANCE IS INSTALLED IN AN ENCLOSED AREA, SUCH AS

A GARAGE OR UTILITY ROOM, WITH ANY CARBON MONOXIDE PRODUCING

DEVICES (i.e. AUTOMOBILE, SPACE HEATER, WATER HEATER,ETC.) INSURE

THAT THE ENCLOSED AREA IS PROPERLY VENTILATED.

WARNING

CARBON MONOXIDE (REFERED TO AS CO) CAN CAUSE PERSONAL INJURY

OR DEATH

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS, LOCAL CODES OR NATIONAL

CODES MAY CAUSE FIRE, EXPLOSION, ELECTRICAL SHOCK, PERSONAL

INJURY OR PROPERTY DAMAGE.

FOLLOW ALL LOCAL CODES. IN THE ABSENCE OF LOCAL CODES REFER TO :

NATIONAL ELECTRICAL CODE NFPA 70

NFPA 90A & 90B

UNIFORM MECHANICAL CODE

READ THESE INSTRUCTIONS COMPLETELY BEFORE ATTEMPTING TO INSTALL

OR SERVICE THIS APPLIANCE.

ONLY FACTORY AUTHORIZED KITS OR ACCESSORIES SHOULD BE USED WHEN

INSTALLING OR MODIFYING THIS APPLIANCE, UNLESS OTHERWISE NOTED IN

THESE INSTRUCTIONS.

SOME LOCALITIES MAY REQUIRE THE INSTALLER/SERVICER TO BE LICENSED.

IF IN DOUBT CONTACT YOUR LOCAL AUTHORITIES.

These instructions should be retained and kept adjacent to the unit for future reference.

MODEL # HB M20 HB

MODEL # HB V20 HB

M22

V22

INSTALLATION DATE

The information contained in this booklet is subject to change without notice.

No. 0010572323

G

Page 2

INDEX

TOPIC PAGE

General

Physical dimensions

Replacement Parts Source

Installation Requirements

Air Flow Orientation

Horizontal Left-Hand Instructions

Refrigerant Tubing

Condensate Removal

Electrical Connections

Thermostat Wiring

Orifice Change

Circulating Air Duct

Blower Performance

Start-up

Regular Maintenance

Model Number Explanation

2

3

6

6

7

8

9

10

10

11

12

14

14

15

15

16

The United States Environmental Protection Agency (EPA) has issued various regulations

regarding the introduction and disposal of refrigerants introduced into this unit.Failure to follow

these regulations may harm the environment and can lead to the imposition of substantial fines.

These regulations may vary due to the passage of new laws, it is recommended that any work

on this unit be done so by a certified technician. Should questions arise contact the local EPA

office.

THIS APPLIANCE IS NOT APPROVED FOR OUTDOOR INSTALLATION

THIS APPLIANCE IS NOT TO BE USED AS A CONSTRUCTION HEATER

GENERAL

This appliance was designed certified and must be installed in accordance with published

codes.In the absence of local codes please refer to the following codes:

NFPA 90A NFPA 90B

National Electrical Code NFPA 70

Uniform Mechanical Code

Prior to shipment, this appliance was tested and inspected for damage at the factory.Unpack

carefully and if damage is found, report it immediately to the transportation company.

This appliance is approved for installation in alcoves, basements, attics or crawlway, and is

designed for connection to air distribution ductwork.

2

Page 3

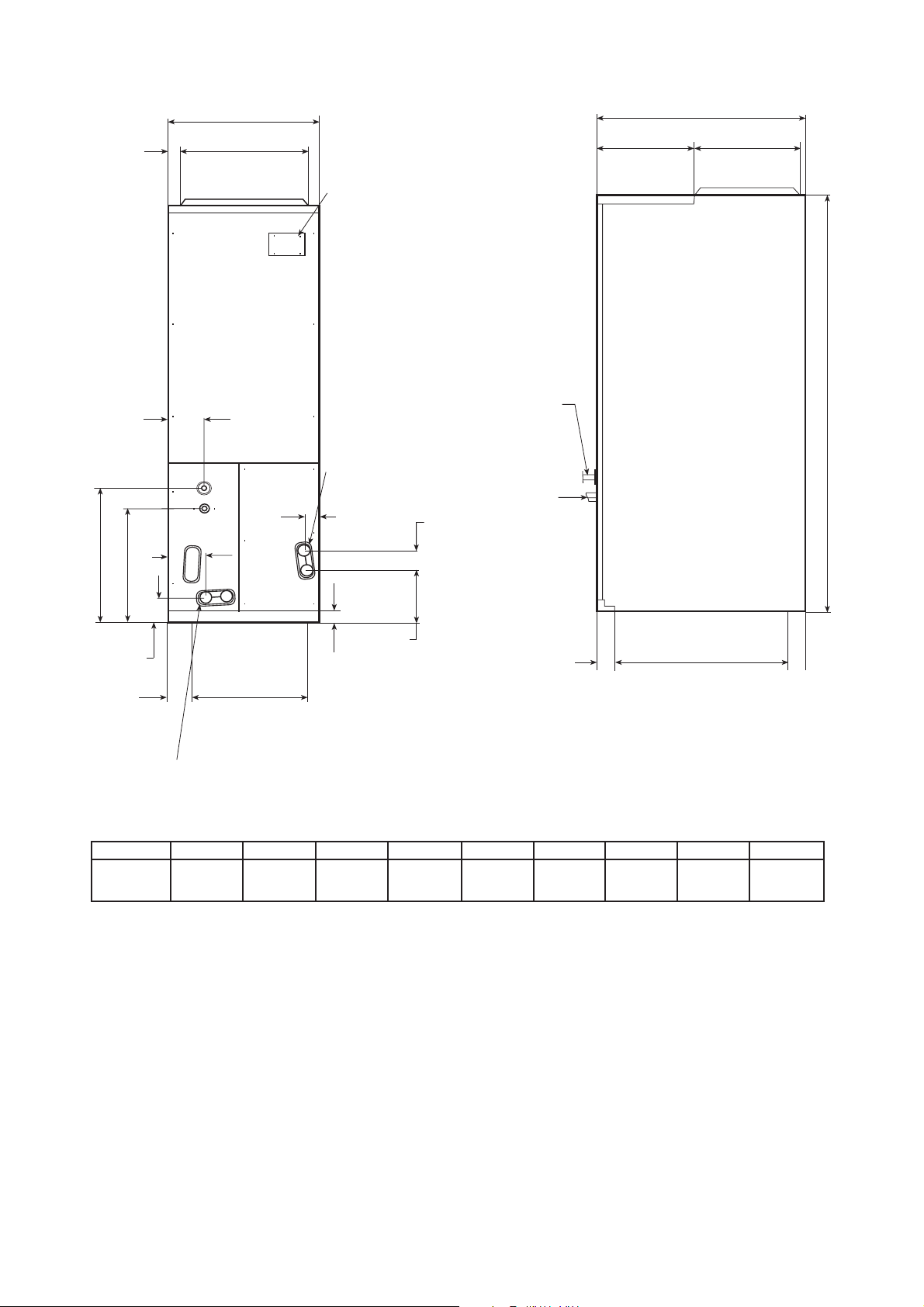

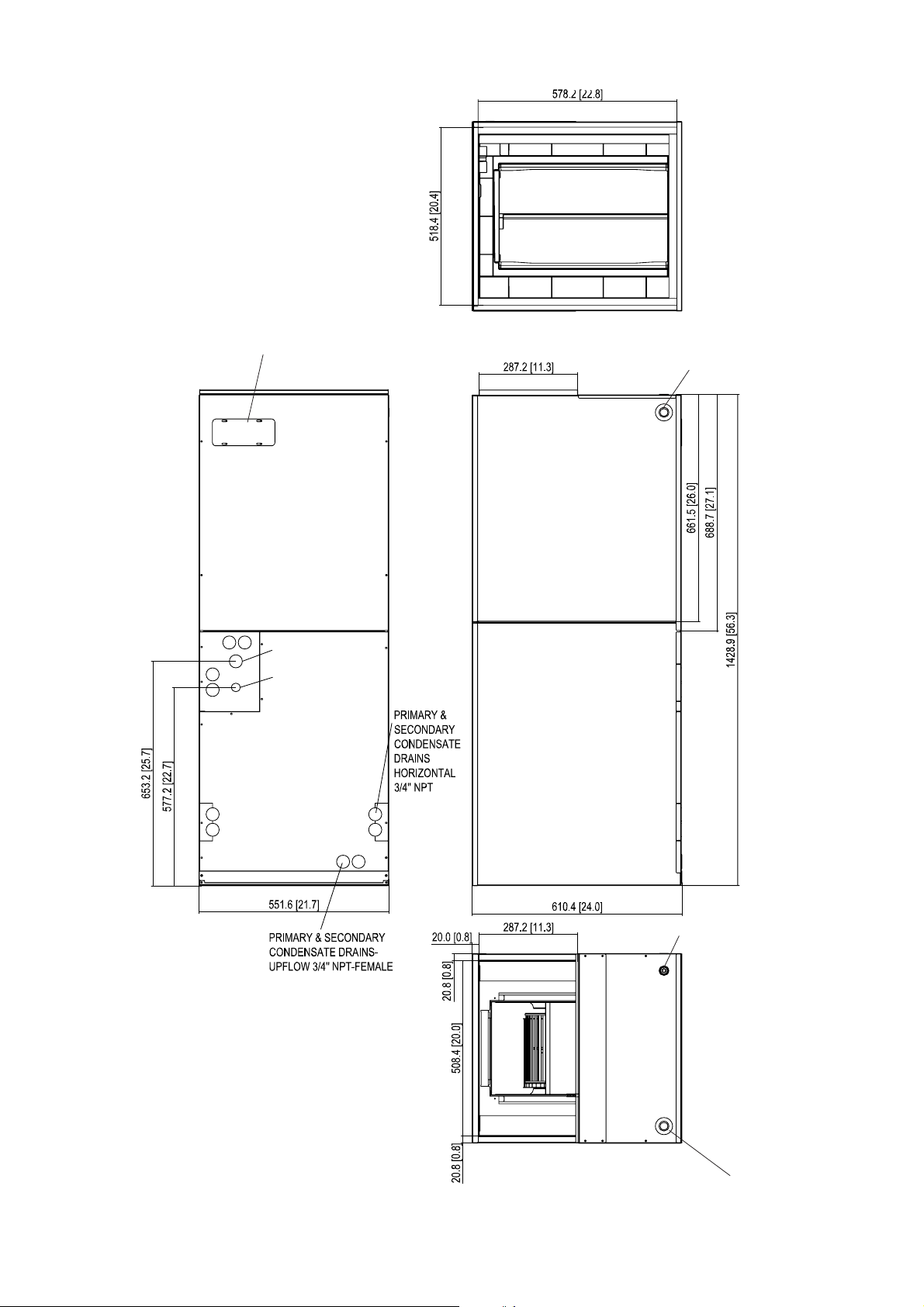

PHYSICAL DIMENSIONS

D

1"

[2.54 cm]

C

of 2 Ton

PLASTIC BREAKER COVER

B

E

11"

[29 cm]

3.3"

[8.3 cm]

F

2.4"

[ 6 cm]

1.2"

[3 cm]

SUCTION LINE

PRIMARY & SECONDARY

CONDENSATE DRAINS-

HORIZONTAL 3/4" NPT

2"

[5.1 cm]

K

G

H

INLET

FRONT VIEW

PRIMARY & SECONDARY

CONDENSATE DRAINS-

UPFLOW 3/4" NPT-FEMALE

1.1"

[2.9 cm]

5"

[12.7 cm]

2"

[5.1 cm]

TYPICAL

LIQUID LINE

1"

[2.54 cm]

J

INLET

RIGHT SIDE VIEW

A

A B C D E F G H J K

46.7 22 18.3 19.7 10 14.5 11.9 17.1 19.8 3.4

[118.7cm] [55.9cm] [46.4cm] [50.0cm] [25.4cm] [36.8cm] [30.3cm] [43.5cm] [50.3cm] [8.6cm]

3

Page 4

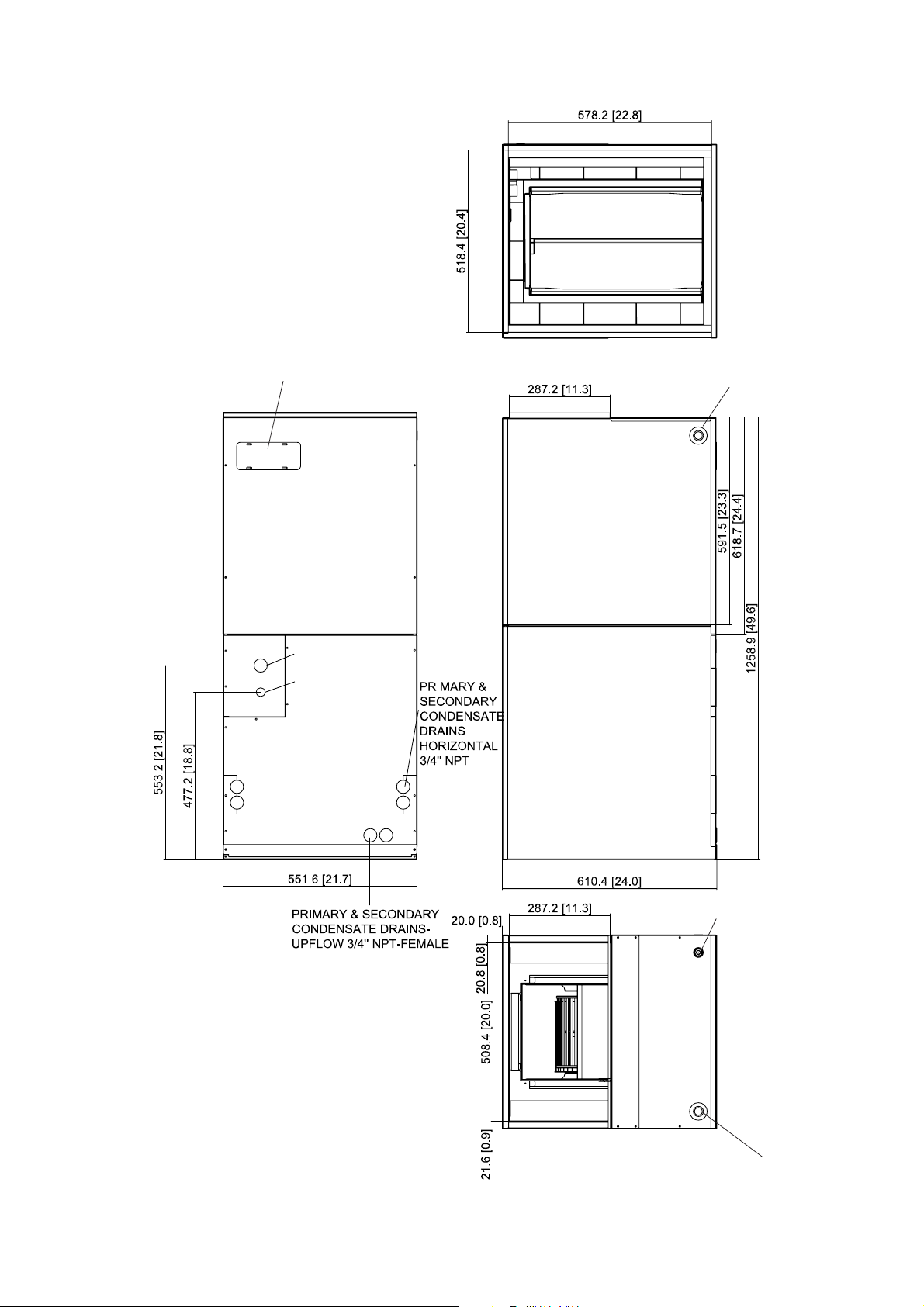

PHYSICAL DIMENSIONS

PLASTIC BREAKER COVER

of 3 Ton

INLET BOTTOM SIDE VIEW

ELECTRICAL POWER SUPPLY

SUCTION LINE

LIQUID LINE

LOW VOLT SUPPLY

ELECTRICAL POWER SUPPLY

4

Page 5

PHYSICAL DIMENSIONS

PLASTIC BREAKER COVER

of 4,5 Ton

INLET BOTTOM SIDE VIEW

ELECTRICAL POWER SUPPLY

SUCTION LINE

LIQUID LINE

LOW VOLT SUPPLY

ELECTRICAL POWER SUPPLY

5

Page 6

REPLACEMENT PARTS SOURCE

Replacement parts are available through local distributors.When ordering replacement parts, give

the COMPLETE model and serial numbers shown on the rating plate.

INSTALLATION REQUIREMENTS

Before installing this appliance insure that it is properly sized and adequate power is available.

This appliance can be installed in the vertical or right horizontal position without modification.

The horizontal left and downflow positions require product modification.

This product is designed for zero inch (0") clearance; however, adequate access for service or

replacement must be considered without removing permanent structure. This unit can be installed

on a platform when deemed necessary.

In an attic installation a secondary drain pan must be provided by the installer and placed under

the entire unit with a separate drain line properly sloped and terminated in an area visible to

the owner. This secondary drain pan is required in the event that there is a leak or main drain

blockage. Closed cell insulation should be applied to the drain lines in unconditioned spaces

where sweating may occur.

Appliances installed in garages, ware houses or other areas where they may be subjected to

mechanical damage must be suitably guarded against such damage by installing behind protective

barriers, being elevated or located out of the normal path of vehicles. When installed on a base,

the base must also be protected by similar means.

Heating and cooling equipment located in garages, which may generate a glow, spark or flame

capable of igniting flammable vapors, must be installed with the ignition source at least 18"

above the floor level.

When more than one appliance is installed in a building, permanently identify the unit as to

the area or space serviced by that applice.

6

Page 7

AIR FLOW ORIENTATION

*Horizontal Right Discharge

Tube and Drain conn. front

Horizontal Left Discharge

Tube and Drain conn. front

(see page 6)

Important:

Remove the horizontal pan when

unit is installed in unconditioned

i.e. (Garage, Attic ) application,

or downflow applications, and

install insulation kit on vertical

( donut shape ) drain pan.

*Upflow Discharge

*Air Handler is factory ready for Upflow & Horizontal Right Discharge Application for 3*4*5 as shown.

*Air Handler is factory ready for Upflow & Horizontal Left Discharge Application for 2 as shown.

7

Page 8

HORIZONTAL LEFT-HAND INSTRUCTIONS

Important: Read instructions below carefully.

Plastic

Drain

cover

Fig.1

oval

gasket

WARNING:

If incorrect knockouts are removed, flooding will occur.

5) Reinstall in the Airhandler, the "A" coil pan assembly with the horizontal drain pan on the

left-hand side.

Note:

Push the assembly completely to the rear of the cavity and assure it slips into channel

bracket at the rear of the cavity.

6) Replace the J-shape metal bracket or brackets on the vertical drain pan and place the

plastic oval gasket on horizontal drain pan. Reinstall access panels and flowrator making

sure not to over torque screws. Snap in the drain cover on the right lower service panel.

7) The Airhandler can now be placed in its left horizontal position as shown in Fig.2. The

Airhandler must be leveled and then pitched 1/4" toward drain side.

Important:

Drain pan

must be tested for proper drainage by pouring water into the pan. Traps must be installed

on the primary drain and on the secondary drain if used.

8) In all cooling applications, a secondary drain pan must be provided by the installer and

placed under the entire unit with a separate drain line properly sloped and terminated in an

area visible to the user.

9)

WARNING:

Before setting up flowrator assembly for field brazing see page 13 or read the

label

on the lower access panel.

The "A" coil contains 150 p.s.i.g. of air pressure.

Warning

10) Failure to follow this installation requirements will cancel product warranty.

Fig.2

8

Air flow

Secondary Knockout

Primary Knockout

Page 9

REFRIGERANT TUBING

Refrigerant tubing should be installed as to avoid undue stress. They must be supported or

routed to avoid strain or vibration. To avoid damage that can be caused by condensate,

insulate the suction tube with a closed cell insulation with the seams sealed. The insulation

should terminate at the tubing entrance to the air handler. Do not reduce the recommended

tubing size.

CONDENSATE REMOVAL

THIS APPLIANCE EMPLOYS A DRAW-THROUGH COIL, THEREFORE A

TRAP MUST BE INSTALLED IN THE DRAIN LINE(S) TO ALLOW FOR

PROPER CONDENSATE DISPOSAL.

The condensate trap must not be the "running" type, or "R" type. A "P " trap is required.

The total workable height of this trap, in inches, must exceed the total negative pressure,

in inches of water, as measured in the return duct.

DRAIN

CONNECTION

UNIT

2" MINIMUM

FLEXIBLE

TUBING-HOSE

OR PIPE

A POSITIVE

LIQUID SEAL IS

REQUIRED

3" MINIMUM

The condensate drain line must be at least 3/4 NPT, for each unit. Precautions must be

used not to over tighten the adapter at the drain pan connection, this precaution will

prevent damage to the plastic drain pan. A joint compound should be used to prevent

leakage and act as a lubricant.

When using copper tubing as a condensate line adequate caution muat be taken to prevent

damage to the plastic drain pan during the soldering process. All condensate drain lines

and drain traps should be adequately insulated.

The unit and the auxiliary drain pan must be adequately elevated to insure proper drainage.

Use of a condensate removal pump is permitted when necessary.This condensate pump

should have provisions for shutting off the control voltage should a blocked drain occur. A

trap must be installed between the unit and the condensate pump. Important: The evaporator

coil is coated with oils that will dissolve Styrofoam and certain types of plastics. Therefore

a removal pump or float switch must not contain any of these materials.

NOTE: AFTER INSTALLATION AND POSITIONING THE UNIT , THE DRAIN

PAN BEING USED SHOULD BE TESTED BY FILLING IT WITH WATER TO

ENSURE PROPER DRAINAGE AND CHECK FOR LEAKS.

9

Page 10

ELECTRICAL CONNECTIONS

The required electrical power supply information is located on the series and rating plate

on the exterior of the unit. Wiring selection must be in accordance with local codes, or in

absence of local code, the National Electrical Code. A disconnect means should be installed

within sight of the unit, when required by code.

Copper wire is recommended for all electrical connections.

When an optional heat kit is installed refer to the electrical requirements in that kit.

The wiring diagram included in the heat kit must be placed over the wiring diagram on the

air handler.

All pertinent information, such as the rating plate, included in the optional heat kit must be

applied to the Air Handler as indicated.

The use of copper connections are recommended inside the control box (see UL 1995,

section 37.9).

Min.

Model

No.

2 Ton 1.2/1.2 15/15 0.9 1/8

3 Ton 2.5/2.5 15/15 2.0 1/3

4 Ton 3.3/3.3 15/15 2.6 1/2

5 Ton 4.4/4.4 15/15 3.5 1/2

5 Ton -E 5.0/5.0 15/15 4.0 3/4

A MEANS OF STRAIN RELIEF MUST BE INSTALLED TO THIS APPLIANCE AT

THE ELECTRICAL SERVICE ENTRANCE.

running

Ampacity

208/230

Max.

Over-current

208/230

WARNING

Blower

Motor

FLA

Blower

Motor

H.P.

When an optional electric heat kit is installed refer to the electrical requirements for that

kit. The ampacity and overcurrent protection shown above is only for "HB" air handlers

installed without a heat kit.

10

Page 11

THERMOSTAT WIRING

For Thermostat Control Environment-temperature and Air Conditioning open/stop, the wiring

diagram as shown diagram 1. Thermostat can be mechanical type or programmable type.

Note: Thermostat C : COM.

R : AC24V

Y : COMPRESSOR

G : FAN

O : 4 -WAY VALUE

For detailed Thermostat, please connect

corresponding terminal according to above

control specification.

For Thermostat only control Air

Conditioning open/stop, hot

control Environment temperature,

can adopt different power switch

show diagram 2. This mode is

control the indoor unit & heat

pump outdoor unit at the same

time no air supply mode. If need

select the air supply mode, switch

can adopt multi-connect switch

or select switch. The detailed

infor see the following diagram

3.

Above diagram: Outdoor Unit

Connection

Left: Indoor and Outdoor unit power

supply Respectively Right: Indoor unit

power supply.

G

TO INDOOR

FAN RELAY

CONTROL

TO OUTDOOR UNIT R,C,Y,O

Diagram 1

RUN SWITCH

TO INDOOR

FAN RELAY

CONTROL

O R

TO OUTDOOR UNIT R,C,Y,O

Diagram 2

SELECT SWITCH

RD

BL

CY

O

OR

O

24V

TRANSFORMER

1

2

3

4

5

6

RD

TERMOSTAT

Y

YL

BL

R

Y

C

MODE SWITCH

BL

COM

OFF

FAN ONLY

E. HEAT

HEAT PUMP

COOLING

R

RD

24V

TRANSFORMER

COM

C

BL

Open for heating

Close for cooling

TO FAN RELAY

CONTROL

Diagram 3

11

YL

BL

YC

TO OUTDOOR UNIT R,C,Y,O

RD

24V

RO

TRANSFORMER

BL

COM

Page 12

For Thermostat Control Environment-temperature and Air Conditioning open/stop, the wiring

diagram as shown diagram 4. Thermostat can be mechanical type or programmable type.

Note: Thermostat C: COM.

TERMOSTAT

R : AC24V

Y : COMPRESSOR

GR

Y

C

G : FAN

For detailed Thermostat, please connect

corresponding terminal according to above

control specification.

TO FAN

RELAY

CONTROL

RD

BL

C

Y

TO OUTDOOR UNIT C,Y

RD

24V

TRANSFORMER

COM

BL

For Thermostat only control Air

Conditioning open/stop, hot

control Environment temperature,

Diagram 4

SWITCH

can adopt different power switch

show diagram 5. This mode is

control the indoor unit & cooling

only outdoor unit at the same time

no air supply mode. If need select

the air supply mode, switch can

adopt multi-connect switch or

select switch. The detailed infor

TO FAN

RELAY

CONTROL

TO OUTDOOR UNIT C,Y

RD

BL

C Y

RD

24V

TRANSFORMER

COM

BL

see the following diagram 6.

Diagram 5

Above diagram: Outdoor Unit

Connection

Left: Indoor and Outdoor unit power

supply Respectively Right: Indoor unit

power supply.

SELECT SWITCH

TO FAN RELAY

CONTROL

Diagram 6

12

1

2

3

4

5

6

RD

BL

YC

TO OUTDOOR UNIT C,Y

RD

24V

TRANSFORMER

COM

BL

Page 13

ORIFICE CHANGE

o

The restrictor (orifice) included in this unit match the comparable capacity of the outdoor

unit. If the indoor unit is greater in capacity than the outdoor condenser, the orifice must

be changed to match the outdoor unit capacity. The restrictor (orifice) should be replaced

before any tubing connections are made.

THE CAPACITY OF THE OUTDOOR UNIT SHOULD NEVER EXCEED THE

CAPACITY OF THE INDOOR UNIT.

To replace the restrictor (orifice), follow the steps below:

WARNING

THIS COIL IS SHIPPED UNDER PRESSURE.

FOLLOW THESE INSTRUCTIONS TO PREVENT INJURY:

1) Remove the 1/4 nut on the liquid line and press the chip of the check valve. No pressure loss indicates p

2) Remove the 13/16 nut .

3) Remove the check piston to verify it is correct. See piston kit table 1 in manual.

4) Use a torch to remove the spin closure on the suction line .

5) Use a torch to remove the check valve on the liquid line .

6) Slide the 13/16 nut into position. Braze tailpiece to the liquid tube.

7) Insert the suction line into the connection, slide the insulation and the rubber grommet at

least 18" away from the braze joint.

8) AFTER THE TAILPIECE HAS COOLED, position the white Teflon seal and hand

tighten the nut.

9) Torque the 13/16 nut to 10-30 ft/lbs. or tighten 1/6 turn.

10) Replace suction line grommet and insulation.

TALL PIECE

13/16" NUT

WHITE TEFLOW SEAL

PISTON

SUCTION LINE

WITH SPIN

CLOSURE

RUBBER

GROMMET

CIRCULATING AIR DUCT

Air duct systems should be designed and installed as per local and/or national code.Refer

to NFPA 90A & 90B and the National Environmental Systems Contractors Association Manual "K".

The use of flexible duct connectors is recommended to minimize the possibility of noise

transmission. These connectors must conform to U.L. standards.

Supply air ducts must be insulated and return ducts must be insulated when passing

through an unconditioned space. When passing through an unconditoned space it may be

necessary to install a vapor barrier to the exterior of the ducts to prevent condensation.

Seams of all supply ducts must be sealed to prevent leakage and return ducts sealed

airtight to prevent infiltration.

The supply plenum should be the dimensions specified by the factory.

13

Page 14

BLOWER PERFORMANCE

CFM versus Static Pressure (inches of water column dry coil w/ filter) 4% reduction for wet coil.

Static Pressure

Model

CFM

0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.5

2 Ton

3 Ton

4 Ton

5 Ton

5 Ton-E

High

Middle

High

Low

High

Low

High

Low

High

Low

900 877 856 835 816 795 766 737

630 614 599 585 571 556 536 515

------ 1240 1208 1177 1148 1121 1091 1061

------ 1125 1093 1062 1033 1006 976 946

------

1480

------

------

------

------

------

------

------ ------

1650

1442

1800

------

1850

------ ------

1605

1404

1745

------

1795

1560

1366

1515

1328

1690 1635

------ ------

1740 1685

------

------ ------ ------

1470

1290

1580

------

1630

1252

1525

------

1575

The air delivery can be varied by changing the blower speeds. This can allow for differences

encountered in installations.

The CFM can be checked by the following method;

(The optional Heat Kit must be installed to continue with this procedure.)

1) All access panels must be in place.

2) Start the unit in the heat mode.

3) Measure the return air temperature.

4) Measure the supply temperature. This measurement should be done in various locations

to obtain an average.

5) Subtract the return temperature from the supply temperature. This is referred to as the

temperature rise.

6) Measure the actual supply voltage and actual amperage at the terminal block/circuit

breaker.

7) The BTUH output = (Voltage x Amps x 3.41)

output (BTUH)

CFM =

1.08 X temperature rise

1425

Should the CFM need to be increased or decreased it may be done by adjusting the blower

speed tap as shown on the wiring diagram.

14

Page 15

START-UP

Prior to initial start-up insure that all electrical connections are properly sized and tightened.

All panels must be in place and secured.

Tubing should be leak free.

Unit should be elevated, trapped and pitched to allow for drainage.

Low voltage wiring is connected.

Auxiliary drain is installed, when necessary, and pitched to allow for drainage.

Drain pans and drain tubing were leak checked with water.

Retrun and supply ducts are sealed.

Unit is elevated when installed in a garage or where flammable vapors may be present.

Unit is protected from vehicular or other physical damage.

Return air is not to be obtained from any areas where there may be objectionable odors,

flammable vapors or products of combustion such as carbon monoxide (CO) which may

cause serious personal injury or death.

REGULAR MAINTENANCE

WARNING

DISCONNECT ALL POWER SUPPLIES BEFORE PERFORMING ANY SERVICE.

The only item to be maintained on a regular basis by the user is to insure that the circulating

air filter(s) is cleaned or replaced. It is recommended that a return air filter grille be

installed.

A certified service technician should perform other services.

15

Page 16

20

17:17"[432mm]

20:20"[497mm]

Unit Width (In.)

Airflow configuration

1M

M:Multi-direction;

22:22"[559mm]

V:Vertical

Design series

D

Coil code

V

Electric

00

Electric heater

1:1st Generation

A:10 SEER A/C coil;

B:11 SEER A/C coil;

Designation

Y:575V-3Ph-60Hz;

V:208/230V-1Ph-60Hz;

00:No;

01:1KW;

Model Number Explanation

C:12 SEER A/C coil

D:13 SEER A/C coil

C:208/230V-3Ph-60Hz;

D:460V-3Ph-60Hz;

A:115V-1 Ph-60Hz

02:2KW;

15:15KW

L (Blue)

H (Black)

M (Blue)

H (Black)

M (Blue)

Motor Speed

Indoor Unit Blower

059

078

073

073

Piston Size

Indoor Unit

HR24D1VAR

HC24D1VAR

HR18D1VAR

HC18D1VAR

Model

Outdoor Unit

L (Blue)

085

078

HC30D1VAR

H (Black)

H (Black)

085

091

HC36D1VAR

HR36D1VAR

HR30D1VAR

L (Blue)

L (Blue)

097

087

HR42D1VAR

HC42D1VAR

H (Black)

H (Black)

097

097

HC48D1VAR

HR48D1VAR

H (Black)

096

HC60D1VAR

H (Black)

096

HR60D1VAR

24

Nominal capacity in

(000) Btuh

B

Blower unit

H

Haier

24:24000BTU/h; 60:

60000BTU/h

B:Blower unit;

C:Evaporater unit

Brand symbol

16

Indoor Unit

Table 1

Model

HB2400VD1V20

HB2400VD1M20

HB3600VD1M22

HB4800VD1M22

HB3600VD1V22

HB4800VD1V22

HB6000VD1M22

HB6000VD1V22-E

HB6000VD1M22-E

HB6000VD1V22

Loading...

Loading...